Extrinsic fiber-optic F-P vibration sensor and system

A vibration sensor and extrinsic technology, which is applied in the field of extrinsic fiber-optic perovskite vibration sensors and systems, can solve the problems of difficult adjustment of the length of the Fizeau cavity, complicated processing methods, and inability to guarantee the verticality of the gradient lens, etc. Difficulty in processing and debugging, overall compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

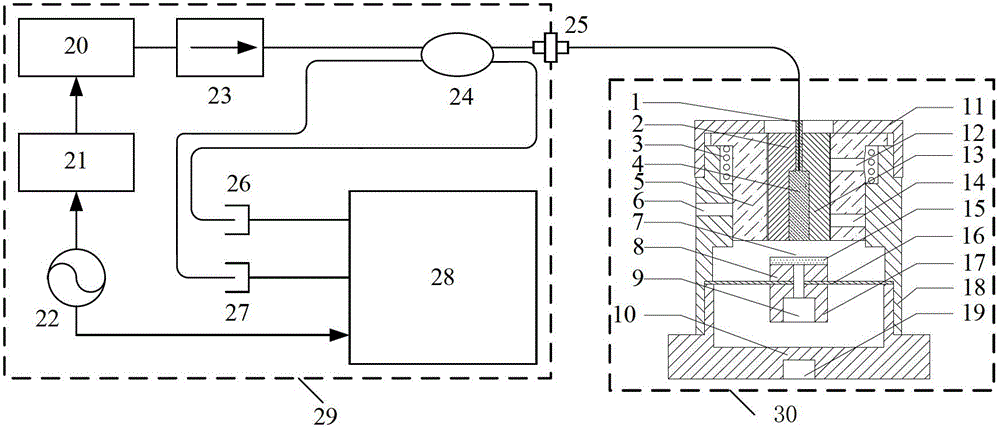

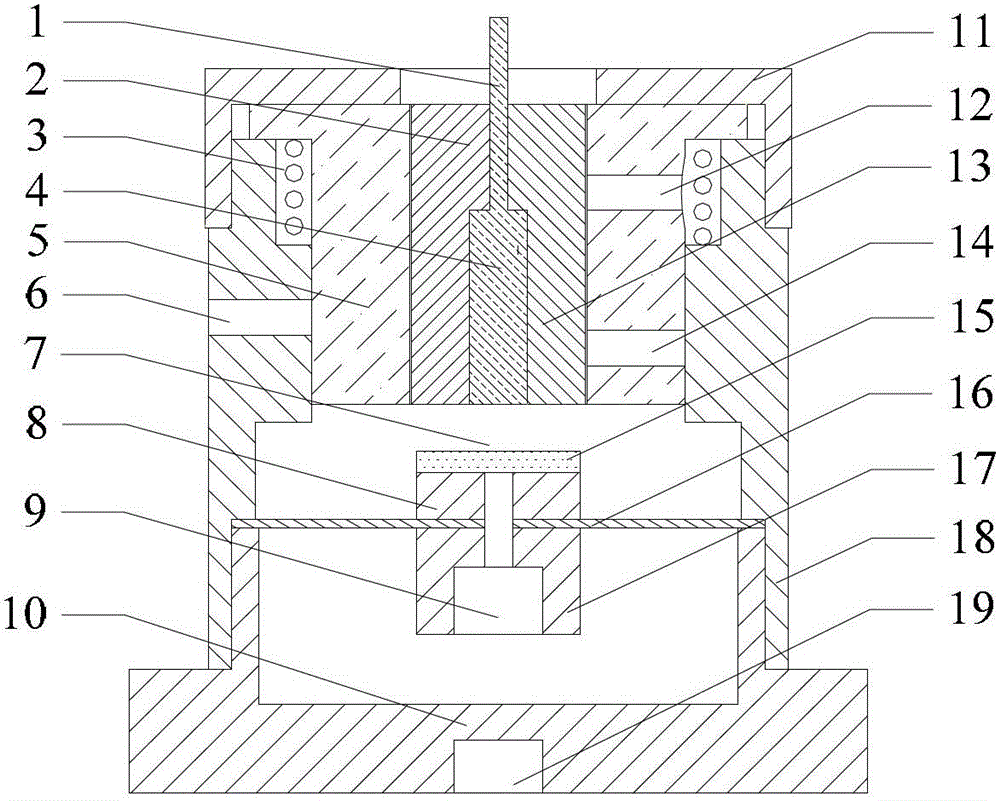

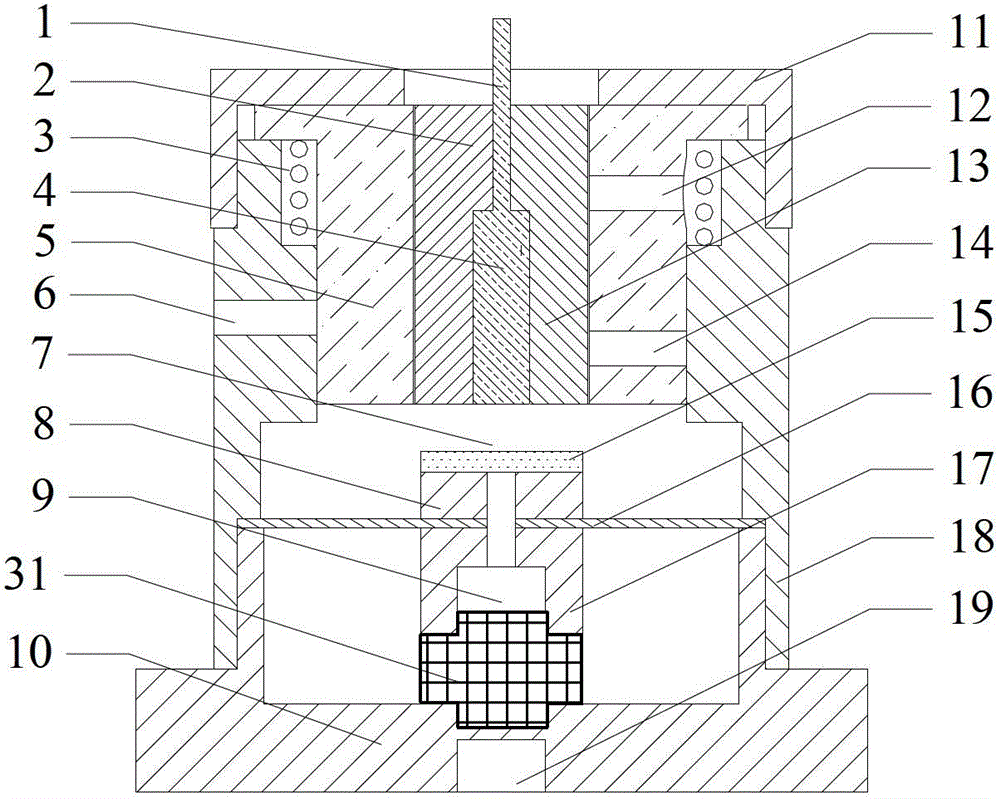

[0022] Please refer to figure 1 , is a structural schematic diagram of an embodiment of the extrinsic fiber optic F-P vibration sensing system provided by the present invention. The system is mainly composed of an extrinsic fiber optic F-P sensor 30 and a phase carrier demodulator 29 .

[0023] Wherein, the structural details of the extrinsic fiber optic F-P sensor 30 are as follows: figure 2 shown. It includes: a shell with an opening, a vibration sensitive element, a reflector 15, a collimating lens 4 with a pigtail 1, a collimating lens clamping device 2, 13, a spring fixing device 5, a spring 3 and an end cover 11.

[0024] Wherein, the shell with opening is mainly composed of a base 10 and a shell 18 , the shell 18 is arranged on the base 10 and screwed with the base 10 , and the opening is set on the shell 18 . And a mounting hole 19 is provided at the bottom of the base 10 for mounting the base 10 on the object to be measured.

[0025] Wherein, the vibration sensit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com