Oscillatory flow reactor of packed bed

An oscillating flow reactor, packed bed technology, applied in chemical instruments and methods, chemical/physical processes, etc., can solve the problems of slow phase interface renewal, reduced phase interface area, poor uniform suspension performance, etc., and achieve particle loss. And the effect of low degree of pulverization, increase of phase interface area, and increase of contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

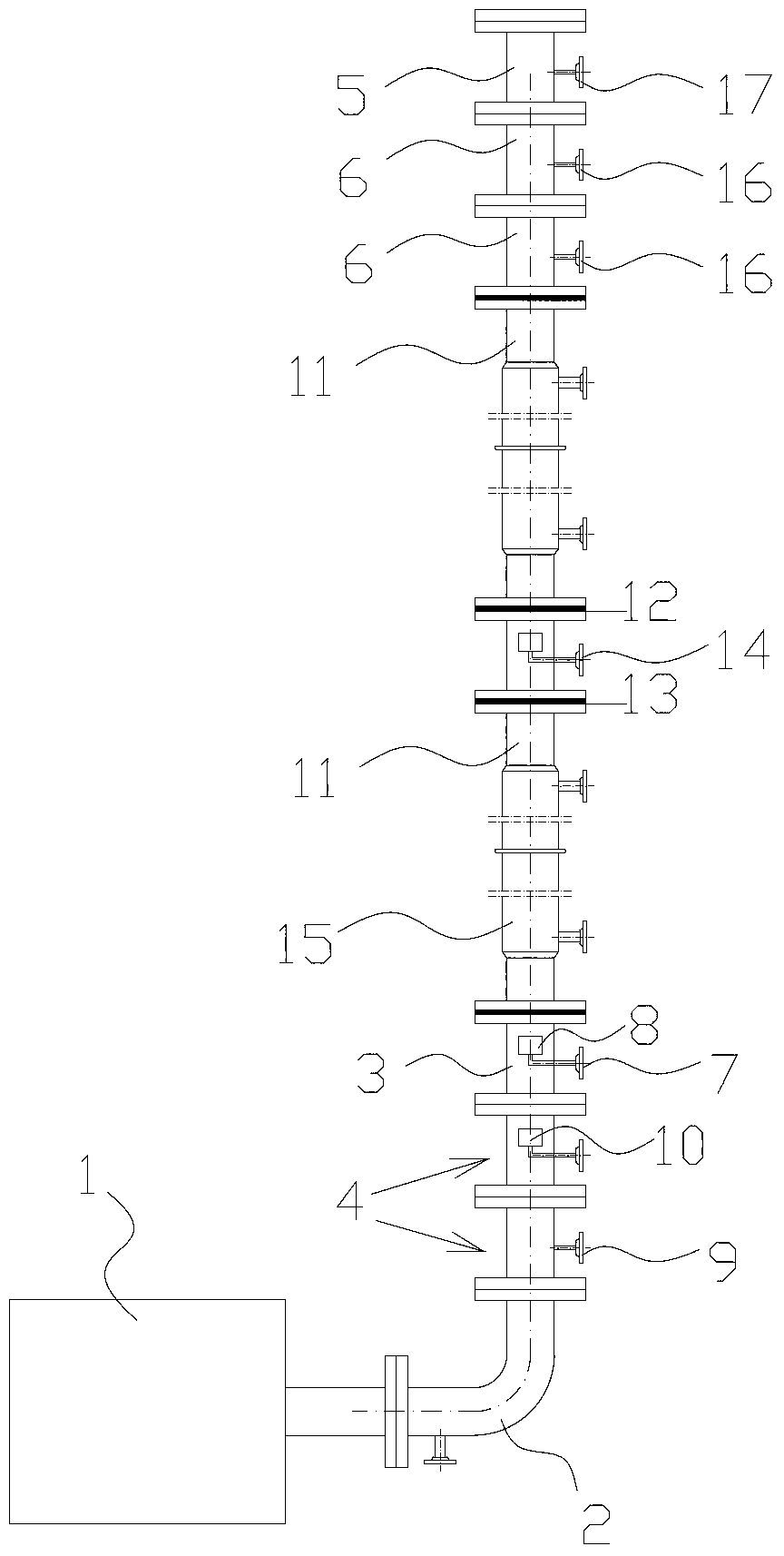

[0039] Such as figure 1Shown is a packed bed oscillating flow reactor, which is used in an industrial gas-liquid-liquid catalytic reaction system. In this reaction system, gas and liquid phase A are reactants, and liquid phase B is a liquid homogeneous catalyst. The oscillation generator is located at the bottom of the reactor, and the packed bed reaction section is divided into upper and lower sections, and each section is connected with a heat exchange jacket for supplying heat to the reactor. The gas inlet section is divided into two sections, which are respectively located at the lower part of the two reaction sections. The gas distributor adopts metal sintered powder filter element structure, and the precision can reach 0.3μm. Liquid phase A and liquid phase B enter the reactor from two liquid inlet sections at the bottom of the reactor respectively, and liquid phase A enters from the upper liquid inlet section, and a liquid distributor is connected to the inlet. The r...

