Pipeline tapping cutting and butt weld welding working station

A technology for welding workstations and butt welds, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of low construction efficiency, time-consuming and laborious, uncontrollable forming effect, etc., and achieve reasonable structure and convenient use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention is not limited by the following examples, and specific implementation methods can be determined according to the technical solutions of the present invention and actual conditions.

[0018] In the present invention, for the convenience of description, the description of the relative positional relationship of each component is based on the accompanying drawings 1 For example, the positional relationship of front, rear, top, bottom, left, right, etc. is determined according to the layout direction of the drawings in the description.

[0019] Below in conjunction with embodiment and accompanying drawing, the present invention will be further described:

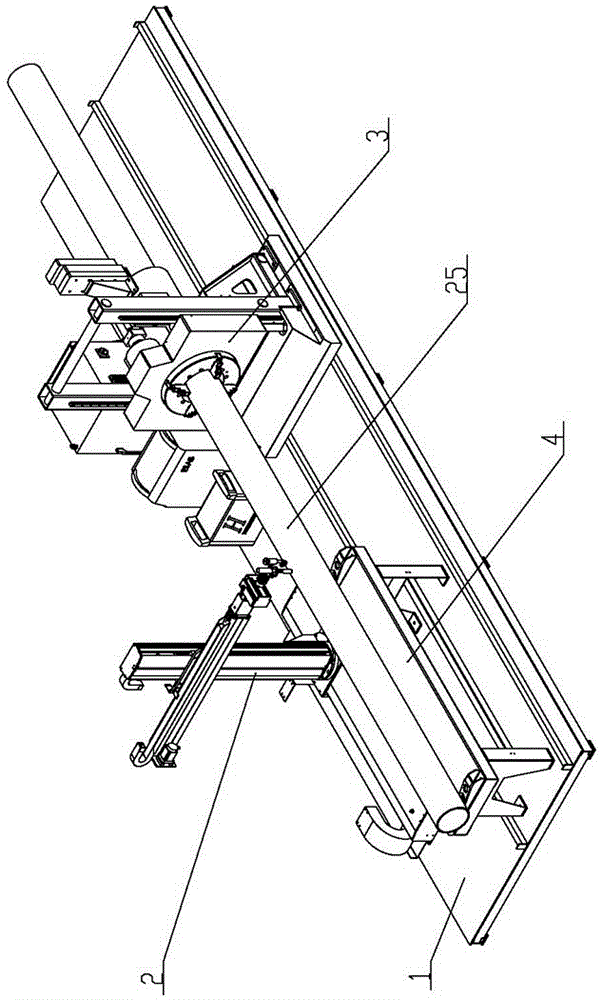

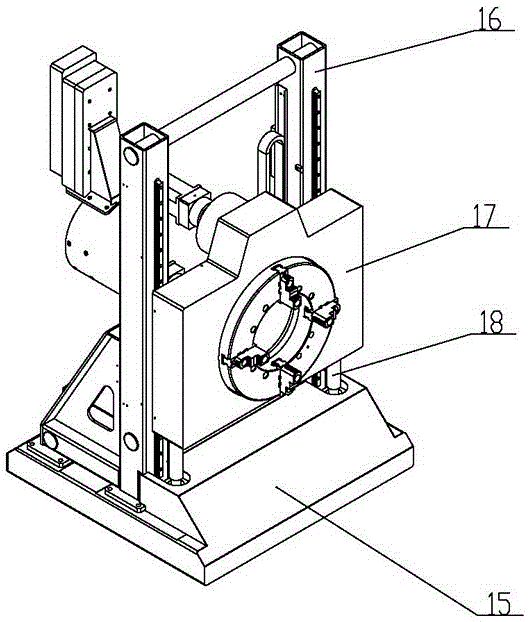

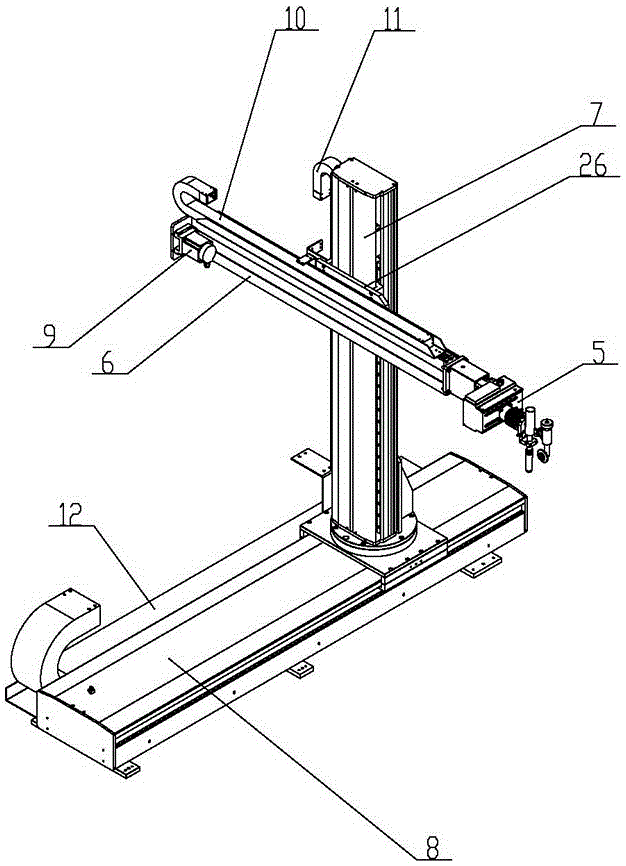

[0020] as attached 1 、 2 、 3 、 4 、 5 As shown, the pipe hole cutting and butt weld welding workstation includes a workbench 1 , mobile manipulator 2 , for clamping pipes 25 positioner 3 , used to support the pipeline 25 support frame 4 ,Motion detector 19 , c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com