Patents

Literature

66results about How to "Adjust parallelism" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

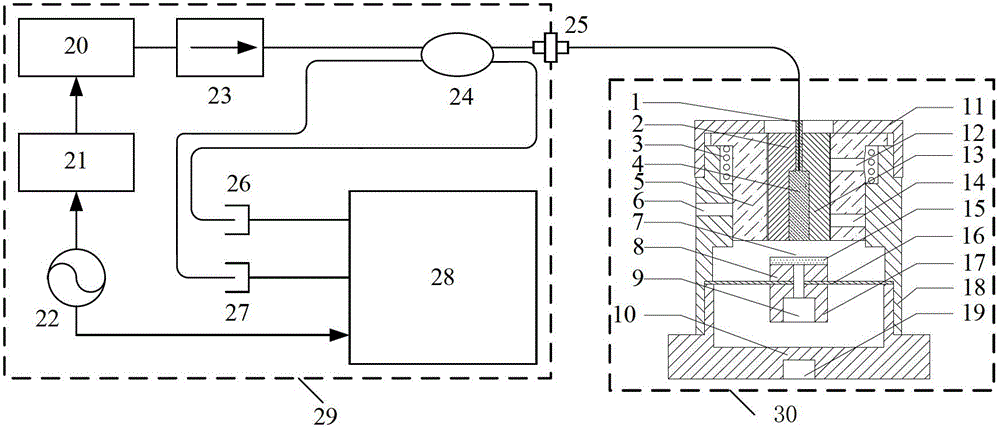

Coherent synthesis phase observe and control apparatus based on stripe characteristic extraction

ActiveCN101393376AAdjust parallelismEasy to controlOptical measurementsSpecial data processing applicationsBeam splitterPhase difference

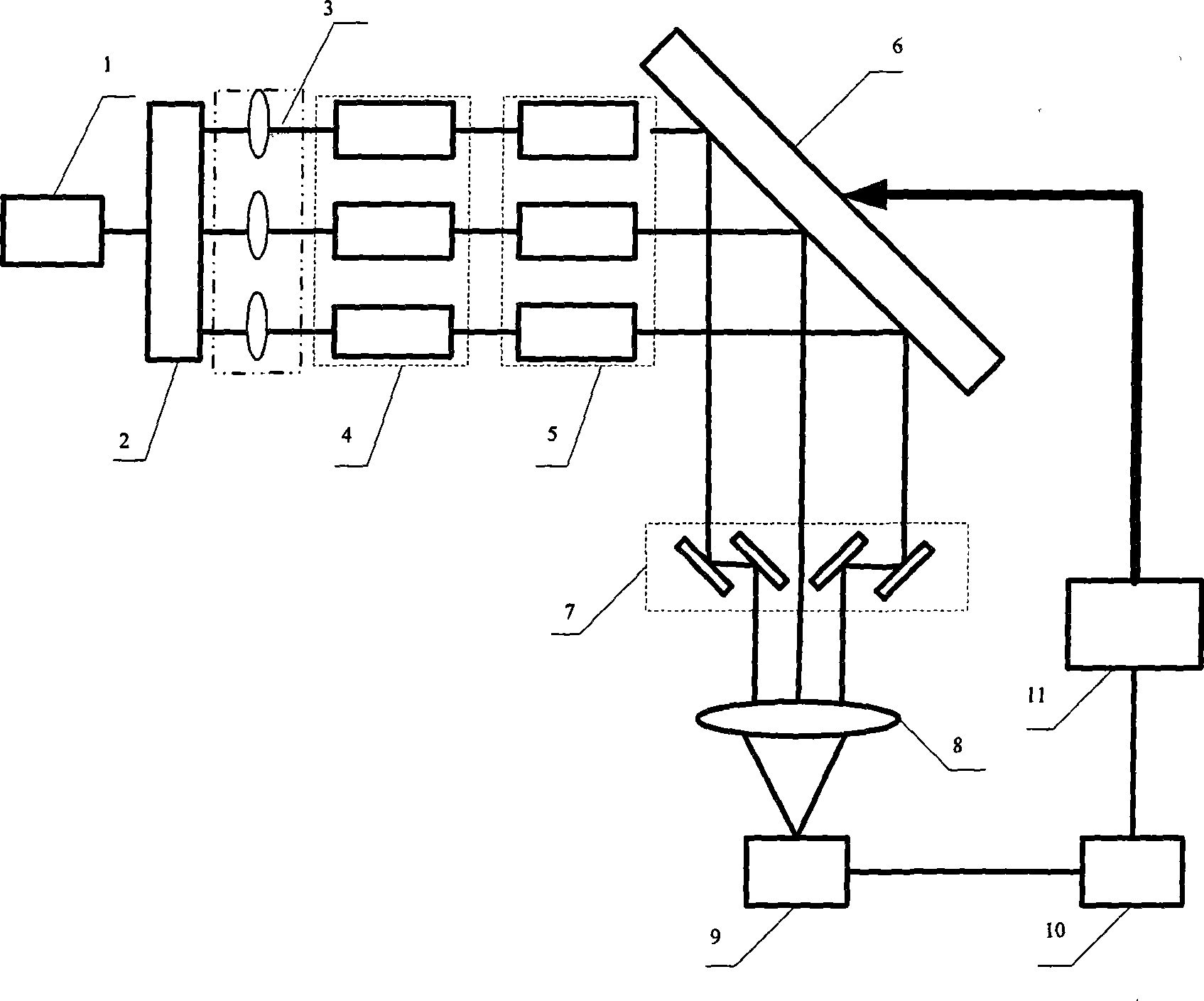

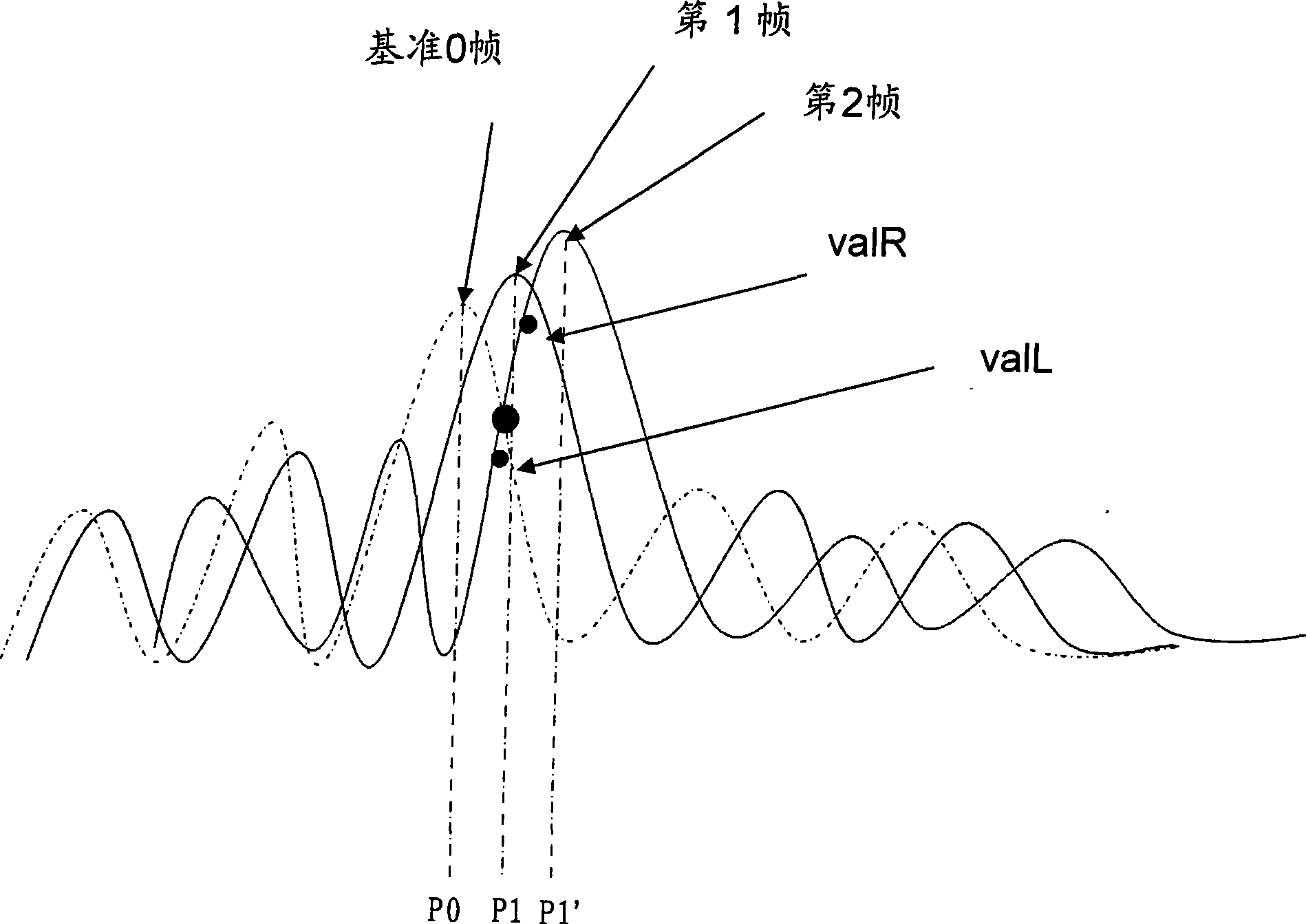

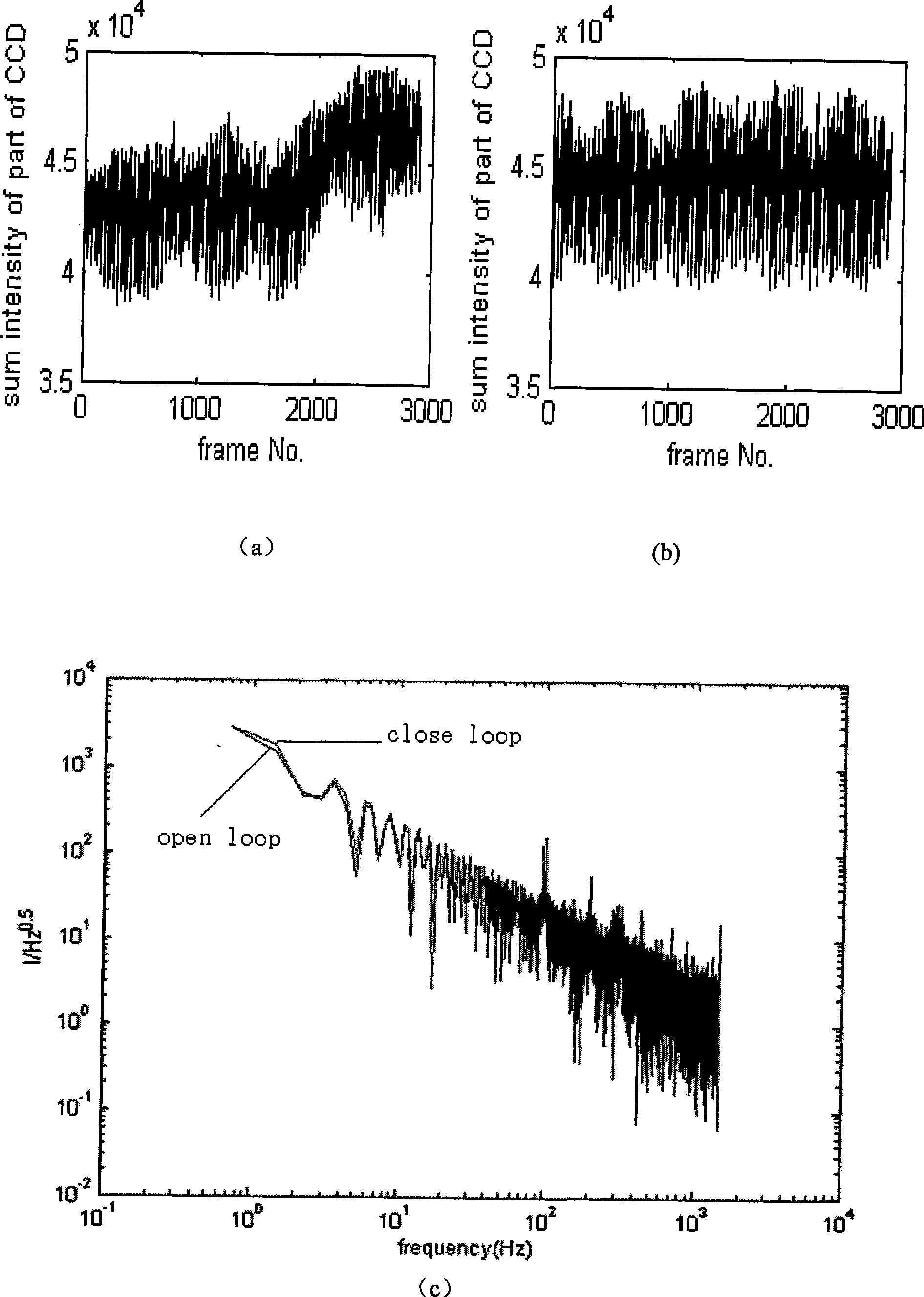

The present invention discloses a coherent composite phase measurement and control device based on fringe feature extraction algorithm. After collimated by a collimator, a laser beam outputted by a seed laser passes through a 1 multiple N beam splitter, and then passes through two-stage laser amplification of a pre-amplification stage and an amplification stage, and is reflected to a steric compression device through a separate type deformable mirror. The laser beam with compressed spatial distance is focused on a far field imaging system through a focusing lens. The far field coherent facula fringe acquired by the far field imaging system is analyzed by the fringe feature extraction algorithm built in a computer. The computer applies required control voltage to each electrode of the separate type deformable mirror by controlling a high voltage amplifier. The separate type deformable mirror is controlled to correct the phase difference between multiple paths of laser beams. The device based on the fringe feature extraction algorithm can visually and accurately measure the curve of the translation phase feature that varies with time. Through the power spectral analysis, the control bandwidth required by the system can be determined, and the control process for the coherent composite of multi-laser beam is simpler and more effective.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

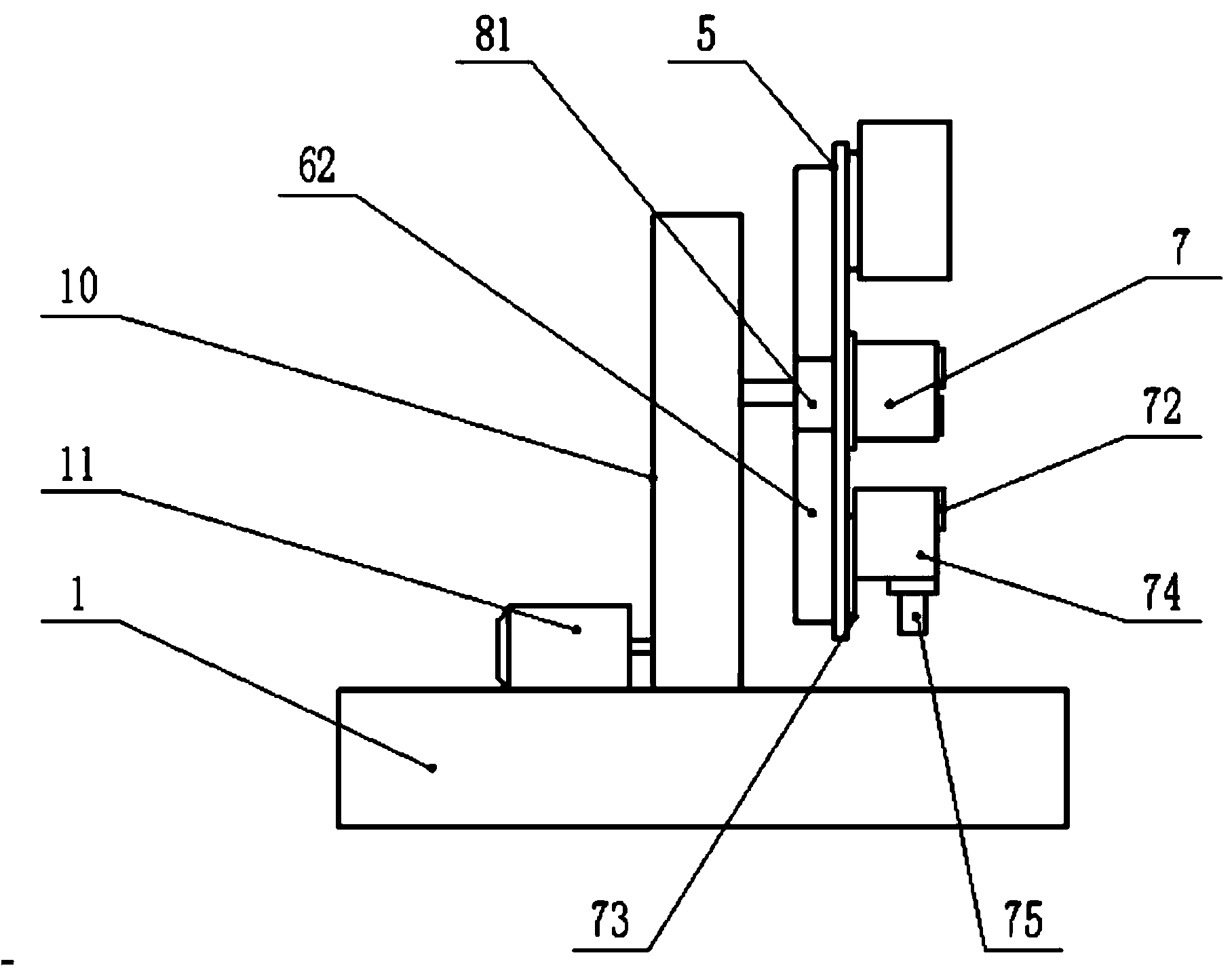

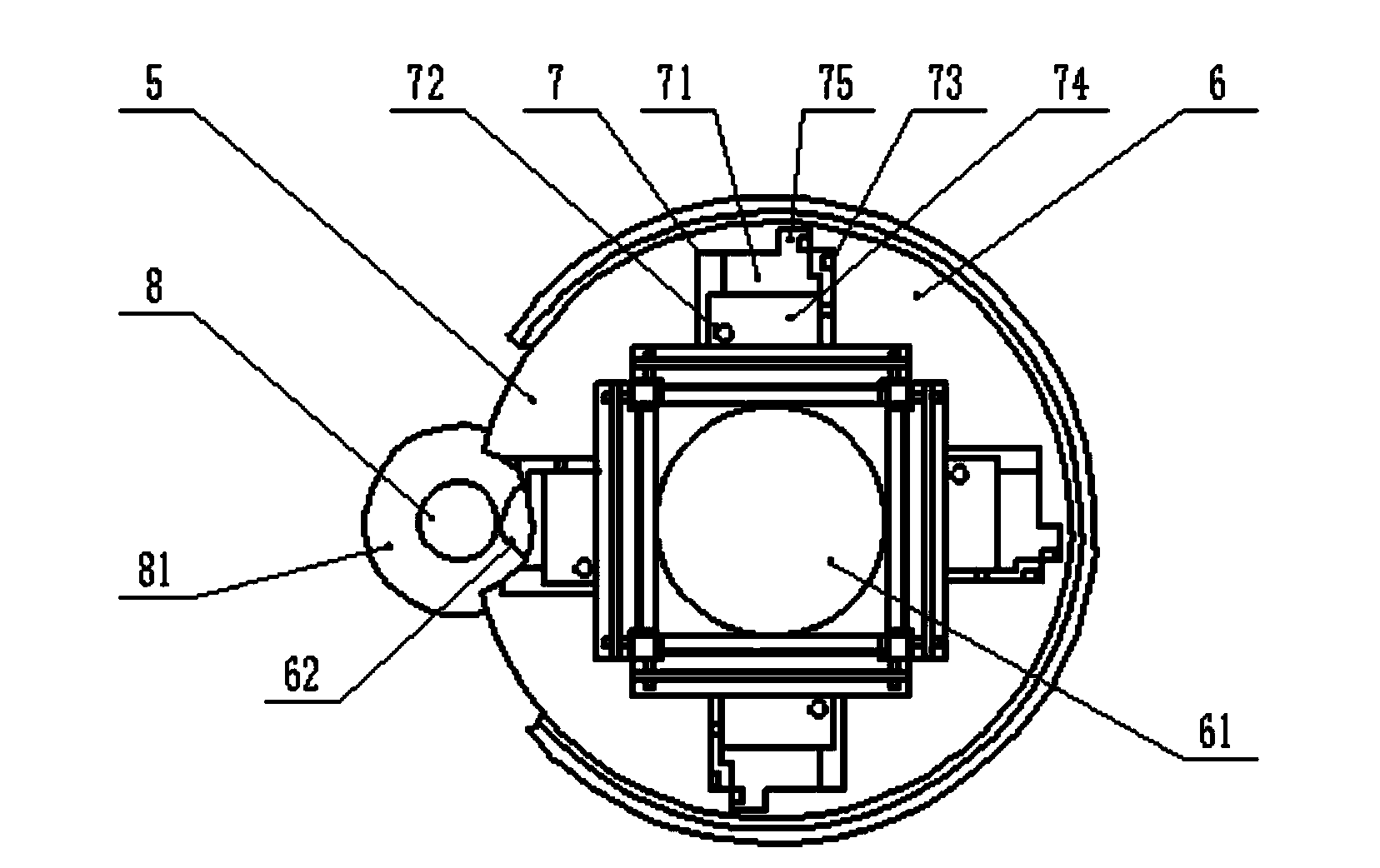

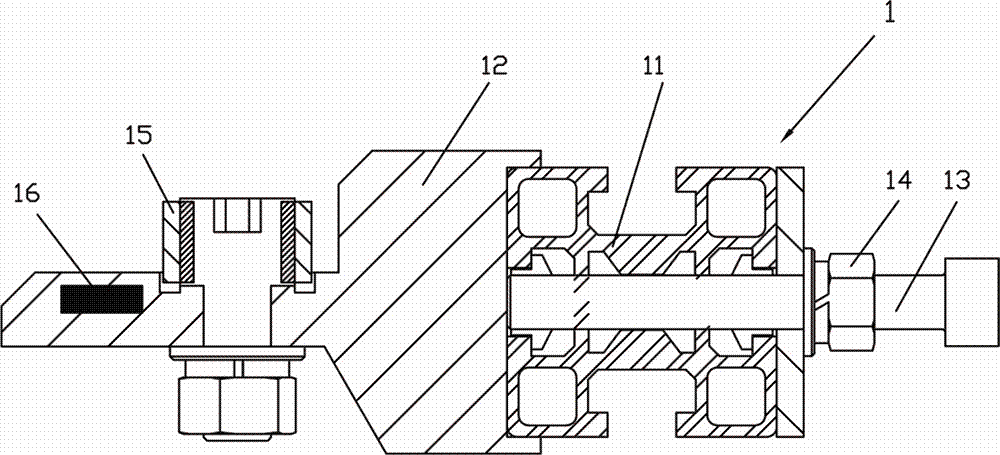

Novel cutting machine device

InactiveCN103949724AImprove efficiencyReduce sync distanceMetal sawing devicesSteel tubeKnife blades

The invention discloses a novel cutting machine device. The novel cutting machine device comprises a frame, wherein a cylinder and a sliding rail are arranged on the frame; a steel tube supporting mechanism connected with the cylinder slides on the sliding rail; a locking component for locking a steel tube is arranged on the steel tube supporting mechanism; a hydraulic motor is arranged on the frame; the hydraulic motor drives a cutter set to rotate through a gearbox; a cutting mechanism is arranged on the outer surface of a circular rotary table on the periphery of a through hole; the cutting mechanism consists of a cutter feeding mechanism and a blade; the blade is arranged at the front end of a cutter holder. Compared with the prior art, the novel cutting machine device has the advantages as follows: the novel cutting machine device improves the cutting efficiency, saves space, is stable in force exerting and easy to control, and ensures the cutting quality; the blade is long in service life, so that the cost is reduced; a steel tube can be adjusted to the required size by the sliding rail for cutting, so that the cutting length is ensured; a height adjusting device can adjust the height and adjust the levelness of a supporting rack and the parallelism of the steel tube.

