Patents

Literature

52results about How to "Prevent coalescing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Emulsive composition containing Dapsone

InactiveUS20060204526A1Stabilizes emulsive compositionAvoid separationAntibacterial agentsBiocideSolubilityEmulsion

The present invention relates to a topical, emulsive composition containing Dapsone or its derivative. The inventive composition incorporates emollients and Dapsone or its derivative in a stable emulsion. The stability is achieved through the use of a combination of certain surfactant mixtures and an enhancer providing solubility of the Dapsone.

Owner:ALLERGAN INC

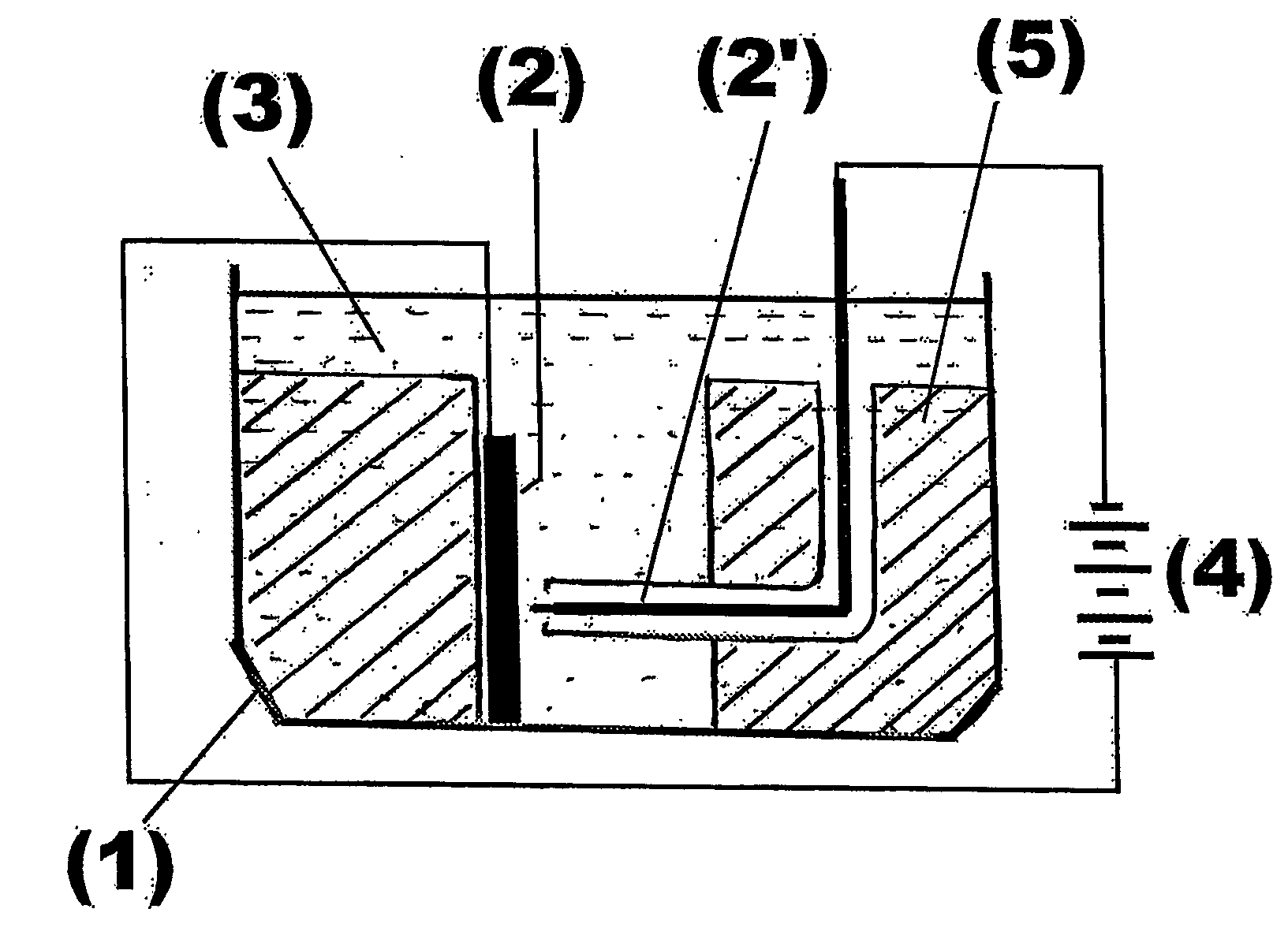

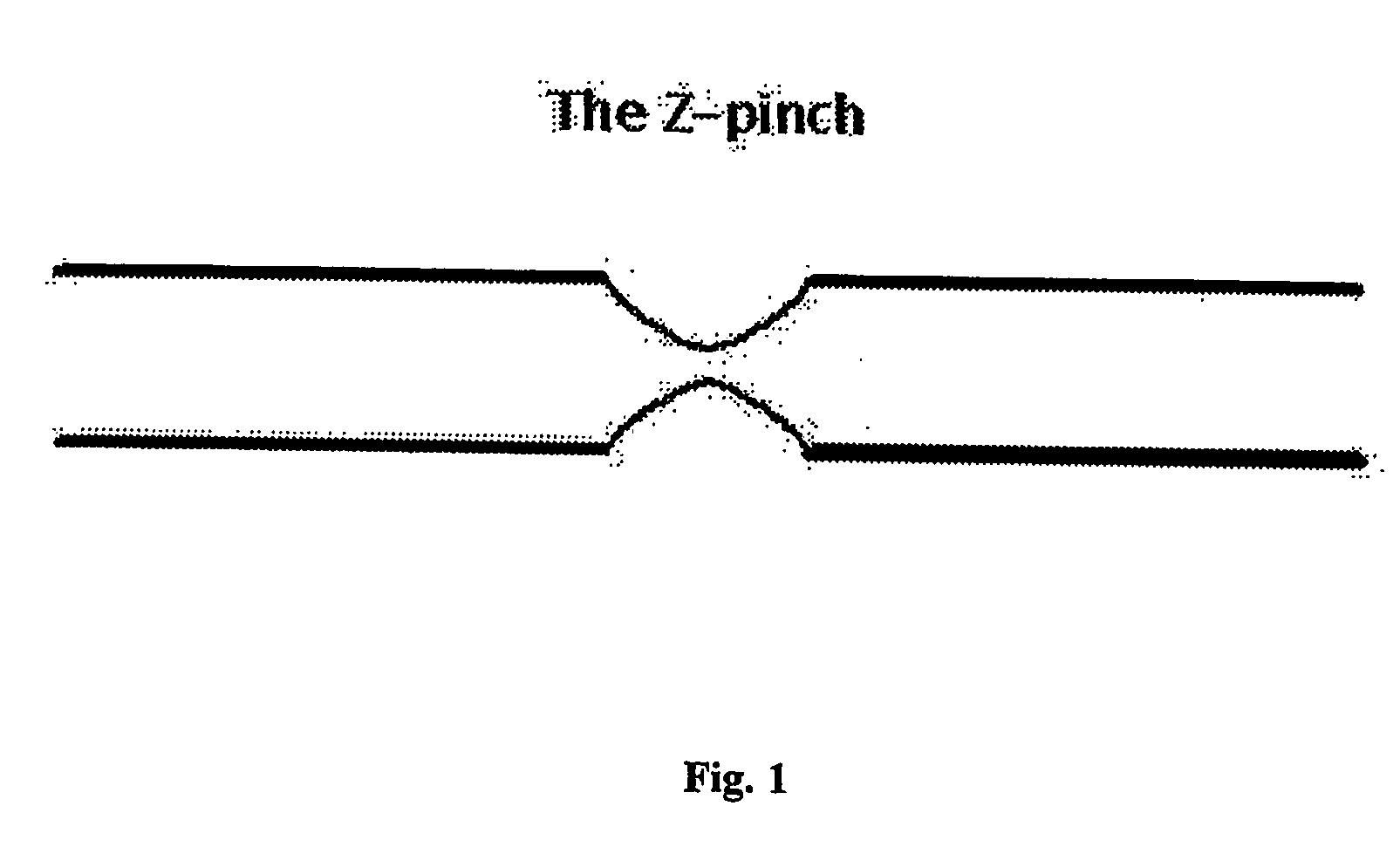

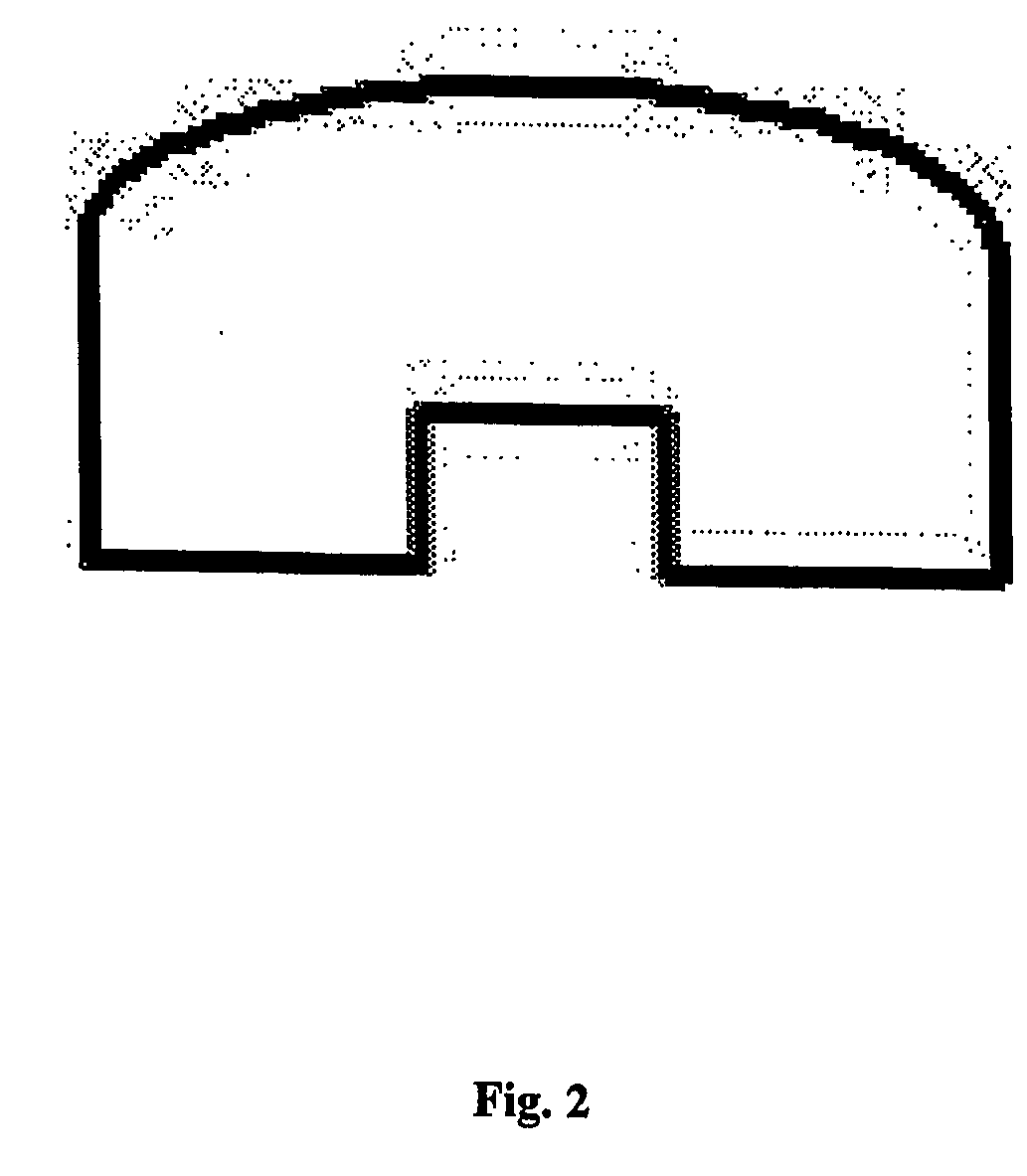

Process and apparatus for producing metal nanoparticles

InactiveUS20070101823A1Increase volumeReduce energy costsMaterial nanotechnologyTransportation and packagingWire rodElectricity

A novel process and apparatus for producing metal nanoparticles by electro-explosion of wires is disclosed. The invention comprises placing a wire and a plate of the same material as two electrodes in a dense medium, preferably water, in such a manner so as to guide the wire in a straight line and applying a voltage of greater than 12V to said electrodes to cause the wire explode into nanoparticles.

Owner:JAWAHARLAL NEHRU UNIVERSITY

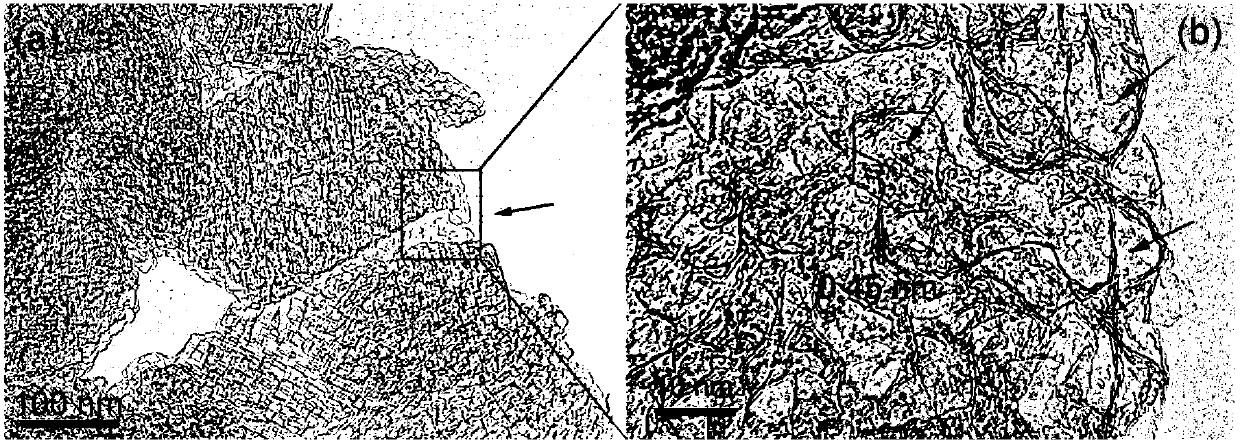

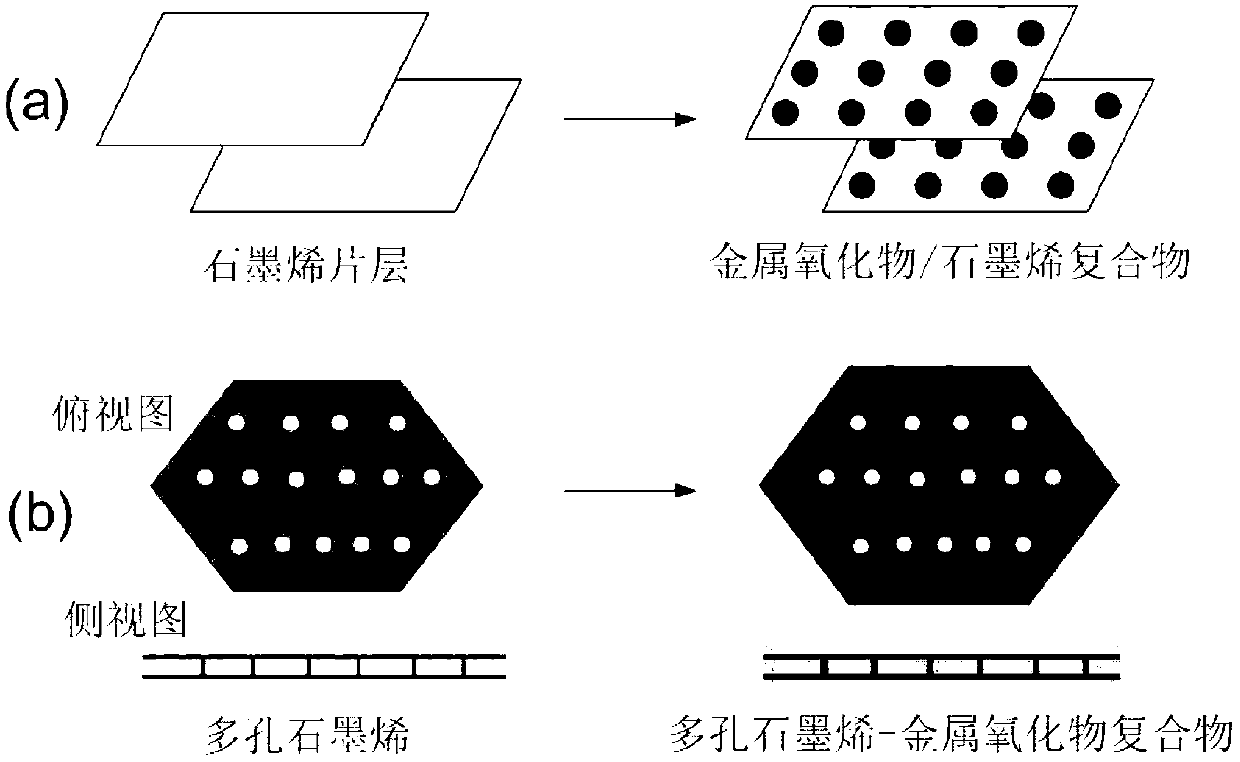

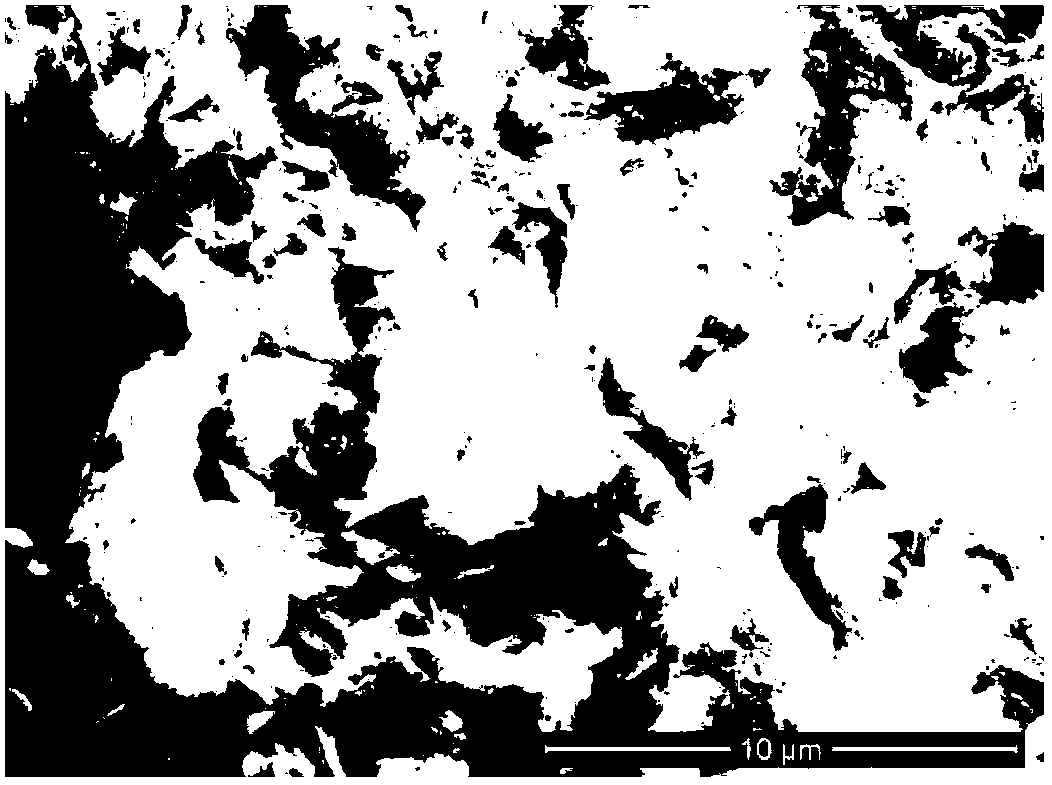

Porous graphene-metal oxide composite material and its preparation method

The invention belongs to the composite material field and discloses a porous graphene-metal oxide composite material and its preparation method. The material is characterized in that porous graphene prepared through a vapor phase chemical deposition method is used as a carrier, and metal oxide particles having diameters of 0.5-100nm are filled to the nanometer pores of the porous graphene. The preparation method is characterized in that an ion exchange process is adopted to make metal salt components enter the pores of the porous graphene, and then the deposition method or the calcining method is utilized to obtain the composite structure of the porous graphene having metal oxide filled meso-pores or micro-pores. The composite material has potential application values in the lithium ion battery field, the super capacitor field, the conductive filling material field, the heterogeneous catalysis field and the like.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

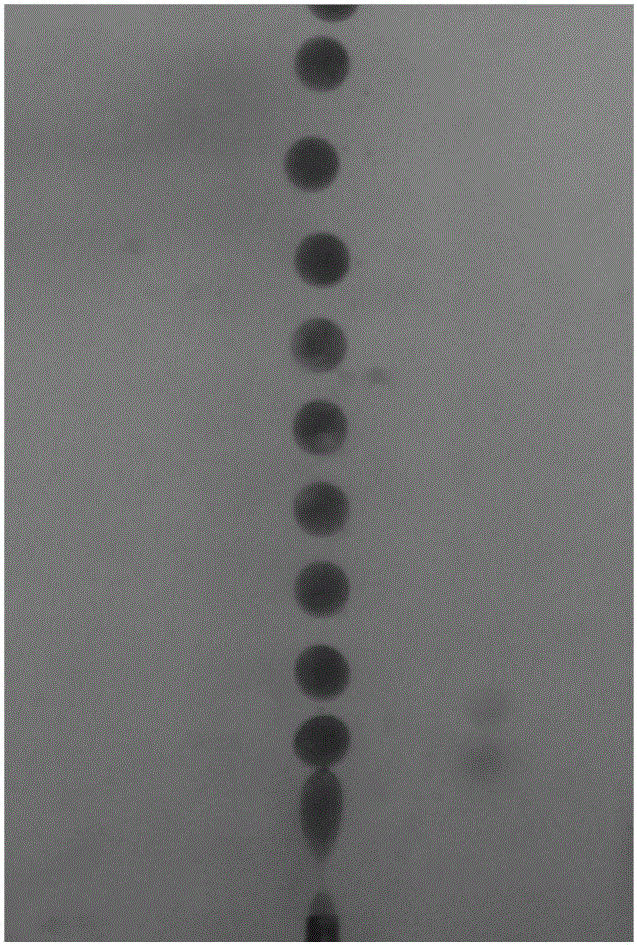

Method for preparing zirconium dioxide ceramic microspheres with microfluid device

The invention relates to a method for preparing zirconium dioxide ceramic microspheres with a microfluid device, belonging to the technical field of material synthesis and formation. The method comprises the following steps: by using zirconium dioxide precursor sol as an inner phase fluid, an oily solution as an intermediate phase fluid and an aqueous solution as a continuous phase fluid, preparing monodisperse water-in-oil-in-water double-emulsion drops with a microfluid device by regulating the flow rates of the three phases of fluids, adding an alkaline solution into the continuous phase to initiate the gel reaction, cleaning and drying the gel microspheres obtained by the gel reaction, and sintering to obtain the ZrO2 ceramic microspheres. The zirconium dioxide ceramic microspheres prepared by the method have the advantages of high sphericity and uniform dimension; on the micrometer level, the action of surface tension of the zirconium dioxide ceramic microspheres is far larger than the deformation generated by gravity; and the reaction synthesis on the sol-gel system by using the double-emulsion drops as the template has universality, thereby having potential application prospects in the nuclear fuel preparation.

