Forklift with anti-vibration mechanism

A shell and mounting seat technology, applied in the direction of shock absorber, mechanical equipment, shock absorber-spring combination, etc., can solve the problems of absorbing vibration and unsatisfactory mounting seat.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

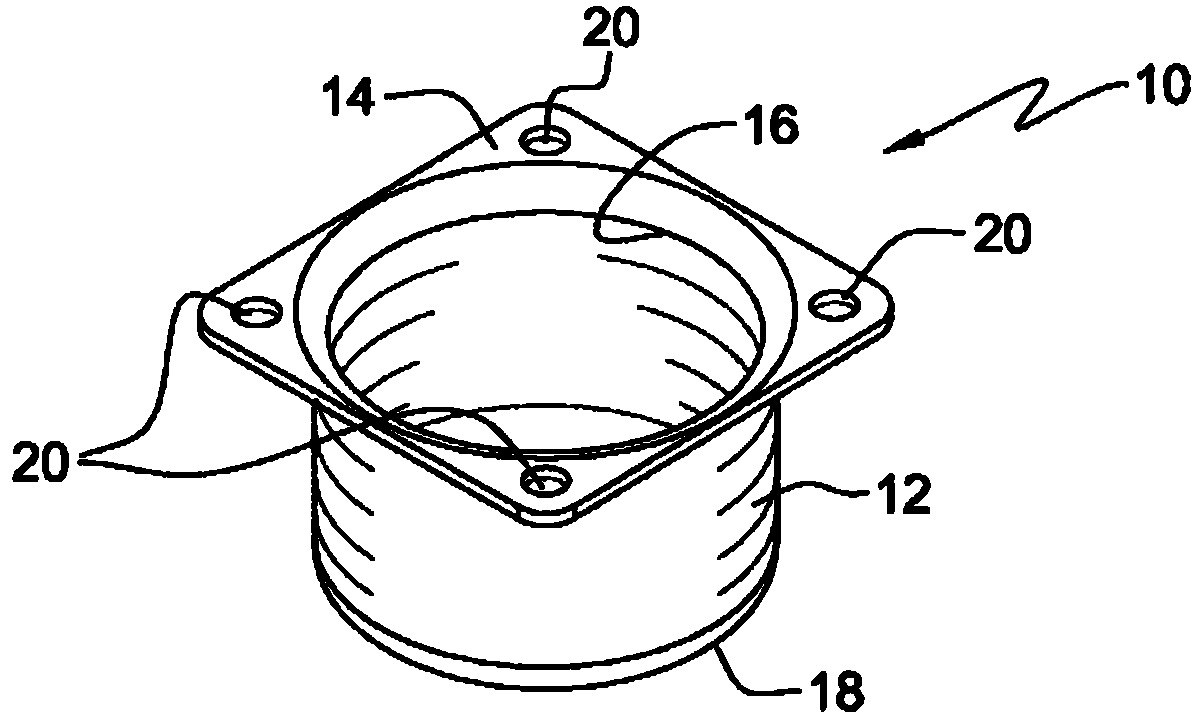

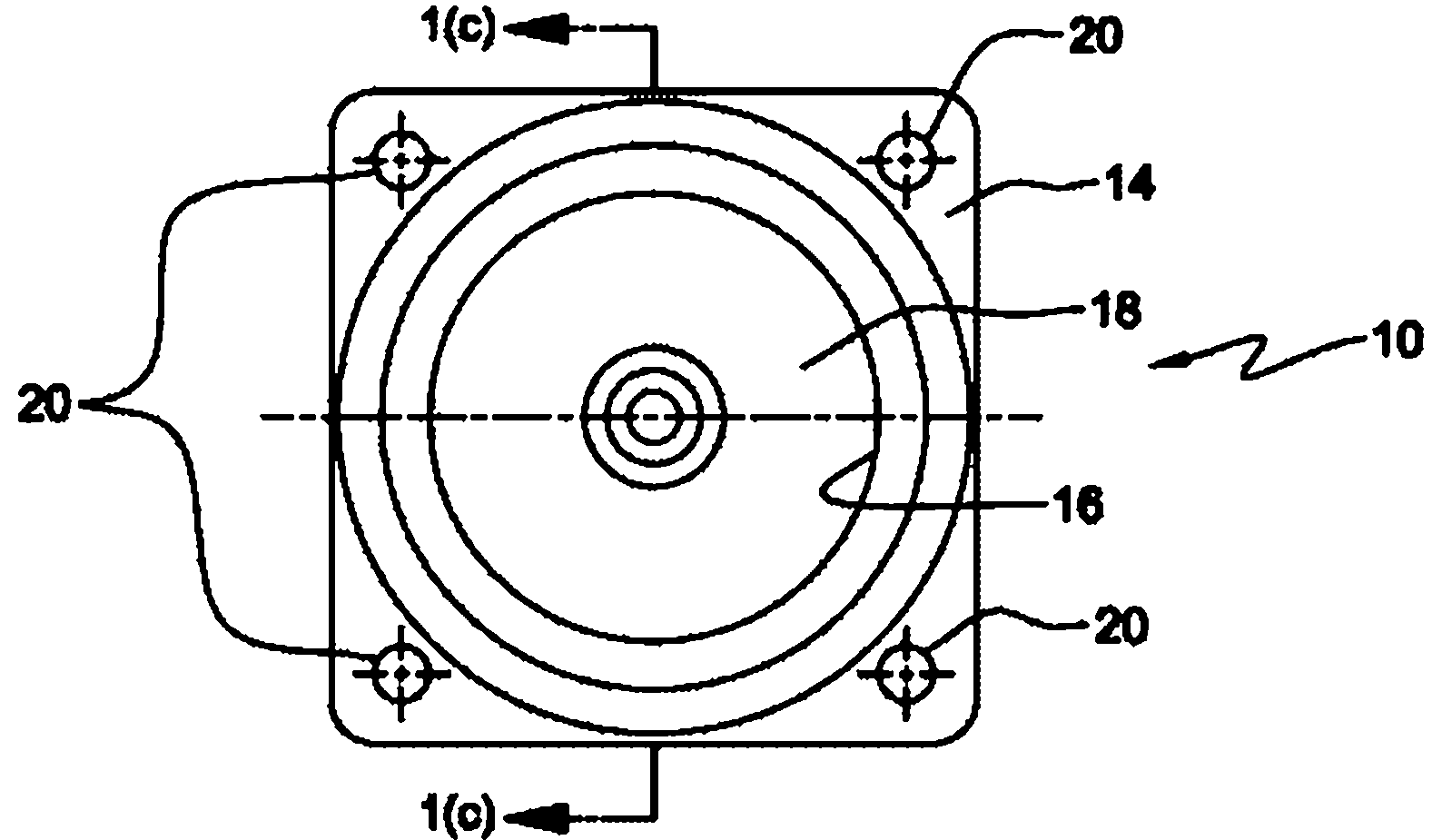

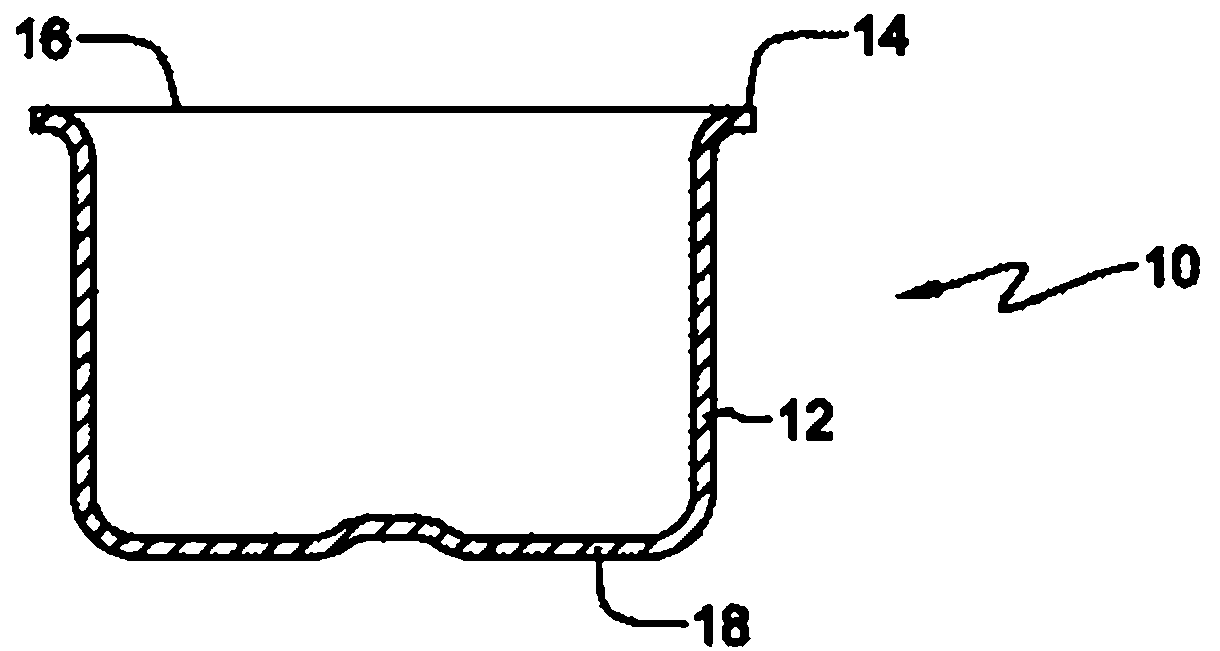

[0043] refer to Figure 1(a)-1(c) , which shows the housing 10 of the mount according to the invention. The housing 10 is preferably cup-shaped and is composed of a cup-shaped portion 12 and a flange portion 14 projecting radially outward from the cup-shaped portion 12 . Cup portion 12 and flange portion 14 are preferably made from a single piece of metal. However, it should be understood that the cup portion 12 and flange portion 14 could also be made of plastic material. The housing 10 includes an open end 16 adjacent to the flange portion 14 and a closed end 18 remote from the flange portion 14 . As shown in the top view of FIG. 1( b ), the flange portion 14 is preferably approximately square. As a result, the flange portion 14 forms four lugs around the outer circumference of the housing 10 . Each lug of the flange portion 14 is provided with a threaded hole 20 . As shown in FIG. 1( b ), the upper surface of the flange portion 14 serves as a first mounting surface of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com