Owner:SUZHOU TAKESHENG ELECTRONICS SCI & TECH

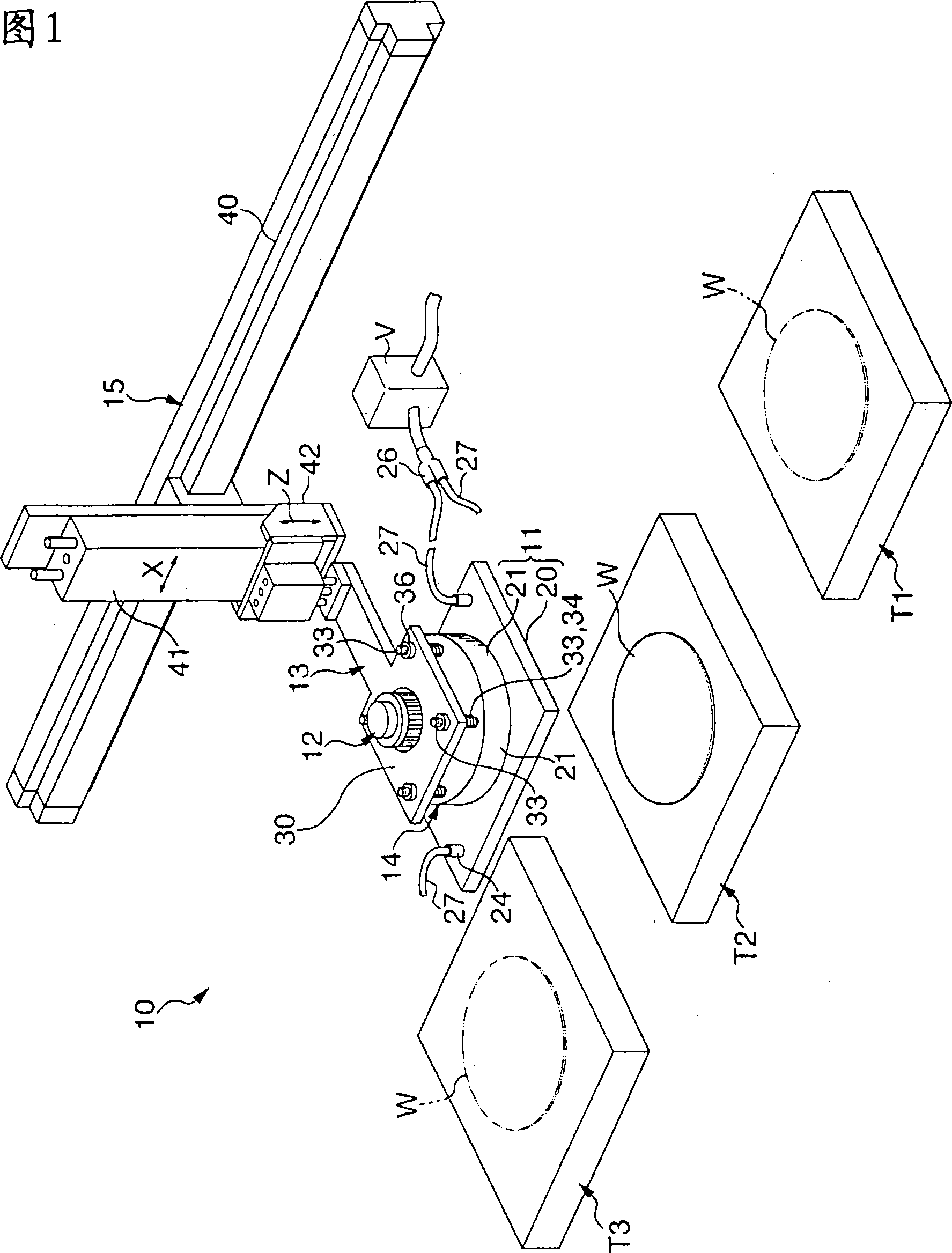

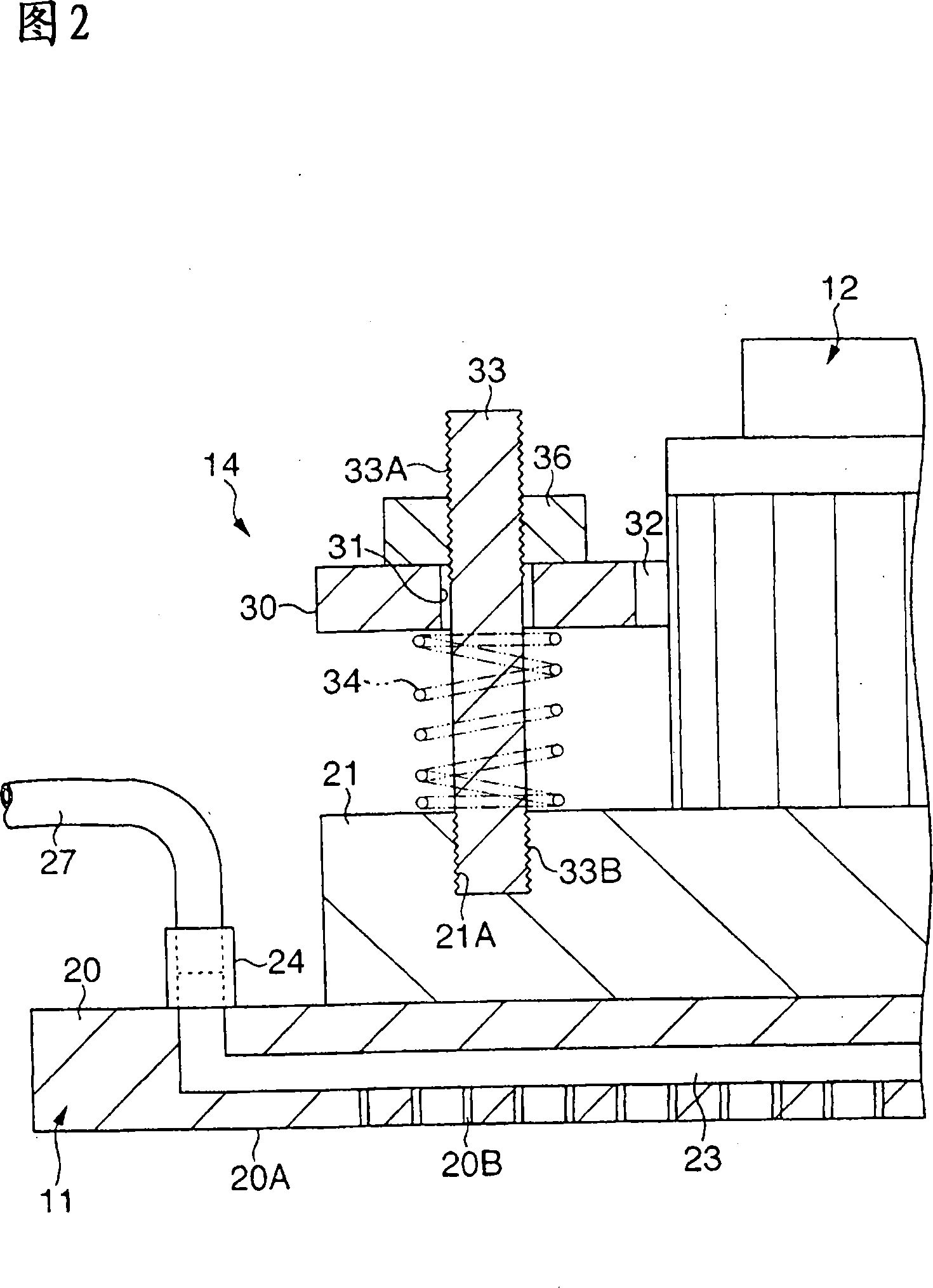

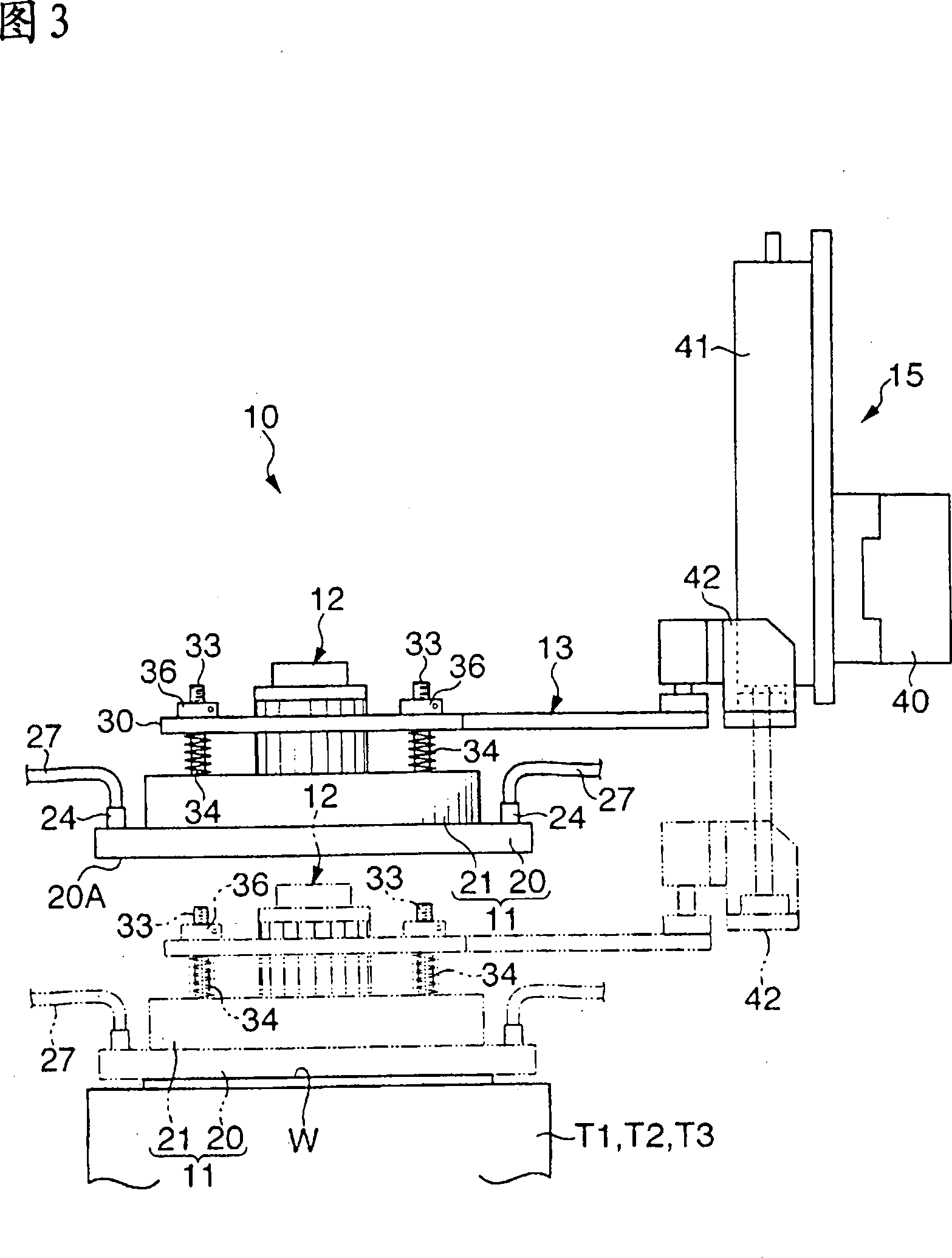

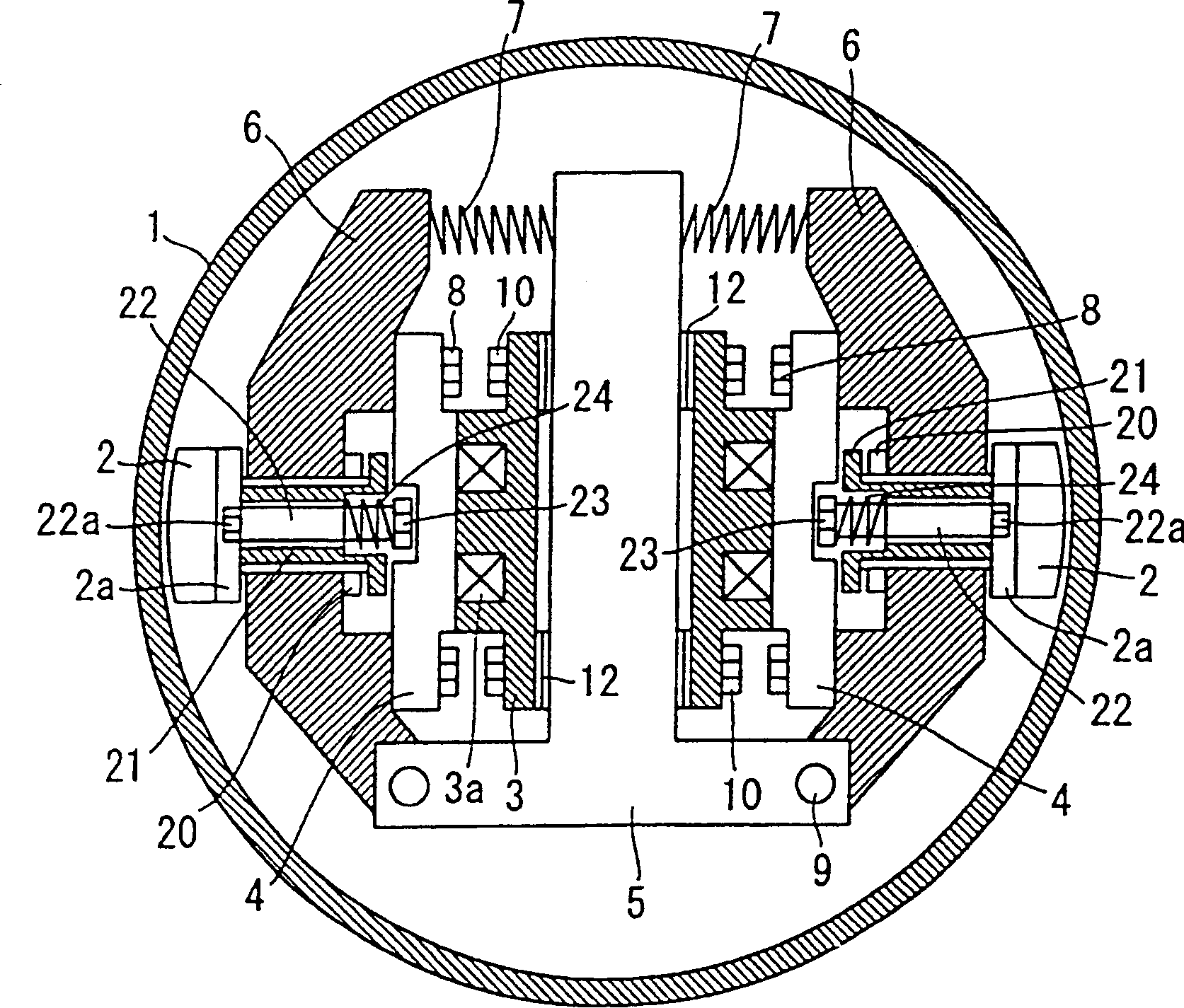

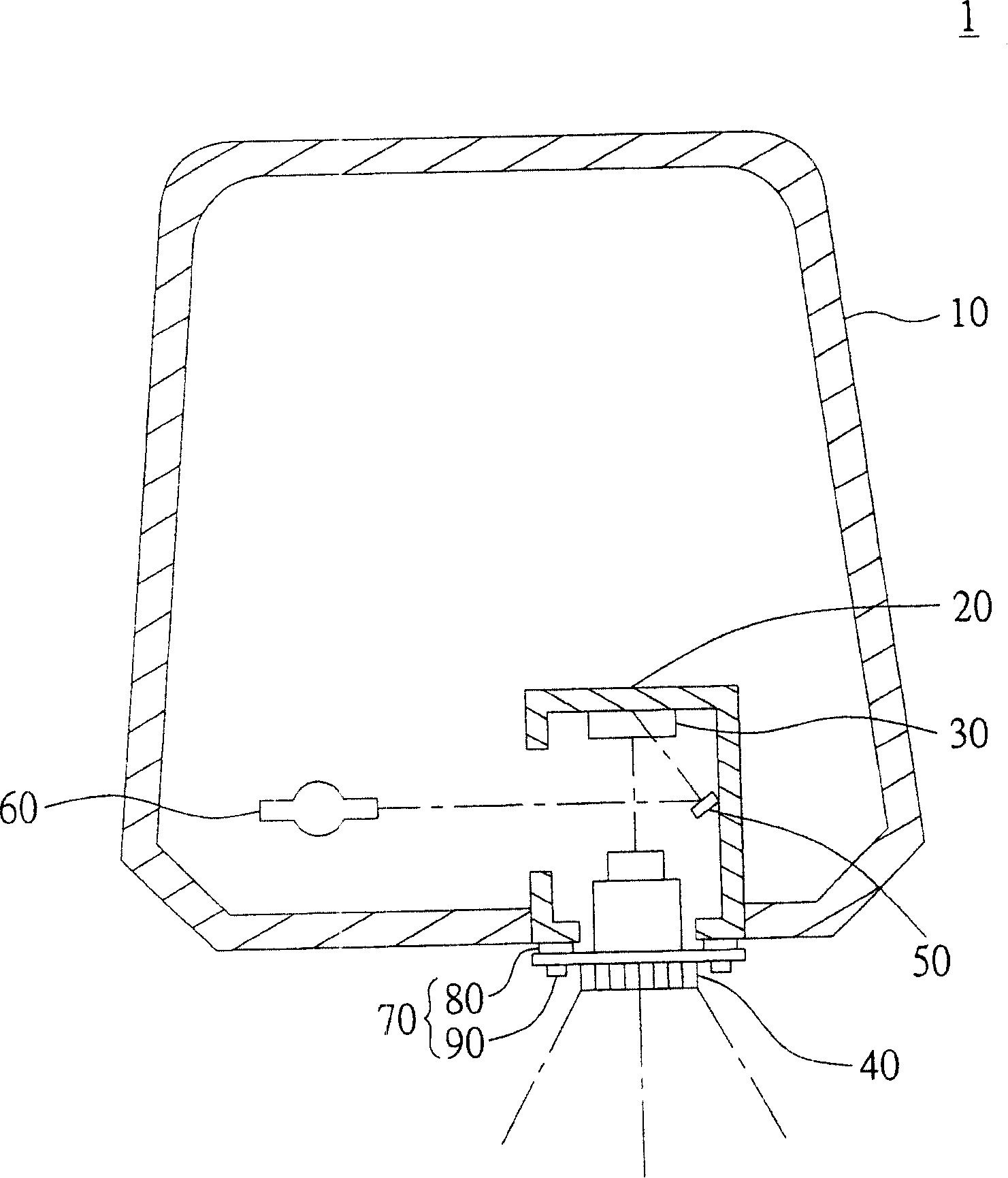

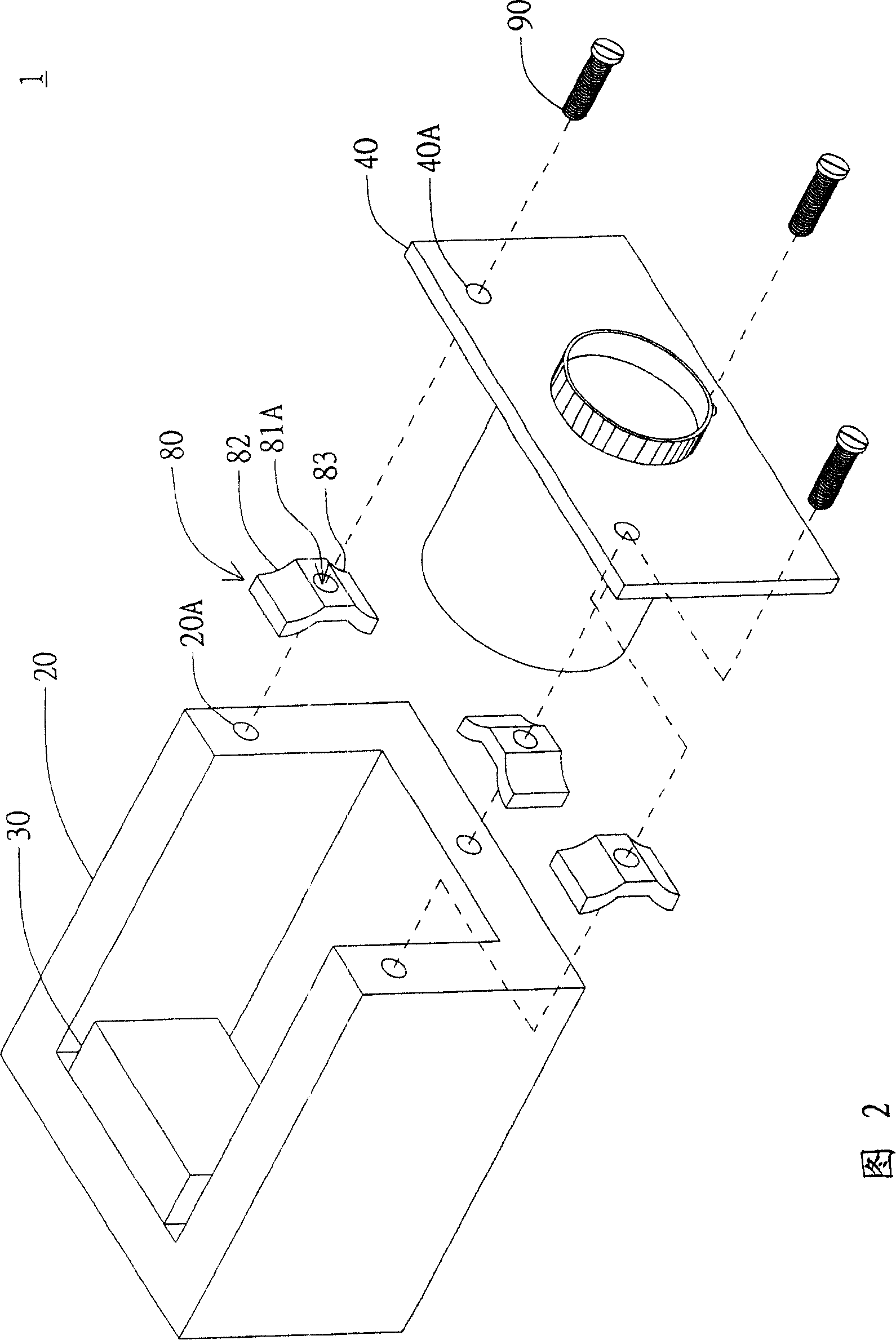

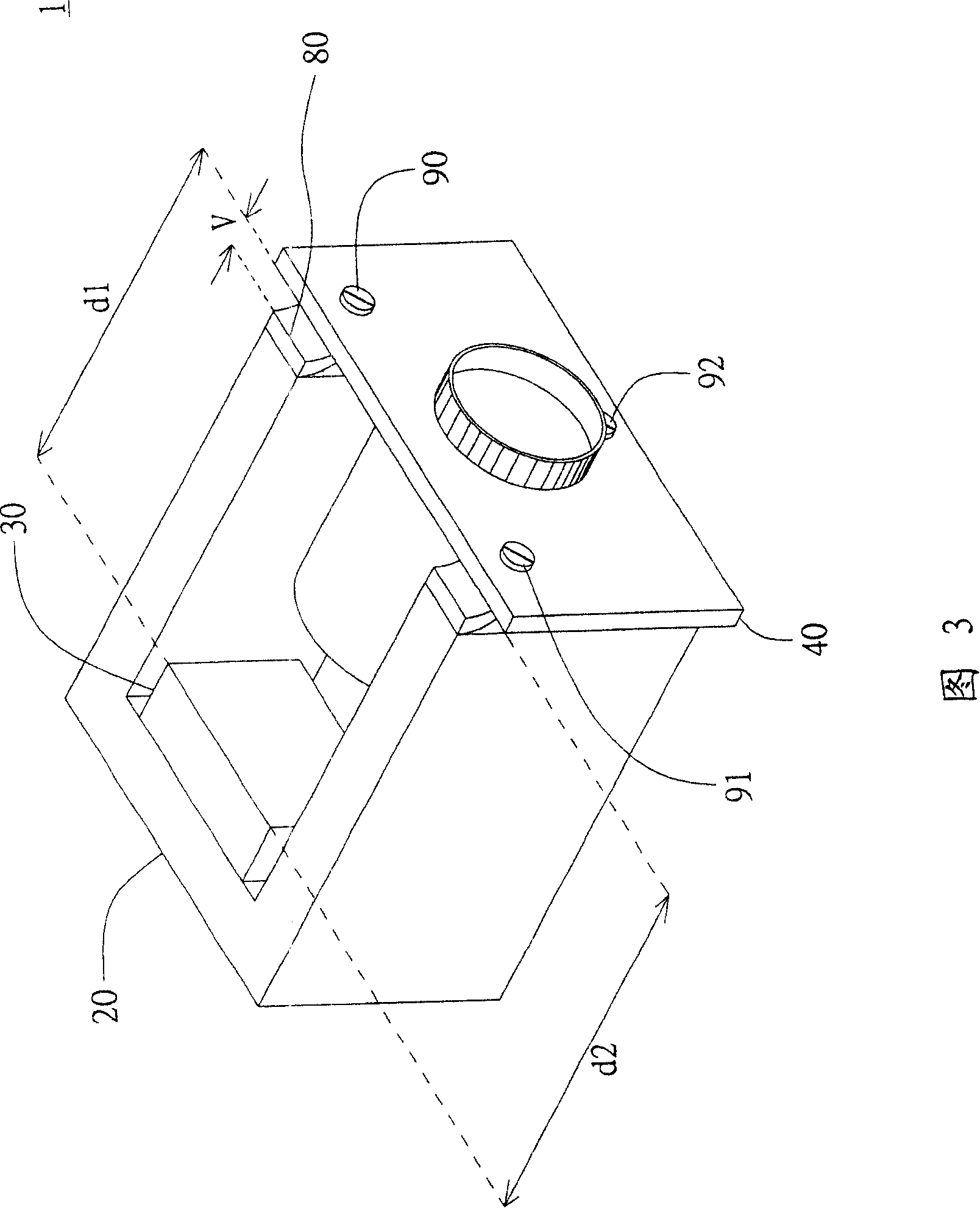

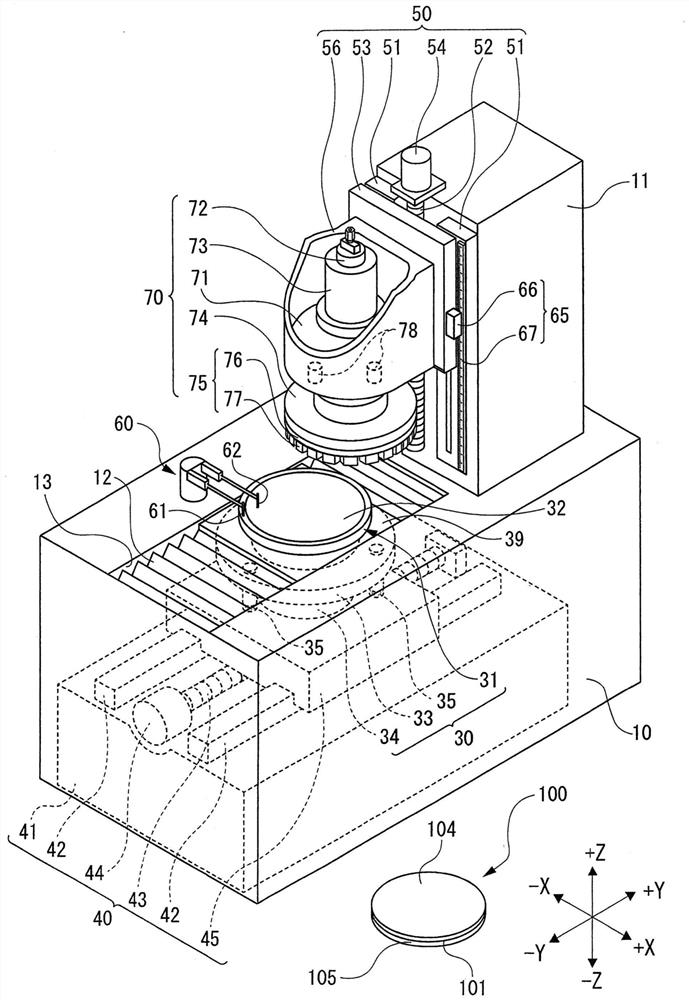

Transfer equipment

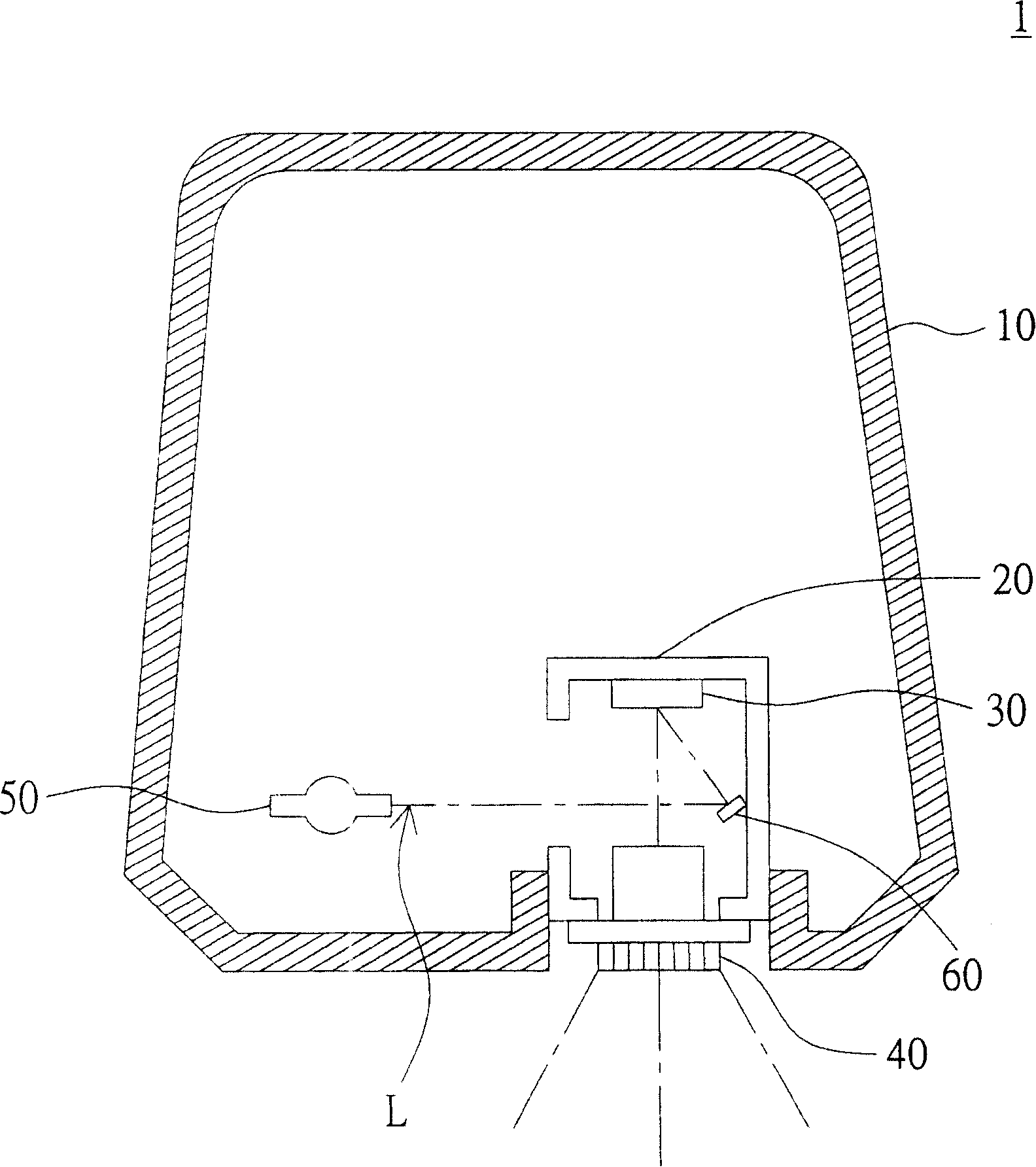

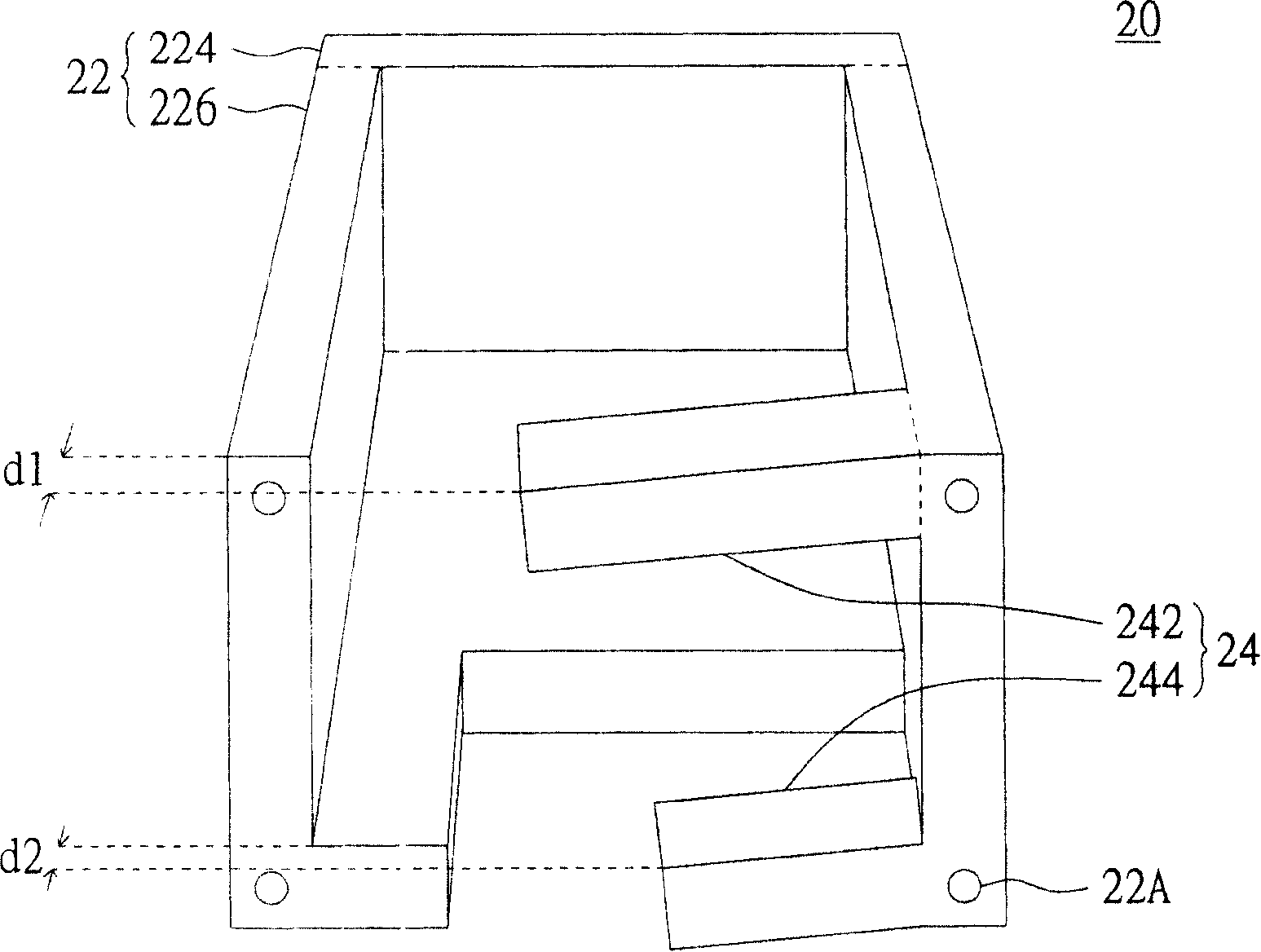

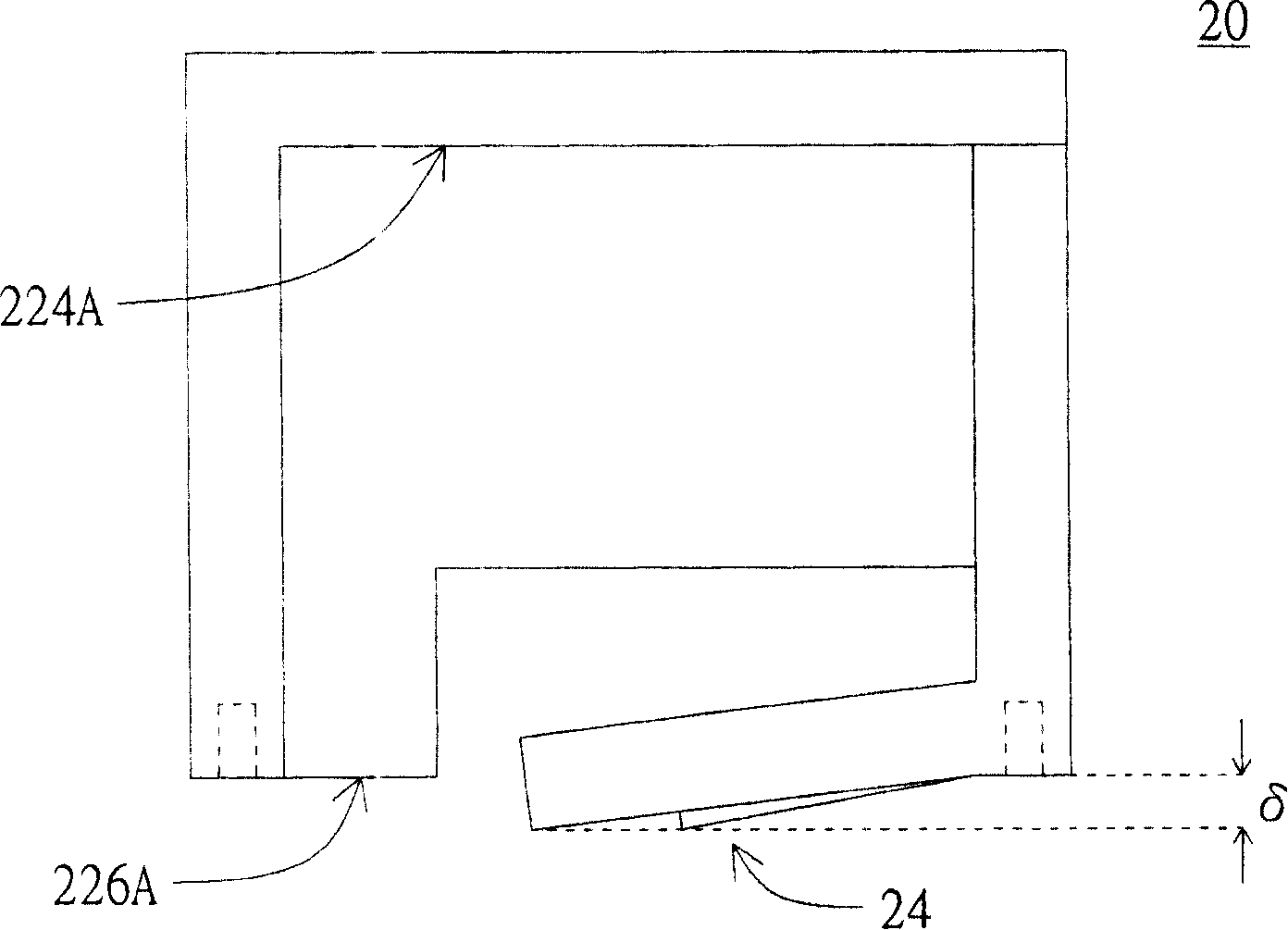

InactiveCN1981370AAdjust parallelismAvoid damage such as ruptureProgramme-controlled manipulatorJointsSemiconductorSupport plane

Transfer equipment (10) is provided with a supporting plate (11) which has a supporting plane (20A) for a semiconductor wafer (W), an arm plate (30) for supporting the supporting plate, and a parallelism adjusting means (14) arranged between the supporting plate and the arm plate (13). The supporting plate is arranged to permit air to be sucked and discharged from the supporting plane, is maintained parallel to the wafer by the reaction when the supporting plate is brought close to the semiconductor wafer (W) in a status where air is discharged. After the supporting plate is brought into contact with the wafer in a status where the parallelism is maintained, the supporting plate sucks the wafer and transfers it.