Embodiment 2

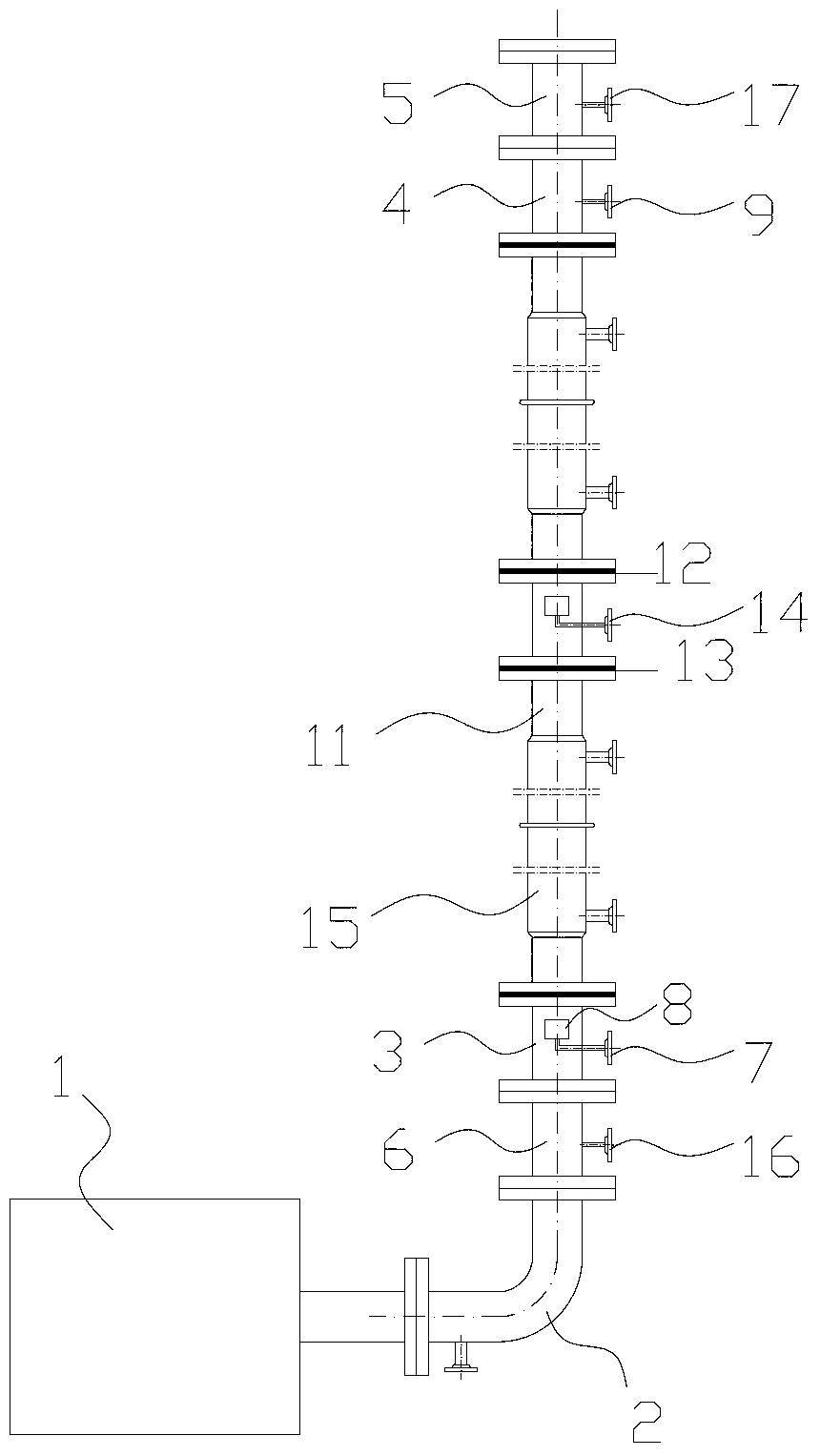

[0044] Such as figure 2 Shown is a packed bed oscillating flow reactor, which is used in an industrial gas-liquid-solid catalytic reaction system. The gas and liquid phases are the reactants, and the solid phase is the catalyst, which is filled in the reaction section. The oscillation generator is located at the bottom of the reactor, and the reaction section is divided into upper and lower sections, and each section is connected with a heat exchange jacket. The gas inlet section is divided into two sections, which are respectively located at the lower part of the two-section reaction section. At this time, the sub-feeding inlet is fed with gas materials, and the gas is fed in two-stage feeding. The gas distributor adopts a metal sintered mesh filter structure. Accuracy 2μm. In the gas outlet section, the gas is separated from the liquid phase and leaves the reactor. The liquid phase enters the reactor from the liquid inlet section at the top of the reactor, and is withdra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com