Owner:TSINGHUA UNIV

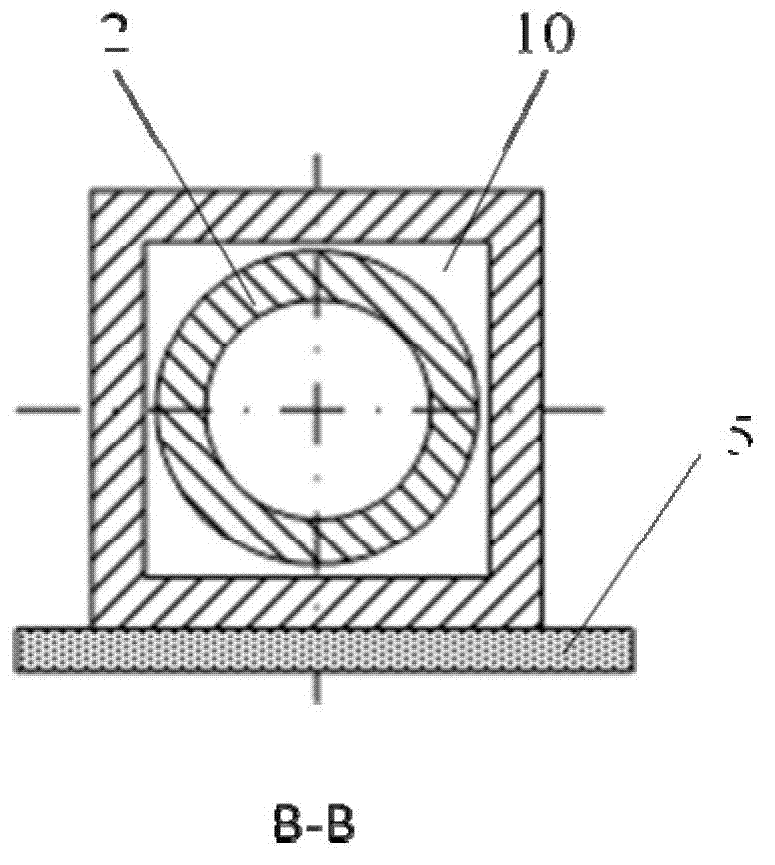

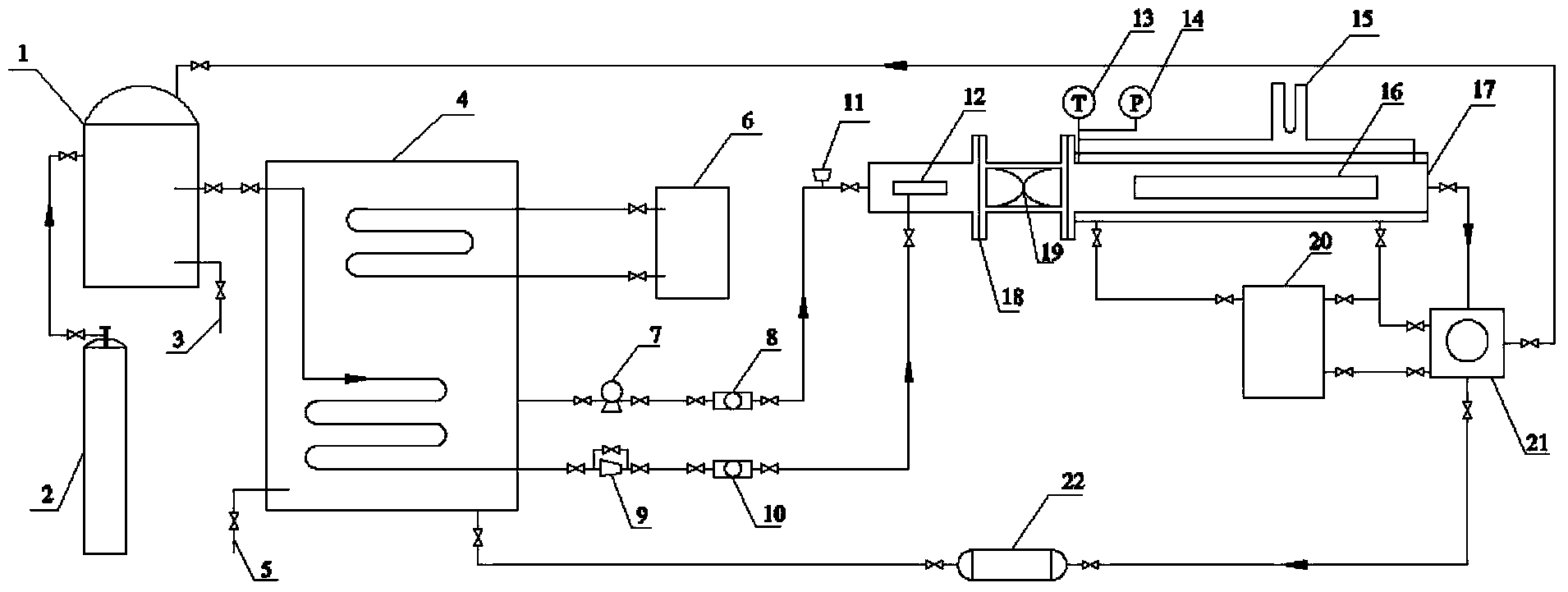

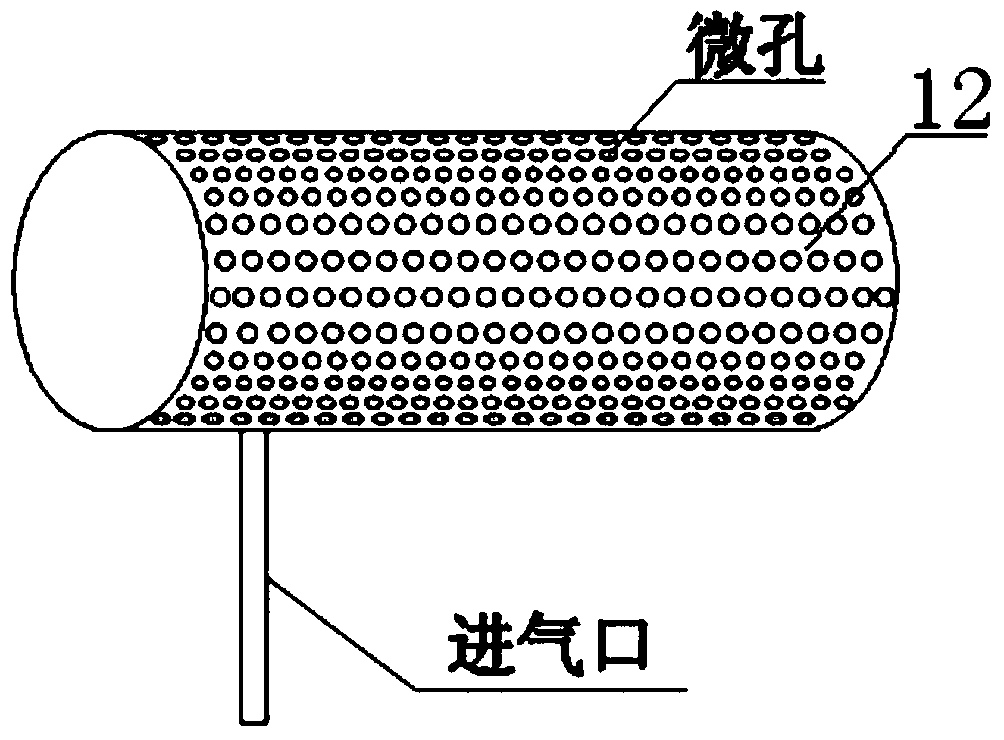

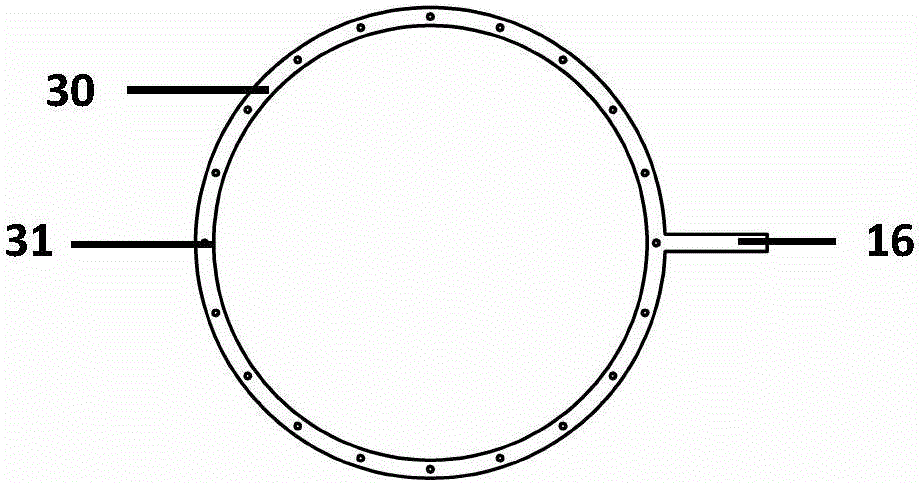

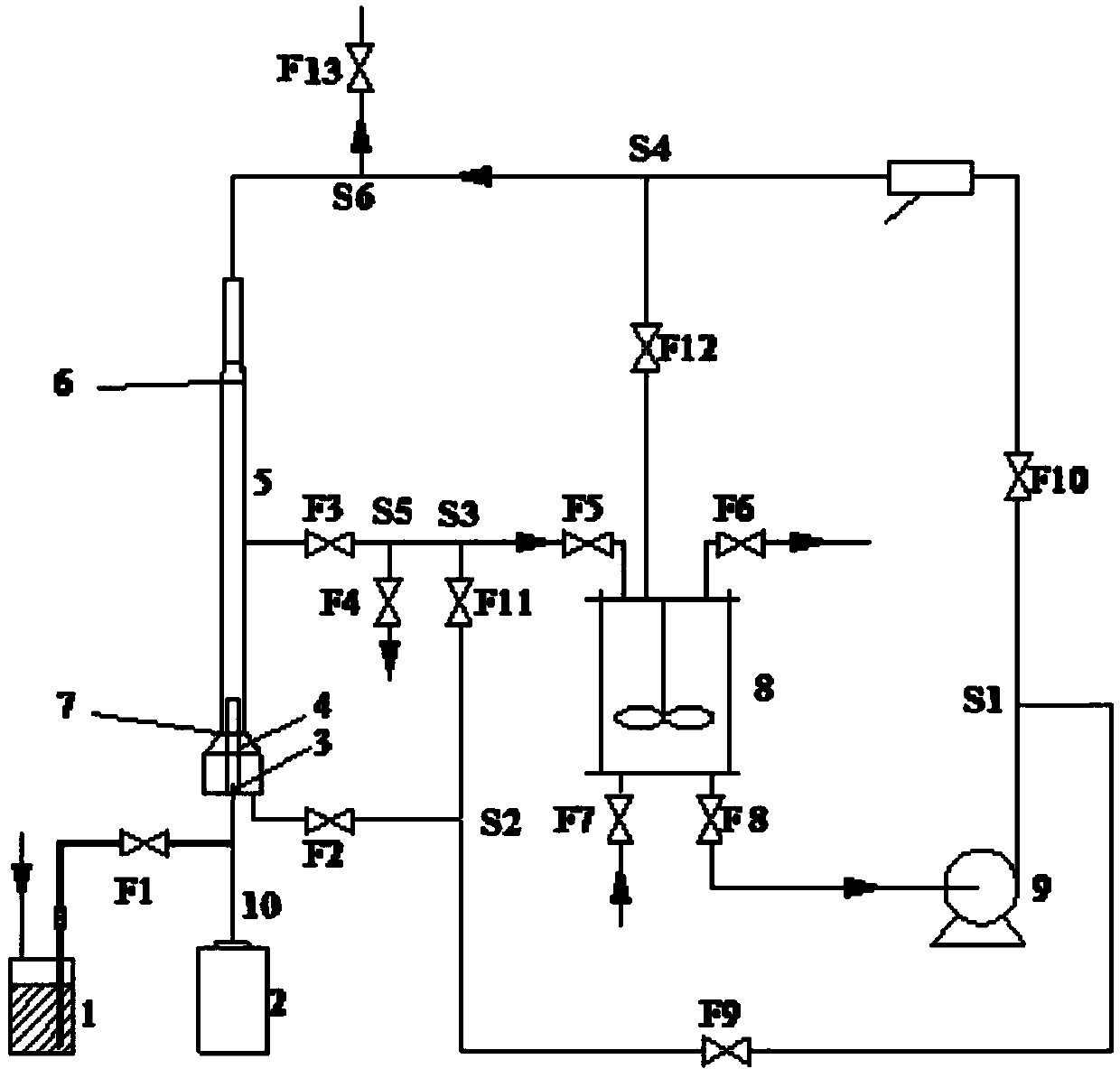

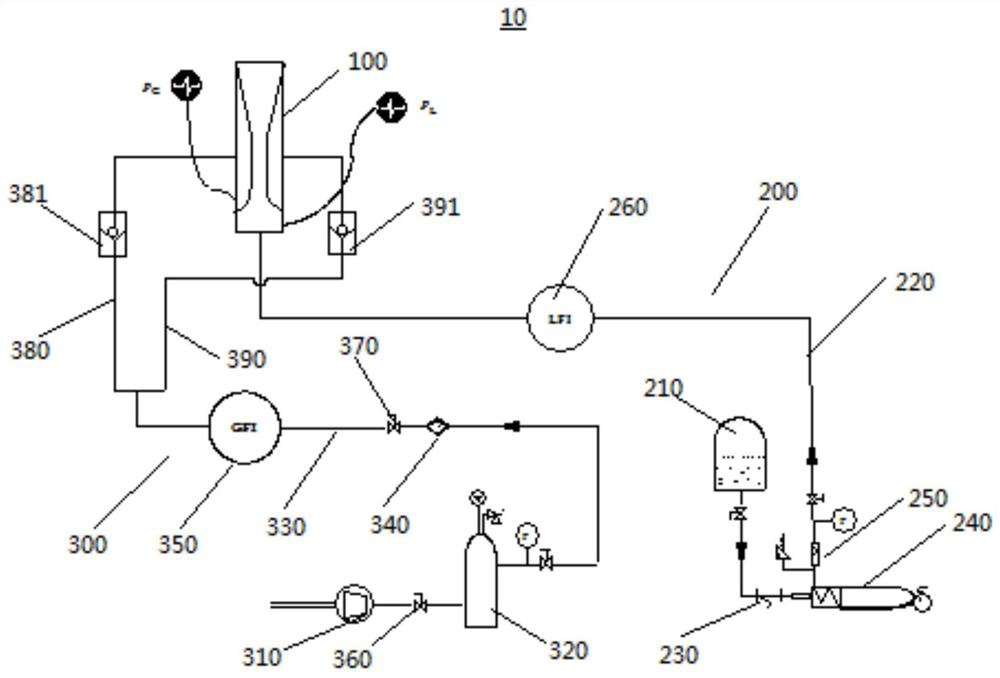

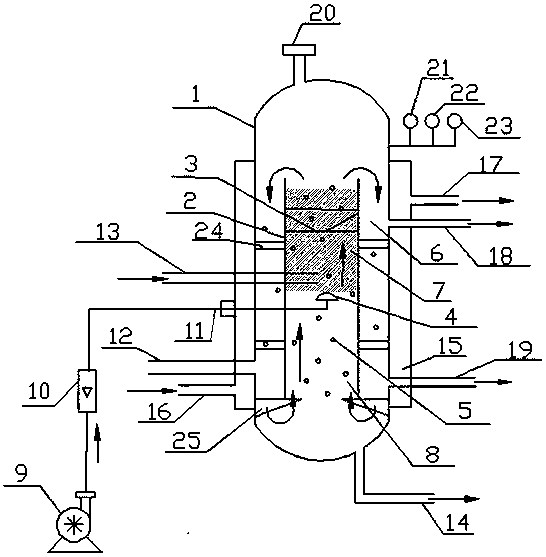

Pipeline type experiment device for generating gas hydrate

ActiveCN103611478AIncrease generation speedRealize intuitive observationLiquid-gas reaction processesWater bathsDifferential pressure

The invention belongs to the technical field of application, storage and transportation of gas hydrates, relates to an experiment device and particularly relates to a pipeline type experiment device for generating a gas hydrate. The pipeline type experiment device comprises a gas-liquid conveying system, a cooling system and a hydrate pipeline generation system, wherein the gas-liquid conveying system comprises a gas bottle, a bottle storage tank, a discharging opening I, a centrifugal pump, a liquid flow meter, a compressor, a gas flow meter, a separator and a buffering tank; the cooling system comprises a cooling tank, a discharging opening II, a cooling water bath I and a cooling water bath II; the hydrate pipeline generation system comprises a chemical feed opening, a micro-bubble generator, a connection flange, a twisted strip type spiral generator, a temperature sensor, a pressure sensor, a differential pressure meter, an observation window and an experiment pipe section. The whole set of the experiment device is convenient to operate and low in operation cost; the requirements of hydrate slurry generation and flowing principle experiments are met.

