Heat treatment method for pre-aging, re-solid-solution and re-aging of Al-Cu-Li alloy

A heat treatment method and pre-aging treatment technology, applied in the field of aluminum alloy heat treatment and metal material heat treatment, can solve the problems of unusable structural parts, unshown, affecting the dimensional accuracy of structural parts, etc., and achieve improved electrical conductivity and stress corrosion resistance. The effect of improving corrosion resistance, plasticity and stress corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

[0051] Single-stage peak aging (T6) treated Al-Cu-Li alloy.

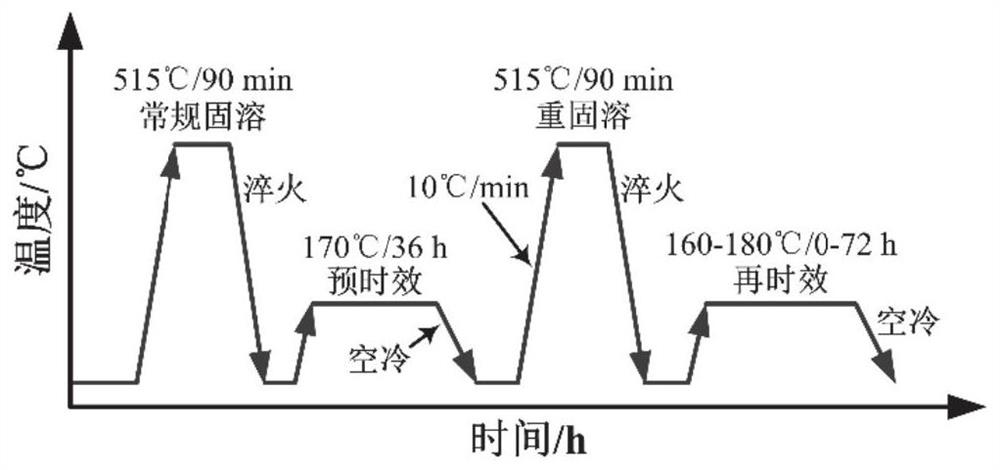

[0052] The material used in the experiment is a 5mm thick Al-Cu-Li alloy extruded plate, and the mass percentage of each chemical composition is: Al-3.0Cu-1.4Li-0.42Mg-0.32Ag-0.26Zn-0.11Zr. Put the processed block sample and the tensile sample of standard size into a tube furnace at 515°C for 90 minutes, then take it out immediately and quench it. The quenching transfer time is <5s. Then put the sample in an oil bath at 170°C for 36 hours, take it out and air cool to room temperature. The hardness test, tensile property test and electrical conductivity test were carried out on the samples after aging treatment.

experiment example 2

[0054] Overaged Al-Cu-Li Alloy

[0055] Put the processed 5mm thick Al-Cu-Li alloy plate sample and the standard size tensile sample into a tube furnace at 515°C for 90min, then take it out immediately and quench it. The quenching transfer time is <5s. Then put the sample into an oil bath at 170°C for 72 hours, take it out and air cool to room temperature. The hardness test, tensile property test and electrical conductivity test were carried out on the samples after aging treatment.

Embodiment 3

[0057] Al-Cu-Li alloys with pre-aging and re-solution treatment

[0058] Put the processed 5mm thick Al-Cu-Li alloy plate sample and the standard size tensile sample into a tube furnace at 515°C for 90min, then take it out immediately and quench it. The quenching transfer time is <5s. Then put the sample in an oil bath at 170°C for 36 hours, take it out and air cool to room temperature. Then put the sample into a tube furnace at 515°C for 90 minutes, then take it out immediately and quench it. The quenching transfer time is <5s. The hardness test, tensile property test and electrical conductivity test were carried out on the samples after pre-aging re-solution treatment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com