An anti-corrosion and fire-resistant cable

An anti-corrosion and fire-resistant technology, applied in the direction of insulated cables, cables, circuits, etc., can solve the problems of low anti-corrosion effect and poor fire-resistant effect of cables, and achieve the effect of increasing heat transfer space, saving materials, and strengthening fastening effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

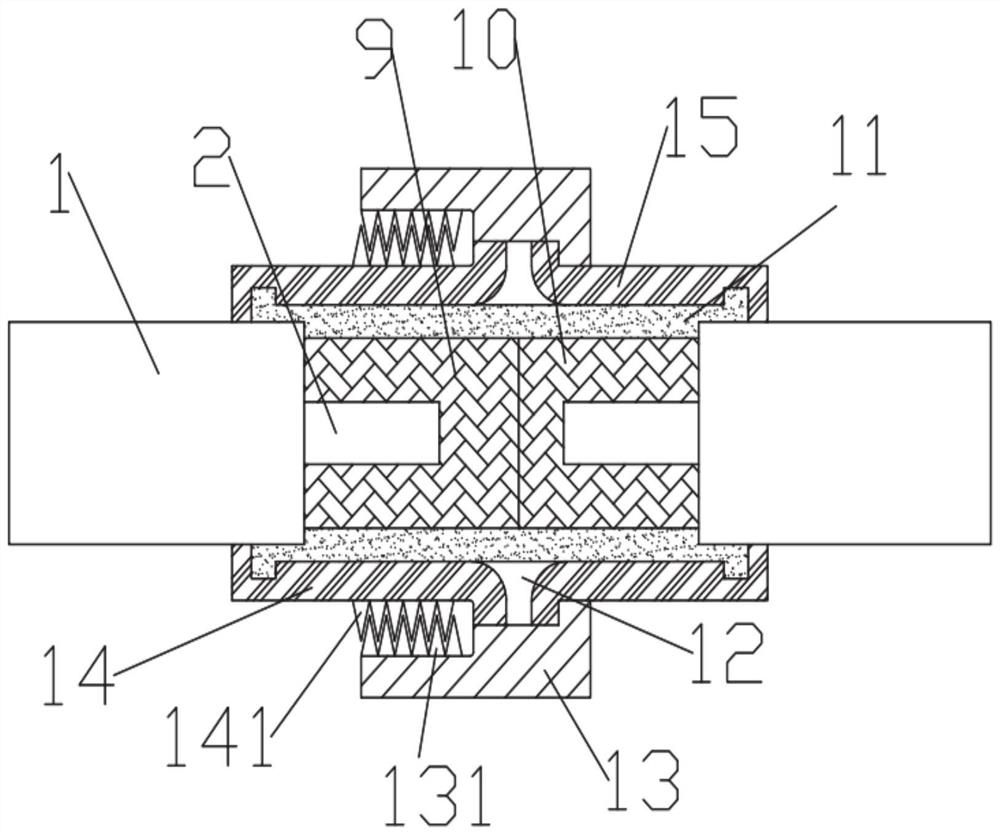

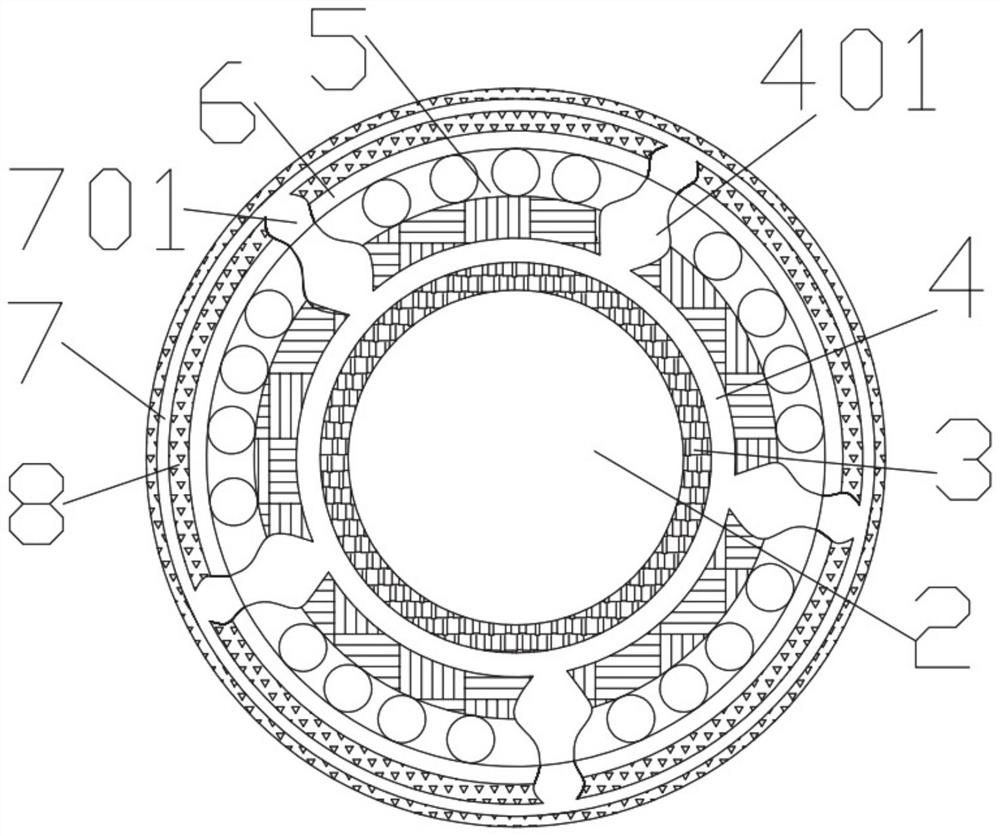

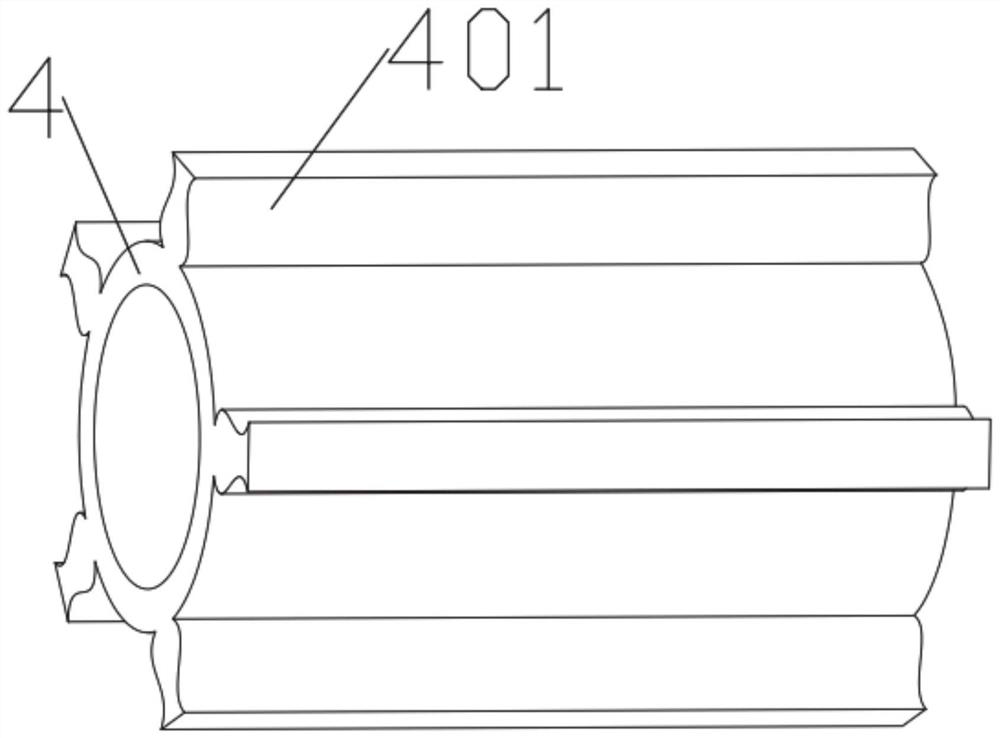

[0026] Below will combine the appended in the embodiment of the present invention Figure 1-4 , to clearly and completely describe the technical solutions in the embodiments of the present invention, and both the sub-conductor and the parent conductor in the present invention can be purchased from the market.

[0027] see Figures 1 to 4 , the present invention provides a technical solution:

[0028] An anti-corrosion and fire-resistant cable, including a cable body 1, a sub-conductor 9, a female conductor 10, a fireproof sleeve 11, a heat shrinkable tube 12, a rotating cover 13, an internal thread 131, a sub-joint pipe 14, an external thread 141 and a female Joint pipe 15, cable body 1 includes conductive core 2, insulating layer 3, aluminum sleeve 4, aluminum sleeve foot 401, mineral filling layer 5, mica tape 6, heat conduction ring 7, heat conduction ring support 701, anti-corrosion layer 8, conductive core 2 The outer layer is fixedly connected to the inner layer of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com