Automatic adjustment device and method for levelness of plasma etching machine

An automatic adjustment and etching machine technology, which is applied in the direction of discharge tubes, electrical components, circuits, etc., can solve the problems of limited accuracy of naked eye observation, decreased accuracy, and inability to know the level of etching machines.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Specific embodiments of the present invention will be described below in conjunction with the accompanying drawings.

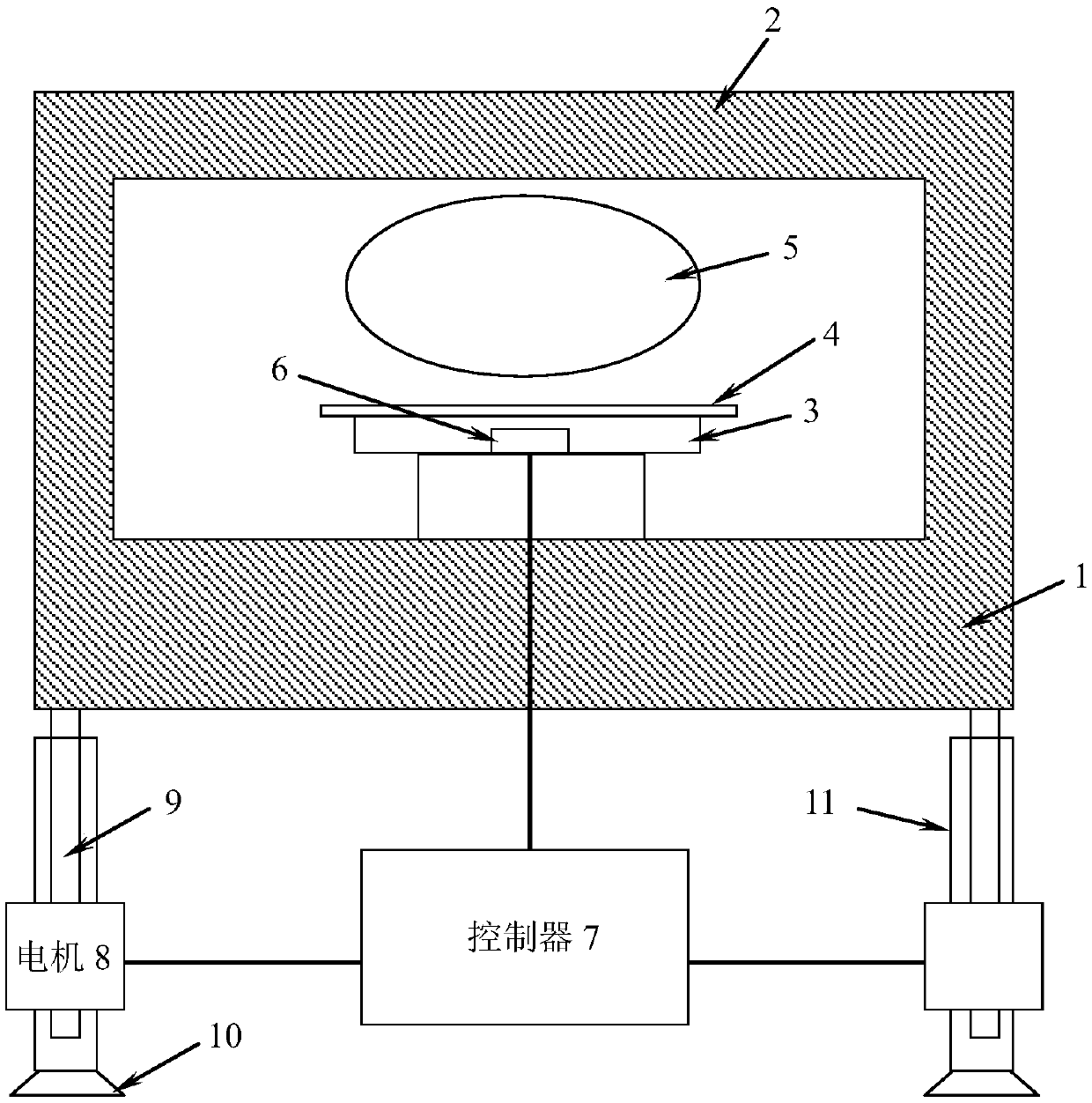

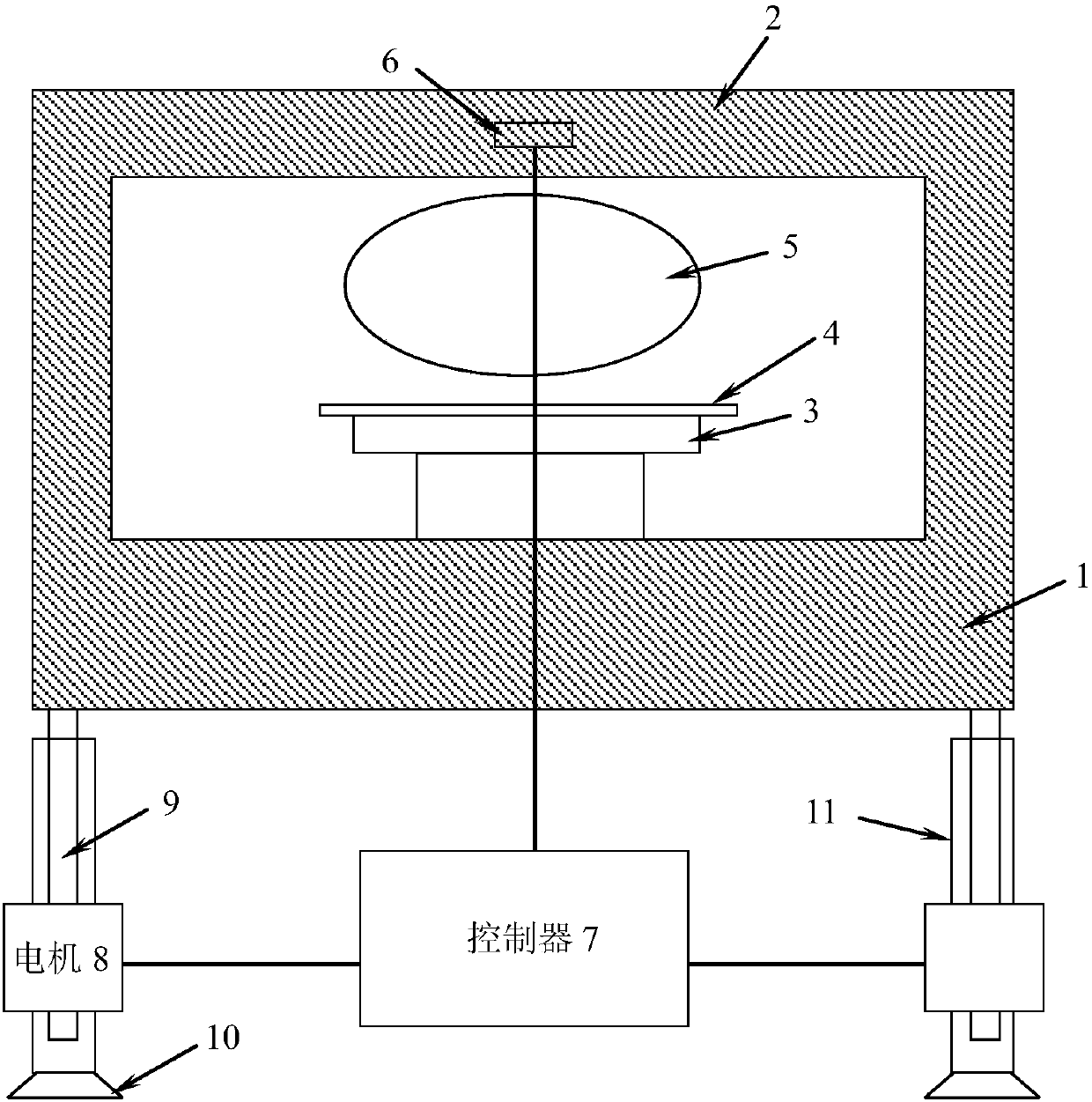

[0028] Such as figure 1 As shown, the present invention provides an automatic adjustment device for the levelness of a plasma etching machine. Wherein, the plasma etching machine includes an etching machine cavity 1, which is composed of a top cover 2 at the top, a bottom wall at the bottom, and a side wall connected between the top cover and the bottom wall to form an airtight The permanent internal reaction space is in a vacuum state during the plasma etching process. Wherein, the top cover 2, the bottom wall and the side wall are all made of metal materials and grounded.

[0029] A shower head is provided under the top cover 2 of the etching machine cavity 1 for introducing the reaction gas for etching the substrate into the etching machine cavity 1 and maintaining a certain flow rate. The top cover 2 is provided with a first motor and grounded. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com