Heat treatment process of aluminum alloy components, aluminum alloy components and 3D printing method

An aluminum alloy component and heat treatment technology, applied in the field of material processing, can solve the problems of loss of precipitation phase dispersion strengthening, low level of plasticity and toughness, reduced mechanical strength of materials, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

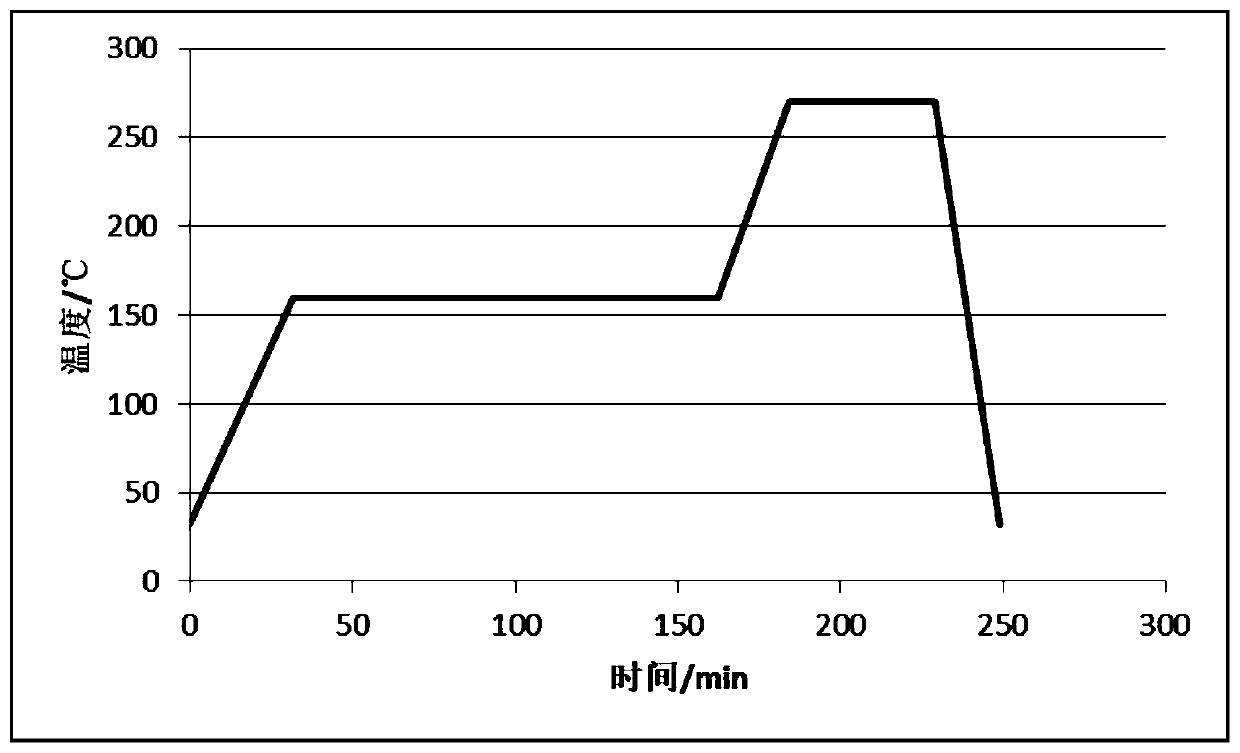

[0037] A heat treatment process for an aluminum-silicon-based aluminum alloy component manufactured by additive manufacturing. The grade of the aluminum alloy component is AlSi10Mg, such as figure 1 As shown, the heat treatment process includes the following steps:

[0038] (1) Put the components into an air heat treatment furnace, and heat them to heat up the components to the stress relief treatment temperature, and control the heating rate to 4°C / min;

[0039] (2) Control the stress relief treatment temperature to be 160°C, keep warm for 130min, and complete the stress relief treatment;

[0040] (3) Continue to heat the component that has completed the stress relief treatment in the air heat treatment furnace, so that the temperature of the component is raised to the temperature of the plasticizing and toughening treatment, and the heating rate is controlled to be 5°C / min;

[0041] (4) Control the plastic-toughening treatment temperature to 270°C, keep warm for 45 minutes,...

