Coaxiality adjusting-correcting method for long shaft coupler

A coupling and coaxiality technology, used in the field of long shaft coupling coaxiality adjustment, can solve the problem of torque reduction, unsuitable for transmitting high revolutions, high torque, difficult to erect dial indicators, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

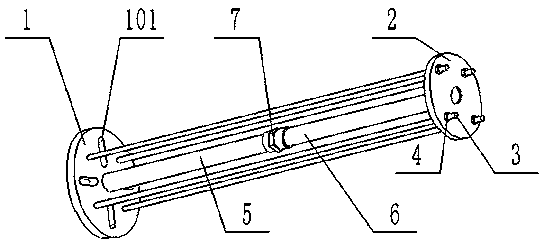

[0033] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0034]A method for adjusting the coaxiality of a long-axis coupling. Before installing a connecting shaft between two half-couplings arranged at relative intervals, an adjustment method is set between the first half-coupling and the second half-coupling. Calibration device, the calibration device is connected with the first half-coupling, and forms an alternative plane at the end facing the second half-coupling. Parallel, a dial indicator is set on the basis of the replacement plane, and the first half coupling is rotated, the rotation of the first coupling drives the replacement plane to rotate coaxially, and the dial indicator is perpendicular to the end surface to be detected on the second half coupling and The contact is measured against the end face to be tested, and the axial deviation between the corresponding end faces of the first half coupling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com