A snapping and aligning device for large-format steel plates

A technology of snapping device and large format, which is applied in auxiliary devices, plasma welding equipment, laser welding equipment, etc., can solve the problems of large deformation of thin steel plates, no adjustment, and high mechanical properties, and achieves simple and practical device structure and convenient main coordination. The effect of fine-tuning and reducing the processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 3

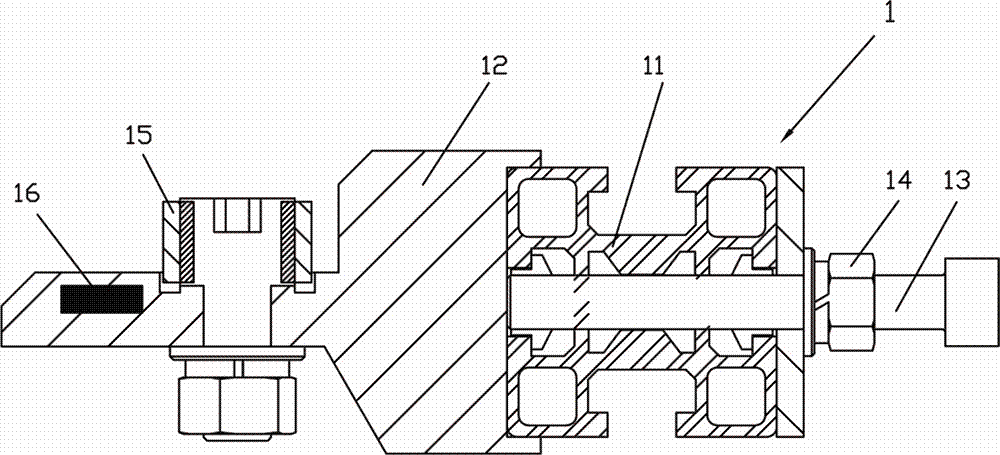

[0053] see Figure 5 , which shows the third embodiment of the positioning device of the present invention, the positioning device 1 also includes,

[0054] Two guide profiles 17, 17' are respectively arranged on one side of the positioning base 11 where the sliding groove is provided;

[0055] The positioning mounting frame 12 is arranged between the two guide profiles 17, 17', and the positioning mounting frame 12 adopts a split structure, including:

[0056] Install the slide block 122, set the positioning block 15 in the center of its upper end surface, and set the magnet 16 in the two sides;

[0057] Two installation brackets 123, 123' are arranged between the two guide profiles 17, 17', guide grooves 1231 are provided on the front side of the installation brackets 123, 123', and the inner sides of the installation brackets 123, 123' are arranged along the length direction. Step surfaces 1232, 1232' for sliding the sliding block 122; on both sides of the sliding block 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com