Owner:江苏卓燃知识产权运营有限公司

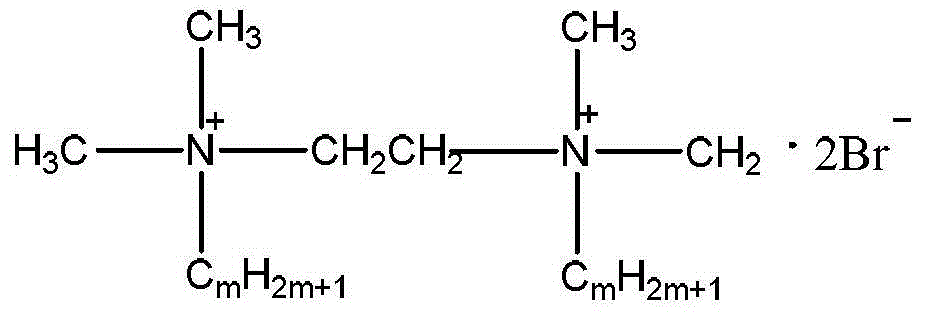

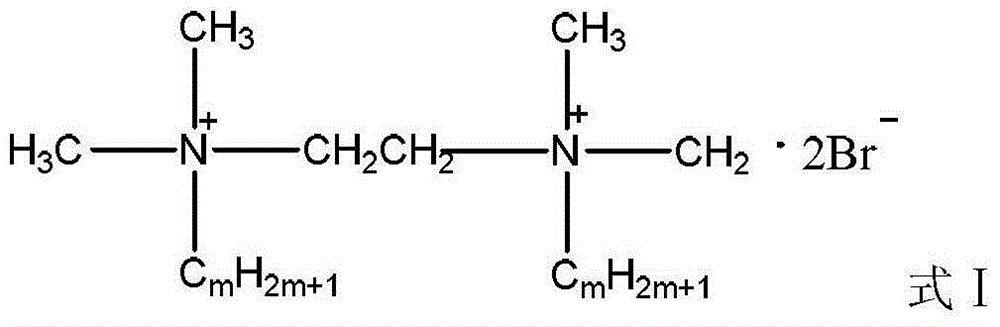

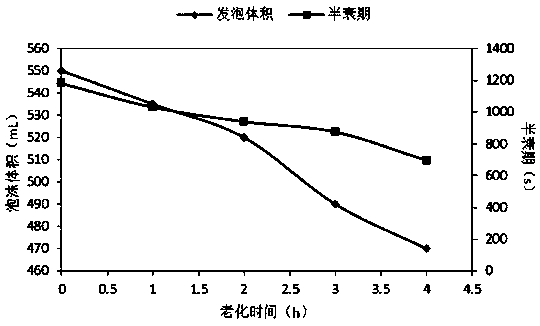

High temperature-resistant high-mineralization degree foam scrubbing agent and its preparation method and use

ActiveCN104974730AImprove compactnessImprove performanceFluid removalDrilling compositionSulfonateAlpha-olefin

The invention provides a high temperature-resistant high-mineralization degree foam scrubbing agent and its preparation method and use. The high temperature-resistant high-mineralization degree foam scrubbing agent comprises, by mass, 15-40% of an anionic surfactant, 5-15% of a cationic surfactant and the balance deionized water. The anionic surfactant comprises fatty alcohol polyoxyethylene ether sulfate, sodium alpha-olefin sulfonate or sodium dodecyl sulfate. The cationic surfactant comprises a cationic Gemini surfactant. The invention provides a preparation method of the high temperature-resistant high-mineralization degree foam scrubbing agent. The preparation method comprises adding the anionic surfactant and the cationic surfactant into a reaction container by one step, adding deionized water into the reaction container to obtain a mixed solution, heating the mixed solution to a temperature of 50-60 DEG C and carrying out stirring to obtain the foam scrubbing agent. The foam scrubbing agent solves the problem that the existing foam scrubbing agent has suddenly reduced foam properties in temperature and mineralization degree increasing and can be used for a draining and gas production technology of a deep high temperature high-mineralization degree gas well.

Owner:PETROCHINA CO LTD

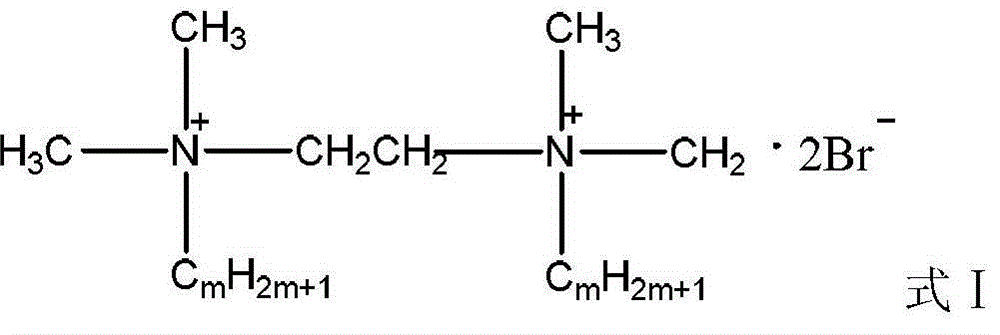

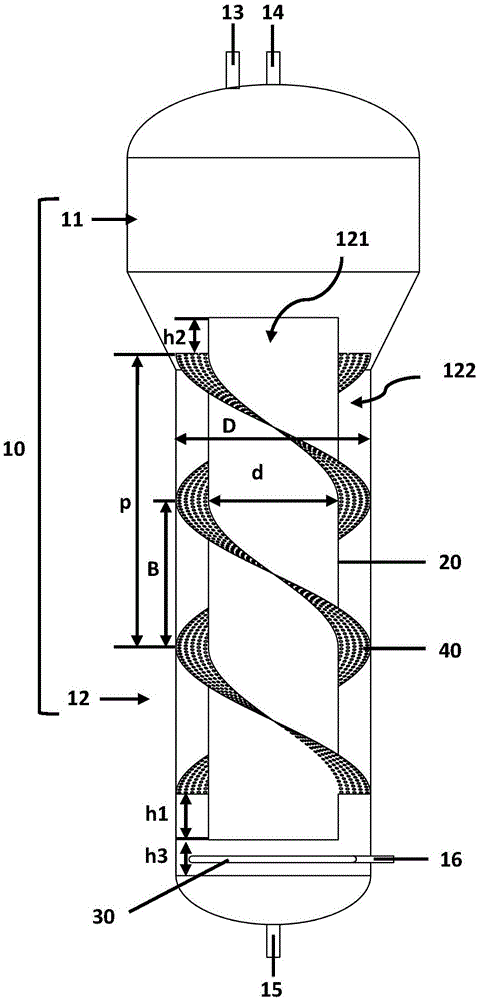

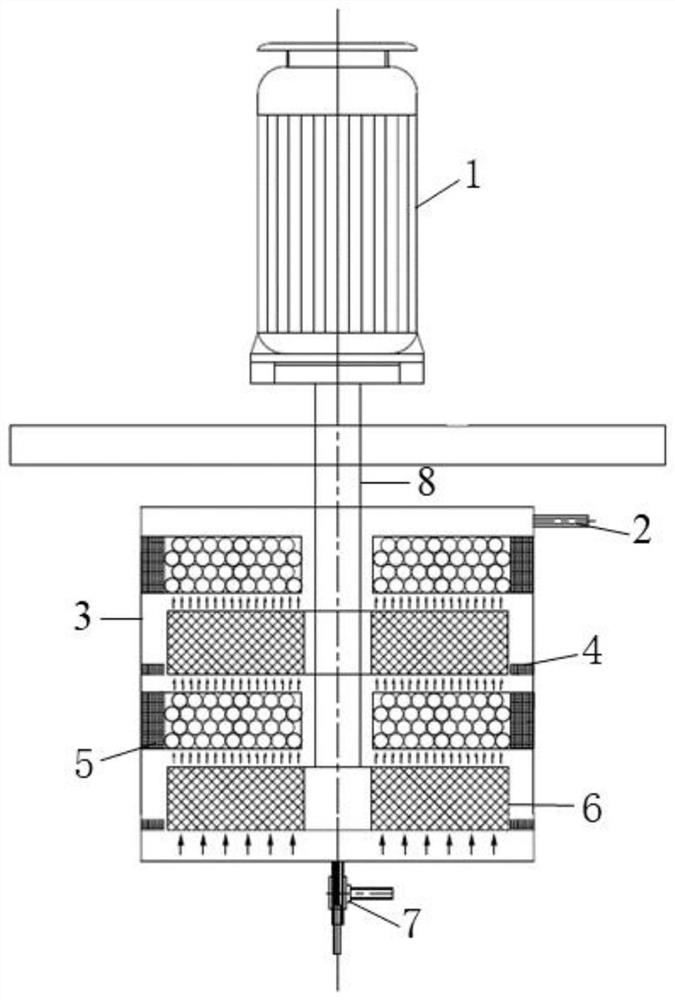

Airlift reactor having spiral porous sieve plate

ActiveCN106552560AExtended effective operating rangeExtended stayBioreactor/fermenter combinationsBiological substance pretreatmentsAirlift reactorEngineering

The invention discloses an airlift reactor having a spiral porous sieve plate. The reactor includes a reaction tank body. A flow guide cylinder and a gas distributor are arranged in the reaction tank body. The gas distributor is disposed under a raising section of the flow guide cylinder. A spiral porous sieve plate is arranged in the raising section of the flow guide cylinder. The body of the spiral porous sieve plate is in a spirally raising shape, so that a part of two / three-phased flow in the raising section is guided. There are a plurality of sieve pores in the body of the spiral porous sieve plate, so that the rest of the two / three-phased flow in the raising section is subjected to flow guiding and bubble breaking. The airlift reactor considers both macroscope mixing and microscope mixing, wherein the liquid is driven by ejected gas to flow cyclically, so that raising large bubbles are broken into small bubbles. The reactor can effectively inhibit aggregation of bubbles, increases gas holdup, and increases volume mass transfer coefficient.

Owner:JIANGNAN UNIV

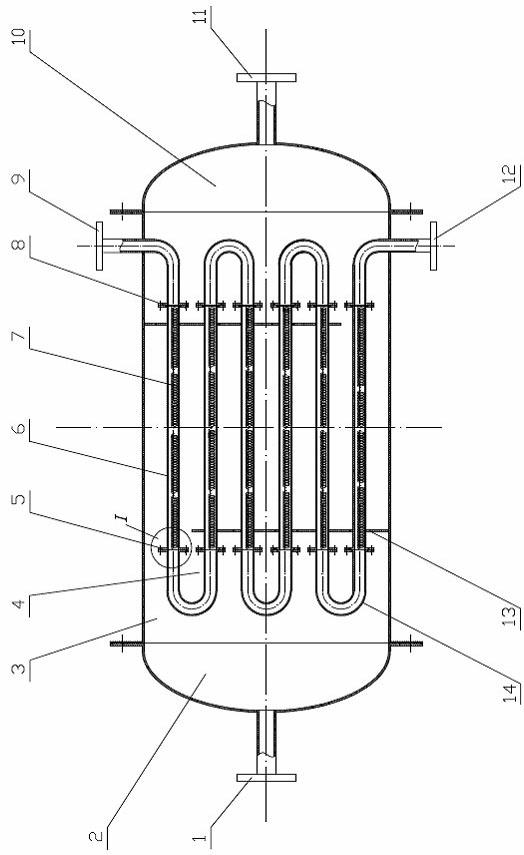

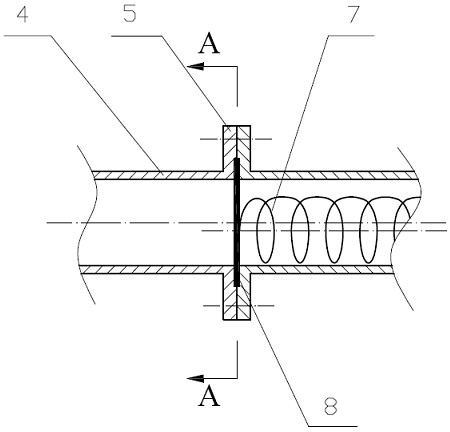

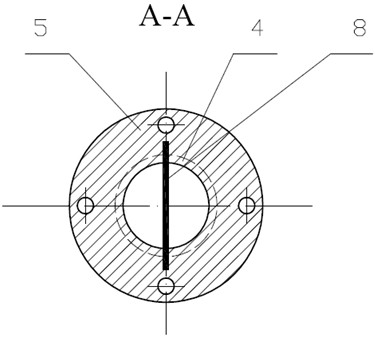

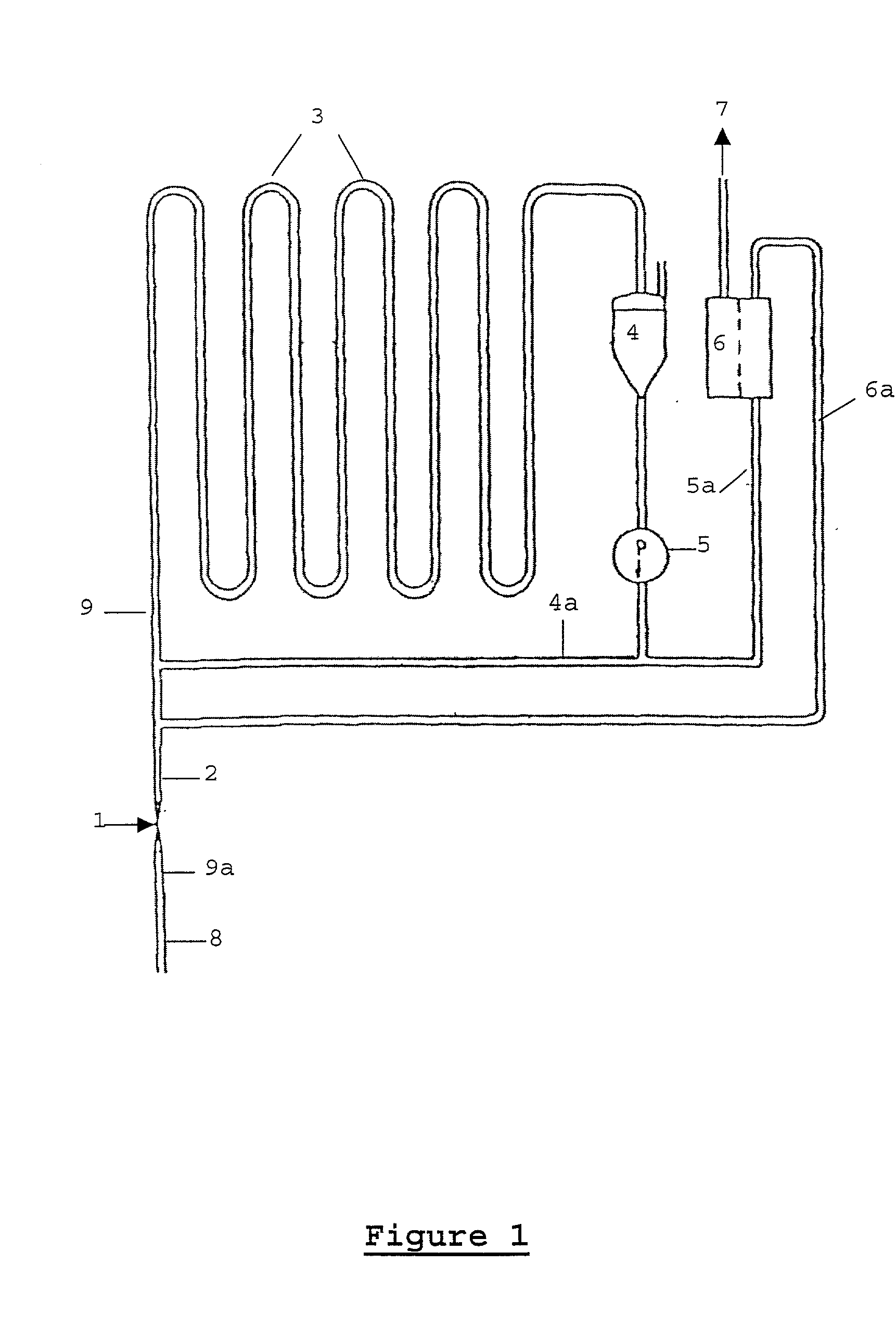

Built-in spring tubular reactor

InactiveCN102160986AIncrease disturbanceQuick breakChemical/physical/physico-chemical processesEngineeringReaction tube

The invention discloses a built-in spring tubular reactor. A gland of a shell is provided with heat exchange carrier inlet and outlet; the gland is connected with the shell through a flange; the shell is provided with reaction material inlet and outlet; an S-shaped reaction tube, a spring and a baffle plate are arranged inside the shell; the S-shaped reaction tube comprises a horizontal straight pipe and a U-shaped connecting pipe; the horizontal straight pipe is connected with the U-shaped connecting pipe through a pipe flange; the spring is fixed in the horizontal straight pipe; a metal slender rod is embedded into the pipe flange; one end of the S-shaped reaction tube is connected with the reaction material outlet, and the other end of the S-shaped reaction tube is connected with the reaction material inlet. The built-in spring tubular reactor has the advantages that: the built-in spring tubular reactor has temperature conductivity higher than that of the normal tubular reactor, can effectively prevent coalescence of bubbles and formation of plug flow of gas-liquid two-phase section, and can operate reliably for a long term under the condition that fluid gas content is high. Even through under the condition of low mean velocity, the built-in spring tubular reactor also has a good reaction effect. The built-in spring tubular reactor is suitable to be used for generating gas in the reaction process and forming the reaction process of gas-liquid two-phase flow.

