Patents

Literature

35results about How to "Prevent re-precipitation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

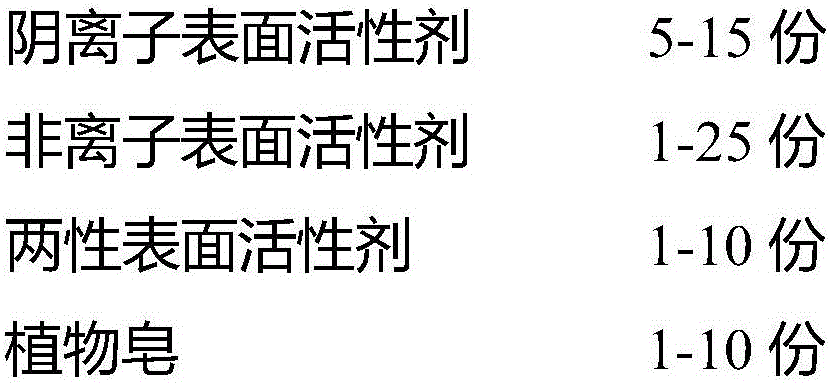

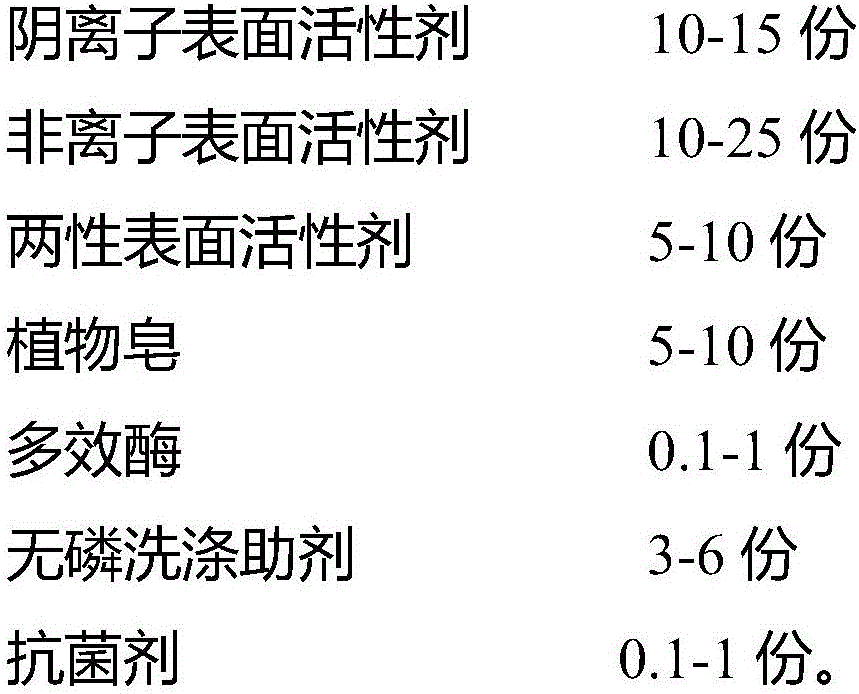

High-efficiency concentrated laundry detergent

InactiveCN105907503ADisperses dirt wellPrevent re-precipitationSurface-active non-soap compounds and soap mixture detergentsAmpholytes/electroneutral surface-active compoundsNonionic surfactantActive component

The invention provides a high-efficiency concentrated laundry detergent which is composed of the following main active components in parts by mass: 10-15 parts of anionic surfactant, 5-10 parts of nonionic surfactant, 5-10 parts of amphoteric surfactant and 5-10 parts of additive plant soap. The high-efficiency concentrated laundry detergent can remove stains efficiently, and has the characteristics of fine foam, no optical bleacher, excellent flexibility, excellent antibacterial property, high detergent power and low irritation.

Owner:PANROSA JIANGSU BIOTECH CO LTD

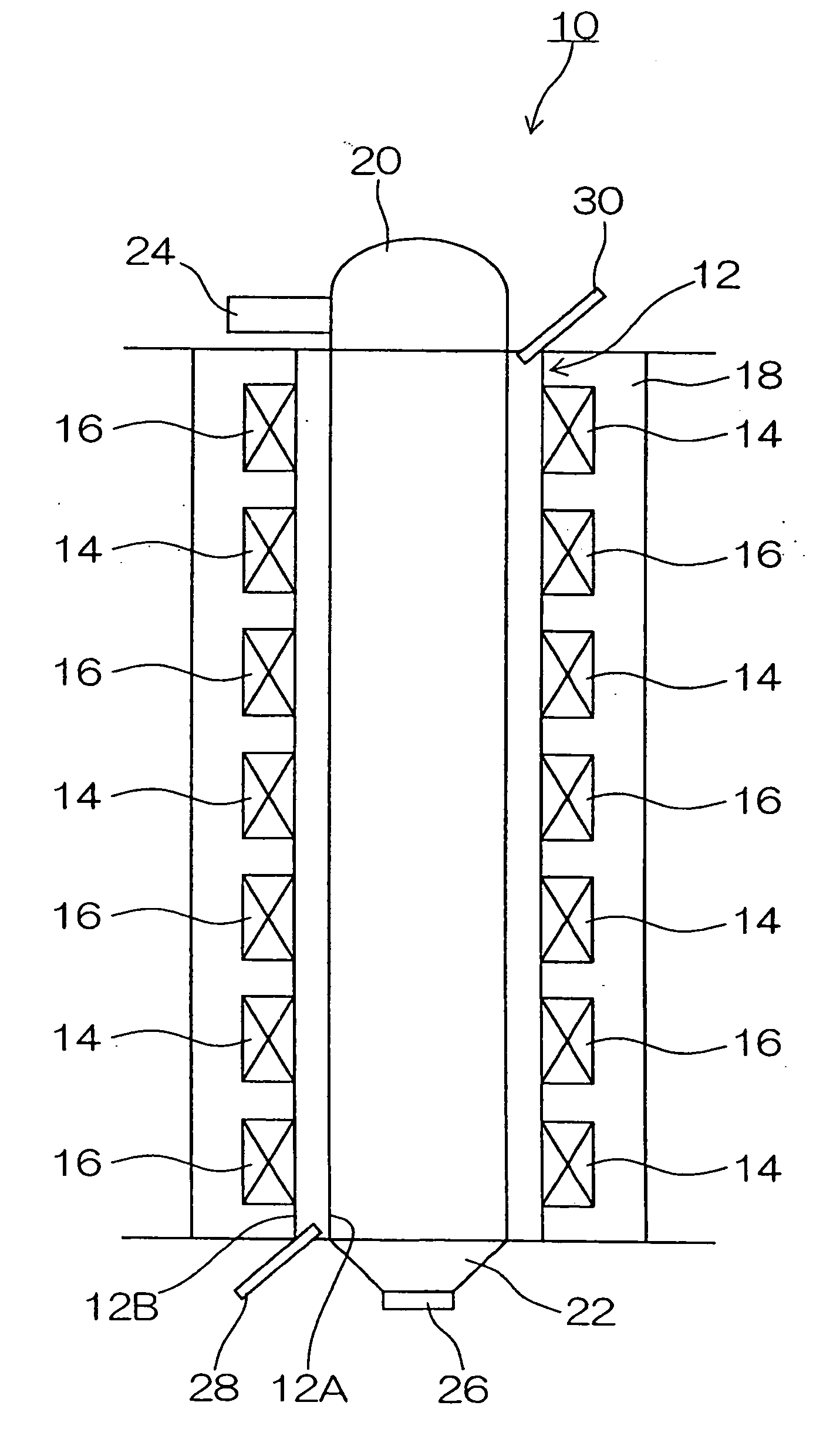

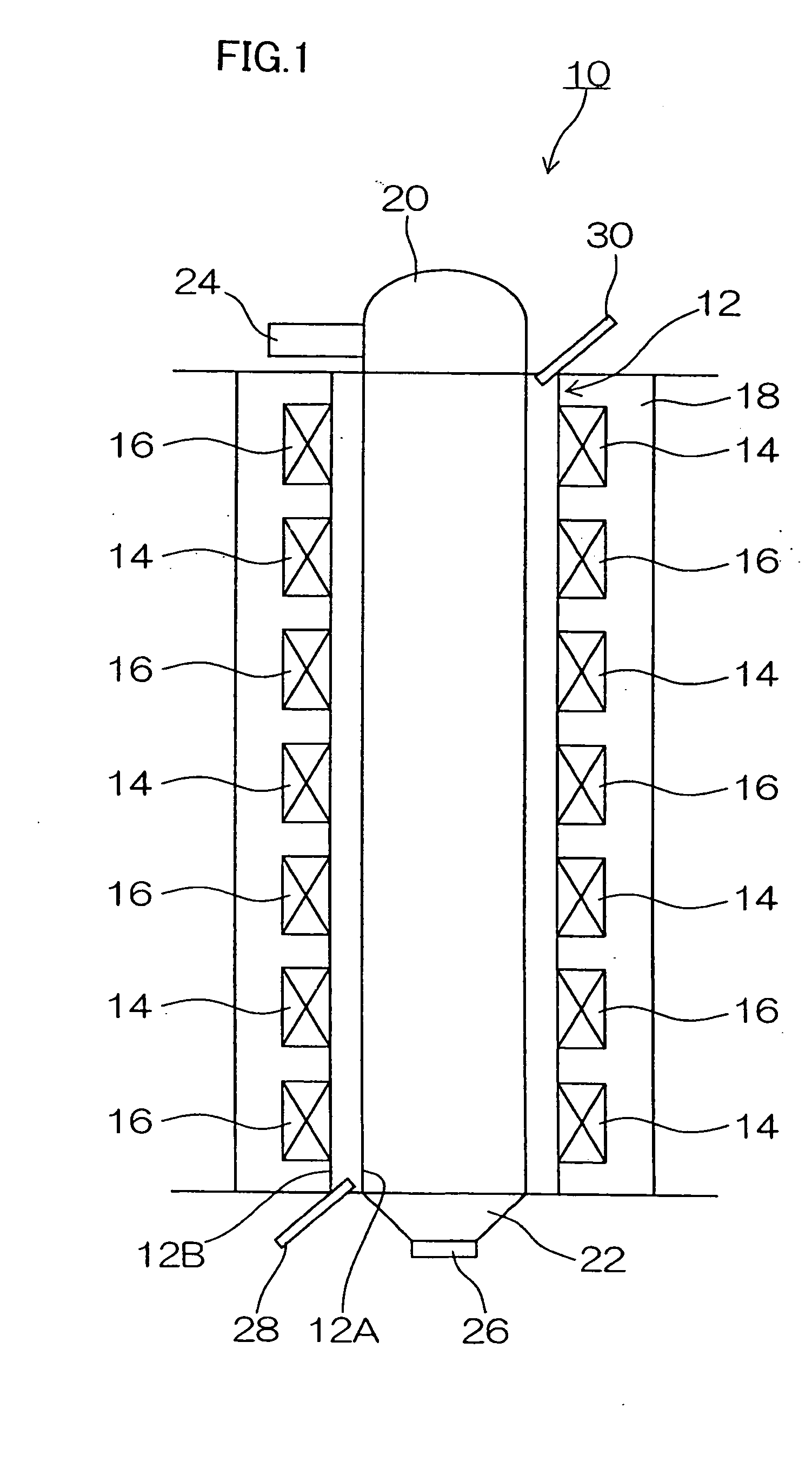

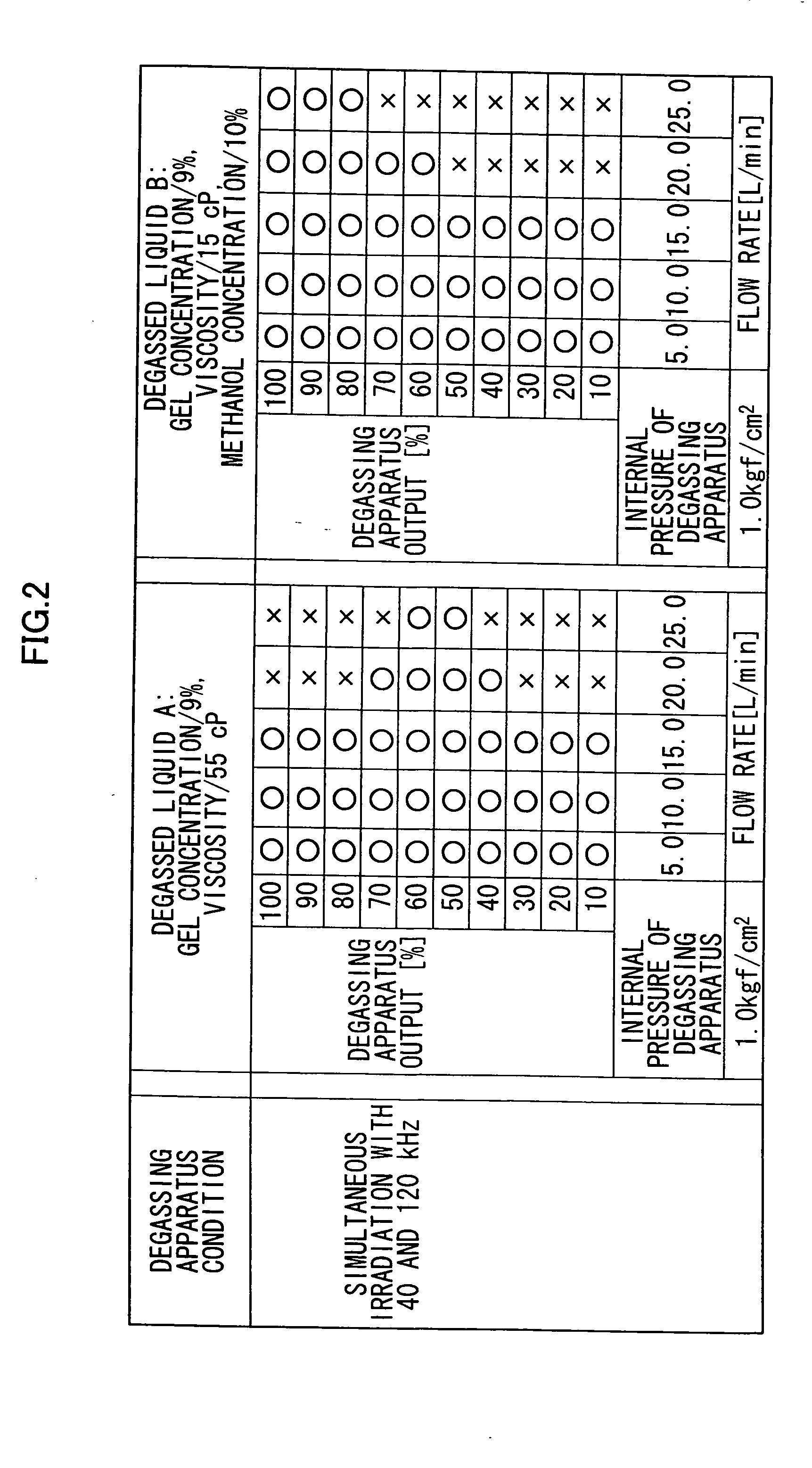

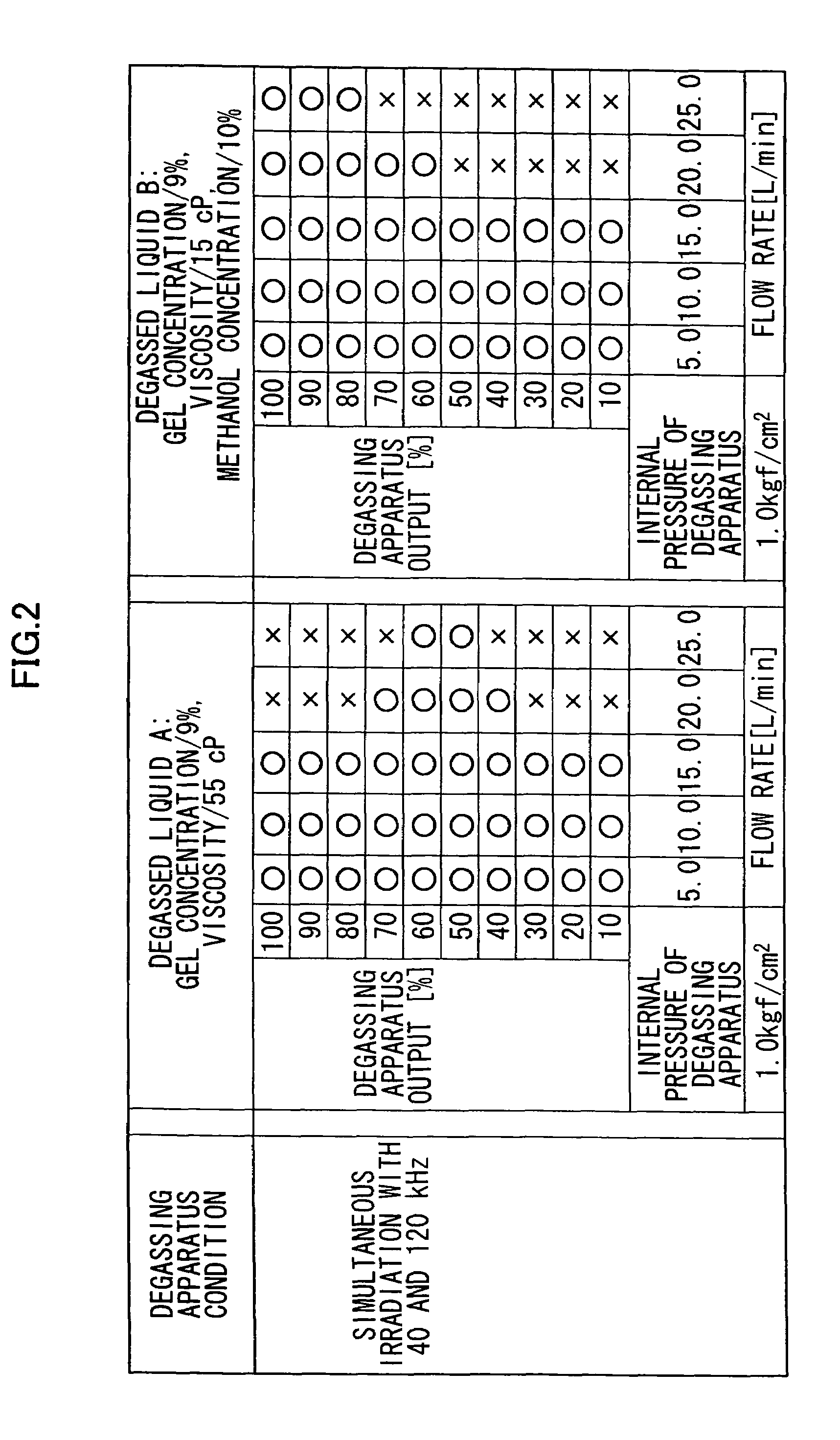

Method and apparatus for degassing coating liquid

ActiveUS20050115405A1Preventing bubble defectsEfficient removalPretreated surfacesPhotothermographic systemsMaterials scienceFrequency band

Owner:FUJIFILM CORP +1

Phosphorus-free degreaser

The invention discloses a phosphorus-free degreaser. The phosphorus-free degreaser is prepared from the following raw materials in percentage by weight: 10-36 percent of sodium hydroxide, 0-25 percent of potassium hydroxide, 2-4 percent of sodium carbonate, 2-3 percent of sodium citrate, 2-4 percent of sodium gluconate, 0.5-2 percent of poly-aspartic acid, 0.8-3 percent of polyacrylic acid sodium salt, 0.8-4 percent of a nonionic surfactant and the balance of water. According to the phosphorus-free degreaser disclosed by the invention, saponification is carried out on the sodium hydroxide, the potassium hydroxide and oil; the sodium carbonate and the sodium citrate provide an alkaline condition; reaction is carried out on the sodium gluconate, the poly-aspartic acid and metal ions in the oil; and the polyacrylic acid sodium salt and the surfactants are capable of weakening the surface tension of water. A method provided by the invention is used for solving the technical problems of poor stability and environmental pollution of a degreaser in the prior art. The invention provides the phosphorus-free degreaser which is high storage stability and does not contain harmful elements including heavy metals, phosphorus and the like.

Owner:武汉钢铁有限公司

Leather cleaning, nourishing and care cream and production method thereof

The invention discloses leather cleaning, nourishing and care cream, which comprises the following components in percentage by weight: 1 to 5 percent of molecular distilled monoglyceride, 1 to 5 percent of stearic acid, 8 to 15 percent of medical white vaseline, 1 to 5 percent of methyl phenyl polysiloxane, 2 to 6 percent of alcohol 16-18, 1 to 5 percent of coconut water oil-fatty acid-diethanol amide, 0.5 to 2.5 percent of lanolin, 0.2 to 1 percent of diazolidinyl urea, 0.2 to 1 percent of plant essence, 0.2 to 1 percent of aloe liquid, 0.5 to 3 percent of vegetable wax, 0.1 to 0.5 percent of natural zeolite, and 50 to 85 percent of deionized water. The invention also provides a production method for the cream. The cream integrates maintenance and care into a whole, is environment-friendly, has the properties of cleaning and polishing leather and resisting water, cracking, mildew and bacteria, is safe, healthy and natural, does not contain paraffin, is not greasy or sticky, keeps the natural color of the leather, is anti-fouling and clean, and is applied widely.