Owner:LINTEC CORP

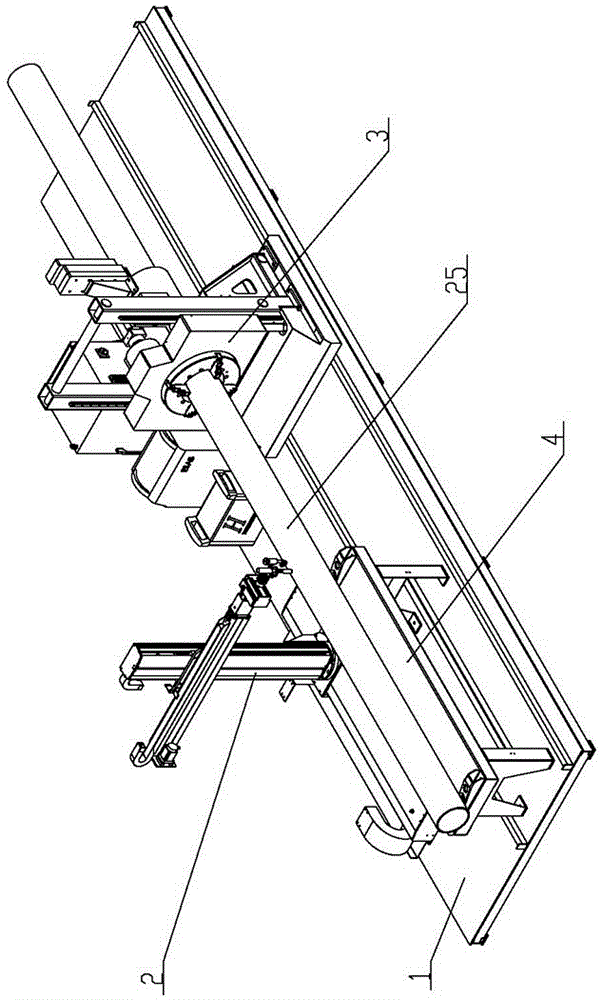

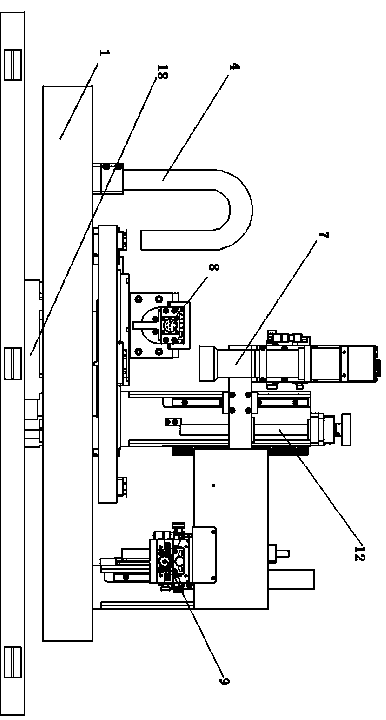

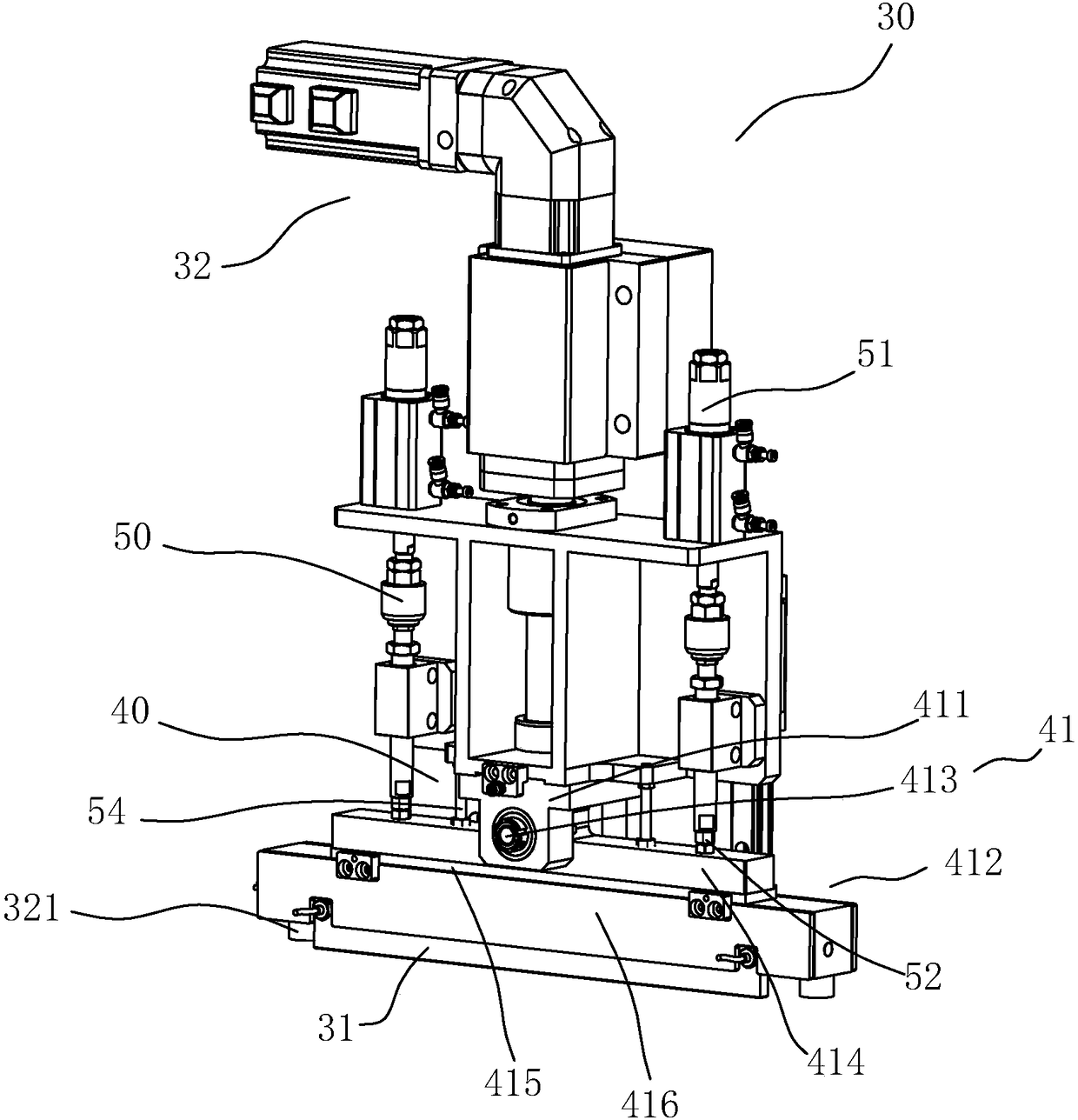

Pipeline tapping cutting and butt weld welding working station

ActiveCN105904132AAdjust levelAdjustabilityWelding/cutting auxillary devicesAuxillary welding devicesButt weldingControl engineering

The invention relates to the technical field of pipeline machining devices, in particular to a pipeline tapping cutting and butt weld welding working station. The pipeline tapping cutting and butt weld welding working station comprises a mobile manipulator, a displacement sensor, a controller and a displayer. The mobile manipulator comprises a manipulator head, a transverse arm, a stand column, a base, a first drive mechanism, a second drive mechanism and a third drive mechanism; the displacement sensor is mounted on the manipulator head, the displacement sensor is connected with the controller, and the controller is connected with the first drive mechanism, the second drive mechanism, the third drive mechanism and the displayer; the manipulator head is carried with the displacement sensor, and therefore the different opposite positions of the manipulator head and a pipeline are transformed; data are introduced into the controller, various parameters of the pipeline are obtained, and the position of the pipeline is manually or automatically adjusted; and in the cutting and welding process, real-time measuring is achieved, the opposite position of the manipulator head and the pipeline is corrected, the influence of disturbing and jumping of the long pipeline in the rotating process on cutting and welding quality and the forming effect is eliminated, and the beneficial effects of being safe, labor-saving, easy, convenient and efficient are achieved.

Owner:新疆威奥科技股份有限公司

Elevator hoist and elevator device

InactiveCN1450974AAdjust the clearanceEasy to adjustBuilding liftsHoisting equipmentsEngineeringMechanical engineering

An elevator hoist, wherein mechanisms for adjusting a gap between linings formed so as to come into contact with and separate from a brake drum and the brake drum when the linings are separated from the brake drum are installed in an arms for supporting the linings, whereby the adjustment of the gap between the linings and the brake drum can be performed easily in a short time.

Owner:MITSUBISHI ELECTRIC CORP

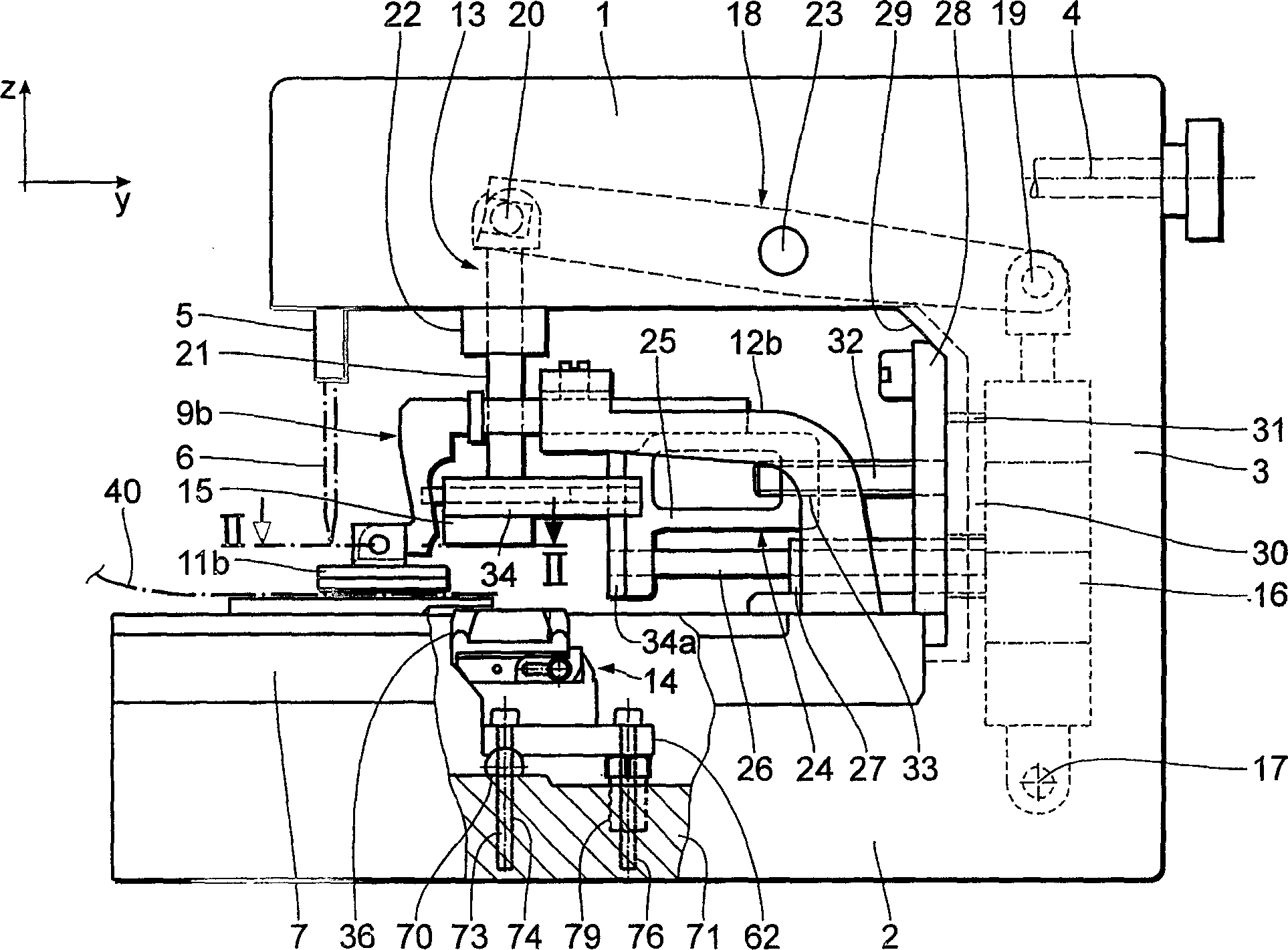

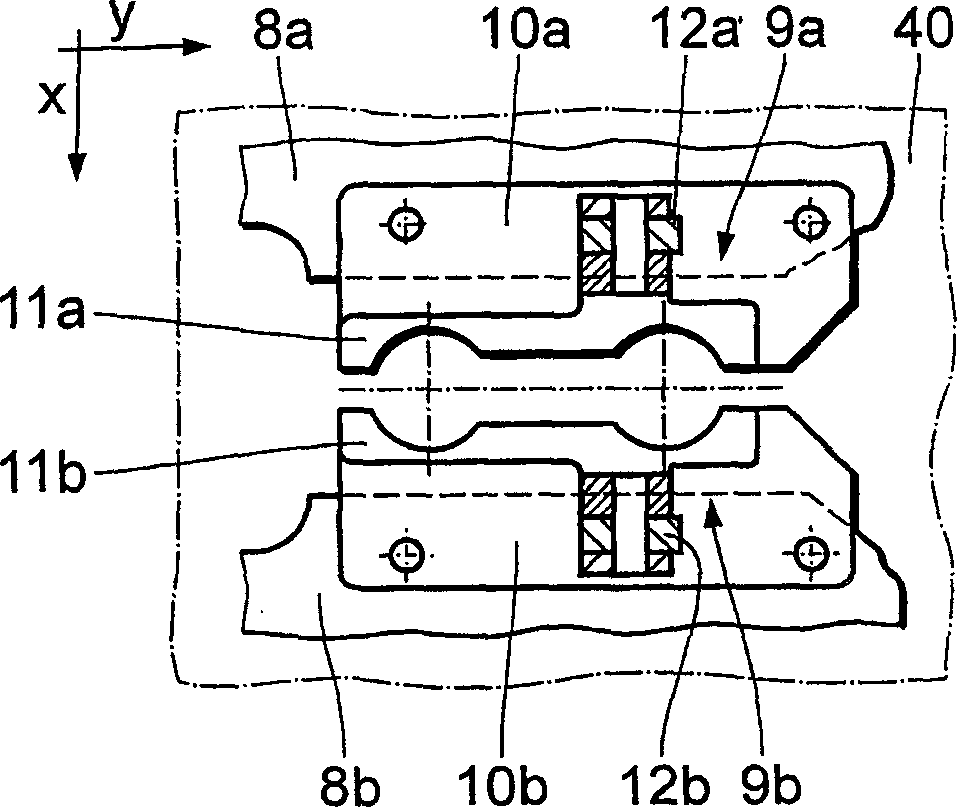

Buttonhole sewing machine

InactiveCN1692191ASimple Structural MeasuresAdjust parallelismWorkpiece carriersEngineeringSewing machine

A buttonhole sewing machine comprising an upper arm (1) with a needle (6), which can move up and down, and a base plate (2). A buttonhole cutting device (13), comprising a blade (36), which is arranged on the base plate (2) and consists of a cutting part (37) which extends in a straight line in direction y and an eye cutting part (38), is also provided. A cutting block (15) cooperates with the blade (36). The blade (36) and the cutting block (15) can be displaced by means of a motor in relation to each other in direction y.

Owner:DURKOPP ADLER AG

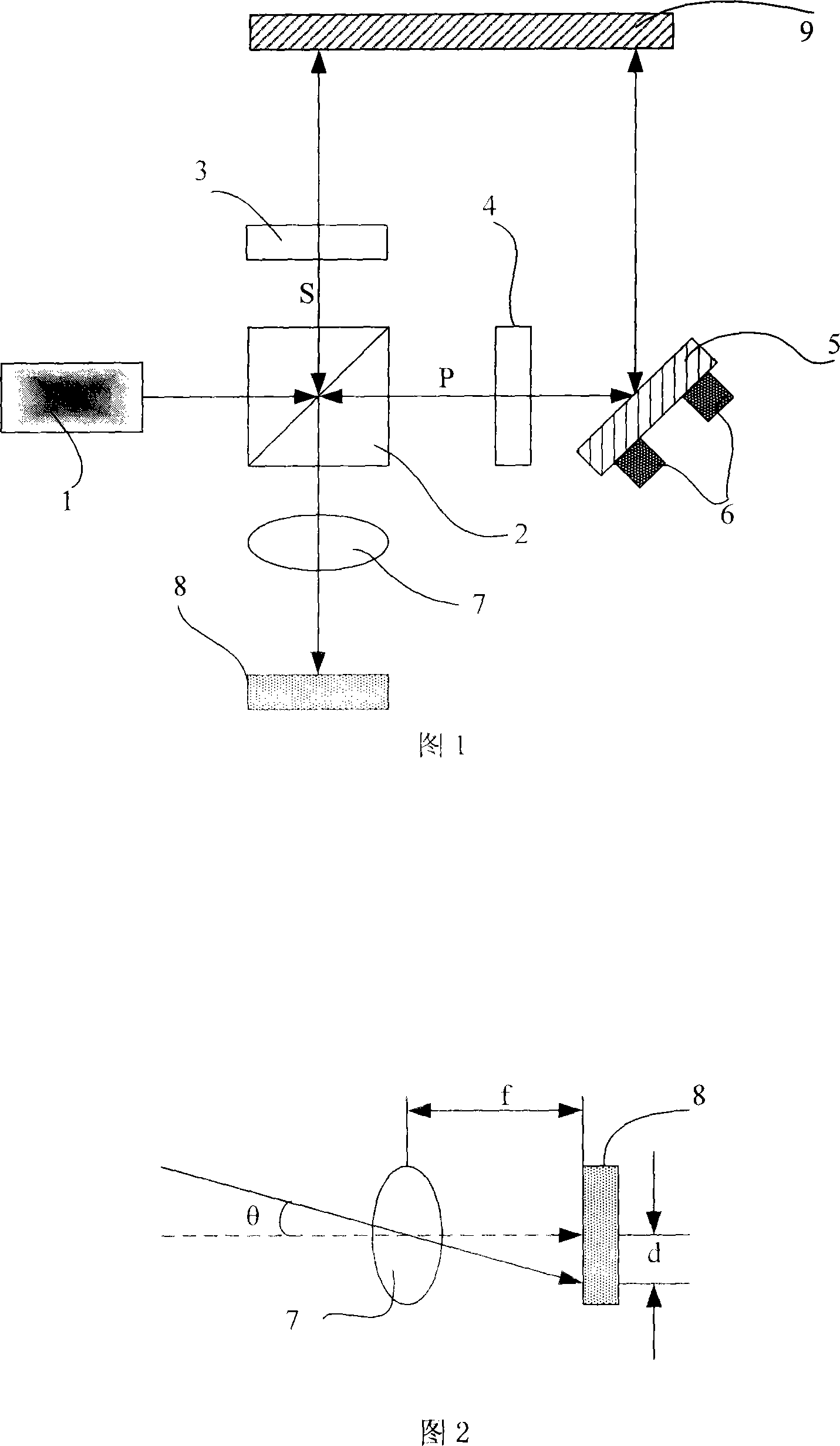

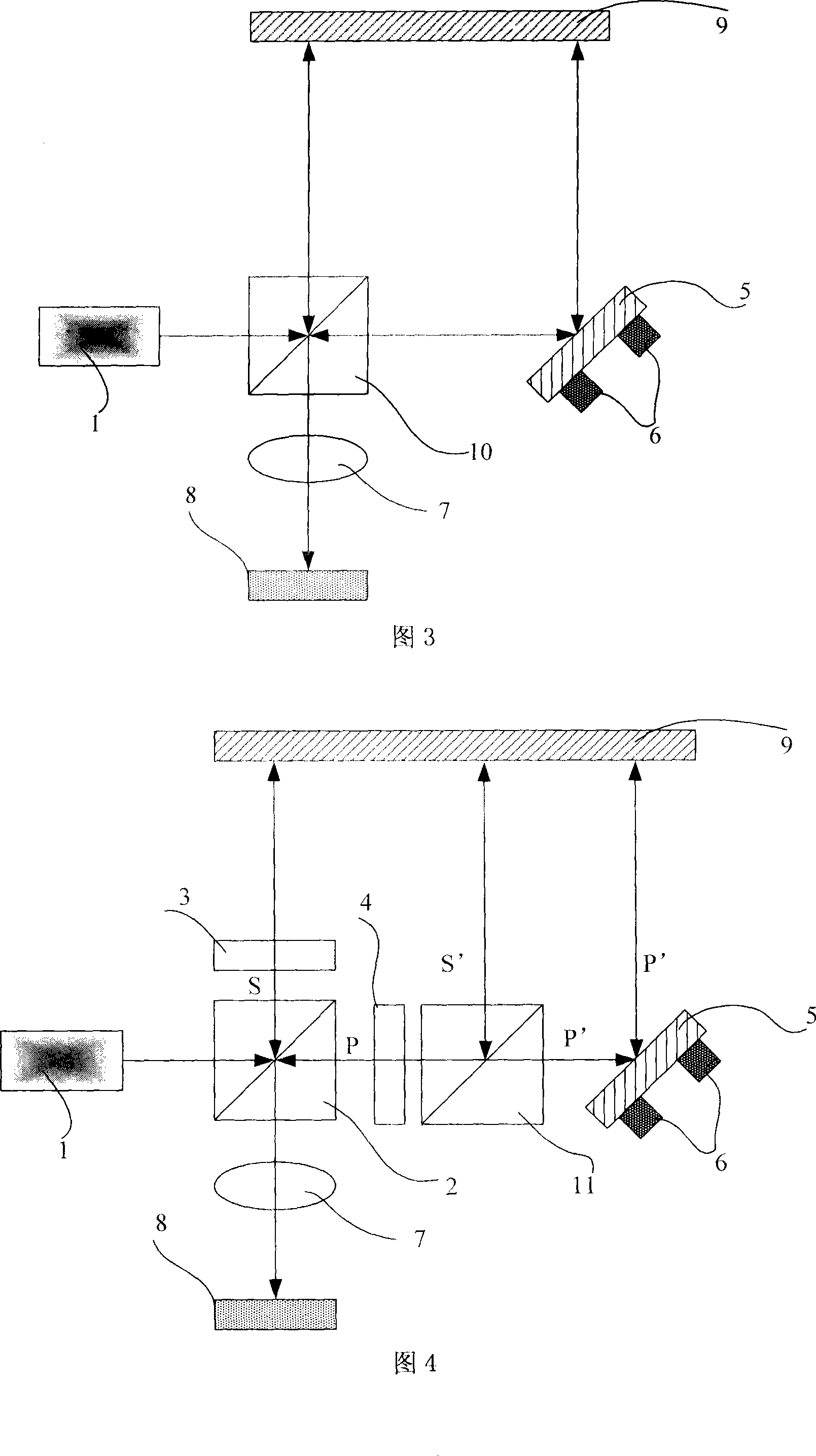

Light ray parallel adjusting device and method

InactiveCN101236304ASimple AdjustabilitySimple methodUsing optical meansOptical elementsLight beamOptoelectronics

The invention relates to a device for adjusting light rays in parallel and a method thereof and belongs to the photoelectric detection technical field. The invention uses a collimation laser (1) with high stability to emit collimation laser lights and splits the laser lights through a polarization light splitter (2); a lambda / 4 wave plate is respectively placed on a reflected light circuit and a transmitted light circuit of the polarization light splitter (2); the fast axle direction of the wave plate and the polarization direction of the laser lights become 45 degrees. Through the same planar reflector (9), rays are reflected inversely; the rays which need to be adjusted enter to the same angle measuring detector (8) successively; through adjusting a two-dimensional reflector (6), the parallelism of two emergent rays reaches below 1 arcsecond. The method can also adjust the parallelism of a plurality of light beams and is simple in structure, flexible in use, strong in universality, low in cost, high in adjusting precision and convenient to calibrate.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