Owner:ZHEJIANG UNIV

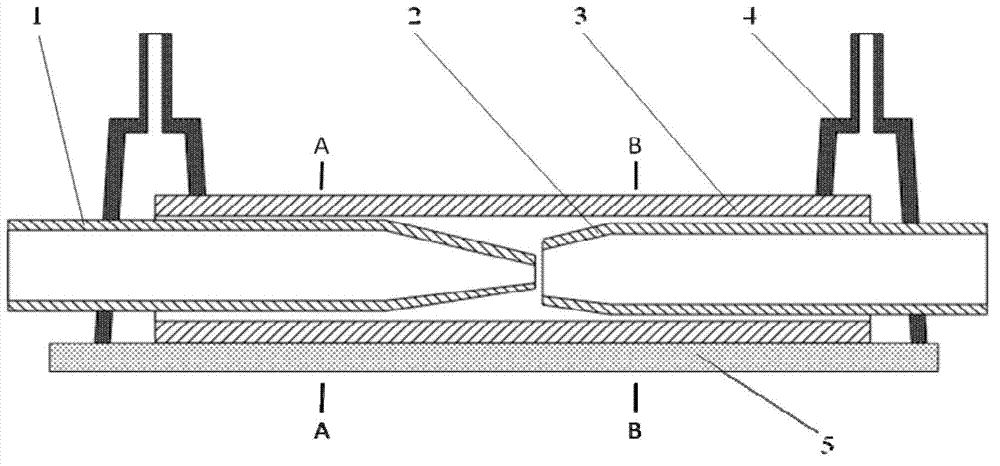

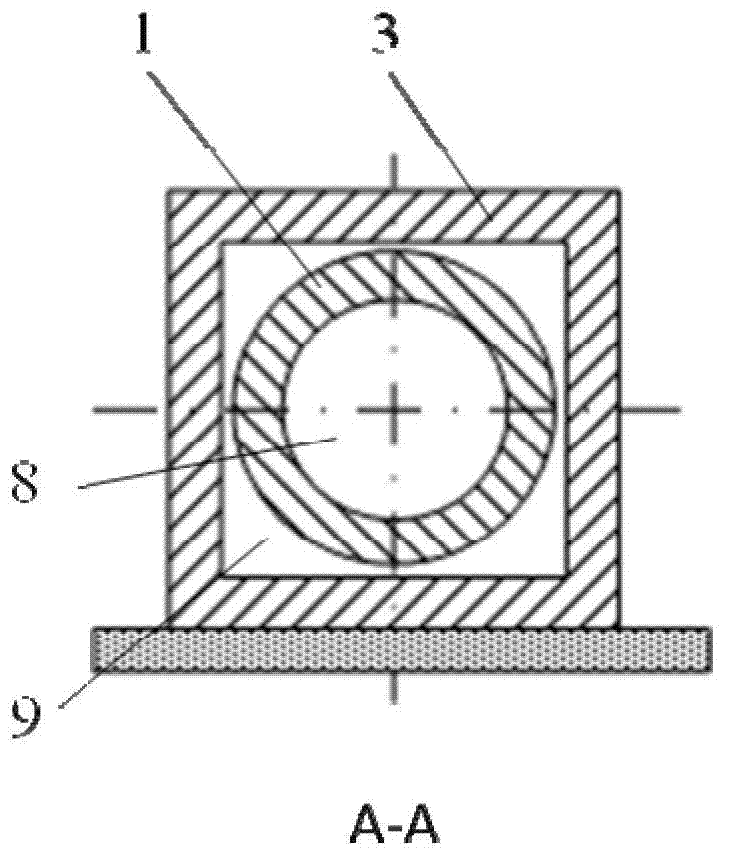

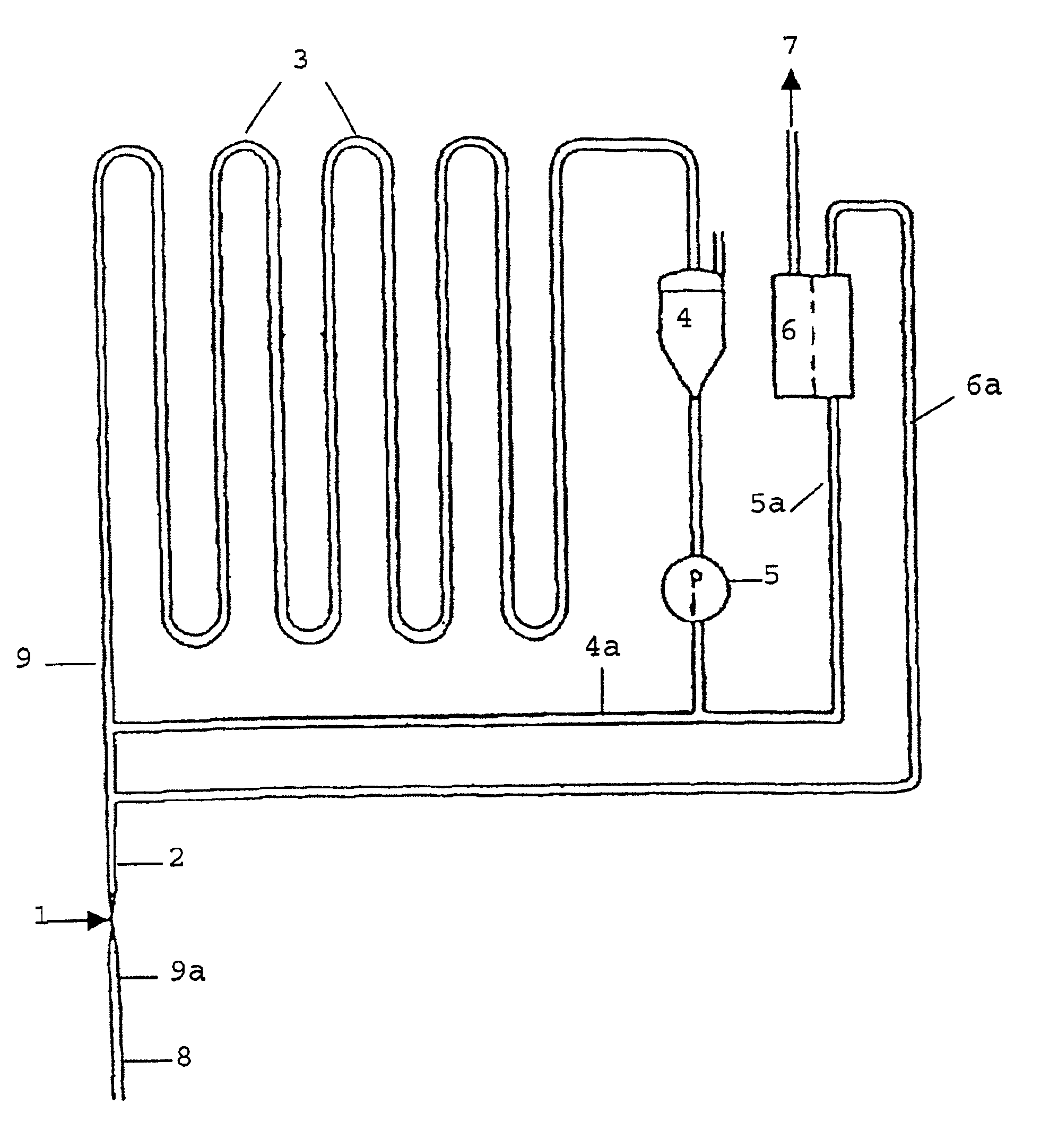

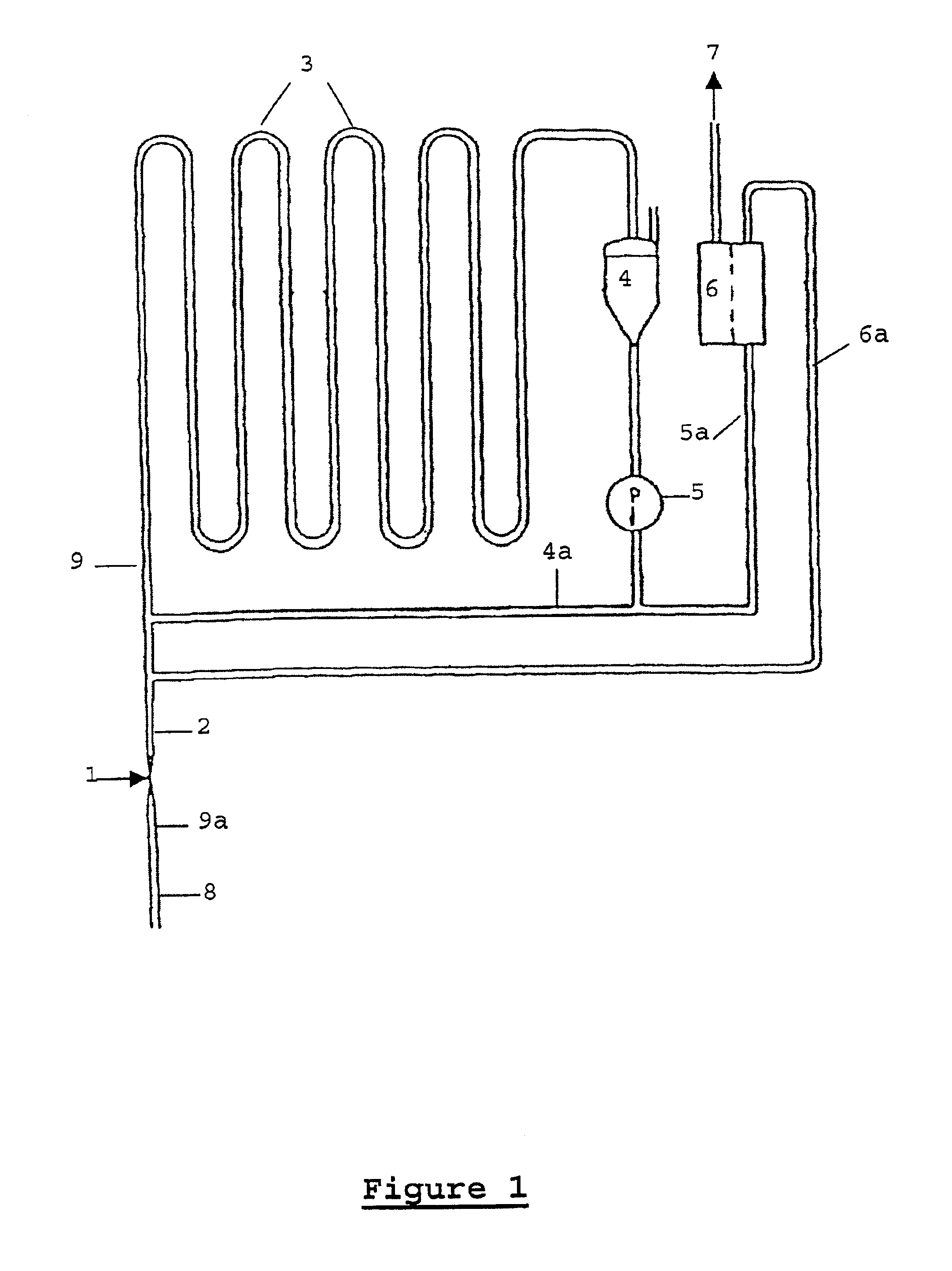

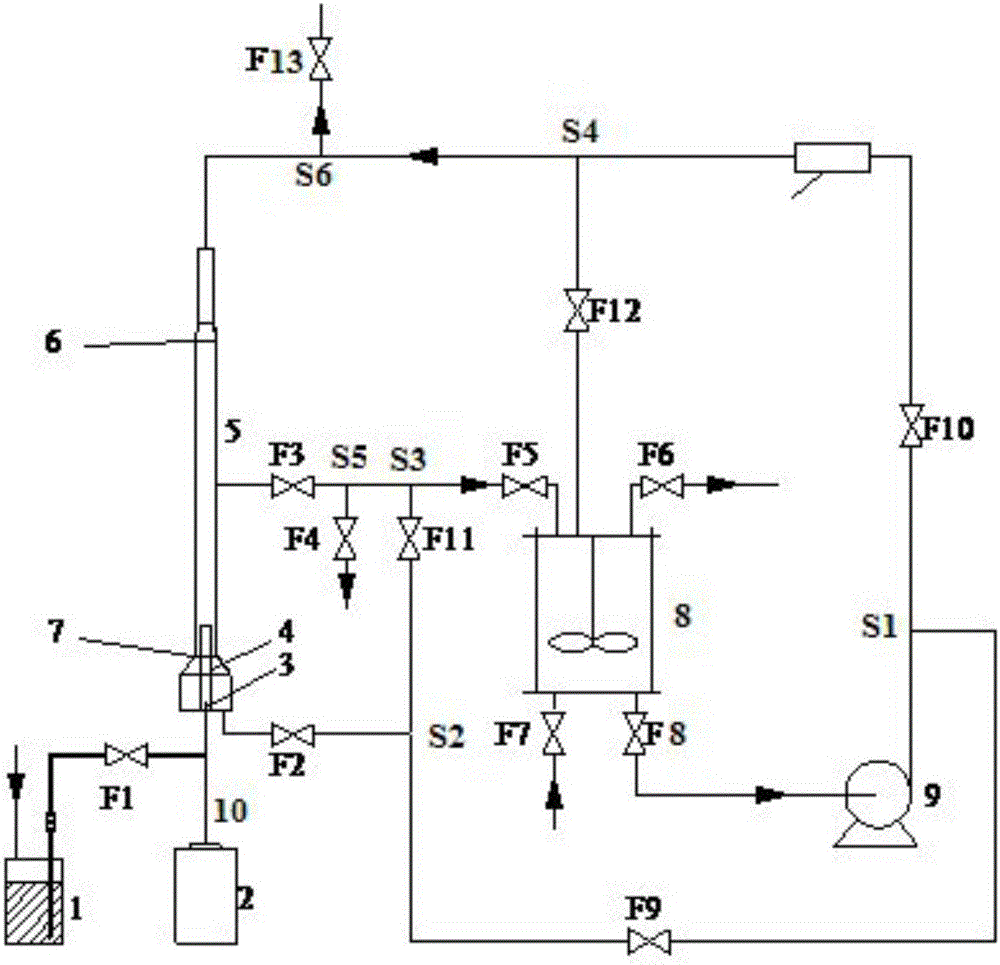

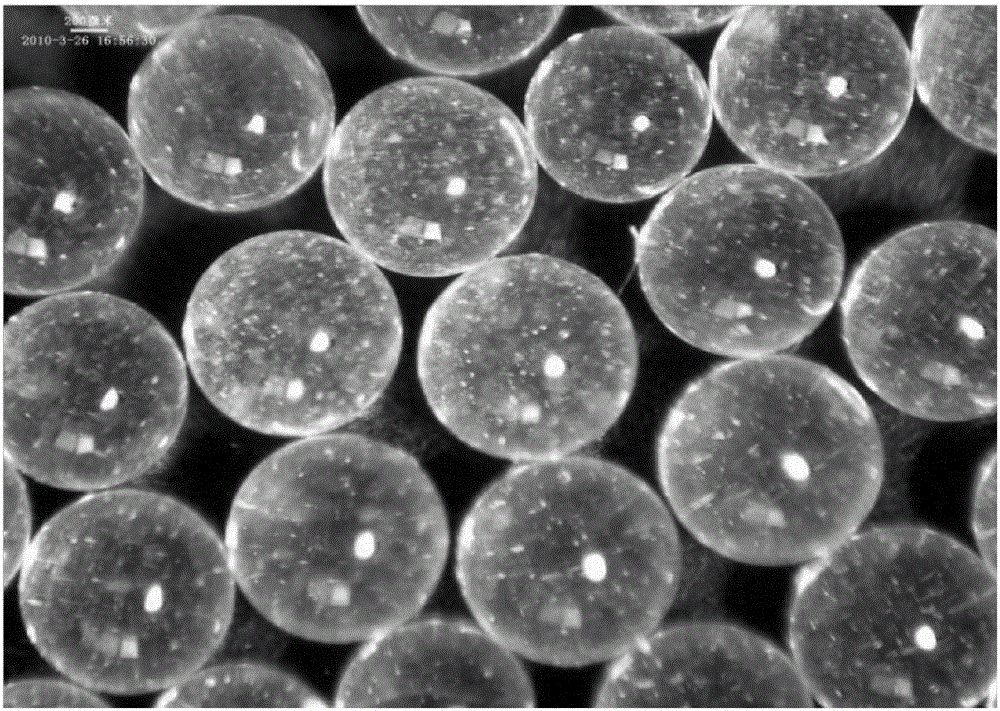

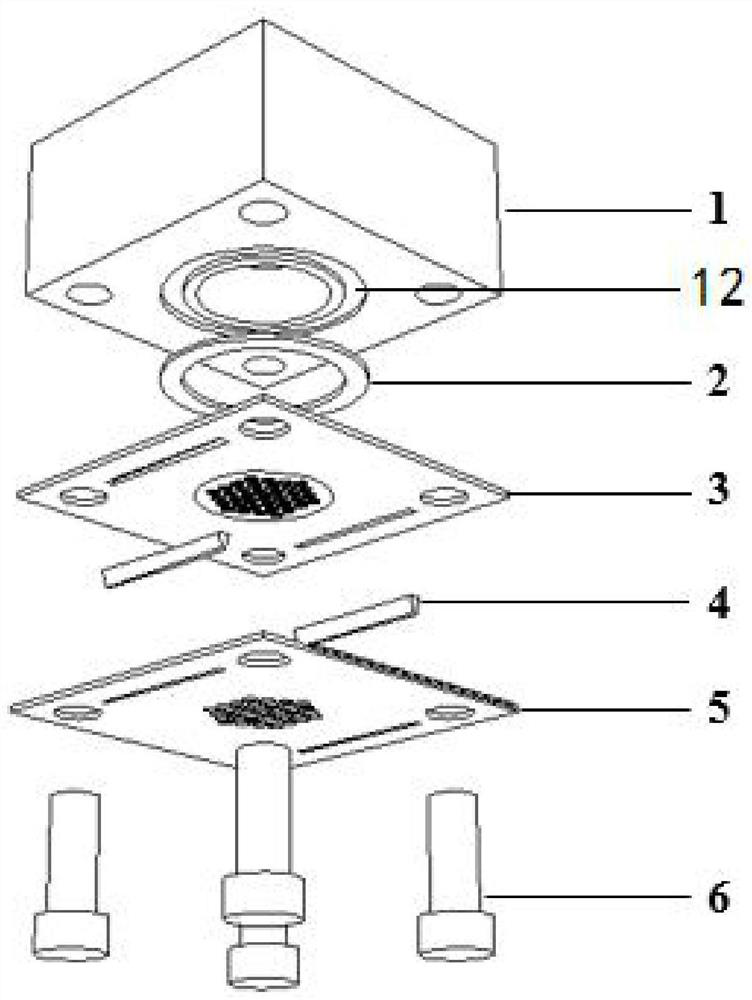

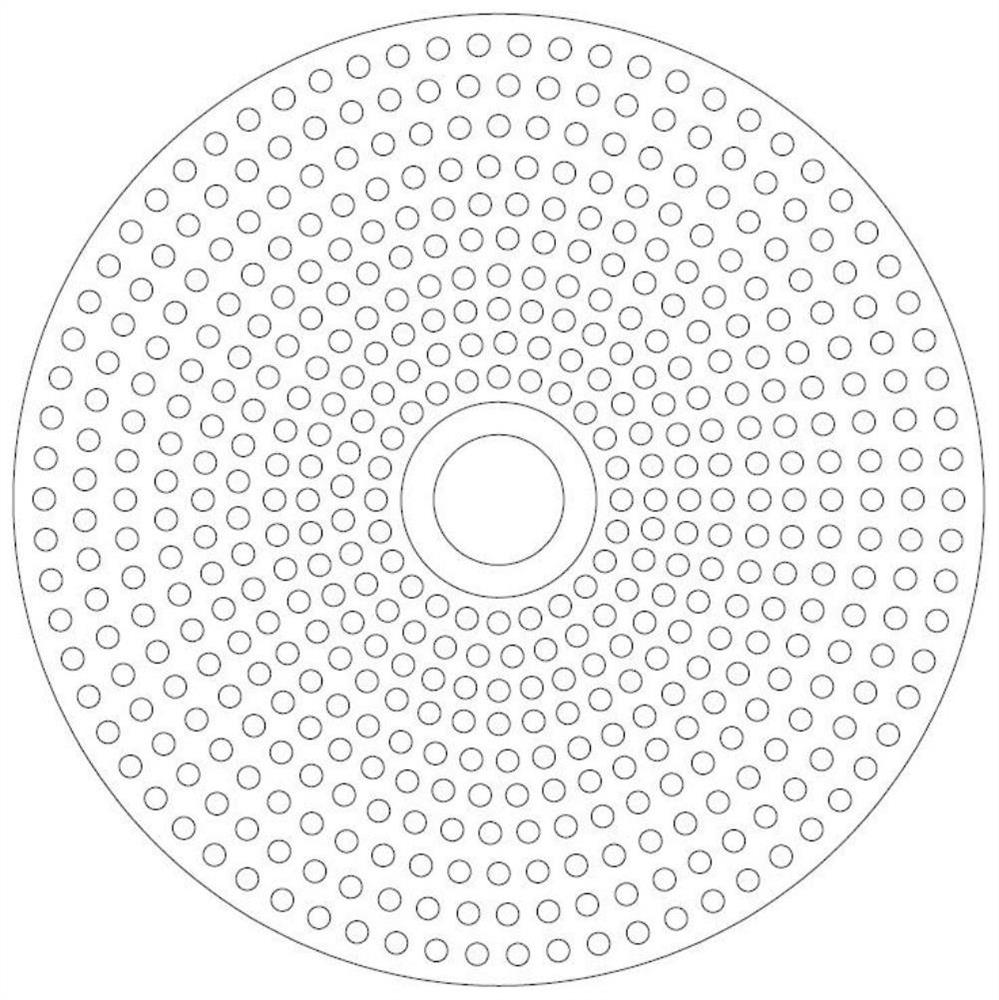

Device and method for preparing monodisperse ion exchange resin

ActiveCN104193853AUniform particle sizeHave monodisperse propertiesIon-exchange resinBiomedical engineering

The invention discloses a device and method for preparing a monodisperse ion exchange resin. The device comprises a raw material tank (1), a vibration generator (2), a sprayer (3), a polymerizer (5), a stirring polymerization kettle (8), a transfer pump (9), and pipelines, valves and T joints connected among device rooms, wherein the inside of the lower part of the polymerizer (5) is provided with a feed pipe (4); the diameter of the lower part of the polymerizer (5) is greater than that of the upper part; the internal surface of the middle upper part of the polymerizer (5) is connected with an upper porous plate (6); the internal surface of the lower part of the polymerizer (5) is connected with a lower porous plate (7); and the feed pipe (4) penetrates through the lower porous plate (7). The device and method can be used for preparing the gel-type or macroporous ion exchange resin with the particle size of 1-3.5mm; and the prepared ion exchange resin has uniform particle size and monodispersity.

Owner:TIANJIN UNIV

Method for preparing large-diameter high-sphericity polymer hollow micro-spheres

InactiveCN106040116AInhibited DiffusionDelayed curing speedMicroballoon preparationMicrocapsule preparationChemistryEmulsion

The invention discloses a method for preparing large-diameter high-sphericity polymer hollow micro-spheres. The method has the advantages that curing speed reducing and rotary curing processes are organically combined with one another, curing containers are sealed in procedures for preparing polymer hollow micro-spheres by the aid of microfluidic technologies, the quantities of dual-emulsion particles in external water phases and the quantities of preliminarily added organic solvents are changed, diffusion of the organic solvents towards the external water phases can be suppressed by the aid of the solubility of the organic solvents in the external water phases, the curing speeds of dual-liquid droplet can be reduced, and spheroidization of the dual-emulsion particles can be promoted; horizontal inclination angles, rotation modes and the rotational speeds of rotary flasks are controlled, accordingly, dispersion states of the dual-emulsion particles in the external water phases can be controlled, adhesion, coalescence and emulsion breaking of the dual-emulsion particles due to mutual collision can be prevented, non-spheroidization tendency of the dual-emulsion particles can be lowered, and the large-diameter high-sphericity polymer hollow micro-spheres can be prepared; the large-diameter high-sphericity polymer hollow micro-spheres can be applied to laser inertial confinement fusion physical experiments.

