Production method for thick Z-direction wind power steel

A production method and thick-gauge technology, applied in rolling mill control devices, metal rolling, manufacturing tools, etc., can solve the problems of poor laminar tear resistance, increased user cost, and high production cost, and improve labor production. Efficiency, quality loss cost reduction, scrap rate reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

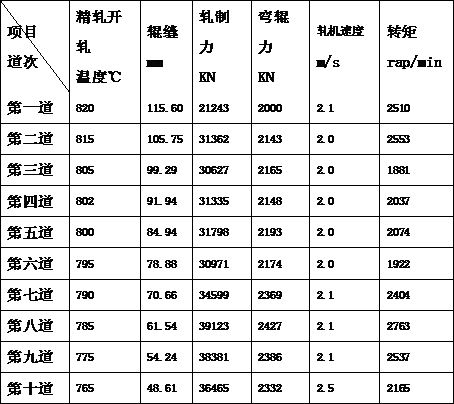

[0022] A thick specification Z to wind electric steel production method, in accordance with the following steps, 1, first adjust steelmaking ingredients WT.%: C 0.14, Si 0.36, Mn 1.30, P 0.014, S 0.007, V 0.016, Nb 0.018 ALS 0.033, Ti 0.022, Ca 0.002, the balance is iron and impurities; 2. Designed according to the alloy element, the thickness of the steelmaking smelting is 250mm, the width is 1800mm, and the length is 3.8m, the initial rolling is performed on the thick rolling mill. The thickness of 110 mm has a thickness of 10 mm, and the rolling mill is formed into a finished wind power steel plate having a thickness of 50 mm. The rolling process design parameter: the temperature of the heating furnace temperature is 1240 ° C, the thick rolling temperature is 1050 ° C, the finishing temperature is 790 ° C, the red temperature 580 ° C, where the thick rolling process design parameters are as follows:

[0023] Rough rolling process design:

[0024]

[0025] Fine rolling process...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com