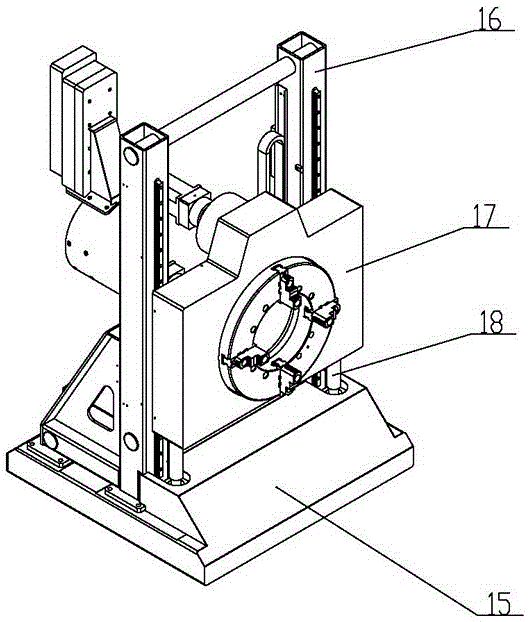

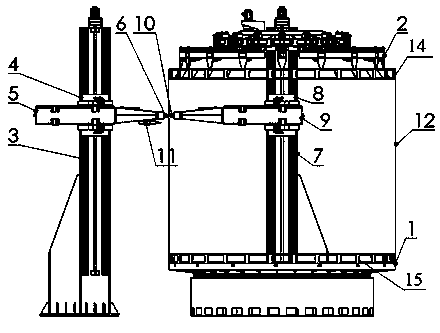

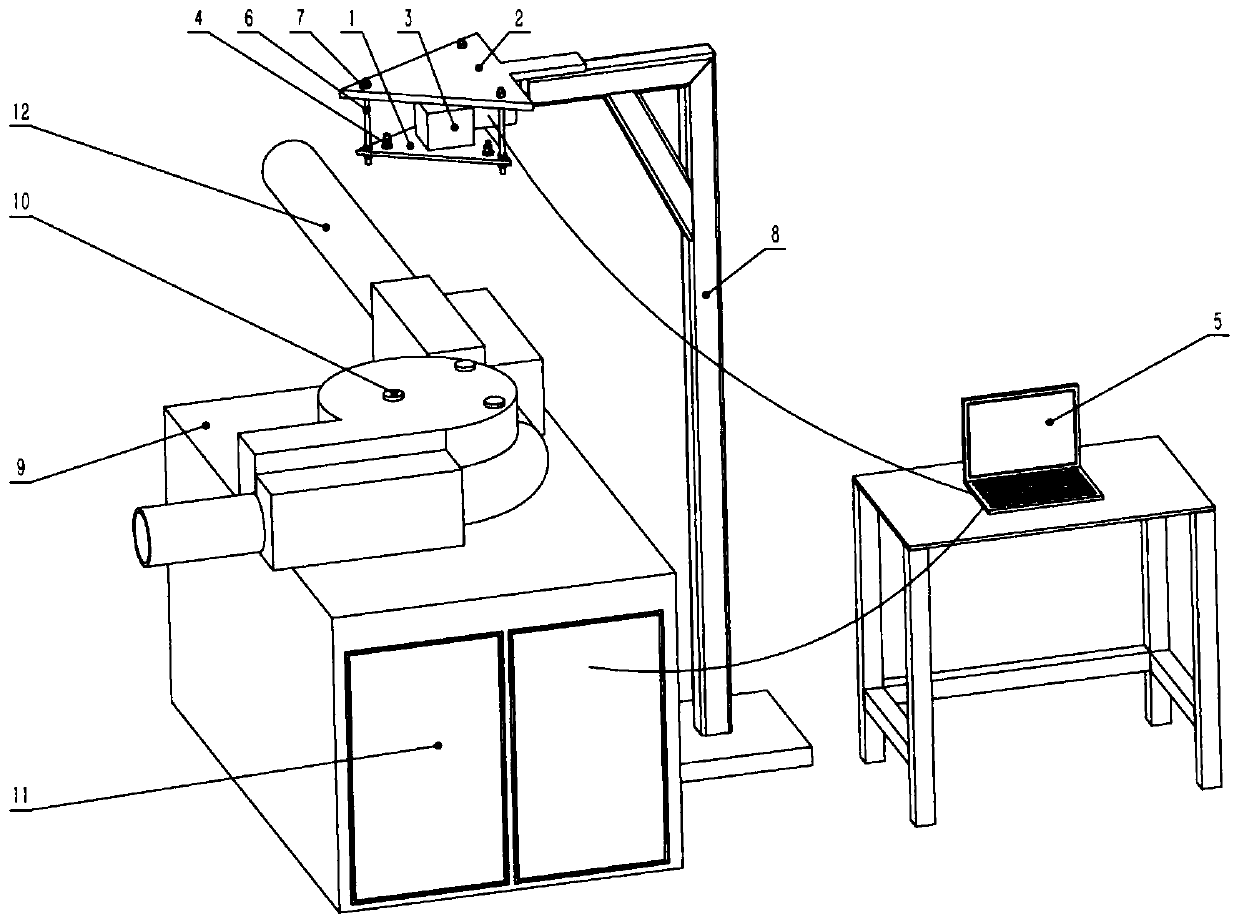

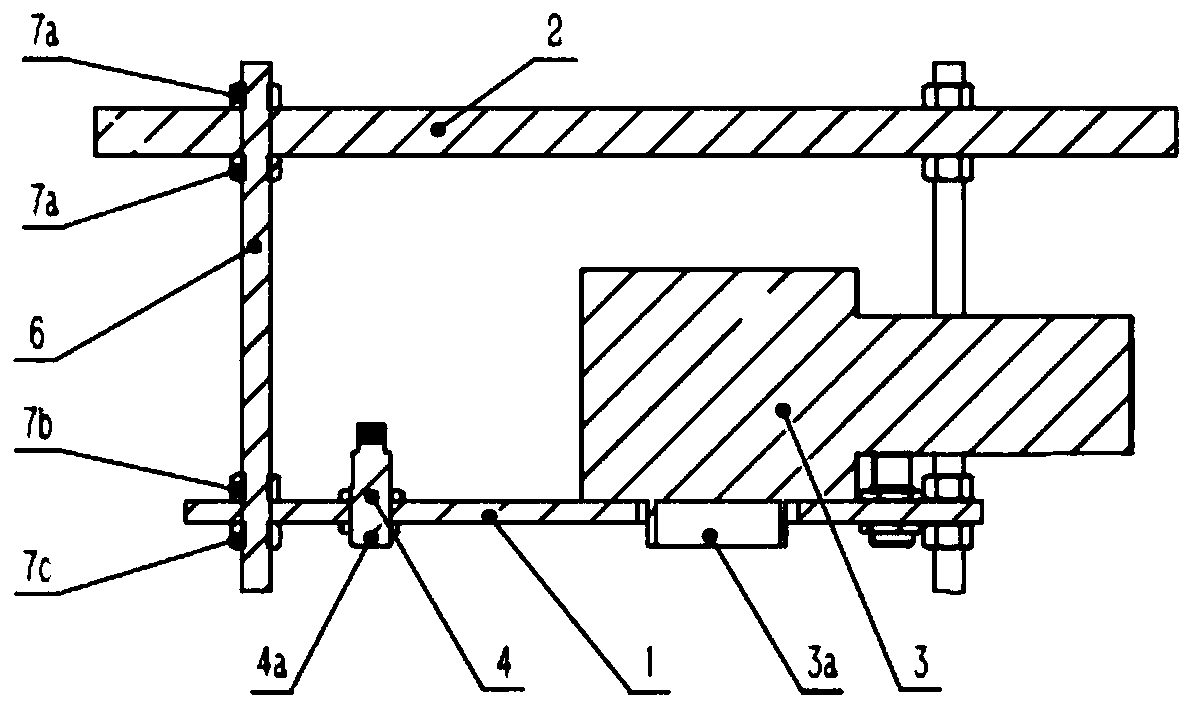

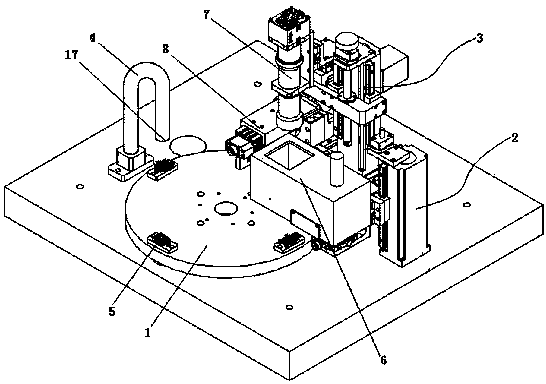

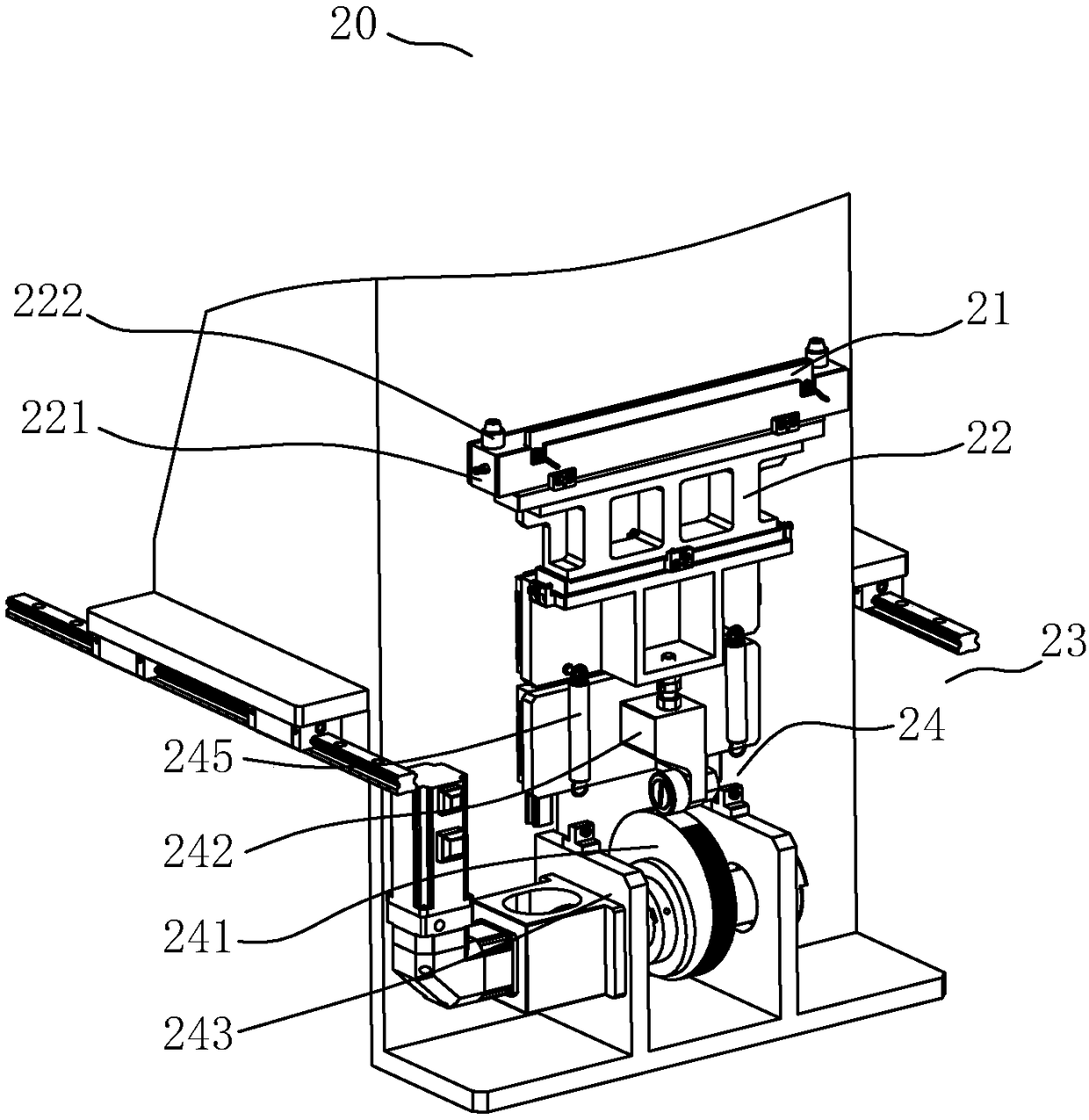

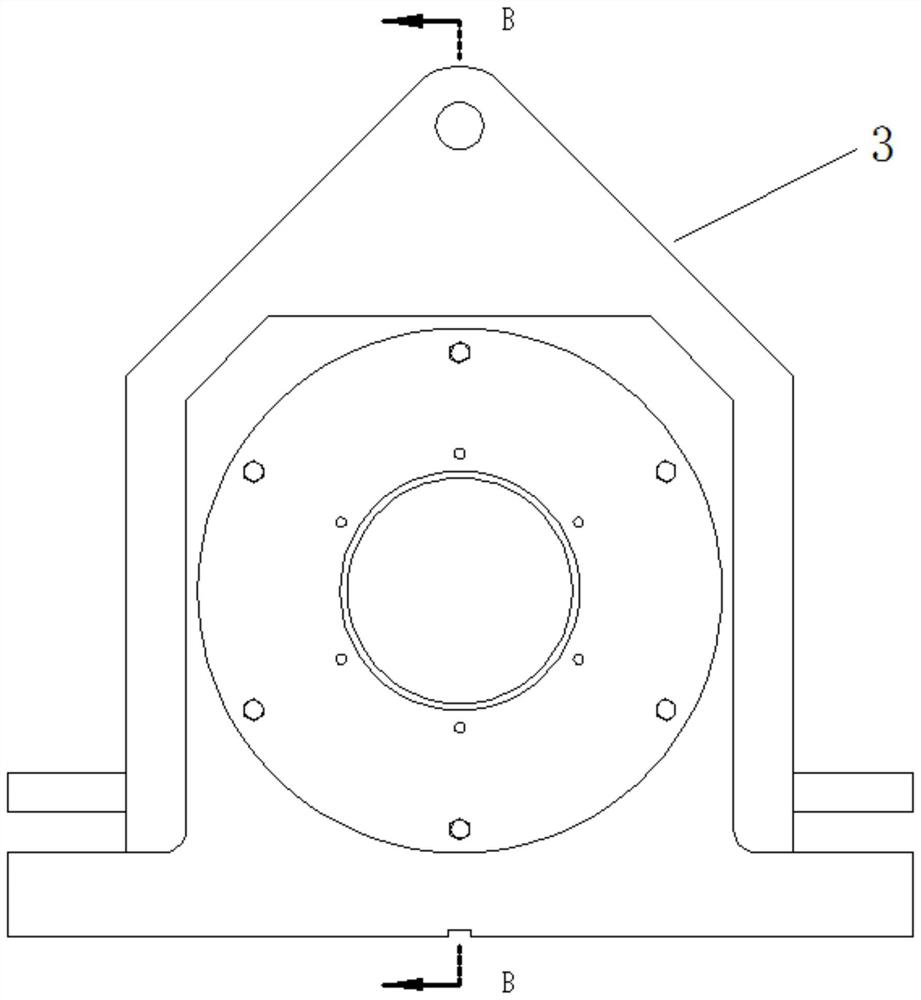

Integrated riveting device and integrated riveting method of large-scale cylinder section component

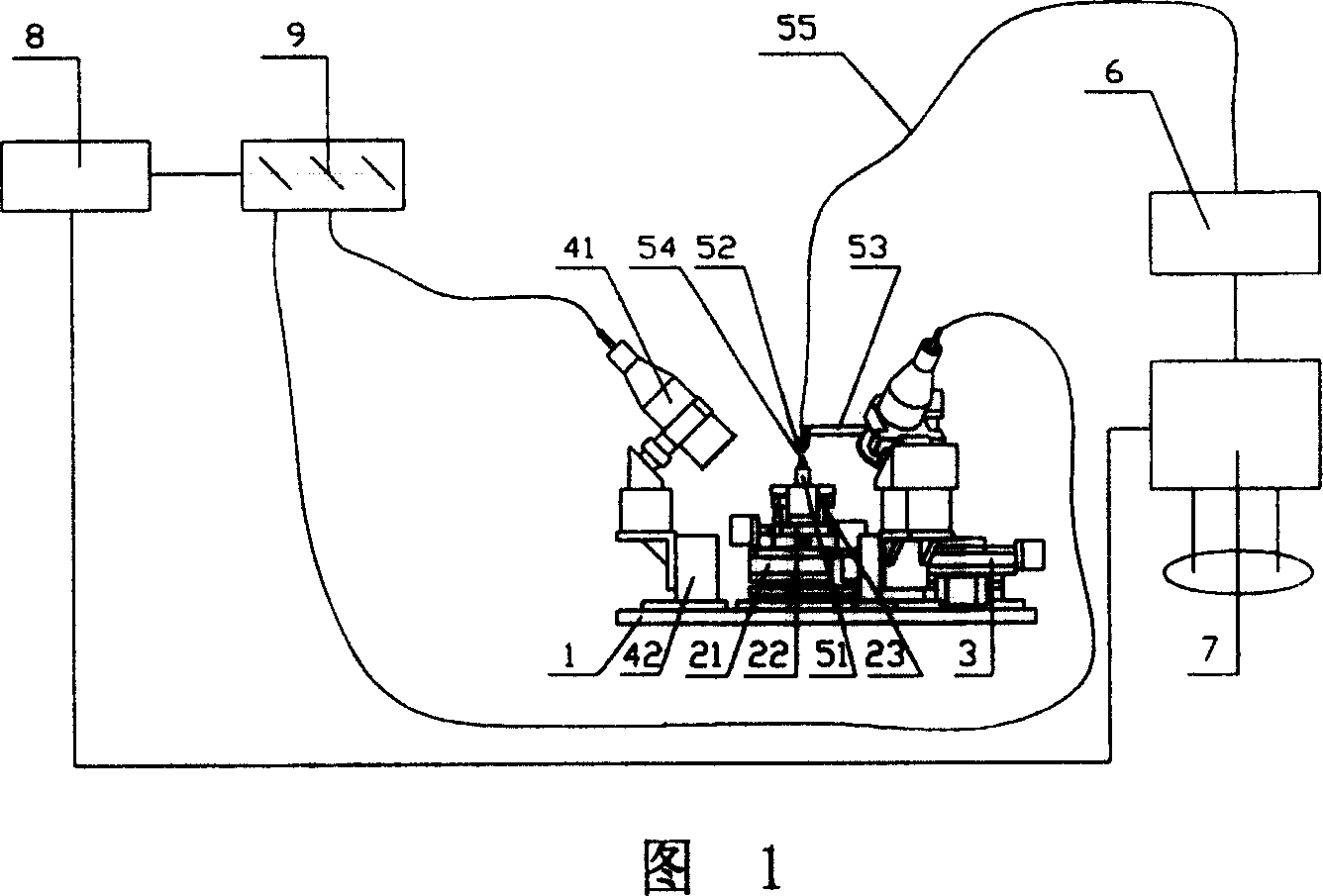

ActiveCN103386455AGuaranteed shape accuracyGuaranteed positioning accuracyAutomationNumerical control system

The invention discloses an integrated riveting device and an integrated riveting method of a large-scale cylinder section component. The integrated riveting device comprises a rotating table, a flexible clamping system with a liftable top part, a nail conveying device, a press riveting device, a left upright, a right upright, an upper location tool piece and a lower location tool piece, wherein the upper end of at least one workpiece is arranged on the flexible clamping system with the liftable top part through one upper location tool piece, the lower end of the workpiece is arranged on the rotating table through one lower location tool piece, the nail conveying device is positioned on the left upright, and the press riveting device is positioned on the right upright. According to the integrated riveting device disclosed by the invention, the integrated riveting of a large-scale cylinder section workpiece can be accurately realized, all the riveting work can be automatically completed once a numerical control system is set, human intervention is not needed, and the automation degree is high. The integrated riveting device has a strong universality and can be applied to the integrated riveting and processing of thin-wall cylinder section components in various diameters and various heights.

Owner:SHANGHAI TOPNC NUMERICAL CONTROL TECH CO LTD

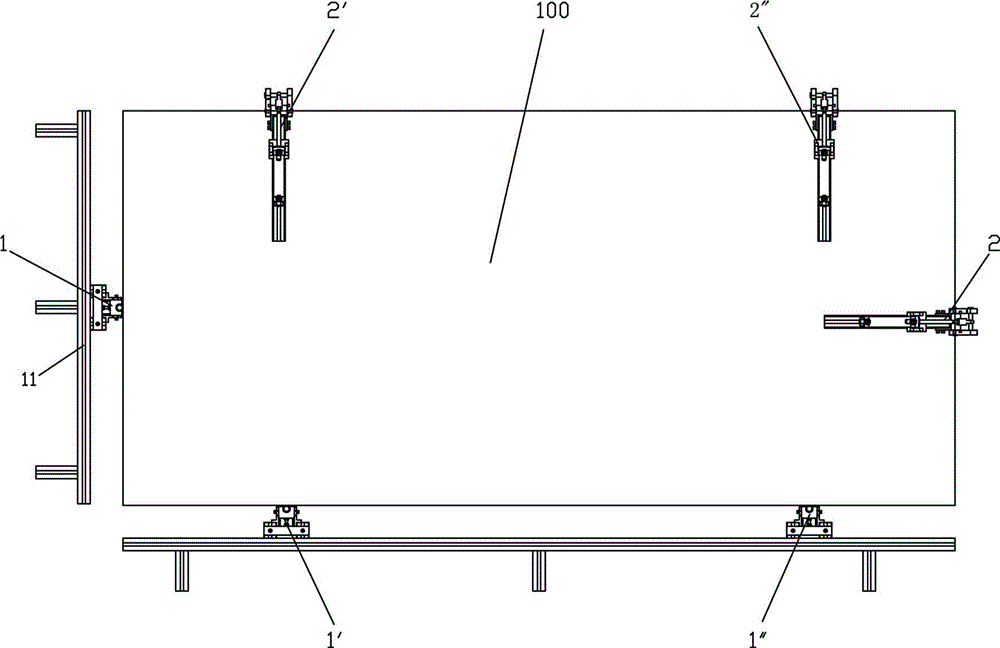

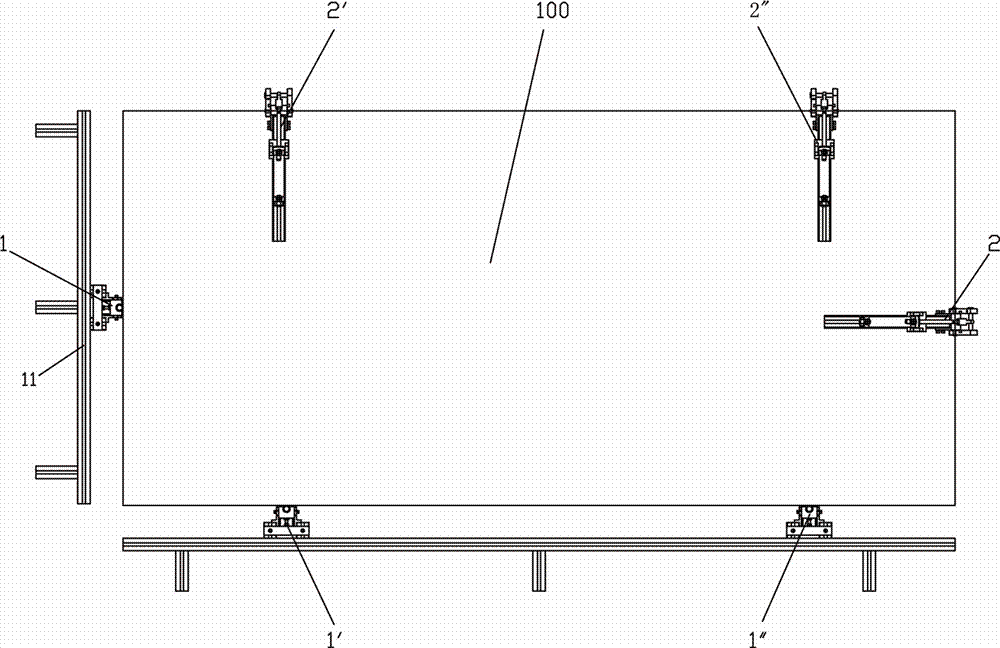

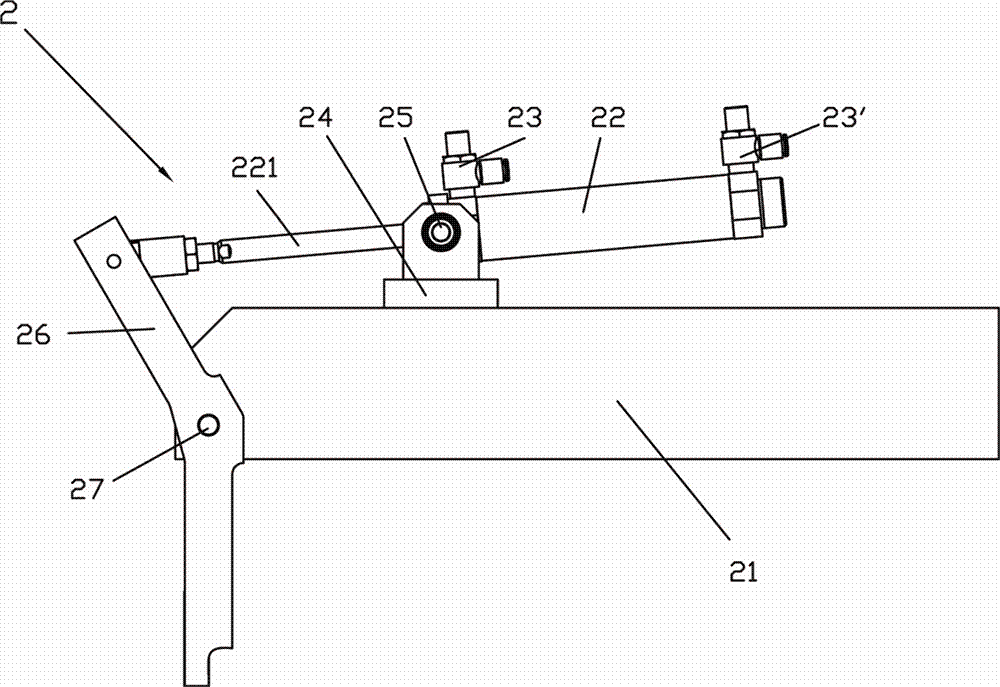

Device used for neatly beating and aligning large-width steel plate

ActiveCN105108411AMatched to achieveEffectively align homeworkWelding/cutting auxillary devicesAuxillary welding devicesDual actionEngineering

A device used for neatly beating and aligning a large-width steel plate comprises at least three positioning devices. At least one positioning device is arranged on the lateral side in the width direction of the steel plate. At least two positioning devices are arranged on the lateral side in the length direction of the steel plate. Each positioning device comprises a positioning base, a positioning installation frame and at least three neatly beating devices, wherein a slide groove is formed in a side face of the base, one end of the positioning installation frame is positioned in the slide groove of the positioning base and is movably connected to the positioning base through an adjustment bolt, a positioning block is arranged at the other end of the positioning installation frame, at least one neatly beating device is arranged on the lateral side in the width direction of the steel plate, and at least two neatly beating devices are arranged on the lateral side in the length direction of the steel plate. Each neatly beating device comprises an installation machine frame, a piston cylinder, a dual-action cylinder and a neatly beating plate, wherein cylinder bodies are arranged on the installation machine frame through fixing shafts and cylinder installation blocks, the upper portion of the neatly beating plate is movably connected to a piston rod of the piston cylinder through a pin shaft, the middle of the neatly beating plate is connected to one end of the installation machine frame through a pivoting shaft, an angle lager than 90 degrees is formed by the upper portion and the lower portion of the neatly beating plate, and the neatly beating plate is driven by the piston cylinder through the piston rod to rotate around the fixing shaft in a reciprocating mode.

Owner:BAOSHAN IRON & STEEL CO LTD

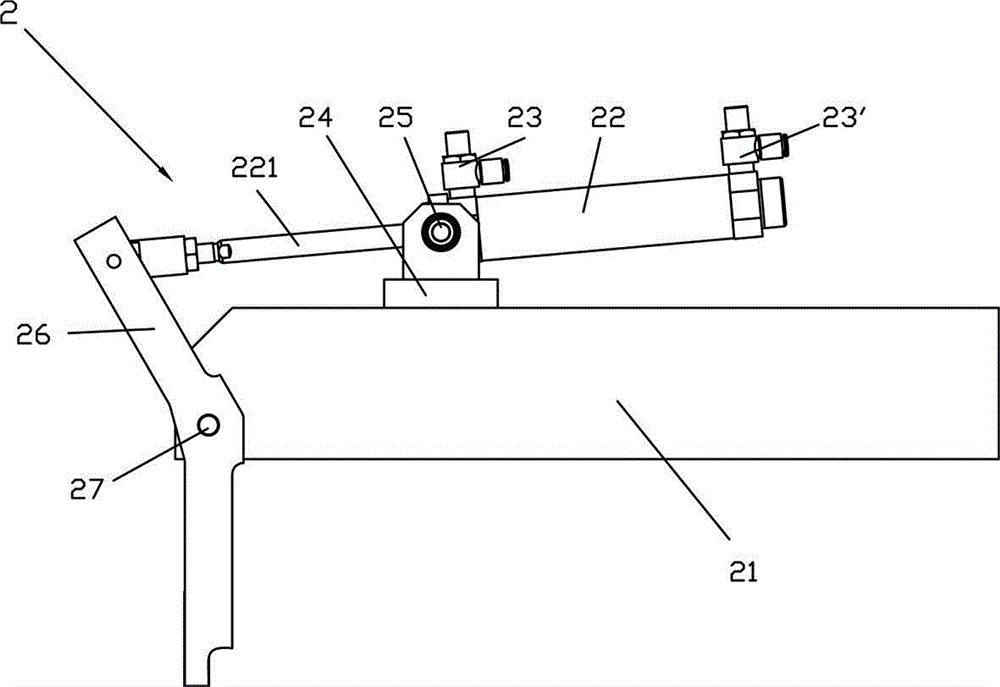

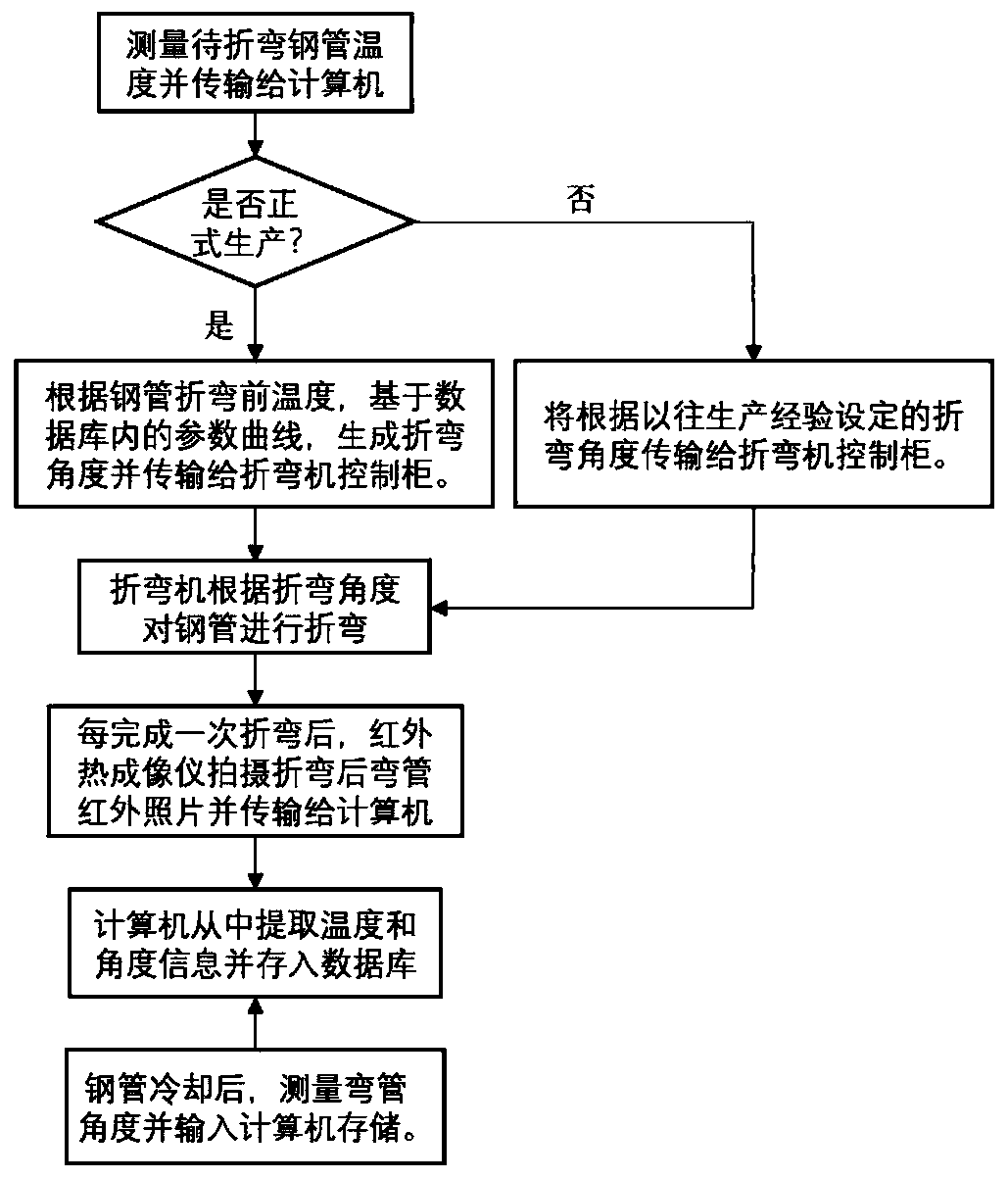

Angle control device for bending pipe

ActiveCN111389981ASolve the problem that the amount of rebound cannot be controlledEasy to controlThermographic cameraEngineering

The invention discloses an angle control device for a bending pipe. The angle control device comprises a supporting frame, a fixing device, an infrared thermal imager, a distance measuring sensor anda computer, wherein the supporting frame is supported on one side of a bending machine, the fixing device is arranged on the supporting frame, and the infrared thermal imager and the distance measuring sensor are fixed on the fixing device; and a lens of the infrared thermal imager is opposite to the working surface of the bending machine, a signal emitting end of the distance measuring sensor isopposite to a positioning point on the bending machine, the infrared thermal imager is connected with a first port of the computer through a signal line, and a second port of the computer is connectedwith a control cabinet of the bending machine through a signal line. According to the angle control device for the bending pipe, temperature and angle parameters before and after bending of the bending pipe can be collected, a database of bending process parameter groups of the bending pipe is established, and the control over the angle of the bending pipe is realized by calling the parameter groups of the database.

Owner:山东信创信息科技服务有限公司

Coaxiality adjusting-correcting method for long shaft coupler

InactiveCN108817934AAdjust parallelismAvoid measurement errorsMetal working apparatusMechanical measuring arrangementsCouplingEngineering

Owner:CHINA METALLURGICAL CONSTR ENG GRP

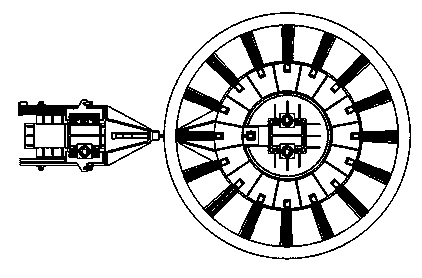

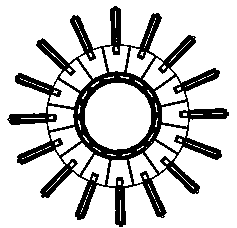

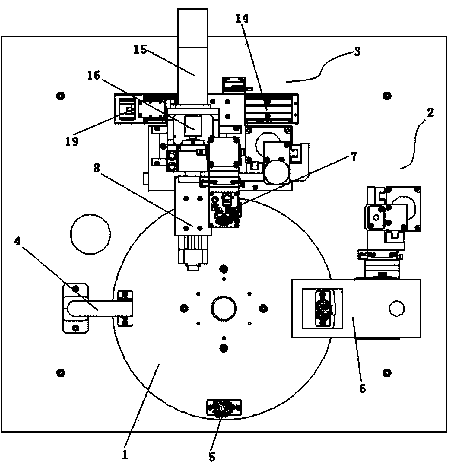

Automatic tag inspection and detection assembly

InactiveCN104237250AAdjust parallelismEasy to useOptically investigating flaws/contaminationWorkstationComputer science

The invention relates to an automatic tag inspection and detection assembly. The automatic tag inspection and detection assembly comprises a circular detection disc, as well as a first detection device, a second detection device and a code spraying labeling device, which are sequentially arranged on the side circumference along the rotation direction of the detection disc, wherein at least four tag workstations are arranged on the edge of the upper surface of the detection disc at intervals, the first detection device, the second detection device and the code spraying labeling device are respectively and correspondently arranged on the outer sides of three adjacent tag workstations in sequence, and each tag workstation is used for storing a tag. According to the automatic tag inspection and detection assembly, the planar detection and the linear detection are integrated into one device, various flaws can be detected at one time, and different labels can be respectively sprayed onto the tags with different flaws by the code spraying labeling device, so that the tags can be arranged in a classifying manner, the parallelism between a lens and the tag can be better adjusted by a plane adjusting device, the focal length can be adjusted by a lifting device, the use is more convenient, and the automatic tag inspection and detection assembly is suitable for detecting various tags.

Owner:SUZHOU JQS INFO TECH CO LTD

Projection device

The invention discloses a projecting device comprising an optical machine casing, an optical module and a fine tuning structure. The optical module is arranged on the optical machine casing. The fine tuning structure comprises a flexible element and a latch fitting, wherein, the flexible element is arranged between the optical machine casing and the optical module and has a height, and the latch fitting is in coupling with the flexible element for connecting the optical machine casing and the optical module. When the latch fitting is adjusted, the distance between the optical machine casing and the optical module is changed; the optical machine casing and the optical module simultaneously are used to compress or release the flexible element, thereby changing the height of the flexible element and maintaining the distance through the flexible element after the latch fitting is adjusted.