Owner:广州市美可生物科技有限公司

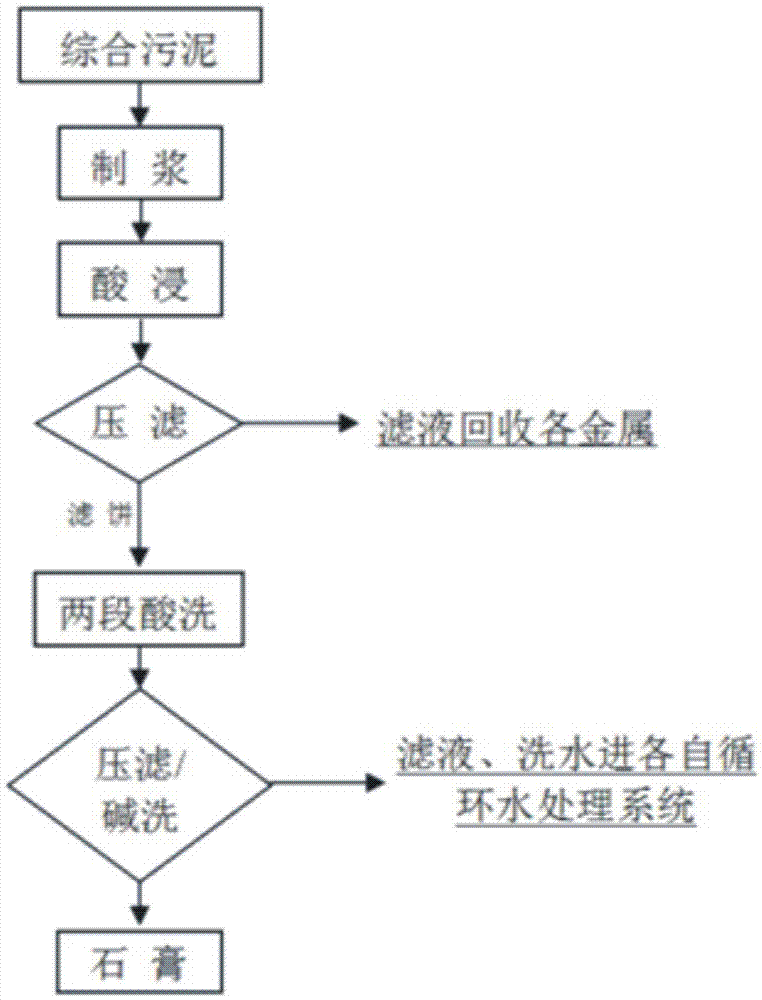

Method for treating tailings after extracting metal from electroplating sludge

The invention relates to the technical field of metal-containing hazard waste treatment and comprehensive utilization, and particularly relates to a method for treating tailings after extracting metal from electroplating sludge. The method comprises the following steps: pulping comprehensive sludge, adding sulfuric acid, and leading chromium, cadmium, copper, nickel, zinc and other heavy metals to enter a solution; extracting, performing filter pressing, and washing filter cake with water having a pH value of 0.5 until the washing water is colorless; and performing two-step pickling, press-filtering / alkali-washing and other steps to finally obtain gypsum of which the main ingredient is calcium sulfate dihydrate having dry basis content of more than 75 percent and accords with the requirement of GB / T5483-2008 (second grade), wherein the content of heavy metals including chromium, cadmium, copper, nickel and zinc is lower than the limit value of the national environmental quality standard for soil (third grade), the treated tailings can be directly used in cement manufacture instead of natural gypsum, and the preparation process cannot generate waste water or waste residue and is friendly to the environment.

Owner:青川县天运金属开发有限公司

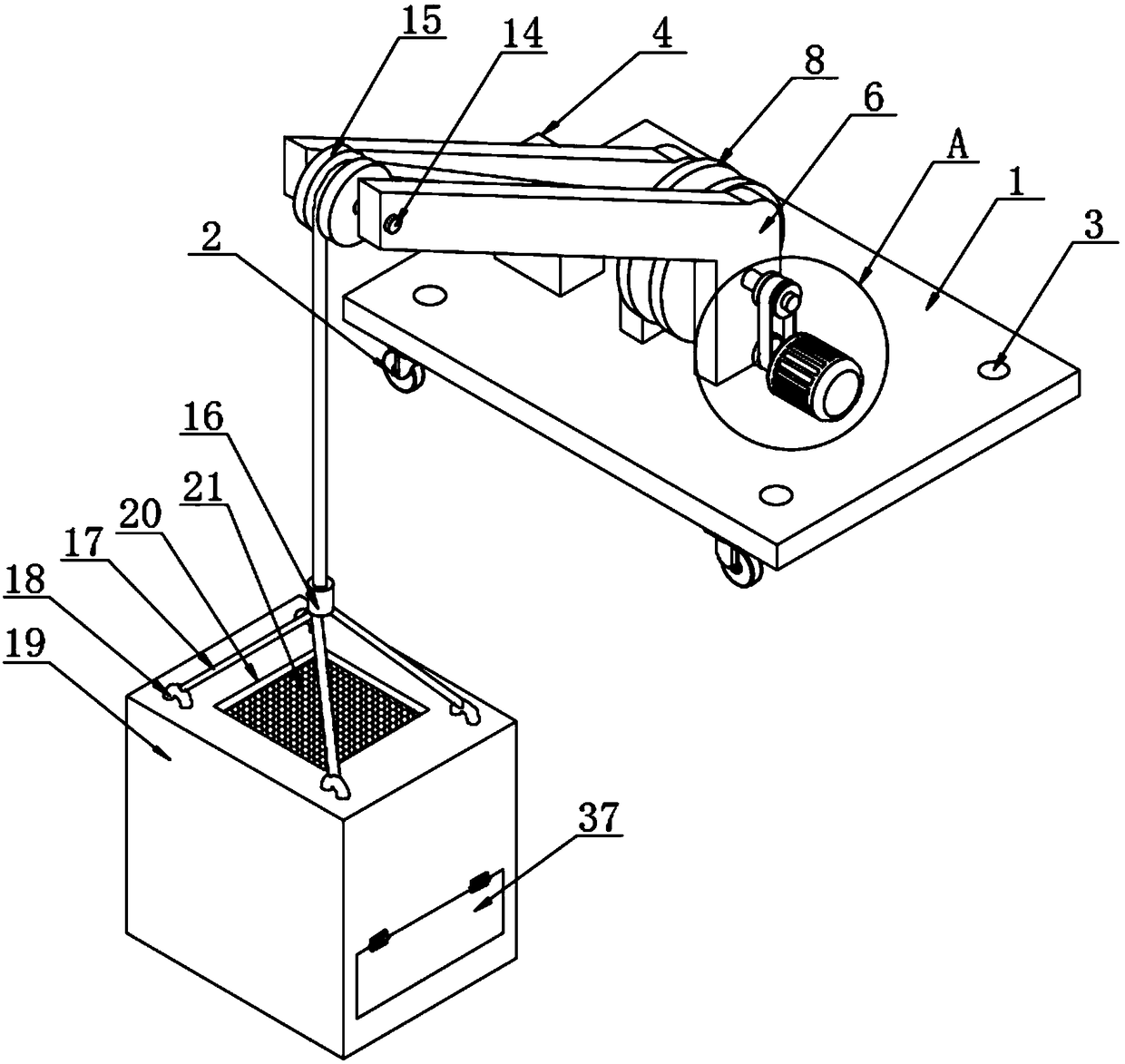

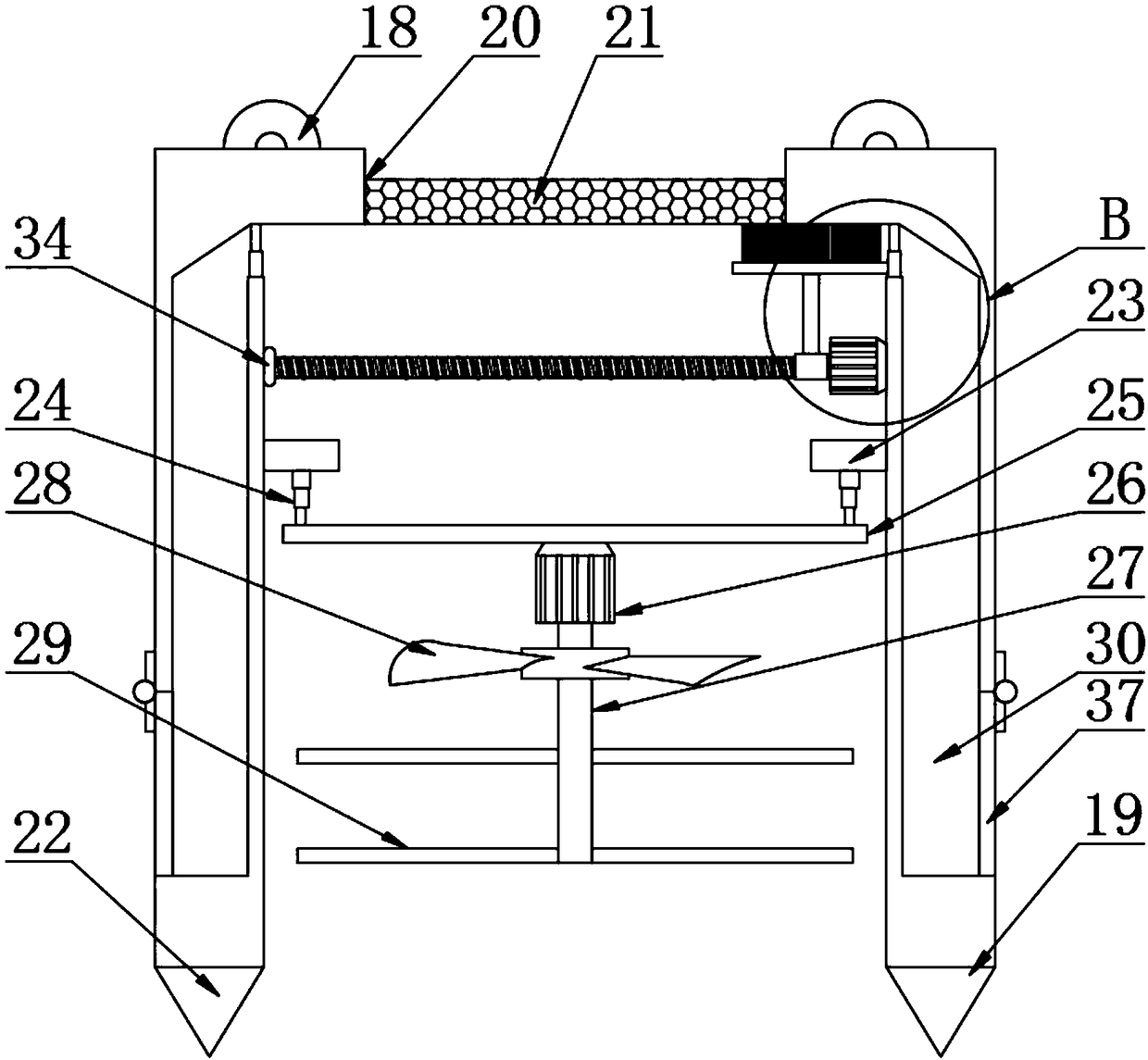

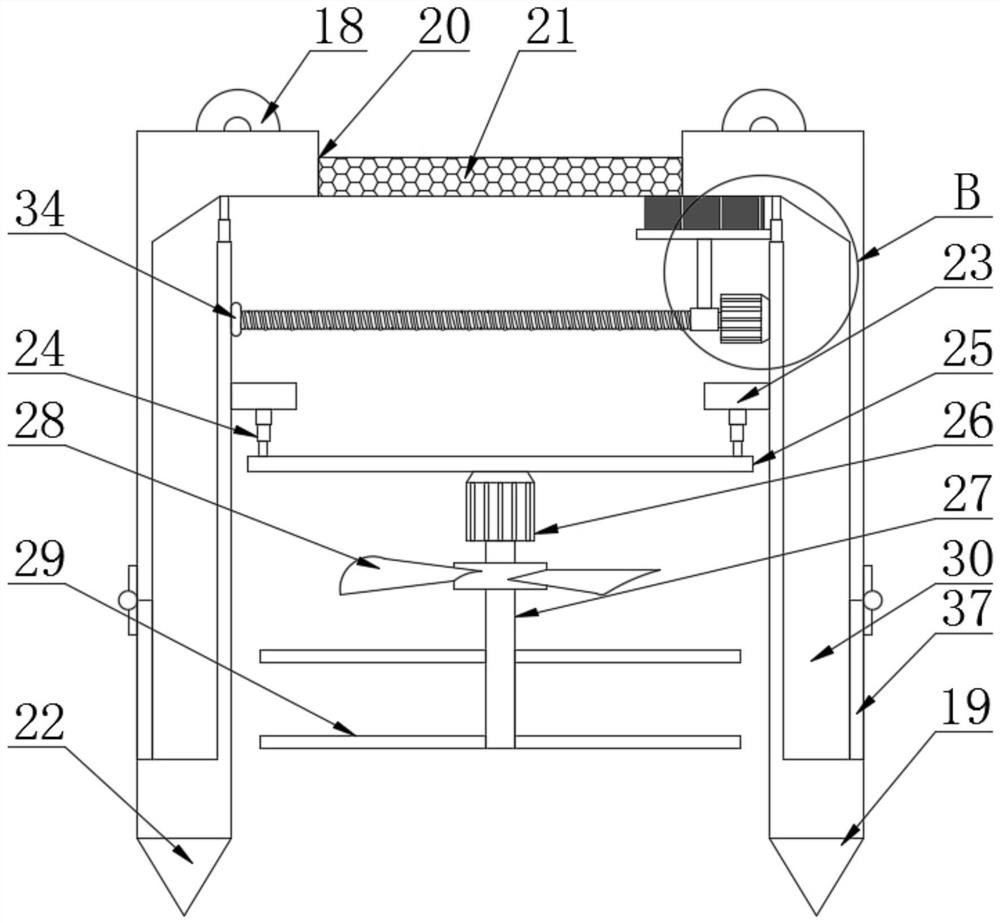

Dredging device for water environment treatment

ActiveCN108755814AScientific and reasonable structureEasy to useSoil-shifting machines/dredgersSludgeWater quality

The invention discloses a dredging device for water environment treatment. The dredging device comprises a dredging tank, a water through port, a filter net, collection tanks, electric valves, a cleaning motor, a lead screw, a connection bearing, a slide block and a cleaning brush; the water through port is formed in the top of the dredging tank; the filter net is installed inside the water through port; the collection tanks are correspondingly arranged on the two sides of the dredging tank; and the electric valves are installed on one sides of the collection tanks. The dredging device for water environment treatment is scientific and reasonable in structure and safe and convenient to use; when a muddy water mixture passes through the filter net, the filter net will allow water in the muddy water mixture to pass through, sludge and sundries are blocked, and the situation that the muddy water mixture flows into water flow and then water quality becomes poor is avoided conveniently; andthe cleaning brush sweeps the sludge and sundries filtered by the filter net into the collection tanks, and the sludge and sundries are conveniently prevented from precipitating in the river bottom after the water flow is static.

Owner:安徽中疆数字科技有限公司

Oral cleaning effervescent tablet with functions of diminishing inflammation and arresting bleeding and preparation method thereof

InactiveCN102440912ASignificant effectSmall side effectsCosmetic preparationsToilet preparationsSodium bicarbonatePeppermints

The invention discloses an oral cleaning effervescent tablet with functions of diminishing inflammation and arresting bleeding and a preparation method thereof. The effervescent tablet is prepared from the following components in certain parts by weight: aloe leaf, ginkgo, ginkgo leaf, peppermint leaf, honeysuckle flower, wild chrysanthemum flower, lemon essential oil, peppermint essential oil, rosemary essential oil, clove seed essential oil, eucalyptus leaf essential oil, tea tree essential oil, sodium bicarbonate, citric acid, sodium dodecylsulfate, calcium sulfate, adhesive, sweetening agent and sodium stearate. The invention uses a simple method to prepare the oral cleaning effervescent tablet with functions of diminishing inflammation and arresting bleeding, thereby satisfying the increasingly high requirements of people for oral sanitation; a surfactant and a friction producing material are used, so that the oral cleaning effervescent tablet has favorable dirt-removing power; effective pharmaceutical components are introduced to treat and prevent oral inflammation; the oral cleaning effervescent tablet has the advantages of stable properties and outstanding effect; and the test and clinical application prove that the oral cleaning effervescent tablet has obviously curative effect on preventing and treating oral inflammation.

Owner:董根荣

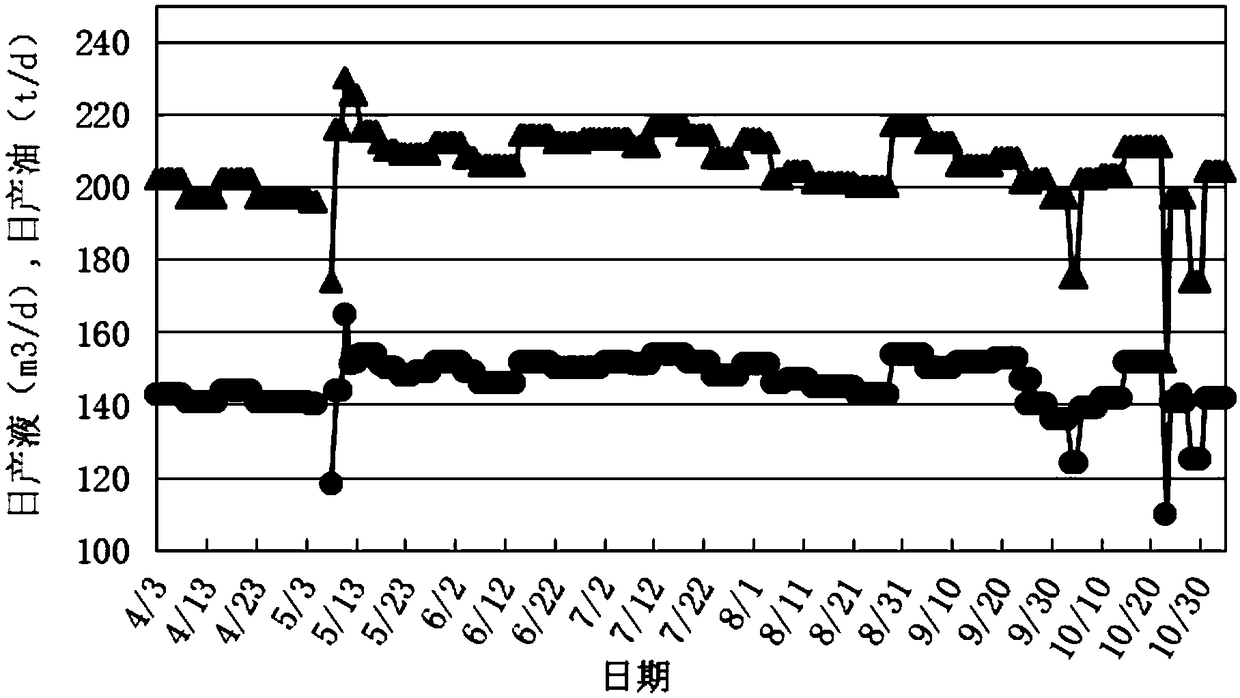

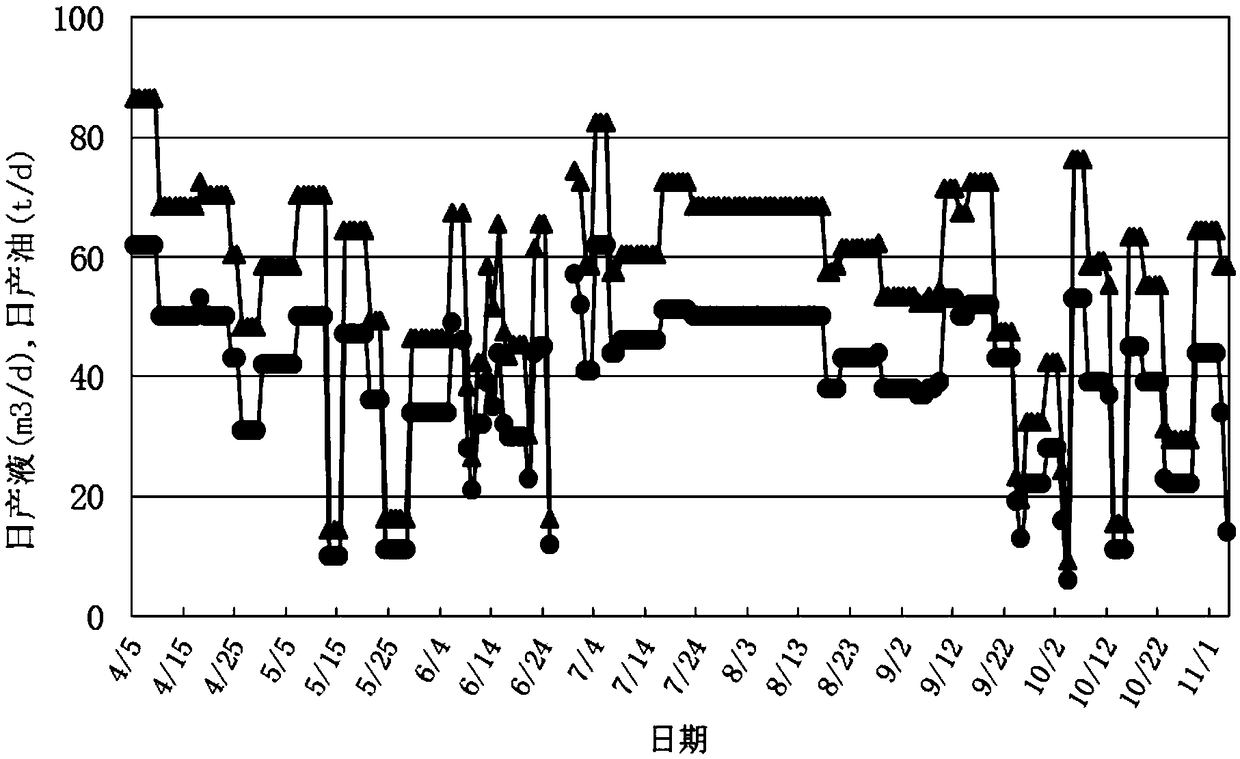

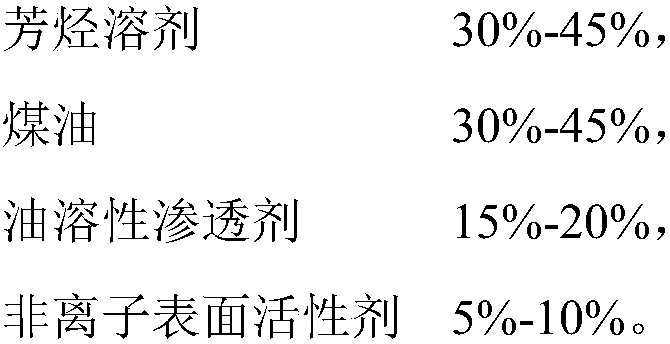

Oil well de-blocking agent as well as preparation method and application thereof

ActiveCN108690589AGood securitySimple preparation processCleaning apparatusDrilling compositionKeroseneChemistry

The invention provides an oil well de-blocking agent as well as a preparation method and application thereof. The oil well de-blocking agent is prepared from the following ingredients through being metered by regarding the total weight of the de-blocking agent as 100 percent: 30 to 45 percent of aromatics solvents, 30 to 45 percent of kerosene, 15 to 20 percent of oil soluble penetrating agents and 5 to 10 percent of nonionic surfactants. Compared with the existing oil well de-blocking agent, the oil well de-blocking agent has the advantages that the open flash point can reach a value being 50DEG C or above; the safety is high; the preparation process is simple; the de-blocking efficiency on asphaltene and colloidal sediments is high; the solution after the de-blocking does not need to bedischarged out and can directly enter a ground surface manifold system; safety and environment protection are realized; the de-blocking agent is applicable to the oil well and near-well zone blockingmaterial de-blocking in the oil well mining process.

