Patents

Literature

36results about How to "Optimized rolling process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Steel bar with high weather resistance, low cost and seawater corrosion resistance and production process

ActiveCN108251746AGood weather resistanceLow costProcess efficiency improvementWeather resistanceRebar

The invention provides a steel bar with high weather resistance, low cost and seawater corrosion resistance and a production process. The steel bar comprises the following elementary compositions of,by weight, 0.04%-0.10% of C, 0.10%-0.50% of Si, 0.5%-1.6% of Mn, 0.03% or less of P, 0.02% or less of S, 2%-4% of Cr, 0.3%-0.5% of Cu, 0.2%-0.6% of Ni, and the balance Fe and inevitable impurities. According to the steel bar, the mechanical property meets the requirement of the steel bar for corrosion resistance, the aging strain is low, and the corrosion rate is lower than 70% that of common steel bars. The technical path of the process comprises a 70-ton ultrahigh-power electric furnace, LF ladle refining, deoxidation and alloying after steel discharging, argon blowing, continuous casting of165 square billets at four streams by four machines, a heat accumulating type stepping heating furnace, 18 non-twist tandem mills, controlled-rolling and controlled-cold cooling, finishing, packagingand storage.

Owner:福建三宝钢铁有限公司

Production technology for 1070A alloy aluminum foil with ultrahigh strength and high elongation for lithium battery

InactiveCN106929713AImprove mechanical performance indexImprove inner qualityCasting cleaning apparatusNon-aqueous electrolyte accumulator electrodesPerformance indexAlloy

The invention relates to a production technology for 1070A alloy aluminum foil with the ultrahigh strength and the high elongation for a lithium battery. The aluminum foil for the lithium battery comprises, by mass percentage, less than or equal to 0.2% of Fe; less than or equal to 0.1% of Si, less than or equal to 0.1% of Cu, less than or equal to 0.05% of Mn, less than or equal to 0.03% of Mg, less than or equal to 0.03% of Zn, less than or equal to 0.04% of Ti, and greater than or equal to 99% of Al. The preparation method comprises the steps of (1) smelting, and cast rolling; (2) cold rolling; and (3) aluminum foil rolling, specifically, cutting a aluminum foil coil to obtain the finished aluminum foil for the lithium battery. The production technology has the beneficial effects that a newly improved 1070A alloy is adopted, the proportion is reasonable, an electrolytic aluminum liquid with the high purity is adopted, a novel tubular filter box is adopted for production in the cast rolling process, the technology is scientific, the mechanical performance indexes of products can be improved, the tensile strength and the elongation of the products are higher than those of similar products in China, and the use requirements of customers can be met.

Owner:ZOUPING DELI TECH

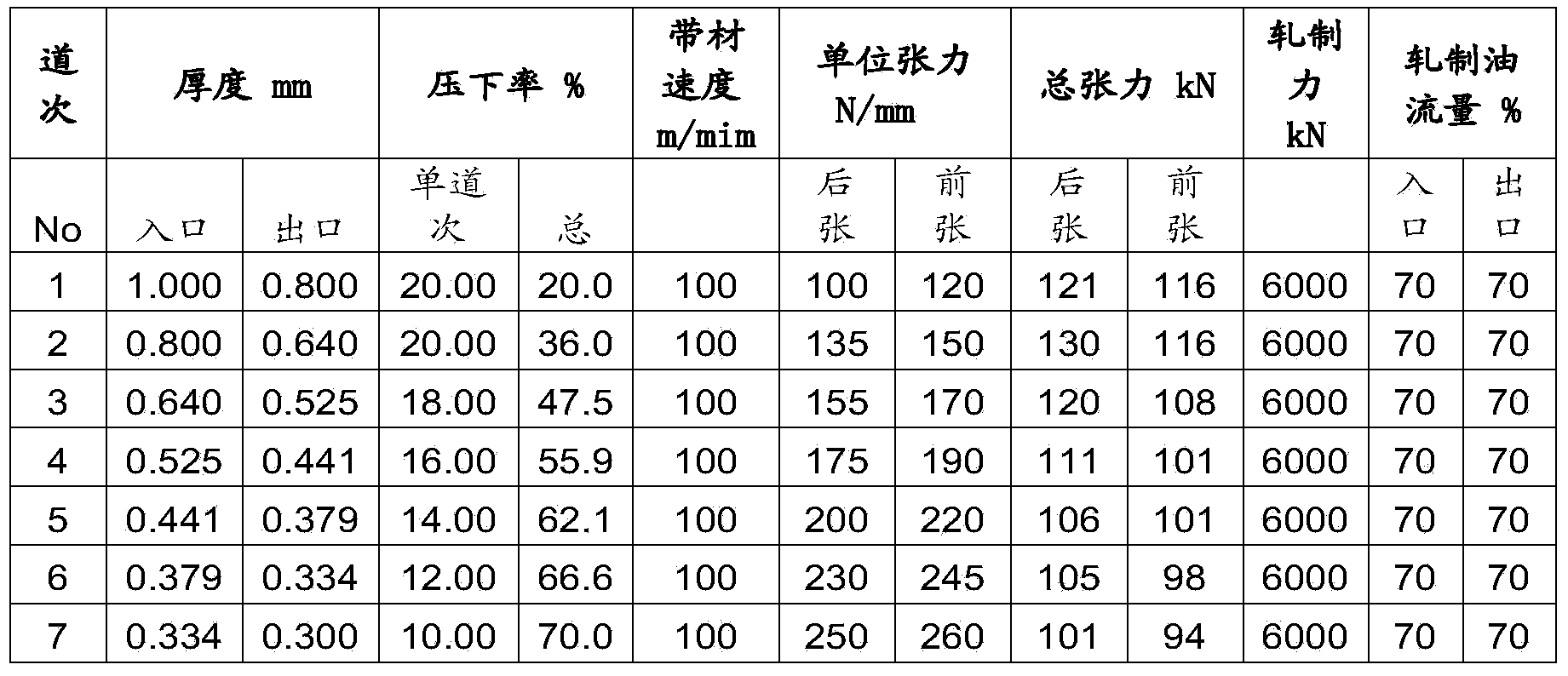

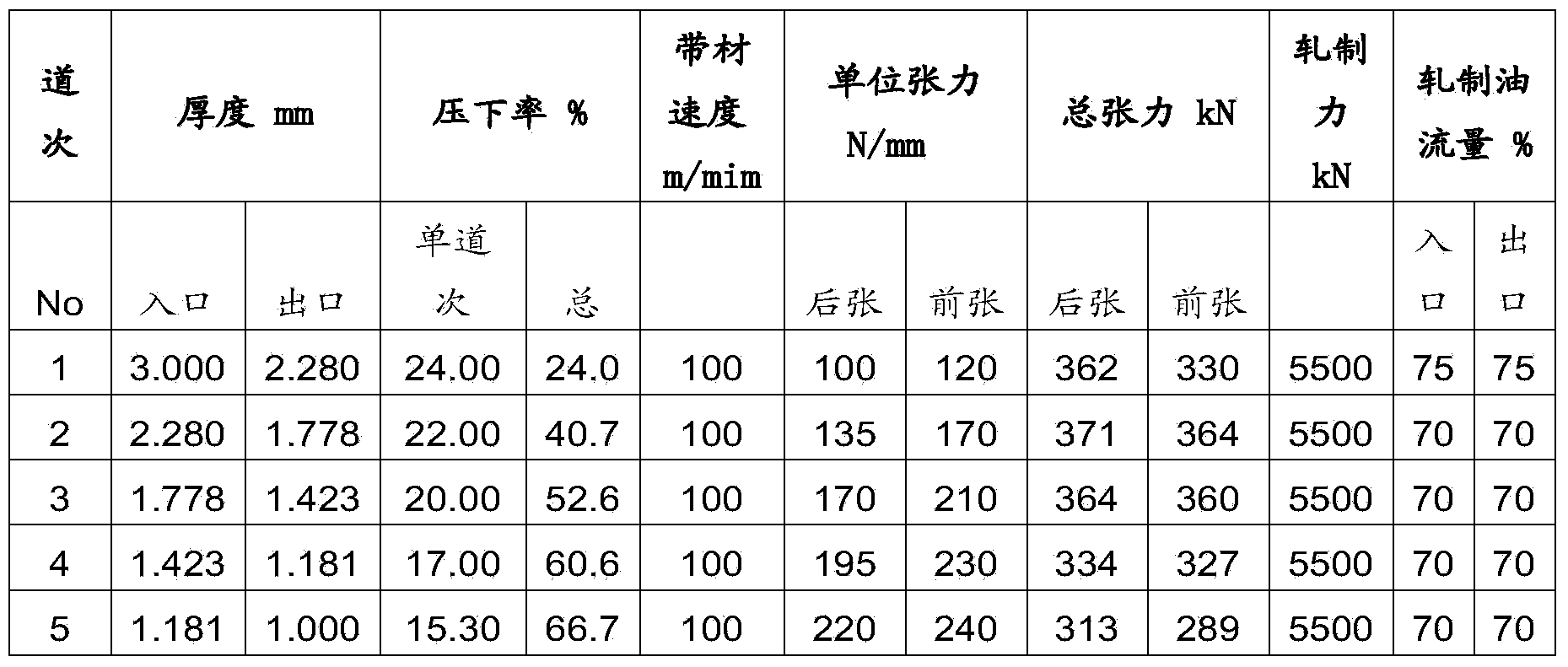

Method for producing metal titanium roll with thickness not more than 0.3mm through twenty-roller cold rolling unit

ActiveCN103706636AOptimized rolling processControl rolling speedTension/compression control deviceMetal rolling arrangementsControl systemTitanium

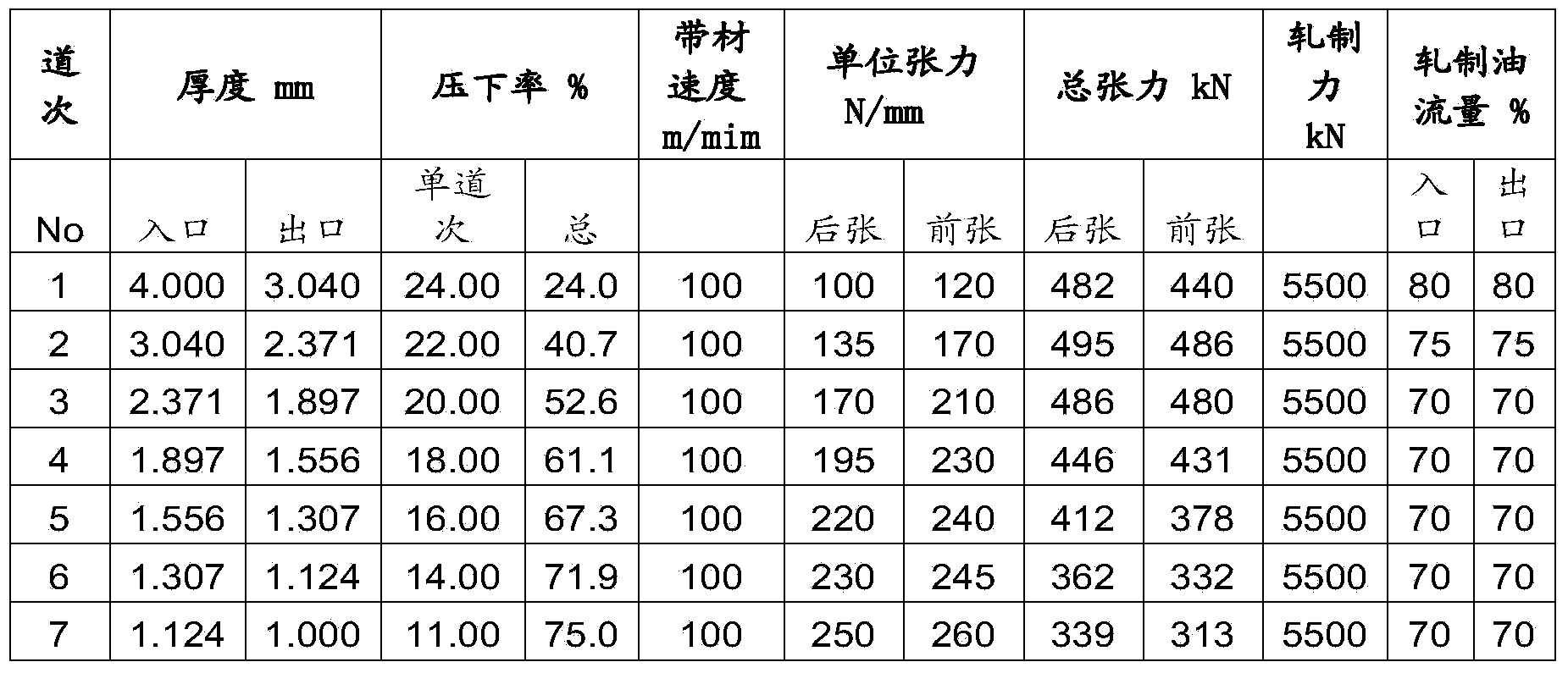

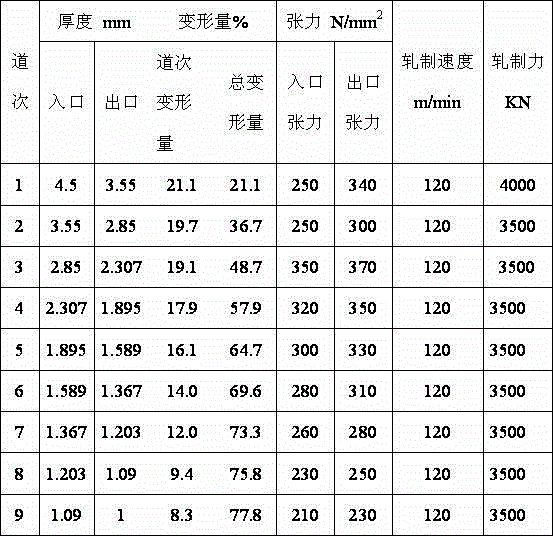

The invention provides a method for producing a metal titanium roll with the thickness not more than 0.3mm through a twenty-roller cold rolling unit. The method comprises two rolling processes. The first rolling process is that an annealing state titanium roll with the thickness ranging from 2mm to 4mm is rolled 5-10 times to achieve the target thickness, and the second rolling process is that a titanium roll with the thickness ranging from 0.7mm to 1.5mm is rolled 6-13 times to achieve the thickness not more than 0.3mm, wherein the pressing rate in the two rolling processes ranges from 8% to 25%, the pressing rate of one time of single rolling is 80-100% of the pressing rate of the previous single rolling, the rolling speed is kept between 50m / min and 120m / min, and the unit forward pull is 1-1.3 times that of the unit backward pull. An effective strip surface lubrication system and a model control system are established through an existing twenty-roller reversible type cold rolling unit, the rolling technology of an ultrathin titanium is optimized, the total deformation of each rolling process is controlled within 80%, and the requirement-conformed thin titanium coiled stock with the thickness not more than 0.3mm can be produced.

