Bare engine module

An optical-mechanical module and planar technology, applied in optics, instruments, projection devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

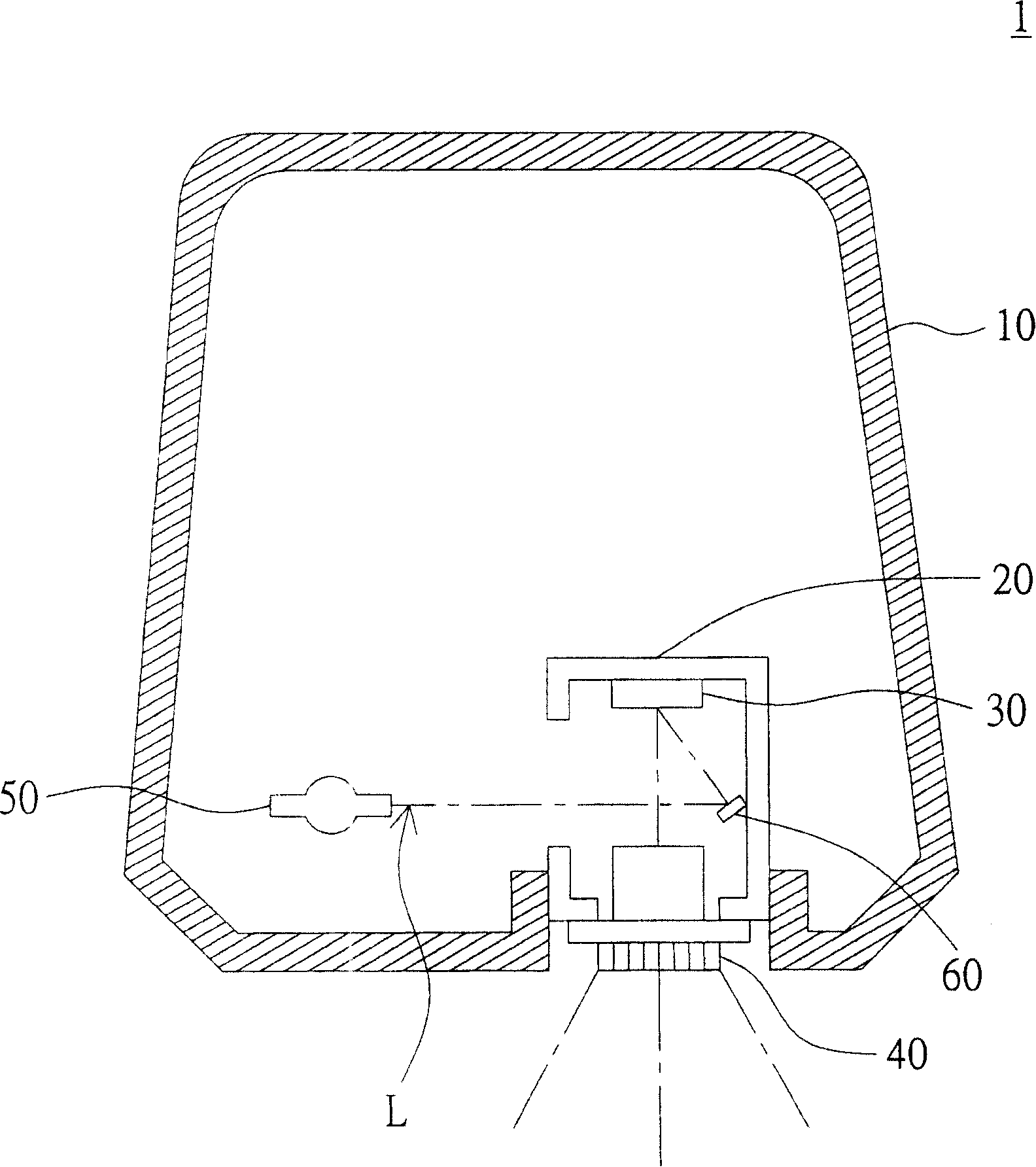

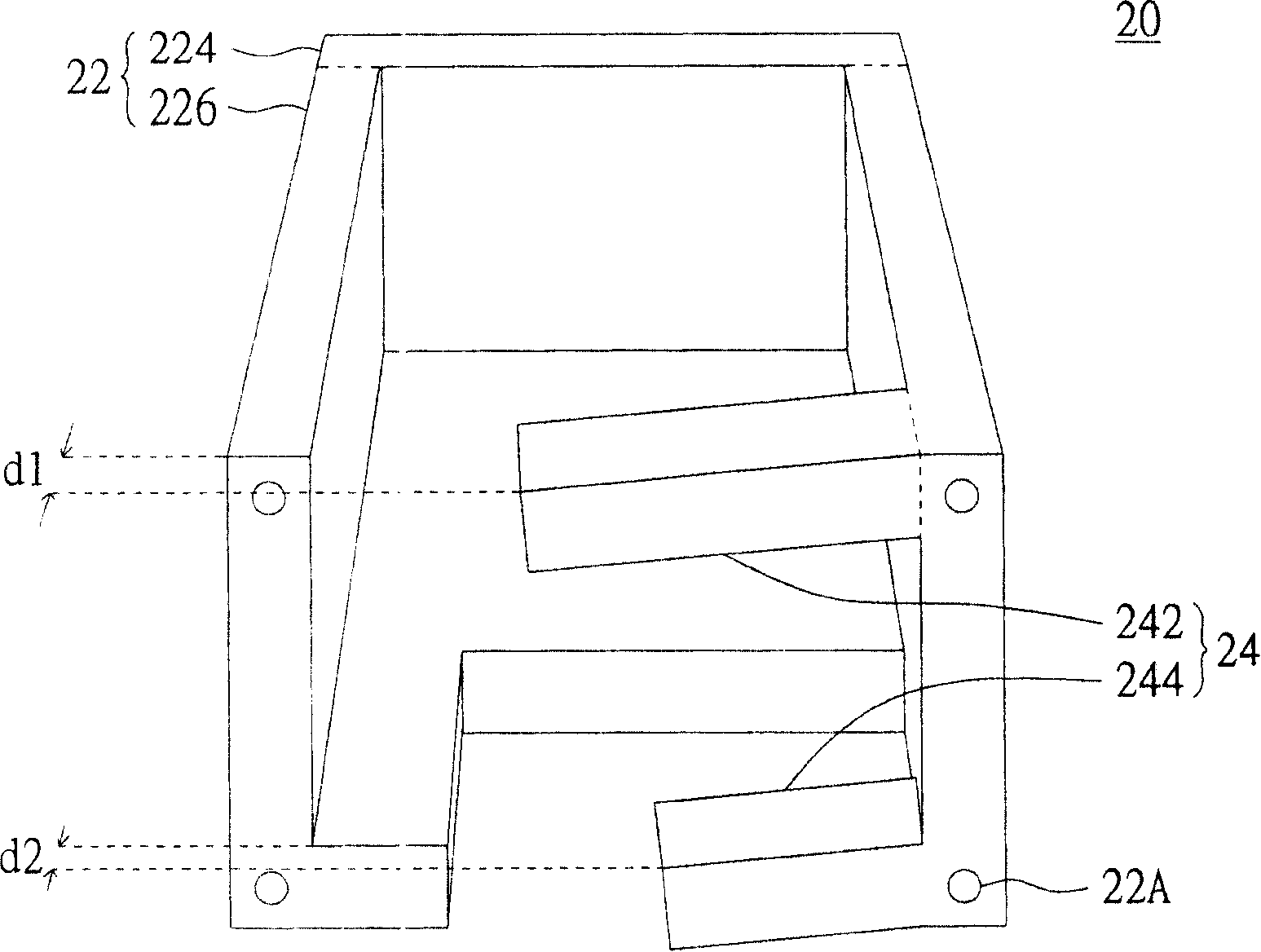

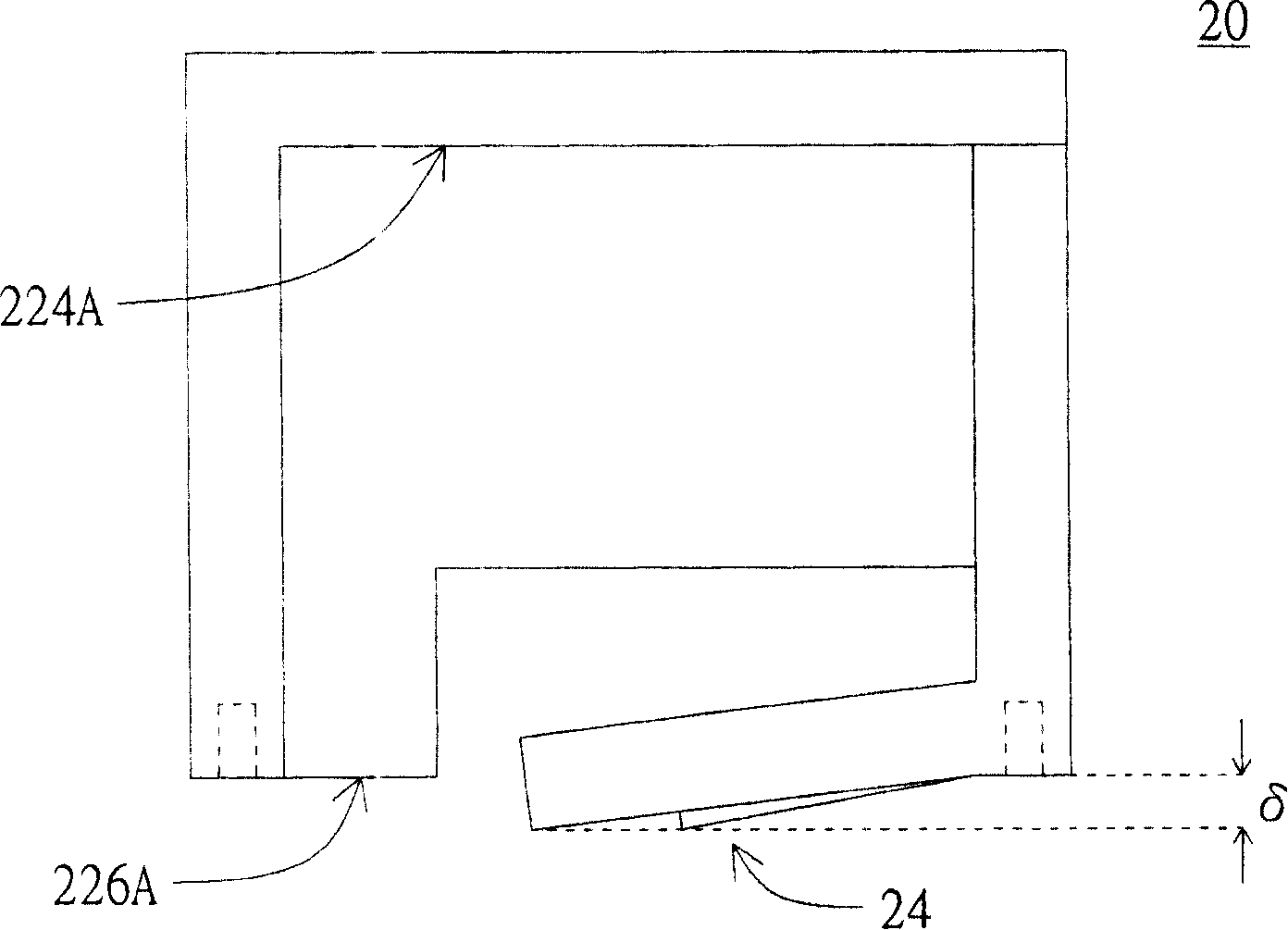

[0050] Please refer to figure 1 , which shows a schematic diagram of a projection device according to a preferred embodiment of the present invention. Such as figure 1 As shown, the projection device 1 includes a housing 10 , a support structure 20 , a first module 30 , and a second module 40 . The bulb 50 and the reflector 60. The supporting structure 20 , the first module 30 , the second module 40 , and the reflector 60 are the optical-mechanical modules of the projection device 1 . The supporting structure 20 and the bulb 50 are respectively disposed inside the casing 10 , and the first module 30 , the second module 40 and the reflector 60 are respectively disposed in the supporting structure 20 . Wherein, the light bulb 50 is used to generate the light L to pass through the reflective lens 60 and pass through the first module 30 and the second module 40 in sequence to send the image out from the projection device 1 .

[0051] The first module 30 , such as a digital mic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com