Owner:PETROCHINA CO LTD

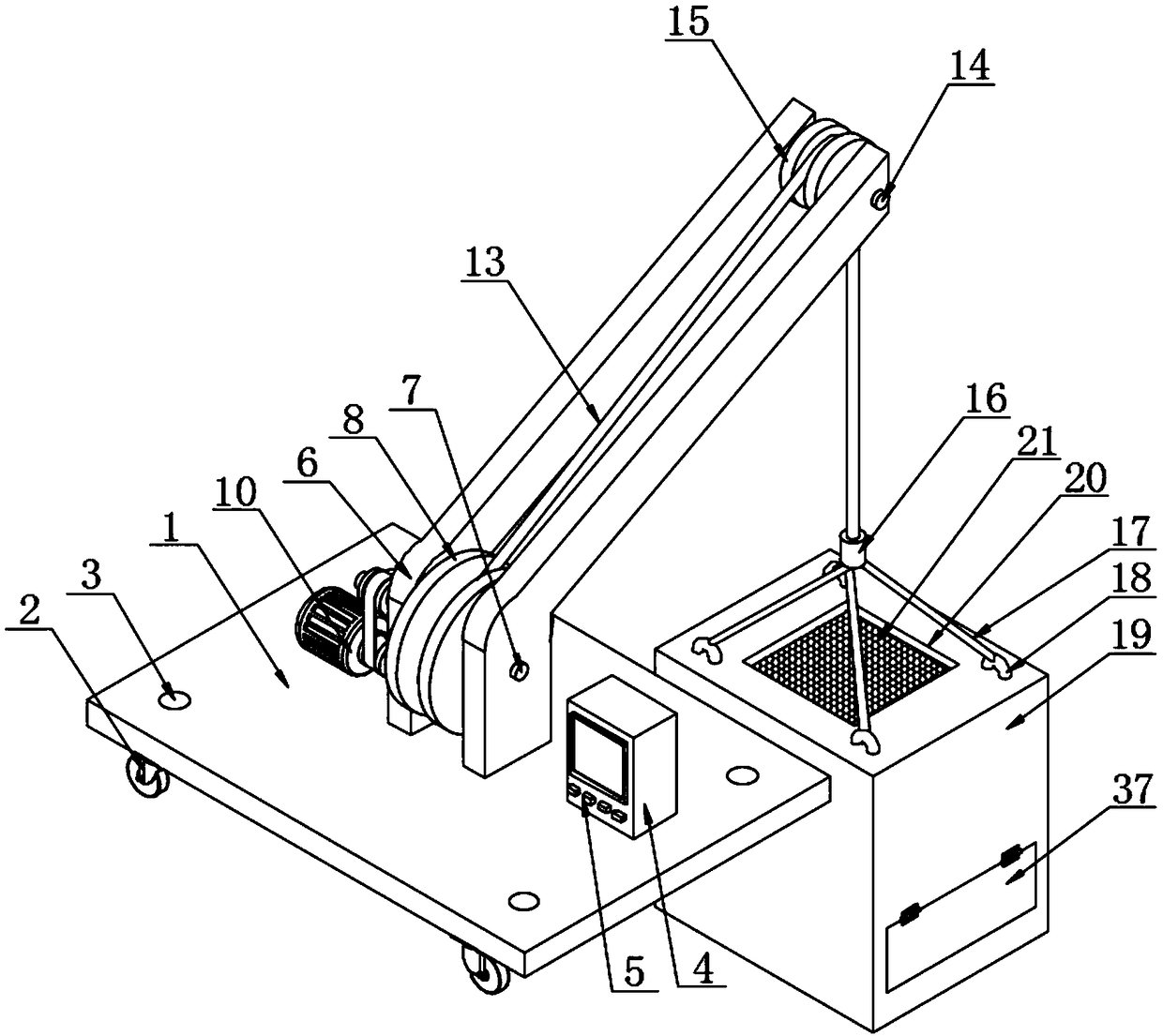

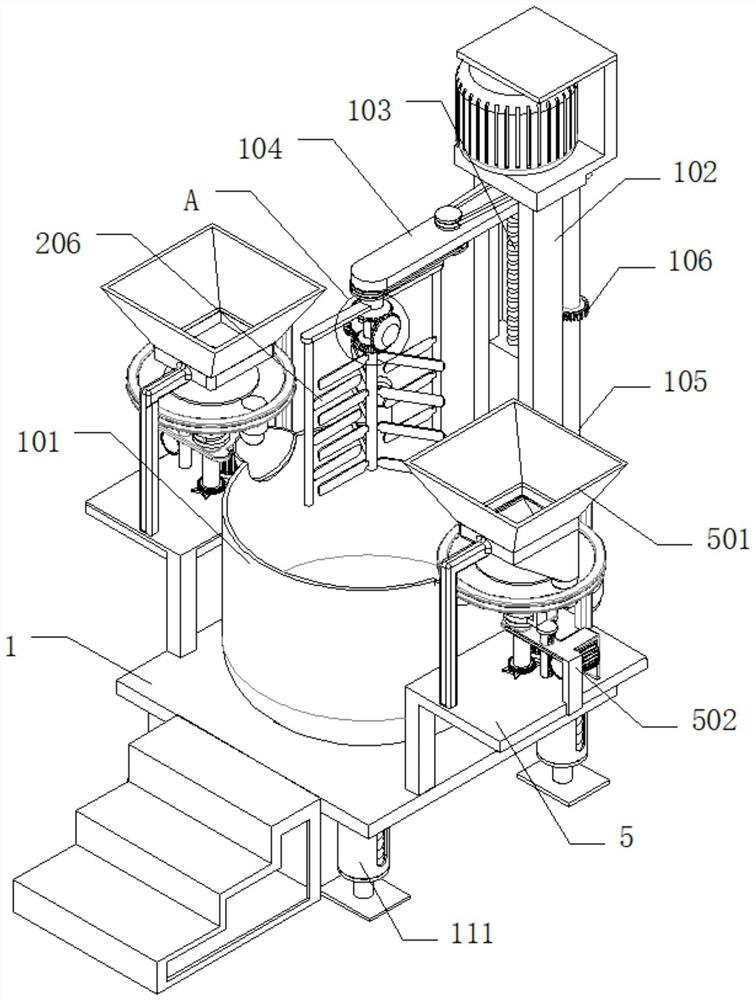

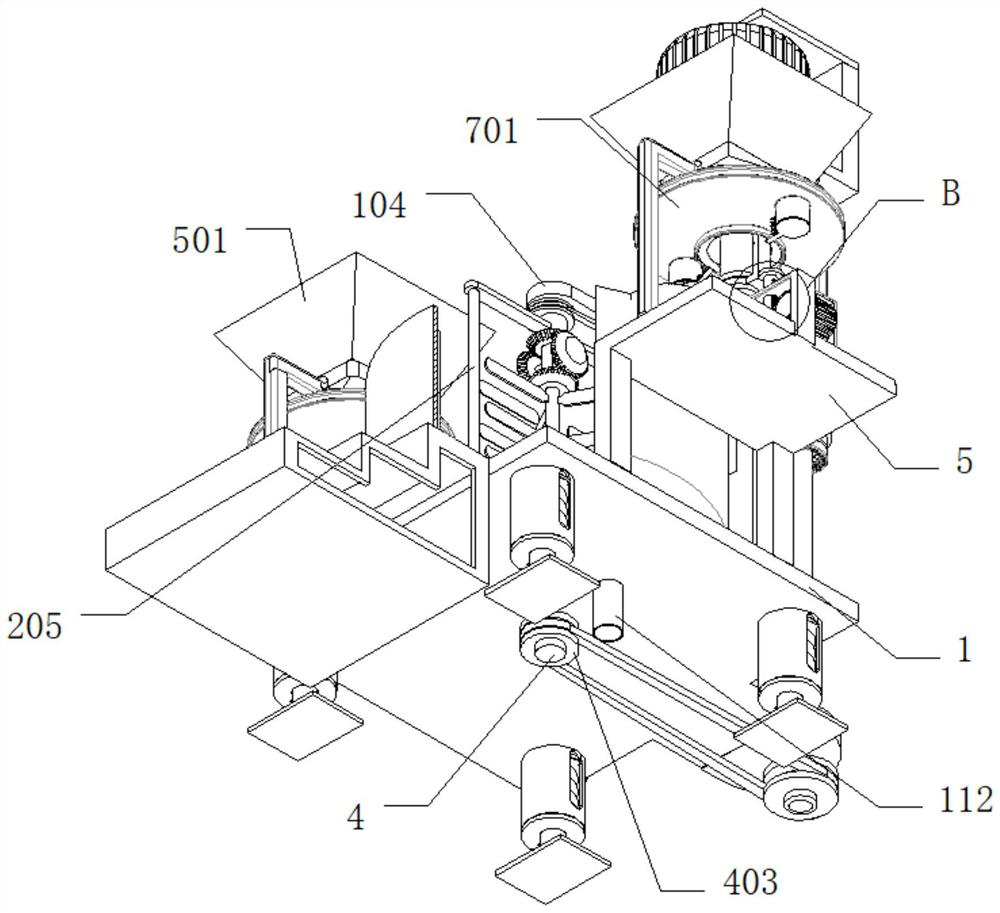

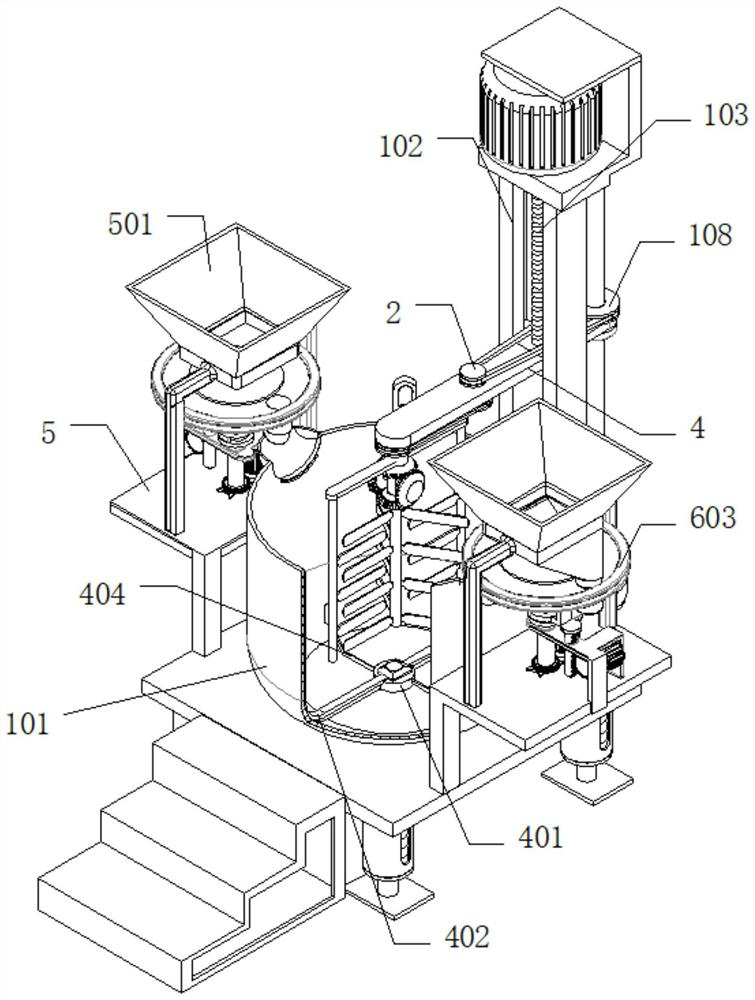

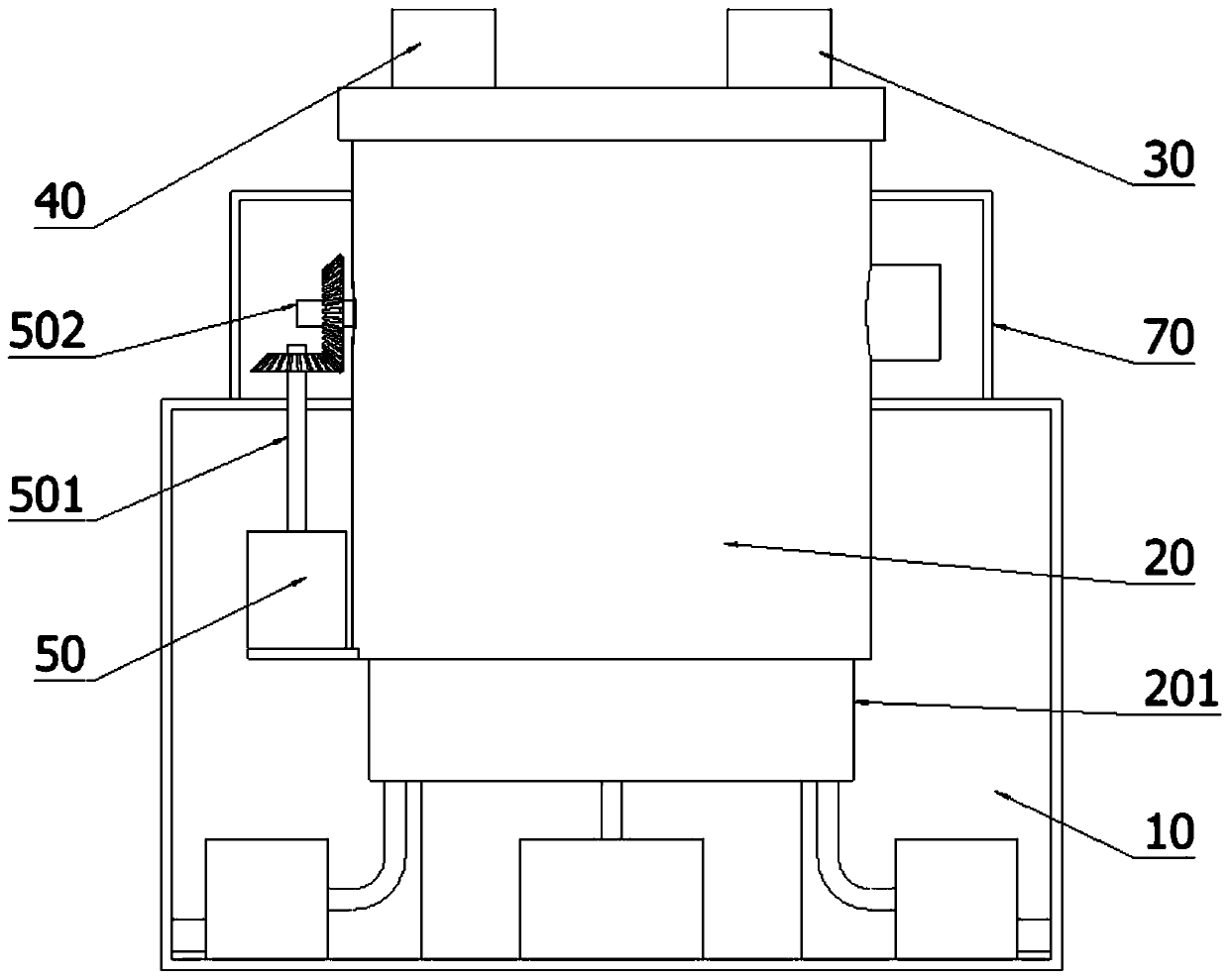

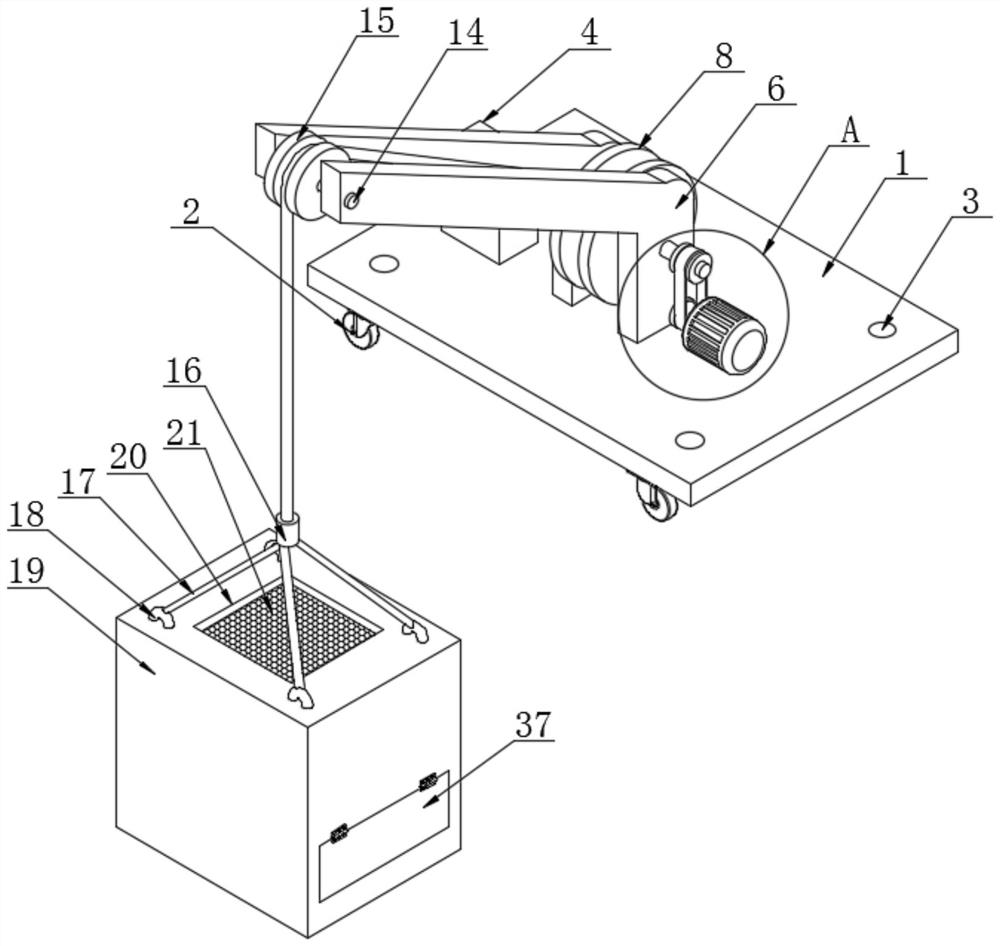

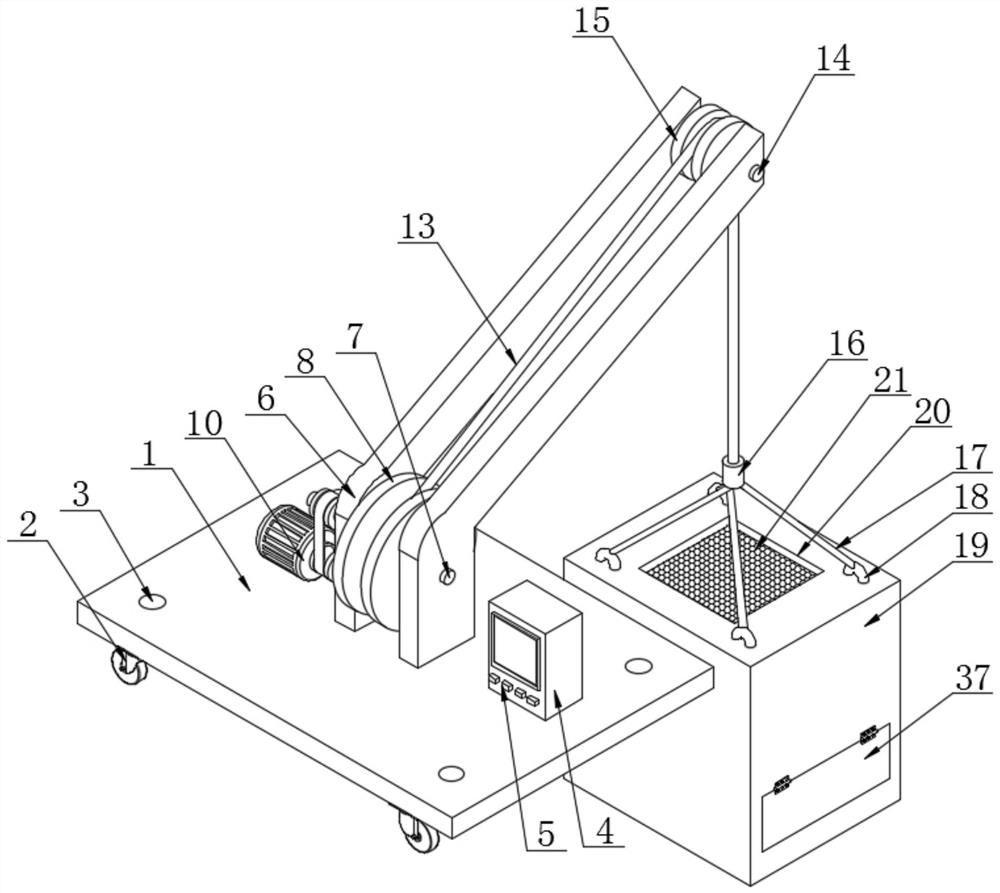

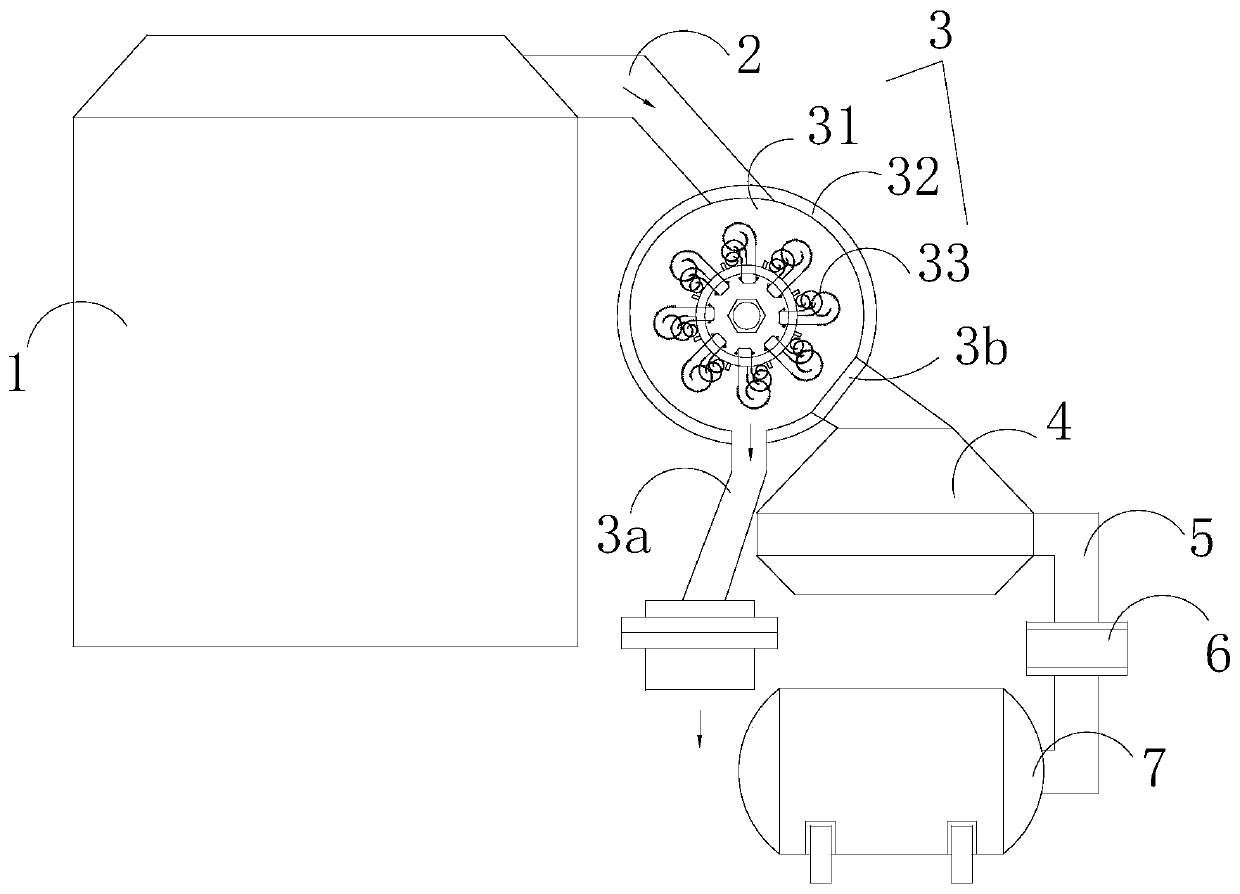

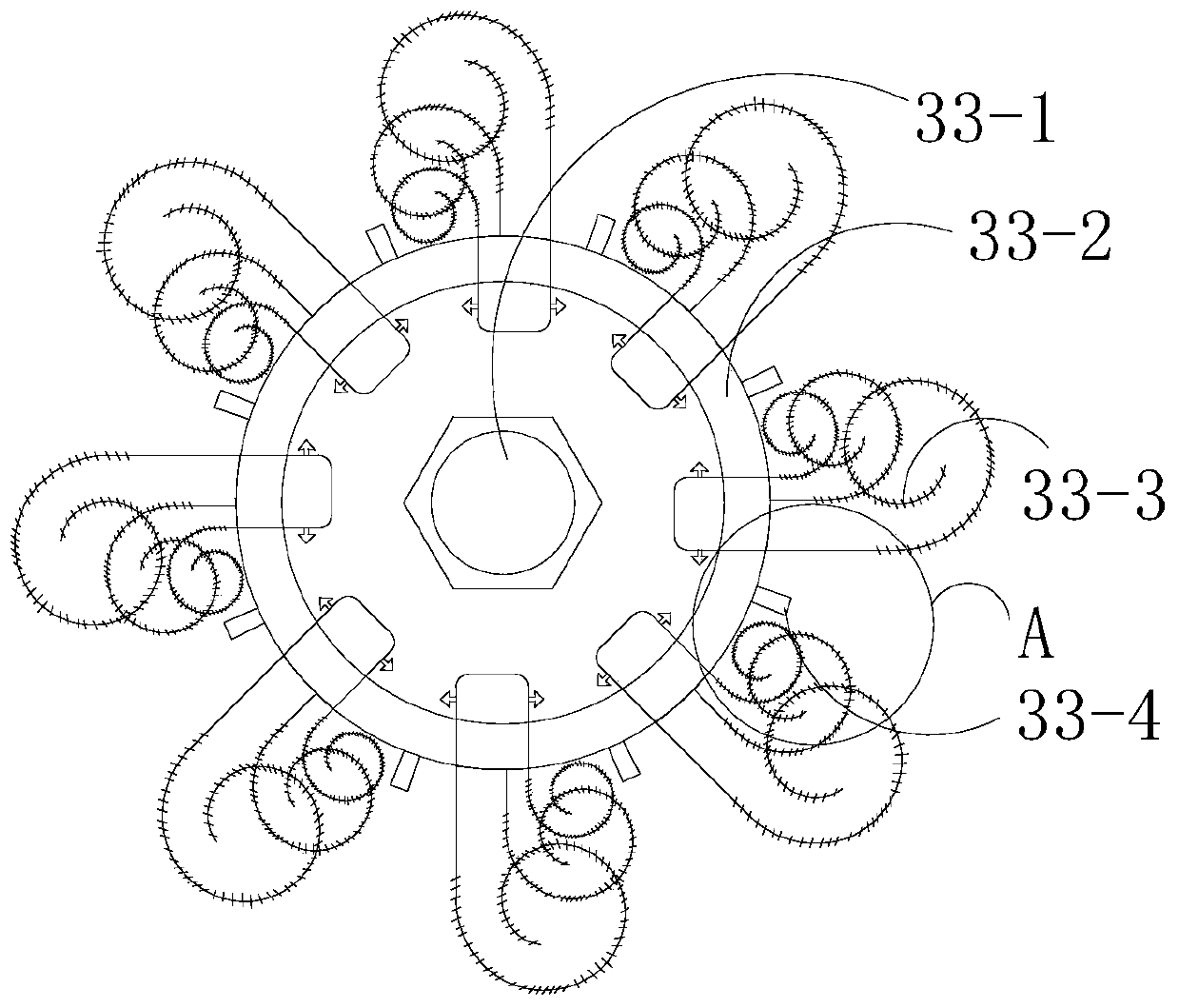

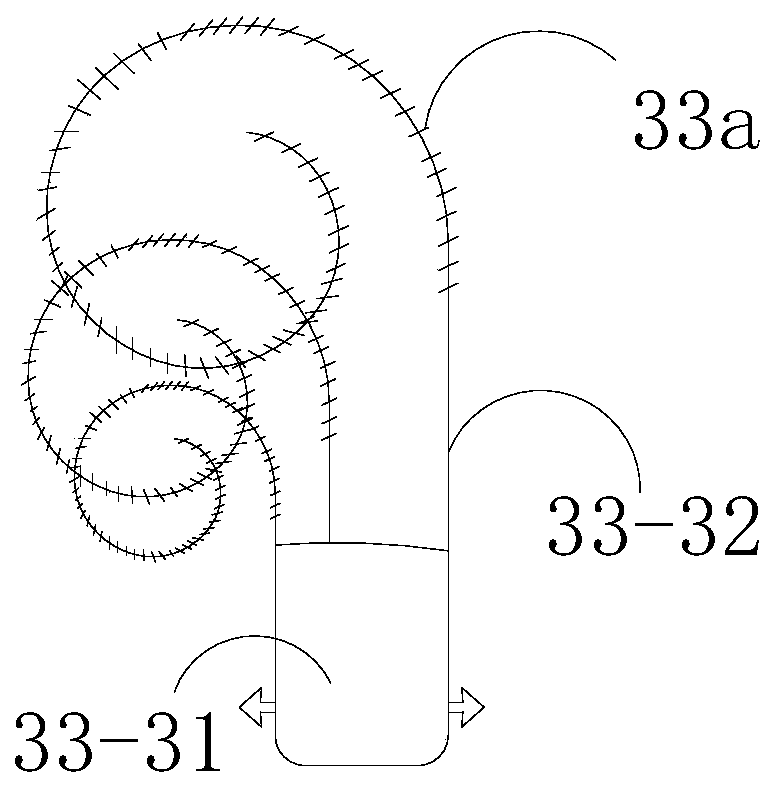

Raw material blending treatment device for cosmetic production and processing and using method thereof

InactiveCN112957945APrevent re-precipitationAvoid residueTransportation and packagingRotary stirring mixersElectric machineryIndustrial engineering

The invention discloses a raw material blending treatment device for cosmetic production and processing, and belongs to the field of cosmetics. A raw material blending treatment device for cosmetic production and processing comprises a bottom plate, a stirring tank is fixedly connected to the top wall of the bottom plate, a lifting frame is further fixedly connected to the top wall of the bottom plate, a lead screw is rotatably connected to the lifting frame, the top end of the lead screw is fixedly connected with the output end of a first driving motor, the lifting frame is slidably connected with a lifting plate, a first rotating shaft is further rotatably connected to the top wall of the bottom plate, the first rotating shaft is slidably connected with the lifting plate, the top wall of the lifting plate is rotatably connected with a first sleeve, the top of the first sleeve is fixedly connected with a first belt wheel, the other end of the first sleeve is fixedly connected with a gear ring, a second stirring device is arranged on the bottom wall of the bottom plate, and the top wall of the bottom plate is further fixedly connected with feeding devices which are symmetrically arranged about the stirring tank. The stirring is uniform, the interior of the stirring tank can be easily cleaned for use at next time, manual feeding is not needed, the automation degree is high, manpower is saved, and the working efficiency is improved.

Owner:付婷

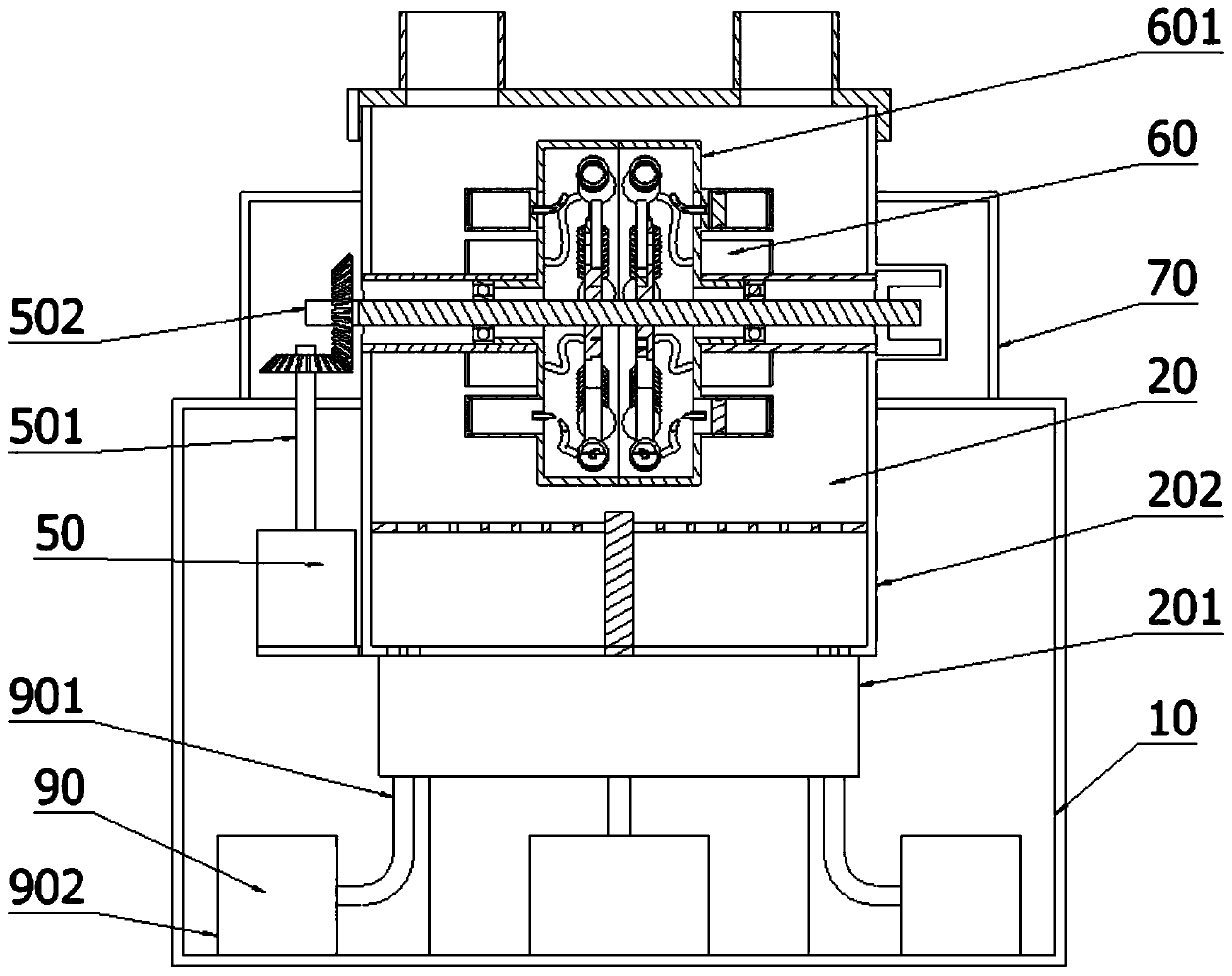

Neodymium iron boron waste material screening device and using method