Owner:湖南湘投金天钛金属股份有限公司

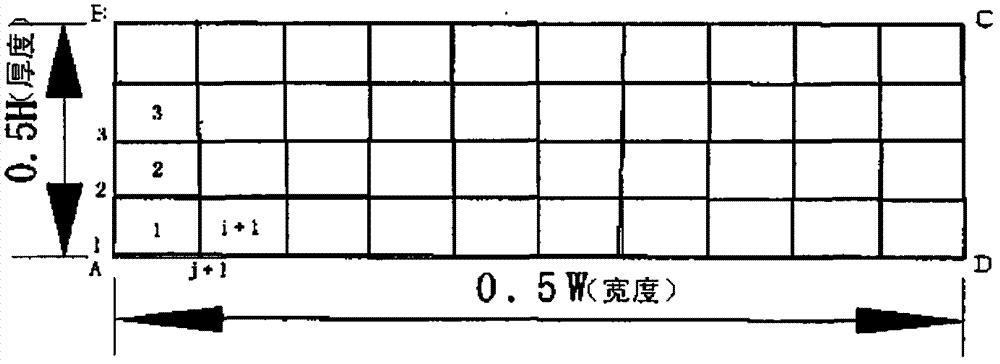

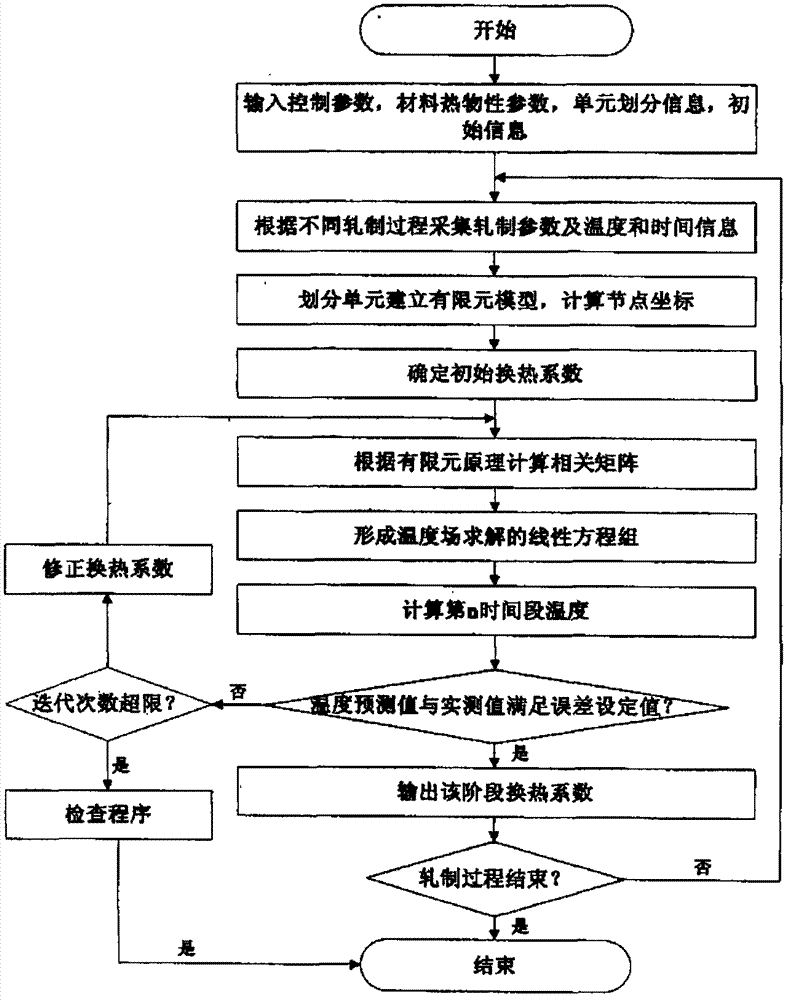

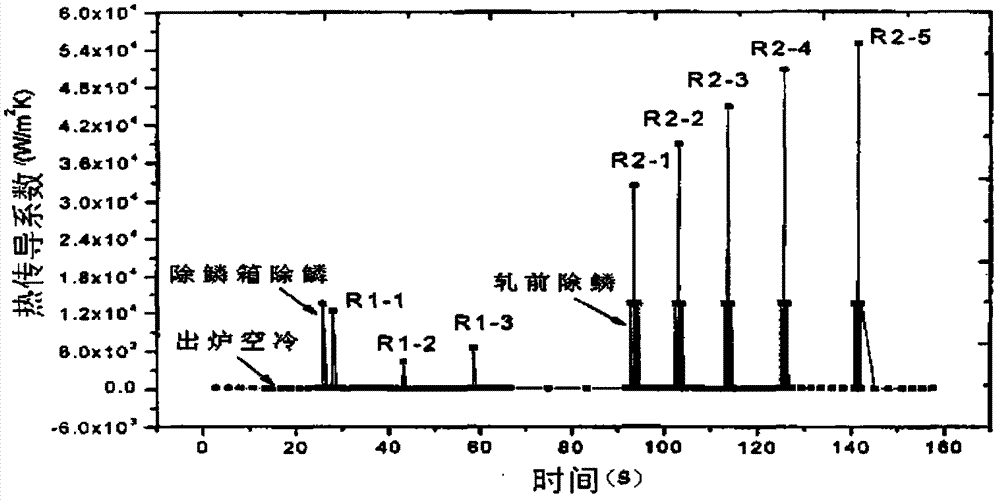

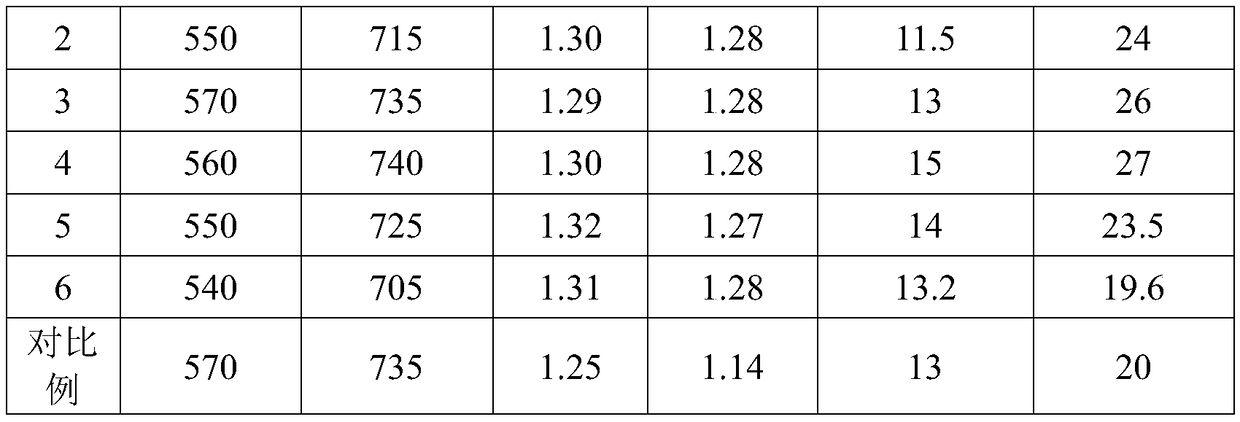

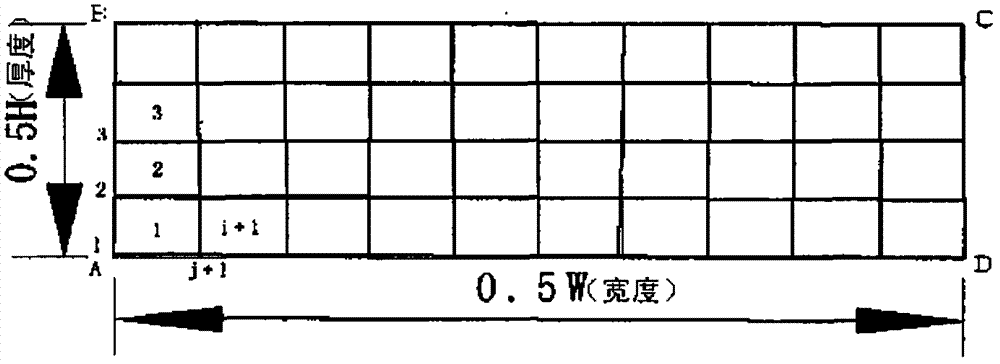

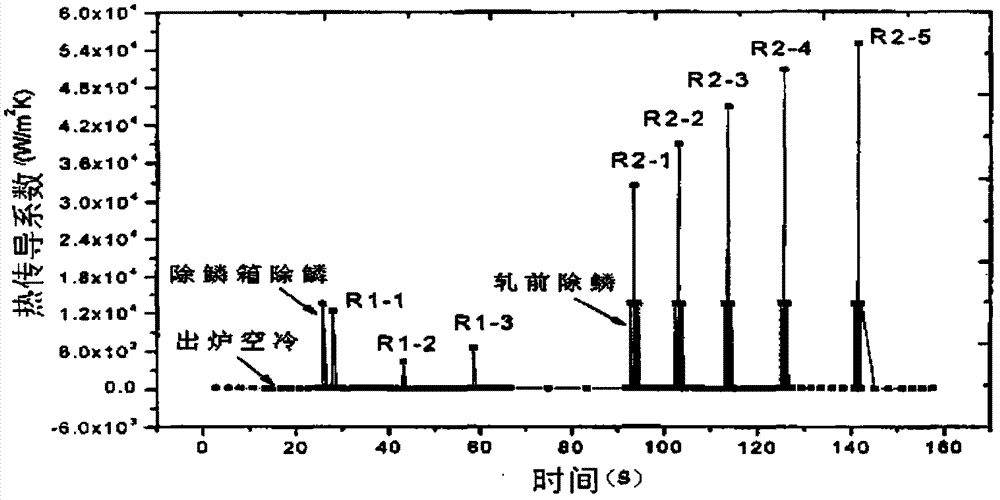

Method for predicting strip surface coefficients of heat transfer in hot rolling procedures

ActiveCN103761370AImprove forecast accuracyDetailed and accurate informationSpecial data processing applicationsElement modelPredictive methods

The invention discloses a method for predicting strip surface coefficients of heat transfer in hot rolling procedures. The method includes predicting strip surface coefficients of heat transfer by the aid of a finite-element model and heat transfer modifier formulas; determining the strip surface coefficients of heat transfer according to comparison values of measured temperatures and computed temperatures of strips. The method has the advantages that the method is specially used for predicting the strip surface coefficients of heat transfer in the strip hot rolling procedures, change of the strip surface coefficients of heat transfer in the integral rolling procedures can be acquired, information is detailed and accurate, the strip surface coefficients of heat transfer are high in prediction precision, and setting and optimizing parameters can be provided for the rolling procedures; the method is high in applicability and computational efficiency and is applicable to roughing mills and finishing mills in hot continuous rolling procedures.

Owner:NORTHEASTERN UNIV

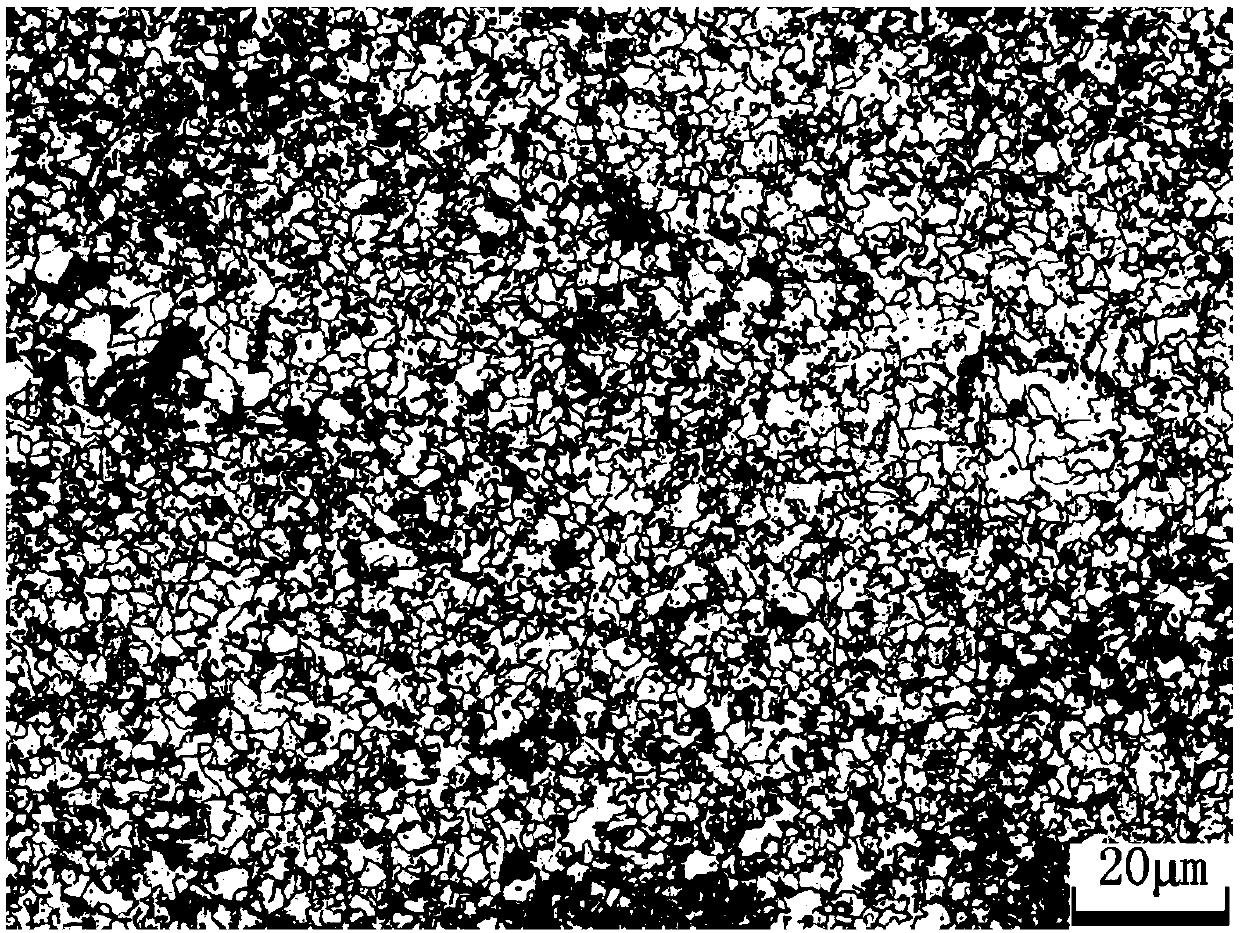

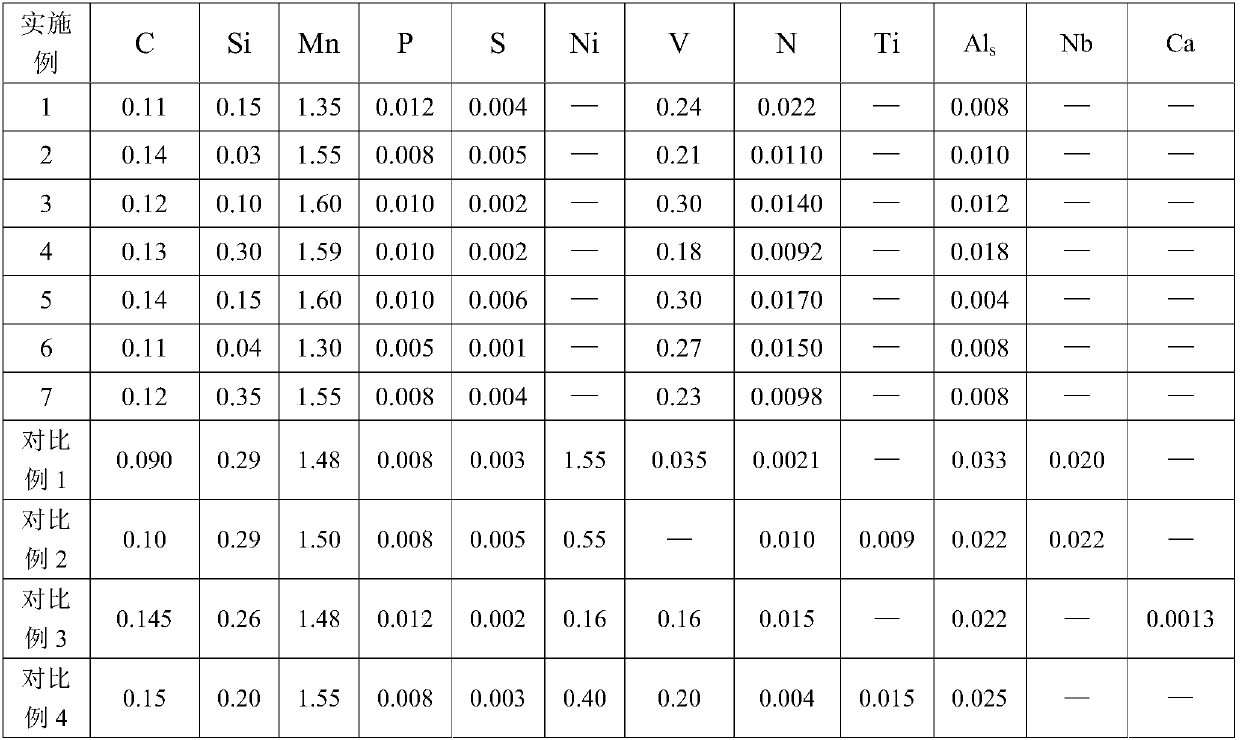

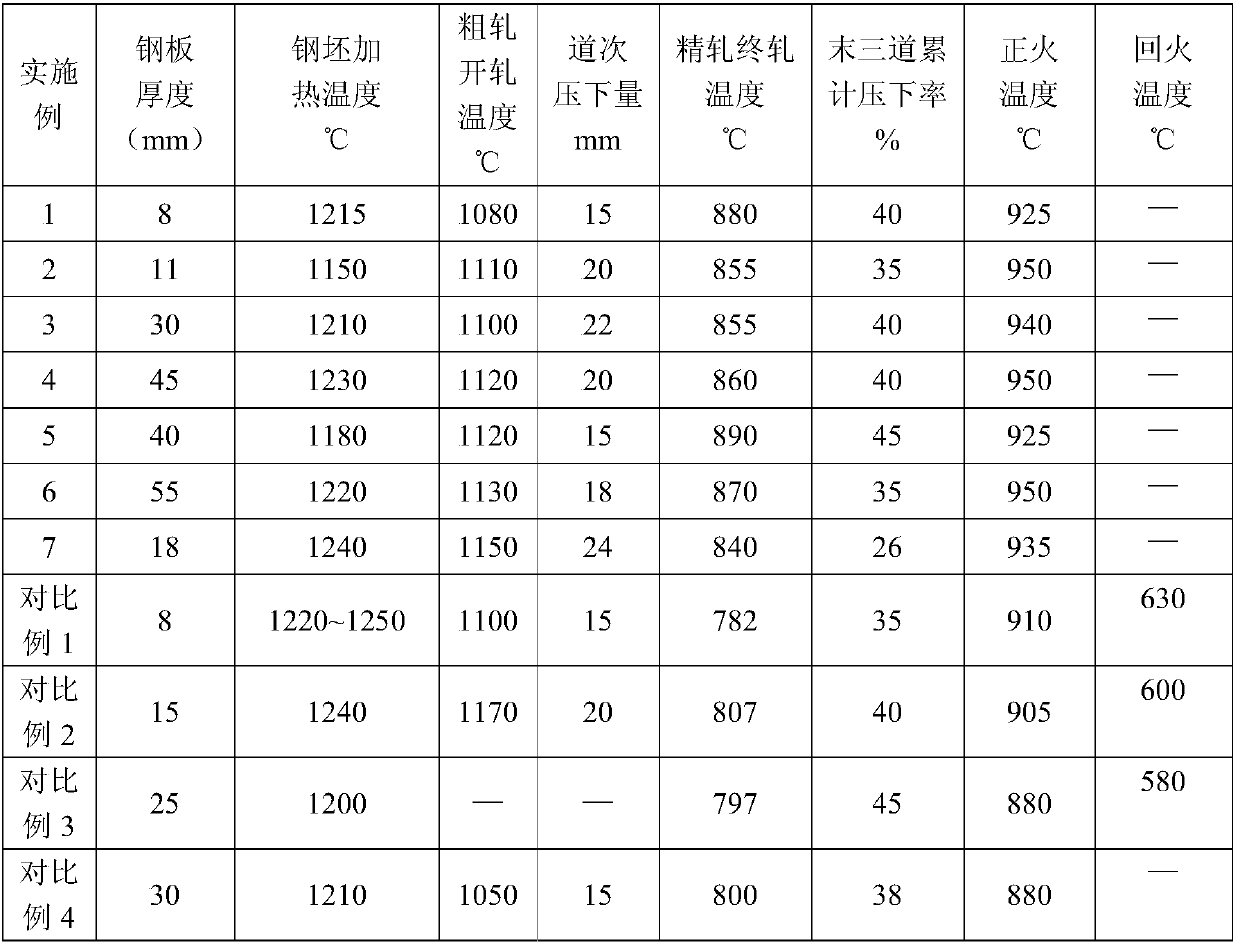

Steel plate for low-temperature pressure container and manufacturing method thereof

