Cutting machine

A cutting machine, sticky technology, applied in the field of cutting machines, can solve the problems of high cost, increased wear, difficult cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

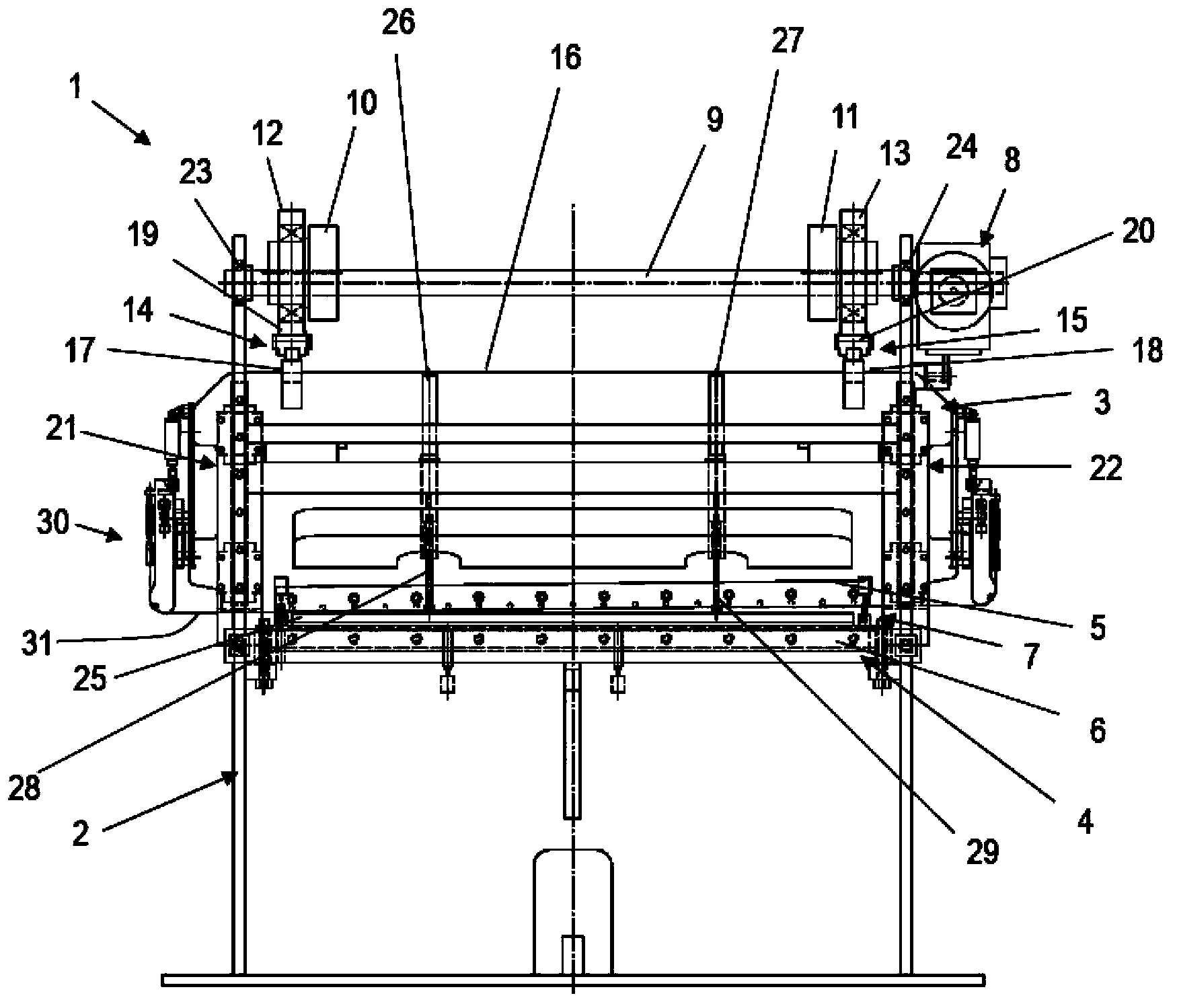

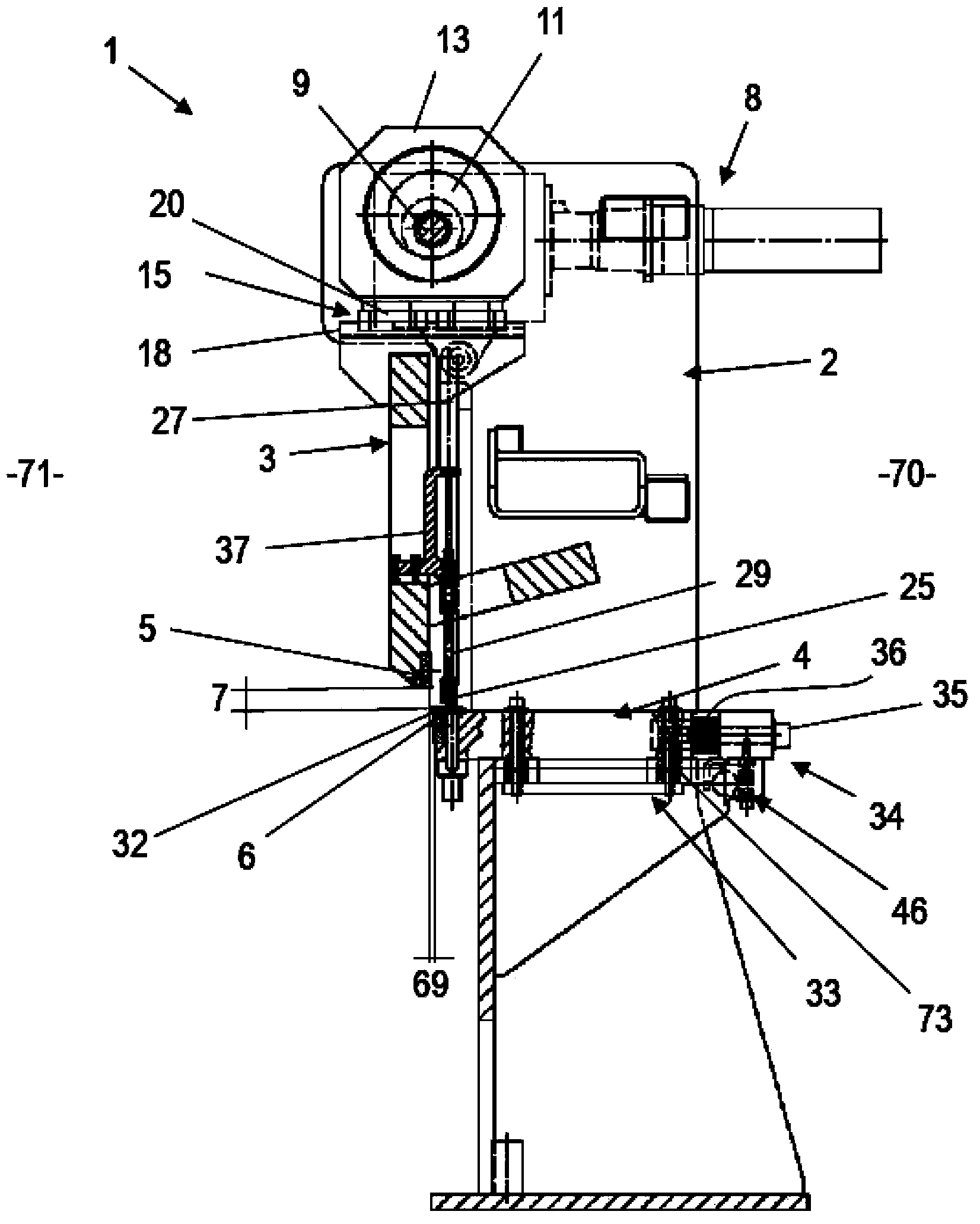

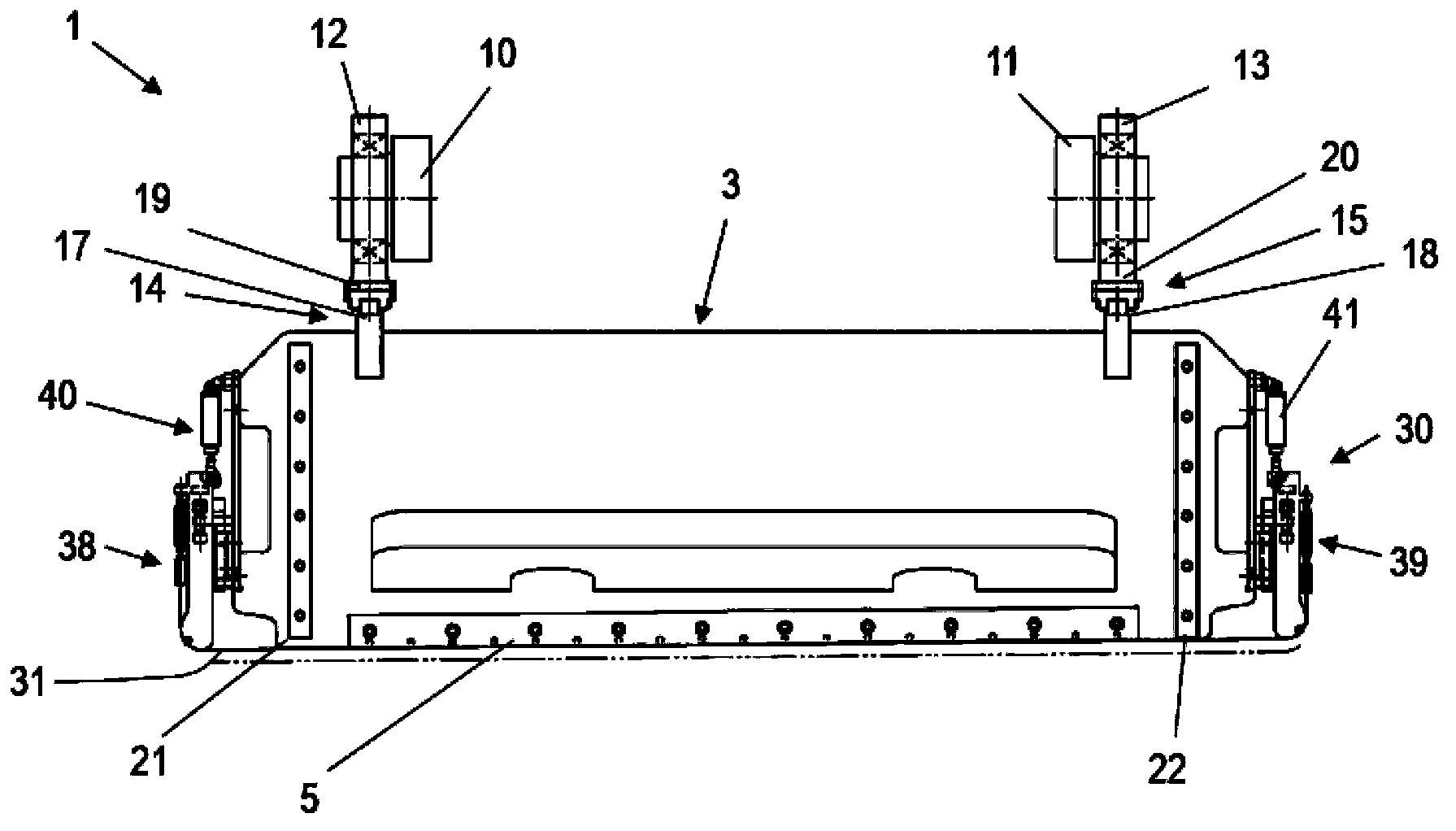

[0036] figure 1 A cutting machine 1 for cutting thin adhesive tapes is shown, having a knife holder 3 guided on a main frame 2 and a table 4 arranged immovably in vertical direction relative to the main frame 2 . In the lower region of the tool holder, an upper blade 5 is fastened, which interacts with a lower blade 6 which is arranged on the table 4 . Between the upper blade 5 and the lower blade 6 a cutting edge 7 is formed in the vertical direction and a cutting gap 69 is arranged in the horizontal direction.

[0037] for cutting according to figure 1 In the view of the belt introduced into the plane of view by the platen 4, the knife holder 3 with the upper blade 5 moves vertically downwards, so that the knife edge 7 closes and the belt is drawn between the upper blade 5 and the lower blade 6 cutting. In order to move the tool holder 3 , a drive 8 is provided which is fastened to the main frame 2 . The drive 8 drives a drive shaft 9 , which is mounted eccentrically in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com