Transfer equipment

A transfer device, plate-shaped body technology, applied in the directions of transportation and packaging, furnace, charge control, etc., can solve the problems of assembly device difficulty, cracking, wafer scratches, etc., avoid damage such as cracking, and shorten the processing time of temperature adjustment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

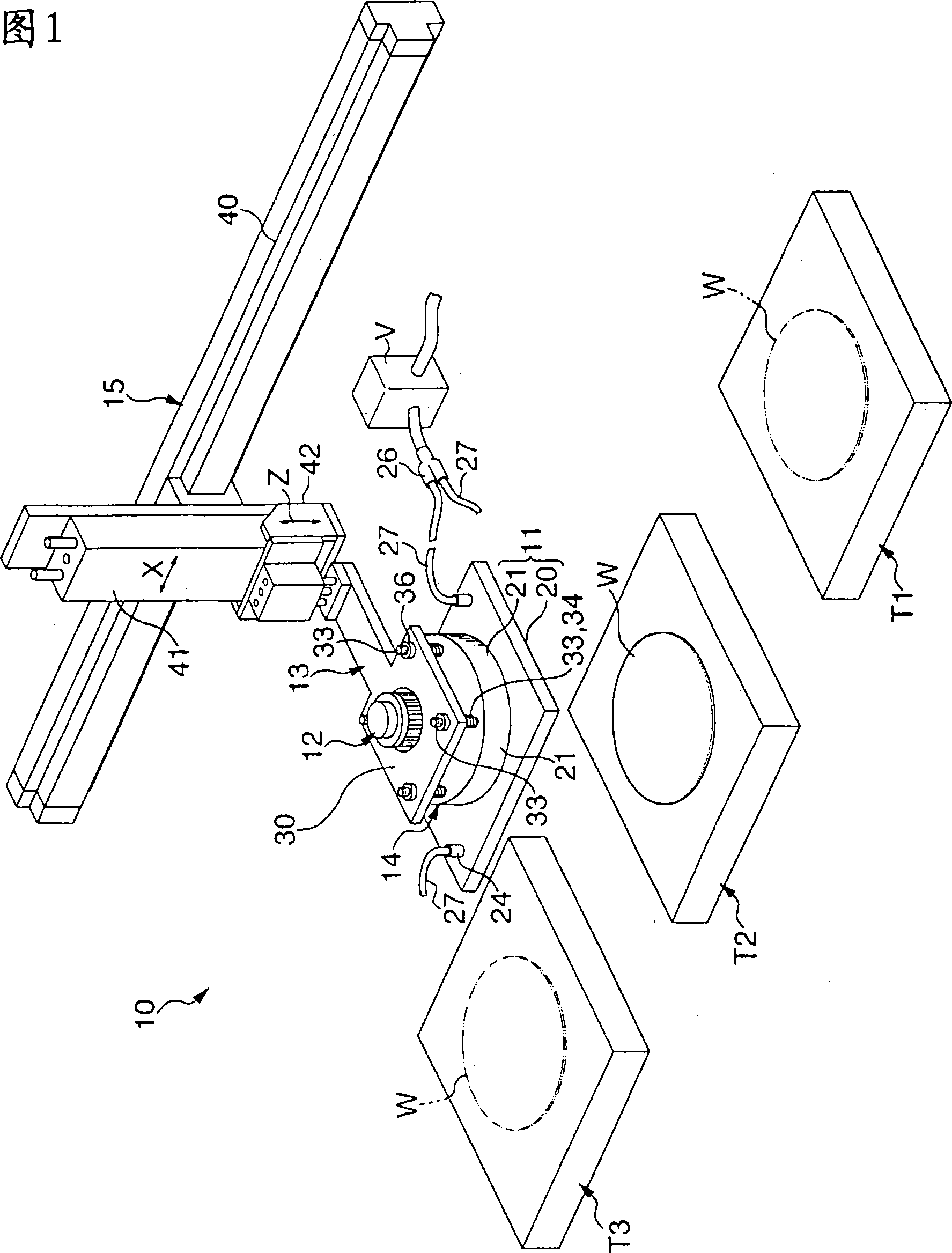

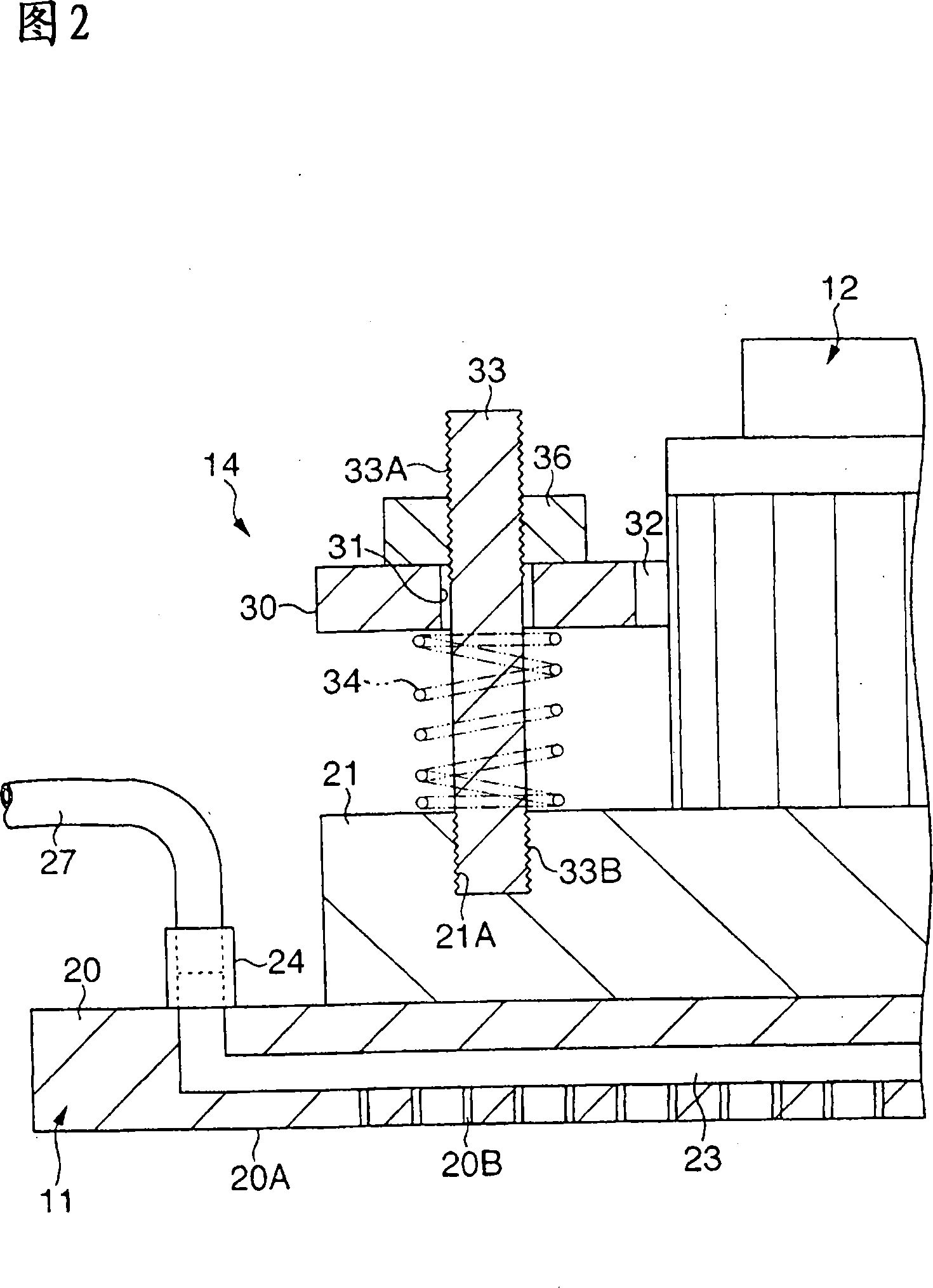

