Fine adjustment thread assembly and processing apapratus

A technology for fine-tuning screws and assemblies, used in grinding devices, grinding drive devices, metal processing equipment, etc., can solve the problem of difficulty in applying measurement loads, and achieve the effect of simple adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

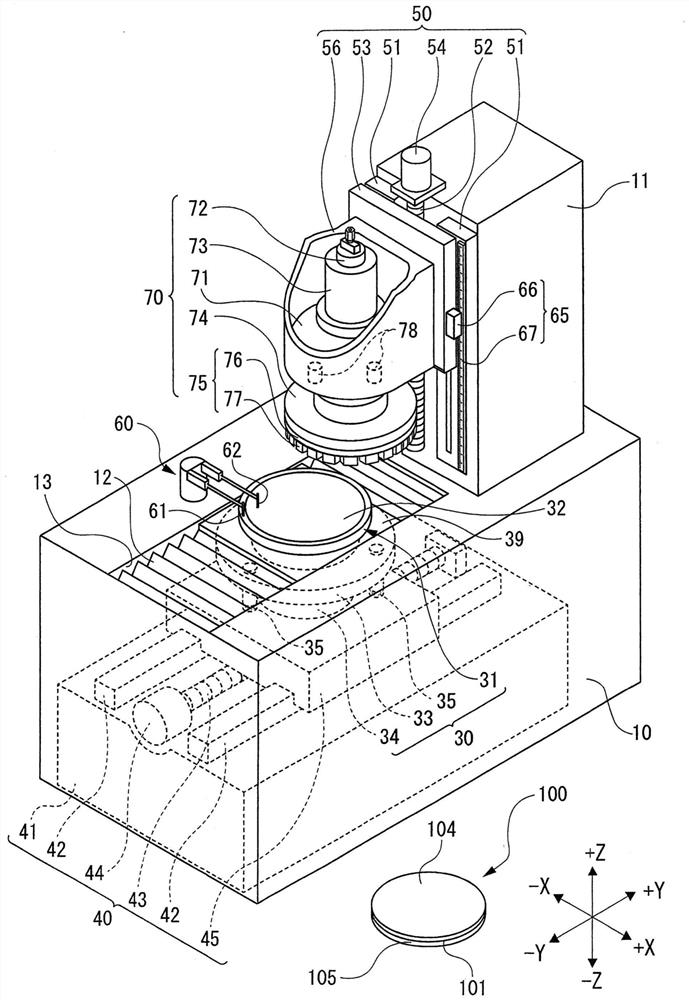

[0023] like figure 1 As shown, the grinding apparatus 1 of this embodiment is an apparatus for grinding a wafer 100 as a workpiece, and has a rectangular parallelepiped main casing 10 and a column 11 extending upward.

[0024] The wafer 100 is, for example, a circular semiconductor wafer. exist figure 1 Among them, a plurality of devices are formed on the front surface 101 of the wafer 100 facing downward, and are protected by sticking a protective tape 105 . The back surface 104 of the wafer 100 is a surface to be processed which is subjected to grinding.

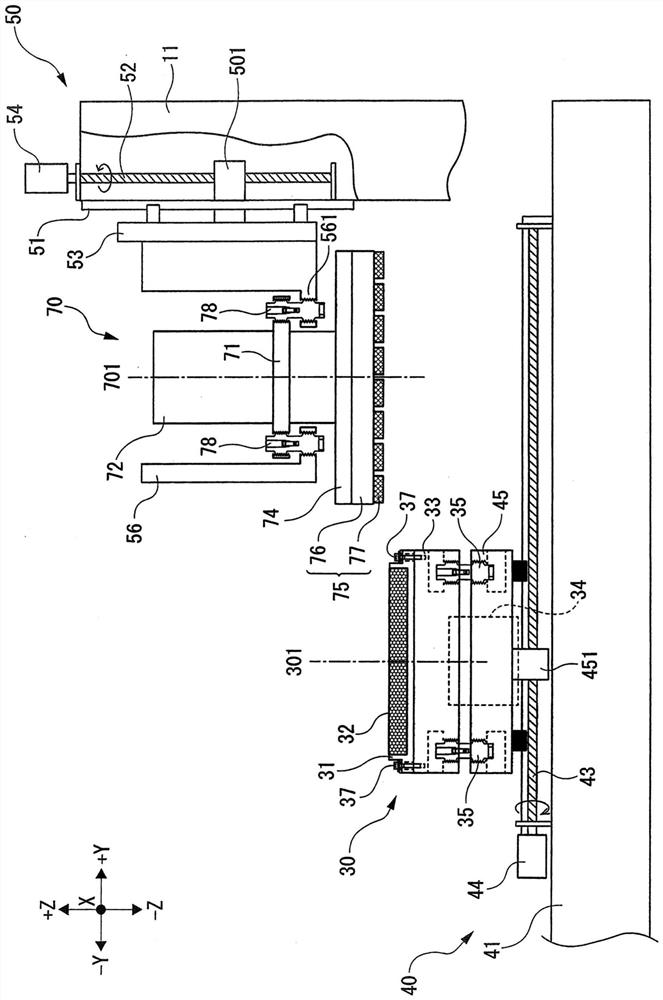

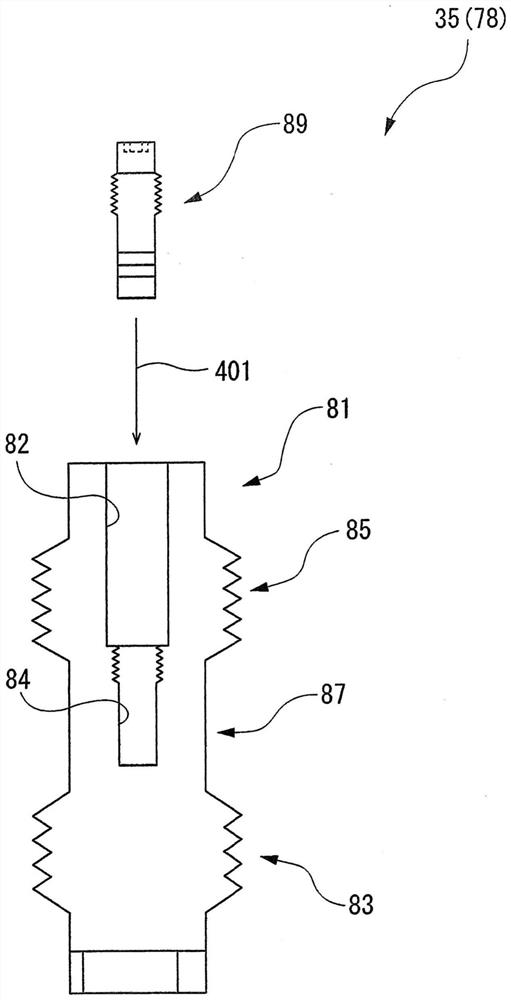

[0025] An opening 13 is provided on the upper surface side of the main case 10 . Furthermore, a holding unit 30 is arranged in the opening 13 . The holding unit 30 includes: a chuck table 31 having a holding surface 32 holding the wafer 100 ; and a support member 33 that supports the chuck table 31 . like figure 2 As shown, the support member 33 and the chuck table 31 are screwed together by screws 37 .

[0026] f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com