The invention discloses a neodymium iron boron waste material screening device, and relates to the technical field of neodymium iron boron processing. The screening device comprises a base body, a placing part, a protective cover, a rotating part and a control part, wherein a containing space is formed in the base body; the placing part is connected with the base body, and the placing part comprises a connecting body arranged inside the base body; the protective cover is arranged above the base body, and the protective cover and the placing part have same axis; the rotating part is arranged inside the placing part, and the rotating part comprises a rotating shell arranged inside the placing part; and the control part is arranged on one side of the placing part, and the control part comprises a driven shaft, wherein the driven shaft is fixedly connected with the connecting body, the driven shaft penetrates through the rotating part, and the driven shaft and the rotating part have same axis. According to the neodymium iron boron waste material screening device, when being subjected to recovery treatment, a neodymium iron boron waste material is cleaned and screened first, so that theeffect of the treatment process is ensured; and meanwhile, impurities in the cleaned neodymium iron boron waste material are reduced, so that the workload during recovery treatment is reduced.

Owner:XINFENG BAOGANG XINLI RARE EARTH

Method for removing titanium based coating film or oxidew of titanium

InactiveCN1507504APrevent precipitationPrevent re-precipitationManufacturing toolsHoneycombTitanium ion

There are here disclosed a method for removing a titanium-based film from a honeycomb-molding die having on the surface of a base material coated with the titanium-based film, and a method for removing an oxide of titanium from a honeycomb-molding die having the oxide of titanium adhered / deposited on the surface of a base material. In each method, a removing solution comprising a mixture of an acid and hydrogen peroxide is used. According to the methods for removing the titanium-based film and the oxide of titanium, a large amount of the titanium-based film as well as the oxide of titanium adhered / deposited on the base material of a honeycomb-molding die can be removed by use of a small amount of the removing solution without corroding the base material of honeycomb-molding die while re-deposition of dissolved titanium ions on the base material is prevented.