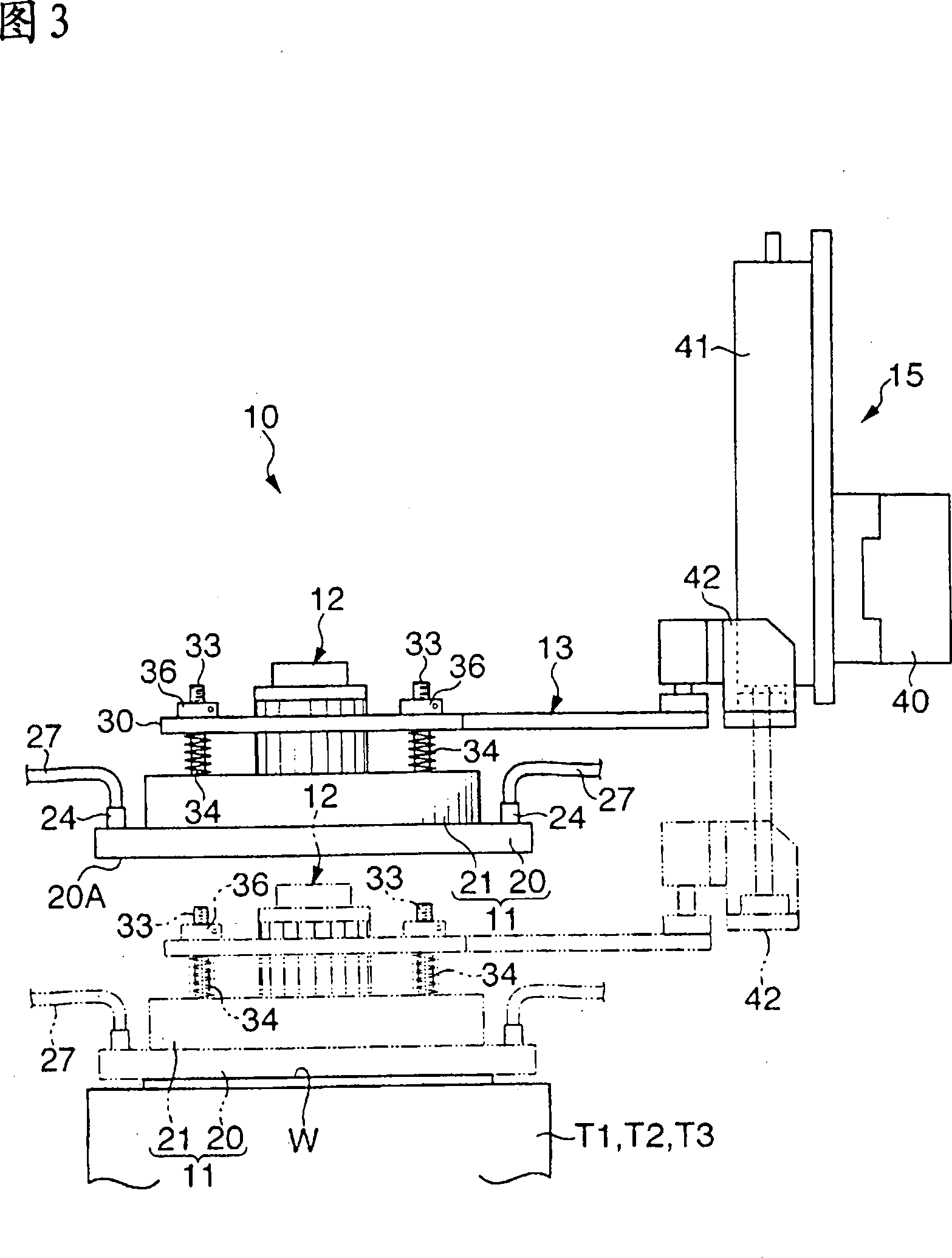

[0039] The schematic structure of the transfer apparatus of this embodiment is shown in FIG. 1. As shown in FIG. In this figure, the transfer device 10 includes a support plate 11 for a wafer W as a plate-shaped body, a temperature adjustment device 12 for adjusting the temperature of the support plate 11, and a holding member 13 for holding the support plate 11. A parallelism adjustment mechanism 14 between the support plate 11 and the holding member 13, and a moving device 15 for moving the support plate 11 in the X and Z directions in FIG. 1 .

[0040] First to third stages T1 , T2 , and T3 are disposed below the support plate 11 , and a wafer W is transferred between these stages T1 to T3 by a transfer device 10 . These stages T1 to T3, whose detailed structures are omitted here, include means for controlling the temperature of the wafer W to a predetermined temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com