Embodiment 2

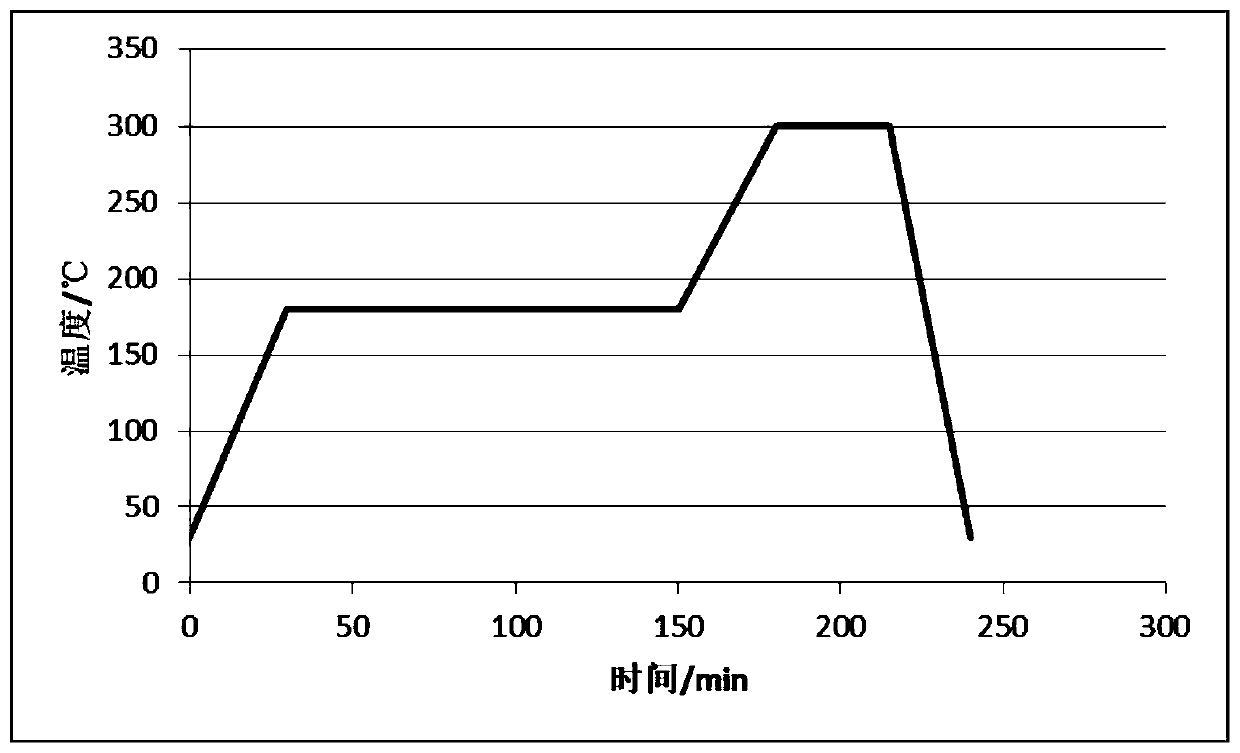

[0052] A heat treatment process for additively manufactured aluminum-silicon-based aluminum alloy components. The grade of the aluminum alloy component is AlSi7Mg, which is processed into components by 3D printing. The specific method of 3D printing is realized according to the existing technology, such as image 3 As shown, the heat treatment process includes the following steps:

[0053] (1) Put the component into an air heat treatment furnace and heat it to heat up the component to the stress relief treatment temperature, and control the heating rate to 5°C / min;

[0054] (2) Control the stress relief treatment temperature to be 180°C, heat for 120 minutes, and complete the stress relief treatment;

[0055] (3) Continue to heat the component that has completed the stress relief treatment in the air heat treatment furnace, so that the temperature of the component is raised to the temperature of the plasticizing and toughening treatment, and the heating rate is controlled to b...