Owner:NGK INSULATORS LTD

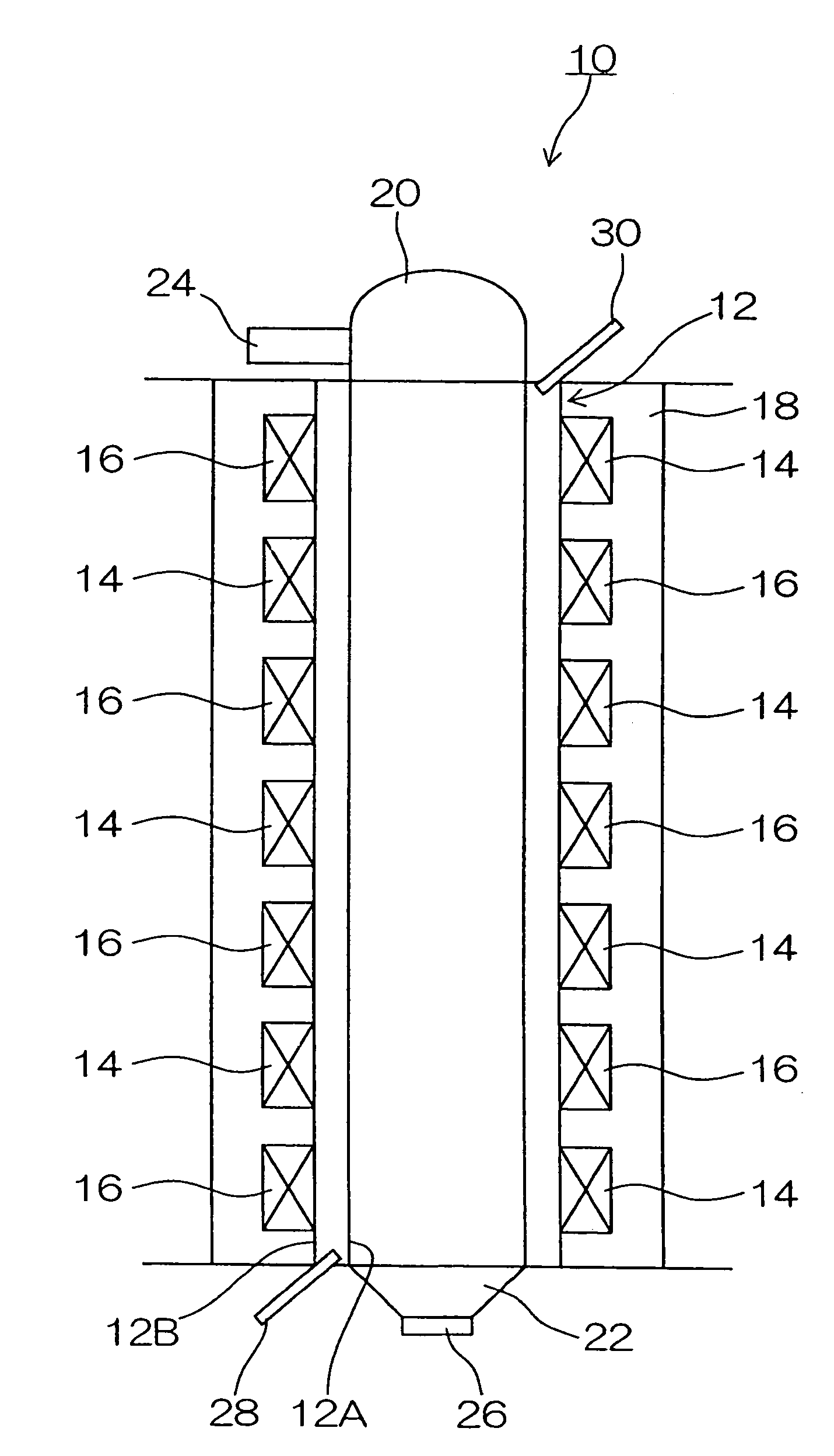

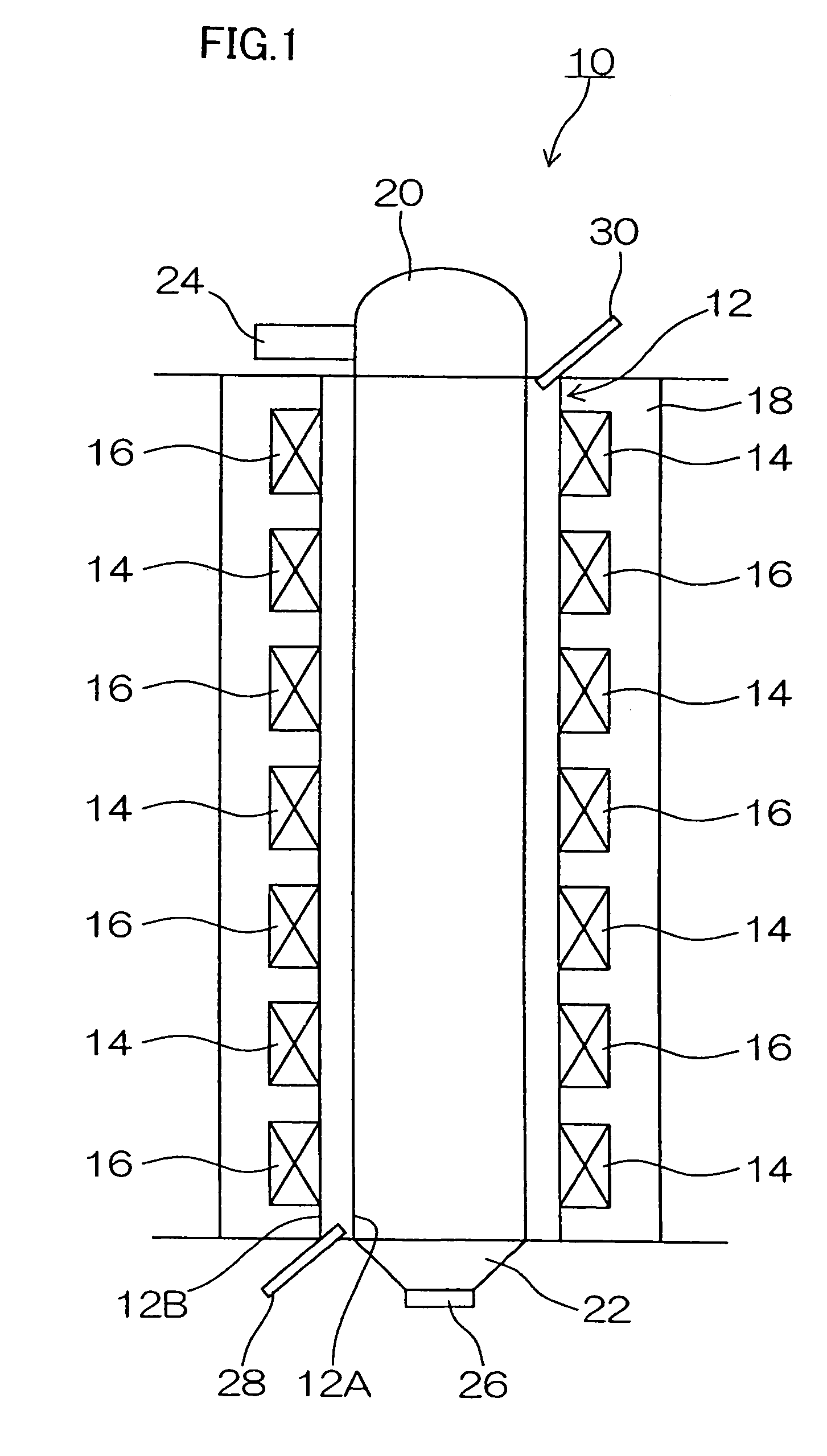

Method and apparatus for degassing coating liquid

ActiveUS7294171B2Preventing bubble defectsEfficient removalPretreated surfacesPhotothermographic systemsMaterials scienceFrequency band

Owner:FUJIFILM CORP +1

Environment-friendly degreasant for automobile coating and application method of environment-friendly degreasant

The invention discloses environment-friendly degreasant for automobile coating and an application method of the environment-friendly degreasant. The environment-friendly degreasant comprises alkaline matter, an auxiliary cleaning agent, a chelating agent, surfactant and 34%-77% of deionized water. The alkaline matter comprises, by weight, 5%-20% of sodium hydroxide and 10%-25% of potassium hydroxide. The auxiliary cleaning agent comprises, by weight, 1%-3% of sodium carbonate. The chelating agent comprises, by weight, 2%-5% of sodium citrate and 3%-6% of sodium diethylenetriamine pentaacetic acid. The surfactant comprises, by weight, 1%-3% of ester anionic surfactant and 1%-4% of fatty alcohol-polyoxyethylene ether. The environment-friendly degreasant for automobile coating is non-phosphorus alkaline environment-friendly degreasant without phosphorus or nitrogen, has the same degreasing performance with original phosphorus containing alkaline degreasant, and solves the technical problems that in the prior art, due to the fact that phosphorus containing matter exists in the alkaline degreasant, certain difficulty is caused to following process wastewater treatment, and emission and following treatment cost of pollutants are increased.

Owner:武汉钢铁有限公司

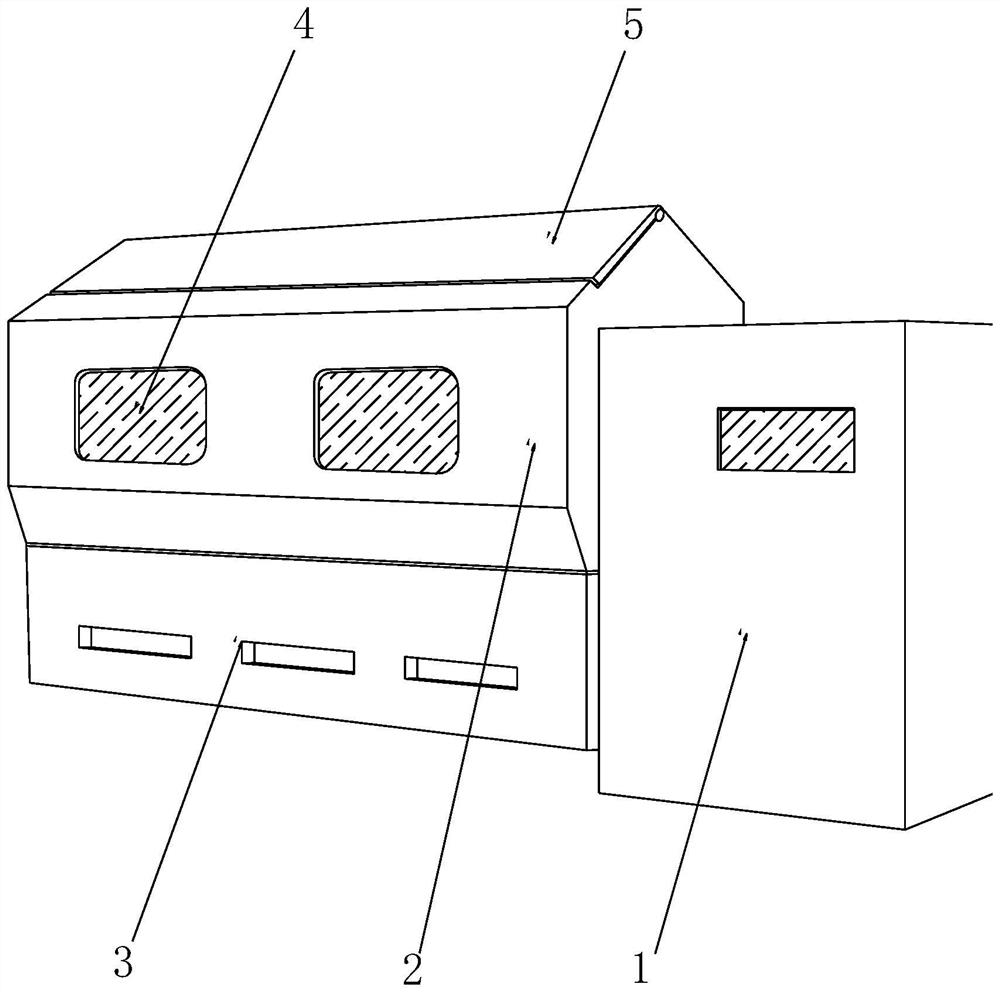

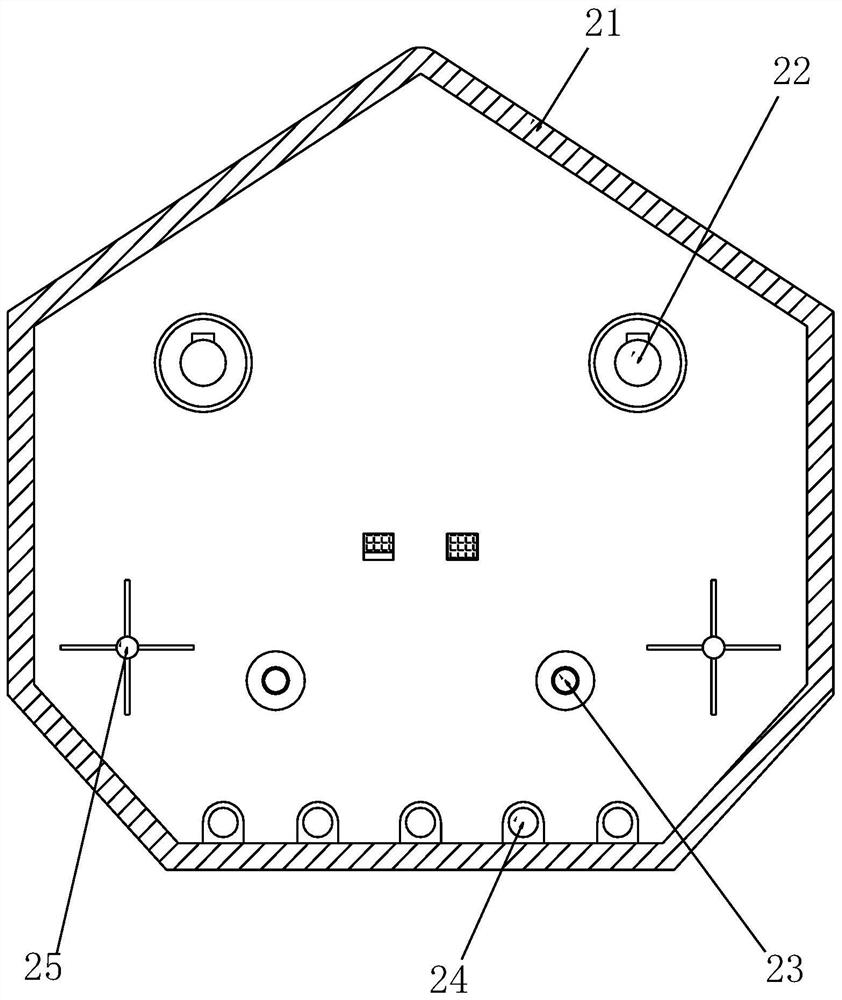

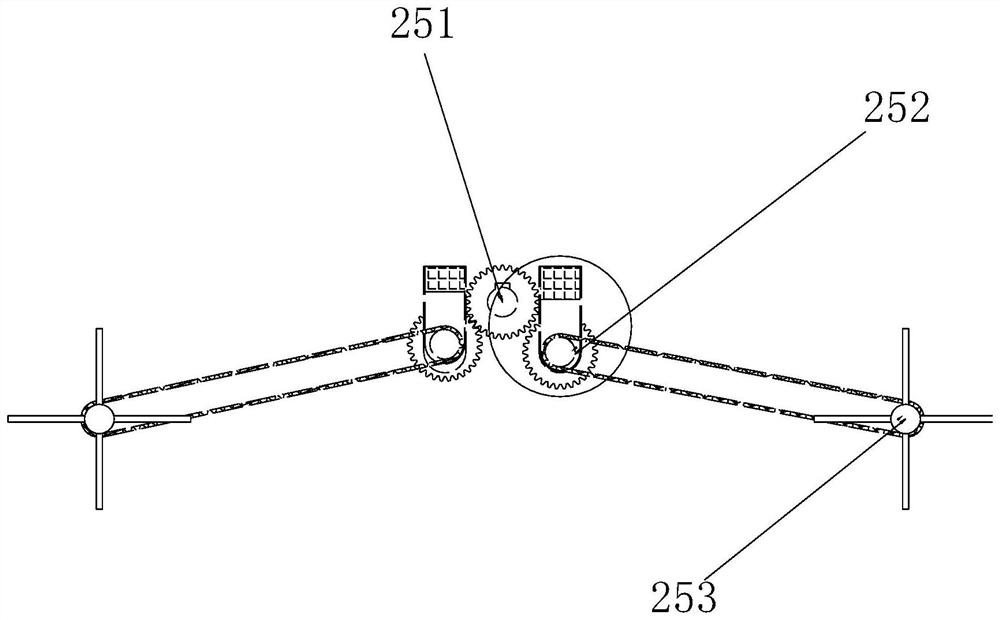

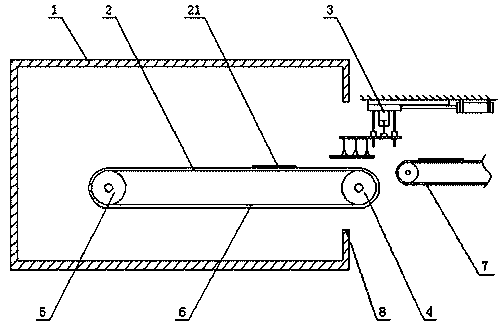

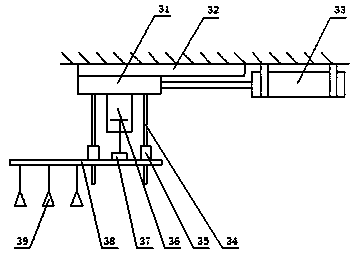

Dip dyeing equipment for bamboo charcoal fiber fabric

PendingCN112981783AAvoid temperature differencesPrevent re-precipitationLiquid/gas/vapor treatment machines driving mechanismsTextile treatment containersProcess engineeringDyeing

The invention discloses dip dyeing equipment for a bamboo charcoal fiber fabric. The dip dyeing equipment structurally comprises a control box, a dip dyeing bin, a bottom frame, an observation window and a bin cover, the left end of the control box is installed at the right end of the dip dyeing bin, a motor is arranged in the control box, the upper end of the bottom frame is welded to the lower end of the dip dyeing bin, the observation window is connected to the front face of the dip dyeing bin through a flange, and the bin cover is connected to the upper part of the dip dyeing bin through a hinge. According to the dip dyeing bin, when a heater just starts to operate, before the dye is raised to the coloring temperature, or when the temperatures of the upper part and the lower part of liquid in a dip dyeing cylinder are not consistent, the dye in the dip dyeing bin can be continuously stirred, and the situation that color lakes and color spots are generated on the surface of the fabric due to the fact that the dissolved dye precipitates and cakes again is prevented. By means of a water scooping barrel, more high-temperature steam can be generated in the dip dyeing bin, the temperature above liquid and the temperature below the liquid can be rapidly balanced, the temperature difference is effectively prevented, and the situation that the dyed bamboo charcoal fiber fabric finished product is unqualified due to the fact that the fabric has multiple color differences is avoided.

Owner:向敏

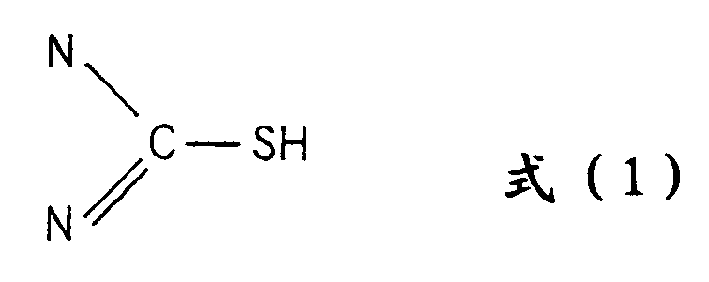

Resist removing agent

InactiveCN1533516APrevent re-precipitationSemiconductor/solid-state device manufacturingPhotosensitive material processingResistCopper

The resist removing agent is prepared as an alkali aqueous solution containing at least a heterocyclic compound having the structure expressed by formula (1) in the molecule as an additive. The solution prevents re-crystallization of tin on copper caused by copper ions dissolving in the resist removing agent.

Owner:MELTEX

Long-acting toilet cleaning block and preparation method thereof

InactiveCN113583759AHigh mechanical strengthSlow release rateInorganic/elemental detergent compounding agentsSurface-active detergent compositionsCelluloseCHITOSAN PCA

The invention discloses a long-acting toilet cleaning block, which comprises 10-15 parts of carboxymethyl cellulose, 10-15 parts of sodium alginate, 5-8 parts of hydroxyethyl cellulose ether, 6-11 parts of modified starch, 4-8 parts of chitosan particles, 3-5 parts of ethanol, 10-15 parts of anhydrous sodium sulphate, 5-10 parts of sodium dodecyl benzene sulfonate, 3-5 parts of pigment, 1-3 parts of essence and 1-3 parts of chitosan, and also discloses a preparation method of the long-acting toilet cleaning block. The invention relates to the technical field of toilet cleaning agents, and particularly provides the long-acting toilet cleaning block and the preparation method thereof. The carboxymethyl cellulose and sodium alginate serve as framework materials, the mechanical strength of the toilet cleaning block is effectively improved, and the release speed of active ingredients of the toilet cleaning block is slowed down; the modified starch is added, so that the slow-release, long-acting and biological deodorization bacterium carrier effects are achieved, the ethanol is added, so that the dirt can be effectively prevented from being re-precipitated, and the chitosan has a deodorization effect.

Owner:WEIFANG VOCATIONAL COLLEGE

Flexible treatment liquid and method for treating pull ring material by using same

ActiveCN109183053AOvercome the problem of high toxicity of traditional hexavalent chromium passivationImprove corrosion resistanceAnodisationMetallic material coating processesOrganic filmSilanes

The invention discloses a flexible treatment liquid and a method for treating a pull ring material by using the same. The flexible treatment liquid comprises the following raw materials of magnesium fluoride, sodium tripolyphosphate, hexafluorozirconic acid, sodium fluorosilicate, hydrochloric acid, nitric acid, phosphoric acid, vinyl triethoxy silane, sulfuric acid, calcium nitrate, water, dialkyl peroxide, bicarbonate peroxide, propyl epoxy acrylate, nano silicon dioxide and aluminum oxide. Through reasonable proportioning, the flexible treatment liquid can solve the problems that in a traditional process, hexavalent chromium passivation is large in toxicity, and the chromium-free passivation is low in toxicity but the corrosion resistance is poor, meanwhile, the problems that the treatment of liquid medicine used when an organic film is coated on the surface of an inorganic film in a composite passivation process is complex, and the adhesive force is poor are solved, good corrosionresistance and fingerprint resistance are achieved, the effects of being strong in adhesive force, safe, non-toxic and simple in process are achieved, and therefore, the flexible treatment liquid is suitable for industrial production.

