Oil well de-blocking agent as well as preparation method and application thereof

A plug-removing agent and technology for oil wells, applied in chemical instruments and methods, earth-moving drilling, wellbore/well components, etc. Simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

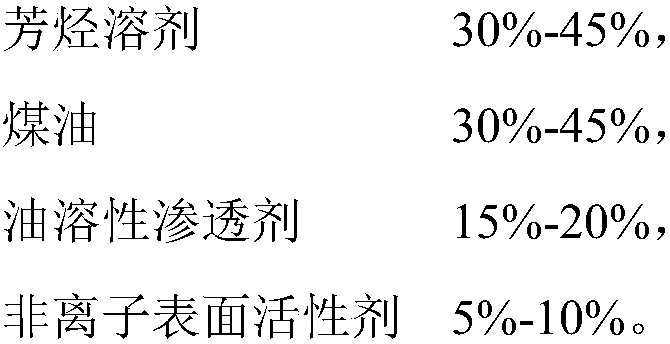

[0026] This embodiment provides an oil well plugging remover, the raw material components of which include:

[0027] 30% aromatic hydrocarbon solvent (composition of S-100 and xylene mass ratio of 2:1), 45% aviation kerosene, 15% oil-soluble penetrant (oleic acid diethanolamide and linoleic acid diethanolamide quality ratio is 3:1 composition) and 10% nonionic surfactant (sorbitan monostearate (Span60) and sorbitan fatty acid ester (Span80) mass ratio is the combination of 2:1 things).

[0028] This implementation also provides the preparation method of this oil well plugging remover, it comprises the following steps:

[0029] According to the above-mentioned raw materials and their proportions, add aromatic hydrocarbon solvent, aviation kerosene, oil-soluble penetrant and non-ionic surfactant into the reaction kettle, and stir at a constant temperature of 35-45°C for 1-1.5h to obtain the oil well plugging remover .

[0030] This embodiment also provides the application of ...

Embodiment 2

[0033] This embodiment provides an oil well plugging remover, the raw material components of which include:

[0034] 45% aromatic hydrocarbon solvent (composition of S-100 and xylene mass ratio of 2:1), 30% aviation kerosene, 20% oil-soluble penetrating agent (oleic acid diethanolamide and linoleic acid diethanolamide quality ratio is 1:1 composition) and 5% nonionic surfactant (sorbitan monostearate (Span60) and sorbitan fatty acid ester (Span80) mass ratio is the combination of 1:1 things).

[0035] This implementation also provides the preparation method of this oil well plugging remover, it comprises the following steps:

[0036] According to the above-mentioned raw materials and their proportions, add aromatic hydrocarbon solvent, aviation kerosene, oil-soluble penetrant and non-ionic surfactant into the reaction kettle, and stir at a constant temperature of 35-45°C for 1-1.5h to obtain the oil well plugging remover .

[0037] This embodiment also provides the applicat...

Embodiment 3

[0040] This embodiment provides an oil well plugging remover, the raw material components of which include:

[0041] 40% aromatic hydrocarbon solvent (composition of S-100 and xylene mass ratio of 2:1), 35% aviation kerosene, 18% oil-soluble penetrant (oleic acid diethanolamide and linoleic acid diethanolamide quality ratio is 1:3 composition) and 7% nonionic surfactant (sorbitan monostearate (Span60) and sorbitan fatty acid ester (Span80) mass ratio is the combination of 1:2 things).

[0042] This implementation also provides the preparation method of this oil well plugging remover, it comprises the following steps:

[0043] According to the above-mentioned raw materials and their proportions, add aromatic hydrocarbon solvent, aviation kerosene, oil-soluble penetrant and non-ionic surfactant into the reaction kettle, and stir at a constant temperature of 35-45°C for 1-1.5h to obtain the oil well plugging remover .

[0044] This embodiment also provides the application of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Open flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com