Wide pure-nickel strip cold-rolling process

A pure nickel and strip technology, applied in metal rolling, manufacturing tools, metal rolling, etc., can solve the problem of continuous rolling of wide and thin nickel strips, and achieve the goal of avoiding impurity intrusion and optimizing rolling process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

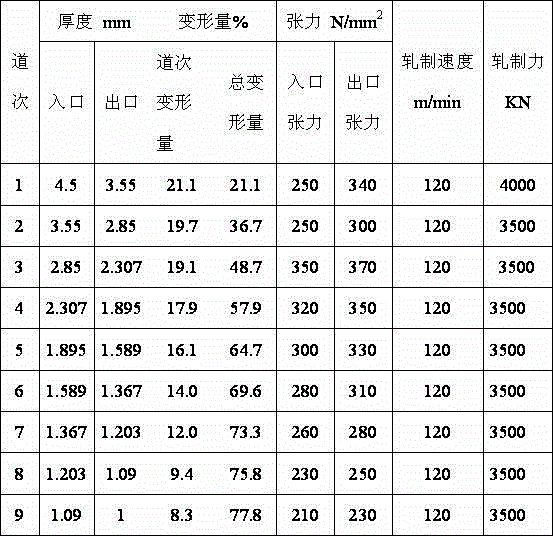

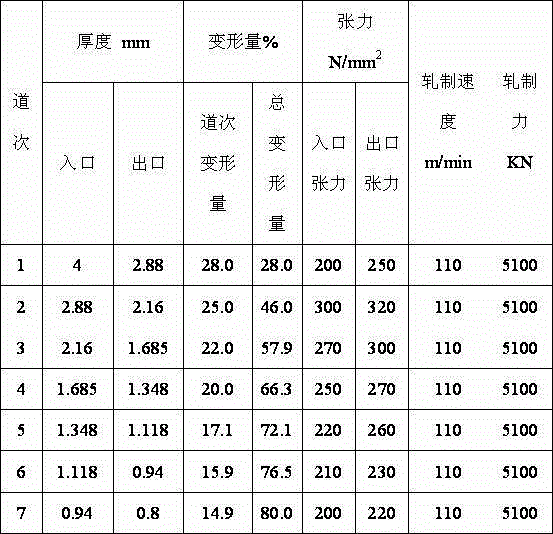

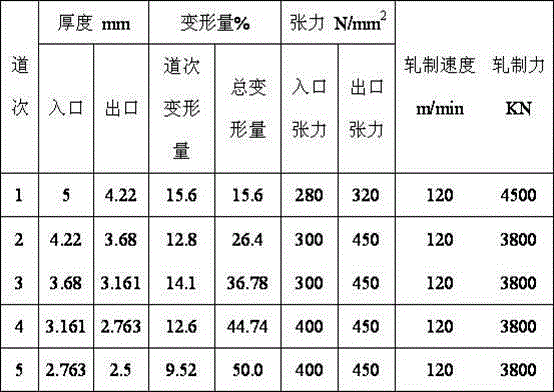

Examples

Embodiment Construction

[0013] Specific embodiments of the invention will be described in detail below, but the invention can be practiced in many different ways as defined and covered by the claims.

[0014] The pickled nickel strip coil with a thickness of 4.0~6.0mm and a width of 1300-1400mm is sent to the uncoiler through the winding car, and the center line of the nickel coil coincides with the center line of the unit, and the diameter of the mandrel expands. Complete the roll-up work.

[0015] After the winding is completed, use the winding trolley to withstand the coil, cut the steel strip manually, send the strip head to the entrance turning roller through the movable guide plate, bend the strip head with the entrance pressure roller, and send the strip through the entrance plate shape roller, entrance horizontal Cutting shears, entrance thickness gauge, entrance oil strips, entrance copper rolls enter the main rolling mill, pass through the main rolling mill, exit copper rolls, exit oil stri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com