Owner:BENQ CORP

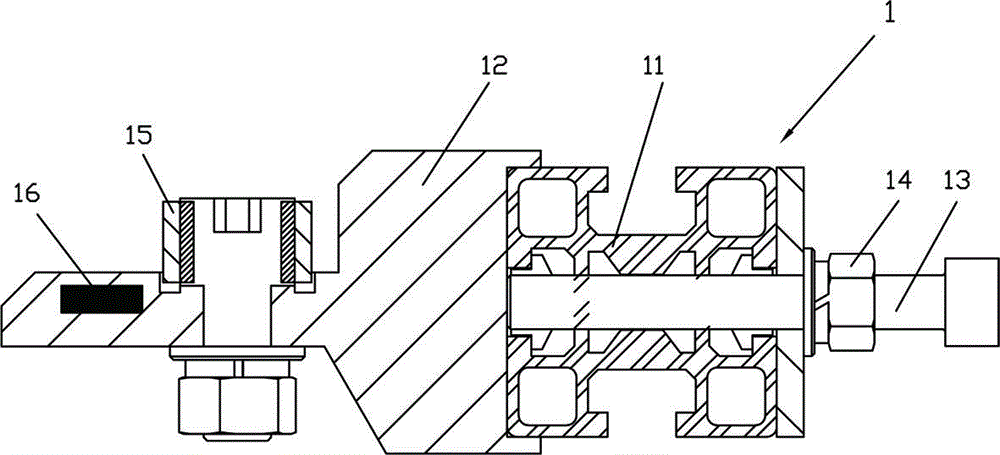

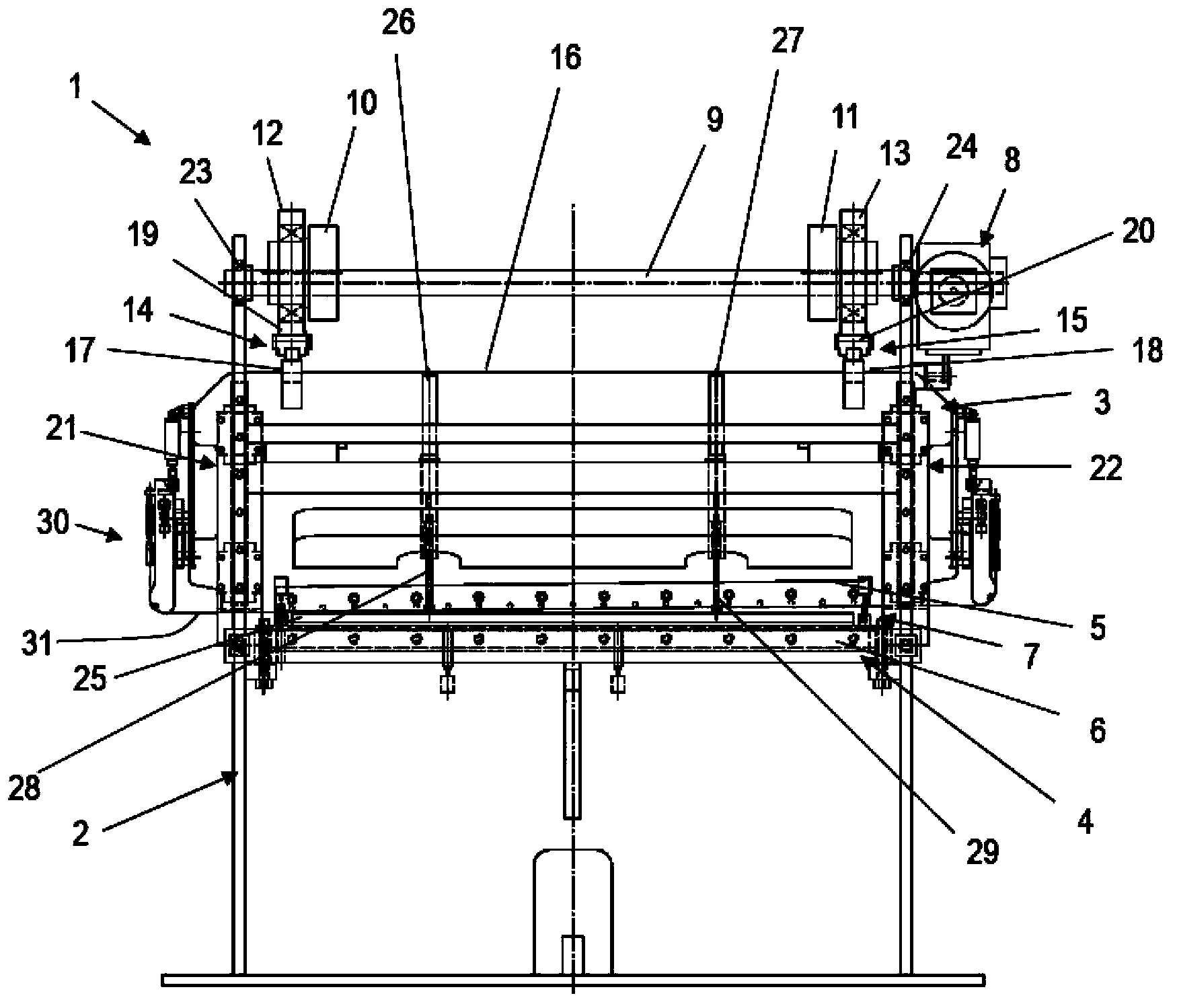

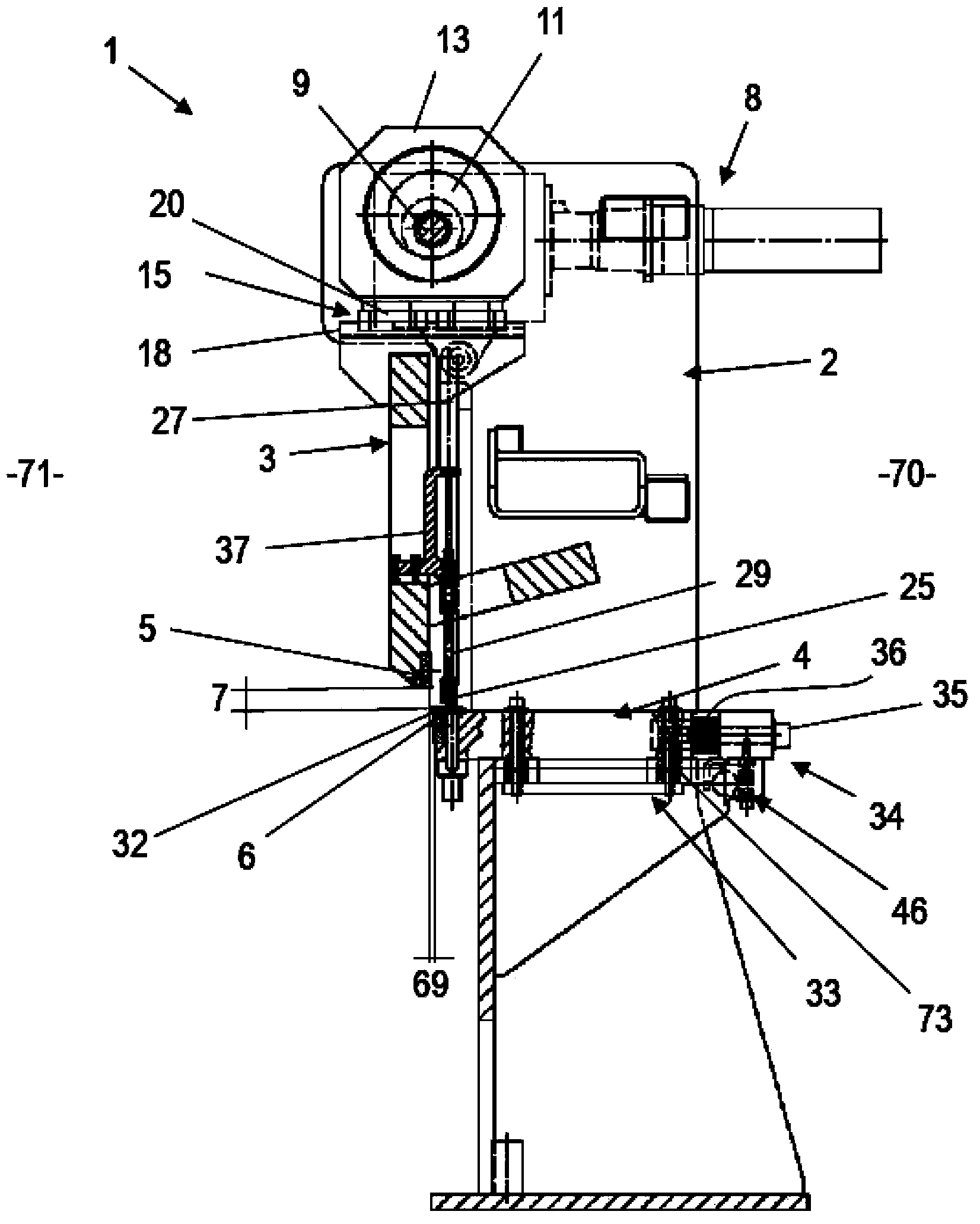

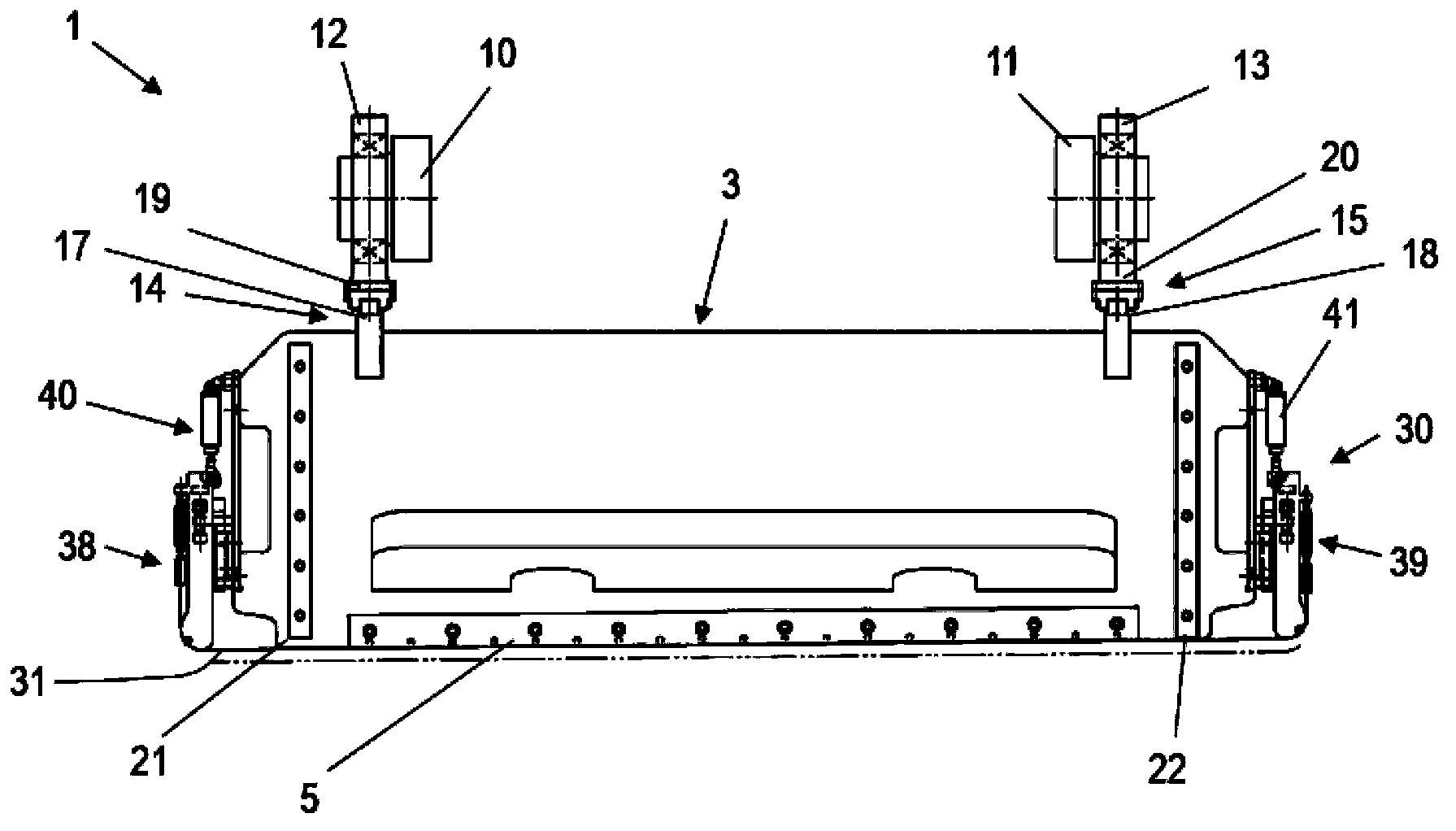

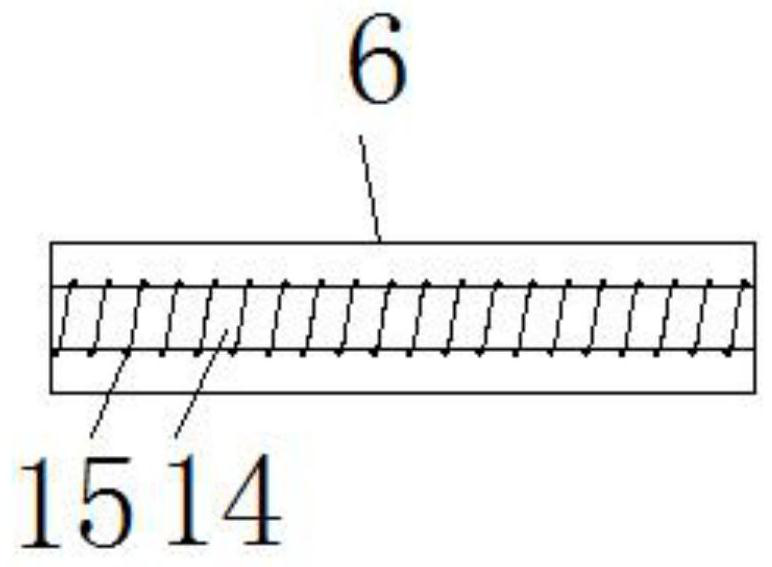

Cutting machine

The invention relates to a cutting machine for cutting sticky ribbons, particularly the ribbon comprises sticky thin cord fabric material comprising spinning silk and / or steel wire. The cutting machine comprises a main frame (2), a knife rest (3), a platen (4) with a lower blade (6), and a driving device (8) with a driving shaft (9), wherein the knife rest (3) with an upper blade (5) can vertically move and support on the main frame (2), a knife edge (7) is arranged between the upper blade (5) and the lower blade (6), the driving device (8) is used for driving the knife rest (3) with the upper blade (5) to vertically move relative to the main frame (2). In order to realize high hardness, the driving shaft (9) eccentrically supports in at least one bearing shell (12 or 13), and the bearing shell only can horizontally move and support on the knife rest (3) through linear guide parts (14 and 15).

Owner:KARL EUGEN FISCHER GMBH

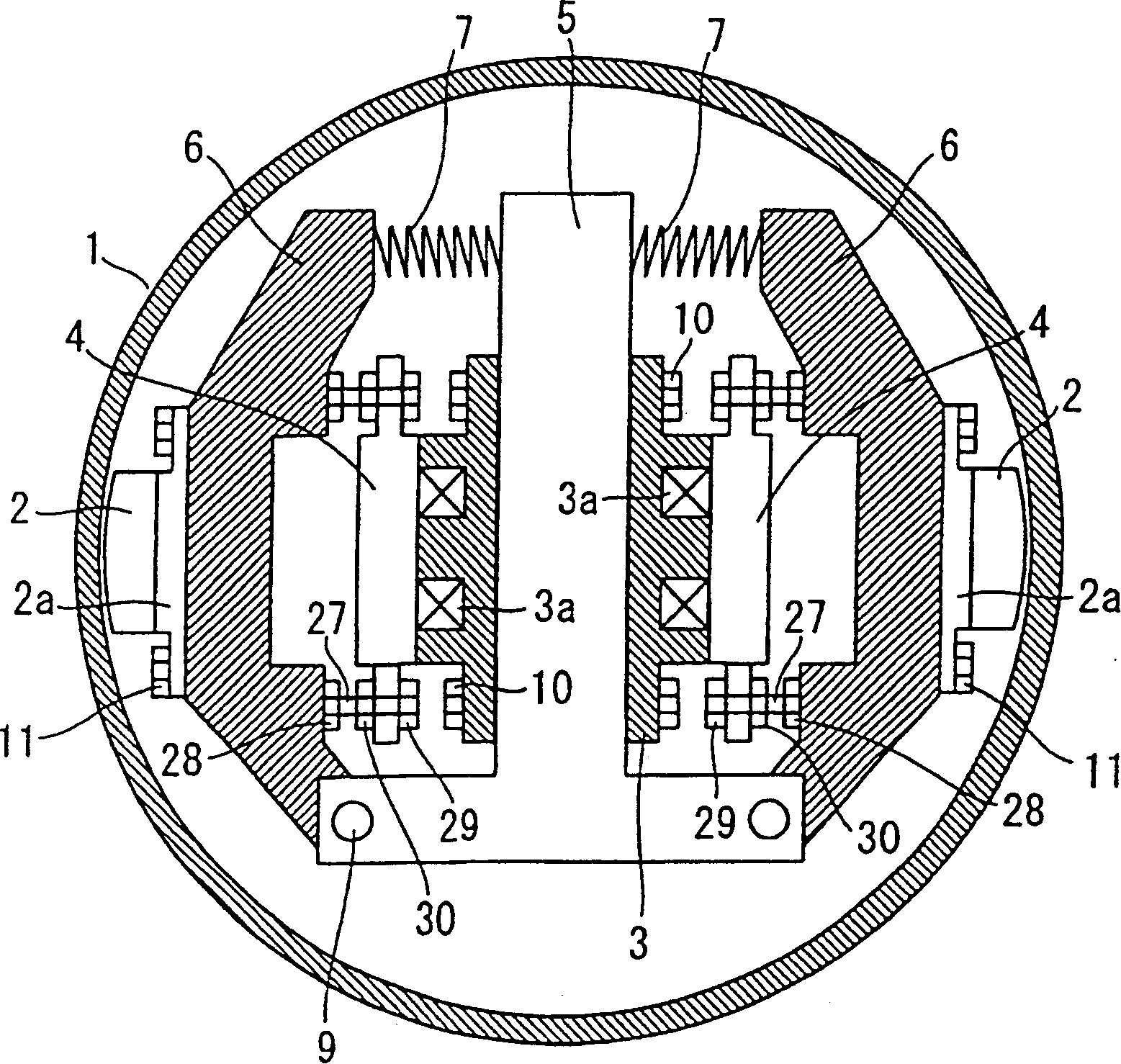

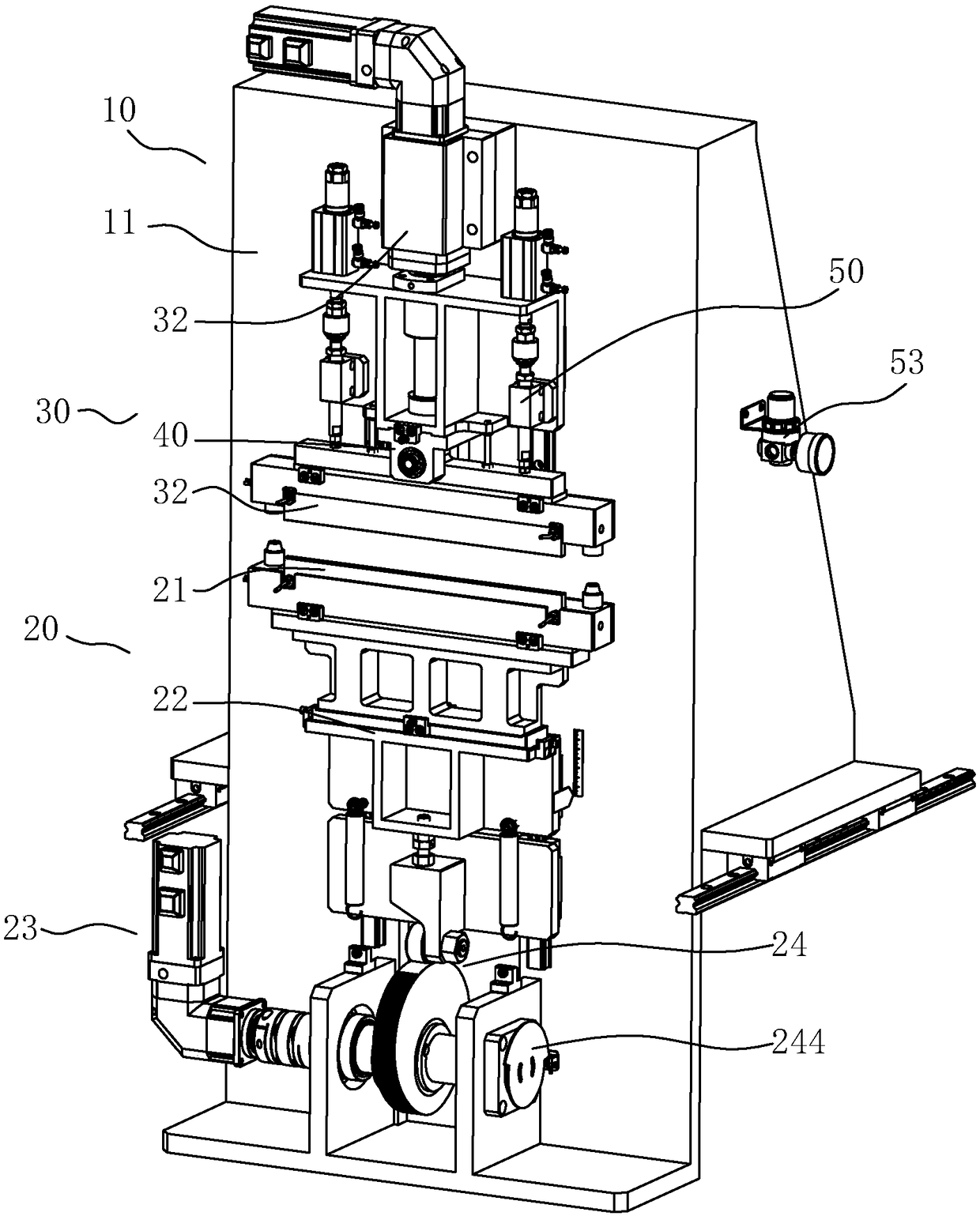

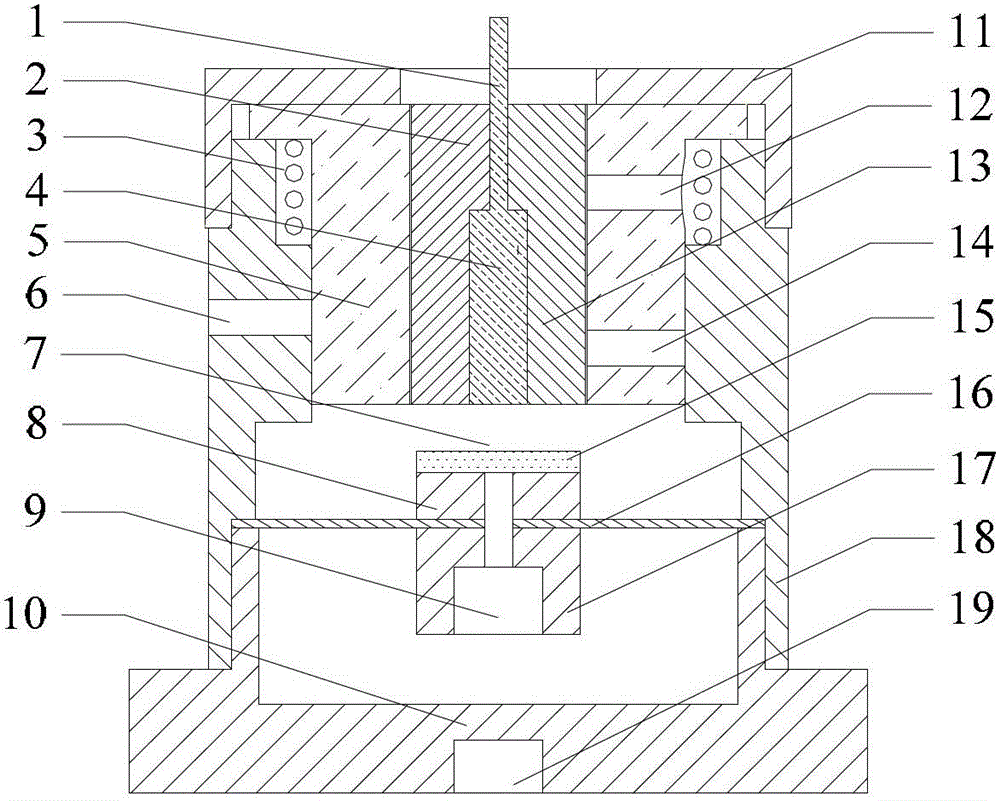

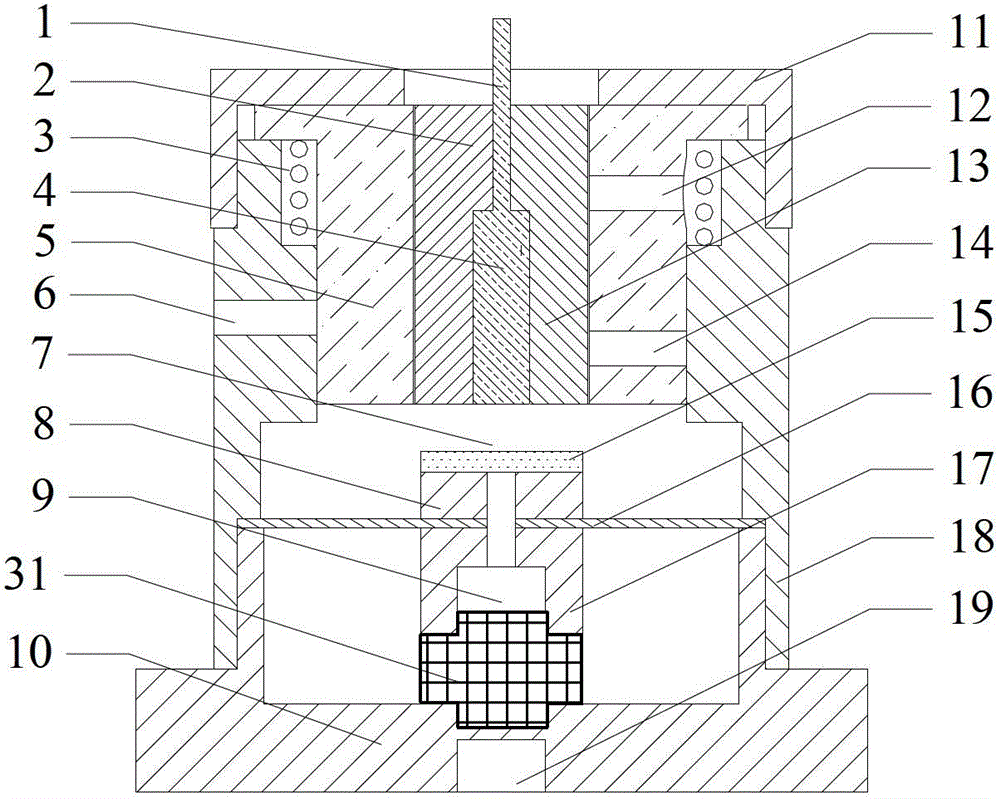

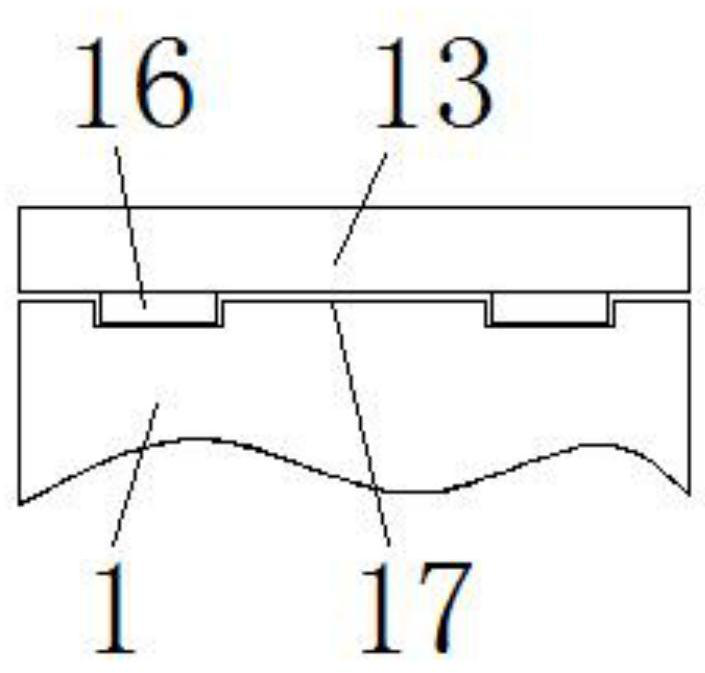

Self-adjusting heat-sealing mechanism of soft package battery

PendingCN108448153AImprove heat sealing qualityAdjust parallelismAssembling battery machinesFinal product manufactureEngineeringSelf adjustment

The invention discloses a self-adjusting heat-sealing mechanism of a soft package battery. The self-adjusting heat-sealing mechanism comprises a mounting base, a lower heat-sealing mechanism, an upperheat-sealing mechanism and at least two elastic adjusting parts, wherein the mounting base is provided with a vertical mounting surface; the lower heat-sealing mechanism is mounted at the lower partof the vertical mounting surface, and the lower heat-sealing mechanism is provided with a lower supporting part capable of horizontally and fixedly supporting a lower heat-sealing head during heat-sealing; the upper heat-sealing mechanism is mounted at the upper part of the vertical mounting surface, and the upper heat-sealing mechanism comprises an upper driving part and an upper heat-sealing head connected with the output end of the upper driving part through a floating mechanism; the at least two elastic adjusting parts are arranged at the upper parts, positioned on two sides of the floating mechanism, of the upper heat-sealing mechanism, and the elastic adjusting parts can stretch out in the vertical direction to abut the floating mechanism and link with the floating mechanism. The self-adjusting heat-sealing mechanism of the soft package battery disclosed by the invention can realize self-adjustment of the heat-sealing mechanism according to the soft package battery during heat-sealing of the soft package battery, so that the heat-sealing quality of the soft package battery is improved.

Owner:SHENZHEN HYMSON LASER INTELLIGENT EQUIP CO LTD

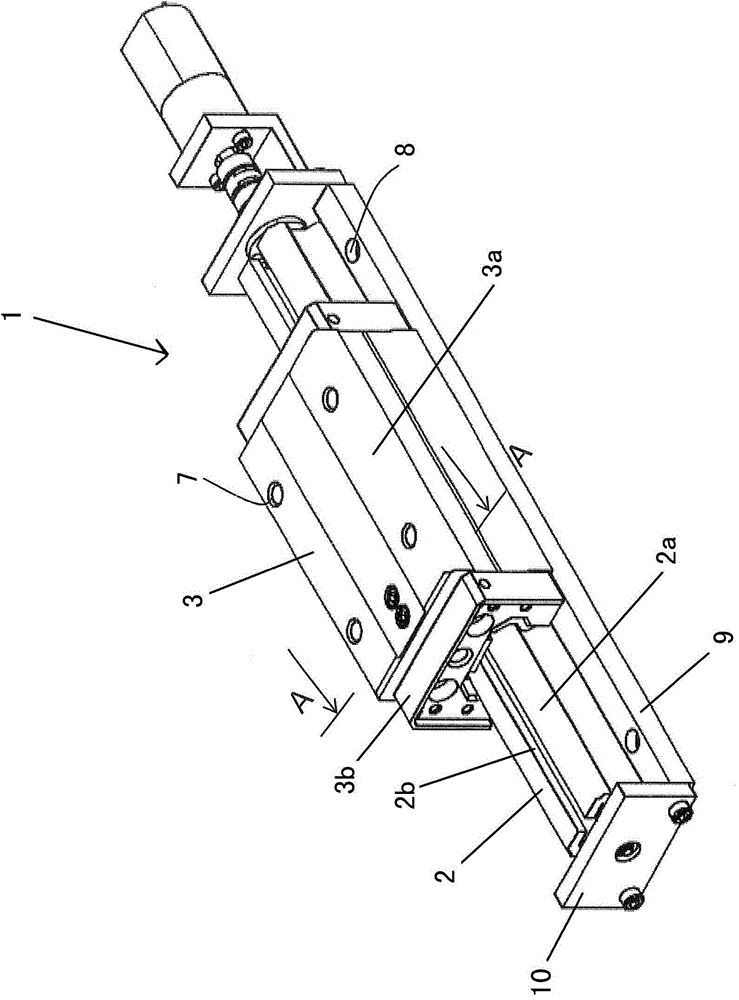

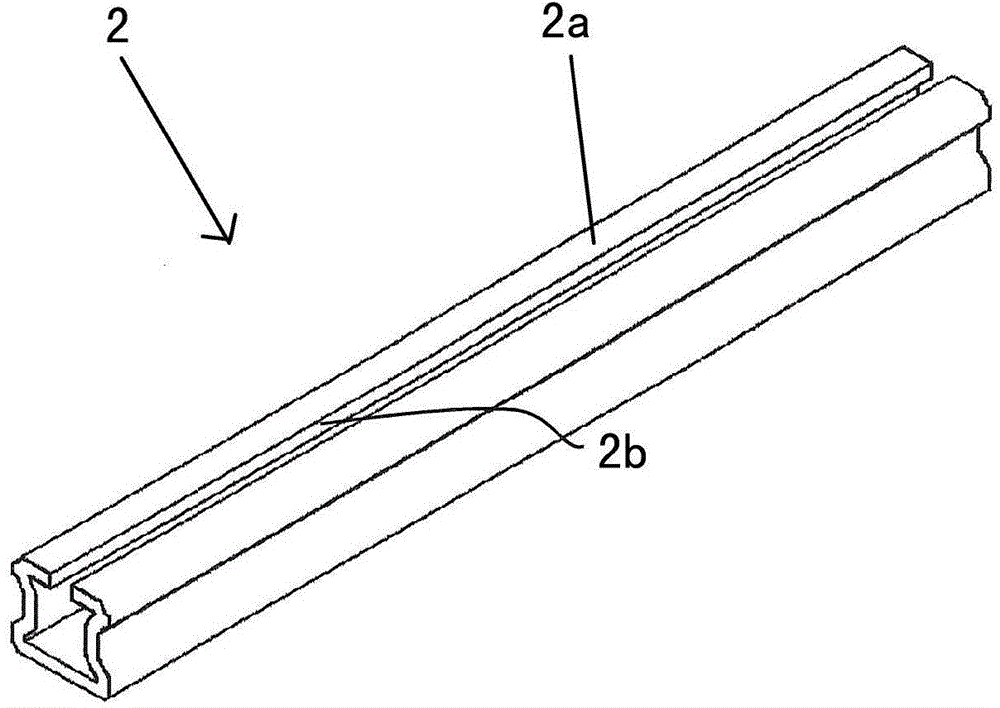

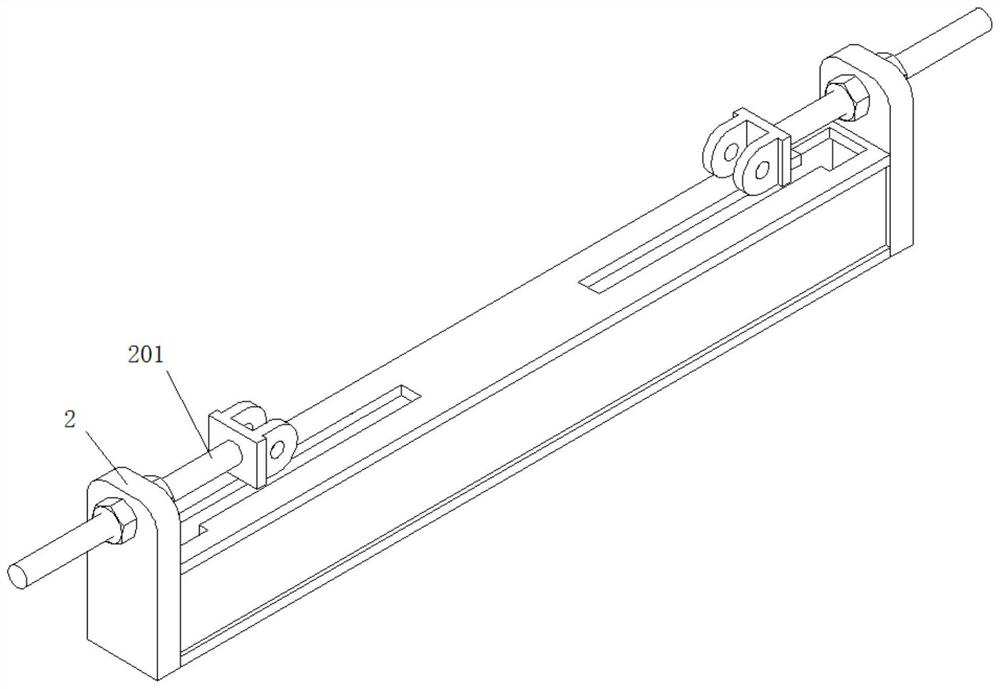

Linear movement device

The invention provides a linear movement device. The linear movement device is characterized by comprising a hollow supporting body, a movable body and a nut. The movable body can move on the hollow supporting body through a plurality of rolling bodies. The nut is arranged in the hollow supporting body and combined with a screw shaft for driving the movable body in a threaded mode. The hollow supporting body is provided with a cut groove extending in the length direction, and the cut groove is formed in the surface opposite to the movable body. A protruding part arranged on the nut is fixed in a groove in the movable body through the cut groove. In this way, in the linear movement device, the nut can be easily positioned relative to the movable body and can be easily assembled, and the parallelism of the screw shaft combined with the nut in a threaded mode and the supporting body can be easily adjusted.