Owner:LASER FUSION RES CENT CHINA ACAD OF ENG PHYSICS

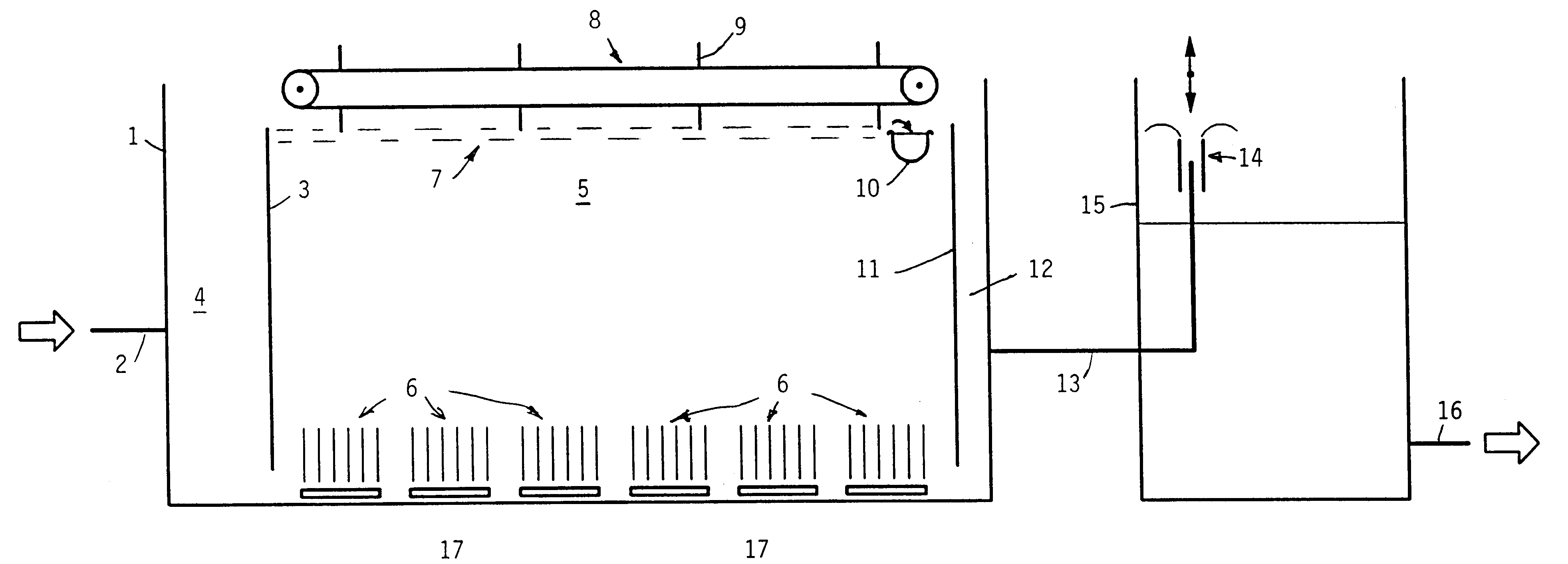

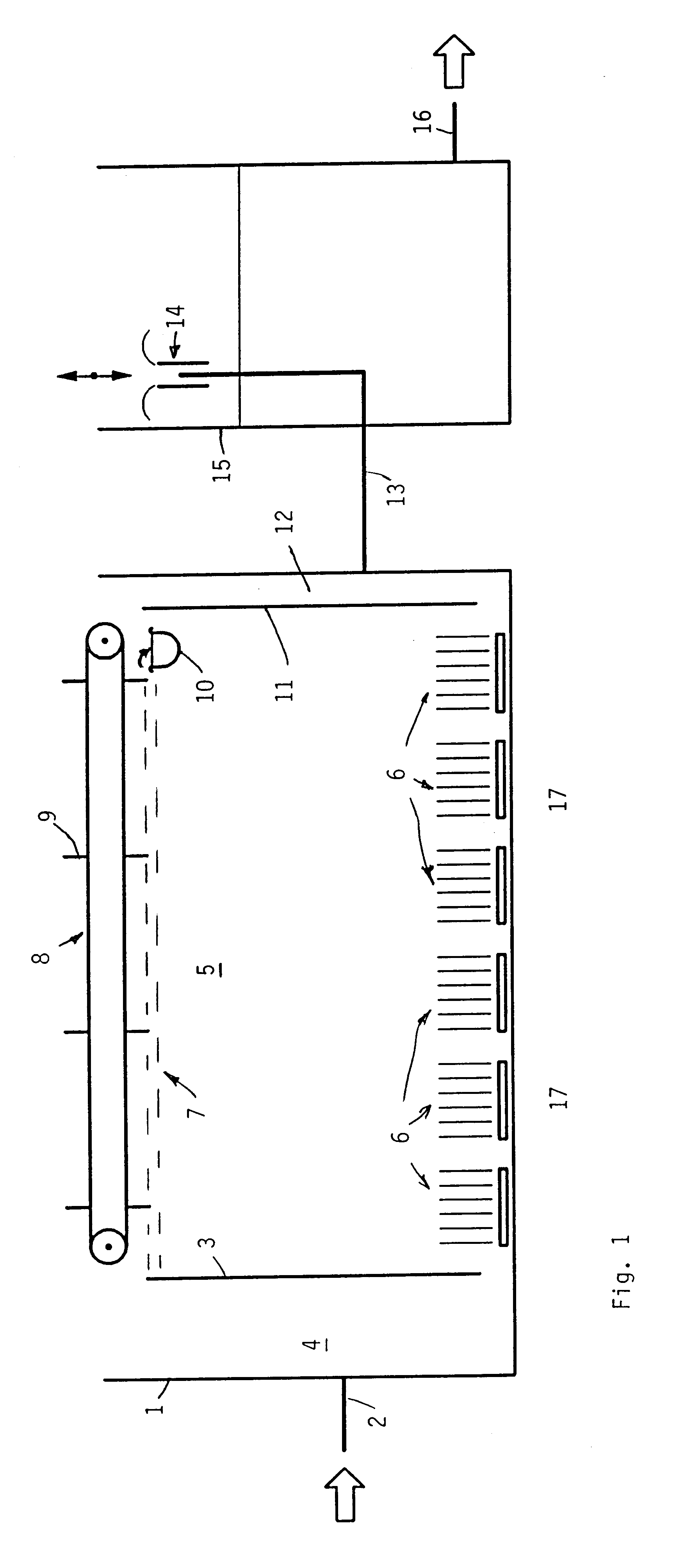

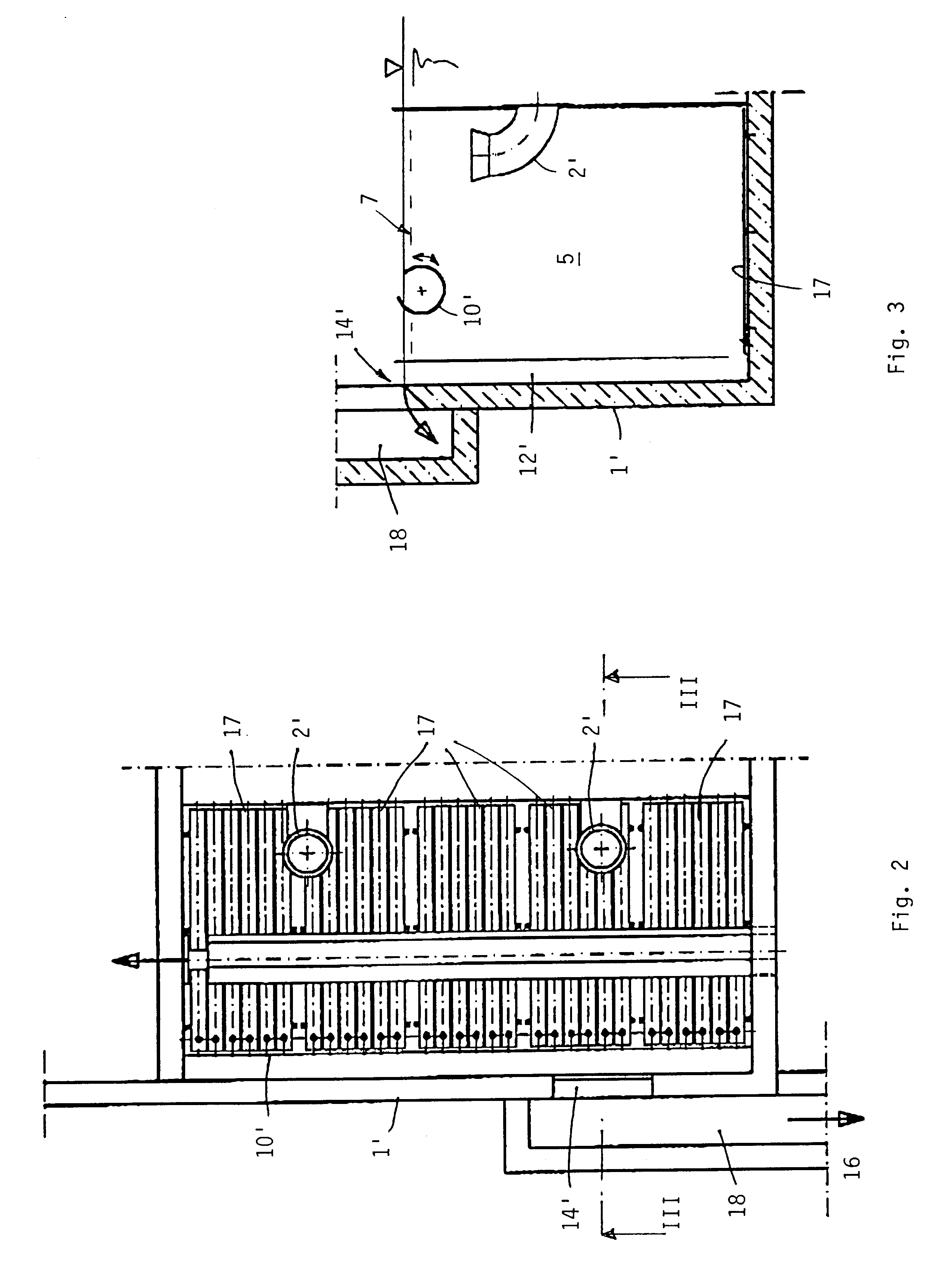

Flotation plant

InactiveUS6344147B1Promote resultsDegree of improvementCarburetting airTreatment using aerobic processesAir bubbleAeration

A flotation plant comprises air supply means with which air bubbles can be supplied to a basin to which untreated water is supplied so as to cause flakes suspended in the untreated water to float by aid of the air bubbles; the air supply means includes strip- or plate-shaped aeration means having perforated membranes and to be installed in the bottom region of said basin.

