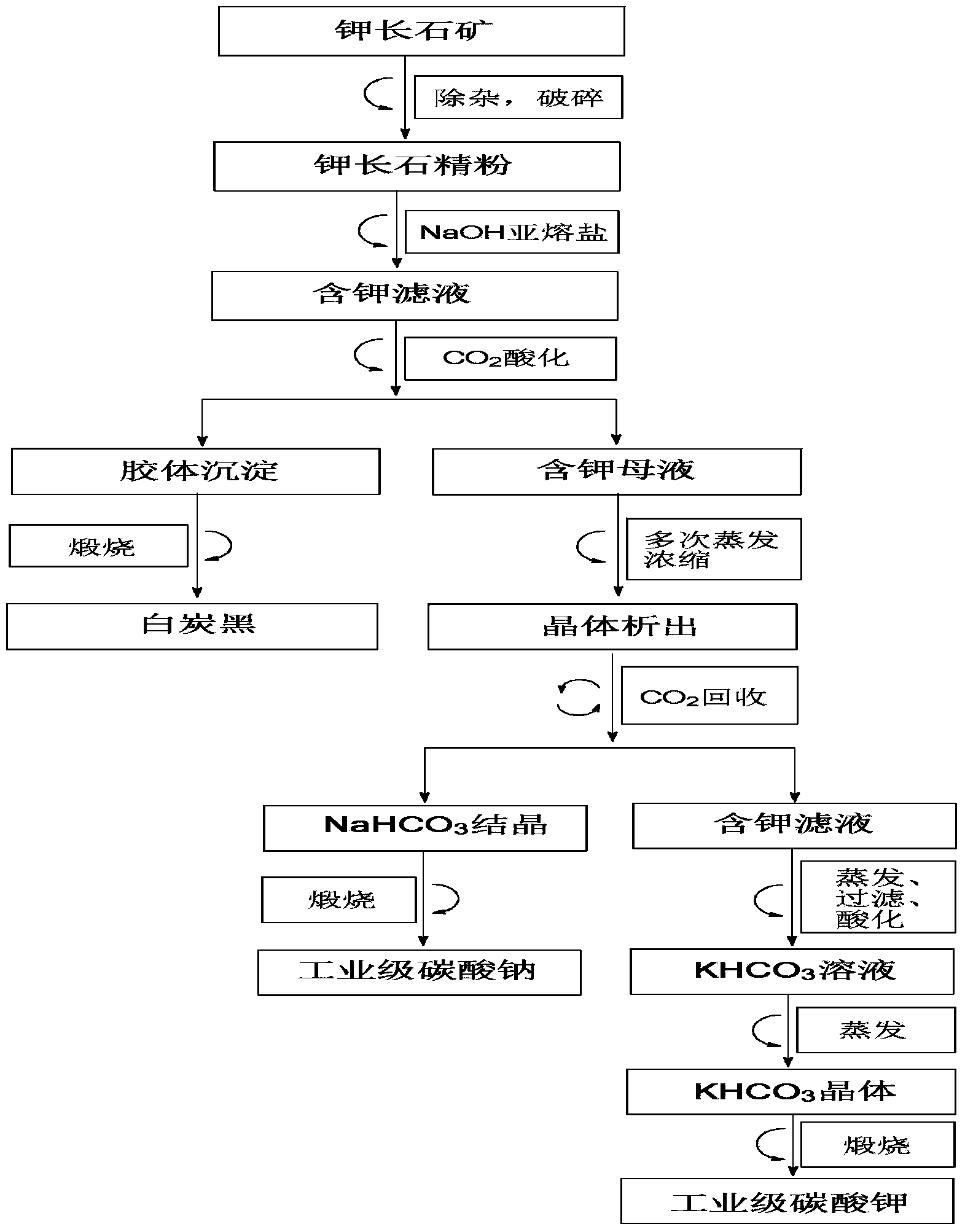

Method for treating potassium feldspar according to sub-molten salt method to prepare potassium carbonate

A sub-molten salt method, potassium feldspar technology, applied in the direction of alkali metal carbonate, chemical instruments and methods, alkali metal compounds, etc., to achieve the effect of strengthening reaction and transfer, reducing reaction temperature, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 1) will K 2 The potassium feldspar ore powder (i.e. potassium feldspar fine powder) with a weight percentage of 7.53% is processed and crushed to 200 meshes, and the NaOH solution with a mass fraction of 60% is mixed in a ratio of 1:5 by weight, and stirred evenly Finally, the stirring rate is 400r / min, and the reaction temperature is 160°C under normal pressure conditions to react for 130min; after cooling at room temperature, the resulting mixture is filtered and washed repeatedly to obtain a potassium-containing filtrate, and the dissolution rate of potassium is 98.58%. ; The resulting filtrate was transferred to a three-necked flask, and CO was passed into the resulting filtrate 2 Carry out acidification and neutralization. During the acidification process, white precipitates are produced. Stop the reaction after the pH of the solution drops to 8, and filter out the precipitates (hydrated silica precipitates); 2) Evaporate the filtered potassium-containing mothe...

Embodiment 2

[0034] 1) will K 2 The O weight percentage content is 16% and is processed and crushed to 200 mesh potassium feldspar fine powder and the NaOH solution that the mass fraction is 80% is mixed in the ratio of 1:4 by weight, after being stirred evenly, be placed in the tank with agitator In the condensing reflux device, the stirring rate is 400r / min, and the reaction temperature is 210°C under normal pressure conditions for 120min; after cooling at room temperature, the resulting mixture is filtered and washed repeatedly to obtain a potassium-containing filtrate. The dissolution rate of potassium was 98.25%; the resulting filtrate was transferred to a three-necked flask, and CO was passed into the resulting filtrate 2 Carry out acidification and neutralization. During the acidification process, white precipitates are produced. After the pH of the solution drops to 8, the reaction is stopped, and the precipitates (hydrated silica precipitates) are filtered off; Evaporate, crystal...

Embodiment 3

[0036] 1) will K 2 The O weight percentage content is 7.53% and is processed and pulverized to 150 mesh potassium feldspar fine powder and the NaOH solution that the mass fraction is 60% is mixed in the proportion that is 1:4.5 by weight, after being stirred evenly, place in the tank with agitator In the condensing reflux device, the stirring rate is 500r / min, and the reaction temperature is 150°C under normal pressure conditions for 135min; after cooling at room temperature, the resulting mixture is filtered and washed repeatedly to obtain a potassium-containing filtrate. The dissolution rate of potassium Be 98.67%; Gained filtrate is transferred in the three-necked flask, feeds CO to the gained filtrate 2 Carry out acidification and neutralization. During the acidification process, white precipitates are produced. Stop the reaction after the pH of the solution drops to 8, and filter out the precipitates (hydrated silica precipitation); 2) Evaporate the filtered potassium-con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

| decomposition efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com