Low-yield-strength anti-seismic steel plate for building and production method of steel plate

A low-yield strength, construction-use technology, applied in the field of iron and steel metallurgy, can solve problems such as increasing construction costs and affecting the appearance of buildings, and achieve the effects of optimizing the rolling process, reducing the effect of grain boundary strengthening, and good low-cycle fatigue characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

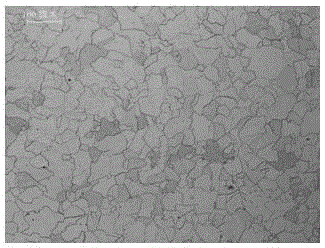

Image

Examples

Embodiment 1

[0018] Embodiment 1: The low-yield-strength anti-seismic steel plate used in this building adopts the following chemical composition and production process.

[0019] Chemical composition (wt): C0.026%, Si0.041%, Mn0.58%, P0.01%, S0.005%, N0.0050%, Ti0.034%, the balance is Fe and unavoidable impurities .

[0020] Production process: (1) Steel slabs are prepared by conventional smelting and continuous casting processes; the thickness of the steel slabs is 220mm.

[0021] (2) Rolling process: the heating temperature of the billet is 1200°C; the starting rolling temperature of the first stage (rough rolling) is 1110°C, the final rolling temperature is 1040°C, and the thickness to be warmed is 90mm; the starting rolling temperature of the second stage (finish rolling) is 930°C , The final rolling temperature is 880°C; hot straightening after rolling, and air cooling to obtain a steel plate with a thickness of 40mm.

[0022] (3) Heat treatment process: the heating temperature of t...

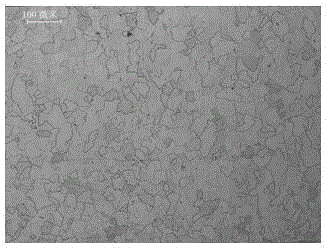

Embodiment 2

[0024] Embodiment 2: The low-yield-strength anti-seismic steel plate used in this building adopts the following chemical composition and production process.

[0025] Chemical composition (wt): C0.033%, Si0.046%, Mn0.42%, P0.018%, S0.008%, N0.0048%, Ti0.029%, the balance is Fe and unavoidable impurities .

[0026] Production process: (1) The billet is prepared by conventional smelting and continuous casting process; the thickness of the billet is 230mm.

[0027] (2) Rolling process: the heating temperature of the billet is 1220°C; the starting rolling temperature of the first stage (rough rolling) is 1120°C, the final rolling temperature is 1050°C, and the thickness to be warmed is 120mm; the starting rolling temperature of the second stage (finish rolling) is 950°C , the final rolling temperature is 900°C; hot straightening after rolling, and air cooling to obtain a steel plate with a thickness of 55mm.

[0028] (3) Heat treatment process: the heating temperature is 900° C.,...

Embodiment 3

[0030] Embodiment 3: The low-yield-strength anti-seismic steel plate used in this building adopts the following chemical composition and production process.

[0031] Chemical composition (wt): C0.010%, Si0.024%, Mn0.60%, P0.012%, S0.010%, N0.0035%, Ti0.01%, the balance is Fe and unavoidable impurities .

[0032] Production process: (1) The billet is prepared by conventional smelting and continuous casting process; the thickness of the billet is 230mm.

[0033] (2) Rolling process: the heating temperature of the billet is 1250°C; the starting rolling temperature of the first stage (rough rolling) is 1100°C, the final rolling temperature is 1050°C, and the thickness to be warmed is 100mm; the starting rolling temperature of the second stage (finish rolling) is 960°C , The final rolling temperature is 910°C; hot straightening after rolling, and air cooling to obtain a steel plate with a thickness of 45mm.

[0034] (3) Heat treatment process: the heating temperature is 920° C., ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com