Owner:DIPL ING UDO MEYER AQUACONSULT GMBH

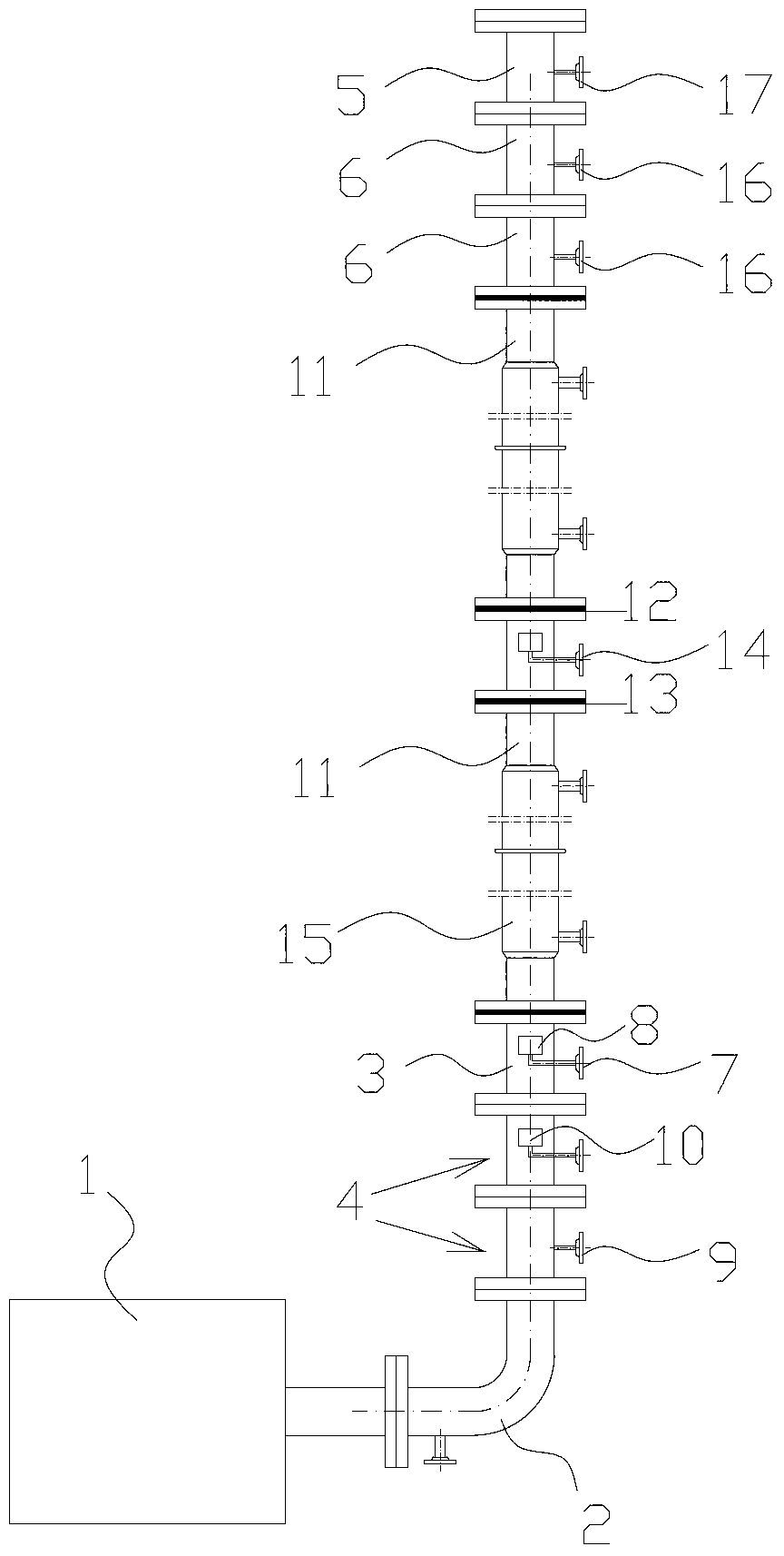

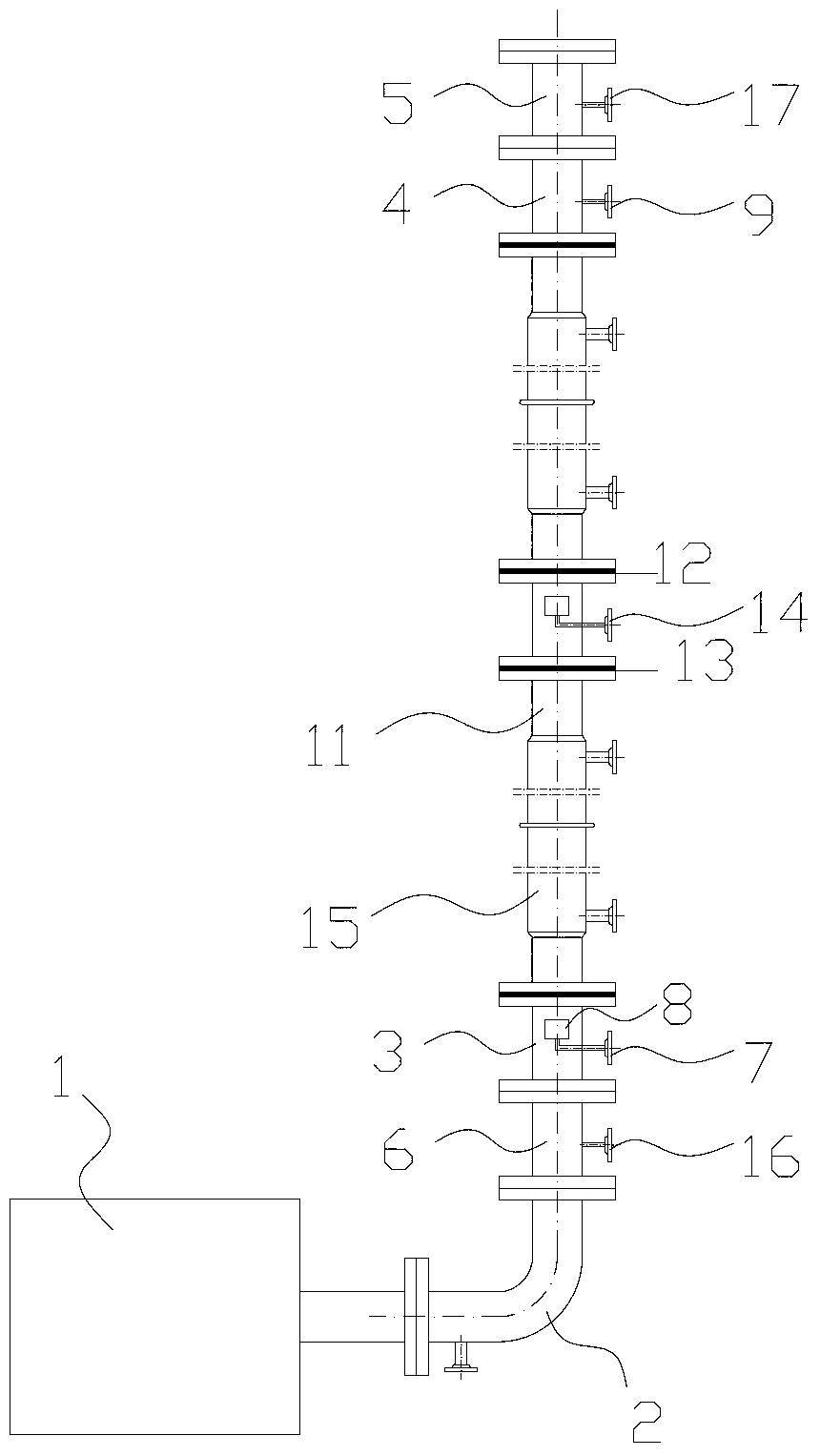

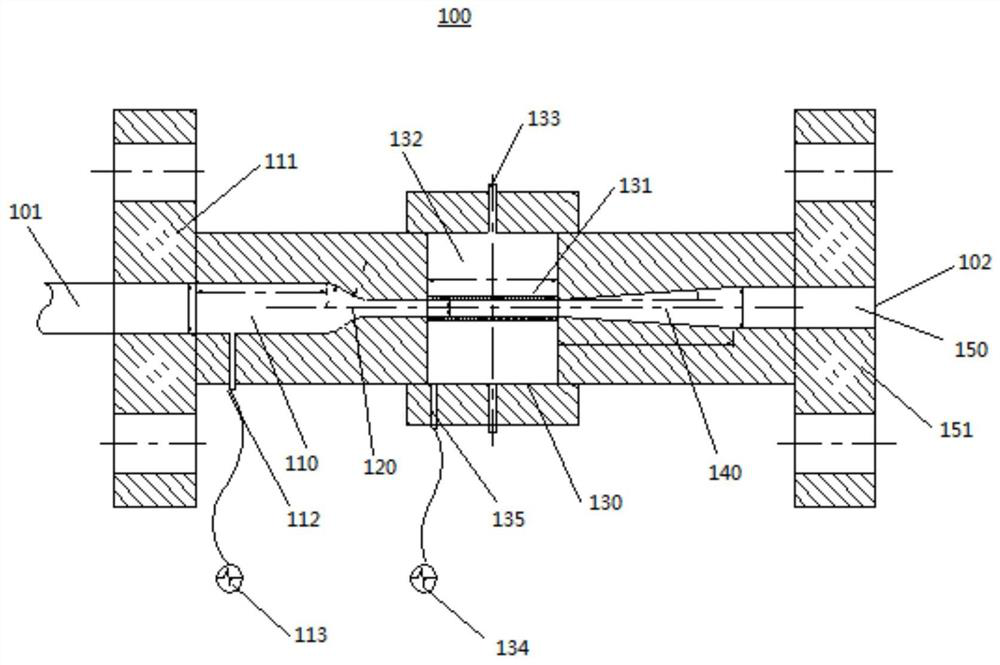

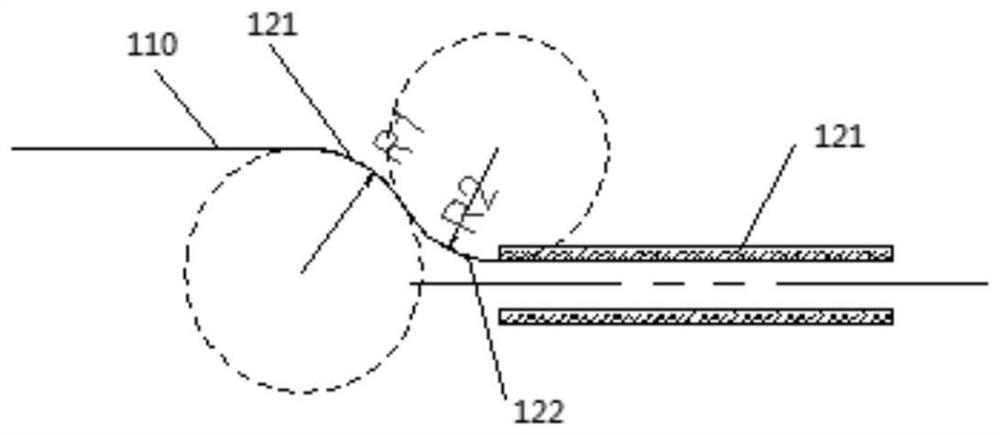

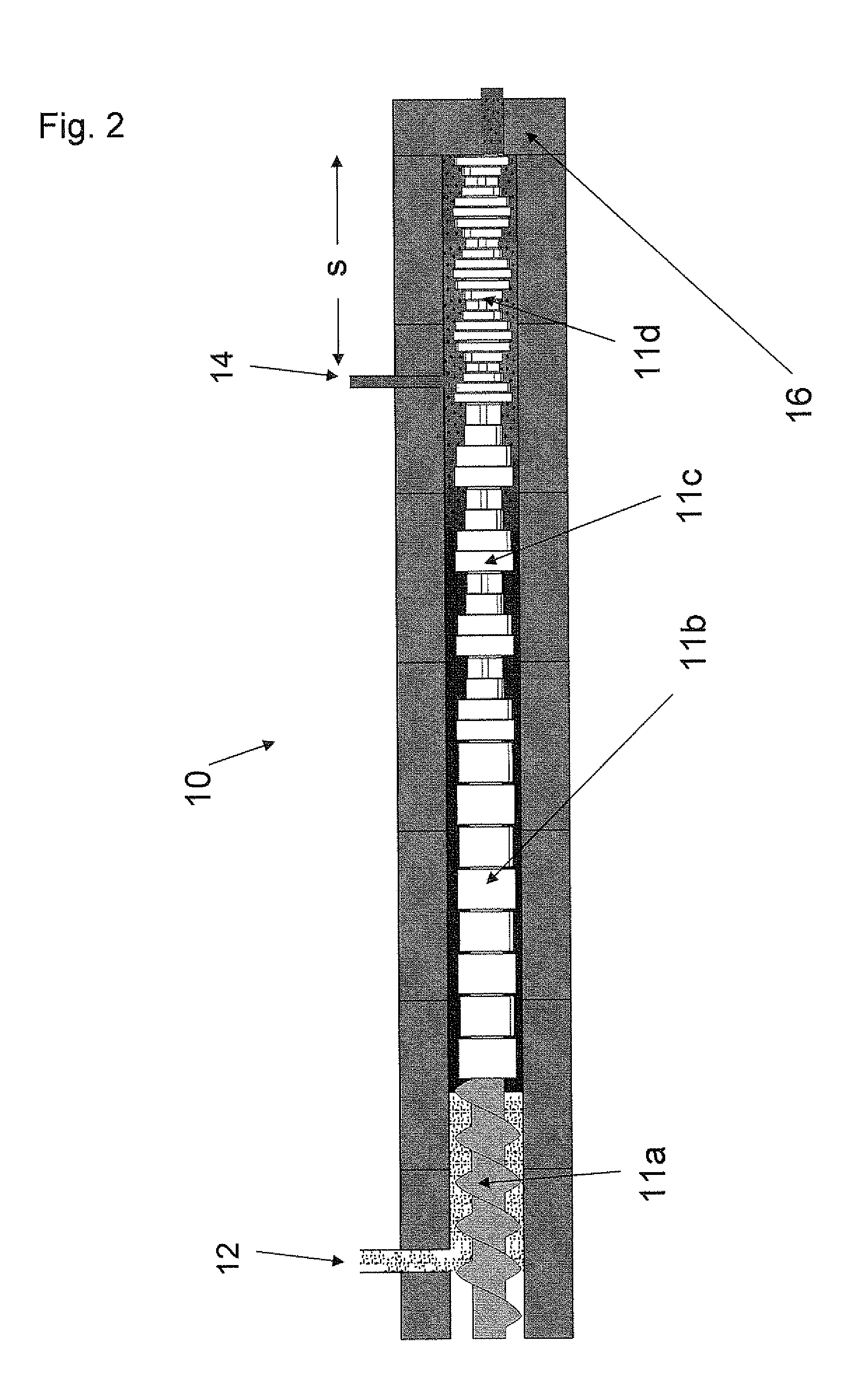

Oscillatory flow reactor of packed bed

The invention discloses an oscillatory flow reactor of a packed bed. The oscillatory flow reactor comprises an oscillation generating mechanism, an inlet segment, a reaction segment and an outlet segment which are sequentially connected, wherein the inlet segment is composed of an air inlet segment and a liquid inlet segment which are connected in series, and the outlet segment is composed of an air outlet segment and a liquid outlet segment which are connected in series; the air inlet segment is provided with an air feeding hole and an air distributor located at the downstream of an air discharging hole; the liquid inlet segment is provided with a liquid feeding hole and a liquid distributor located at the downstream of a liquid discharging hole; the reaction segment is provided with a vertically-arranged reaction tube which is filled with filler or solid catalyst particles in the middle, a supporting device at the bottom and a pressing device at the top. The oscillatory flow reactor of the packed bed is suitable for industrial gas-liquid reaction taking the liquid phase as a main body, gas-liquid-liquid reaction or gas-liquid-solid three-phase reaction system containing a solid catalyst and can continuously and stably operate for a long term.

Owner:吴嘉

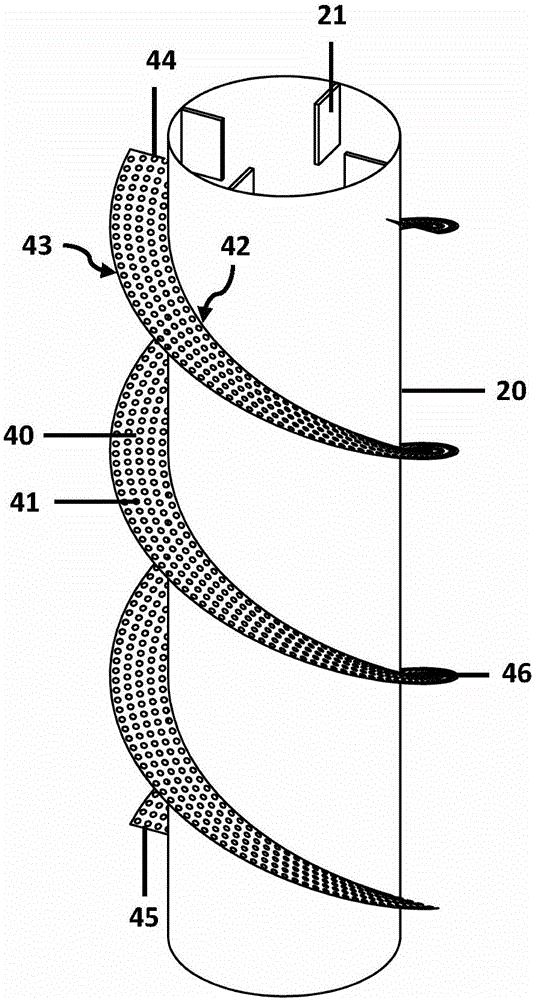

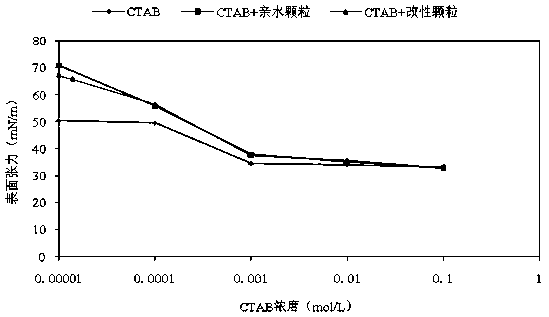

Surface cationized silicon dioxide nanoparticles

InactiveCN111171798APrevent coalescingPrevent disproportionationMaterial nanotechnologySilicaSilicic acidActive agent

The invention relates to surface cationized silicon dioxide nanoparticles. A preparation method comprises the following steps: weighing dialkyl dimethyl tertiary amine and putting the dialkyl dimethyltertiary amine into a three-neck flask; adding absolute ethyl alcohol, and stirring and slowly heating the mixture in an oil bath pan; continuing to dropwise add 3-chloropropyltrimethoxysilane, and introducing nitrogen for a period of time; maintaining the temperature, and carrying out reflux reaction to obtain a silicon dioxide particle modifier; uniformly mixing absolute ethyl alcohol, purifiedwater and ammonia water, putting the mixture into a three-neck flask, stirring the mixture, and uniformly mixing and quickly pouring tetraethoxysilane, the prepared silicon dioxide particle modifierand absolute ethyl alcohol into the three-neck flask; increasing the stirring speed for a period of time, reducing the stirring speed when the solution is milky white, continuously performing a reaction for a period of time, and terminating the reaction; and centrifuging, washing, drying and crushing the reaction product to obtain white powdery cationized nano silicon dioxide particles. The foam stabilizer can generate a synergistic effect with a surfactant to achieve an effect of stabilizing foam, so that the adaptation degree to a high-temperature stratum environment is greatly improved.

Owner:NORTHEAST GASOLINEEUM UNIV

Continuous hydrogenation process

InactiveUS6756028B2Lower overall pressure dropReduce energy costsHydrogen peroxideChemical/physical/physico-chemical stationary reactorsPartial hydrogenationHydrogenation process

Owner:EVONIK OPERATIONS GMBH

Micro-bubble generation device, and micro-bubble generation control method and device

PendingCN112642310AImprove scoreReduce dissipationFlow mixersMixing methodsLiquid statePetrochemical

The invention discloses the technical field of petrochemical engineering, and relates to a micro-bubble generation device, and a micro-bubble generation control method and device. Liquid materials pass through a contraction section, then enter a gas distribution perforated pipe on an gas inlet section, gas and liquid are mixed in the gas distribution perforated pipe, and then a mixture enters an expansion section and a gas-liquid expansion section. According to the micro-bubble generating device, a Venturi tube and micropore distribution principle is utilized, micro-bubbles with high dispersion are formed, fluid effectively shears and crushes the bubbles, and large bubbles are crushed under the action of pressure recovery in the micro-bubble generating device to form the micro-bubbles; and an internal component or a rotational flow device is not adopted, fluid energy dissipation is effectively reduced, coalescence of tiny bubbles is also avoided, and the micro-bubble fraction is remarkably increased.

Owner:CHINA PETROLEUM & CHEM CORP +1

Continuous hydrogenation process

InactiveUS20020052532A1Lower overall pressure dropReduce energy costsHydrogen peroxideHydrocarbon by hydrogenationPartial hydrogenationHydrogenation process

A continuous catalytic hydrogenation process, in which a reaction mixture containing the substance to be hydrogenated, the hydrogenation product, hydrogen and the hydrogenation catalyst suspended in the reaction mixture is recirculated in a reactor. Part of the hydrogenation product is removed from the reactor and the substance to be hydrogenated and hydrogen are fed into the reaction. In this process the substance to be hydrogenated and the hydrogen are mixed before entering the reactor. A venturi nozzle is particularly suitable as the mixing device.

Owner:EVONIK OPERATIONS GMBH

Composite ammonia nitrogen removal agent and using method thereof

The invention provides a composite ammonia nitrogen removal agent. The composite ammonia nitrogen removal agent comprises the following components by weight percent: 53-86 percent of nano particles and 14-47 percent of organic alcohols. The 0.11-0.19g / L composite ammonia nitrogen removal agent is put into waste water to be uniformly mixed, so that the ammonia nitrogen removal agent can be used for sewage treatment. By the removal agent, the ammonia nitrogen in ammonia nitrogen waste water with high concentration can be effectively removed, and the removal rate is up to 92-99.99 percent; and moreover, the composite ammonia nitrogen removal agent is low in operation cost, easy to acquire, low in gas-liquid ratio and short in reaction time.

Owner:CHANGZHOU UNIV

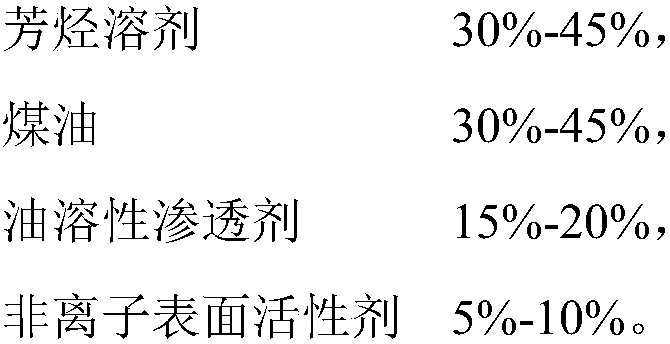

Oil well de-blocking agent as well as preparation method and application thereof

ActiveCN108690589AGood securitySimple preparation processCleaning apparatusDrilling compositionKeroseneChemistry

The invention provides an oil well de-blocking agent as well as a preparation method and application thereof. The oil well de-blocking agent is prepared from the following ingredients through being metered by regarding the total weight of the de-blocking agent as 100 percent: 30 to 45 percent of aromatics solvents, 30 to 45 percent of kerosene, 15 to 20 percent of oil soluble penetrating agents and 5 to 10 percent of nonionic surfactants. Compared with the existing oil well de-blocking agent, the oil well de-blocking agent has the advantages that the open flash point can reach a value being 50DEG C or above; the safety is high; the preparation process is simple; the de-blocking efficiency on asphaltene and colloidal sediments is high; the solution after the de-blocking does not need to bedischarged out and can directly enter a ground surface manifold system; safety and environment protection are realized; the de-blocking agent is applicable to the oil well and near-well zone blockingmaterial de-blocking in the oil well mining process.

Owner:PETROCHINA CO LTD

Emulsive composition containing dapsone

InactiveUS20130018104A1Stabilises emulsive compositionAvoid separationAntibacterial agentsOrganic active ingredientsActive agentPerylene derivatives

The present invention relates to a topical, emulsive composition containing Dapsone or its derivative. The inventive composition incorporates emollients and Dapsone or its derivative in a stable emulsion. The stability is achieved through the use of a combination of certain surfactant mixtures and an enhancer providing solubility of the Dapsone.

Owner:ALLERGAN INC

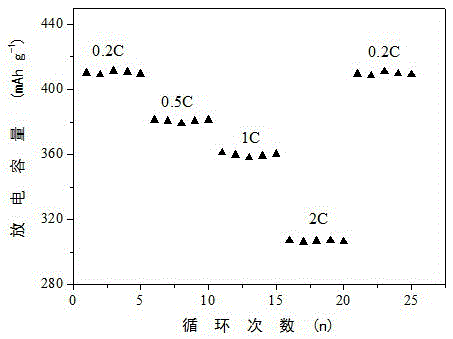

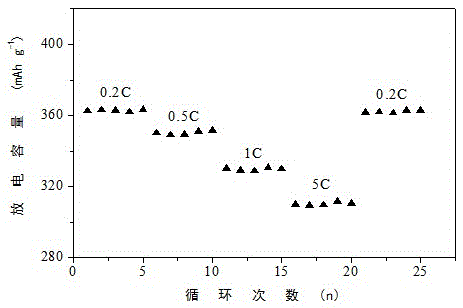

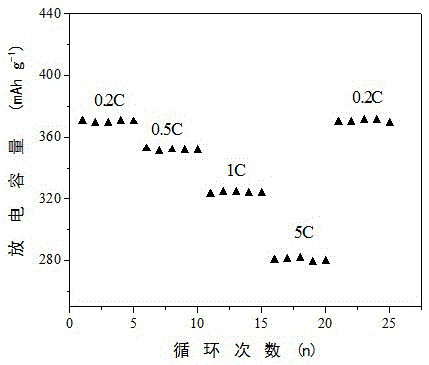

Graphene-based lithium-ion battery cathode and preparation method thereof

InactiveCN105489838AImprove power performanceReduce usageCell electrodesSecondary cellsEnvironmental resistanceDoped graphene

The invention relates to a graphene-based lithium-ion battery cathode and a preparation technology thereof. According to the technology, cathode slurry taking graphite doped graphene as an active substance is prepared and applied to copper foil, and the lithium-ion battery cathode is prepared. A novel polystyrene-polyisoprene-polystyrene block polymer binder is adopted in the technology, has higher binding force for graphene and can provide high elasticity and improve performance of the graphene-based lithium-ion battery cathode, the obtained high-energy density type cathode has 410 mAh / g of energy density during 0.2 C charging and discharging, and the power type cathode has 310 mAh / g of energy density during 5 C charging and discharging. Raw materials are economical and easy to obtain, and the technology is simple and environment-friendly.

Owner:ZHEJIANG EPTONG TECH CO LTD

Airlift reactor for treating soybean oil refining waste water by viscid trichosporon cutaneum

ActiveCN108545837ASimple structureTheoretical perfectionWater treatment parameter controlBiological treatment apparatusWater bathsChemical industry

The invention relates to an airlift reactor for treating soybean oil refining waste water by viscid trichosporon cutaneum, and belongs to the technical field of waste water treatment. Aiming at the features of the soybean oil waste water, the airlift reactor which can not only realize the soybean oil refining waste water treatment and resource utilization but also obviously improve the waste watertreatment efficiency for treating soybean oil refining waste water by viscid trichosporon cutaneum is designed. A water bath jacket is coated outside a reaction tank; a heat insulation water inlet and a heat insulation water outlet are formed in the water bath jacket; a tube body is arranged inside the reaction tank body through a support block, wherein the upper part and the lower part of the tube body are communicated with the reaction tank body; the upper half part of the tube body is a low pH region; the lower half part is a high PH region; an air pipe passes through the reaction tank body and the air outlet of the tube body is arranged between the low PH region and the high PH region; in addition, the air outlet is upward; a gas distributor is arranged in an air outlet position of the air pipe; a cyclone plate is arranged at the upper end of the tube body. The air is used as thrust for realizing a multi-flow-phase reactor realizing the water circulation flowing and no need of mechanical stirring and pump lifting. The airlift reactor has the characteristics of simple structure, low energy consumption and the like, and can be widely applied to various fields of biological engineering, energy chemical industry, environment protection and the like.

Owner:NORTHEAST DIANLI UNIVERSITY

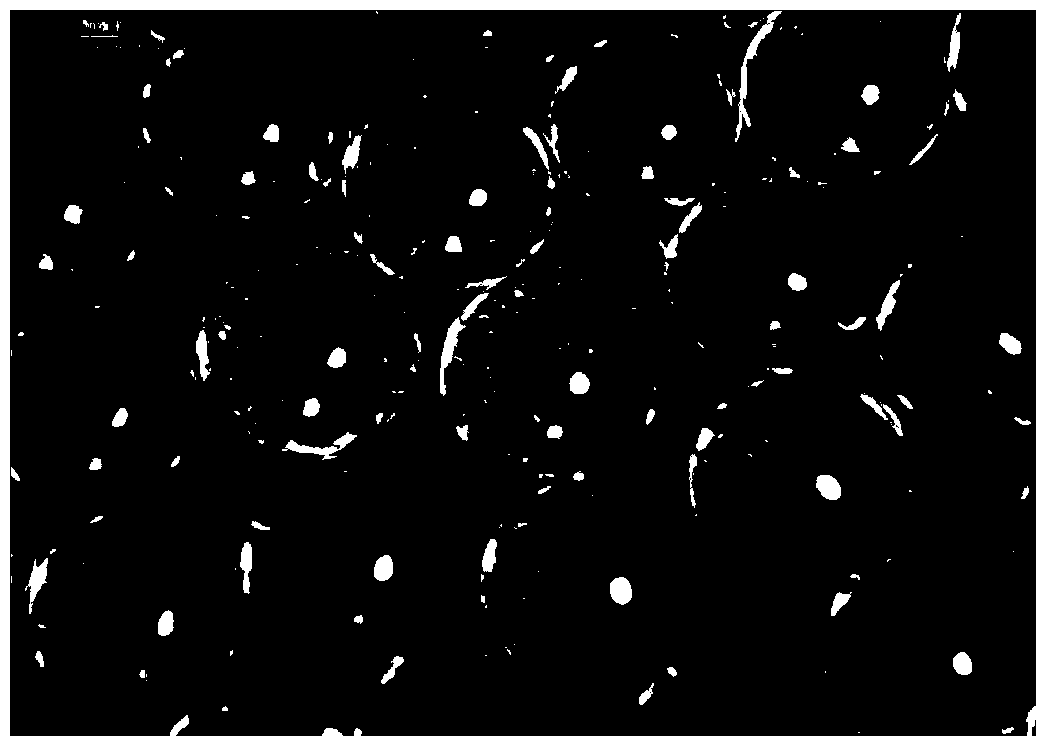

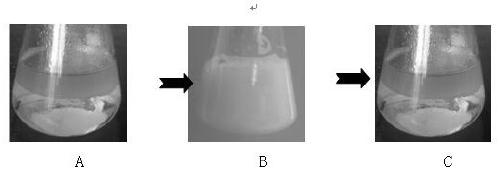

Polyacrylamide microsphere emulsion and preparation method thereof

The invention relates to submicron polyacrylamide microsphere emulsion with high solid content and high stability as well as a preparation method thereof. The problems in the prior art that the use amount of an emulsifier in preparation of the polyacrylamide microsphere emulsion by a reversed-phase microemulsion method as well as the solid content is slightly low and the stability is low in preparation of a product by the common reversed-phase emulsion method are mainly solved. According to the technical scheme which adopts a composite emulsifier system and a composite initiator, the polyacrylamide microsphere emulsion is prepared by polymerizing: a) 10 to 40 parts by weight of an oil phase, b) 1 to 8 parts by weight of a composite emulsifier system, c) 50 to 80 parts by weight of an aqueous phase containing a polymerization monomer, wherein the content of the polymerization monomer in the aqueous phase is 40 to 70 percent, and d) 0.01 to 1.0 part of reversed-phase emulsion system suchas a crosslinking agent, so that the problems are solved well, and the polyacrylamide microsphere emulsion can be applied to field application capable of increasing recovery ratio, such as profile modification in depth, water plugging and oil displacement for tertiary oil recovery of medium-low permeability oil fields.