Owner:山东龙口三元铝材有限公司 +1

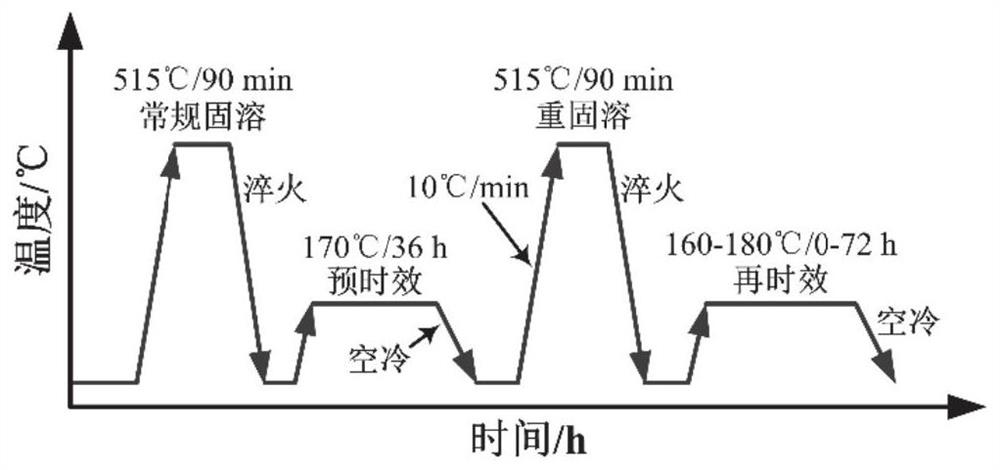

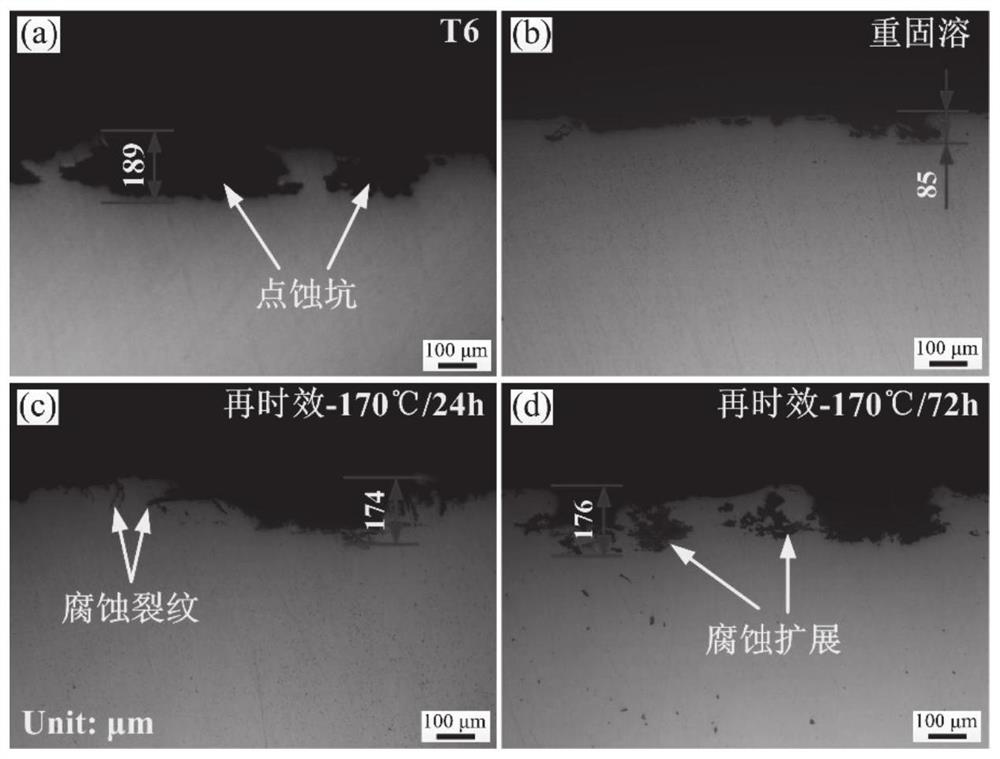

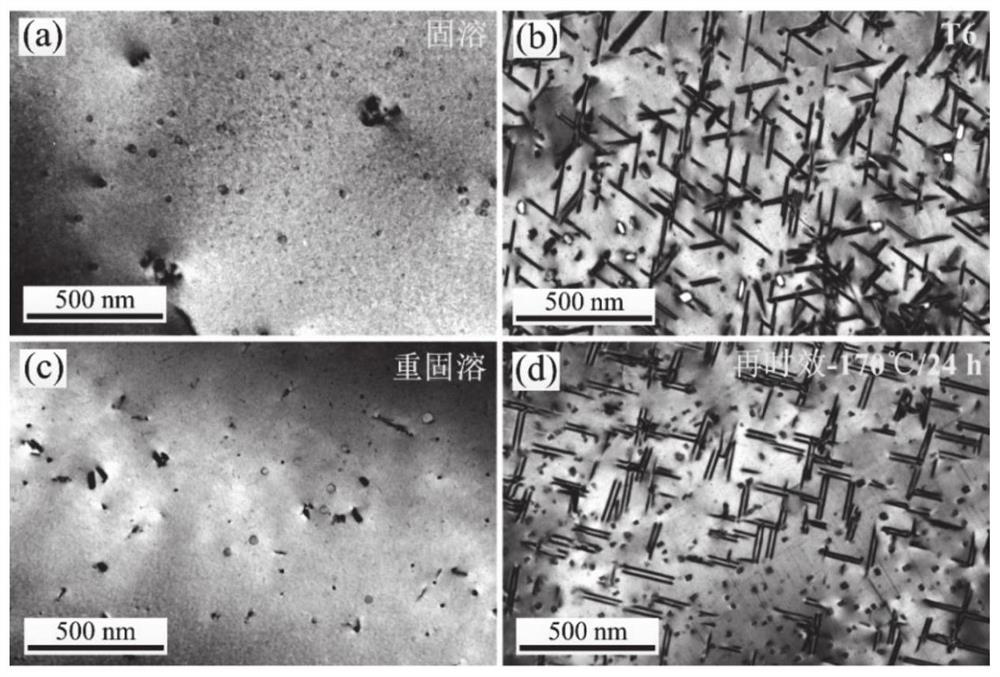

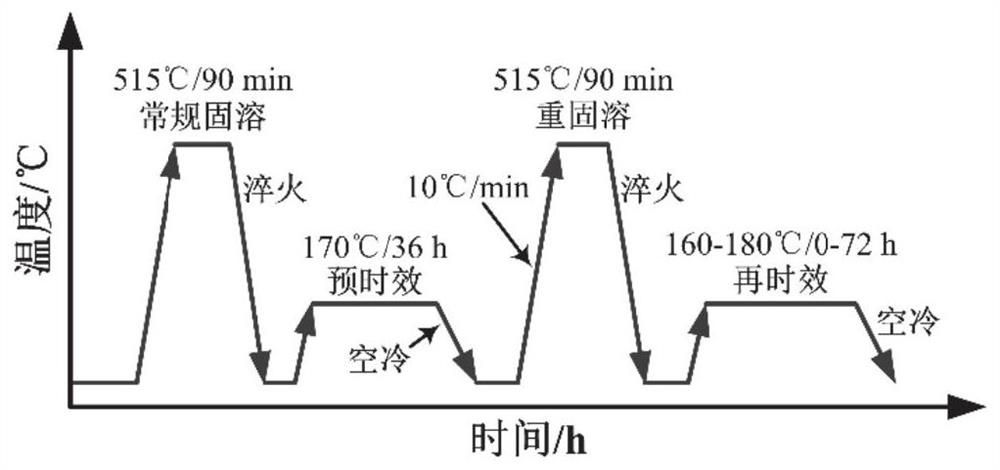

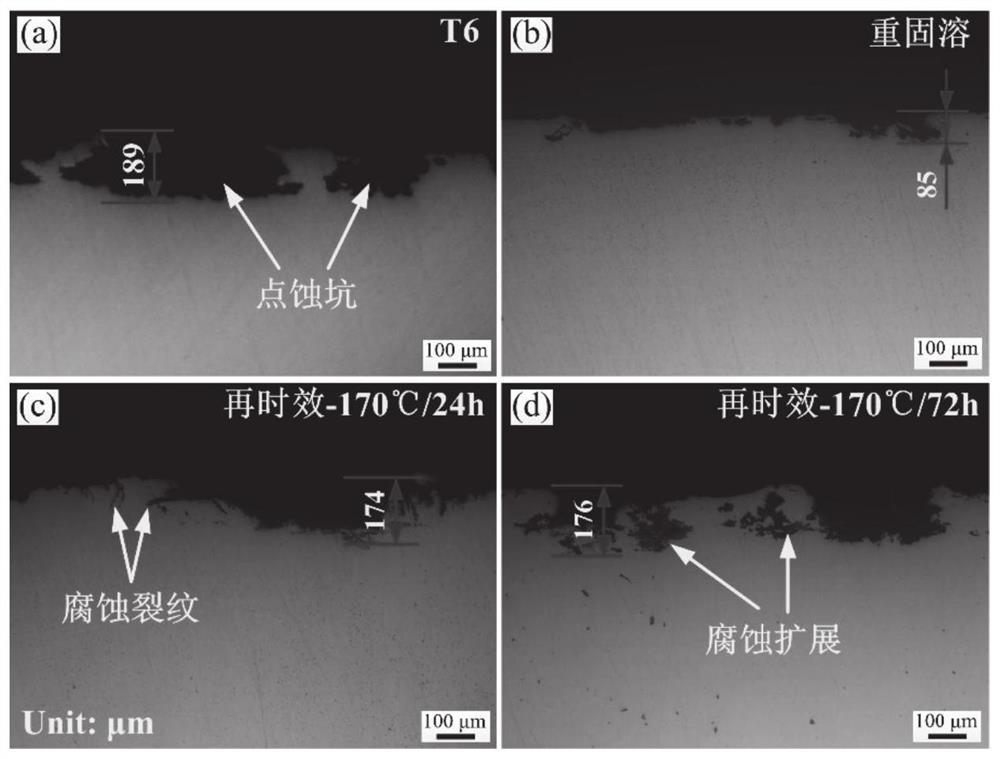

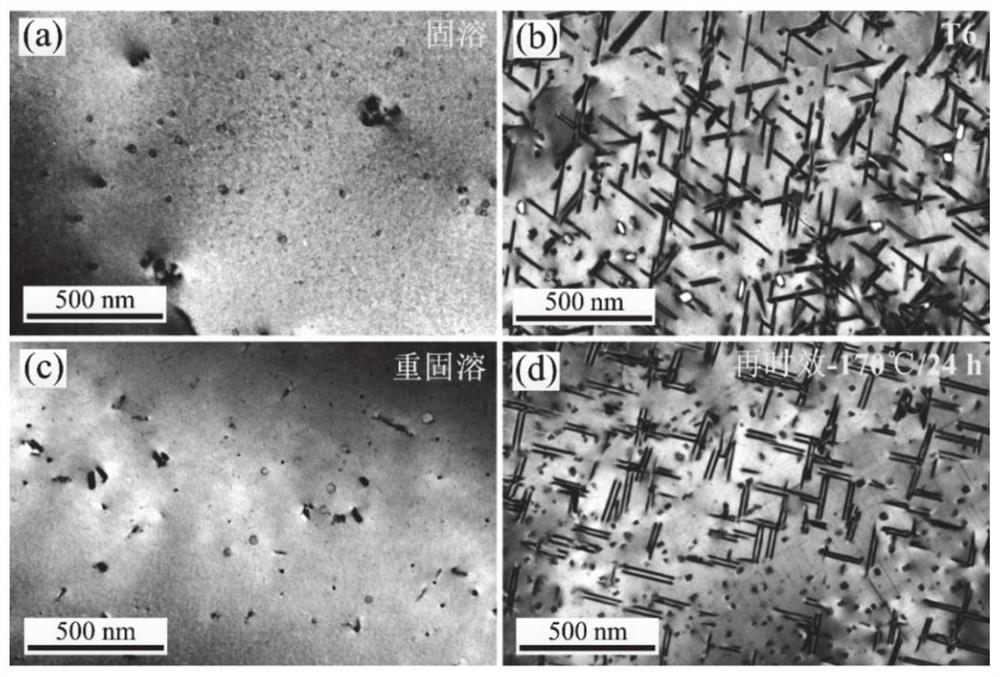

Heat treatment method for pre-aging, re-solid-solution and re-aging of Al-Cu-Li alloy

ActiveCN112281092AReduce the effect of strengtheningHigh strengthSolution treatmentHeat conservation

The invention discloses a heat treatment method for pre-aging, re-solid-solution and re-aging of an Al-Cu-Li alloy, belongs to the field of material heat treatment, and aims to perform conventional solid-solution, pre-aging, re-solid-solution and re-aging treatment on an Al-Cu-Li alloy extruded plate by controlling a heat treatment process system and parameters thereof. The conventional solid solution and re-solid solution treatment temperature is 515 + / -10 DEG C, heat preservation is performed for 60-90 min, then water quenching is performed, and the quenching transfer time is shorter than 5s. The pre-aging and re-aging treatment temperature is 160-180 DEG C, heat preservation is performed for 24-48 hours, and the product is taken out for air-cooling. The strength of the alloy can be reduced through re-solid-solution treatment, the plasticity of the alloy is improved, and correction and reprocessing processes are facilitated. The re-aging treatment can effectively regulate and control the variety, density and distribution of precipitated phases, thereby enhancing the strength of the alloy. In addition, due to coarsening of discontinuous grain boundary precipitated phases in the alloy and increasing of the copper content, on the premise that the strength of the alloy is basically not lost, the stress corrosion resistance, the intergranular corrosion resistance and the electrochemical corrosion resistance are improved, and the plasticity of the alloy is improved. The process is simple and feasible and is not limited by the thickness of the plate.