Owner:THK CO LTD

Improved leather tension detection device

InactiveCN104749028AEasy to fixWon't fall offMaterial strength using tensile/compressive forcesEngineeringSlide plate

Owner:ZHEJIANG FUBANG GRP CO LTD

Printing head self-adaptive adjustment device and printer thereof

The invention provides a printing head self-adaptive adjustment device which comprises a fixing rack, a connecting rack and a connecting component; the fixing rack is arranged on a printer base; a printing head is arranged on the connecting rack; the connecting rack is connected with the fixing rack by the connecting component; the connecting rack has a locking state and a rotation adjustment state relative to the fixing rack; the connecting component comprises a connecting piece and an elastic piece; the connecting rack is connected with the fixing rack through the connecting piece; and the elastic piece generates pressure on the matching end faces of the connecting piece and the fixing rack. In a rotation adjustment state, the printing head deflects relative to a rubber roller, by this time, the pressure on the contact line of the printing head and the rubber roller is not balanced, and then torque driving the connecting rack to deflect is generated till the contact line of the printing head and the rubber roller is stressed uniformly. Self-adaptive adjustment on the parallelism degree of the printing head and the rubber roller is realized, the contact line of the printing head and the rubber roller is stressed uniformly, and thus the printing quality is improved.

Owner:XIAMEN HANIN ELECTRONICS TECH CO LTD

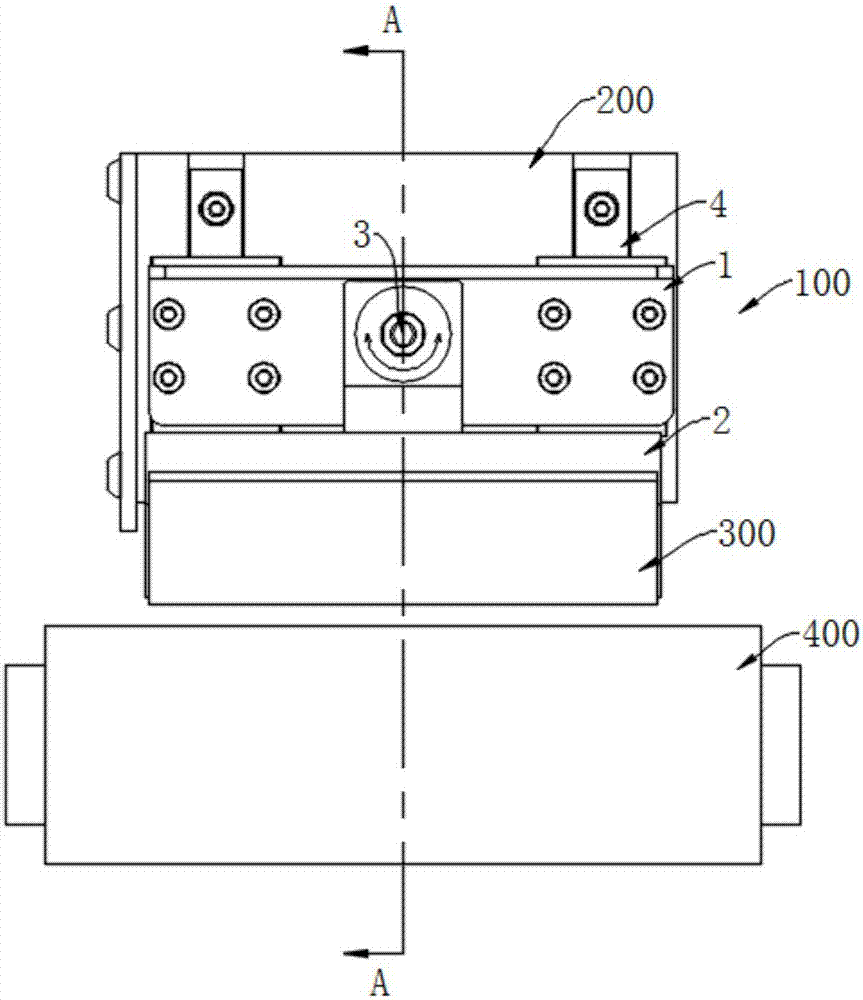

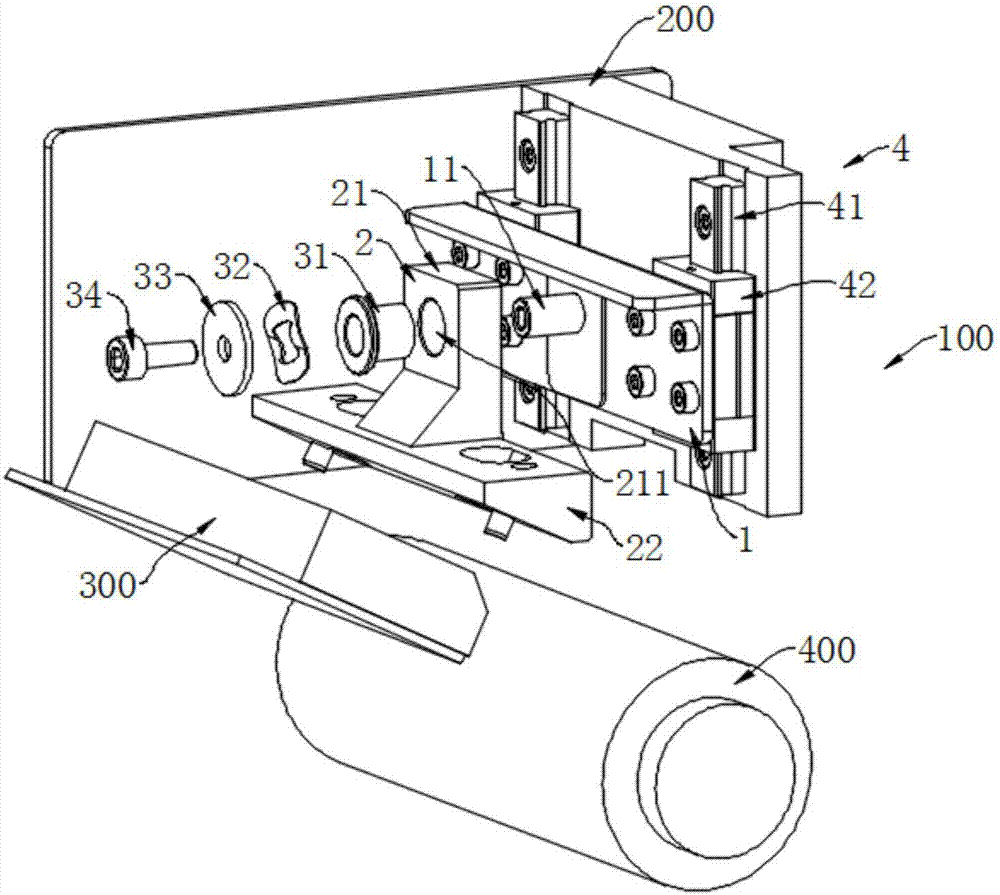

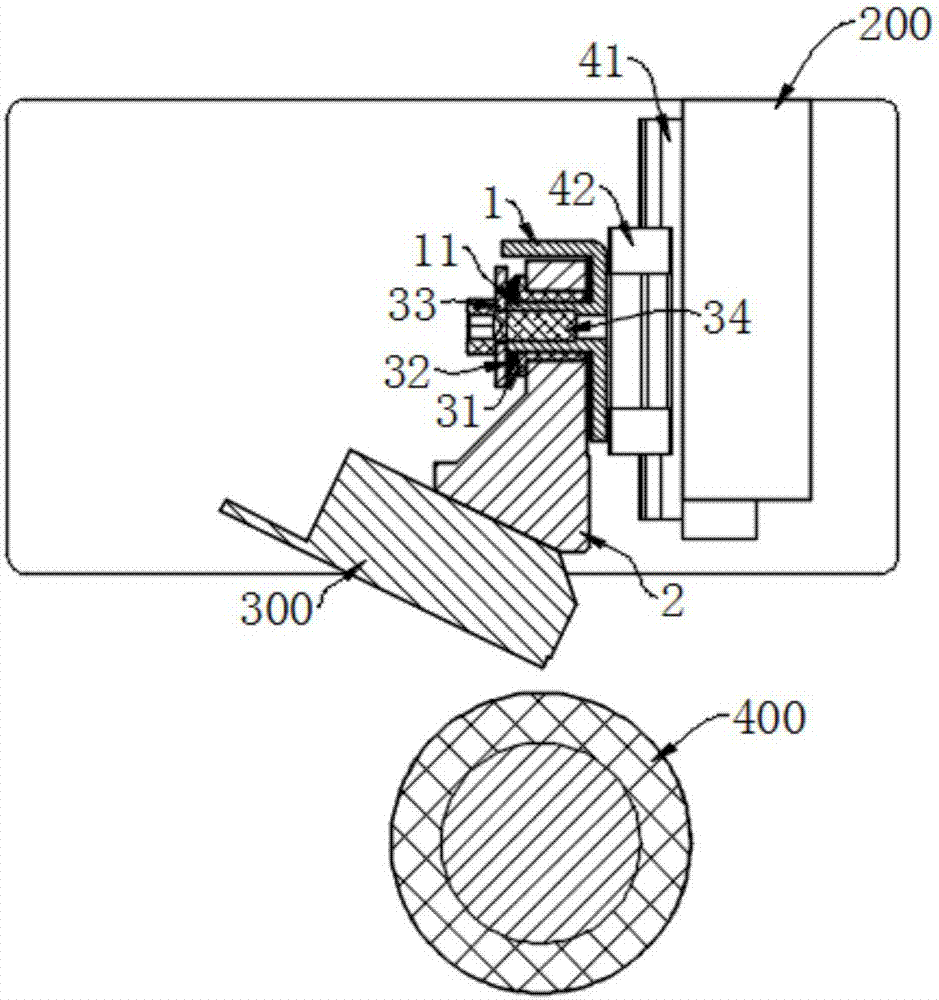

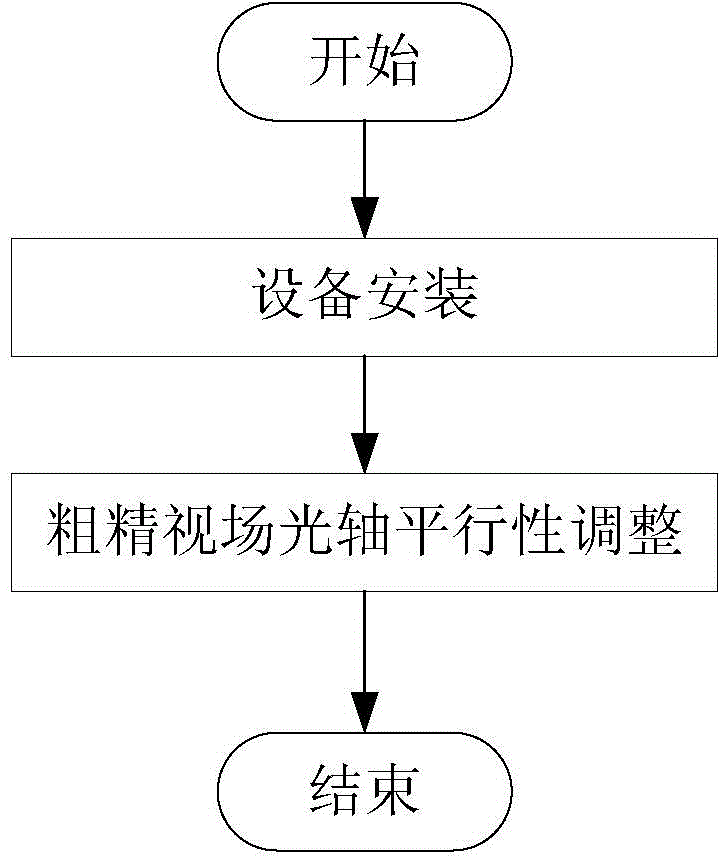

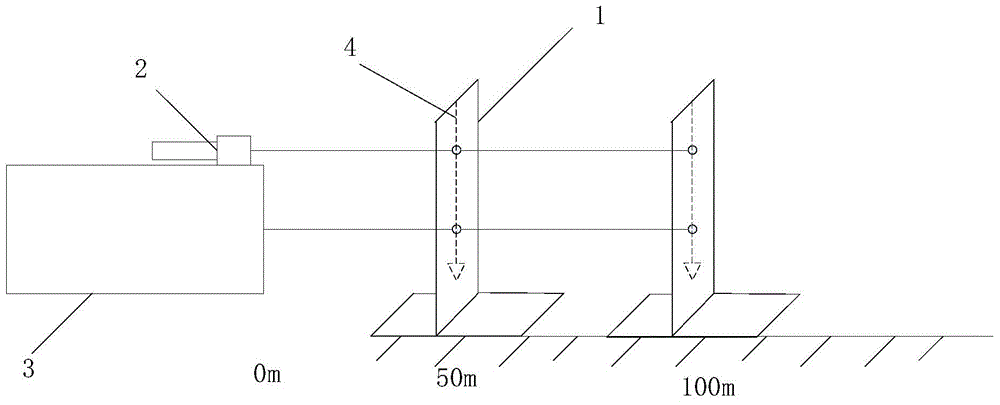

Method for adjusting optical axis parallelism of fine and rough fields of view

ActiveCN105630000AAdjust parallelismMeet the 1km distance focusing aiming requirementsPosition/direction controlOptical axisComputational physics

The invention belongs to the technical field of engineering measurement, in particular relates to a method for adjusting the optical axis parallelism of fine and rough fields of view, and aims to solve the problem of large limitations of a conventional adjusting method. The method comprises two steps of equipment mounting and adjustment of the optical axis parallelism of the fine and rough fields of view. According to the invention, target screens are disposed at different distances, two optical axis target points are carried on the screens, a relative position relation of the target points is obtained, and the optical axis parallelism is adjusted. The adjustment accuracy is estimated that if the relative position of optical axes shifts not more than 10mm in the adjusting process of 50m to 97m, then the adjustment error is 20mm in a range of 100m, the offset of the two optical axes in the range of 1km can be controlled to be 200mm, and as the reception area of the target screens is 500mm in the experiment, the requirement of focusing and pointing at a distance of 1km can be met.

Owner:BEIJING AEROSPACE INST FOR METROLOGY & MEASUREMENT TECH +1

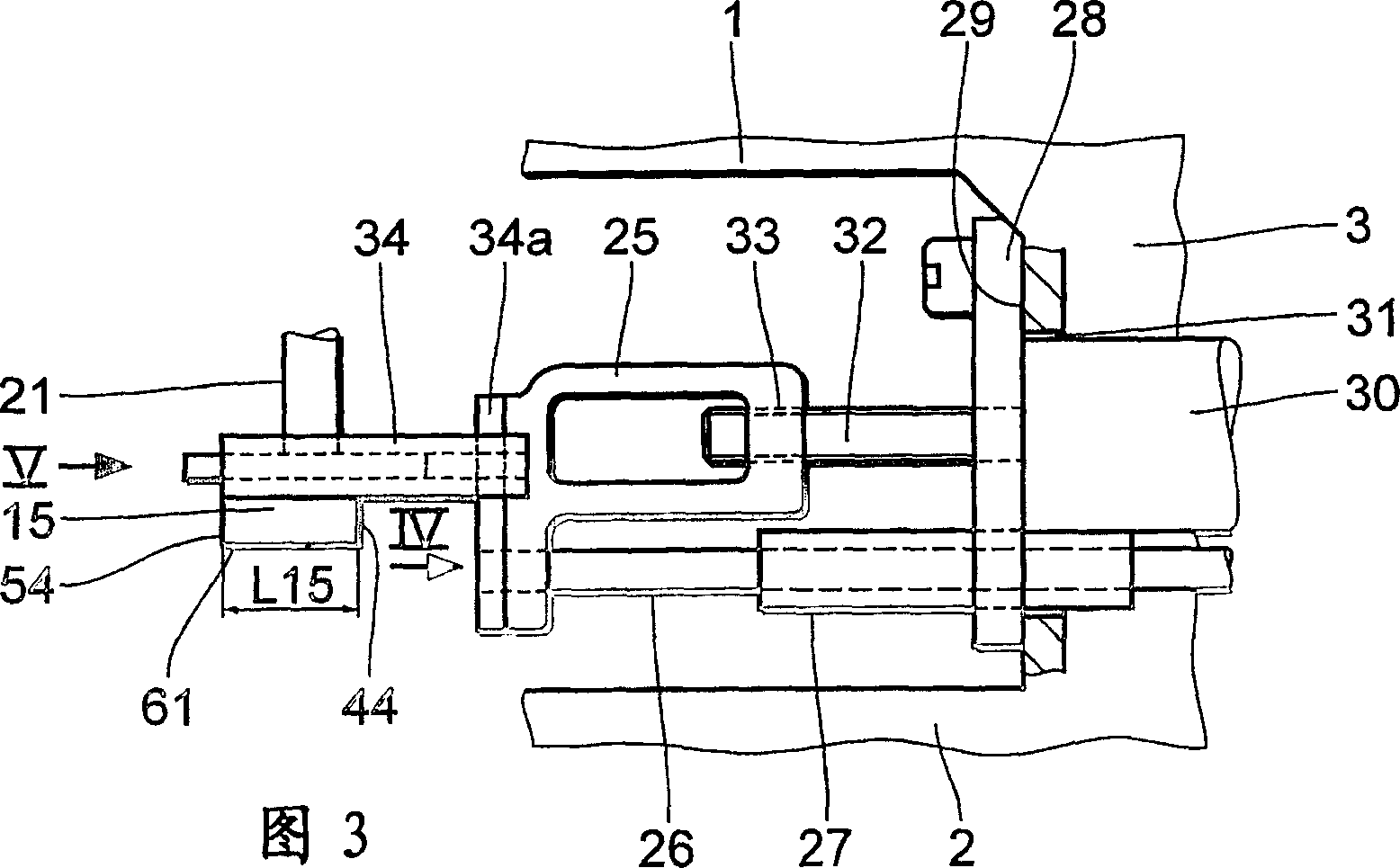

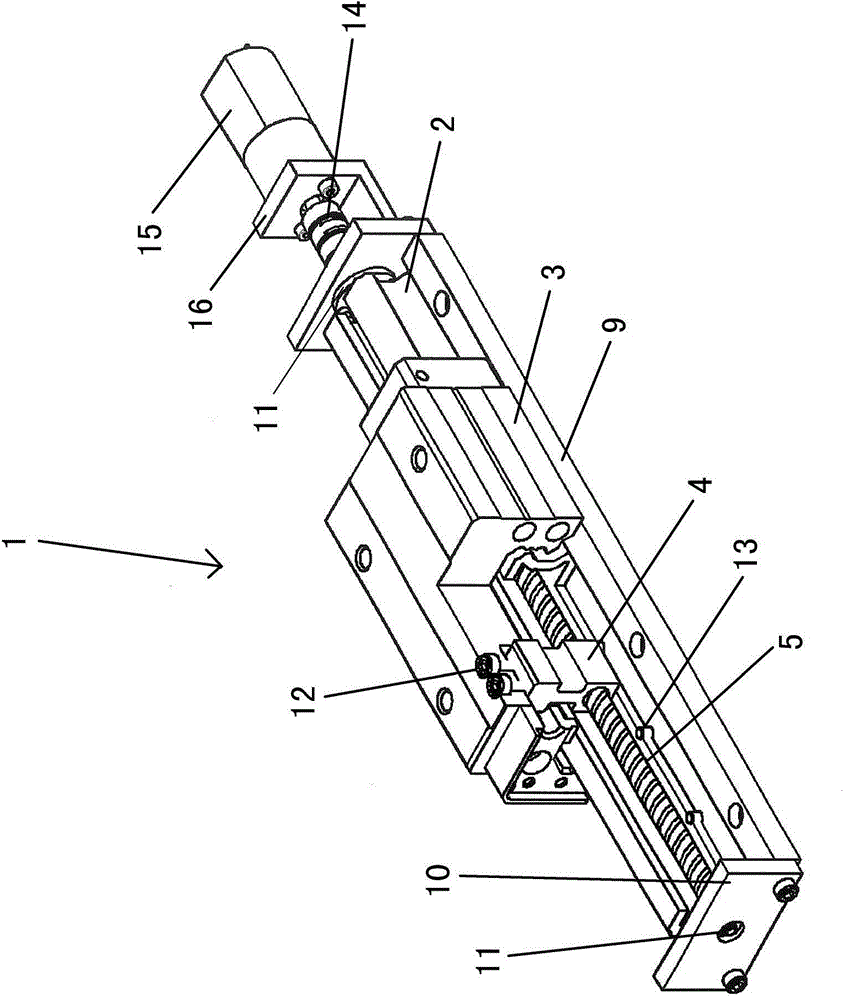

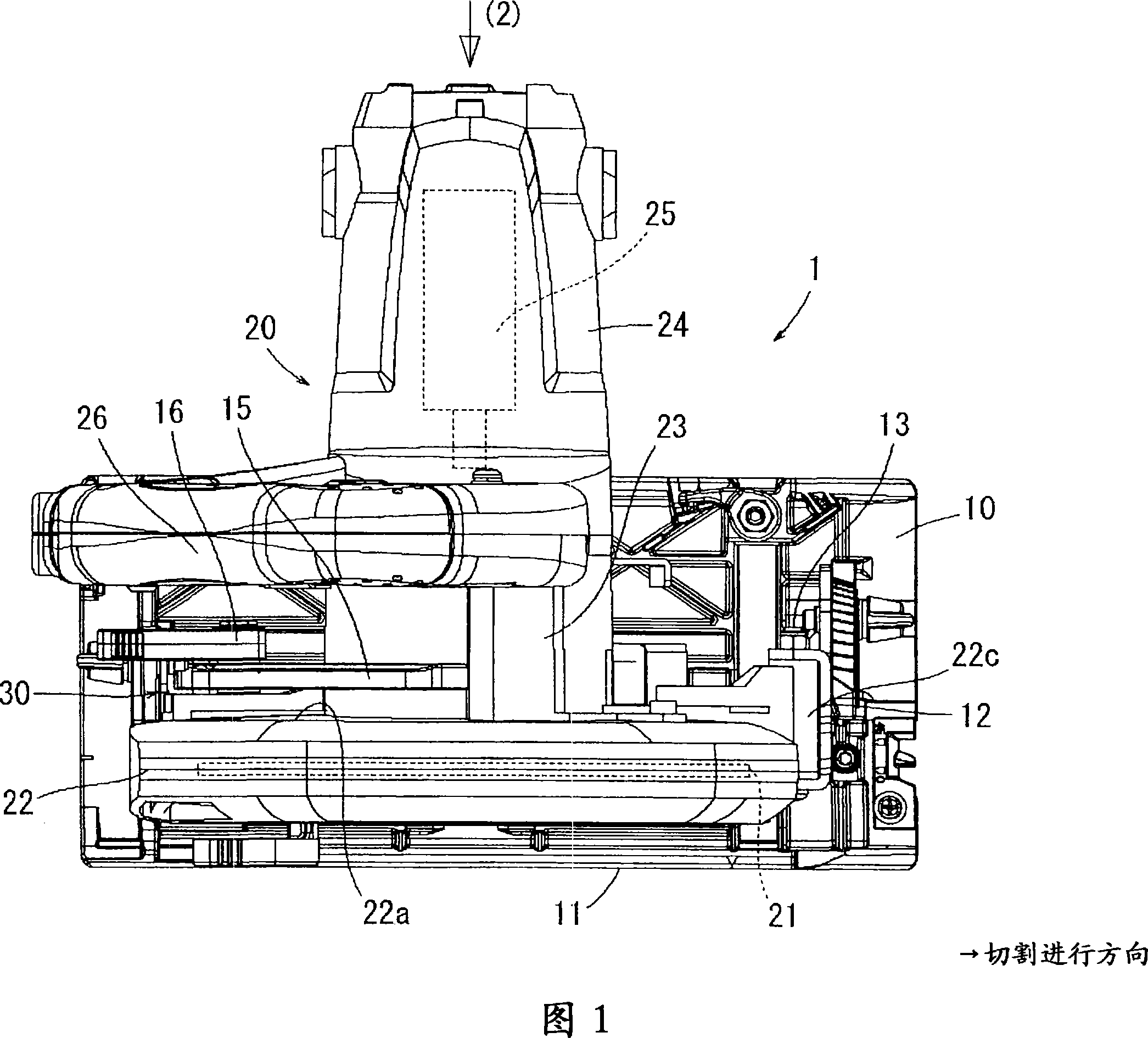

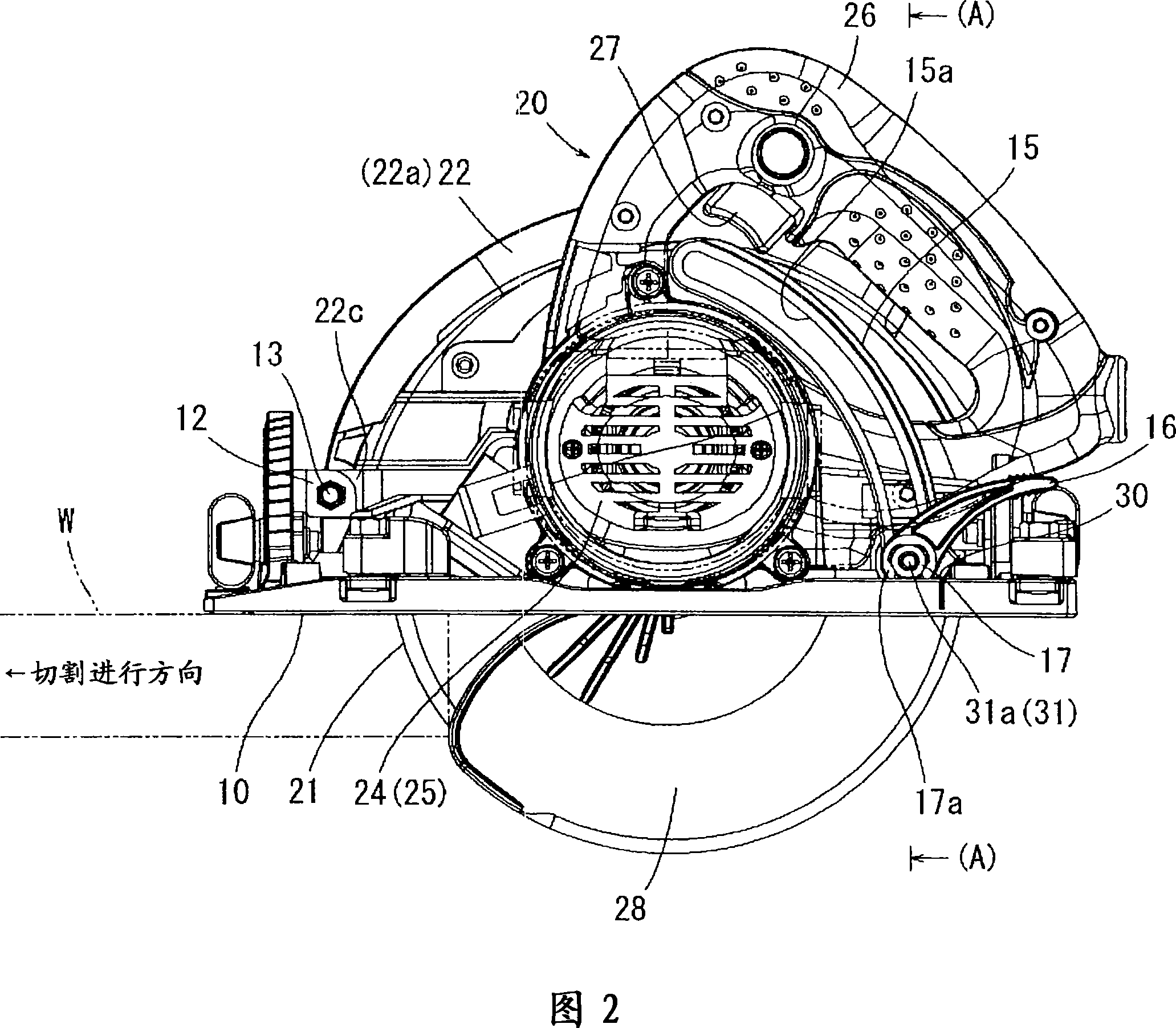

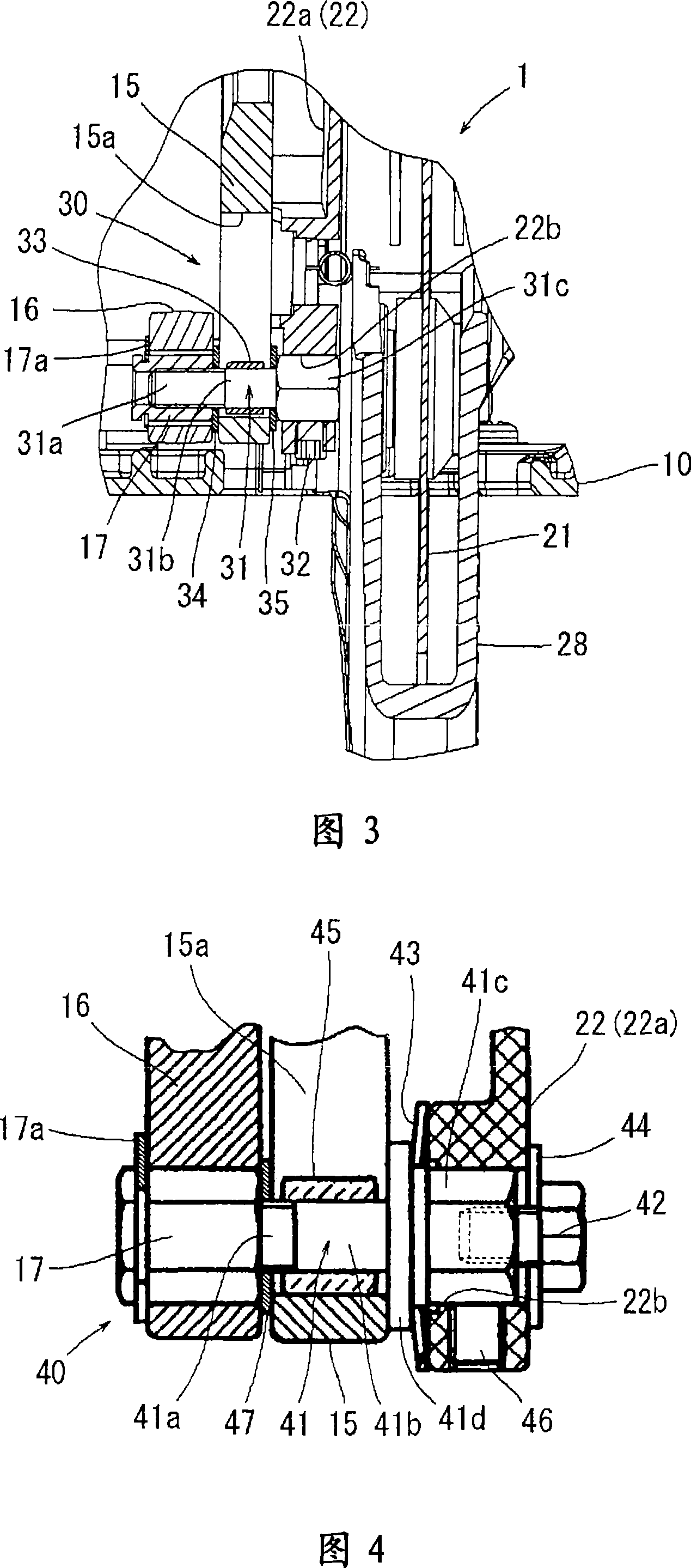

Portable fretsaw

InactiveCN101234513AParallelism can be adjustedAdjust parallelismStone-like material working toolsCircular saw

The present invention provides a portable circular saw, which is a type in which the cutting depth of the saw blade is adjusted by swinging the saw blade guard up and down with the front side of the saw blade guard as the center. Problems such as shaking in the parallelism fine-tuning mechanism for adjusting the parallelism of the saw blade relative to the guide surface of the base. In the portable circular saw (1) of the type in which a depth-of-cut guide (15) for adjusting the depth of cut is disposed along the back (22a) of the blade guard (22), the rear of the blade guard (22) There is a cover fixing bolt (31) on the upper part, through the cover fixing bolt (31), the rear part of the saw blade guard (22) is fixed on the depth of cut guide (15), by adjusting the cover fixing bolt (31) in The position in the axial direction is used to adjust the position of the rear side of the saw blade guard (22) in the vertical direction of the saw blade surface, thereby adjusting the parallelism.