ActiveCN107937805AImprove mechanical propertiesGood welding performanceChemical compositionEconomic benefits

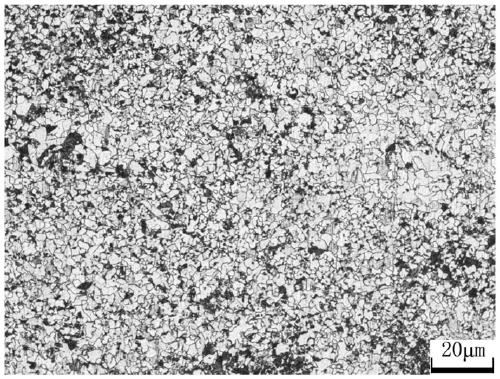

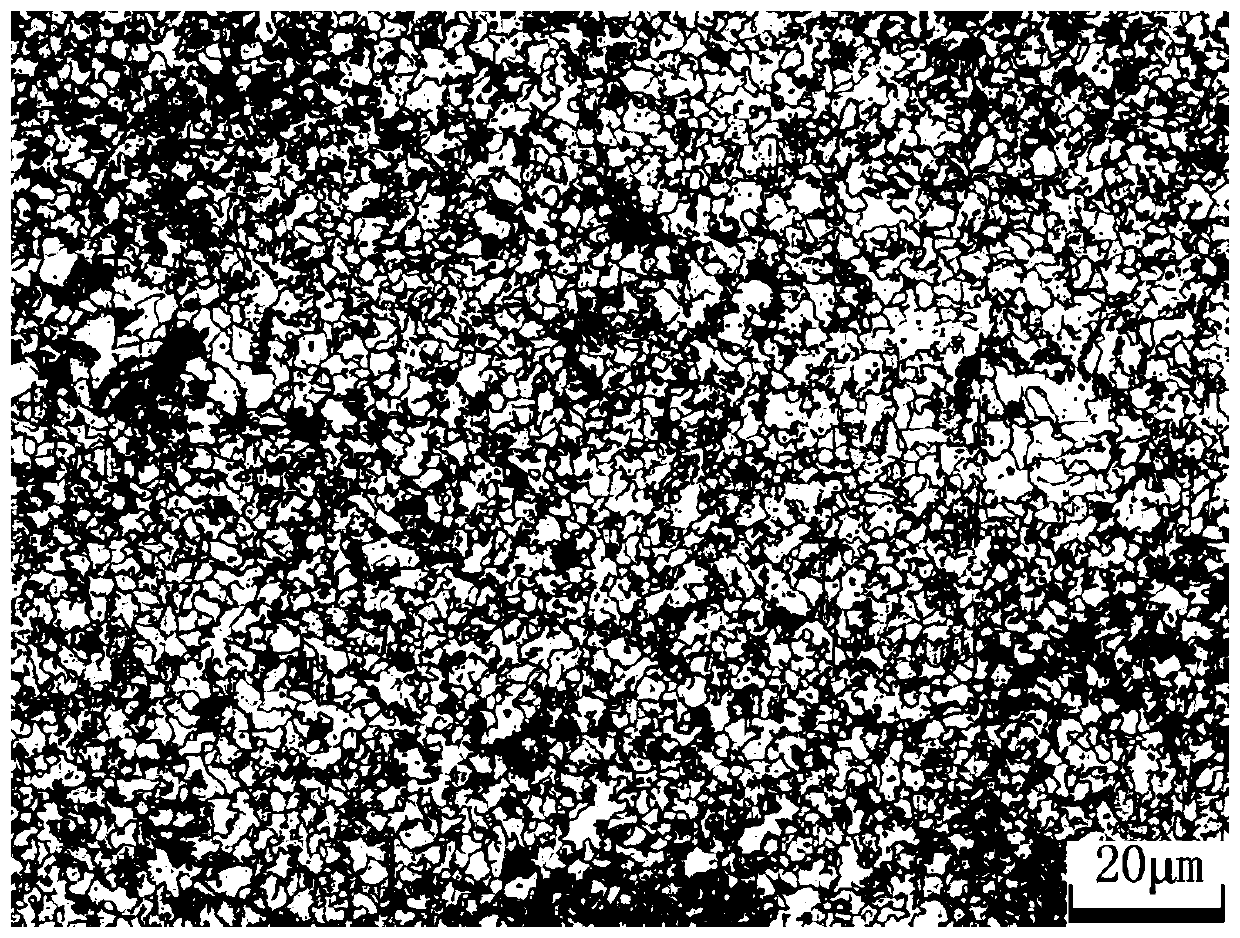

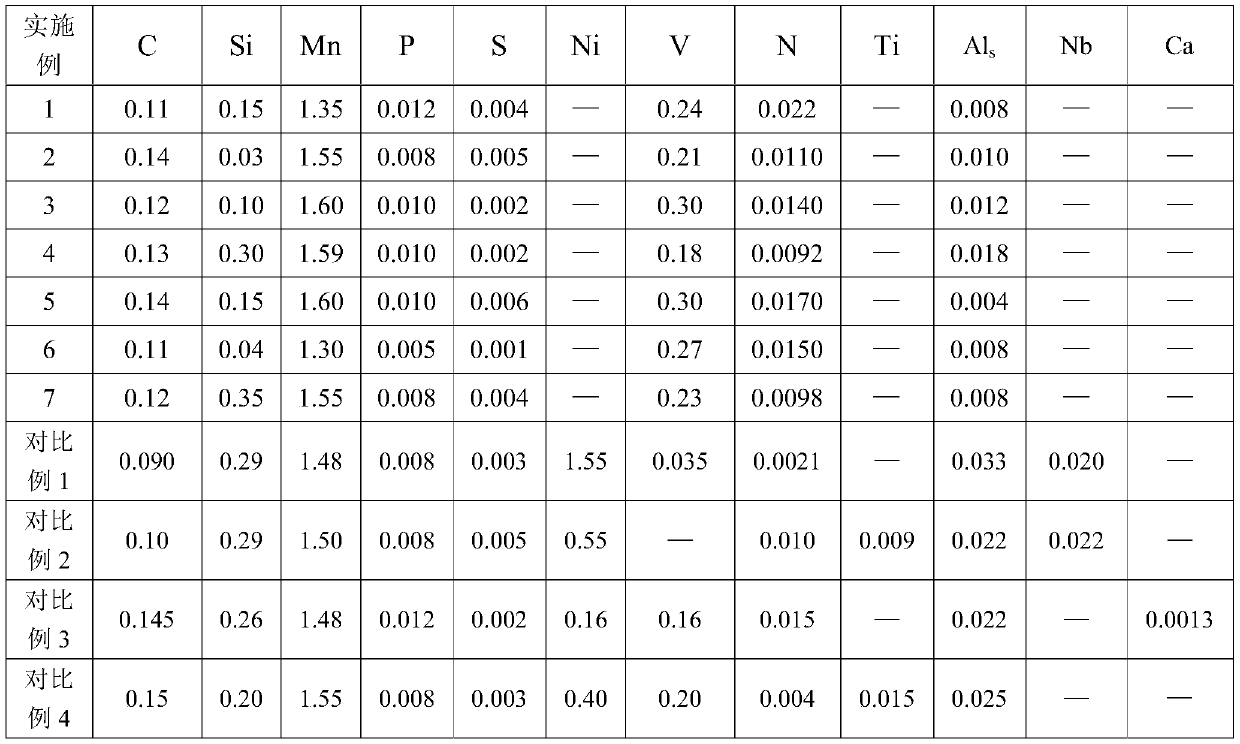

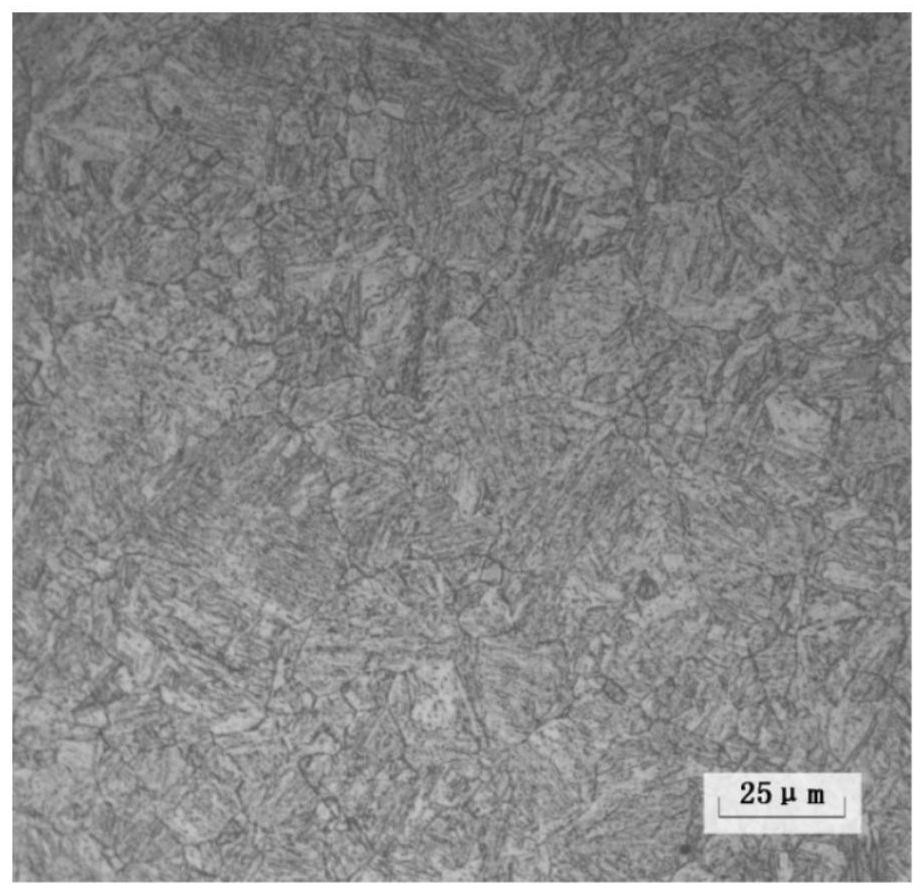

The invention discloses a steel plate for a low-temperature pressure container and a preparation method of the steel plate, the steel comprises the chemical components of, by weight, 0.110-0.140% of C, less than or equal to 0.15% of Si, 1.30-1.60% of Mn, less than or equal to 0.015% of P, less than or equal to 0.005% of S, 0.21-0.30% of V, 0.0090-0.0220% of N, less than or equal to 0.020% of Alt,and the balance Fe and inevitable impurities, and meanwhile, the components satisfy the conditions that V / C is greater than or equal to 1.6 but smaller than or equal to 2.8 and V / (C+Si) is greater than or equal to 0.9 but smaller than or equal to 1.25 simultaneously. According to the steel plate for the low-temperature pressure container and the manufacturing method thereof, the steel strength ishigh, the low-temperature impact toughness is good, KV<2> is greater than or equal to 100 J at -70 DEG C, an excellent manufacturing material is provided for the low-temperature pressure container, afoundation is laid for the large scale and light weight of the movable type pressure container, and the carrying efficiency and the economic benefit of the movable type pressure container are greatlyimproved.

Owner:武汉钢铁有限公司

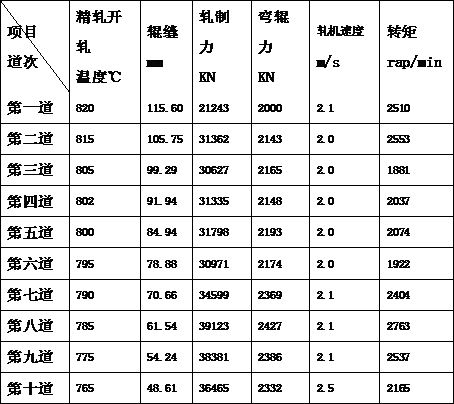

Wide pure-nickel strip cold-rolling process

InactiveCN104998902AOptimized rolling processReduce deformation resistanceRoll force/gap control deviceTension/compression control deviceMaterials scienceRolling mill

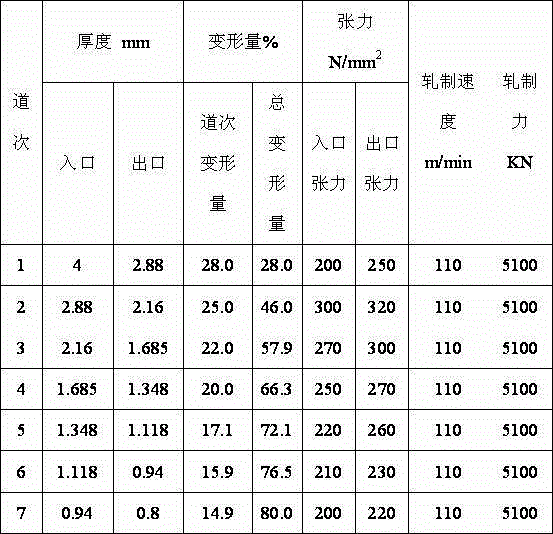

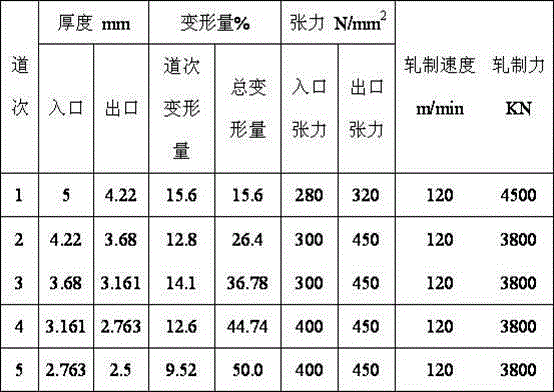

The invention discloses a wide pure-nickel strip cold-rolling process. The wide pure-nickel strip cold-rolling process is characterized in that an annealed pure-nickel strip with a thickness of 4-6.0 mm is rolled by 5-10 passes to a target thickness of 0.8-2.5 mm by adopting a twenty-roll reversible type cold-rolling mill unit, wherein the rolling force is 3000-8000 KN; the deformation per pass is 8%-30%; the deformation at next pass is 75%-94% of the deformation at the last pass; the rolling speed is kept at 30-120m / min; and outlet tension is 1.1-1.5 times inlet tension. According to the wide pure-nickel strip cold-rolling process, in the rolling process, proportion of front and back tension and changes of rolling force are strictly controlled; the deformation per pass is controlled to 8%-30%; difference of rolling force between passes is within 800 KN; the strip shape and the thickness can be controlled very well; and the nickel strip which is 1300-1400 mm wide can still obtain good strip shape without strip breakage even the thickness of the nickel strip is reduced after multi-pass rolling.

