Hot-dip galvanizing method for high-strength steel

A hot-dip galvanizing and hot-dip galvanizing technology, which is applied in hot-dip galvanizing process, metal material coating process, coating, etc., can solve the problems of large fluctuations in the content of alloy elements and the quality of hot-dip galvanized coatings, and reduce the coating quality. The proportion of brittle phase, good corrosion resistance, the effect of eliminating phase and structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1: a kind of hot-dip galvanizing method of high-strength steel, specifically as follows:

[0034] The thickness of the high-strength steel plate in the actual galvanizing experiment is 2 mm, and the chemical composition (mass percentage) contained is C: 0.023, Si: 0.28, Mn: 1.17, P: 0.007, S: 0.003, Mo: 0.365, Al: 0.041.

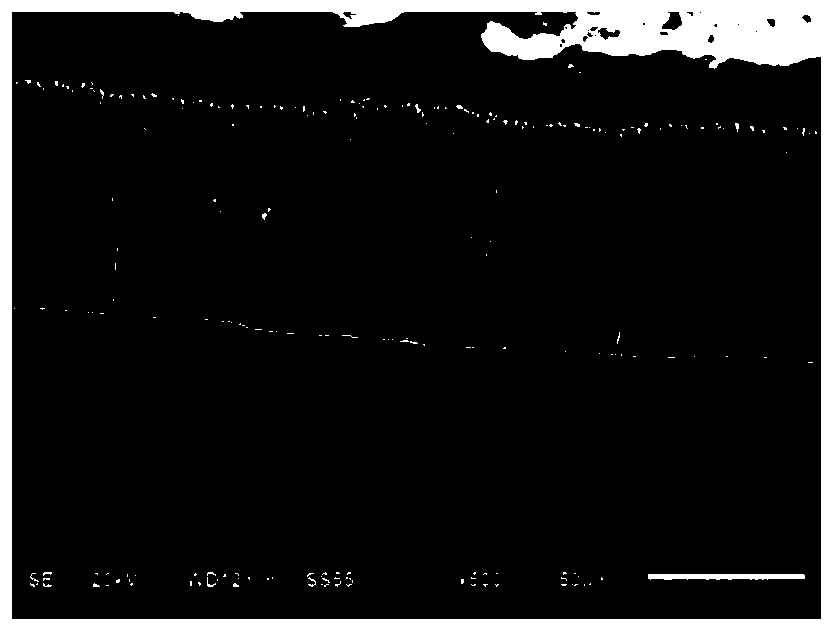

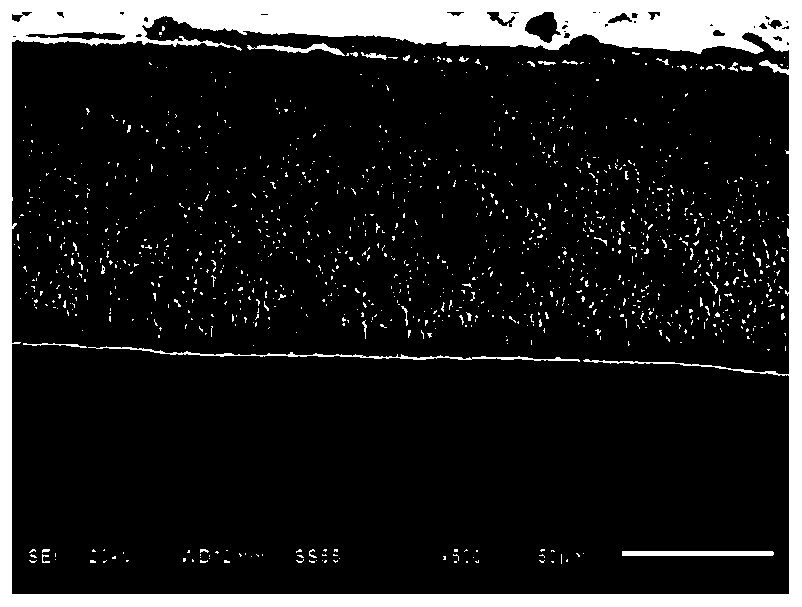

[0035] Using this high-strength steel hot-dip galvanizing process for hot-dip galvanizing, the microstructure of the coating cross-section and the surface morphology of the coating are as follows figure 1 , figure 2 shown. The specific steps of the hot-dip galvanizing method are as follows:

[0036] (1) High-frequency heating: According to the formula in step (1), the heating frequency is determined to be 40 kHz, and the heating temperature is 600° C. for 1 minute and air-cooled. Realize high-frequency heating only on the surface of high-strength steel. Due to the heating, the alloy elements contained in the surface of high-strength ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com