Owner:MAKITA CORP

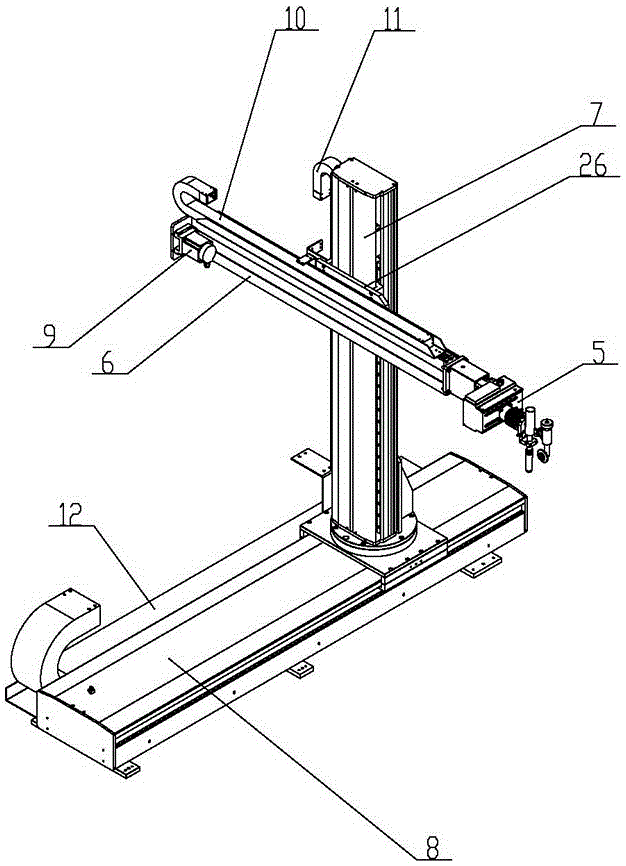

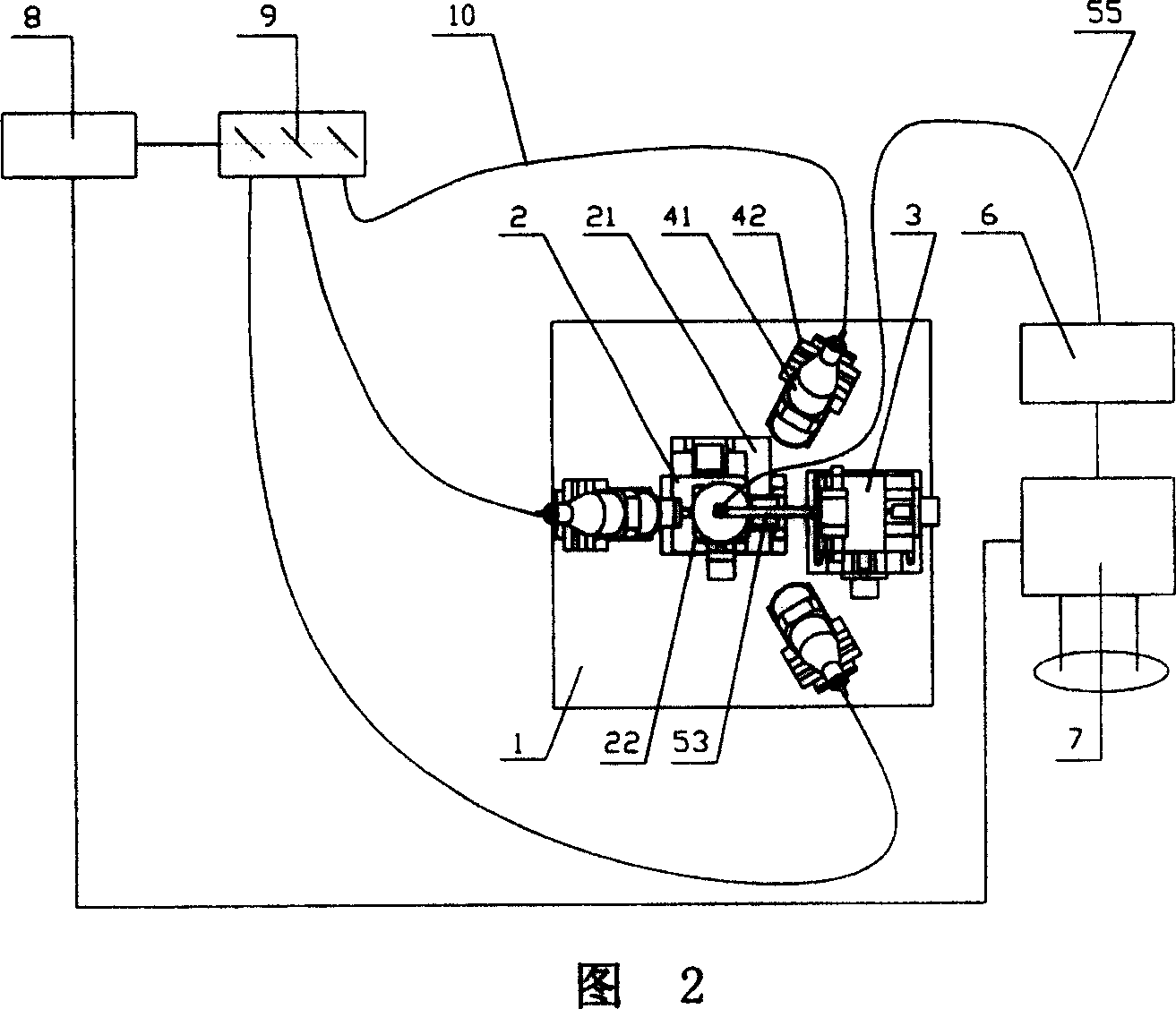

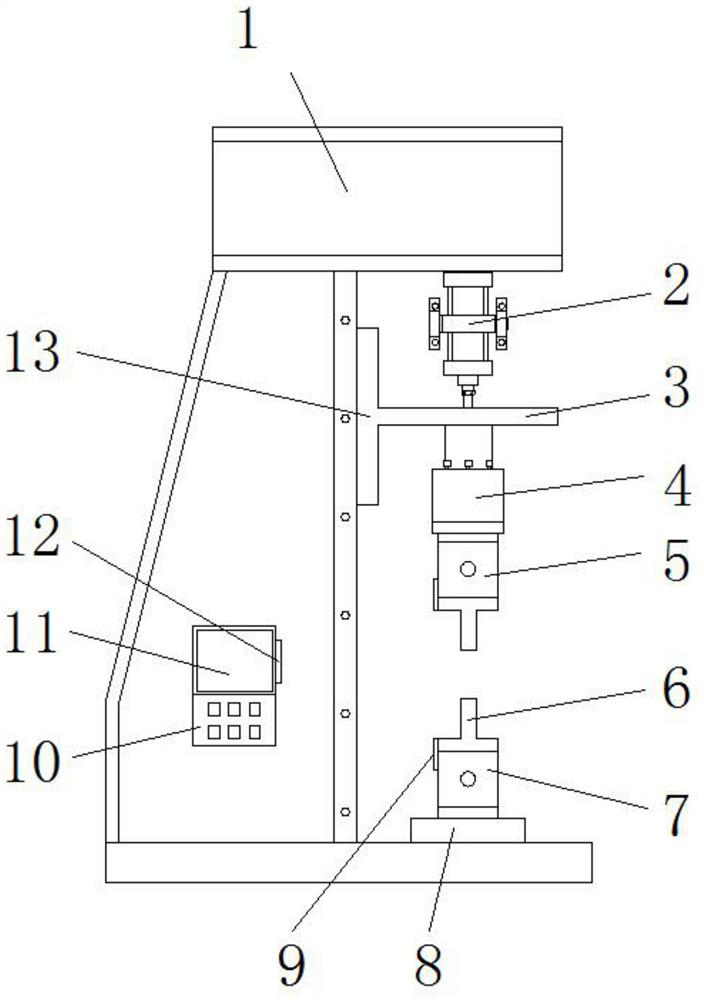

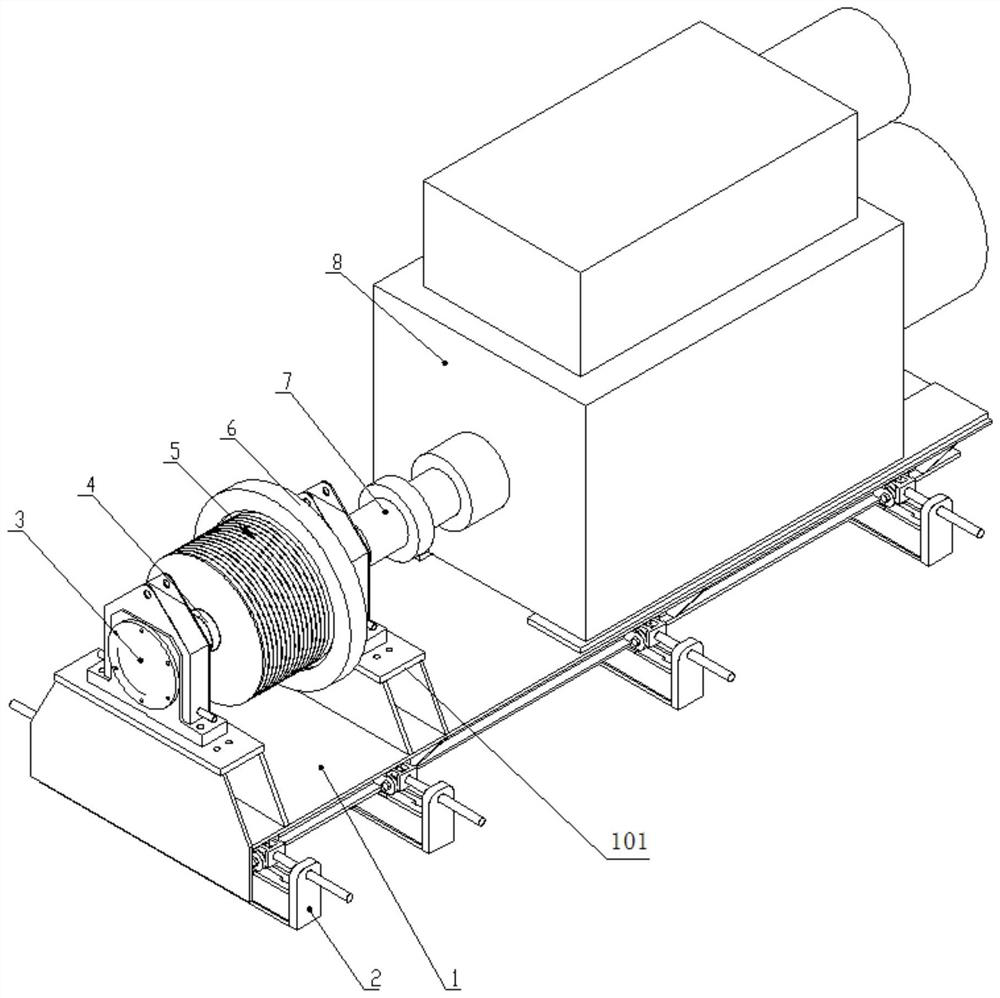

Automatic laser welding device for fibre-optical active component

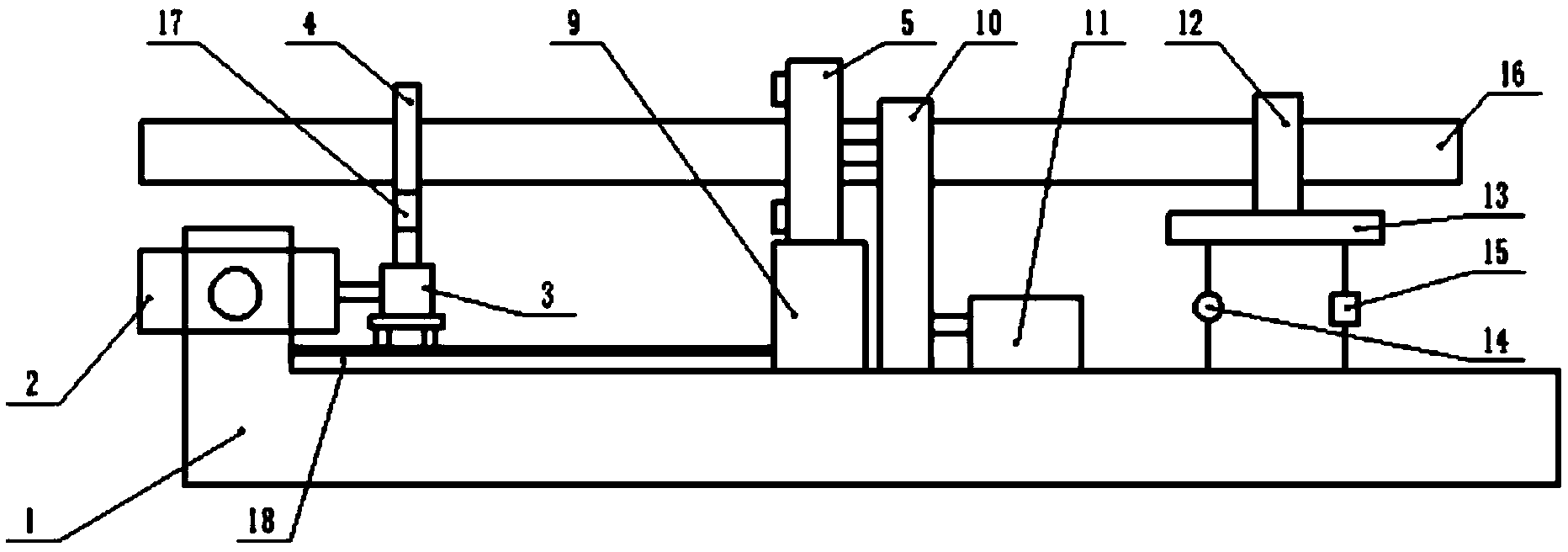

InactiveCN100351033CAdaptableIncrease flexibilityLaser beam welding apparatusFiberOptical power meter

The automatic laser welding apparatus for active fiber device includes a work table, a control unit, a laser welding mechanism and a precise butt jointing mechanism, and the laser welding mechanism and the precise butt jointing mechanism are installed on the work table. The precise butt jointing mechanism includes a fiber position regulating mechanism and a light source device position regulating mechanism, the fiber position regulating mechanism includes three successively superposed 1D translation stages and one fiber device fixture on the stages, and the light source device position regulating mechanism includes one 2D inclined stage and two orthogonal micro platforms in the same structure and on the inclined stage. The control unit includes one host control computer and one light power meter and is connected via cables to other mechanisms. The present invention has the advantages of simple structure, simple control, low cost, great stroke, high resolution, etc.

Owner:NAT UNIV OF DEFENSE TECH

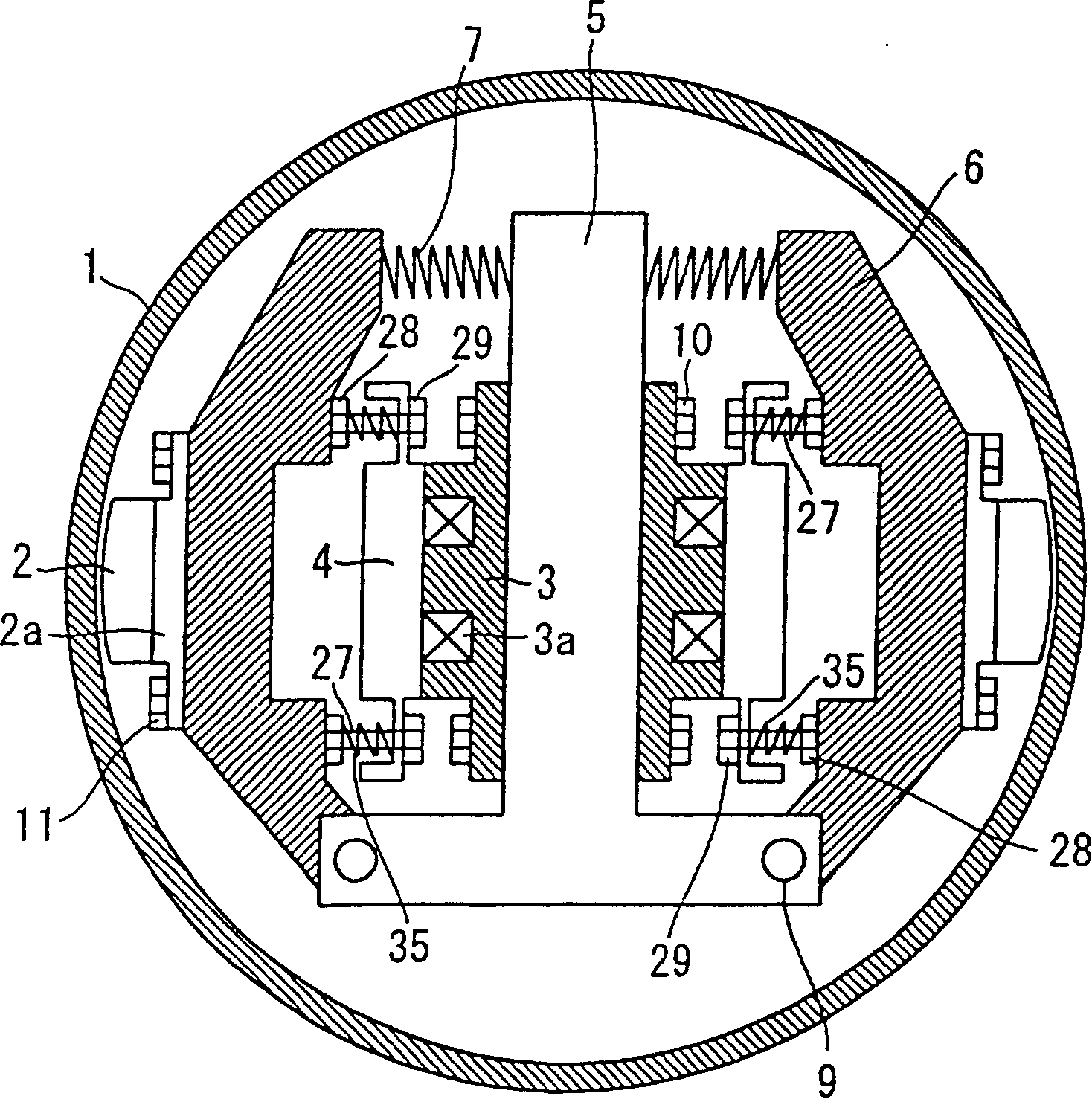

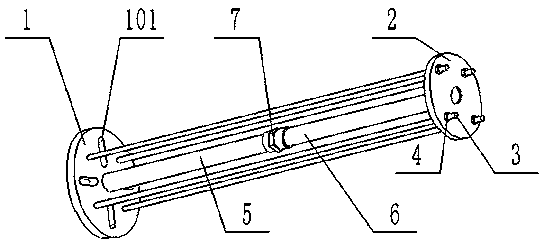

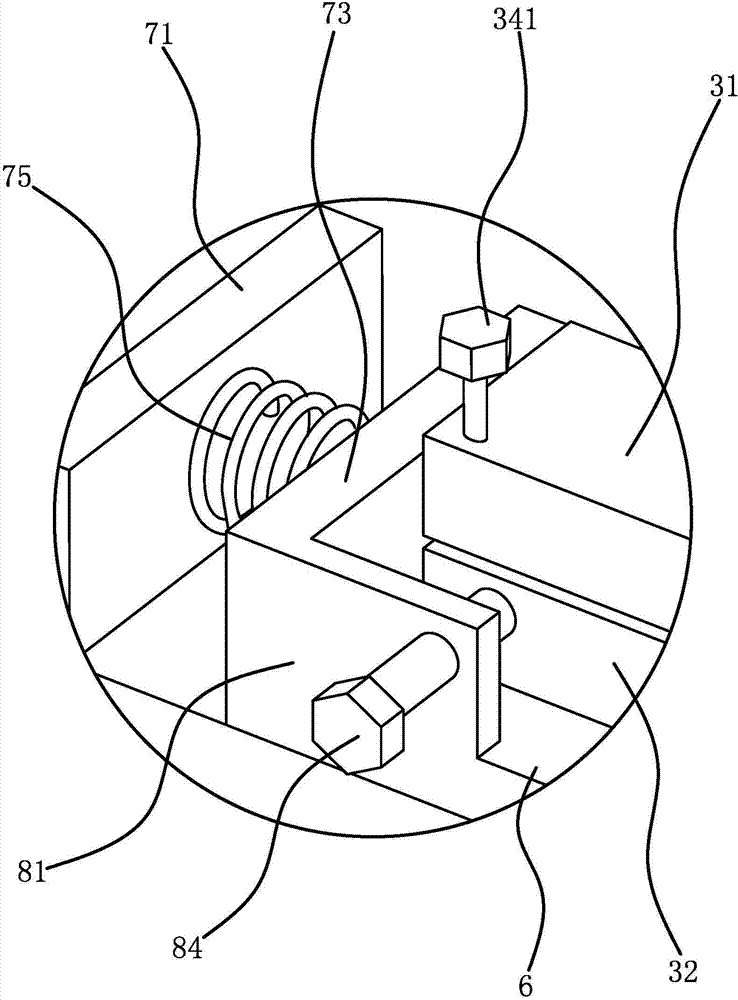

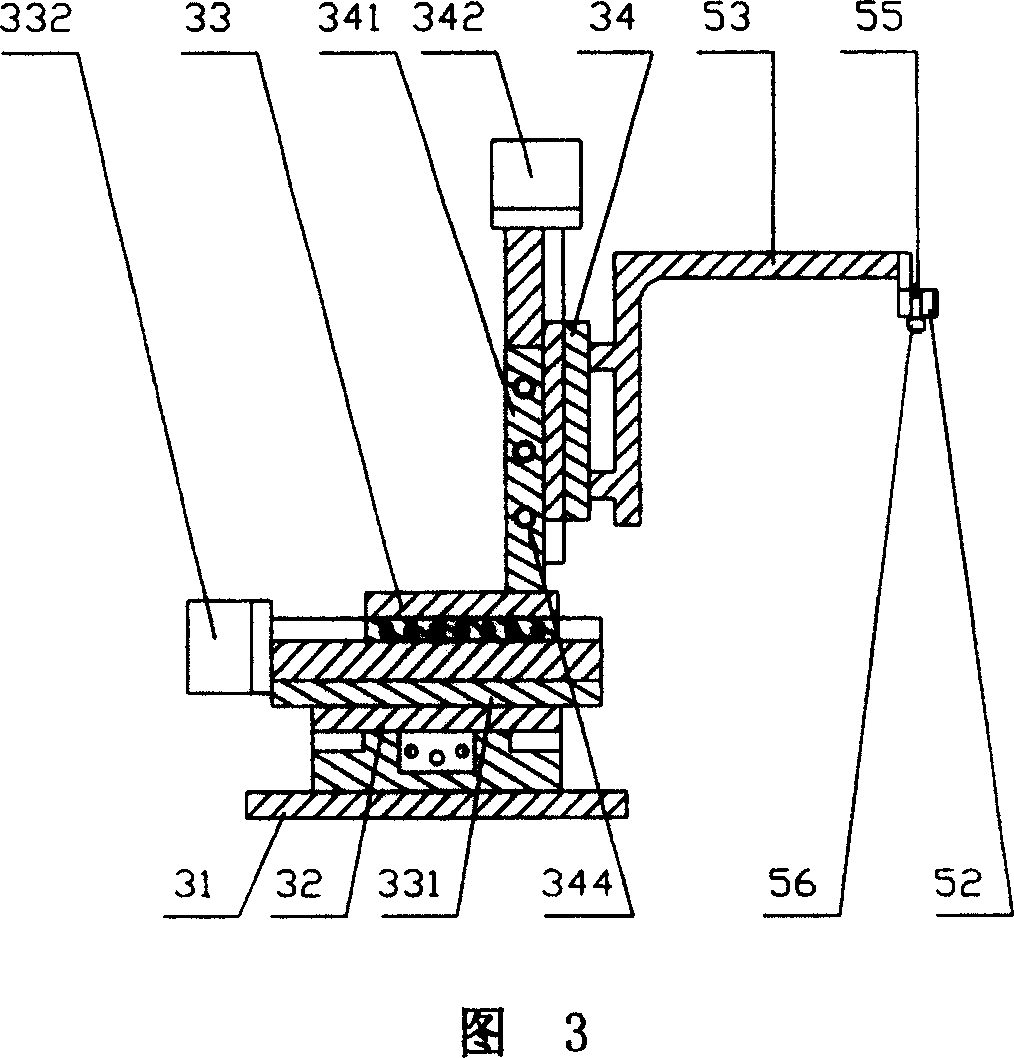

Extrinsic fiber-optic F-P vibration sensor and system

ActiveCN103245408BAdjust parallelismEasy to operateSubsonic/sonic/ultrasonic wave measurementUsing wave/particle radiation meansFiberVibration sensor

The invention provides an extrinsic optical fiber Fabry-Perot vibration sensor and a system. The system comprises a phase carrier demodulator and the extrinsic optical fiber Fabry-Perot vibration sensor, wherein the extrinsic optical fiber Fabry-Perot vibration sensor comprises a casing with an opening, a vibration sensitive element, a reflecting mirror, a collimating lens with a tail fiber, collimating lens clamping devices, a spring fixing device, springs and an end cover; after the reflecting mirror is arranged in the middle of the vibration sensitive element, the vibration sensitive element is connected inside the casing; after the collimating lens are clamped with the collimating lens clamping devices, the spring fixing device is placed in and mounted on the casing, and the springs are supported between the casing and the spring fixing device; the spring fixing device is locked on the casing with fastening bolts; the end cover is arranged at the opening of the casing and is in threaded connection with the casing; and the light emergence surface of the collimating lens and the reflecting mirror are parallel and form a Fabry-Perot cavity. According to the extrinsic optical fiber Fabry-Perot vibration sensor and the system, the length of the Fabry-Perot cavity and the parallel degree between the light emergence surface of the collimating lens and the reflecting mirror are extremely easy to adjust.