Owner:BAOJI TITANIUM IND

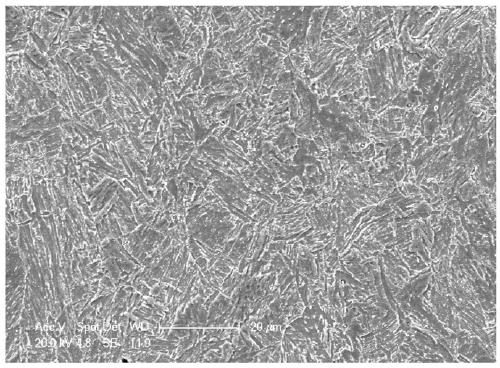

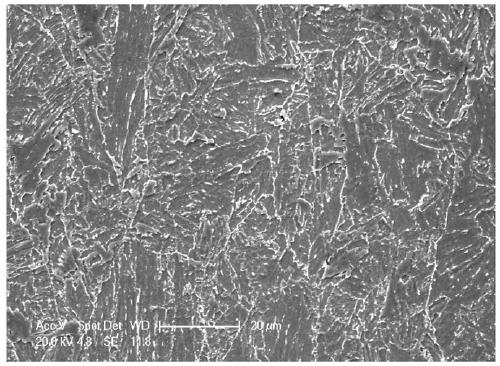

Method for reducing medium-chromium ferritic stainless steel surface rough belt

ActiveCN110252809AImprove the heating effectOptimized rolling processTemperature control deviceMetal rolling arrangementsFurnace temperatureChromium

The invention belongs to the field of steel rolling, and relates to a method for reducing a medium-chromium ferritic stainless steel surface rough belt. The method for reducing the medium-chromium ferritic stainless steel surface rough belt sequentially comprises the steps of heating, descaling at ultrahigh pressure, rough rolling and fine rolling, wherein when the temperature of the nature is smaller than 20 DEG C, the furnace temperature of a heating zone for heating is 1150 to 1200 DEG C, and the furnace temperature of a soaking zone is 1200 to 1250 DEG C; and when the temperature of the nature is more than 20 DEG C, the furnace temperature of the heating zone 1100 to 1160 DEG C, and the furnace temperature of the soaking zone is 1150 to 1200 DEG C. According to the method for reducing the medium-chromium ferritic stainless steel surface rough belt provided by the invention, the ferritic stainless steel surface rough belt is reduced, and the stable mass production of chromium ferritic stainless steel is realized.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Production method of GH5188 square exhaust nozzle used for aircraft engine

ActiveCN104227344AUniform wall thicknessAccurate distributionJet propulsion plantsForming processesAviation

The invention discloses a production method of a GH5188 square exhaust nozzle used for an aircraft engine. The production method comprises the steps of blanking, heating, heading, punching, rolling and the like, wherein a ring blank obtained by rolling is extruded into a square billet by adopting a squaring process, and a mandrel supporter and a square saddle are adopted to form the exhaust nozzle finally. The production method has the following beneficial effects that blank production adopts bending after rolling, the wall thickness is uniform and segregation is accurate, so that the wall thickness is uniform after a forge piece is formed, and the utilization rate of raw materials is improved; rolling is adopted during blank production, the mandrel supporter and the square saddle are adopted during forming, and rolling and forming processes are optimized, so that the forge piece has uniform tissue and stable mechanical property, and the service life is prolonged.

Owner:GUIZHOU AVIATION TECHN DEV

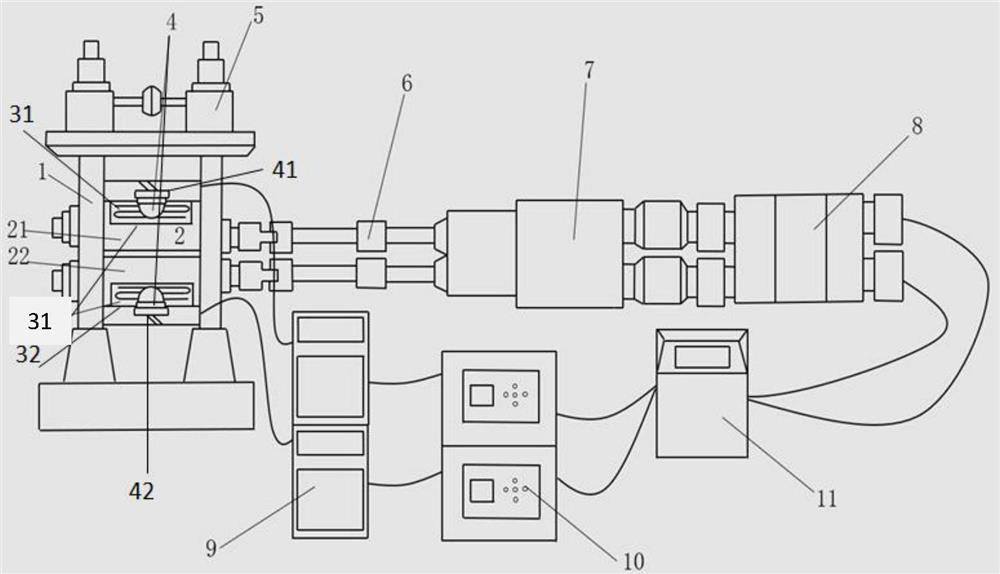

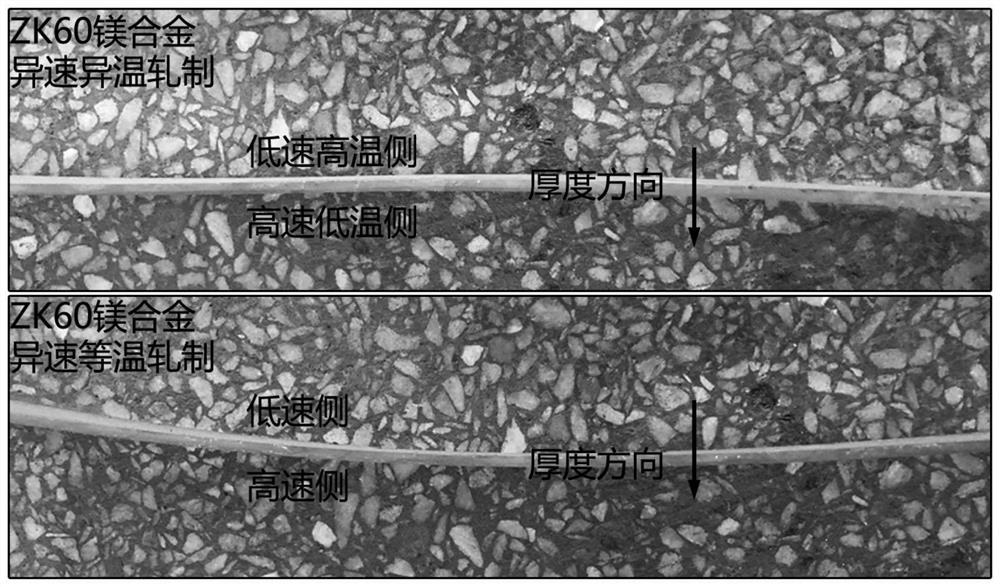

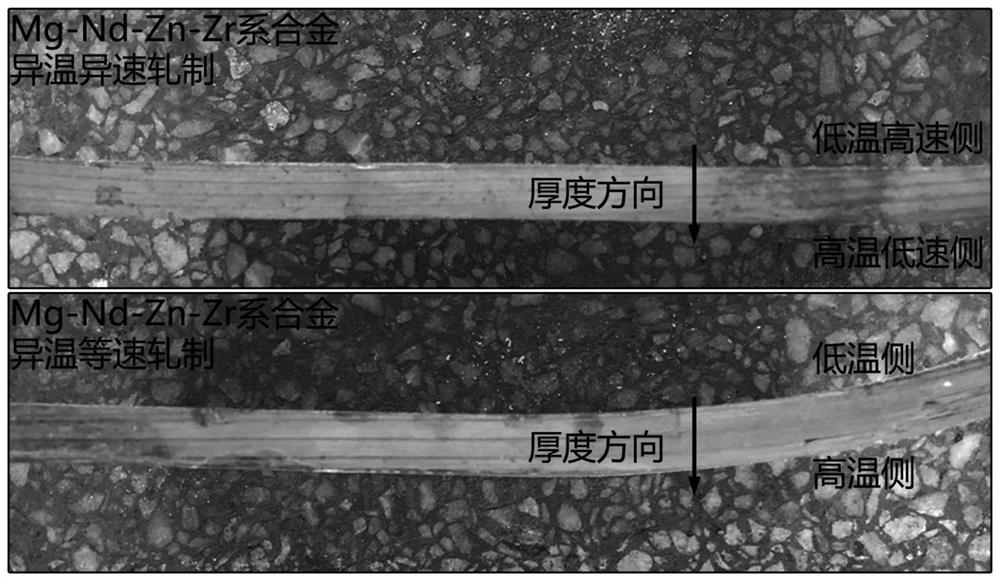

Magnesium alloy plate strip different-temperature different-speed coordinated rolling device and application

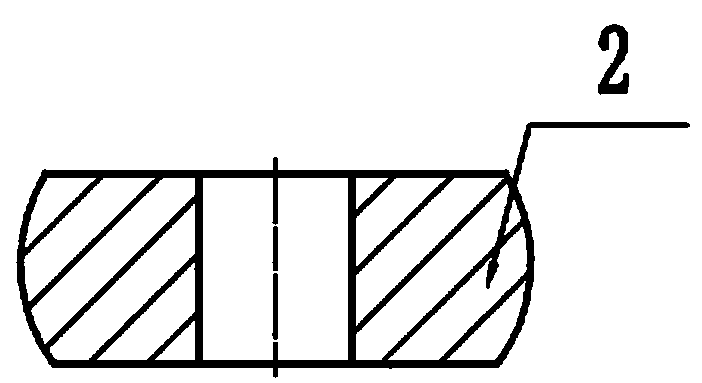

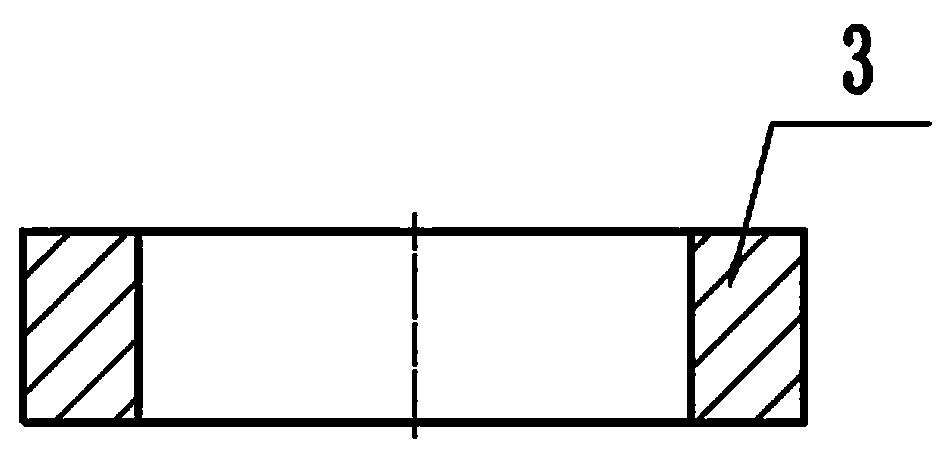

PendingCN114226461AEasy to bendIngenious designTemperature control deviceRollsReduction driveElectric machinery

The invention provides a magnesium alloy plate strip different-temperature different-speed coordinated rolling device and application, and belongs to the field of magnesium alloy machining. According to the different-temperature and different-speed coordinated rolling device, a roller induction heating system and a roller speed adjusting system are arranged on a rolling mill; the roller induction heating system comprises an induction coil, and the heating temperature of the upper temperature measuring probe is controlled by a heating system console. The roller speed adjusting system comprises a motor, a speed reducer, a coupler and the like which are respectively connected with the upper roller and the lower roller; the temperatures and the speeds of the upper roller and the lower roller are independently adjusted through a master console. According to the device, the different-speed ratio and the different-temperature ratio of the upper roller and the lower roller can be set according to needs, different-temperature and different-speed rolling is conducted on a magnesium alloy plate, and the magnesium alloy plate strip of a thickness-direction gradient structure is prepared. According to the device and the process, the two problems that in the current magnesium alloy field, a gradient structure in the thickness direction of a plate strip is difficult to prepare, and asymmetrical rolling plate type bending is serious are solved at the same time. And technical support is provided for future application expansion of the wrought magnesium alloy.