Owner:CHINA PETROLEUM & CHEM CORP +1

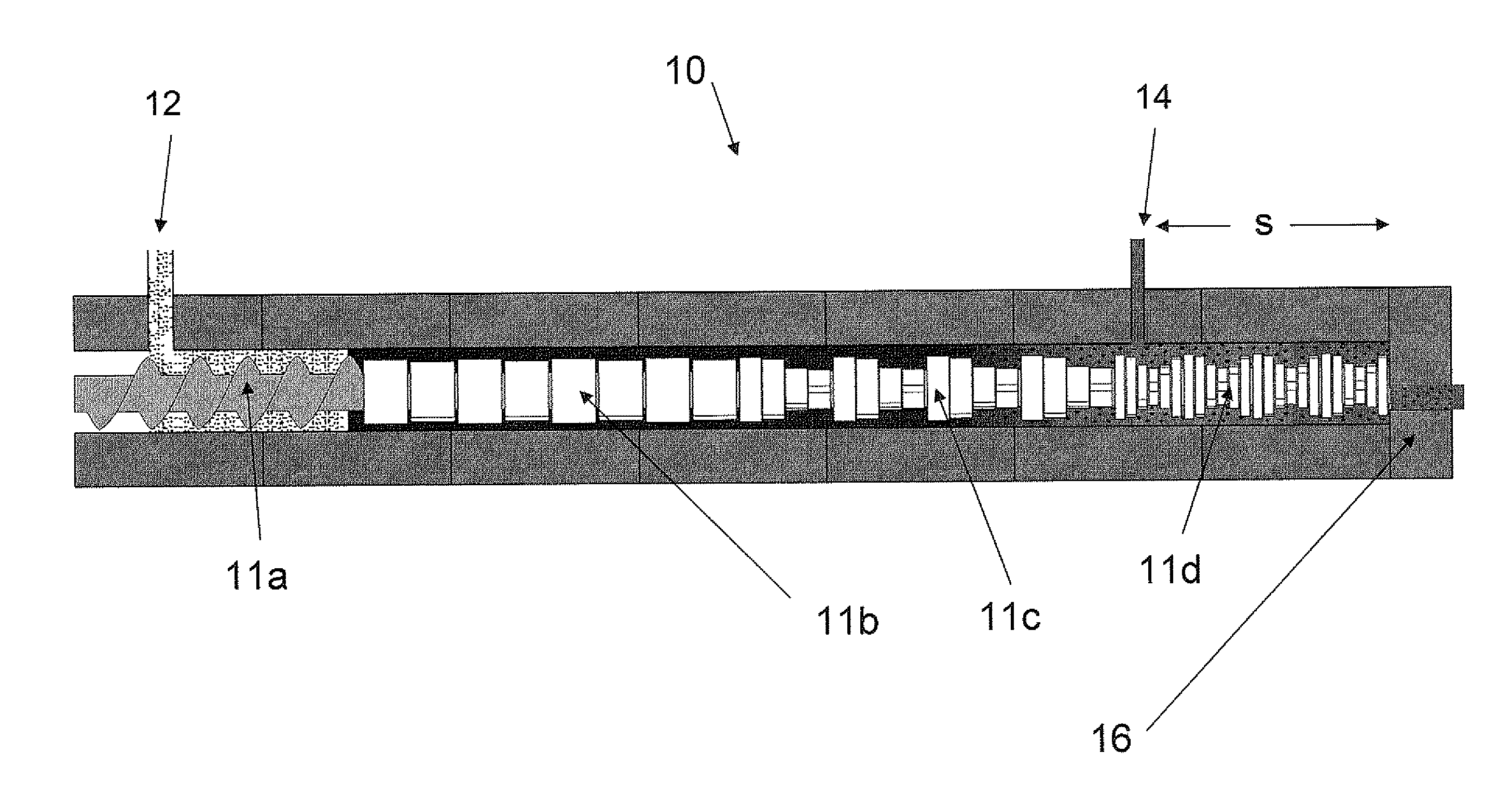

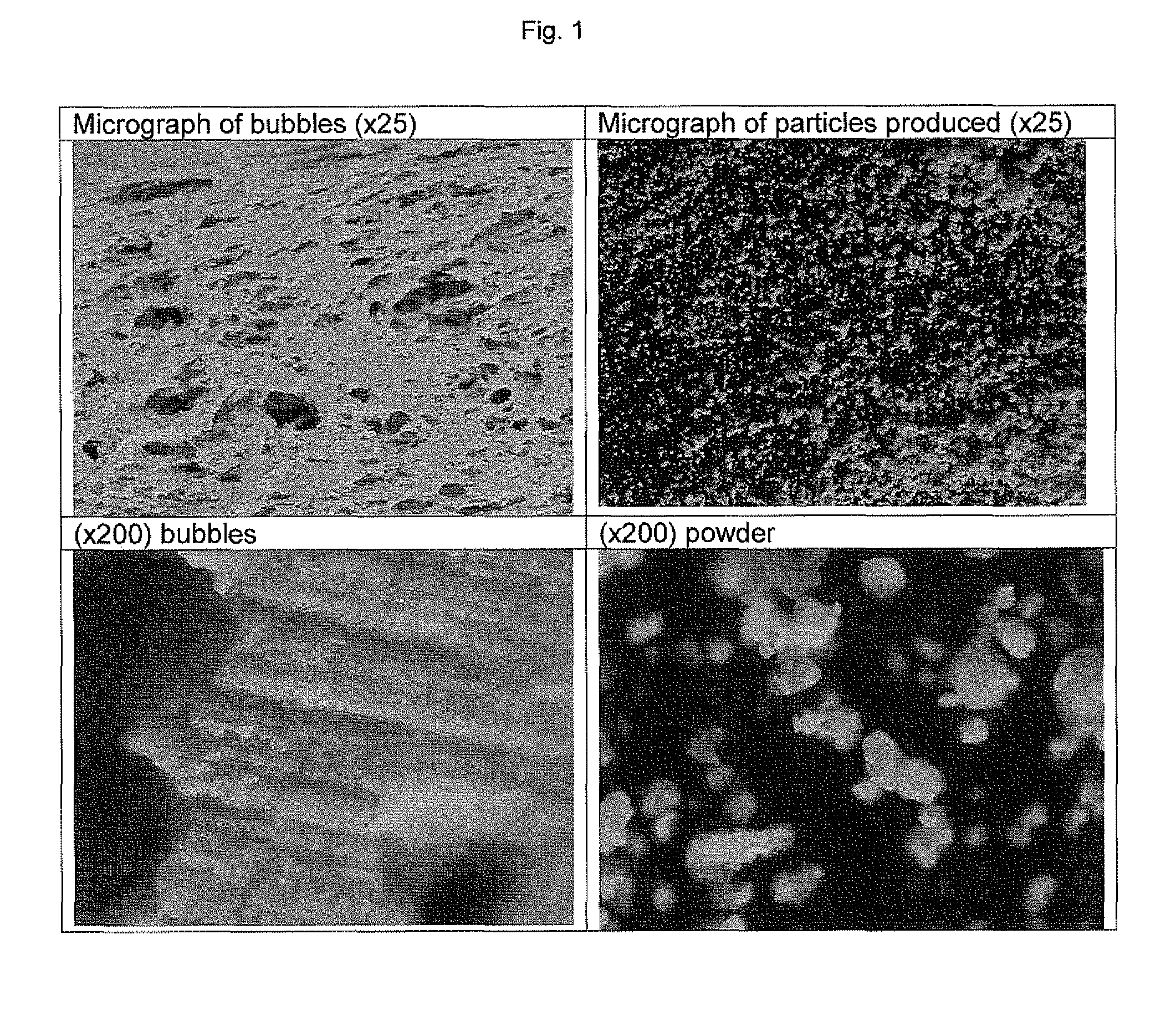

Powder coating extrusion process using liquid

A process for the manufacture of a powder coating comprising the steps of: Preparing a powder coating premix comprising a resin and optionally a crosslinker therefor; Feeding the premix through a melt extruder; Cooling the extruded material; and Comminuting it to fine particles, wherein said process is characterized in that between 1 and 25 wt. % (based on the weight of said premix) of a process liquid is added to the melt extruder, wherein said process liquid is immiscible with at least said resin of the powder coating premix and wherein said process liquid evaporates when the premix leaves the extruder.

Owner:AKZO NOBEL COATINGS INT BV

Equipment and method for preparing monodisperse ion exchange resin

The invention discloses a device and method for preparing a monodisperse ion exchange resin. The device comprises a raw material tank (1), a vibration generator (2), a sprayer (3), a polymerizer (5), a stirring polymerization kettle (8), a transfer pump (9), and pipelines, valves and T joints connected among device rooms, wherein the inside of the lower part of the polymerizer (5) is provided with a feed pipe (4); the diameter of the lower part of the polymerizer (5) is greater than that of the upper part; the internal surface of the middle upper part of the polymerizer (5) is connected with an upper porous plate (6); the internal surface of the lower part of the polymerizer (5) is connected with a lower porous plate (7); and the feed pipe (4) penetrates through the lower porous plate (7). The device and method can be used for preparing the gel-type or macroporous ion exchange resin with the particle size of 1-3.5mm; and the prepared ion exchange resin has uniform particle size and monodispersity.

Owner:TIANJIN UNIV

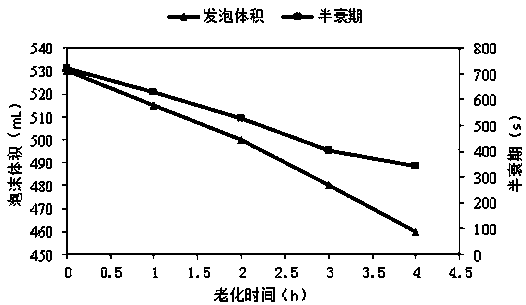

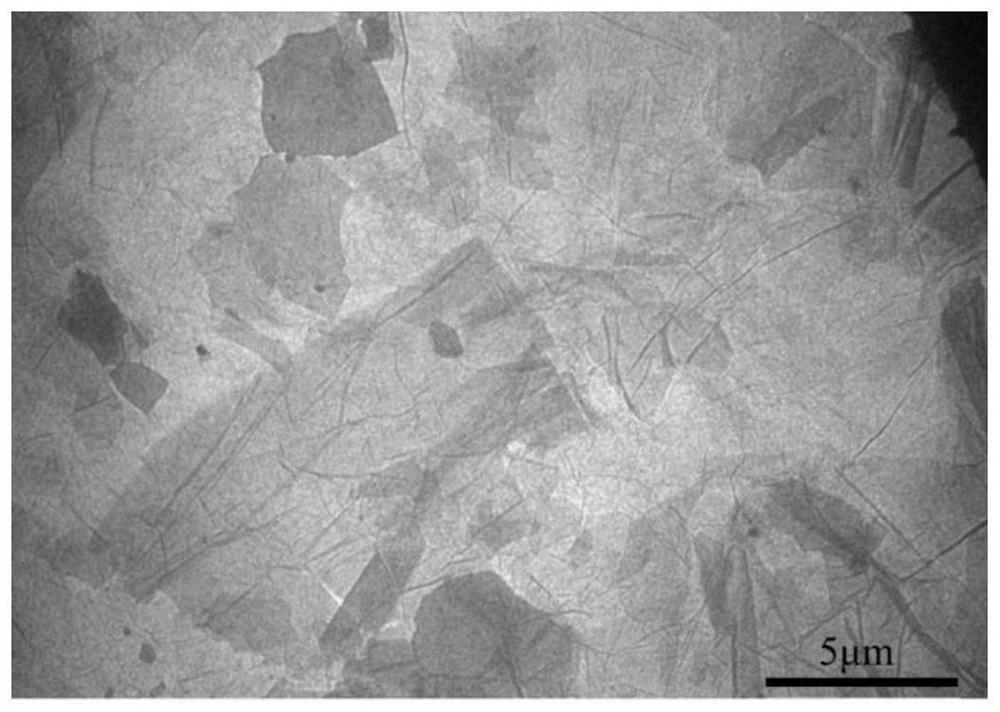

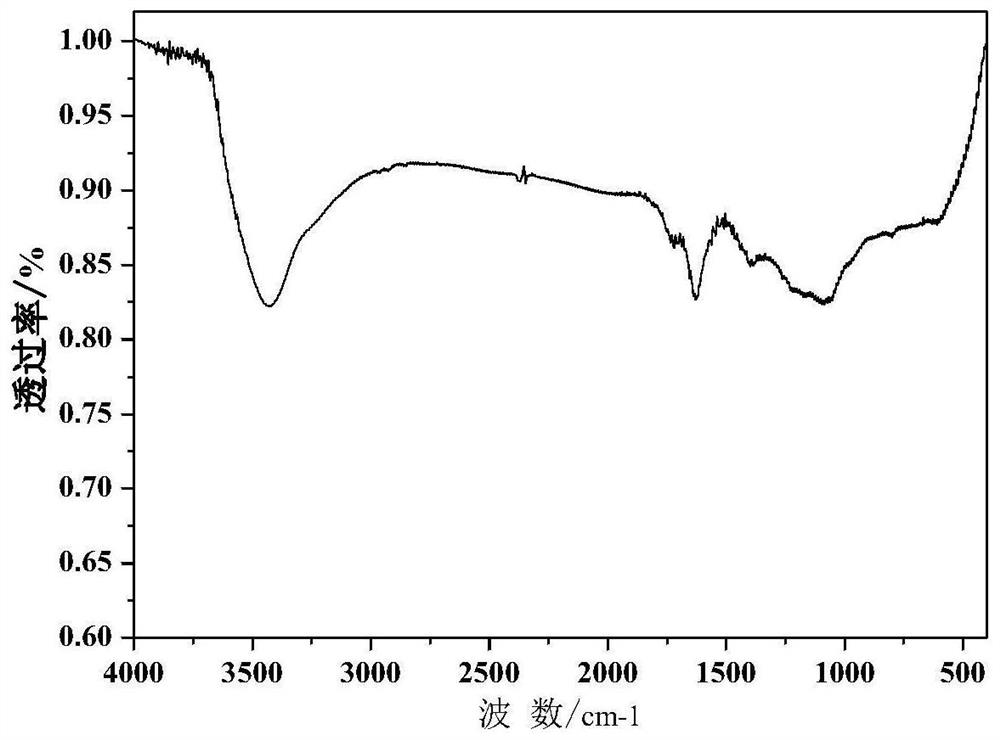

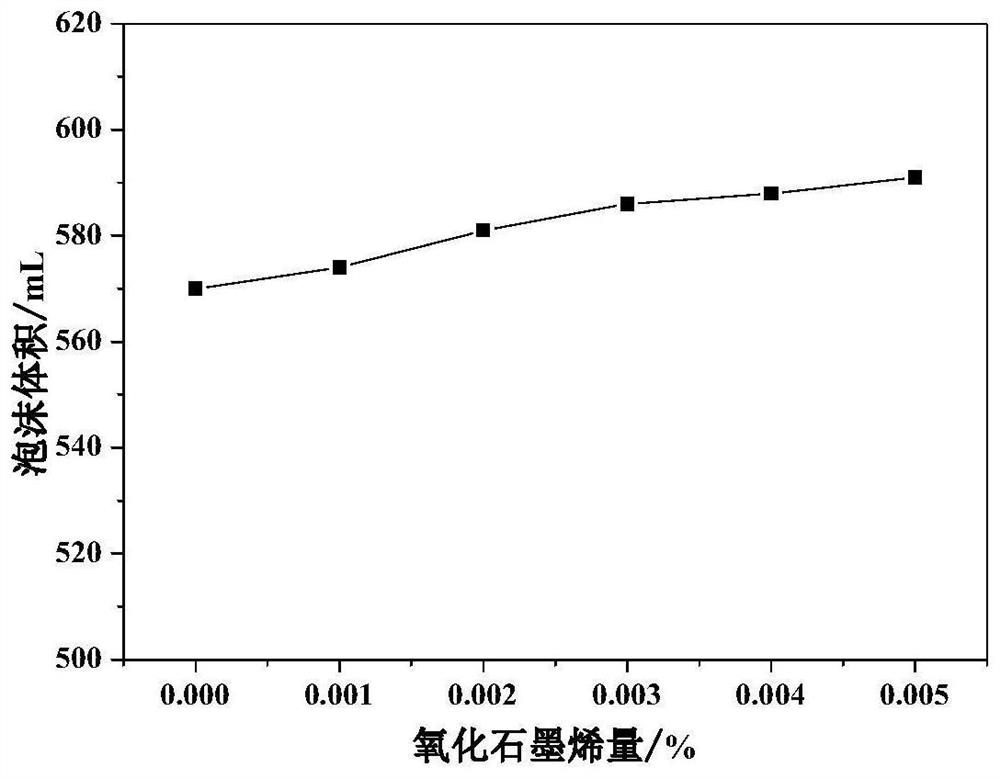

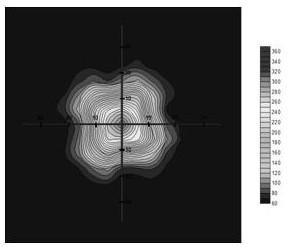

High-stability oil displacement foam system and preparation method thereof

PendingCN112251205APrevent coalescingImprove the performance of emulsified oil washingDrilling compositionAir liquid interfaceFoaming agent

The invention discloses a high-stability oil displacement foam system, which comprises a foaming agent, a stabilizer and water, the foaming agent comprises sodium benzenesulfonate, the stabilizer comprises graphene oxide nanosheets, and the water comprises ionized water. By adding the graphene oxide nanosheets, the graphene oxide nanosheets are adsorbed on a gas-liquid interface forming bubbles, so that gas diffusion is reduced, meanwhile, the nanosheets can be retained at a Plaateau boundary to prevent liquid in a liquid film from being rapidly separated out, and the stability of the foam isgreatly improved; the amphipathy of the graphene oxide nanosheet plays a role in surface activity at the same time, so that the surface tension of the system is reduced, the foam is more stable, and the foaming performance of the system is also improved; the graphene oxide nanosheets can also be adsorbed on the surfaces of tiny oil drops dispersed in the liquid, so that the oil drops are preventedfrom coalescing, and the emulsifying and oil washing performance of a foam system is improved. The preparation method is simple and controllable in process, high in product conversion rate and few inbyproducts, and can be widely applied to actual production.

