Flexible mechanism-based macro-micro coupling trochoid micro-nano scratch testing machine

A flexible mechanism, scratch test technology, applied in the direction of strength characteristics, measuring devices, instruments, etc., can solve the problems of insufficient processing ability of complex surface structures, high assembly accuracy requirements, and difficulty in miniaturization, and achieve continuous large-stroke working range. , Good disassembly, reliable equipment operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

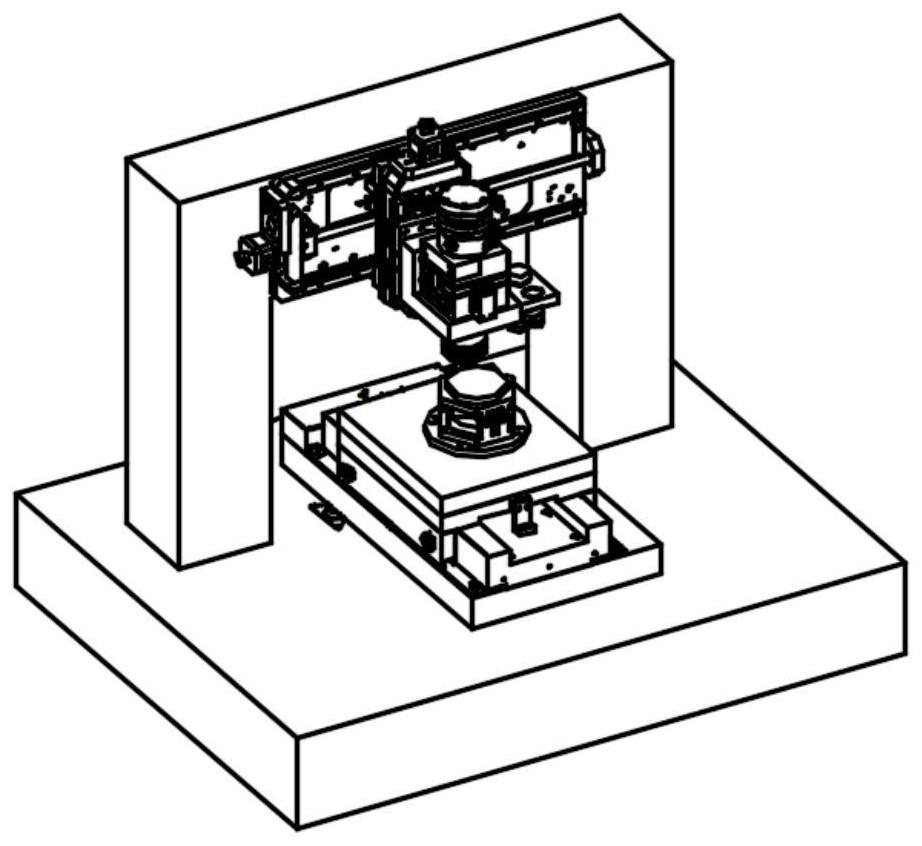

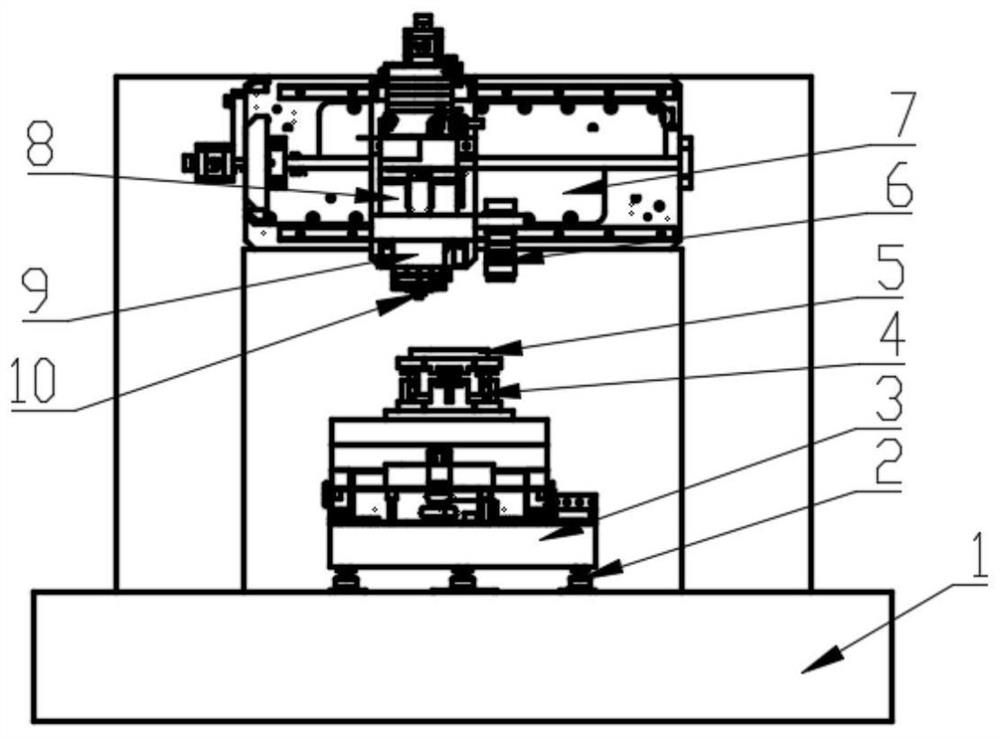

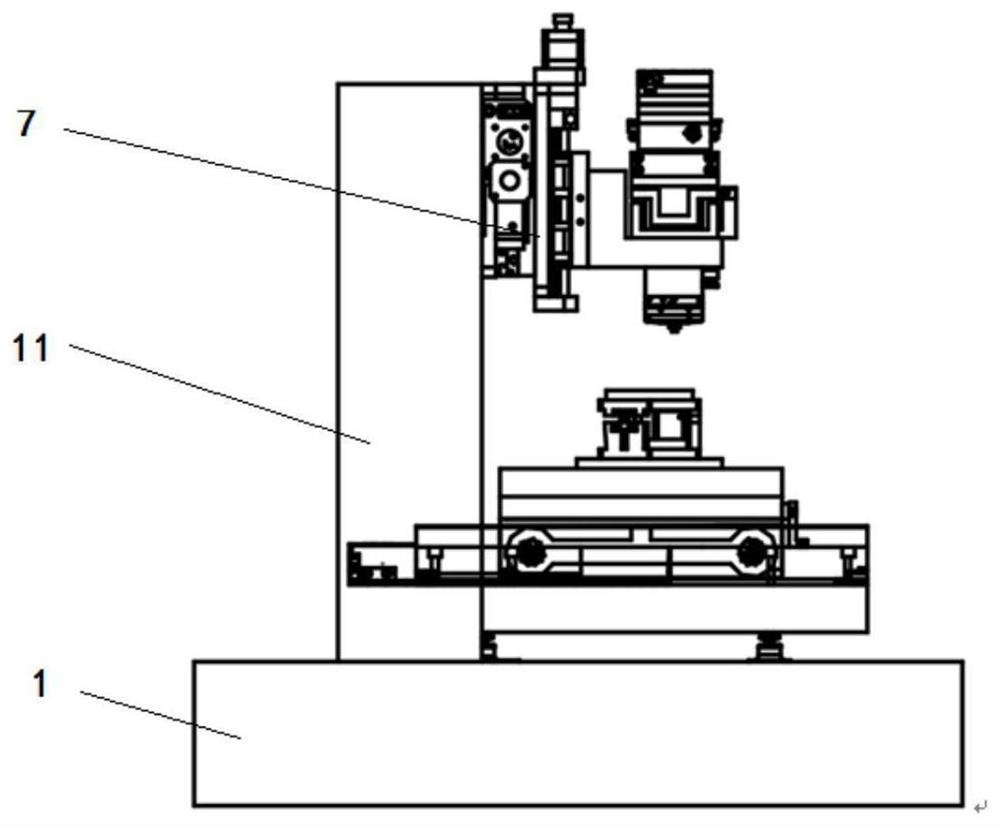

[0023] Specific implementation mode one: combine Figure 1 to Figure 11 Describe this embodiment, the macro-micro coupling trochoidal micro-nano scratch testing machine based on the flexible mechanism in this embodiment includes a mounting table 1, a sample disk carrying assembly, a sample disk 5, a cutter head mounting assembly, and a cutter head 10 and a back plate 11; the sample disc carrying assembly is installed on the upper surface of the mounting table 1, the sample plate 5 is installed on the sample plate carrying assembly, and the back plate 11 is vertically fixed on the upper surface of the mounting table 1, The cutter head installation assembly is installed on the upper part of the back plate 11 , the cutter head 10 is installed on the cutter head assembly, and the cutter head 10 is located above the sample disk 5 .

[0024] Threaded holes are formed on the table surface of the mounting table 1 and are connected with the adjusting feet 2 . The air-floating guide ra...

specific Embodiment approach 2