Owner:HARBIN INST OF TECH AT WEIHAI

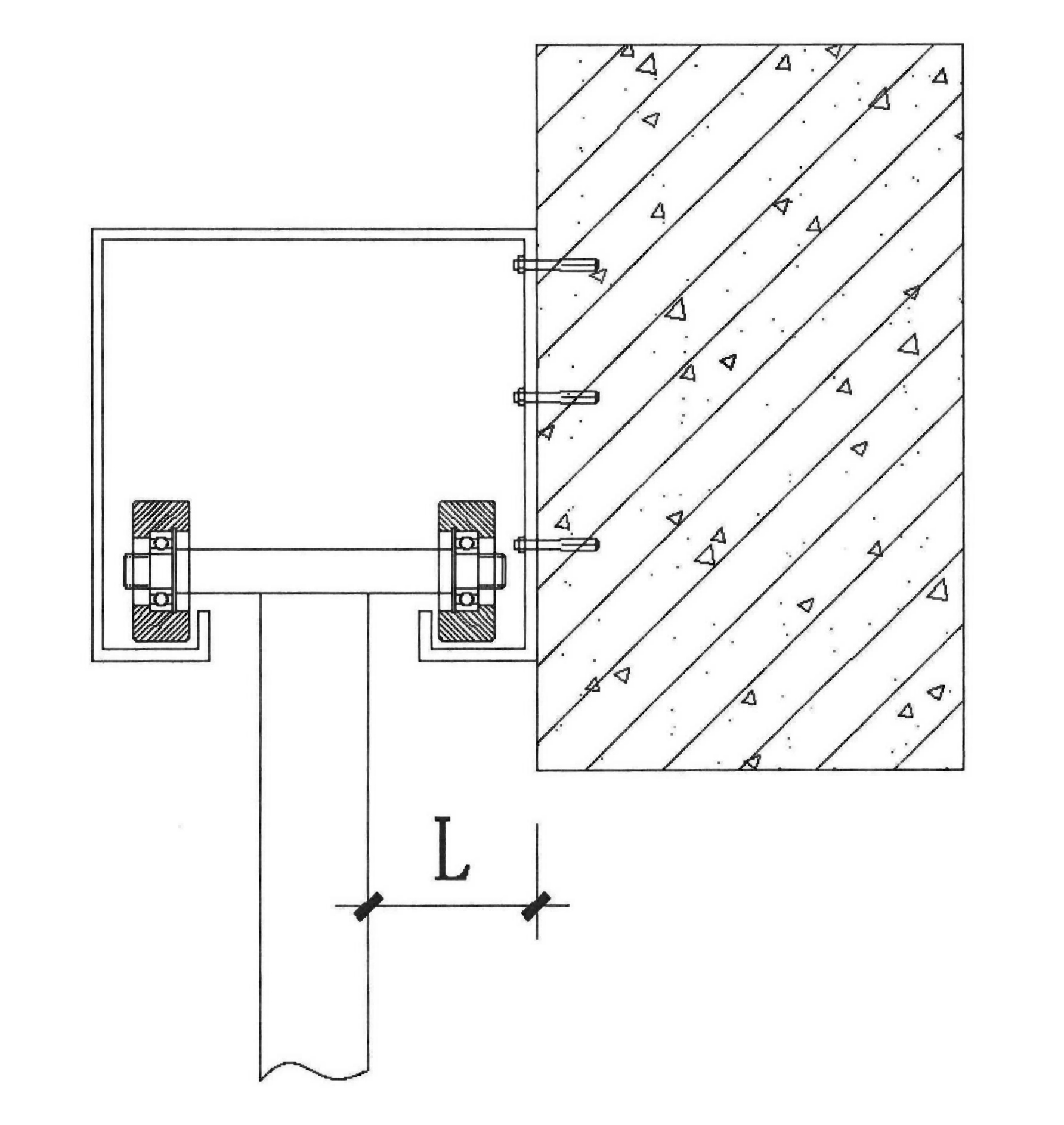

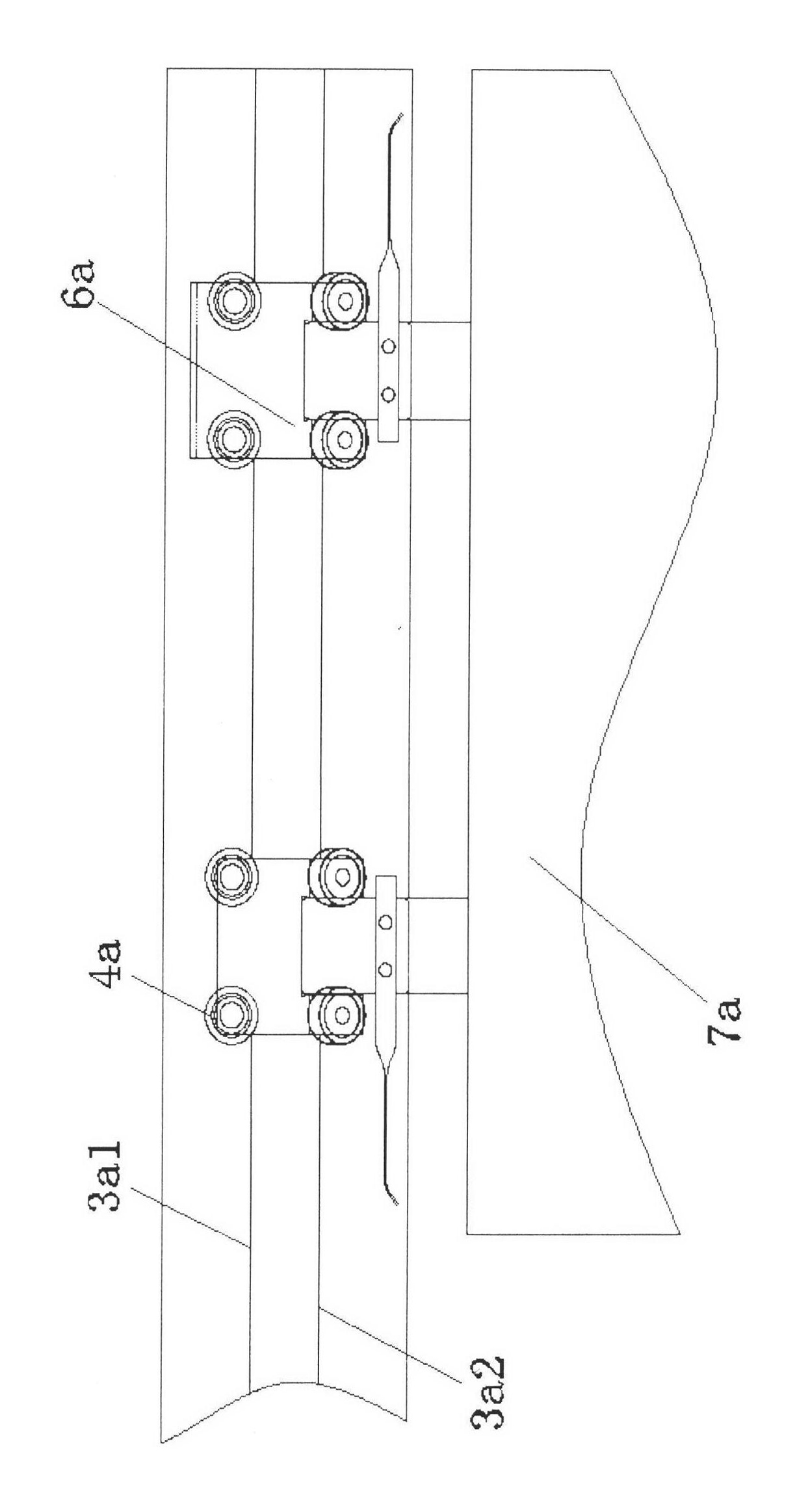

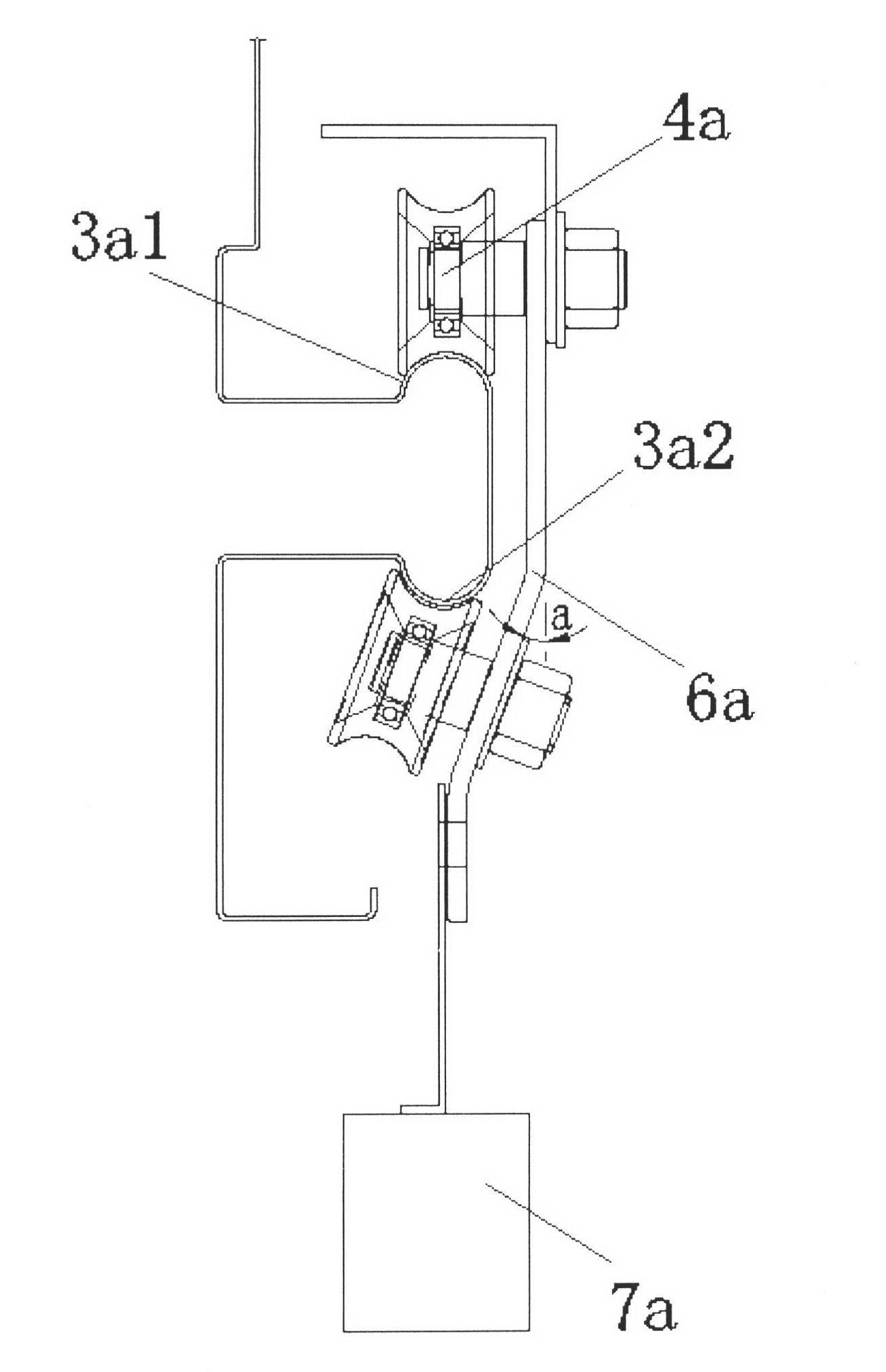

Main frame for suspension type electric sliding door

ActiveCN102409919ALow failure rateReduce the overall heightPower-operated mechanismWing suspension devicesMotor driveManufacturing technology

The invention relates to the field of electric sliding doors, in particular to a main frame for a suspension type electric sliding door. A technical scheme provided by the invention is as follows: a motor 2, a rail 3 and roller wheels 4 which are matched with the rail are arranged at one side of a back plate, which is fixed with a wall surface, on a main frame; door leaf fixing pieces 6 are connected to the roller wheels and the roller wheels are connected with the upper part of a door leaf 7 through the door leaf fixing pieces; and the motor drives the door leaf fixing piece and drives the roller wheels to roll along the rail through a transmission mechanism. The main frame for the suspension type electric sliding door is characterized in that only one working sliding rail is arranged on the rail 3; the roller wheels are in one-to-one correspondence with the door leaf fixing pieces; each roller wheel is further provided with an anti-prying plate 8; the anti-prying plates are fixed and connected with the door leaf fixing pieces; the lower part of each anti-prying plate is provided with a curved surface 9 which is matched with the cross section of the rail and through which the rail can pass; and the roller wheels are arranged in the space which is formed by the door leaf fixing pieces and the anti-prying plates. According to the main frame provided by the invention, the installation space of the main frame is saved, the structure is simple, the manufacture technology requirement is lower and the roller wheel faults are reduced, therefore the working position of the roller wheels in the rail is ensured, and the roller wheels can bear quite large door leaf accidental impact or lateral manmade sabotage.

Owner:李镇瀚

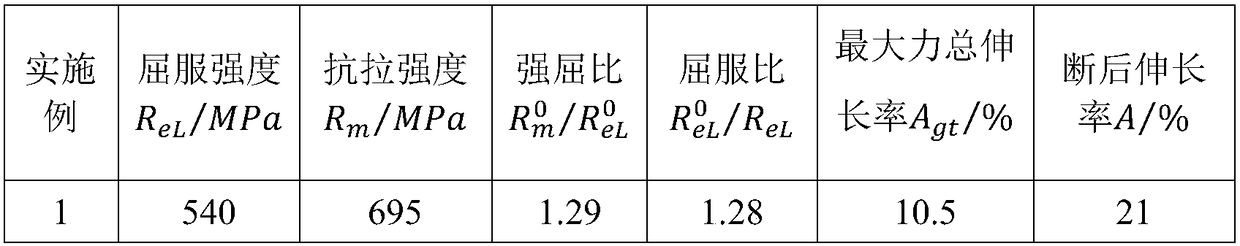

Low-yield-strength anti-seismic steel plate for building and production method of steel plate

The invention discloses a low-yield-strength anti-seismic steel plate for a building and a production method of the steel plate. The production method comprises a rolling procedure and a heat treatment procedure. The anti-seismic steel plate comprises, by mass, 0.010%-0.060% of C, 0.01%-0.05% of Si, 0.30%-0.60% of Mn, 0%-0.020% of P, 0%-0.010% of S, 0.01%-0.05% of Ti, 0%-0.006% of N, and the balance Fe and inevitable impurities. The steel plate does not contain precious metal elements, smelting cost is low, no equipment needs to be added in the production course, the process is simple, and the steel plate has high adaptability and promotional value and meanwhile has a high cost-performance ratio and good market prospects. The yield strength of the anti-seismic steel plate obtained through the method ranges from 205 MPa to 245 MPa, the tensile strength of the anti-seismic steel plate ranges from 300 MPa to 400 MPa, the elongation percentage of the anti-seismic steel plate is larger than 50%, the anti-seismic steel plate has a good low-cycle fatigue property, and various indexes of the anti-seismic steel plate meet anti-seismic property requirements completely. According to the method, the steel plate is made to have excellent welding performance through reasonable composition design, the rolling process and the heat treatment means, and the requirement of the high-performance building steel for the welding performance is met.

Owner:HEBEI IRON AND STEEL

Short-flow rolling preparation process of high-strength and high-plasticity AlN/AZ91D magnesium base composite material plate

ActiveCN107747071AQuality improvementHigh quality and high performanceMagnesium matrix compositeIngot

The invention relates to a short-flow rolling preparation process of a high-strength and high-plasticity AlN / AZ91D magnesium base composite material plate; solid solution and water quenching processesof a cast ingot before rolling are formulated; subsequent rolling and annealing processes are optimized; and a set of cold rolling process for preparing a high-strength and high-plasticity magnesiumbase composite material rolled plate is provided. The cold rolling process is high in reduction in pass, few in annealing times among passes and short in annealing time, and can realize industrial short-flow preparation. In particular, through the patent technology, namely the optimal ratio of solid solution process parameters to water quenching process parameters to rolling process parameters toannealing process parameters, the edge cracking problem in the cold rolling process is solved when the high-strength and high-plasticity cold-rolled plate is obtained, and finally, the high-quality and high-performance magnesium alloy composite material cold-rolled plate can be obtained with high efficiency.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

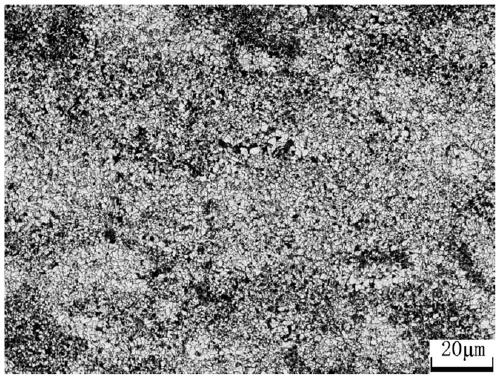

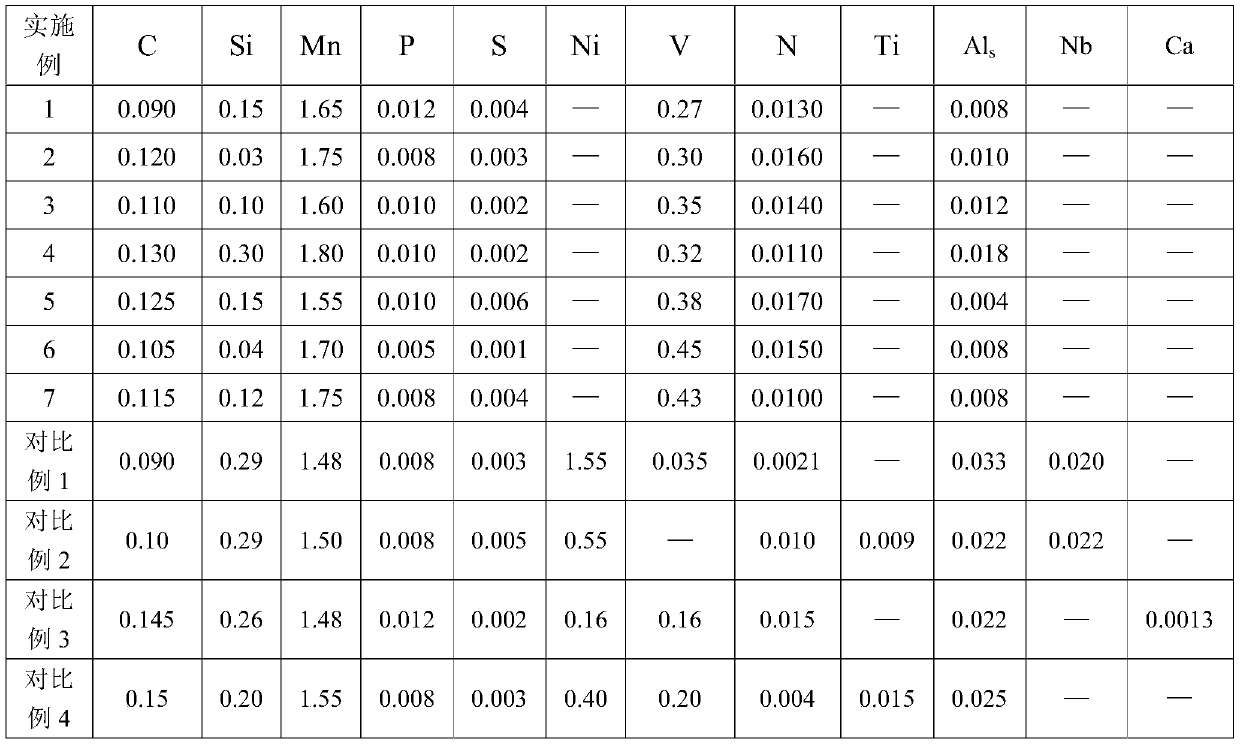

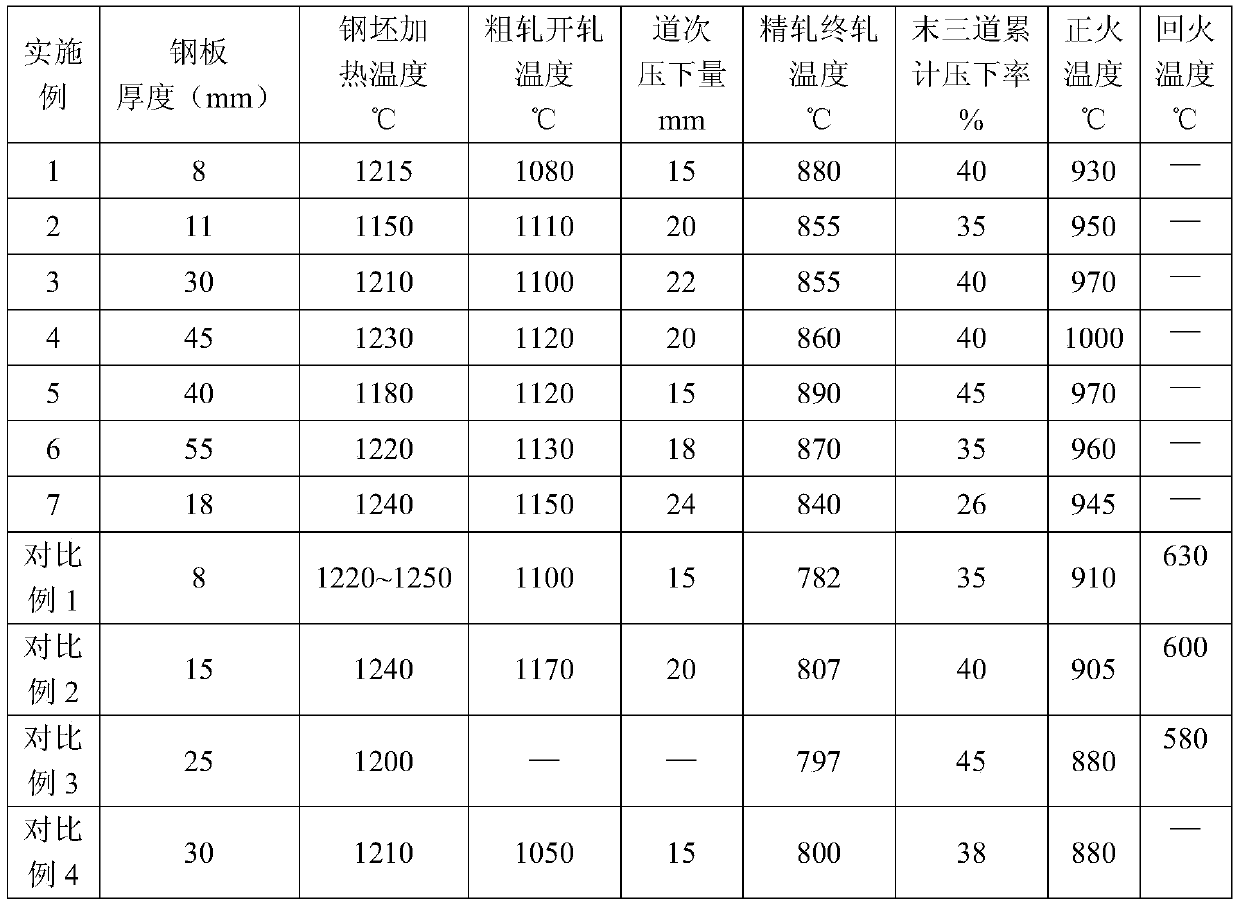

High-toughness steel plate for low-temperature pressure vessel and manufacturing method thereof

