Level adjusting apparatus of substrate processing apparatus and level adjusting method using the same

A technology of a substrate processing device and a level adjustment device, which is applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of different levels of level adjustment, difficulty in achieving small adjustments, and low accuracy of level adjustments. Adjustment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Hereinafter, with reference to the accompanying drawings, various embodiments of the level adjusting device of the present invention will be observed in detail.

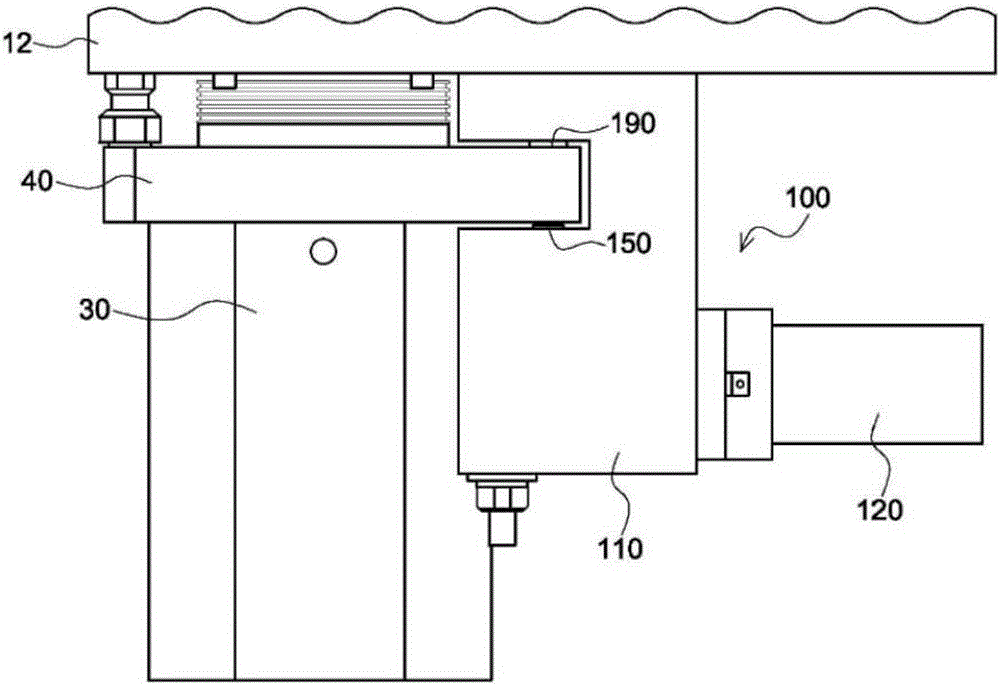

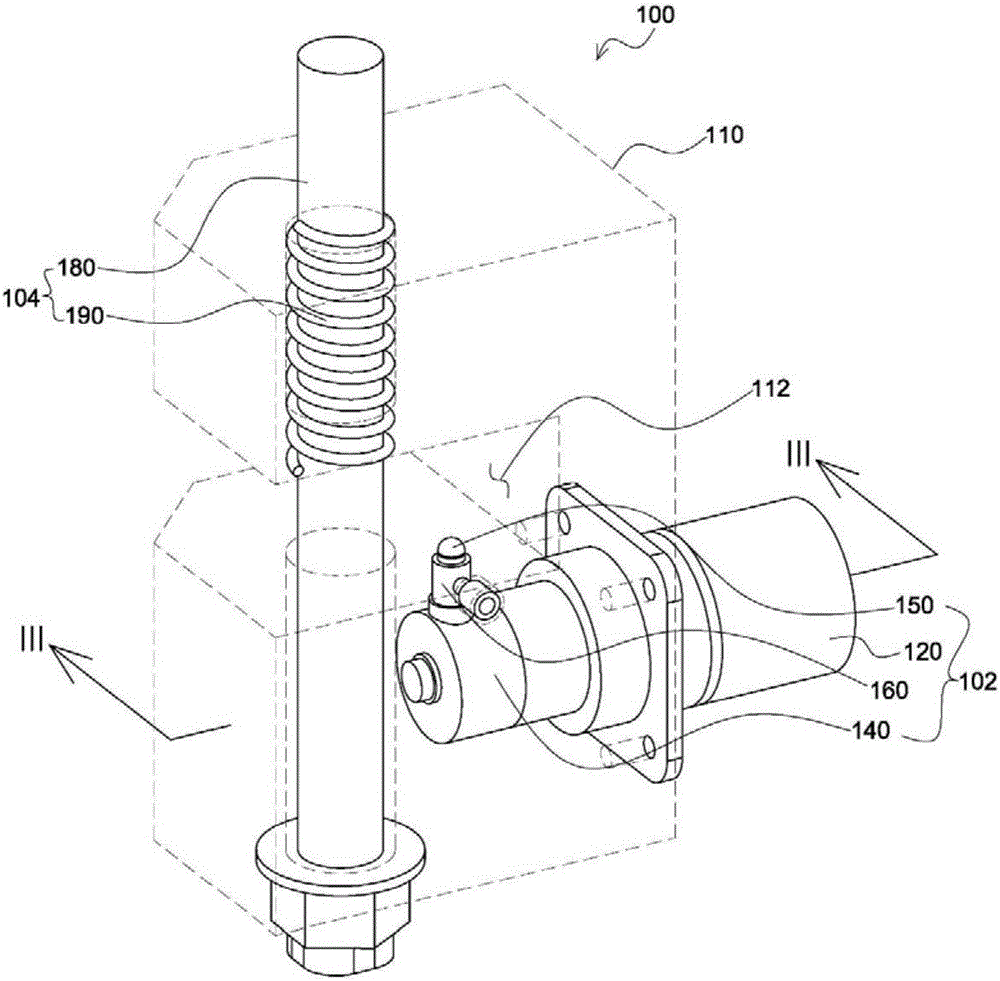

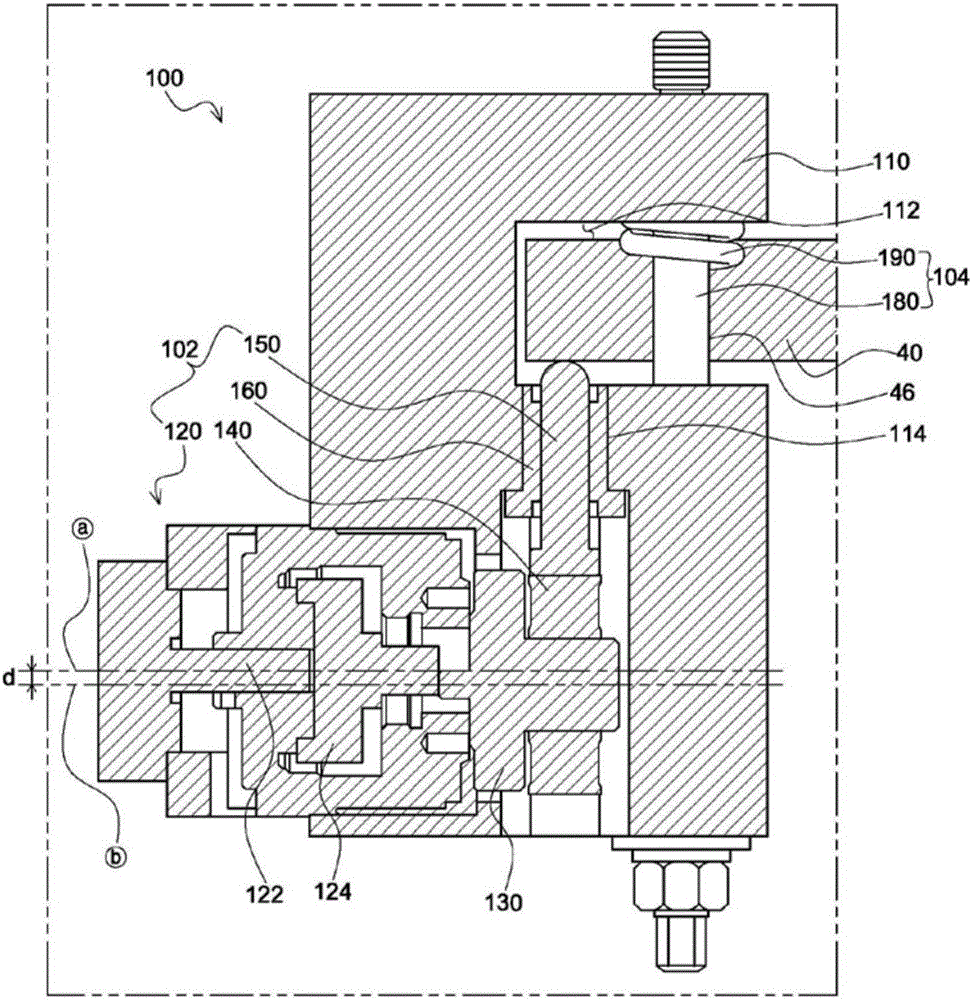

[0032] figure 1 The level adjustment device 100 which shows an embodiment of the present invention is equipped with a schematic diagram below the chamber 12, figure 2 is a perspective view of the level adjustment device 100 . exist figure 1 In the description of the connection structure of the chamber 12 , the support plate 40 , the support rod 30 , the crystal seat 16 and so on, it has been described in detail in the background art, so repeated description is omitted.

[0033] refer to figure 1 and figure 2 , the level adjustment device 100 may include: a first adjustment unit 102, which moves the support plate 40 up and down by a certain distance; and a second adjustment unit 104, which prevents the support plate 40 from negative pressure and move upward.

[0034] That is, the first adjustment uni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com