[0025] Specific implementation mode two: combination Figure 1 to Figure 11 To illustrate this embodiment, the sample plate carrying assembly of the flexible mechanism-based macro-micro-coupling trochoidal micro-nano scratch testing machine in this embodiment includes a plurality of adjustment legs 2, air-floating guide rails 3 and a micro-movement platform 4 ; The air-floating guide rail 3 is installed on the upper surface of the installation table 1, and the lower surface of the air-floating guide rail 3 is provided with a plurality of adjusting legs 2, the micro-movement platform 4 is installed on the air-floating guide rail 3, and the sample disc 5 is fixed on the micro-movement Platform 4 upper surface.

[0026] The micro-motion platform 4 has three degrees of freedom around X, around Y and along the Z axis; wherein, the main function of the degrees of freedom around X and around Y is to adjust the parallelism between the sample disk 5 and the air bearing guide rail 3, re...

specific Embodiment approach 3

[0029] Specific implementation mode three: combination Figure 1 to Figure 11 Describe this embodiment, the micro-movement platform 4 of the macro-micro coupling trochoidal micro-nano scratch test machine based on the flexible mechanism in this embodiment includes a mounting base plate 41, a plurality of piezoelectric ceramics 42, a plurality of capacitance sensors, capacitance sensors Bracket 43 and three-degree-of-freedom flexible hinge structure 44; the installation base plate 41 is horizontally installed on the air bearing guide rail 3, the three-degree-of-freedom flexible hinge structure 44 is installed on the upper surface of the installation base plate 41, and a plurality of piezoelectric ceramics 42 are evenly distributed along the circumferential direction Installed on the three-degree-of-freedom flexible hinge structure 44 , the capacitive sensor bracket 43 is installed in the three-degree-of-freedom flexible hinge structure 44 , and multiple capacitive sensors are in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| stiffness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com