Embodiment 3

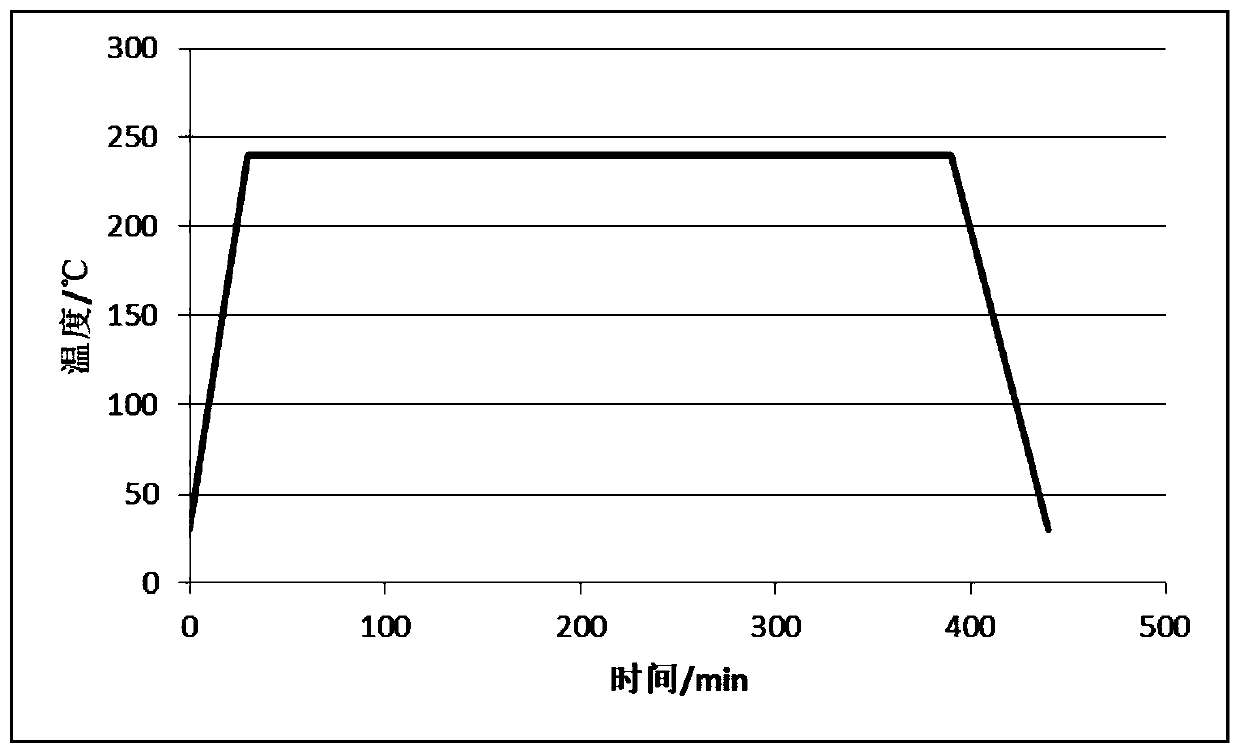

[0060] A heat treatment process for an aluminum-silicon-based aluminum alloy component manufactured by additive manufacturing. The grade of the aluminum alloy component is AlSi12Mg, which is processed into a component by 3D printing. The specific method of 3D printing is realized according to the existing technology, such as Figure 4 As shown, the heat treatment process includes the following steps:

[0061] (1) Put the component into an air heat treatment furnace and perform heat treatment to raise the temperature of the component to the stress relief treatment temperature, and control the heating rate to 4.5°C / min;

[0062] (2) Control the stress relief treatment temperature to be 170°C, keep the heat for 150min, and complete the stress relief treatment;

[0063] (3) Continue to heat the component that has completed the stress relief treatment in the air heat treatment furnace, so that the temperature of the component is raised to the temperature of the plasticizing and tou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com