Owner:SHANDONG UNIV

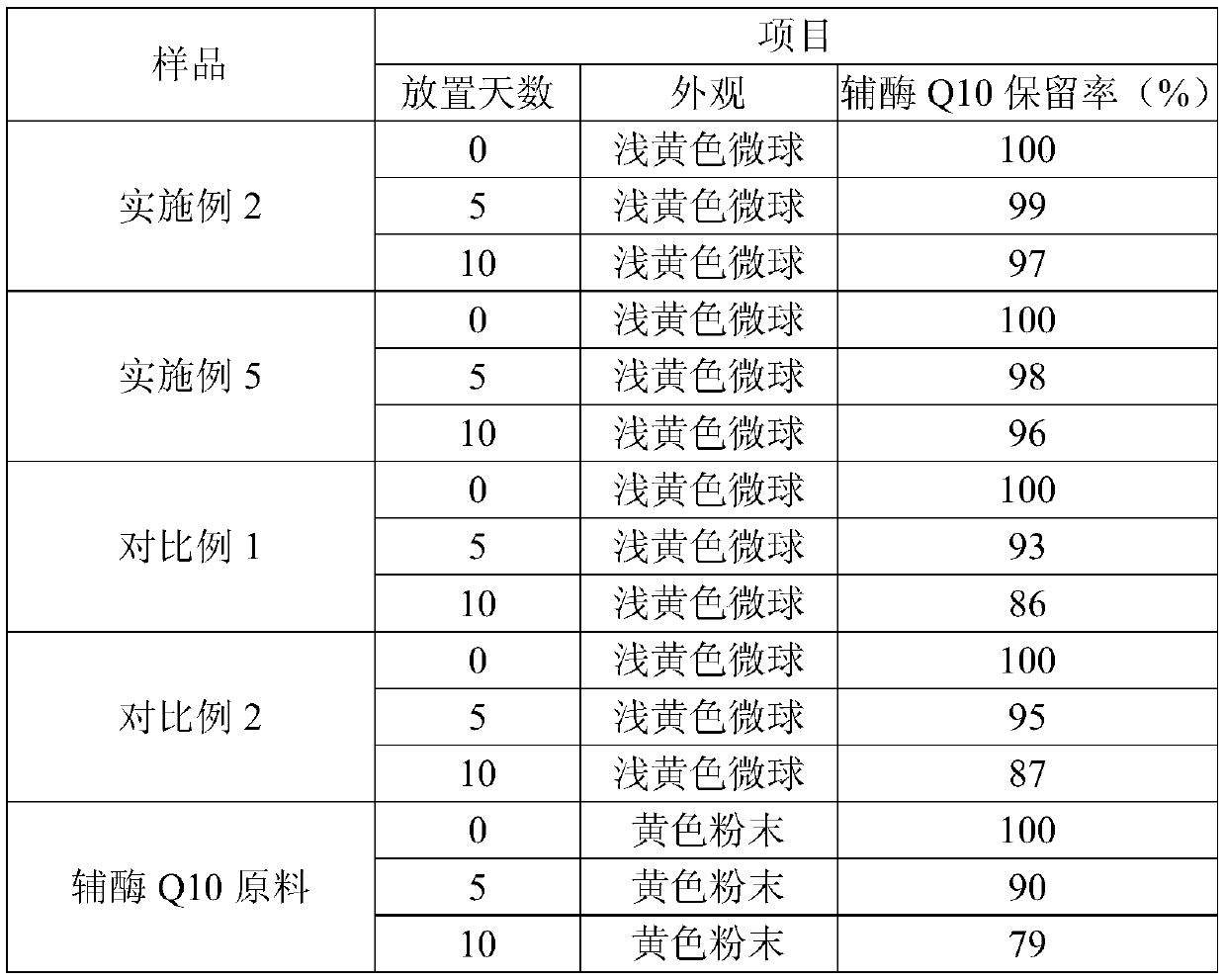

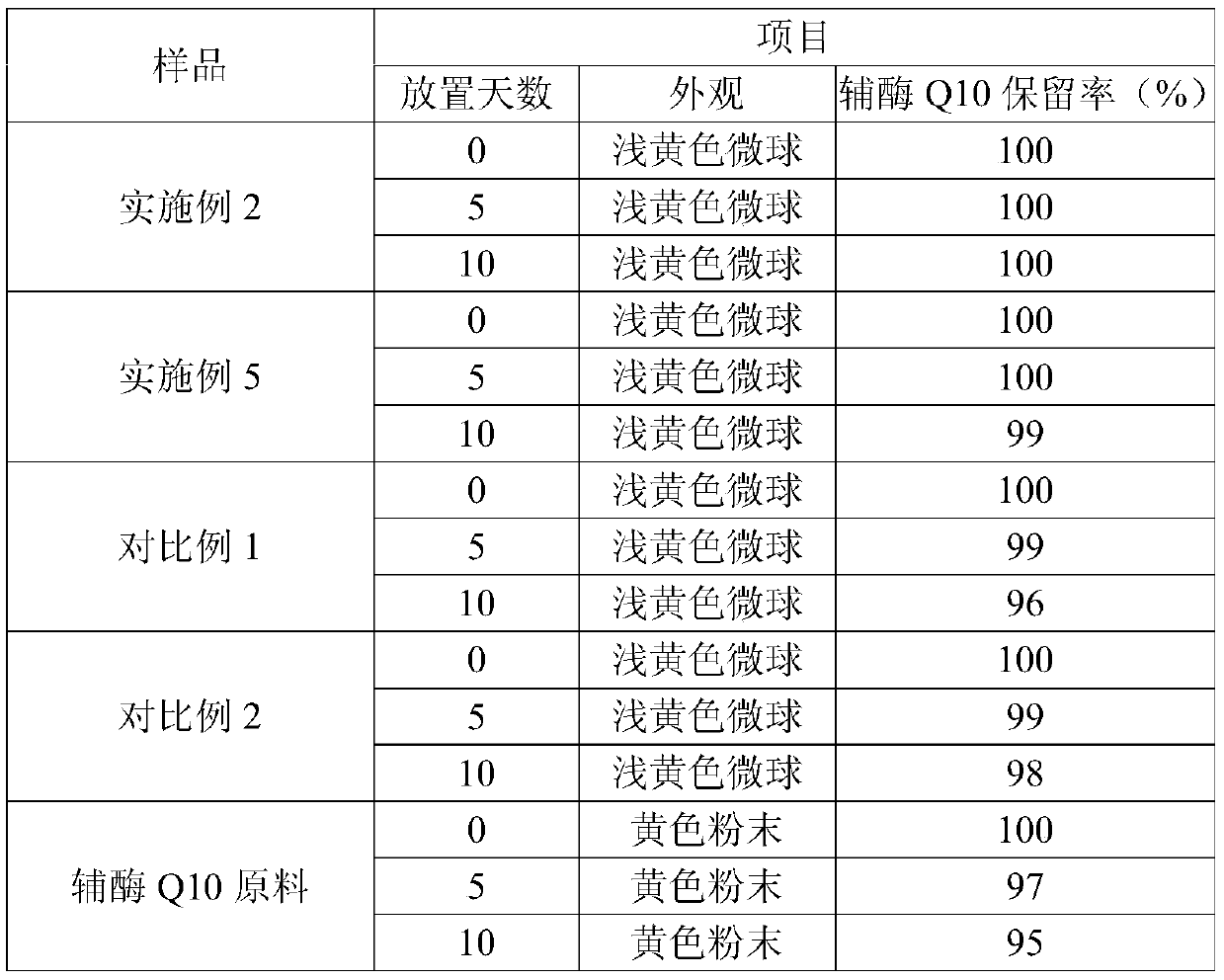

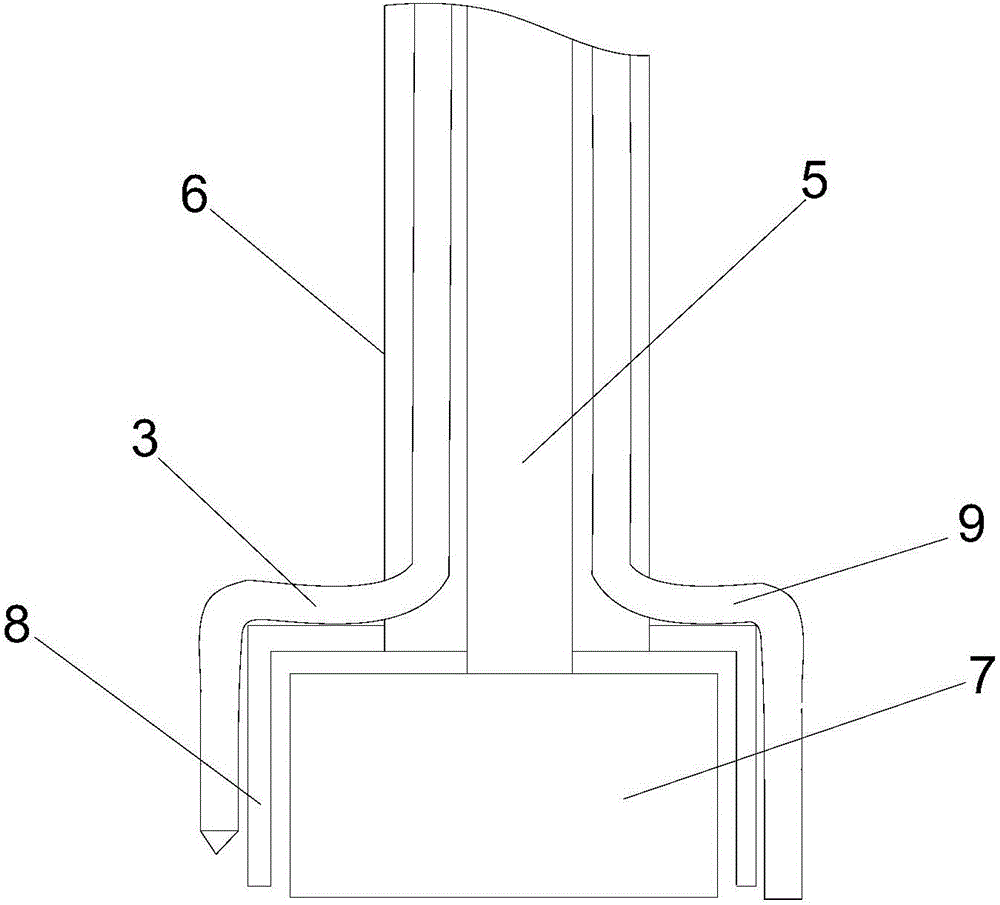

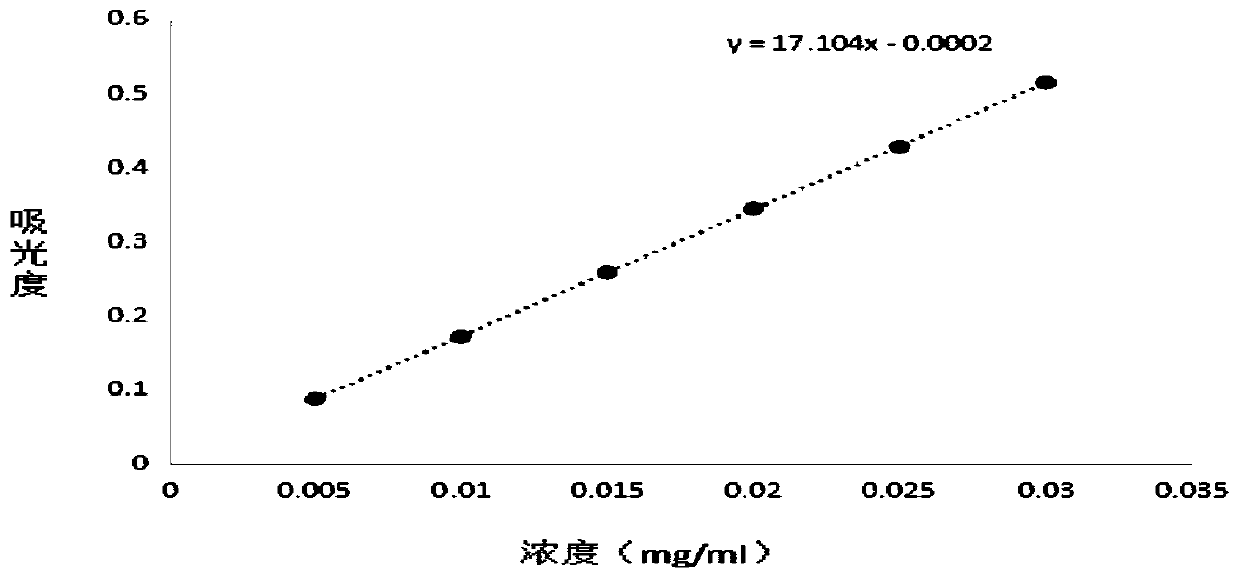

Sodium alginate microspheres of coenzyme Q10 and preparation method thereof

ActiveCN111249249AHigh drug loading and encapsulation efficiencyPrevent re-precipitationOrganic active ingredientsNervous disorderAqueous solutionMicrosphere

The invention provides a method for preparing coenzyme Q10 microspheres. The method includes the following steps: (1) adding an appropriate amount of sodium alginate aqueous solution to coenzyme Q10 inclusion complex aqueous solution, conducting stirring evenly, and then homogenizing to obtain a homogeneous material; (2) adding the homogeneous material dropwise to calcium chloride aqueous solutionwhile keeping stirring, continuing to stir after dropwise adding, so that the sodium alginate can be fully cross-linked, filtering, washing with water, and drying to obtain the sodium alginate microspheres of coenzyme Q10. In the coenzyme Q10 inclusion complex aqueous solution, inclusion wall material is starch wall material, and the mass ratio of water to the starch wall material is 1: (5-30); and the mass ratio among coenzyme Q10, the starch wall material and sodium alginate is 1: (0.5-10): (0.5-10). The invention also provides the sodium alginate microspheres of coenzyme Q10 prepared by the method. The method of the present invention greatly improves the drug loading capacity and encapsulation rate of the coenzyme Q10, can effectively prevent the coenzyme Q10 from being re-precipitated, and improves slow release effect of the coenzyme Q10.

Owner:SHANGHAI YUKING WATER SOLUBLE MATERIAL TECH

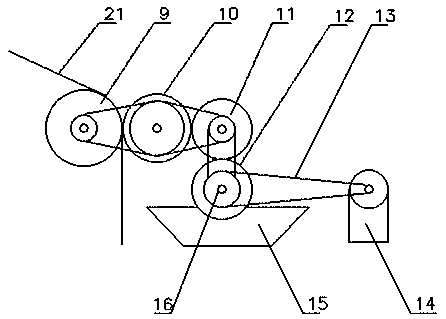

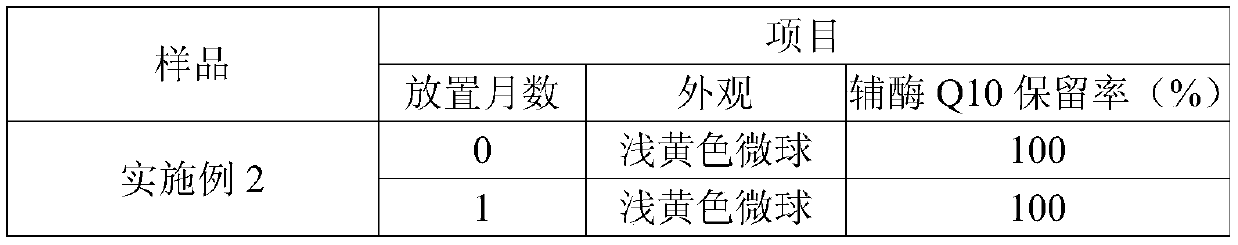

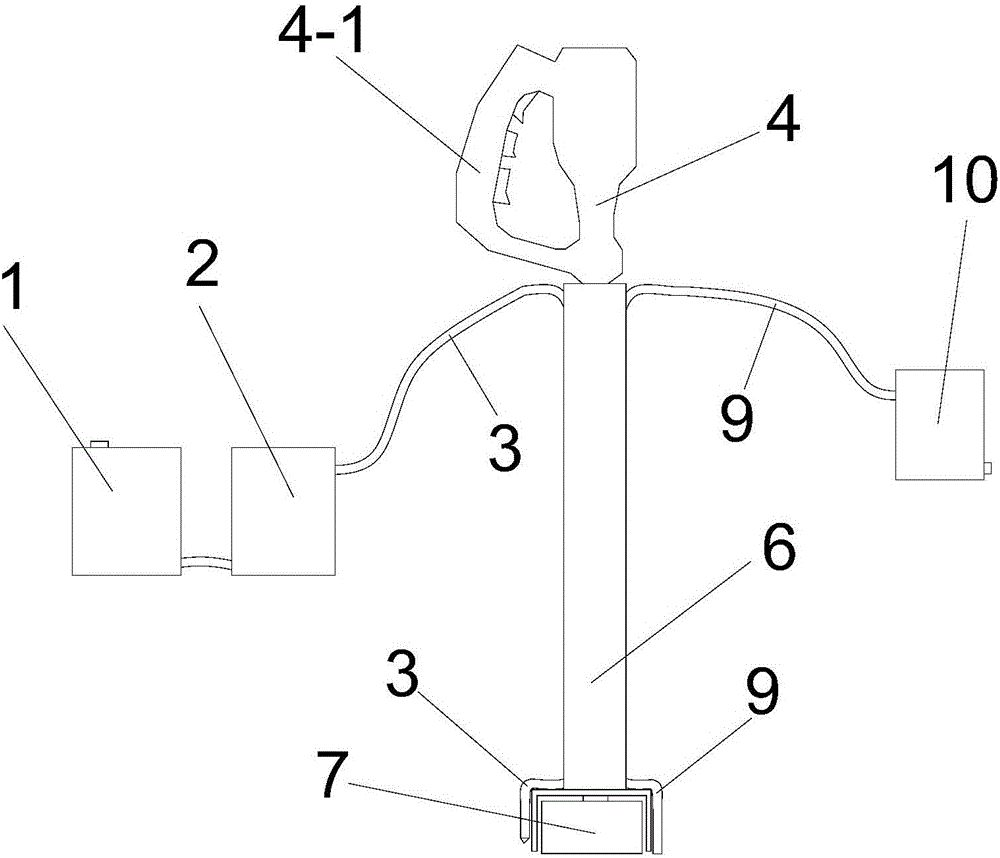

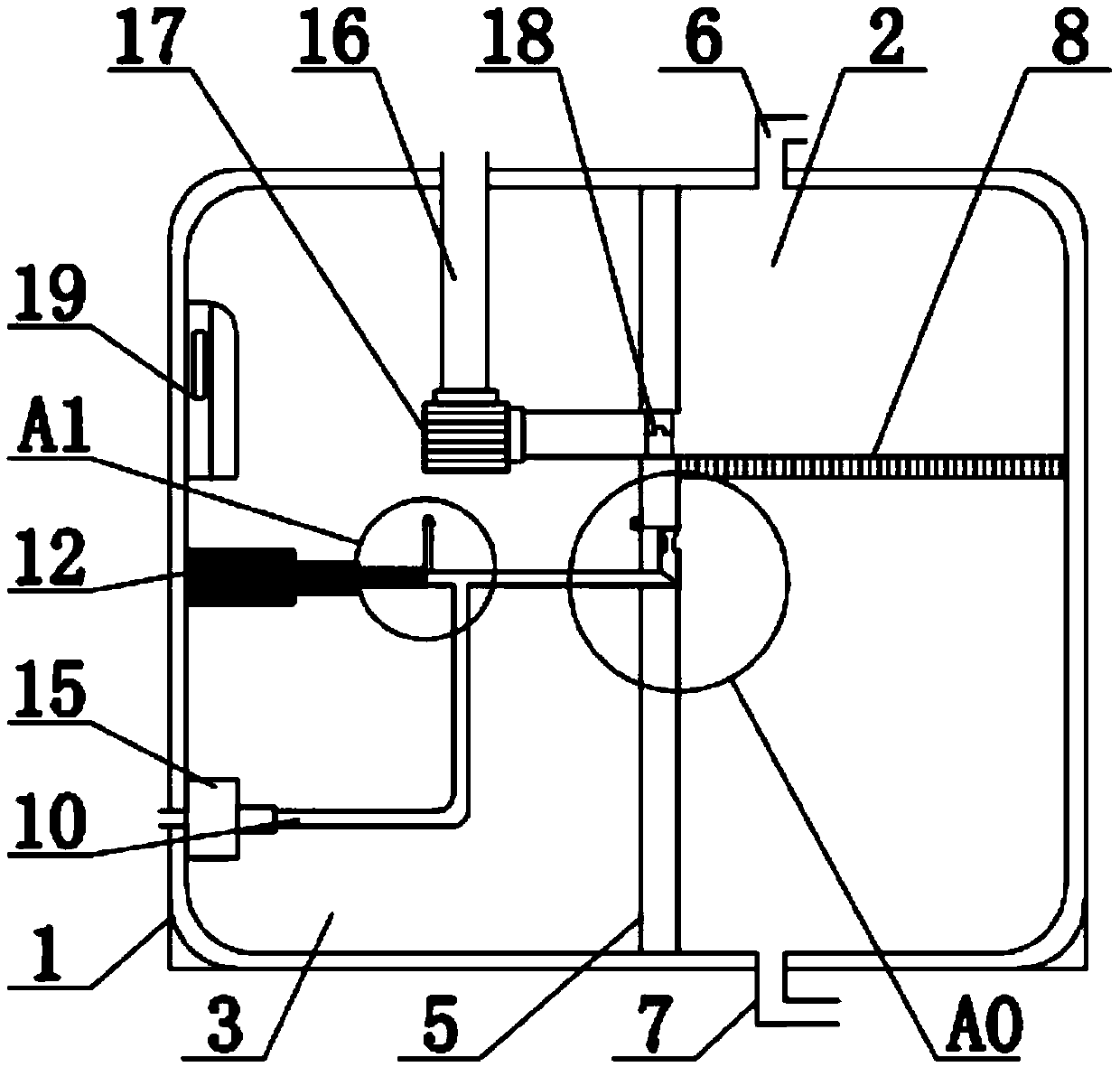

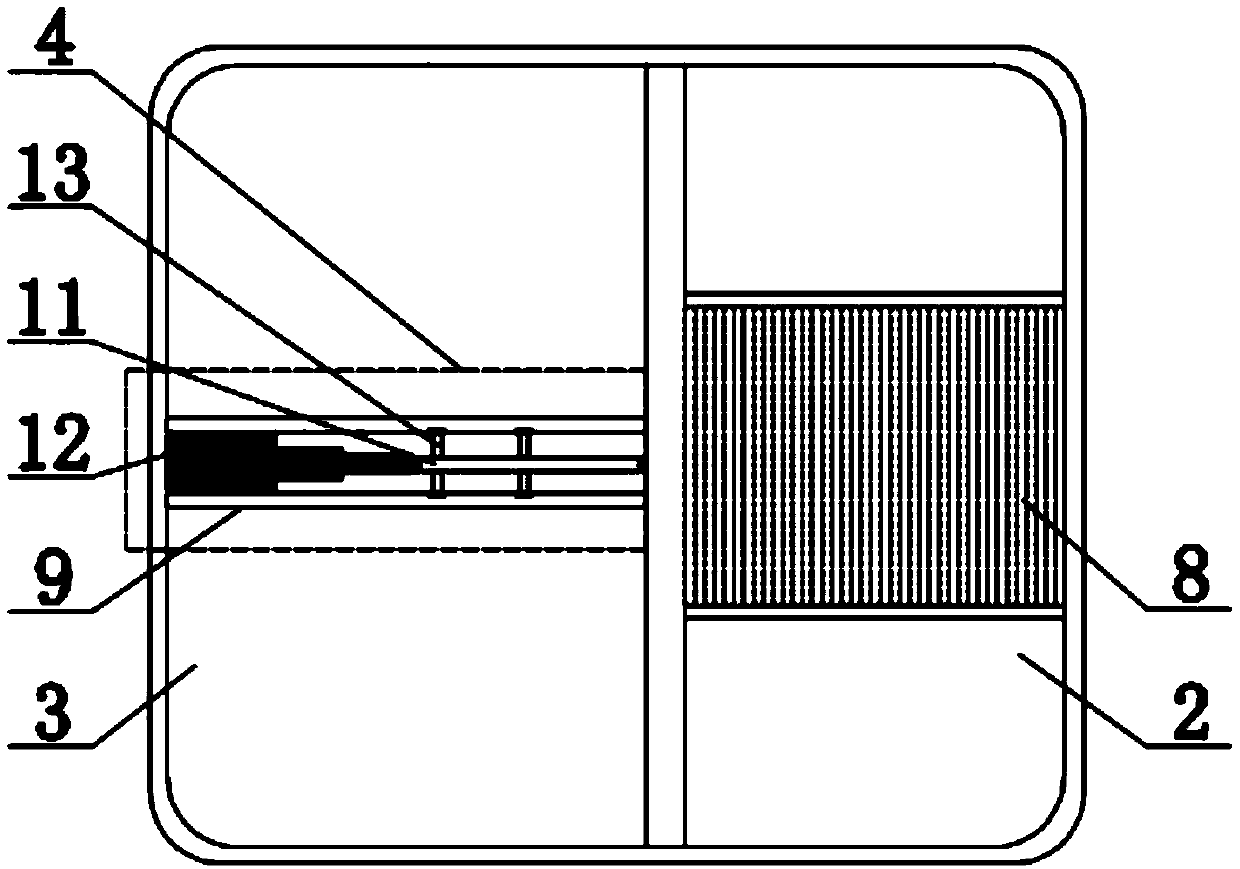

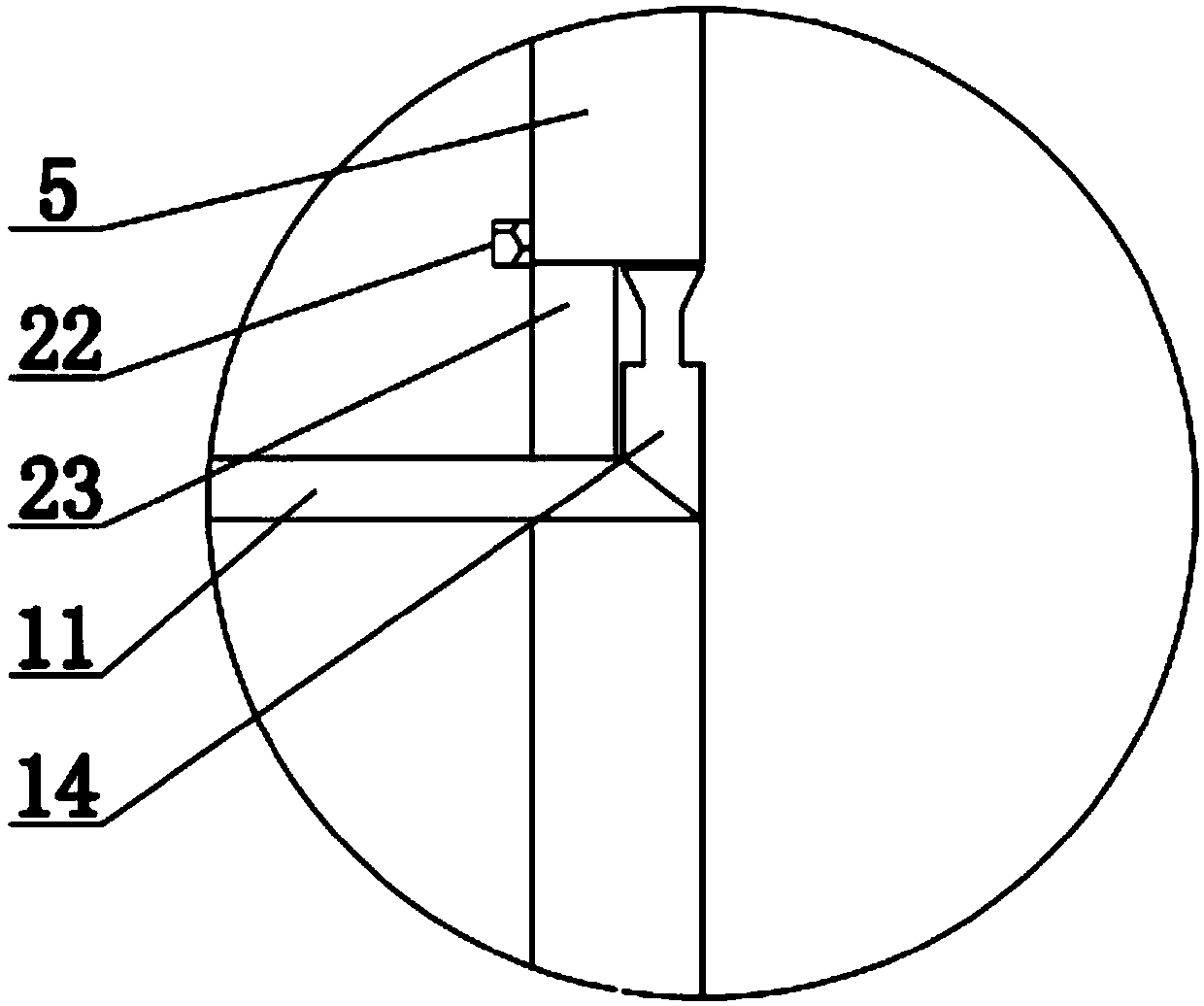

An automobile fuel tank cleaning device

InactiveCN106607417AImprove cleaning efficiencySave cleaning timeHollow article cleaningFuel tankLiquid storage tank

The invention belongs to the technical field of automobile cleaning apparatuses and provides an automobile fuel tank cleaning device comprising a liquid storage tank, a high pressure pump, a water inlet pipe, a motor, a transmission shaft, a sleeve, a cleaning brush, a connecting rack, a water outlet pipe and a negative pressure pump. The motor is connected with the cleaning brush via the transmission shaft; the sleeve is arranged on the transmission shaft in a sleeving manner; the connecting rack is fixedly connected with the end, close to the cleaning brush, of the sleeve; one end of the water inlet pipe is fixed on the connecting rack and the other end of the water inlet pipe is connected with the high pressure pump; the high pressure pump is connected with the liquid storage tank; one end of the water outlet pipe is fixed to the connecting rack and the other end of the water outlet pipe is connected with the negative pressure pump. The device is simple in structure, convenient to operate, good in cleaning effect and highly practical, and is suitable for promotion in the field.

