Patents

Literature

153results about How to "Quality production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

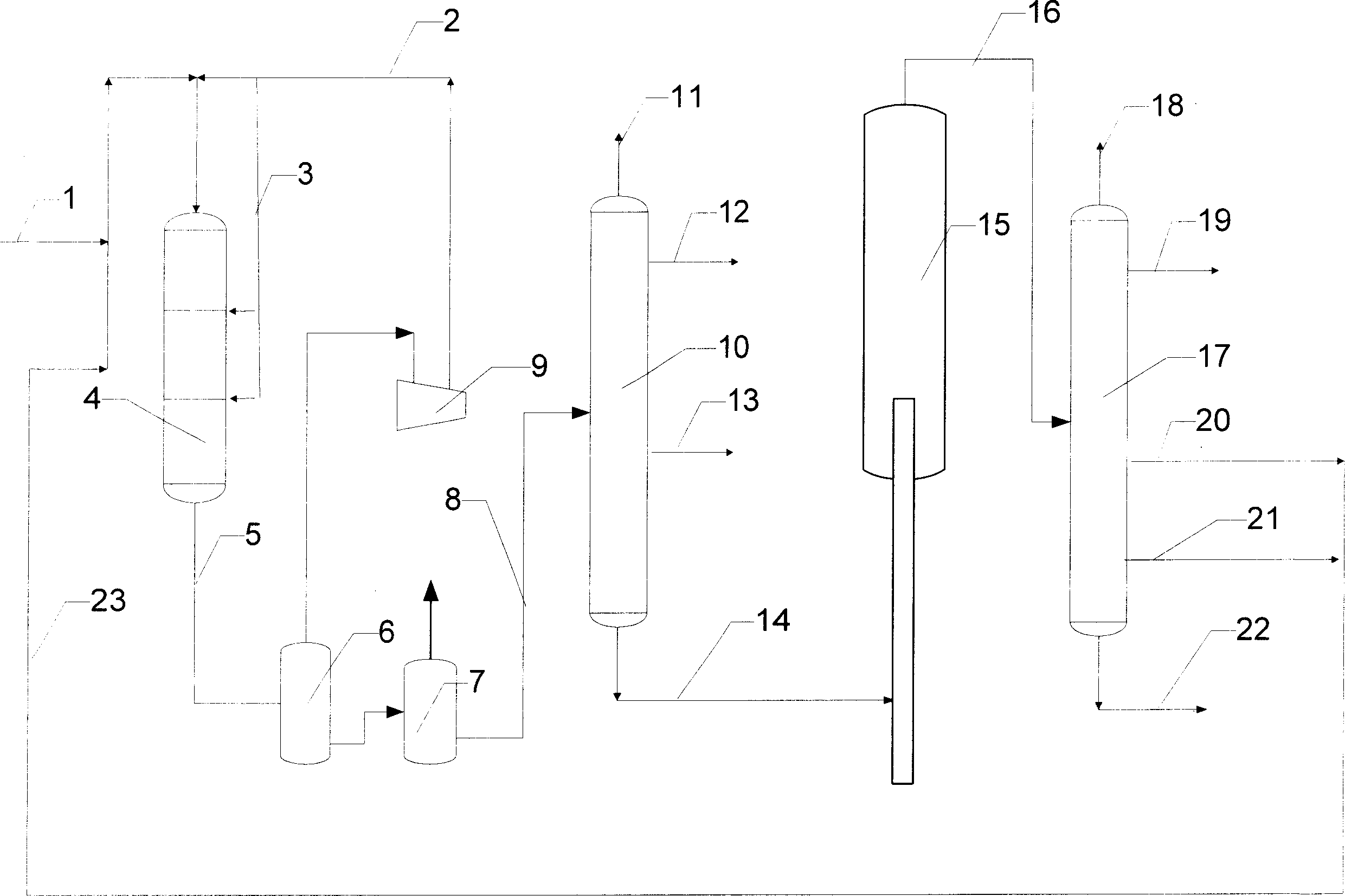

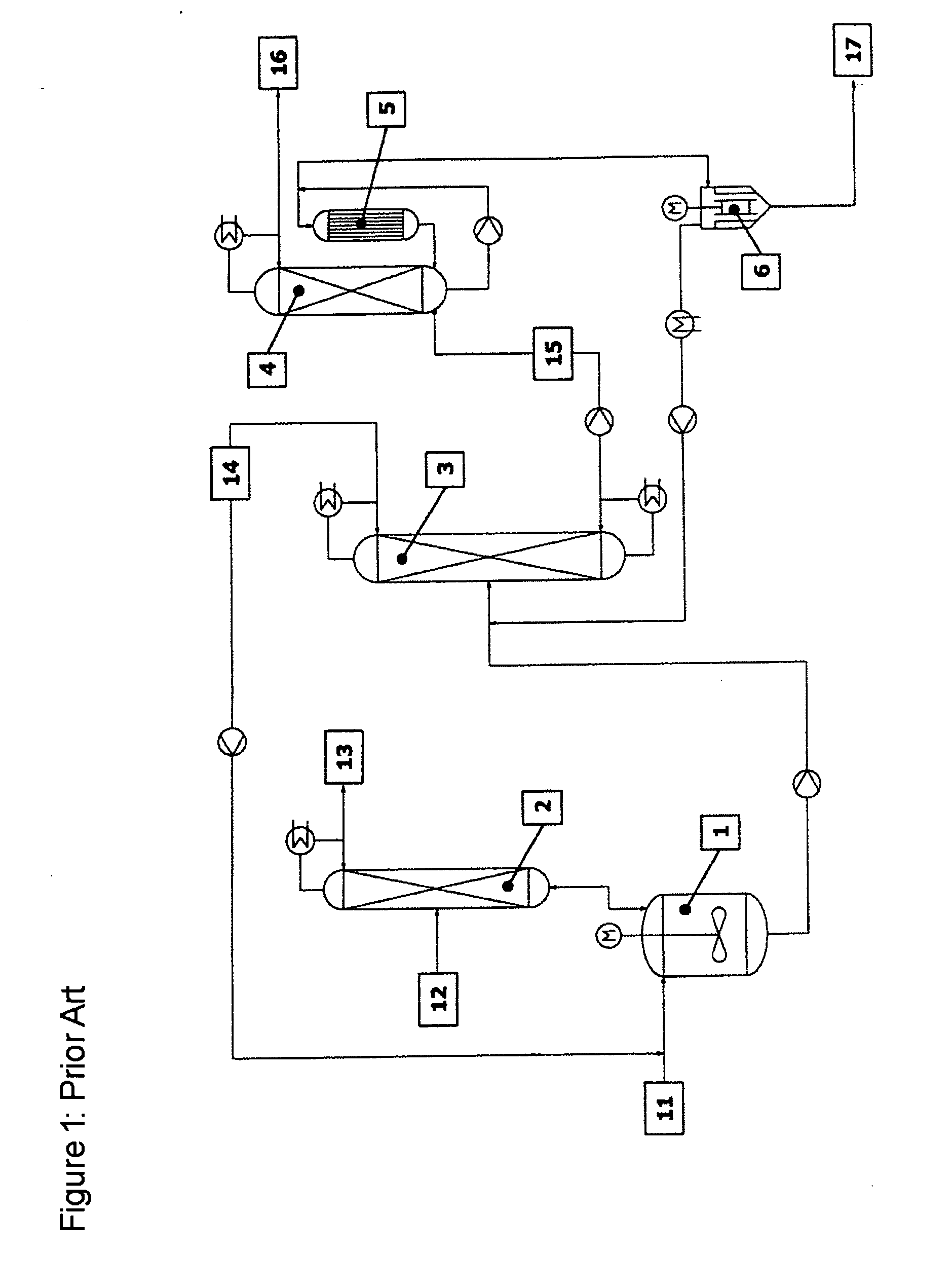

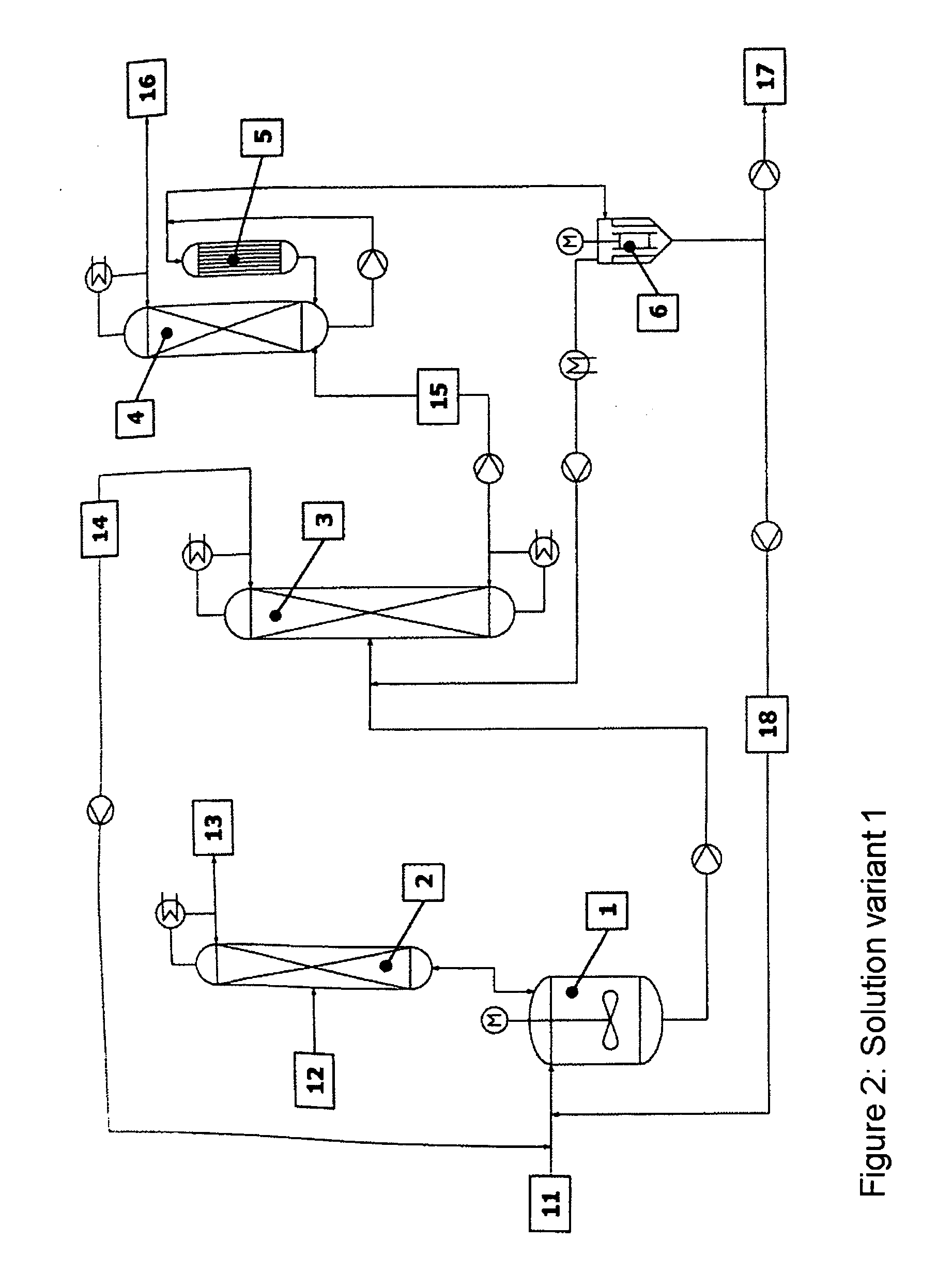

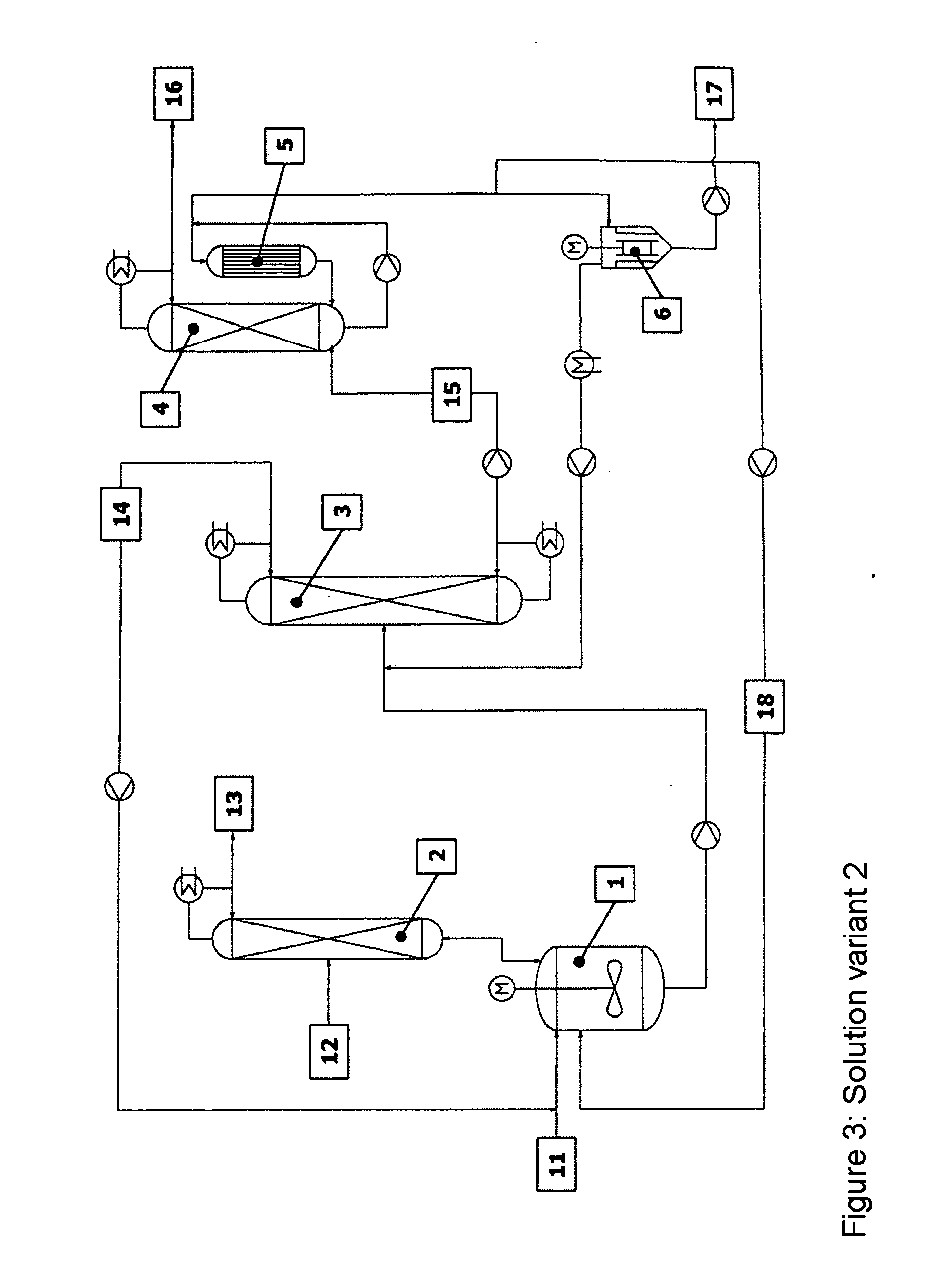

Two-way combined process of wax-oil hydrogenation treatment and catalytic cracking

A two-way combined process of wax oil hydro-process and catalytic crack is carried out by entering wax oil, catalytic cracking re-circulating oil and catalytic cracking diesel oil into hydro-processor, hydrogenation reacting under existence of hydrogen and hydrogenation catalyst, separating for reactant to obtain gas, hydrogenation naphtha oil, hydrogenation diesel oil and hydrogenation tail oil, entering hydrogenation tail oil into catalytic cracker, crack reacting under existence of catalytic cracking agent, separating to obtain dry gas, liquefied gas, catalytic cracking gasoline, catalytic cracking diesel oil and catalytic cracking re-circulating oil and oil slurry, and circulating for catalytic cracking diesel oil and catalytic cracking re-circulating oil to hydro-processor. It has higher recovery rate and cetyl value, less sulfur content, arene content and coke output.