ActiveCN107937804BImprove mechanical propertiesGood welding performanceChemical compositionEconomic benefits

The invention discloses a steel plate used for a high-tenacity low-temperature pressure vessel and a manufacturing method thereof. Steel comprises the following chemical components including, by weight, 0.090-0.130% of C, not greater than 0.15% of Si, 1.40-1.80% of Mn, not greater than 0.012% of P, not greater than 0.004% of S, 0.27-0.45% of V, 0.010-0.020% of N, not greater than 0.020% of Alt andthe balance Fe and inevitable impurities; and meanwhile, V / C is greater than or equal to 3 and smaller than or equal to 4, and V / (C+Si) is greater than or equal to 1.2 and smaller than or equal to 3.The steel provided by the invention is high in strength and good in low-temperature impact toughness, the minus 60 DEG C KV2 is greater than or equal to 80 J, an excellent manufacturing material is provided for the low-temperature pressure vessel, a foundation is laid for enlargement and lightweight of the low-temperature pressure vessel, furthermore, the carrying efficiency of the movable pressure vessel is greatly improved, and the economic benefit of the movable pressure vessel is greatly increased.

Owner:武汉钢铁有限公司

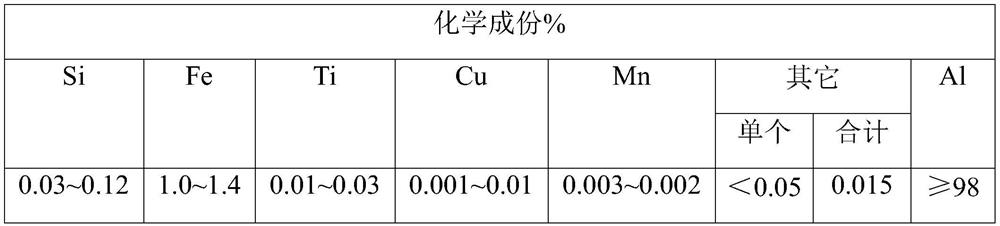

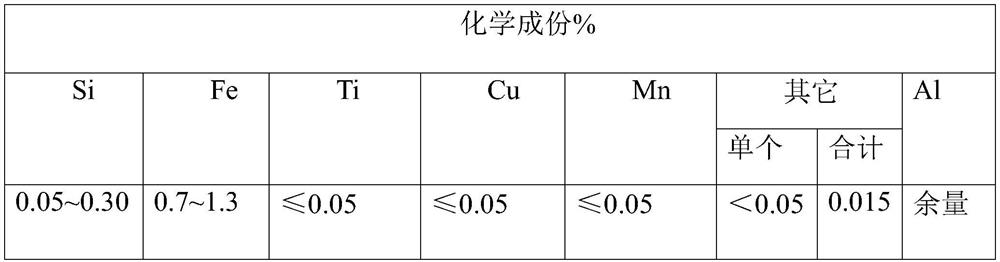

Aluminum foil for high-extension high-deep-drawing-power aluminum-plastic film and production process of aluminum foil

The invention discloses an aluminum foil for a high-elongation high-deep-drawing power aluminum-plastic film and a production process of the aluminum foil. The aluminum foil for the high-elongation high-deep-drawing power aluminum-plastic film comprises the following raw material alloys in percentage by weight: 0.03-0.12% of Si, 1.0-1.4% of Fe, 0.01-0.03% of Ti, 0.001-0.01% of Cu, 0.003-0.02% of Mn, less than 0.05% of other single aluminum, 0.015% of other aluminum and more than or equal to 98% of Al. The aluminum foil for the power aluminum-plastic film has the advantages of good surface quality, good stability, high tensile strength, high tensile strength, high tensile strength, high tensile strength, high tensile strength, high tensile strength, high tensile strength, high tensile strength, high tensile strength, high tensile strength, high tensile strength, high tensile strength, and the product consistency is good, the deep drawability can reach 7.5 mm or above, and the ductility is 20% or above. By systematically improving a casting, hot rolling and cold rolling production process, an aluminum-plastic film aluminum foil rolling process and an annealing process, the aluminum foil for the power aluminum-plastic film has relatively excellent cold stamping forming capacity and good quality stability and consistency, and has important significance in replacing an imported aluminum foil for the power aluminum-plastic film.

Owner:XIAMEN XIASHUN ALUMINUM FOIL

Economical low-temperature structural steel plate for polar region and manufacturing method thereof

The invention relates to an economical steel plate with the thickness reaching 80mm for polar region low-temperature environment and a production method thereof. The economical steel plate is preparedfrom the following components in percentage by weight: 0.04-0.10% of C, 0.15-0.40% of Si, 1.20-1.40% of Mn, 0.020-0.050% of Nb, 0.020-0.050% of V, 0.010-0.030% of Ti, 0.015-0.050% of Als, 0.10-0.40%of Ni, less than 0.010% of P, less than 0.003% of S, less than or equal to 0.40% of CEV, and the balance of Fe and inevitable impurities. Through the component design, by reasonably adjusting the relative content between each element and economically controlling Ni alloy elements beneficial to low-temperature toughness, by combining subsequent strengthening rolling and refined crystalline strengthening to remedy strength loss and improve core performance of a large-thickness steel plate, the whole thickness fracture surface of the obtained steel plate has high toughness, and the demands of polar region rigor application environment on high-performance steel are met.

Owner:SD STEEL RIZHAO CO LTD

An economical low-temperature structural steel plate for polar regions and its manufacturing method

The present invention relates to an economical steel plate for polar low temperature environment with a thickness of 80 mm and a production method thereof. %, Nb: 0.020‑0.050%, V: 0.020‑0.050%, Ti: 0.010‑0.030%, Als: 0.015‑0.050%, Ni: 0.10‑0.40%, P<0.010%, S<0.003%, CEV≤0.40 %, and the rest are Fe and inevitable impurities. In the composition design of the invention, the relative content of each element is reasonably adjusted and the Ni alloy element beneficial to low temperature toughness is economically controlled, and the strength loss is compensated by the subsequent strengthening rolling and grain refinement strengthening, and the performance of the core part of the large-thickness steel plate is improved. The entire thickness of the steel plate has high strength and toughness, and meets the needs of high-performance steel in polar harsh application environments.

Owner:SD STEEL RIZHAO CO LTD

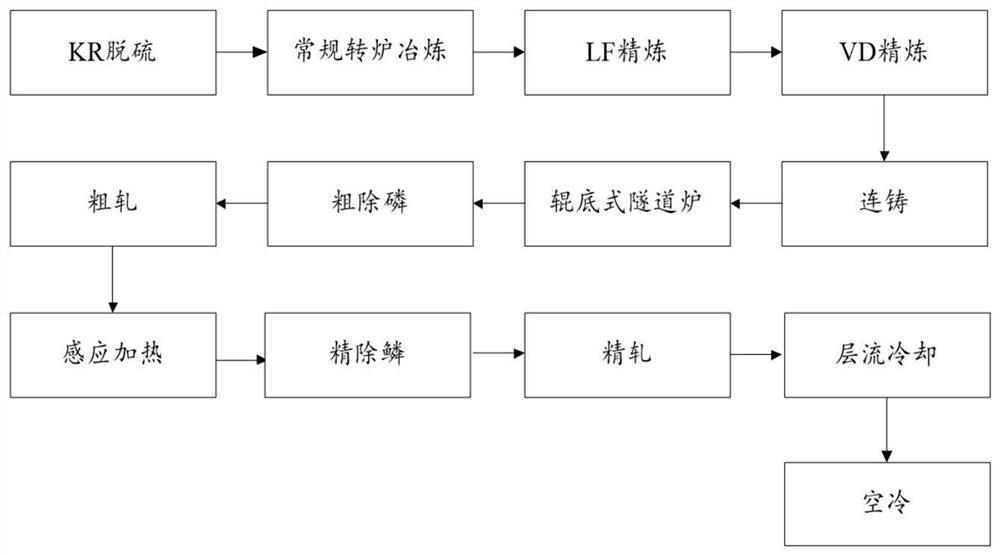

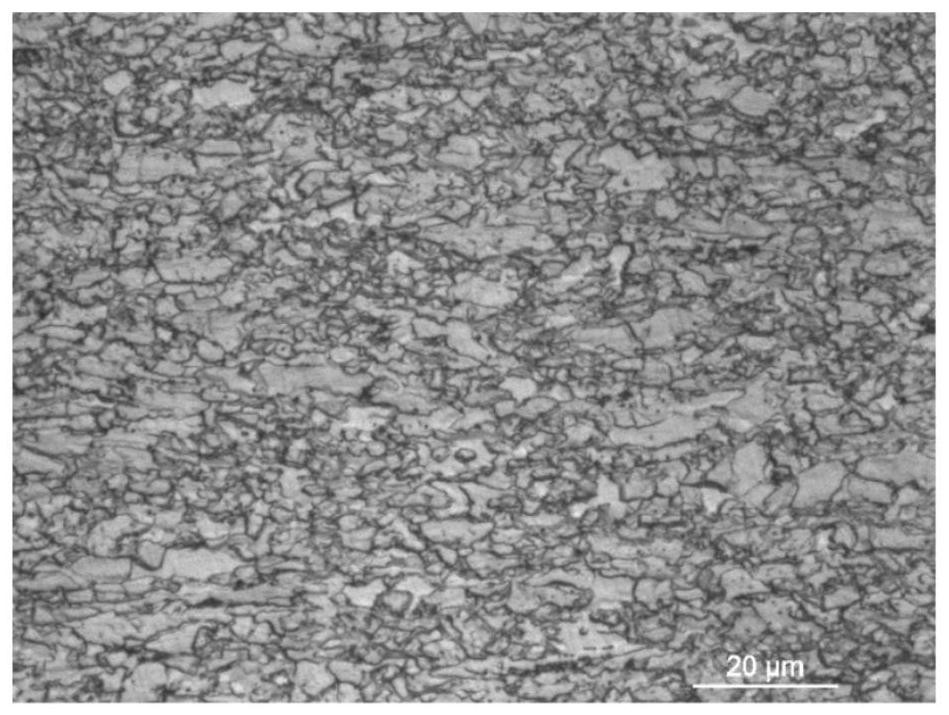

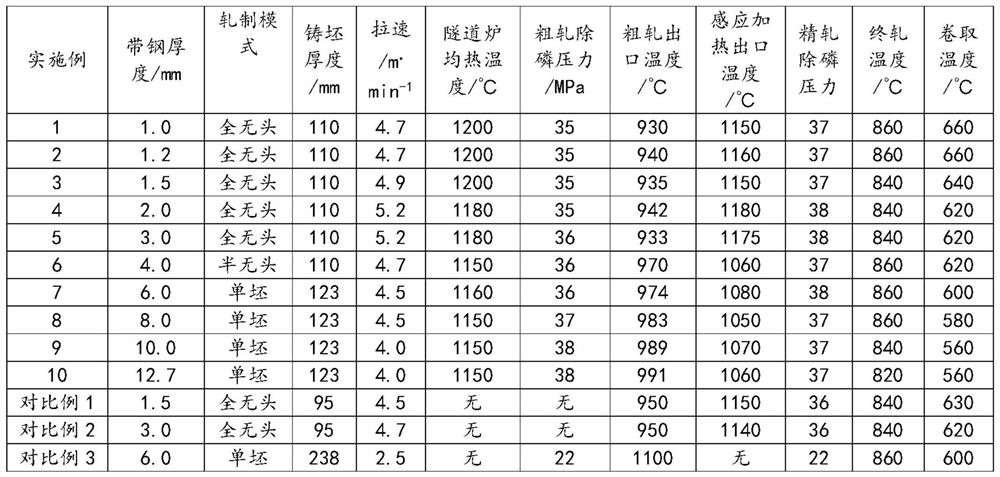

800MPa steel based on multi-mode thin slab continuous casting and rolling production line and production method thereof

InactiveCN113025918AGuaranteed StrengthOptimized rolling processFurnace typesHeat treatment furnacesProduction lineMetallurgy

The invention provides 800MPa steel based on a multi-mode thin slab continuous casting and rolling production line, and belongs to the technical field of steel. The 800MPa steel based on the multi-mode thin slab continuous casting and rolling production line comprises the following chemical components in percentage by mass: 0.03 to 0.15 percent of C, less than or equal to 0.05 percent of Si, 1.3 to 2.1 percent of Mn, 0.02 to 0.35 percent of Al, less than or equal to 0.010 percent of P, less than or equal to 0.005 percent of S, 0.010 to 0.10 percent of Nb, 0.10 to 0.30 percent of Mo, 0.015 to 0.15 percent of Ti, 0.1 to 0.5 percent of Cr, less than or equal to 0.005 percent of N and the balance of Fe and inevitable impurities. By improving the chemical components, the production line and the preparation method for the steel, the obtained steel is good in pattern, high in dimensional precision and small in strength fluctuation. The invention further provides a production method for the 800MPa steel based on the multi-mode thin slab continuous casting and rolling production line.

Owner:SHOUGANG CORPORATION

Production method for improving flaw detection qualified rate of ultra-wide single-weight microalloyed steel plate

InactiveCN111041152AImprove purityReduce sulfur contentMolten metal pouring equipmentsDie castingIngot

The invention discloses a method for improving the flaw detection qualified rate of an ultra-wide single-weight microalloyed steel plate. The production method comprises the following steps: smeltingmolten steel in an electric furnace, refining in an LF refining furnace, carrying out vacuum treatment in a vacuum furnace, carrying out die casting on the molten steel after smelting by adopting a flat steel ingot, carrying out heating, rolling and heat treatment on the steel ingot in a soaking furnace, carrying out flaw detection, and finally obtaining a finished steel plate. According to the method, the process idea of clean steel is adopted, the purity of the molten steel is improved, the sulfur content is reduced, Ca treatment is carried out, the heating and rolling process of the flat steel ingot is optimized, the characteristics of high purity, compact internal quality and the like are achieved, and the width of the obtained ultra-wide single-weight microalloyed steel plate is 3850-4000 mm with a single weight of 15-35t, and the qualified rate of flaw detection is 100%; the averaged transverse impact work of the steel plate at minus 30 DEG C is 180-220J, Z-direction performanceis 55-75%, good comprehensive performance and welding performance are achieved, cost is low, and the application prospects are wide.