Owner:CHONGQING UNIV

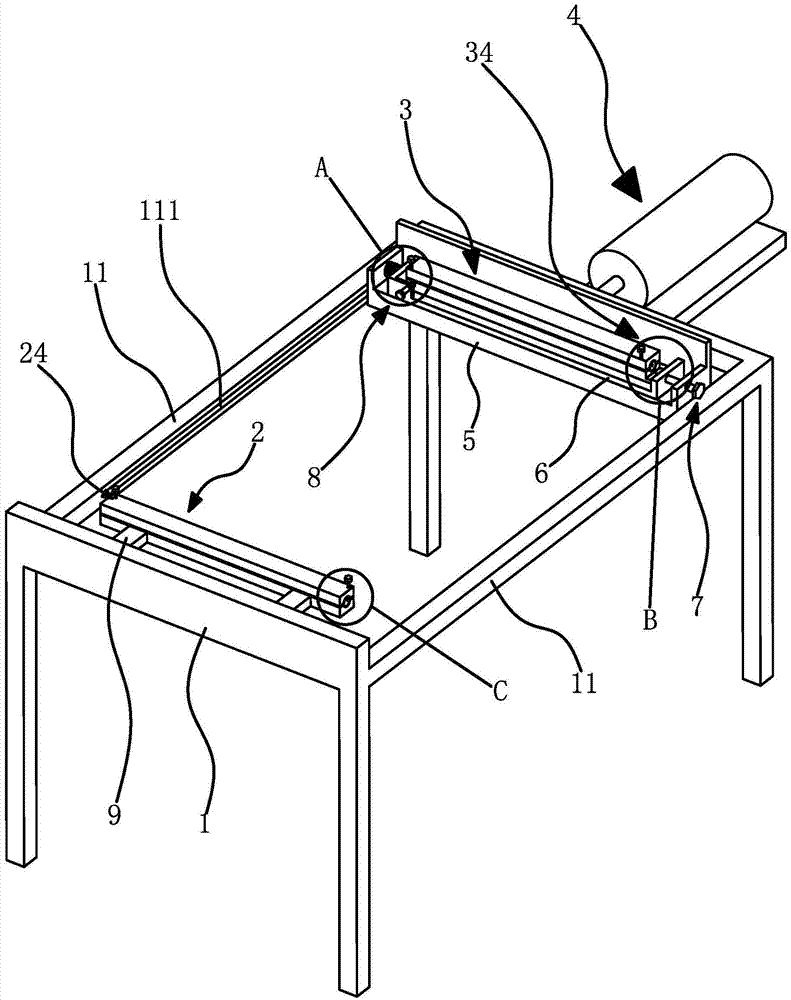

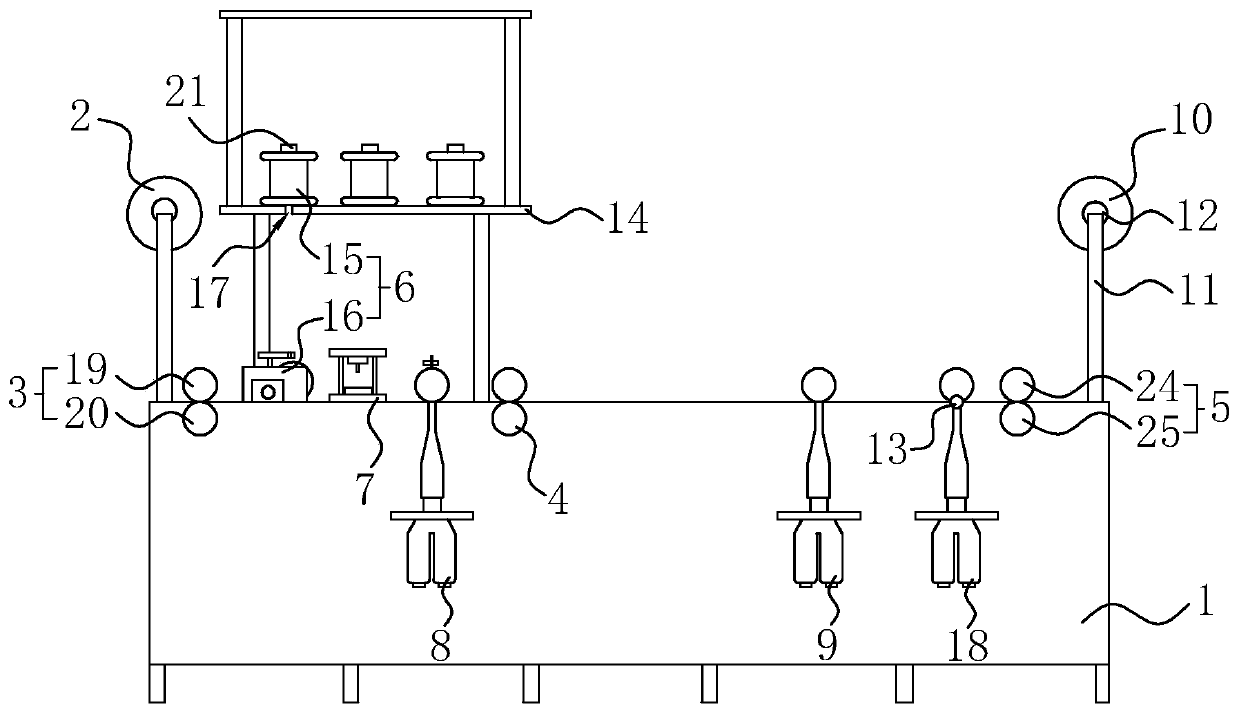

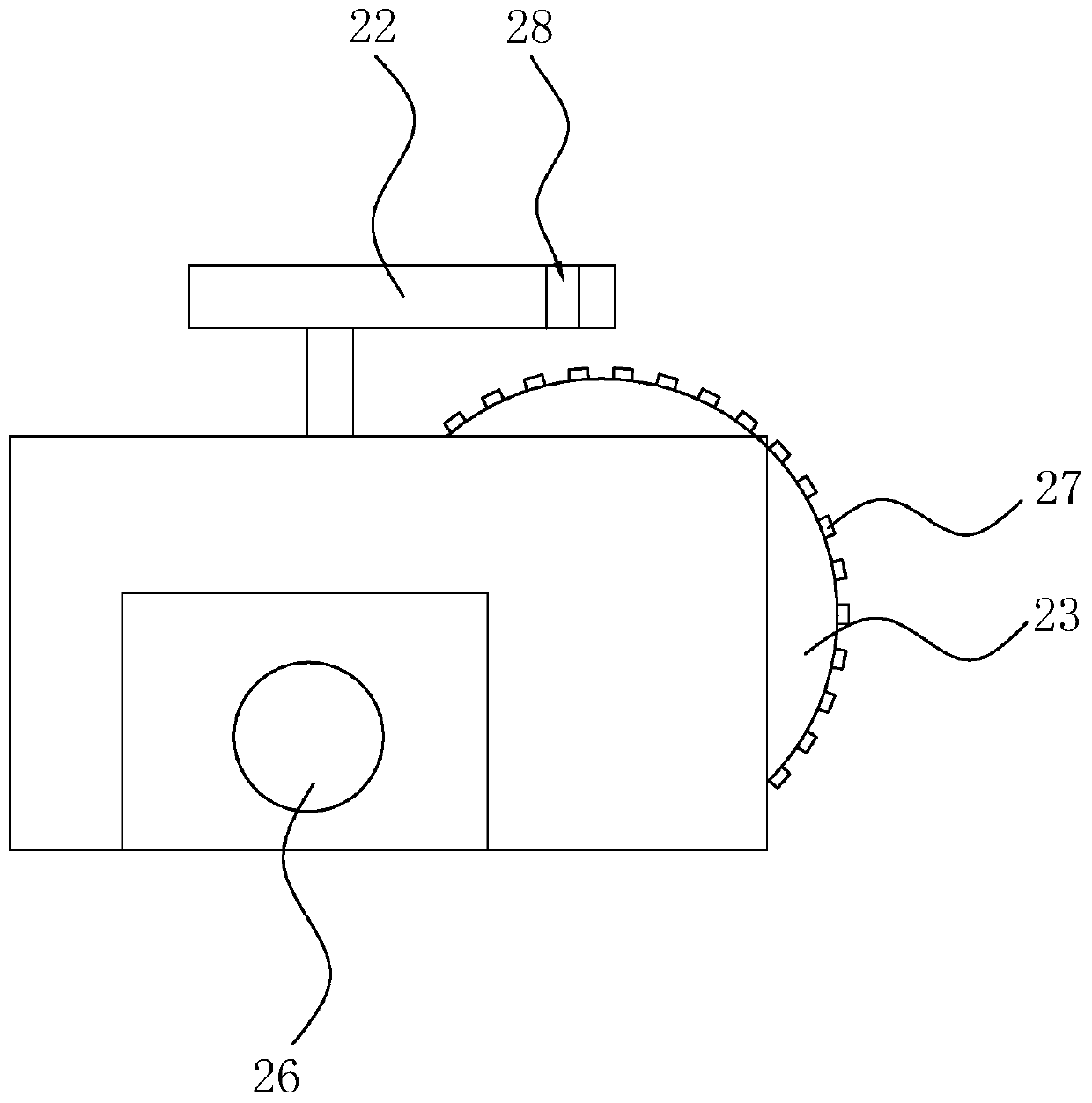

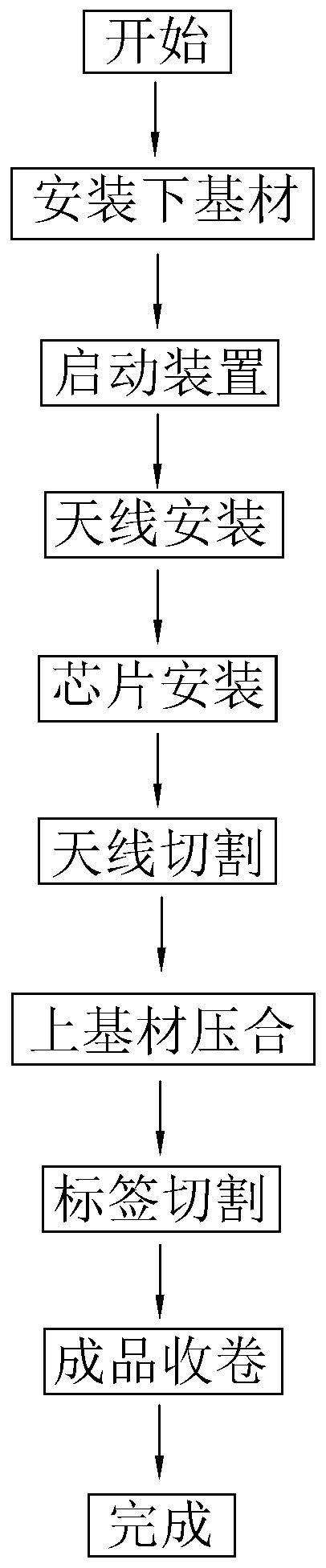

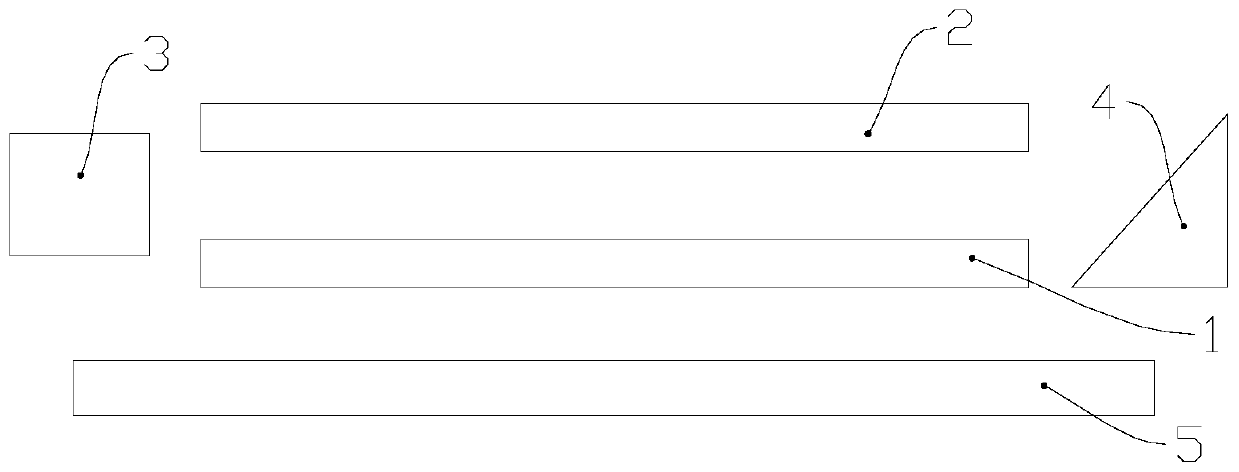

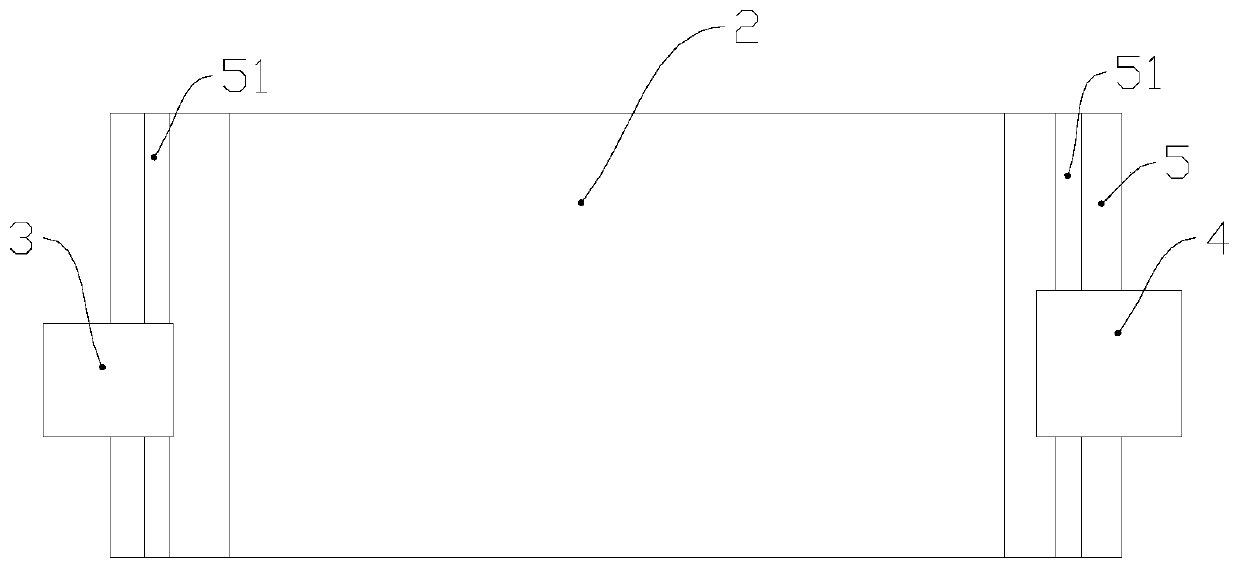

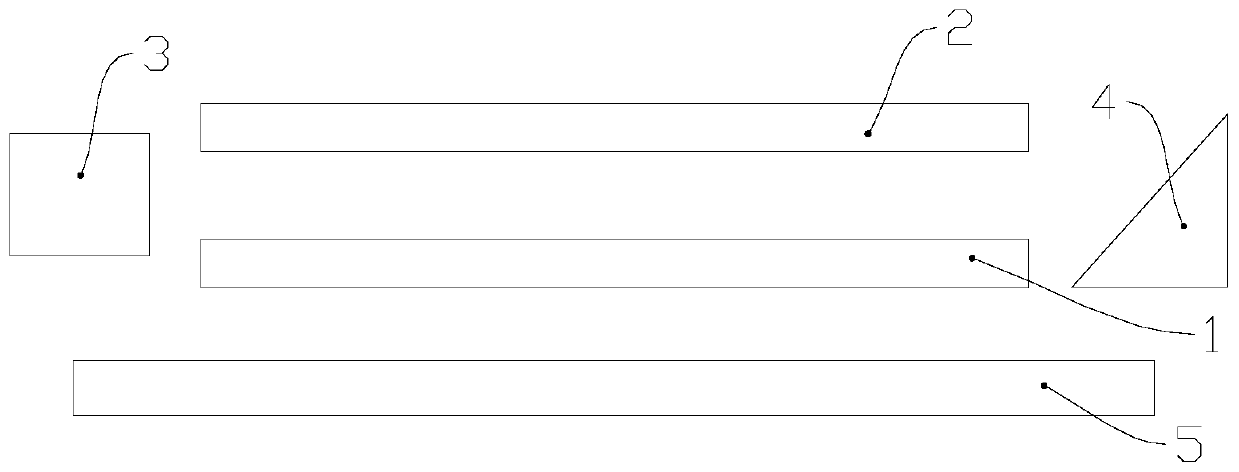

Tire electronic tag production device and method thereof

PendingCN110610223AImprove practicalitySmooth slidingAntenna supports/mountingsRecord carriers used with machinesProduction qualityElectrical and Electronics engineering

The invention discloses a device and a method for producing an electronic tag for a tire. The invention relates to the technical field of electronic tags. Workbench, wherein a feeding mechanism, a conveying mechanism, an antenna installing mechanism, a chip installing mechanism, a cutting mechanism, a pressing mechanism and a receiving mechanism are arranged on the workbench; the lower base material is installed on the feeding mechanism in a material rolling mode and then sequentially conveyed to the antenna installation mechanism, the chip installation mechanism, the conveying wheel, the first cutting device, the pressing mechanism, the second cutting device and the second tensioning wheel, and finally the electronic tag finished product is stored in a rolling mode through the material collecting mechanism. Manual operation is not needed in the production process, the operation flow of the device is clear, the production quality is stable, electronic tags can be produced on a large scale at a time, and the production efficiency is effectively improved.

Owner:SHANGHAI ESTAR TECH

Parallelism detecting device and film sticking machine

ActiveCN109910320AAdjust parallelismWiden perspectiveFinal product manufactureUsing optical meansEngineeringMaterials science

The invention provides a parallelism detecting device. The parallelism detecting device comprises a TOF distance measuring instrument, a reflector and a first driving mechanism, wherein the TOF distance measuring instrument and the reflector are respectively arranged at the two sides of a substrate; the first driving mechanism can drive the TOF distance measuring instrument and the reflector to move along the lateral edge parallel to the substrate; the relative position of the TOF distance measuring instrument and the reflector is unchanged; and the light pulse emitted by the TOF distance measuring instrument can be received by the TOF distance measuring instrument after being reflected by the substrate, a film layer and the reflector. The invention also provides a film sticking machine. The film sticking machine comprises the parallelism detecting device mentioned in the above technical scheme and can adjust the angle of the film layer or / and the angle of the substrate. According to the parallelism detecting device provided by the invention, when moving, the TOF distance measuring instrument emits the light pulse repeatedly, the light pulse is received by the TOF distance measuring instrument after being reflected by the film layer, the substrate and the reflector, and multiple travel time is obtained; and whether the substrate and the film layer are parallel is judged by comparing the travel time. The film sticking machine provided by the invention can adjust the parallelism between the film layer and the substrate.

Owner:SHENZHEN VISION POWER TECH

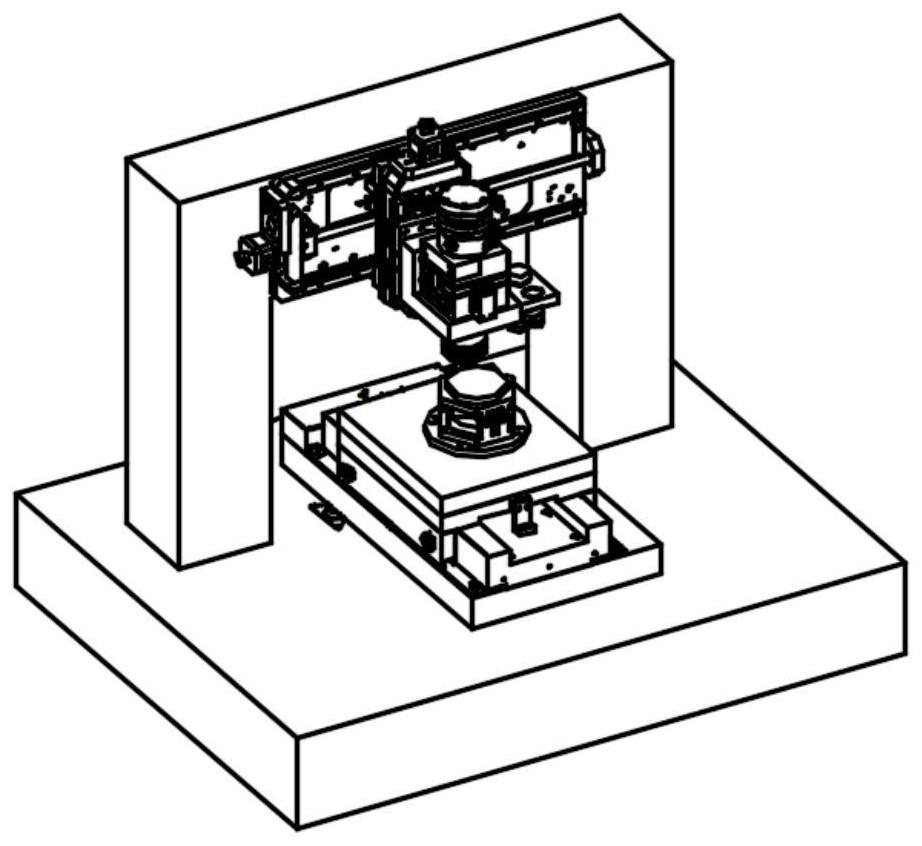

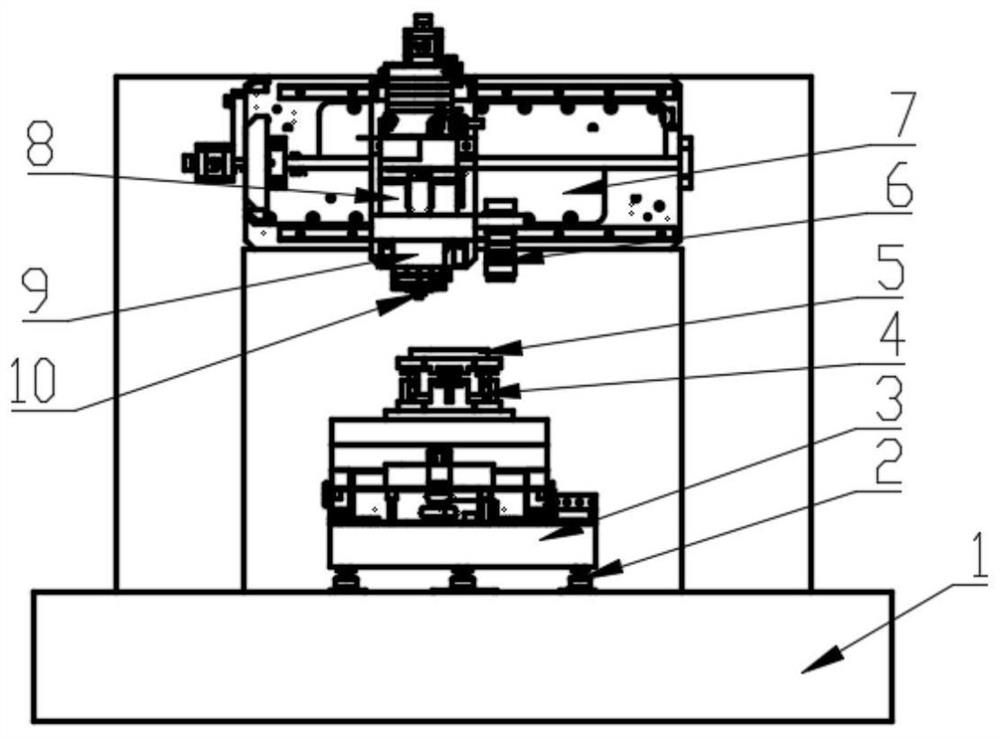

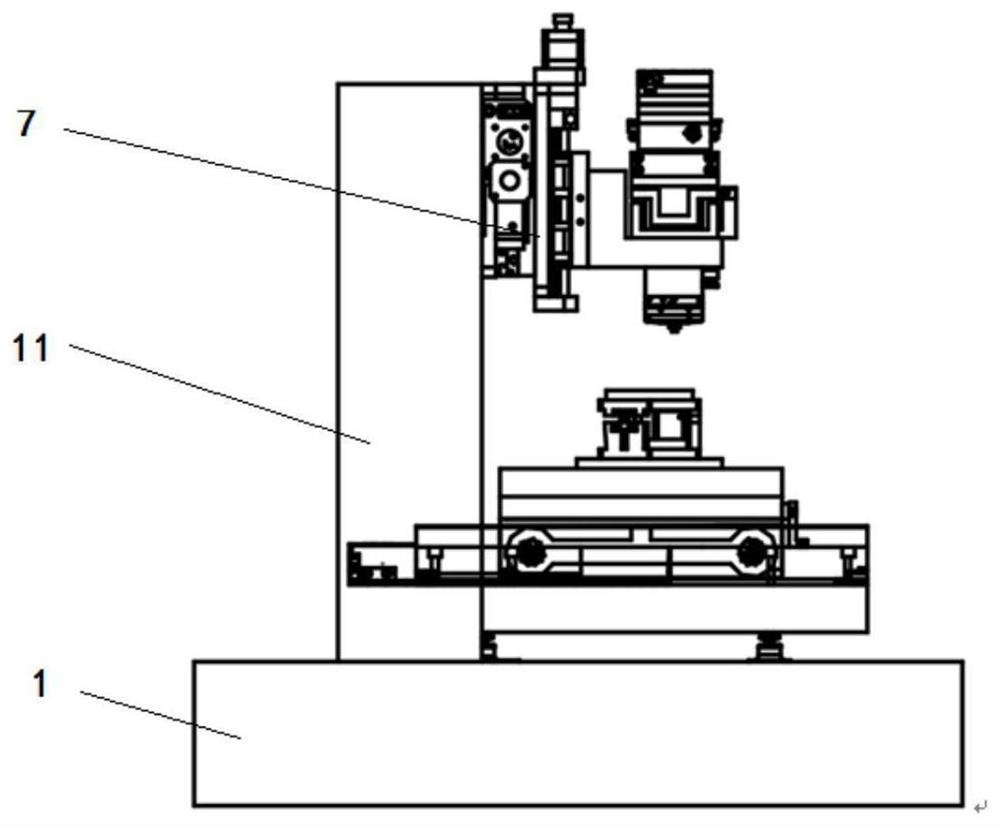

Flexible mechanism-based macro-micro coupling trochoid micro-nano scratch testing machine

PendingCN113790988AImprove detachabilitySimple structureInvestigating material hardnessCompliant mechanismMiniaturization

The invention relates to a scratch testing machine, in particular to a flexible mechanism-based macro-micro coupling trochoid micro-nano scratch testing machine, and relates to a scratch testing machine. The invention aims to solve the problems that most micro-nano machining structures adopt rigid structures, so that the requirements on assembly precision are very high, the stroke is small, the miniaturization is difficult, and the machining capability on complex surface structures is insufficient. The product comprises a mounting table, a sample disc bearing assembly, a sample disc, a cutterhead mounting assembly, a cutterhead and a back plate, the sample disc bearing assembly is mounted on the upper surface of the mounting table, the sample disc is mounted on the sample disc bearing assembly, the back plate is vertically fixed on the upper surface of the mounting table, the cutter disc mounting assembly is mounted on the upper portion of the back plate, and the cutter disc is mounted on the cutter disc mounting assembly and located above the sample disc. The invention belongs to the field of micro-nano processing and manufacturing.

Owner:TIANJIN UNIV

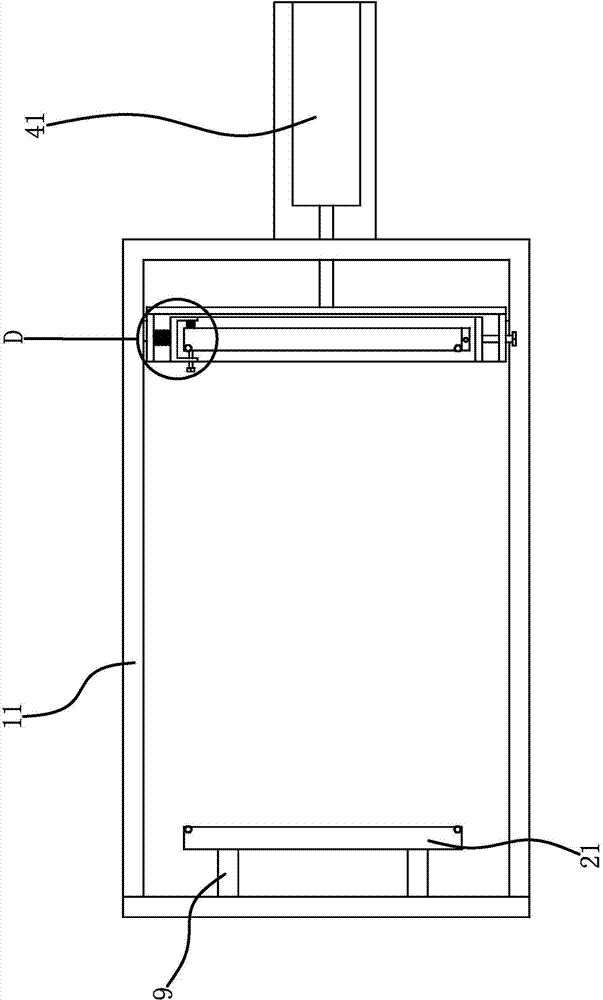

Improved soft package lithium battery aluminum-plastic film manual sealing machine

ActiveCN112803097AIncrease heating rateCentralized heating pointFinal product manufactureCell component detailsDisplay devicePlastic film

The invention discloses an improved soft package lithium battery aluminum-plastic film manual sealing machine. The manual sealing machine comprises a sealing machine body and a PLC, the PLC is arranged on the front end face of the sealing machine body, a display is arranged above the PLC, a timer is arranged on the right side of the display, a sealing air cylinder is arranged in the sealing machine body, a sealing connecting plate is connected to the lower end of the sealing air cylinder, an adjusting plate is arranged on the left side of the sealing connecting plate, an adjusting sliding block is arranged on the surface of the adjusting plate, an adjusting guide rail is arranged outside the adjusting sliding block, a supporting column is connected to the lower end of the sealing connecting plate, and an adjusting top plate is arranged at the lower end of the supporting column. According to the improved soft package lithium battery aluminum-plastic film manual sealing machine, through the arrangement of the adjusting sliding block and the adjusting guide rail, a traditional linear guide column structure can be replaced, precision is improved, meanwhile, movement of the sealing connecting plate can be limited, and the device is more stable.

Owner:南通鼎鑫电池有限公司

A snapping and aligning device for large-format steel plates

ActiveCN105108411BThe installation position can be adjustedAvoid damageWelding/cutting auxillary devicesAuxillary welding devicesDual actionEngineering

A device used for neatly beating and aligning a large-width steel plate comprises at least three positioning devices. At least one positioning device is arranged on the lateral side in the width direction of the steel plate. At least two positioning devices are arranged on the lateral side in the length direction of the steel plate. Each positioning device comprises a positioning base, a positioning installation frame and at least three neatly beating devices, wherein a slide groove is formed in a side face of the base, one end of the positioning installation frame is positioned in the slide groove of the positioning base and is movably connected to the positioning base through an adjustment bolt, a positioning block is arranged at the other end of the positioning installation frame, at least one neatly beating device is arranged on the lateral side in the width direction of the steel plate, and at least two neatly beating devices are arranged on the lateral side in the length direction of the steel plate. Each neatly beating device comprises an installation machine frame, a piston cylinder, a dual-action cylinder and a neatly beating plate, wherein cylinder bodies are arranged on the installation machine frame through fixing shafts and cylinder installation blocks, the upper portion of the neatly beating plate is movably connected to a piston rod of the piston cylinder through a pin shaft, the middle of the neatly beating plate is connected to one end of the installation machine frame through a pivoting shaft, an angle lager than 90 degrees is formed by the upper portion and the lower portion of the neatly beating plate, and the neatly beating plate is driven by the piston cylinder through the piston rod to rotate around the fixing shaft in a reciprocating mode.

Owner:BAOSHAN IRON & STEEL CO LTD

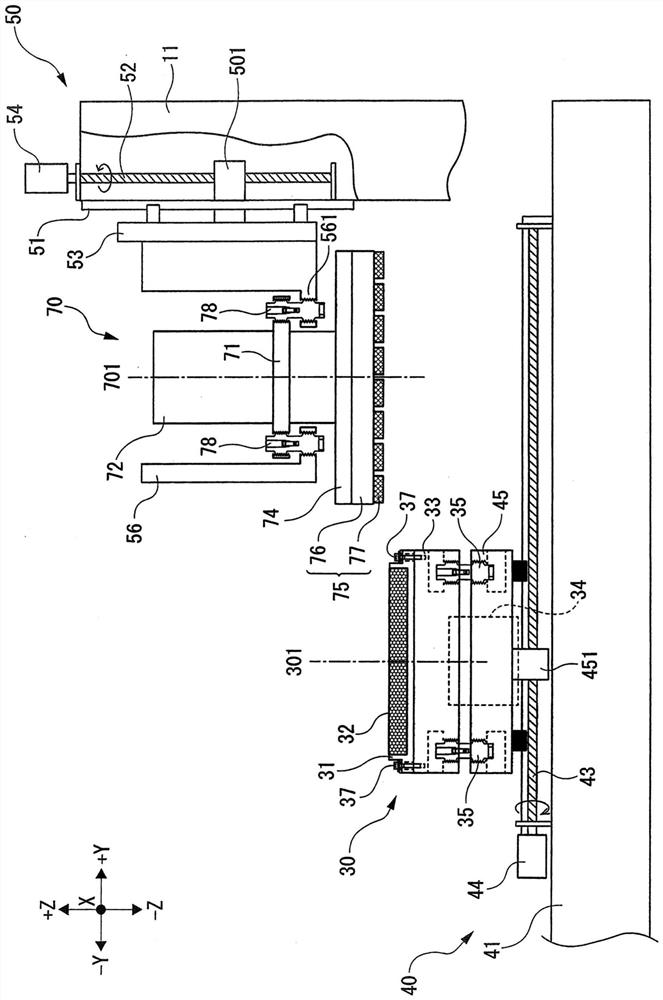

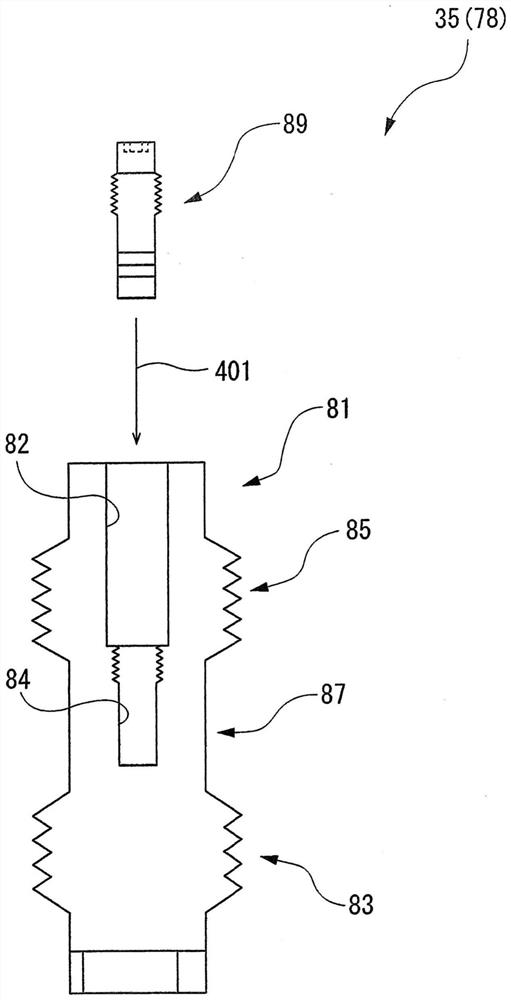

Fine adjustment thread assembly and processing apapratus

PendingCN113334196AAdjust tiltAdjust parallelismEdge grinding machinesGrinding drivesEngineeringMachine tool

The invention provides a fine adjustment screw assembly and a machining device, which can properly measure the load applied to a machining tool of a grinding tool. The fine adjustment thread assembly couples a first part and a second part to each other while keeping the first part and the second part spaced apart, adjusts the distance between the first part and the second part, and detects a load applied to the second part. The assembly includes first external threads that can be brought into threaded engagement with first internal threads formed in the first part, second external threads that are axially spaced from the first external threads, that have a thread pitch different from that of the first internal thread, and that can be brought into threaded engagement with second internal threads formed in the second part. A joint portion between the first external threads and the second external threads houses a load sensor under a compressive load.

Owner:DISCO CORP

Bare engine module

InactiveCN101162357AResolving Imaging Issues Caused by Cumulative TolerancesAdjust parallelismProjectorsEngineeringMechanical engineering

The invention discloses an optical machine module comprising a supporting structure, a first module and a second module. The supporting structure comprises a body part and an adjustment part, wherein, the body part has a first plane and a second plane which are opposite to each other, and the adjustment part comprises a first flexible element and a second flexible element which are respectively arranged on the body part and bulge out of the second plane. The first module is arranged on the first plane, and the second plane is arranged on the second plane and abuts against the first flexible element and the second flexible element, wherein, the arrangement plane of the second module is adjusted by adjusting the adjustment part, thereby adjusting the depth of parallelism of the first module and the second module.

Owner:BENQ CORP

Gap bridge transmission device

InactiveCN111987853AReduced concentricity requirementsAvoid breakingMechanical energy handlingGrain treatmentsElectric machineryEngineering

The invention relates to the field of crushing equipment, in particular to a gap bridge transmission device which comprises a base, a motor, a transmission wheel set, a bearing assembly and an adjusting structure, the transmission wheel set is installed on the base through the bearing assembly, and the motor is connected with the transmission wheel set; the adjusting structure is arranged at the bottom of the base and used for adjusting the connecting posture of the motor and the transmission wheel set. A refrigerating unit is arranged on the bearing assembly and used for cooling the bearing assembly; the bearing assembly comprises a support, a bearing and an end cover, a bearing hole is formed in the support, the transmission wheel set is installed in the bearing hole through the bearing,and the end cover is installed in the bearing hole. The gap bridge transmission device has the beneficial effects that the bearing assembly and the adjusting structure are arranged, the transmissionwheel set is supported, the parallelism of the transmission wheel set and the motor is adjusted, the coaxiality requirement of the motor and the transmission wheel set during mounting is lowered, anda motor shaft of the motor is prevented from being broken off.

Owner:ZAOZHUANG RUILONG MACHINERY MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com