Owner:广西班奇供应链管理有限公司

Water-soluble coenzyme Q10 composition and preparation method thereof

PendingCN111467502AHigh encapsulation efficiencyImprove stabilityCosmetic preparationsOrganic active ingredientsCelluloseAlcohol

The invention provides a preparation method of a water-soluble coenzyme Q10 composition. The preparation method comprises the following preparation steps: (1) dissolving a formula amount of cyclodextrin into a proper amount of water to obtain a cyclodextrin aqueous solution, heating the cyclodextrin aqueous solution, dissolving a formula amount of coenzyme Q10 into a proper amount of absolute ethyl alcohol, then adding the obtained coenzyme Q10 solution into the cyclodextrin aqueous solution, carrying out high-speed homogenization treatment, discharging the mixture into a grinding machine forgrinding, and performing discharging to obtain a primary inclusion compound; and (2) dissolving a secondary embedding wall material in a proper amount of water to form a secondary embedding wall material aqueous solution, adding the secondary embedding wall material aqueous solution into the primary inclusion compound obtained in the step (1), putting the mixture into a high-pressure homogenizer,performing circulating for 1-10 times at 80-180Mpa, and performing discharging and drying. The secondary embedding wall material is selected from one or more of hydroxyethyl cellulose, poloxamer 188,PVP (Polyvinyl Pyrrolidone), PEG4000 (Polyethylene Glycol 4000), PEG6000 (Polyethylene Glycol 6000), gelatin and Arabic gum. According to the preparation method, the encapsulation efficiency of the coenzyme Q10 can be improved, and stability of the coenzyme Q10 composition in an aqueous solution can be effectively improved.

Owner:上海融澈水性材料有限公司

Backwashing filter

InactiveCN109550290AEasy to cleanEasy to rinseStationary filtering element filtersSewage dischargeWaste management

The invention discloses a backwashing filter, which comprises a device shell, a filtering chamber, a rinsing chamber and rinsing assemblies, wherein the top portion and the bottom portion of the filtering chamber are respectively connected to a water inlet and a water outlet, a filtering screen is arranged inside the filtering chamber, sliding grooves are arranged inside the rinsing chamber, a stretching rod is connected in the rinsing chamber, one end of the stretching rod is connected to a rinsing head, both sides of the rinsing head are connected to sliding blocks, the other end of the rinsing head is fixedly connected to a spraying nozzle, the rinsing head is connected to a rinsing pipeline, the rinsing pipeline is provided with a micro booster pump, the upper portion, close to the filtering screen, of a separation plate is provided with a sewage discharge port, the sewage discharge port is connected to a sewage discharge pipeline, the sewage discharge pipeline is provided with a micro suction pump, and a PLC controller is arranged inside the rinsing chamber. According to the present invention, the backwashing filter has advantages of reciprocating washing, convenient and quickwashing and strong washing force, and is mainly used for backwashing the filtering screen in the filter.

Owner:江苏华卓智能过滤装备系统有限公司

Method for Improving Phosphorus Release Rate of Phosphorous Chemical-Biological Mixed Sludge Anaerobic Fermentation

ActiveCN103936249BPrevent re-precipitationAvoid corrosionBiological sludge treatmentResource utilizationSludge

The invention relates to a method for improving anaerobic fermentation phosphorus release rate of phosphorus-containing chemical-biological mixed sludge. The method comprises the following steps: placing the phosphorus-containing chemical-biological mixed sludge in a reactor, performing static settling at room temperature for 24h, and discharging supernatant fluid to obtain the concentrated mixed sludge; adding a certain amount of EDTA-2Na according to the content of total suspended solids in the sludge aiming at the chemical-biological mixed sludge produced by using different chemical reagents to remove phosphorus, maintaining the pH value in the anaerobic fermentation process of the mixed sludge at 6.5-7.5, closing the reactor and performing anaerobic fermentation for 5-10 days at the temperature of 30-50 DEG C. According to the method, a large amount of phosphorus in the chemical sludge produced by chemical phosphorous removal is released, the re-precipitation of phosphorous released by anaerobic fermentation of the sludge can be further prevented, and the phosphorous release rate of the mixed sludge can be further improved. Compared with the prior art, by adopting the method provided by the invention, the total phosphorous release rate of the phosphorus-containing chemical-biological mixed sludge can be improved so as to be conductive to improving the recovery rate of later-stage nitrogen and phosphorous resources, and the resource utilization of the remaining sludge can be realized.

Owner:TONGJI UNIV

Leather cleaning, nourishing and care cream and production method thereof

ActiveCN102516883BFree from harmEliminate secondary damageDetergent compounding agentsAqueous dispersionsWaxMonoglyceride

The invention discloses leather cleaning, nourishing and care cream, which comprises the following components in percentage by weight: 1 to 5 percent of molecular distilled monoglyceride, 1 to 5 percent of stearic acid, 8 to 15 percent of medical white vaseline, 1 to 5 percent of methyl phenyl polysiloxane, 2 to 6 percent of alcohol 16-18, 1 to 5 percent of coconut water oil-fatty acid-diethanol amide, 0.5 to 2.5 percent of lanolin, 0.2 to 1 percent of diazolidinyl urea, 0.2 to 1 percent of plant essence, 0.2 to 1 percent of aloe liquid, 0.5 to 3 percent of vegetable wax, 0.1 to 0.5 percent of natural zeolite, and 50 to 85 percent of deionized water. The invention also provides a production method for the cream. The cream integrates maintenance and care into a whole, is environment-friendly, has the properties of cleaning and polishing leather and resisting water, cracking, mildew and bacteria, is safe, healthy and natural, does not contain paraffin, is not greasy or sticky, keeps the natural color of the leather, is anti-fouling and clean, and is applied widely.

Owner:广州市美可生物科技有限公司

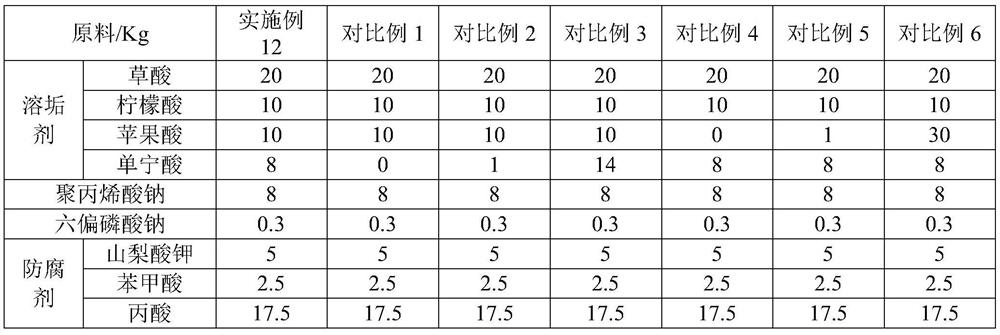

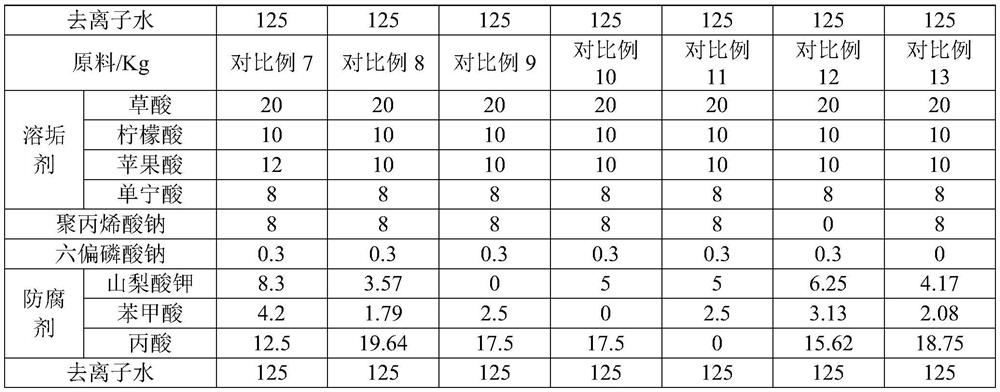

A kind of fast descaling anti-corrosion and environment-friendly descaling agent and its preparation method and application

ActiveCN110921853BImprove descaling efficiencyInhibit growthBiocideSpecific water treatment objectivesOXALIC ACID DIHYDRATECooling tower

The invention discloses a quick descaling antiseptic and environment-friendly descaling agent and its preparation method and application. The descaling agent comprises the following raw materials in parts by weight: 3-40 parts of oxalic acid; 2-20 parts of citric acid; 3-20 parts of malic acid 25 parts; 2-12 parts of tannic acid; 2-15 parts of sodium polyacrylate; 0.05-1 part of dispersant; 10-40 parts of preservative; 50-200 parts of deionized water. The preparation method of the descaling agent is as follows: S1 oxalic acid, citric acid, tannic acid and malic acid are crushed and sieved; S2 is mixed with the mixture of S1 and deionized water to obtain solution A; S3 is added sodium polyacrylate to solution A, Heat and cool to obtain solution B; S4 Add preservative and dispersant to solution B, and mix well. The descaling agent of the invention can be used for descaling of central air-conditioning cooling towers, water treatment pipelines, boilers, etc., and has the advantages of low environmental pollution, high descaling efficiency and certain sterilization rate.

Owner:北京杰信越发建设工程有限公司

A dredging device for water environment treatment

ActiveCN108755814BAvoiding Poor Water Quality SituationsPrevent re-precipitationSoil-shifting machines/dredgersSludgeWater quality

Owner:安徽中疆数字科技有限公司

A kind of heat treatment method of al-cu-li alloy pre-aging re-solution re-aging

ActiveCN112281092BPrevent re-precipitationQuenching transfer time is shortSolution treatmentElectrochemical corrosion

The invention discloses a heat treatment method for Al-Cu-Li alloy pre-aging, re-solution and re-aging, which belongs to the field of material heat treatment. Starting from controlling the heat treatment process system and its parameters, the Al-Cu-Li alloy extruded plate is conventionally Solution, pre-aging, heavy solution and re-aging treatments. The conventional solid solution and heavy solution treatment temperature is 515±10°C, heat preservation for 60-90 minutes, and then water quenching, and the quenching transfer time is <5s. The temperature for pre-aging and re-aging treatment is 160-180°C, keep warm for 24-48 hours, and air-cool after taking it out. Re-solution treatment can reduce the strength of the alloy, improve the plasticity of the alloy, and is beneficial to the orthopedic and reprocessing processes; re-aging treatment can effectively control the type, density and distribution of precipitates, and improve the strength of the alloy. Coupled with the coarsening of discontinuous grain boundary precipitates and the increase of copper content in the alloy, the performance of stress corrosion resistance, intergranular corrosion and electrochemical corrosion is improved under the premise of maintaining the strength of the alloy. Increased plasticity. The process is simple and easy and is not limited by the thickness of the plate.

Owner:SHANDONG UNIV

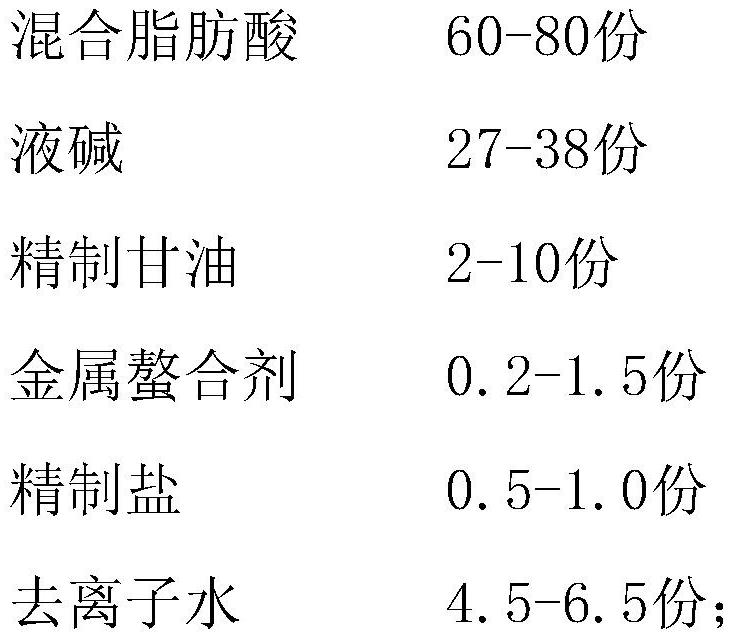

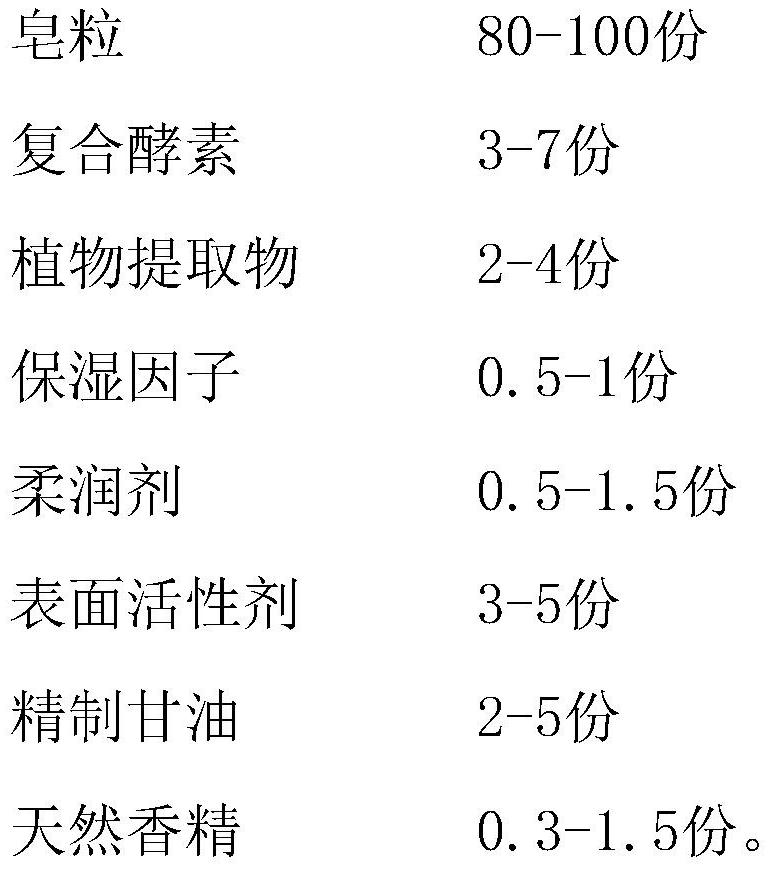

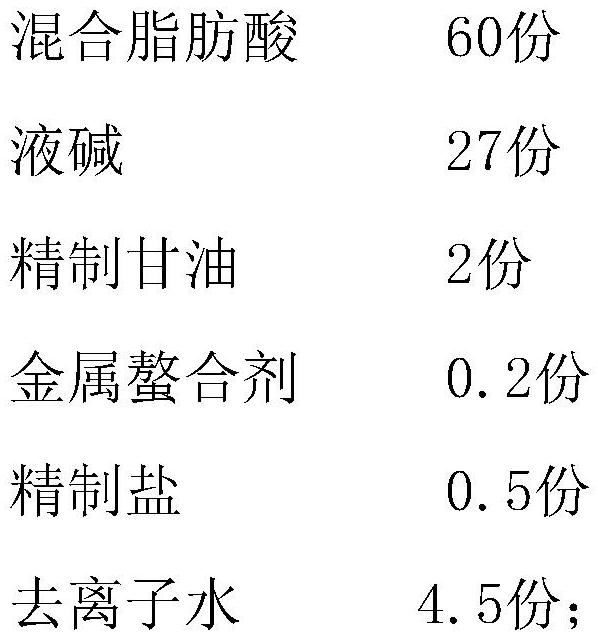

A kind of soap particle containing organic sodium gluconate and environmental protection soap

ActiveCN109825386BPrevent oxidative deteriorationImprove environmental friendlinessSoap detergents with organic compounding agentsSurface-active non-soap compounds and soap mixture detergentsMixed fatty acidSodium polyaspartate

The invention relates to the technical field of daily chemical soap, in particular to a soap particle containing organic sodium gluconate and an environmentally friendly soap. The soap particles include the following raw materials in weight percentage: 60-80 parts of mixed fatty acid, 27-38 parts of liquid alkali, 2-10 parts of refined glycerin, 0.2-1.5 parts of metal chelating agent, 0.5-1.0 part of refined salt and 4.5 parts of deionized water ‑6.5 parts; the metal chelating agent is organic sodium gluconate, or a mixture of organic sodium gluconate, iminodisuccinic acid and sodium dimaspartate. The soap particles of the present invention use organic sodium gluconate as the main chelating agent, which can still chelate heavy metal ions in water and dirt under relatively high pH conditions, and avoid oxidation, deterioration and peculiar smell of the soap particles caused by metal ions, Moreover, the organic sodium gluconate has the environmental protection characteristics of easy biodegradation, which improves the environmental friendliness of the soap particles, and the soap particles have the characteristics of good decontamination effect, no irritation to human skin, and high safety.

Owner:YIHAI DONGGUAN OIL & CHEM IND

A method for stabilizing leachate in calcification vanadium extraction process

ActiveCN105274336BPrevent re-precipitationGuaranteed RecoveryProcess efficiency improvementHigh concentrationPregnant leach solution

The invention discloses a method for stabilizing a leaching solution in a calcification vanadium extraction process and relates to the technical field of vanadium oxide extraction. The method solves the problem that in the leaching solution standing process in a calcification vanadium extraction process, part of vanadium is precipitated out, and the vanadium loss is caused. According to the technical scheme, the initial pH value of the leaching solution is detected firstly, a stabilizer is added to the leaching solution, and the pH value of the leaching solution is adjusted to range from 2.5 to 4.0; when the initial pH value of the leaching solution is larger than 4.0, the stabilizer is organic strong acid or a mixed solution of the organic strong acid; when the initial pH value of the leaching solution is smaller than 2.5, the stabilizer is soluble alkali or a mixed solution of the soluble alkali; and then liquid-solid separation is conducted on the leaching solution with the adjusted pH value, and filter residues and the qualified leaching solution are obtained. According to the method, the pH value of the leaching solution in the calcification vanadium extraction process is adjusted to range from 2.5 to 4.0 by selecting different stabilizers, high-concentration vanadate ions and NH4<+>, or H<+> or Mn<2+> in the leaching solution are prevented from generating vanadium precipitation under the induction of suspended matter with fine particles, the leaching solution is stabilized, the problem that leached vanadium precipitates again in calcification clinker is avoided, and the recycling rate of vanadium is guaranteed.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

An industrial wastewater treatment device

InactiveCN109095633BIncrease the areaArea interceptMultistage water/sewage treatmentWaste water treatment from plant processingFiberIndustrial wastewater treatment

The invention discloses an industrial wastewater treatment device. The industrial wastewater treatment device comprises a wastewater pool, a discharging pipe, a soft thorn collecting mechanism, a settling tank, a ventilation pipe, a valve and a negative pressure pump, wherein the discharging pipe is arranged on the side of the top end of the wastewater pool; one end of the discharging pipe is communicated with the wastewater pool; the other end of the discharging pipe is communicated with the soft thorn collecting mechanism positioned at the diagonal lower part; the setting tank is arranged onthe other side, opposite to the discharging pope, of the soft thorn collecting mechanism and is mechanically connected with the soft thorn collecting mechanism; the mounting position of the setting tank is lower than the soft thorn collecting mechanism; the setting tank is mechanically connected with the negative pressure pump through a ventilation pipe; the valve is arranged at the middle position of the ventilation pipe. According to the industrial wastewater treatment device disclosed by the invention, bubbles bonded with staple fibers are automatically collected and pierced, the stable fibers are bonded in large area and fishing for multiple times is avoided, so that labor intensity is reduced.

Owner:安徽清蓝环保工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com