Owner:WUYANG IRON & STEEL

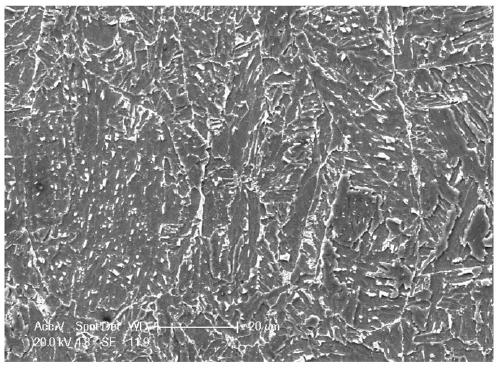

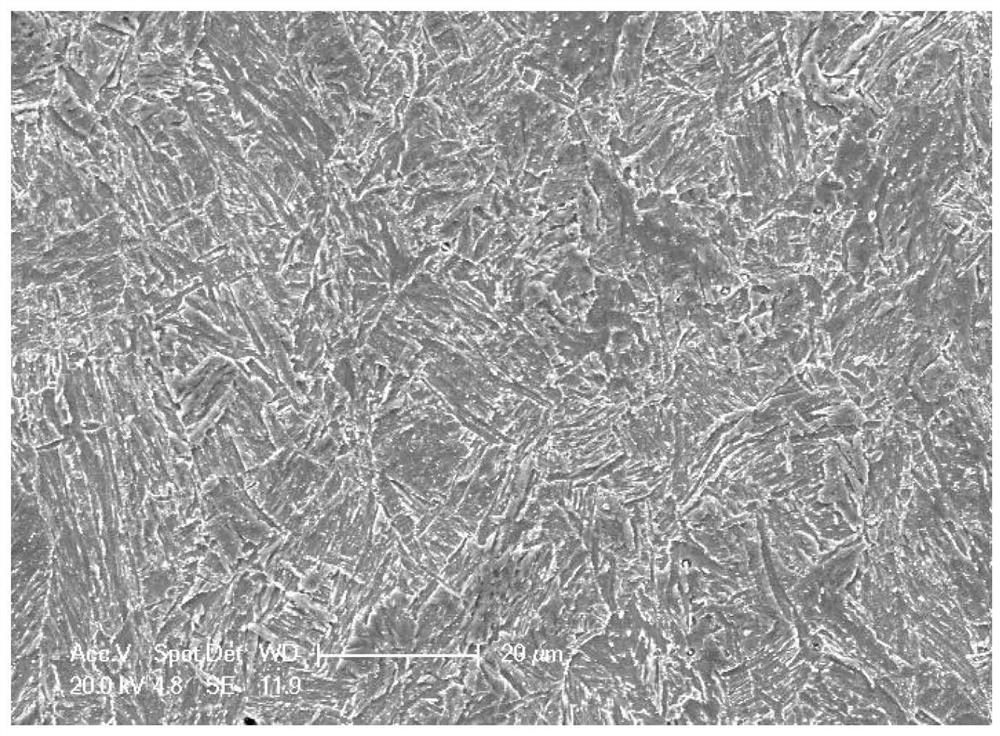

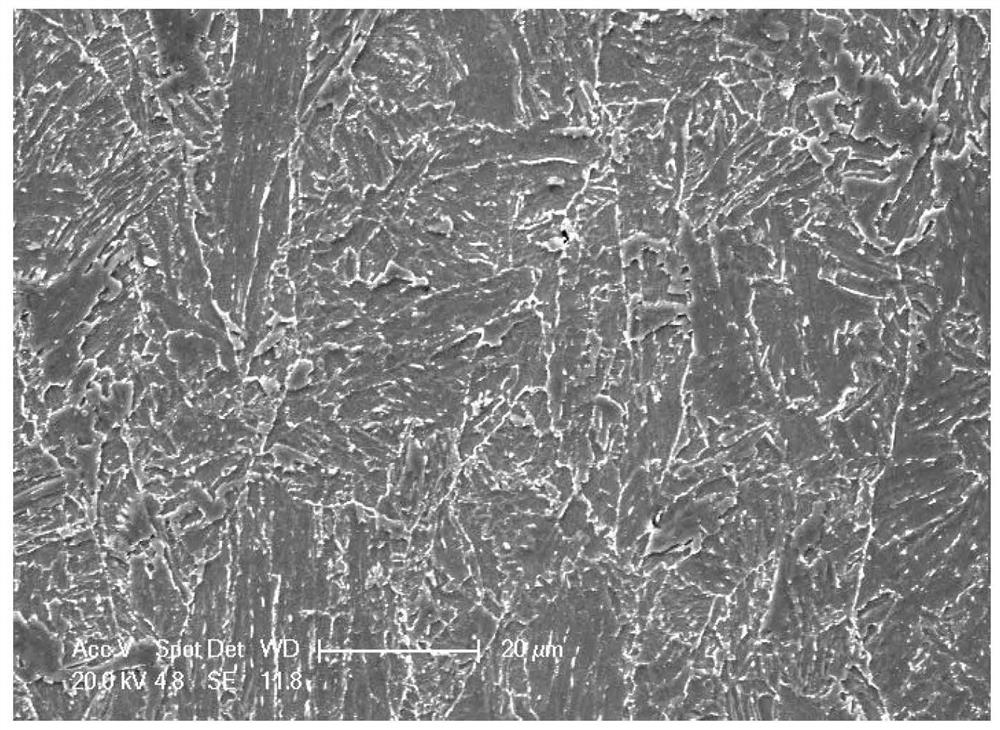

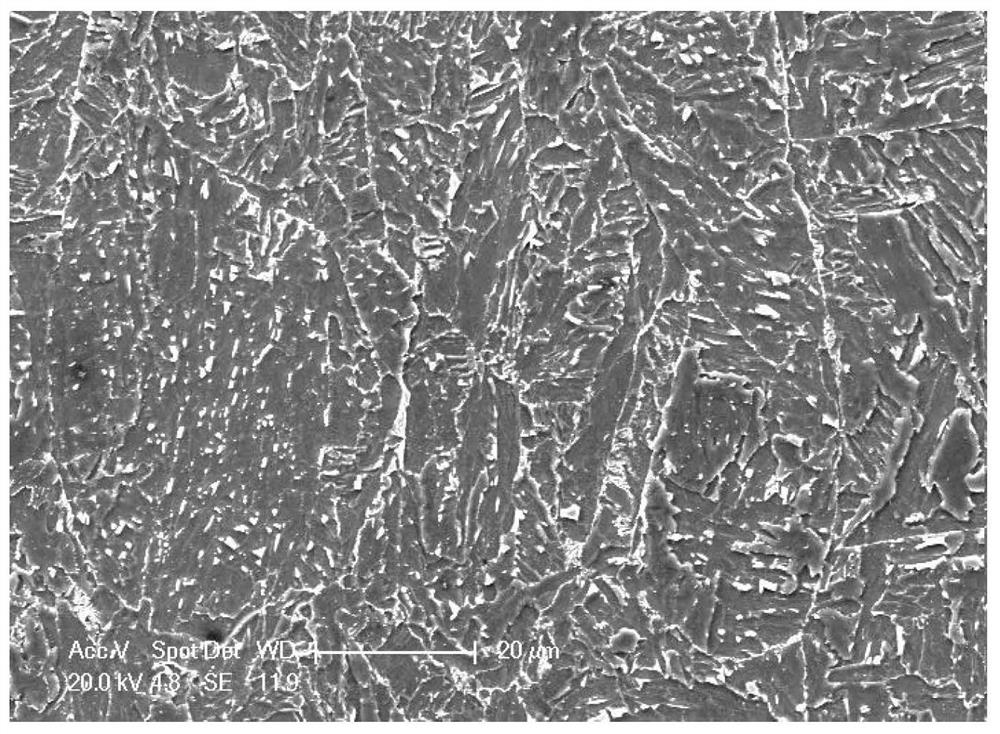

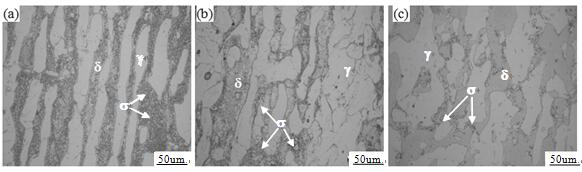

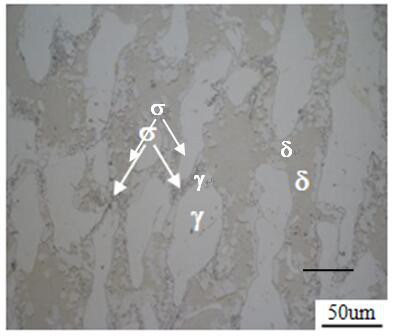

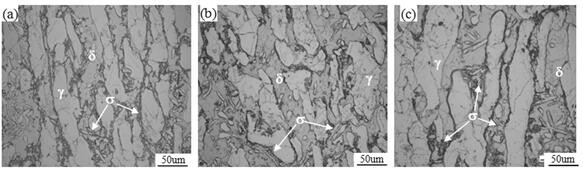

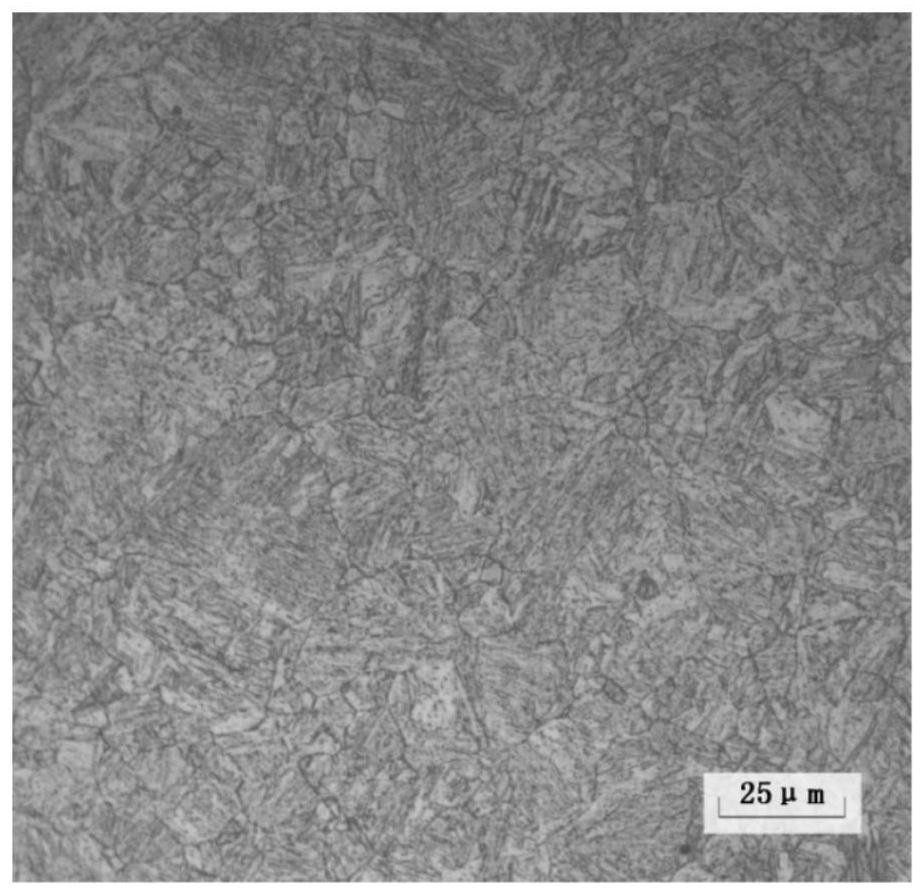

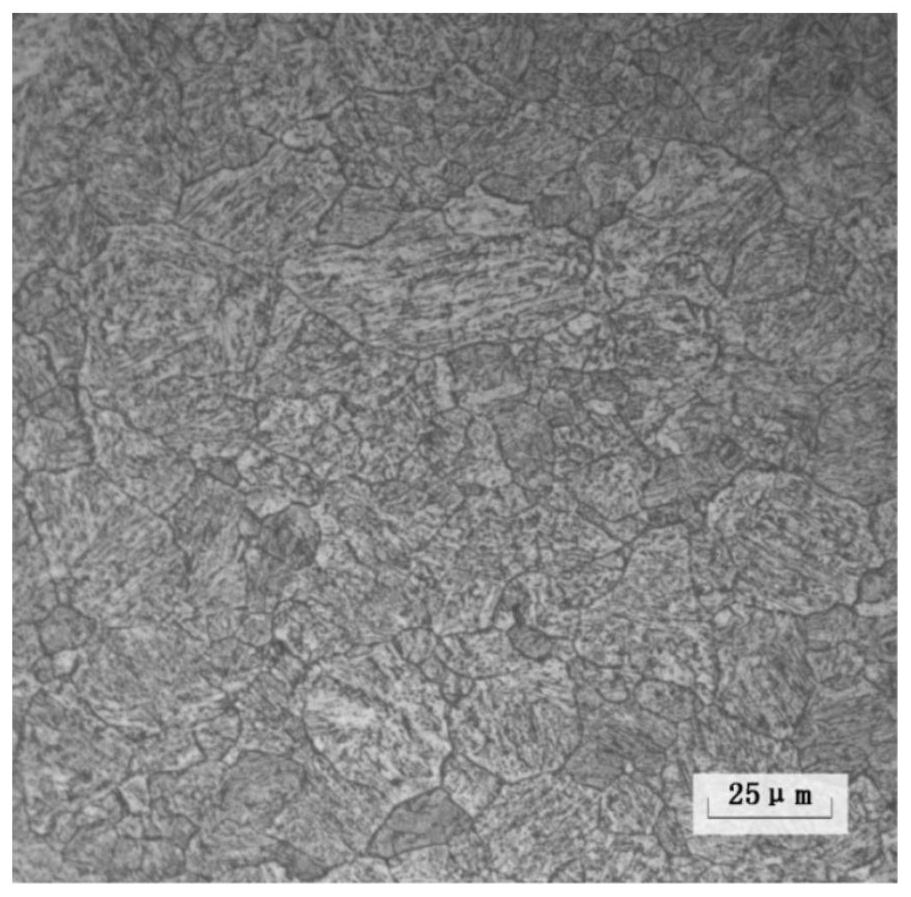

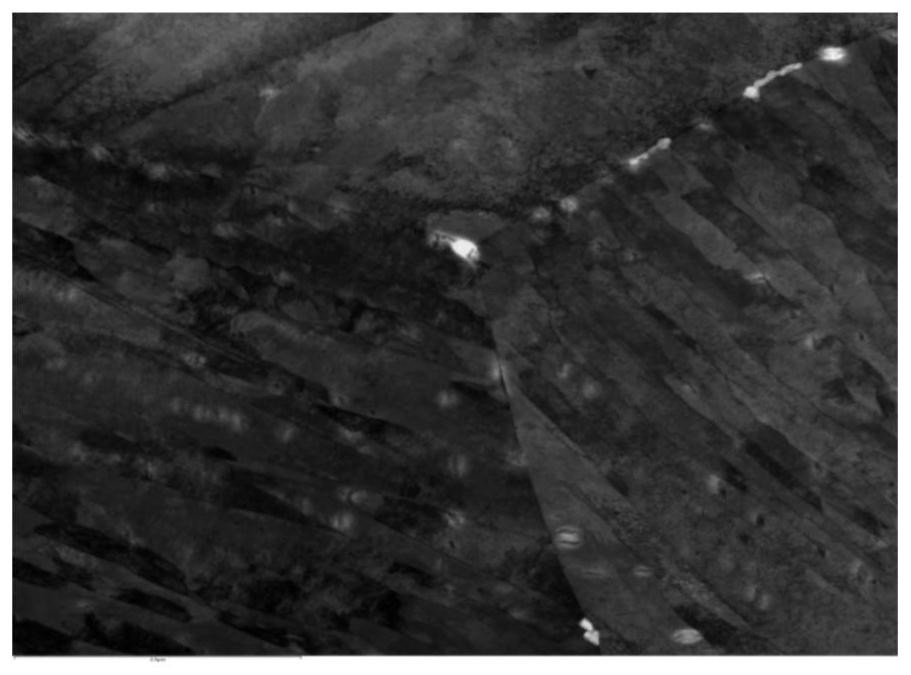

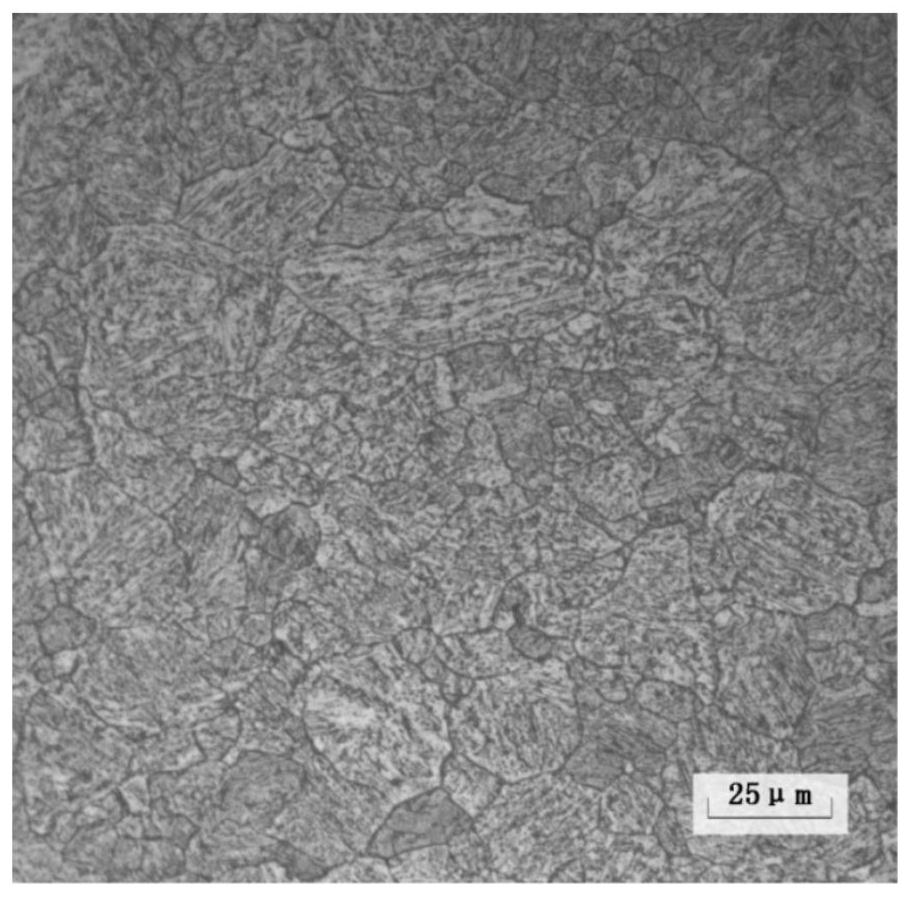

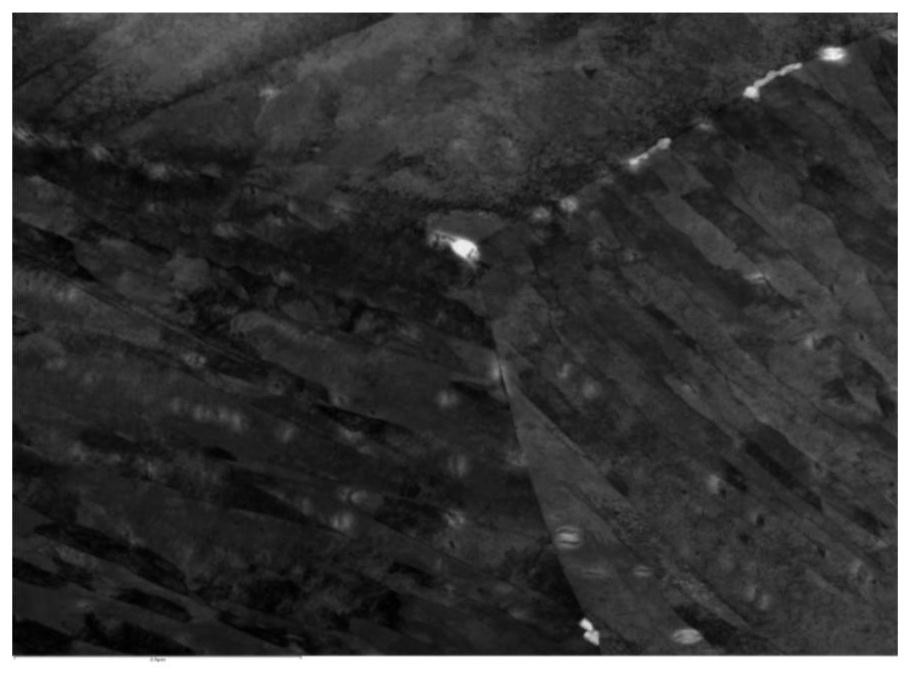

Thermal processing method to control the precipitation of σ phase in nodular ni-type duplex stainless steel at lower processing temperature