Owner:NANJING NORMAL UNIVERSITY

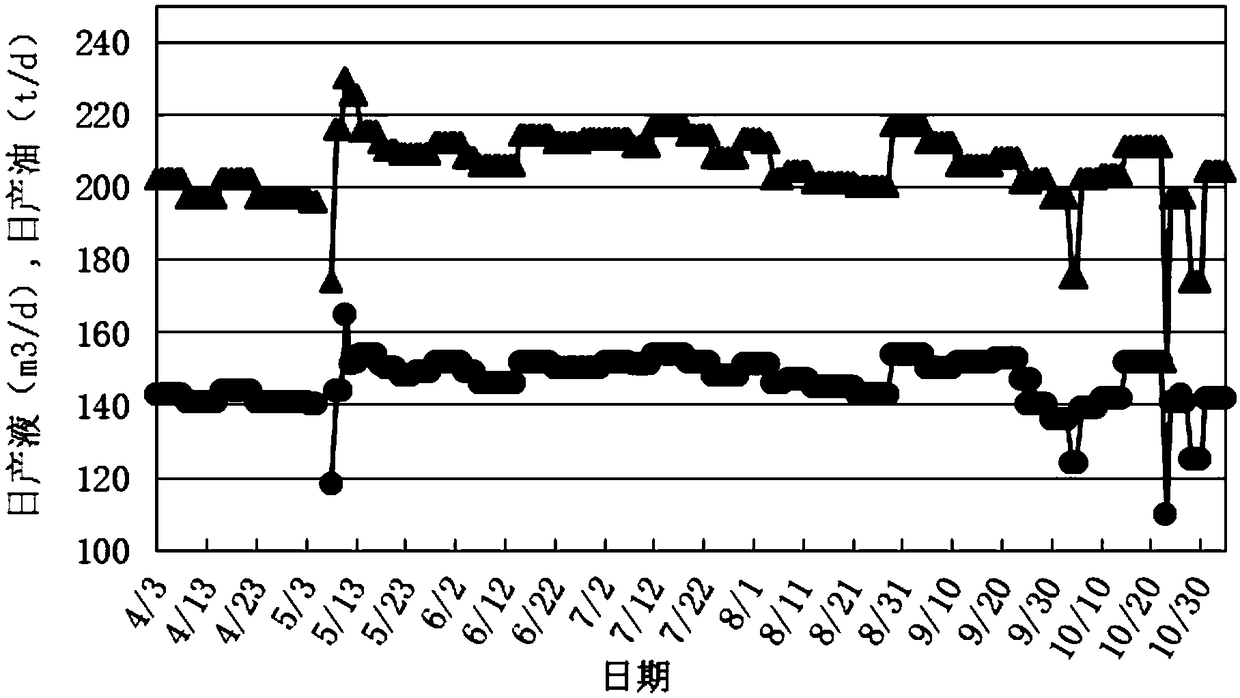

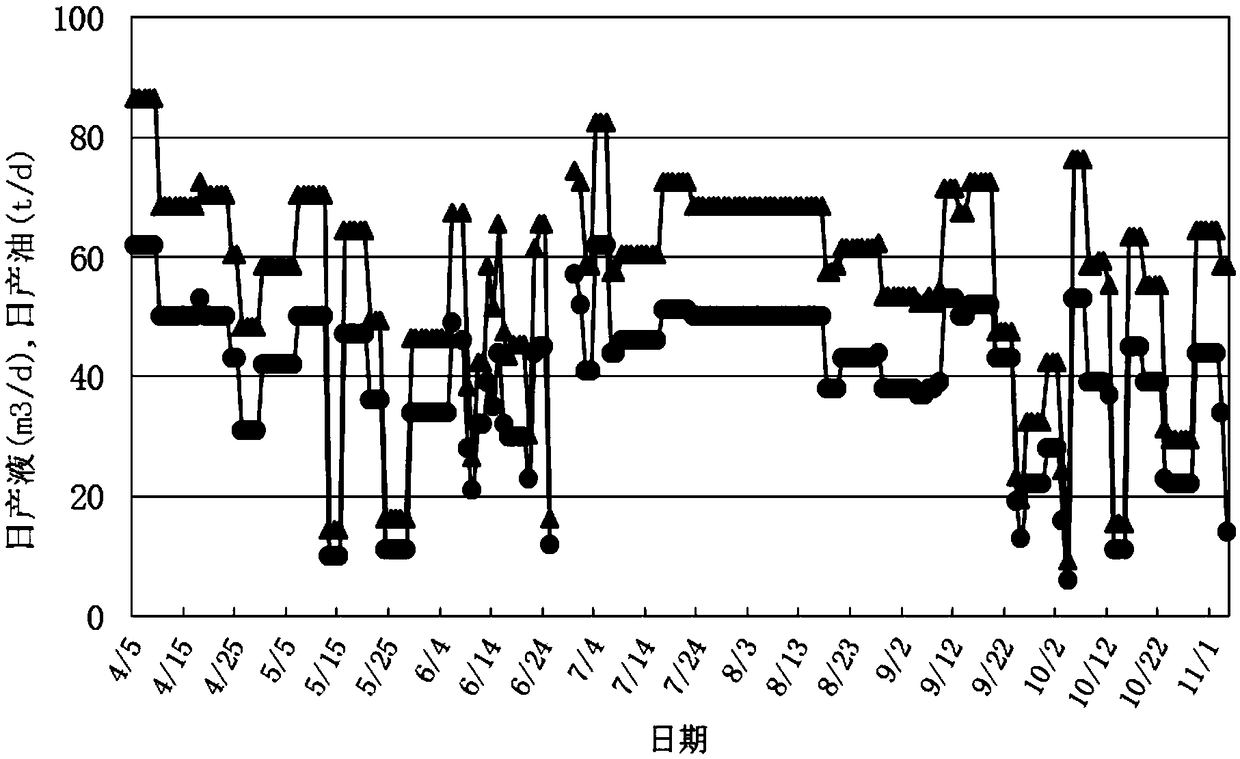

Effective production process for shallow medium-high permeability super heavy oil reservoir

The invention discloses an effective production process for a shallow medium-high permeability super heavy oil reservoir. The process comprises the following steps of emulsifying an oil-soluble viscosity reducer and water into O / W emulsion, wherein the stabilizing time of the emulsion is controlled to be over 2 days; injecting the O / W emulsion into an oil layer; closing a well for reaction, wherein the well closing time is over 3 days; and injecting steam and soaking the well. The injected oil-soluble viscosity reducer emulsion is a thermodynamic unstable system, so that the oil-soluble viscosity reducer is gradually released after construction is finished; and according to the principle of similarity and intermiscibility, the released oil-soluble viscosity reducer acts with crude oil to realize permanent viscosity reduction. The invention also discloses oil-soluble viscosity reducer emulsion which consists of the oil-soluble viscosity reducer and water containing a water-based emulsifier and is O / W emulsion. By the process, the super heavy oil reservoir is changed into a super heavy oil reservoir or even a common heavy oil reservoir in a production range, so that the injection amount of steam can be greatly reduced, energy consumption is greatly reduced, and the requirements of low cost and low energy consumption are met.

Owner:CHINA PETROLEUM & CHEM CORP +1

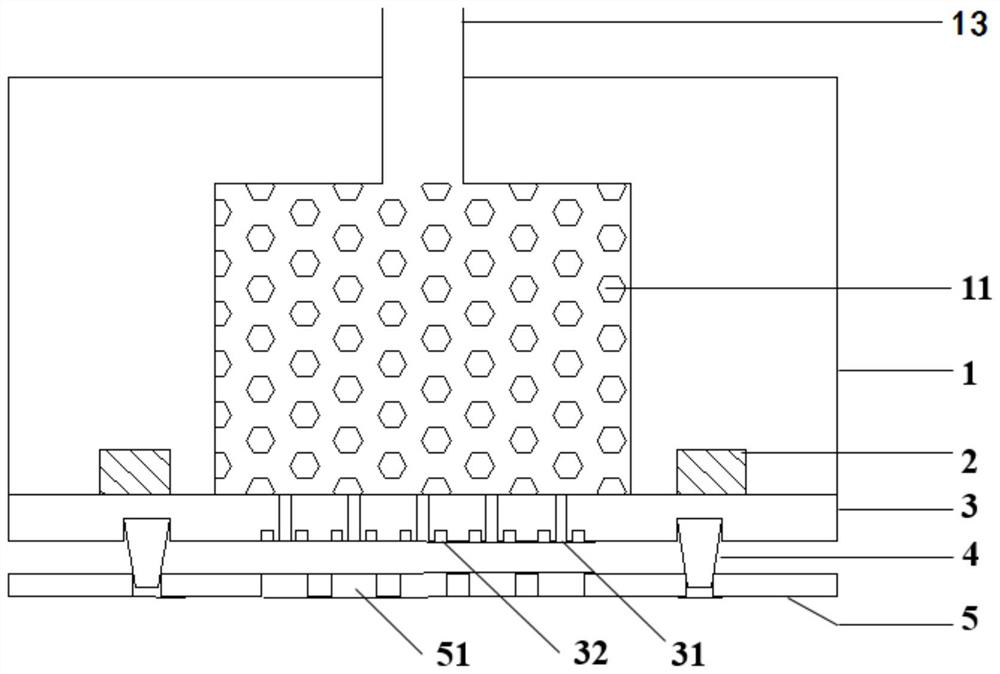

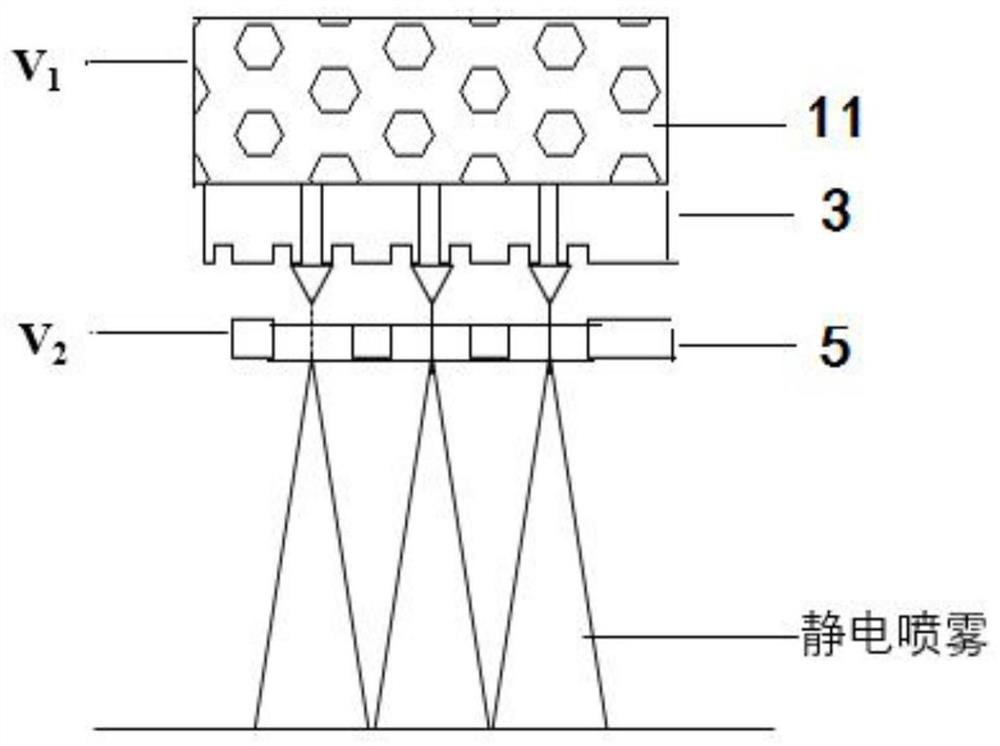

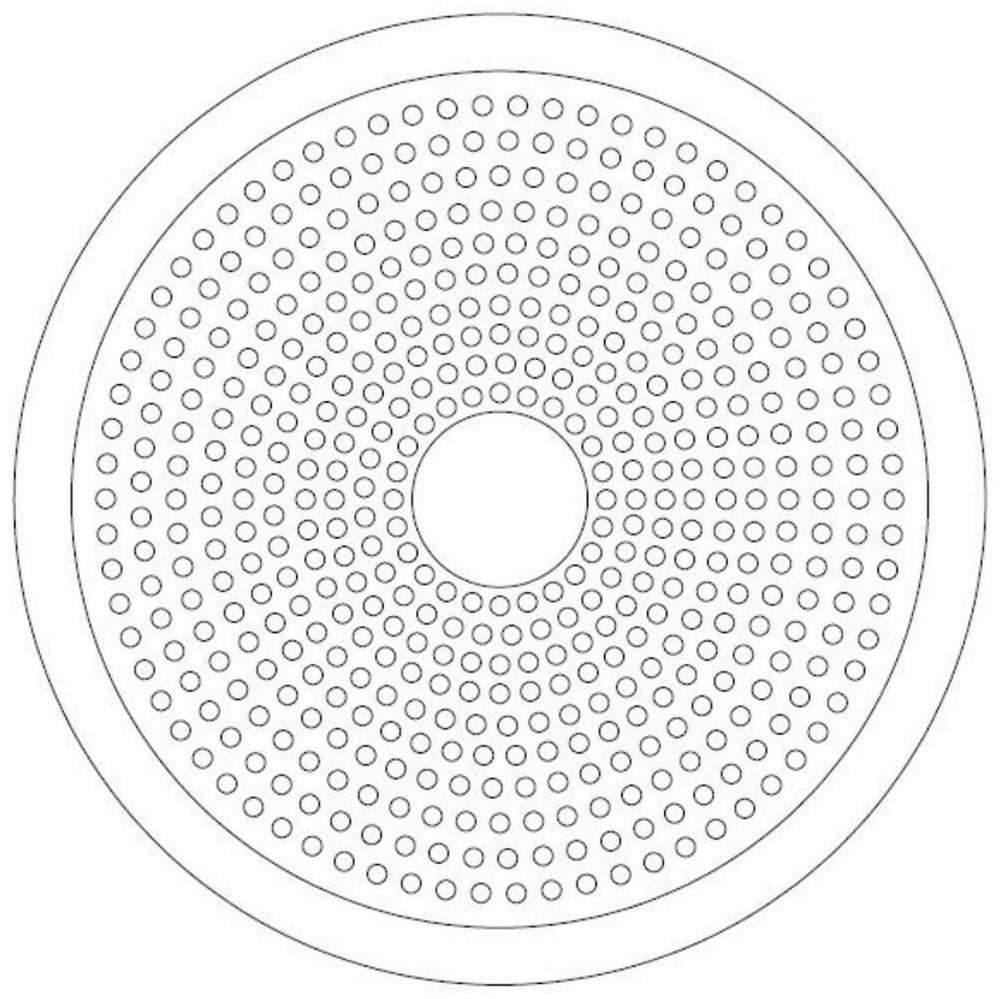

Flat plate electrospray emission device with micro channels

ActiveCN112974007AGuaranteed uptimeImprove scalabilitySpraying power supplyElectrical field strengthPorous medium

The invention discloses a flat plate electrospray emission device with micro channels. The flat plate electrospray emission device comprises a liquid storage tank, a flat plate emitting electrode and an extraction electrode which are sequentially arranged from top to bottom. The flat plate electrospray emission device is characterized in that a porous medium material and working media needed by electrospray are arranged in the liquid storage tank; a liquid outlet hole is formed in the center of a lower end plate of the liquid storage tank, a plurality of emitting holes are formed in the portion, corresponding to the liquid outlet hole, of the flat plate emitting electrode, a plurality of micro holes are formed in the extraction electrode, and the emitting holes correspond to the micro holes one to one; the annular channels are formed in the peripheries of the emitting holes of the flat plate emitting electrode respectively and located on the lower end face of the flat plate emitting electrode; a positioning column is arranged between the flat plate emitting electrode and the extraction electrode; the flat plate emitting electrode is used for distributing the spray flow and controlling the Taylor cone form formed by the electrospray working media near the emitting holes; and the extraction electrode is used for improving the electric field intensity near the emitting holes and controlling the spray plume and the deposition form of the micro holes. The flat plate electrospray emission device can be widely applied to the fields of agriculture, sanitation, mass spectrometry, space propulsion and the like.

Owner:CHONGQING UNIV

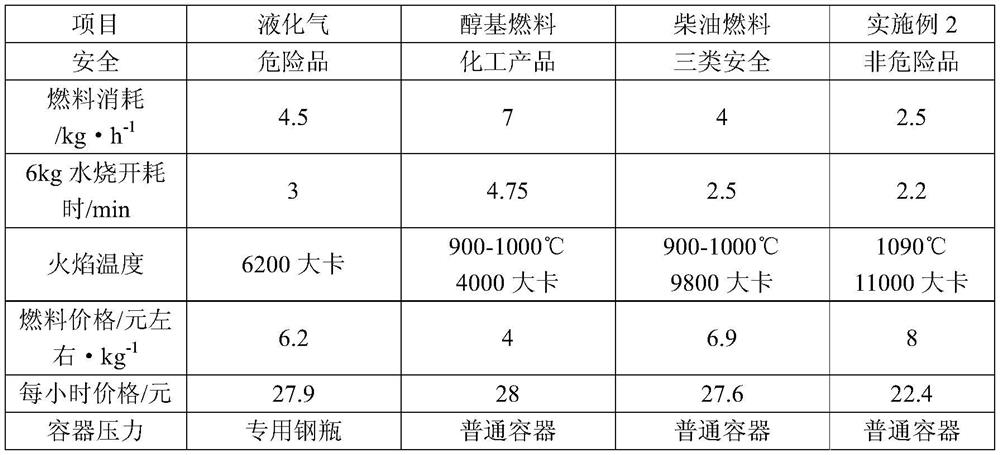

Environment-friendly efficient alcohol-free vegetable oil fuel and preparation method thereof

InactiveCN112940806AHigh calorific valueReduce tensionLiquid carbonaceous fuelsFuel additivesVegetable oilGlycol synthesis

An environment-friendly efficient alcohol-free vegetable oil fuel is prepared from the following raw materials: vegetable oil, polysiloxane, methyl tertiary butyl ether, isopropanol, ethylene glycol, glycerol, absolute ethyl alcohol, magnesium powder, ferrocene and water. The invention also discloses a preparation method of the environment-friendly high-efficiency alcohol-free vegetable oil fuel, which comprises the following steps: S1, preparing methyl tert-butyl ether, isopropanol, ethylene glycol, glycerol and absolute ethyl alcohol into a mixing agent, adding the mixing agent and polysiloxane into the vegetable oil, and uniformly stirring to obtain a mixed solution for later use; s2, adding water into the mixed solution, carrying out ultrasonic dispersion, and uniformly stirring to prepare a water-in-oil mixed solution for later use; and S3, adding magnesium powder and ferrocene into the water-in-oil mixed solution, and uniformly stirring to obtain the magnesium-in-oil composite material. The vegetable oil fuel prepared by the invention is low in flash point, has better properties than liquefied gas, alcohol-based fuel and diesel fuel, and has the advantages of environmental protection, high efficiency, safety, cleanness, energy conservation and good economic benefit.

Owner:NANJING XINGJING CHEM

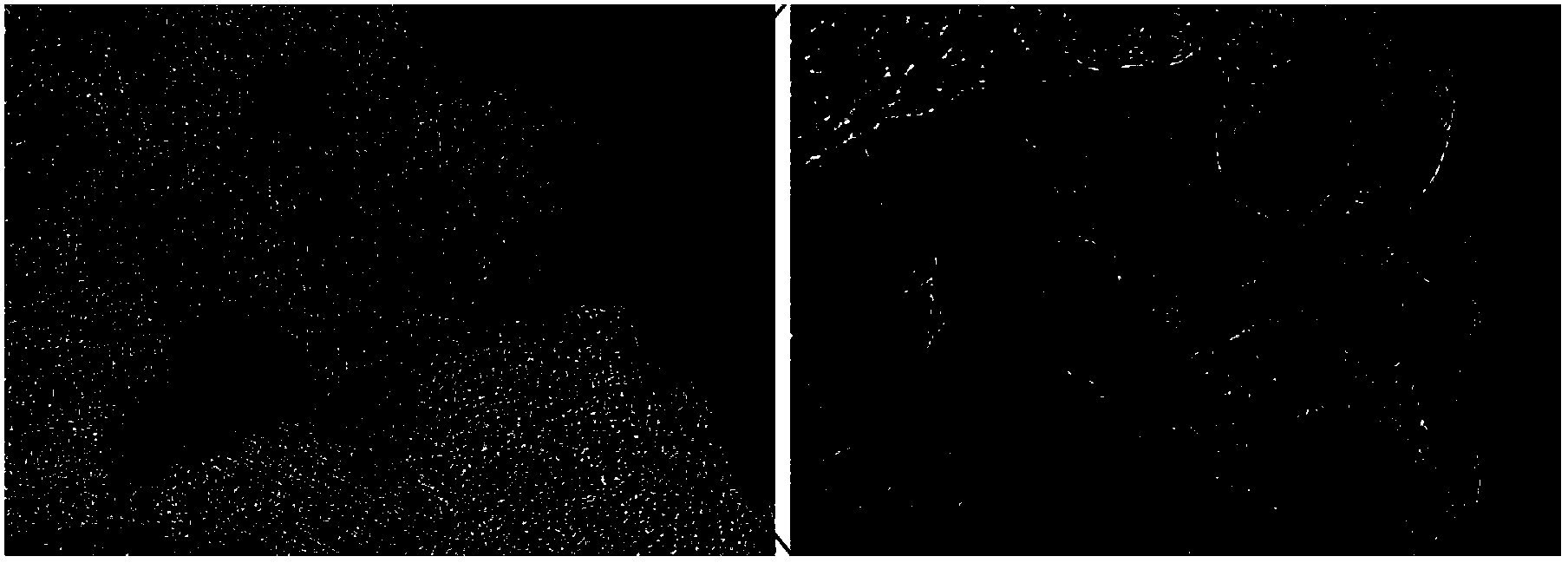

Porous graphene-metal oxide composite material and its preparation method

InactiveCN103137957BImprove stabilityPrevent coalescingCell electrodesPorous grapheneOxide composite

The invention belongs to the composite material field and discloses a porous graphene-metal oxide composite material and its preparation method. The material is characterized in that porous graphene prepared through a vapor phase chemical deposition method is used as a carrier, and metal oxide particles having diameters of 0.5-100nm are filled to the nanometer pores of the porous graphene. The preparation method is characterized in that an ion exchange process is adopted to make metal salt components enter the pores of the porous graphene, and then the deposition method or the calcining method is utilized to obtain the composite structure of the porous graphene having metal oxide filled meso-pores or micro-pores. The composite material has potential application values in the lithium ion battery field, the super capacitor field, the conductive filling material field, the heterogeneous catalysis field and the like.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Supergravity heterogeneous catalytic reactor device and application thereof

PendingCN114849595AReduce volumePrevent coalescingSustainable biological treatmentChemical/physical processesRotational axisElectric machinery

The invention discloses a supergravity heterogeneous catalytic reactor device and application. The supergravity heterogeneous catalytic reactor device comprises a motor, a rotating shaft, a shell, a gas-liquid inlet, a gas-liquid outlet, a static flow guide part, a microbubble generation module and a heterogeneous catalytic reaction module, the rotating shaft serves as an output shaft of the motor and extends into the shell from the center of the top end of the shell. Microbubble generation modules and heterogeneous catalytic reaction modules are alternately arranged in the shell from bottom to top; the middle part of the microbubble generation module is fixed on the rotating shaft, and a gap is formed between the outer edge of the microbubble generation module and the shell; the heterogeneous catalytic reaction module is fixed on the inner wall of the shell, and a gap is formed between the center of the heterogeneous catalytic reaction module and the rotating shaft penetrating through the heterogeneous catalytic reaction module; and the static flow guide part is arranged between the shell and the microbubble generation module and is fixed on the shell. According to the device, the characteristic size of the bubbles can be effectively regulated and controlled by adjusting the rotating speed of the supergravity device, the generation of the microbubbles and the catalytic reaction are synchronously carried out in the same reactor, and the investment of equipment is reduced.

Owner:BEIJING UNIV OF CHEM TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com