The invention discloses a thermal processing method for controlling the precipitation of Ni-type duplex stainless steel at a lower processing temperature σ phase. The amount of σ precipitated phase in the rolling process, the present invention adopts solid solution treatment and high temperature compression test, found the law of the influence of rolling temperature and deformation rate on the behavior of σ phase precipitation in Ni-saving duplex stainless steel plate, and determined the effective avoidance of σ phase The process parameters of phase precipitation and the relationship between the amount of σ phase precipitation and deformation parameters provide guidance for the optimization of the rolling process at lower temperatures. At the same time, this method can be used for the 23%Cr high Mn series Ni-type duplex stainless steel In the field of industrial production such as hot rolling and post-processing of parts, it can solve the problems of deformation and cracking caused by the formation of precipitated phases in the process of hot processing.

Owner:KUNMING UNIV OF SCI & TECH

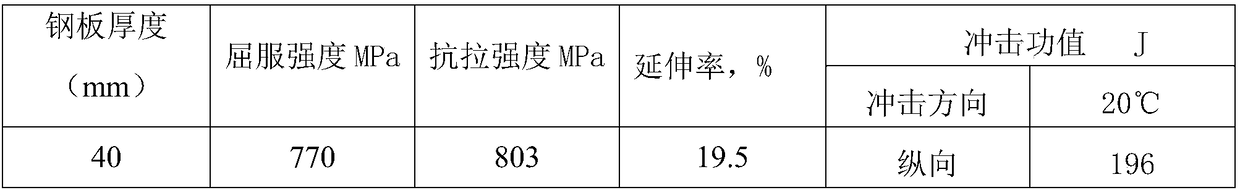

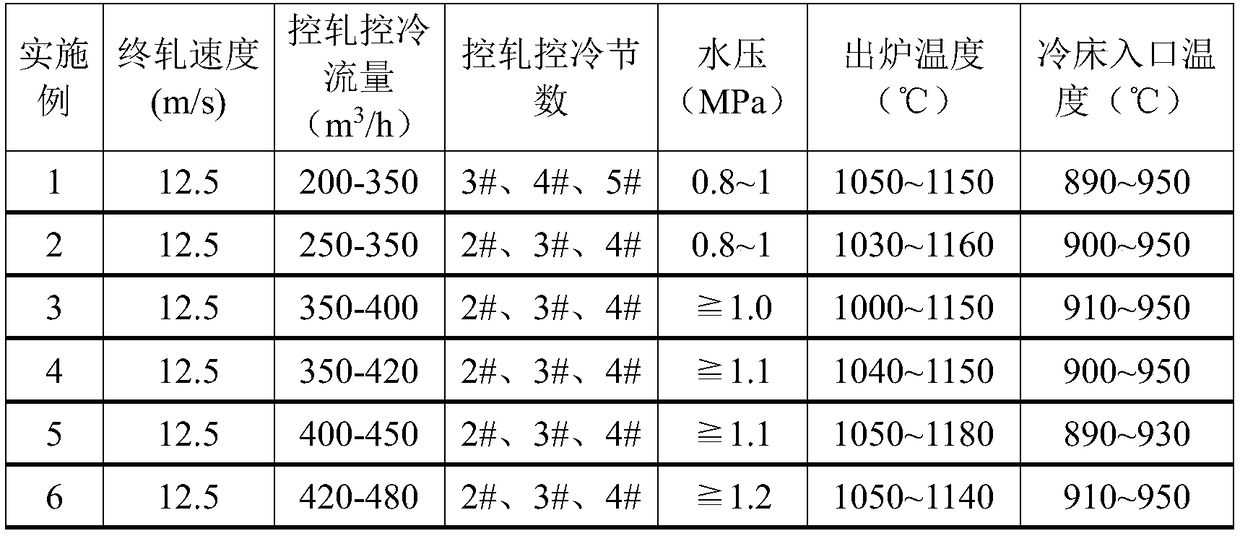

q690d medium-thick steel plate and production method for reducing energy consumption of q690d medium-thick steel plate

The invention provides a Q690D medium steel plate and a production method for reducing energy consumption of the Q690D medium steel plate. The steel plate is prepared from chemical components in percentage by weight as follows: 0.12%-0.14% of C, 0.25%-0.35% of Si, 1.65%-1.75% of Mn, 0.04%-0.05% of Nb, 0.06%-0.08% of V, 0.25%-0.35% of Cr, 0.25%-0.35% of Mo, less than or equal to 0.02% of P, less than or equal to 0.007% of S, 0.017%-0.027% of Als, 0.001%-0.0015% of Ca, 0.01%-0.02% of Ti and the balance of Fe and inevitable impurities. With the production method, production procedures are simplified, the production cost is reduced, the method is simple, easy to implement and convenient to popularize, and the produced Q690D steel type medium steel plate is good in surface quality and excellent in mechanical property.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

A highly weather-resistant, low-cost seawater corrosion-resistant steel bar and its production process

ActiveCN108251746BReasonable design of chemical compositionReduce corrosion rateProcess efficiency improvementWeather resistanceRebar

The invention provides a steel bar with high weather resistance, low cost and seawater corrosion resistance and a production process. The steel bar comprises the following elementary compositions of,by weight, 0.04%-0.10% of C, 0.10%-0.50% of Si, 0.5%-1.6% of Mn, 0.03% or less of P, 0.02% or less of S, 2%-4% of Cr, 0.3%-0.5% of Cu, 0.2%-0.6% of Ni, and the balance Fe and inevitable impurities. According to the steel bar, the mechanical property meets the requirement of the steel bar for corrosion resistance, the aging strain is low, and the corrosion rate is lower than 70% that of common steel bars. The technical path of the process comprises a 70-ton ultrahigh-power electric furnace, LF ladle refining, deoxidation and alloying after steel discharging, argon blowing, continuous casting of165 square billets at four streams by four machines, a heat accumulating type stepping heating furnace, 18 non-twist tandem mills, controlled-rolling and controlled-cold cooling, finishing, packagingand storage.

Owner:福建三宝钢铁有限公司

A Prediction Method of Surface Heat Transfer Coefficient in Strip Hot Rolling Process

ActiveCN103761370BImprove forecast accuracyDetailed and accurate informationSpecial data processing applicationsElement modelPredictive methods

Owner:NORTHEASTERN UNIV LIAONING

Method for Reducing Surface Roughness of Medium Chromium Ferritic Stainless Steel

ActiveCN110252809BImprove the heating effectOptimized rolling processTemperature control deviceMetal rolling arrangementsFurnace temperatureUltra high pressure

The invention belongs to the field of steel rolling, and relates to a method for reducing a medium-chromium ferritic stainless steel surface rough belt. The method for reducing the medium-chromium ferritic stainless steel surface rough belt sequentially comprises the steps of heating, descaling at ultrahigh pressure, rough rolling and fine rolling, wherein when the temperature of the nature is smaller than 20 DEG C, the furnace temperature of a heating zone for heating is 1150 to 1200 DEG C, and the furnace temperature of a soaking zone is 1200 to 1250 DEG C; and when the temperature of the nature is more than 20 DEG C, the furnace temperature of the heating zone 1100 to 1160 DEG C, and the furnace temperature of the soaking zone is 1150 to 1200 DEG C. According to the method for reducing the medium-chromium ferritic stainless steel surface rough belt provided by the invention, the ferritic stainless steel surface rough belt is reduced, and the stable mass production of chromium ferritic stainless steel is realized.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Calendering processing method of high-purity aluminum-magnesium alloy substrate for mechanical hard disk

InactiveCN104941999BOptimized rolling processControl rolling defectsMetal rolling arrangementsMagnetic storageIngot

The invention discloses a rolling processing method of a high-purity aluminum-magnesium alloy substrate for a mechanical hard disk. After rolling an aluminum-magnesium alloy plate ingot for a mechanical hard disk, a high-purity aluminum-magnesium alloy plate meeting processing requirements can be obtained. The steps of the method include: face milling and pretreatment of a plate ingot; hot rolling of a plate ingot; warm rolling of a plate ingot; cold rolling of a plate ingot; micro-calendering of a plate ingot. The present invention utilizes advanced hot, warm and cold rolling units, and advanced micro-rolling technical means to optimize the rolling process, control rolling defects, and combine the MARC computer simulation technology of aluminum alloy deformation to obtain a thickness of 1.775mm and a thickness difference of The high-precision plates for discs controlled within the range of ﹣0.01~﹢0.02 form a complete set of rolling process and technical standards for aluminum-magnesium alloy plates for hard disk magnetic storage.

Owner:UNIV OF SCI & TECH LIAONING

A large-thickness 1000mpa grade non-quenched and tempered high-toughness structural steel and its preparation method

ActiveCN114032453BThickness meetsIncreasing the thicknessMetal rolling arrangementsTemperingChemical composition

The invention provides a non-quenched and tempered high-toughness structural steel with a large thickness of 1000 MPa, which belongs to the field of high-strength structural steel. The chemical composition of the structural steel is: C: 0.08-0.13%, Si: 0.10-0.4%, Mn: 0.8~1.30%, P≤0.012%, S≤0.010%, Ni: 0.9~1.3%, Cr: 0.30~0.70%, Mo: 0.20~0.60%, V: 0.03~0.07%, Cu: 0.2~0.6 %, Nb: 0.02-0.045%, Ti: 0.01-0.02%, B: 0.0007-0.0014%; the rest are Fe and unavoidable impurities. The structural steel of the invention can simultaneously meet the requirements of ultra-high strength, large thickness, high toughness and non-quenching and tempering. The invention also provides a method for preparing non-quenched and tempered high-toughness structural steel with a large thickness of 1000 MPa.

Owner:SHOUGANG CORPORATION

Steel plate for low temperature pressure vessel and manufacturing method thereof

ActiveCN107937805BImprove mechanical propertiesGood welding performanceChemical compositionMetallurgy

Owner:武汉钢铁有限公司

Large-thickness 1000MPa-grade non-quenched and tempered high-toughness structural steel and preparation method thereof

ActiveCN114032453AThickness meetsIncreasing the thicknessMetal rolling arrangementsToughnessMaterials science

The invention provides large-thickness 1000MPa-grade non-quenched and tempered high-toughness structural steel, which belongs to the field of high-strength structural steel. The structural steel comprises the following chemical components: 0.08 to 0.13 percent of C, 0.10 to 0.4 percent of Si, 0.8 to 1.30 percent of Mn, less than or equal to 0.012 percent of P, less than or equal to 0.010 percent of S, 0.9 to 1.3 percent of Ni, 0.30 to 0.70 percent of Cr, 0.20 to 0.60 percent of Mo, 0.03 to 0.07 percent of V, 0.2 to 0.6 percent of Cu, 0.02 to 0.045 percent of Nb, 0.01 to 0.02 percent of Ti, 0.0007 to 0.0014 percent of B and the balance of Fe and inevitable impurities. The structural steel disclosed by the invention can simultaneously meet the requirements of ultrahigh strength, large thickness, high toughness and non-hardening and non-tempering. The invention further provides a preparation method of the large-thickness 1000MPa-grade non-quenched and tempered high-toughness structural steel.

Owner:SHOUGANG CORPORATION

Machining method of iron-chromium-aluminum high-resistance electrothermal alloy

The invention relates to the technical field of electrothermal alloy materials, in particular to a machining method of an iron-chromium-aluminum high-resistance electrothermal alloy. According to the technical scheme, the method comprises the following step of 1) weighing corresponding parts of chromium, aluminum, iron, yttrium, titanium, rhenium, cobalt and rare earth elements of lanthanum and yttrium by weight, fully mixing, and fully stirring for 10 minutes at the temperature of 80-90 DEG C, wherein the components specifically comprise 26.5 parts of chromium, 17.2 parts of aluminum, 33.5 parts of iron, 28.1 parts of yttrium, 1.44 parts of titanium, 8.25 parts of rhenium, 0.6 to 1.3 parts of cobalt, 1.5 parts of silicon, 6.8 parts of manganese, and 0.3-0.4 part of rare earth elements of lanthanum and yttrium. The machining method has the advantages that the oxidation resistance, the heat resistance, the corrosion resistance and the like of the produced iron-chromium-aluminum high-resistance electrothermal alloy can be ensured to be more reliable, the use requirements in a wider use environment can be met, and the overall cost in the production process is ensured to be lower.

Owner:JIANGSU MINGLUSINLESS STEEL

Production method for thick Z-direction wind power steel

InactiveCN113235007AMeet needsAlloy composition structure optimizationRoll force/gap control deviceTemperature control deviceSteelmakingMechanical property

The invention discloses a production method for thick Z-direction wind power steel, which comprises the following steps of: 1, firstly adjusting the formula of steelmaking components in percentage by weight: 0.14wt.% of C, 0.36wt.% of Si, 1.30wt.% of Mn, 0.014wt.% of P, 0.007wt.% of S, 0.016wt.% of V, 0.018wt.% of Nb, 0.033wt.% of Als, 0.022wt.% of Ti, 0.002wt.% of Ca and the balance iron and impurities; and 2, after a qualified blank with the thickness being 250 mm, the width being 1800 mm and the length being 3.8 m is smelted through steelmaking according to the alloy element design requirement, performing primary rolling on the blank to be an intermediate blank with the thickness being 110 mm through a roughing mill, and then rolling the intermediate blank into a finished wind power steel plate with the thickness being 50 mm through a finishing mill. The method mainly controls the contents of sulfur and phosphorus in the components, designs a medium plate rolling process, in the step 3, normalizing treatment is conducted at the temperature of 900 DEG C for 1.6 hours in a furnace, discharged steel plates are subjected to stacking, preserving heat and slowly cooling at the temperature of 400 DEG C for 36 hours through a slow cooling box, hydrogen in the steel can be discharged outwards in a diffusion manner, and therefore, the mechanical property is further optimized.

Owner:XINJIANG BAYI IRON & STEEL

A manufacturing method of gh5188 square tail nozzle for aero-engine

The invention discloses a method for manufacturing a GH5188 square exhaust nozzle for an aero-engine, including blanking, heating, thickening, punching, rolling, etc., wherein: the ring billet obtained by rolling is extruded into billet, and the final shape of the tail nozzle is carried out by using a horse frame and a square horse bar. Beneficial effects of the present invention: Since the billet is bent after rolling, the wall thickness is uniform and the material distribution is accurate, which ensures the uniform wall thickness of the forging after forming and improves the utilization rate of raw materials; since the billet is made by rolling, forming At the same time, the horse frame and square horse bar are used, and the rolling and forming process are optimized, so that the forging has uniform structure, stable mechanical properties, and prolongs the service life.

Owner:GUIZHOU AVIATION TECHN DEV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com