Owner:CHINA PETROLEUM & CHEM CORP +1

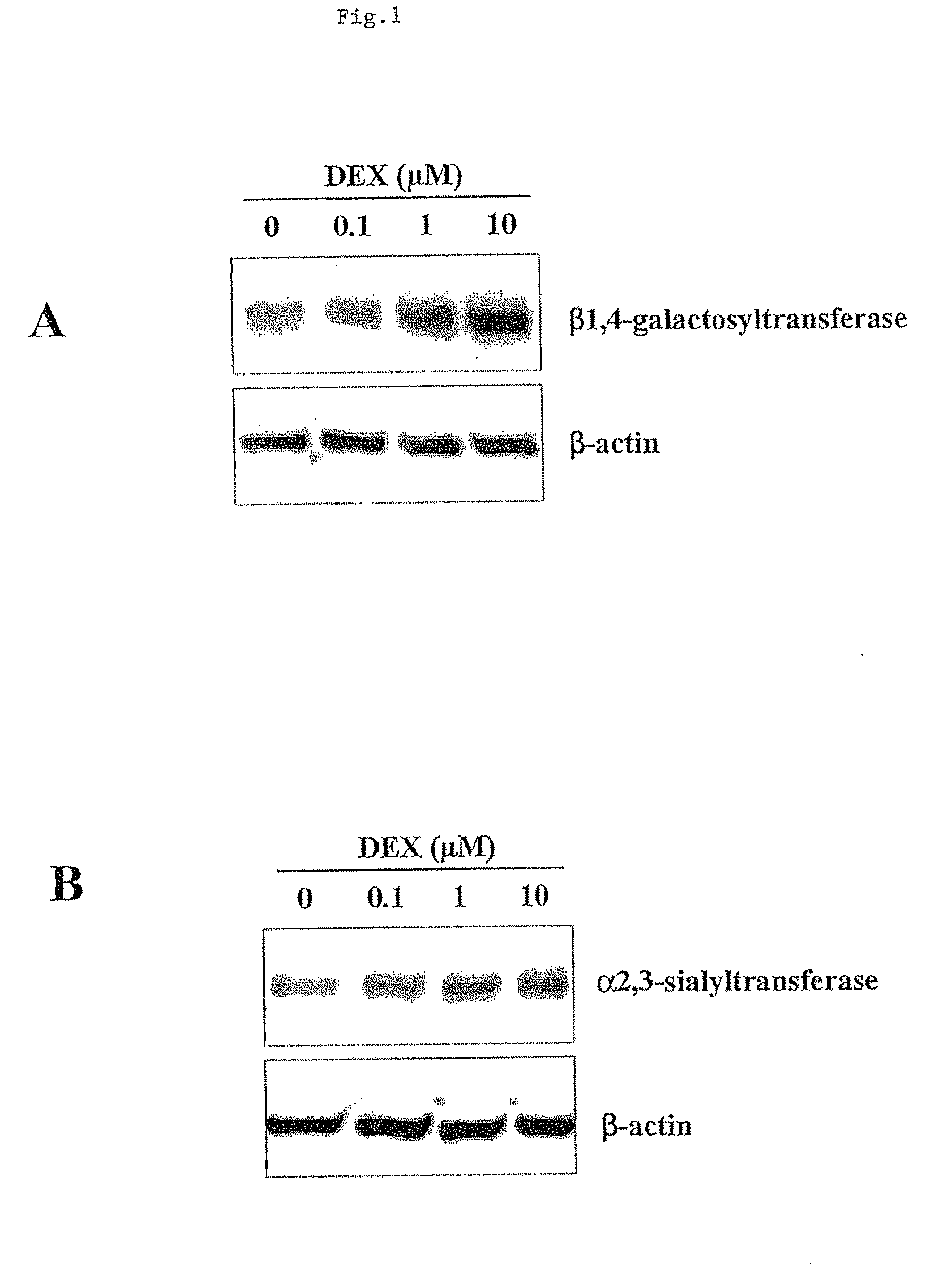

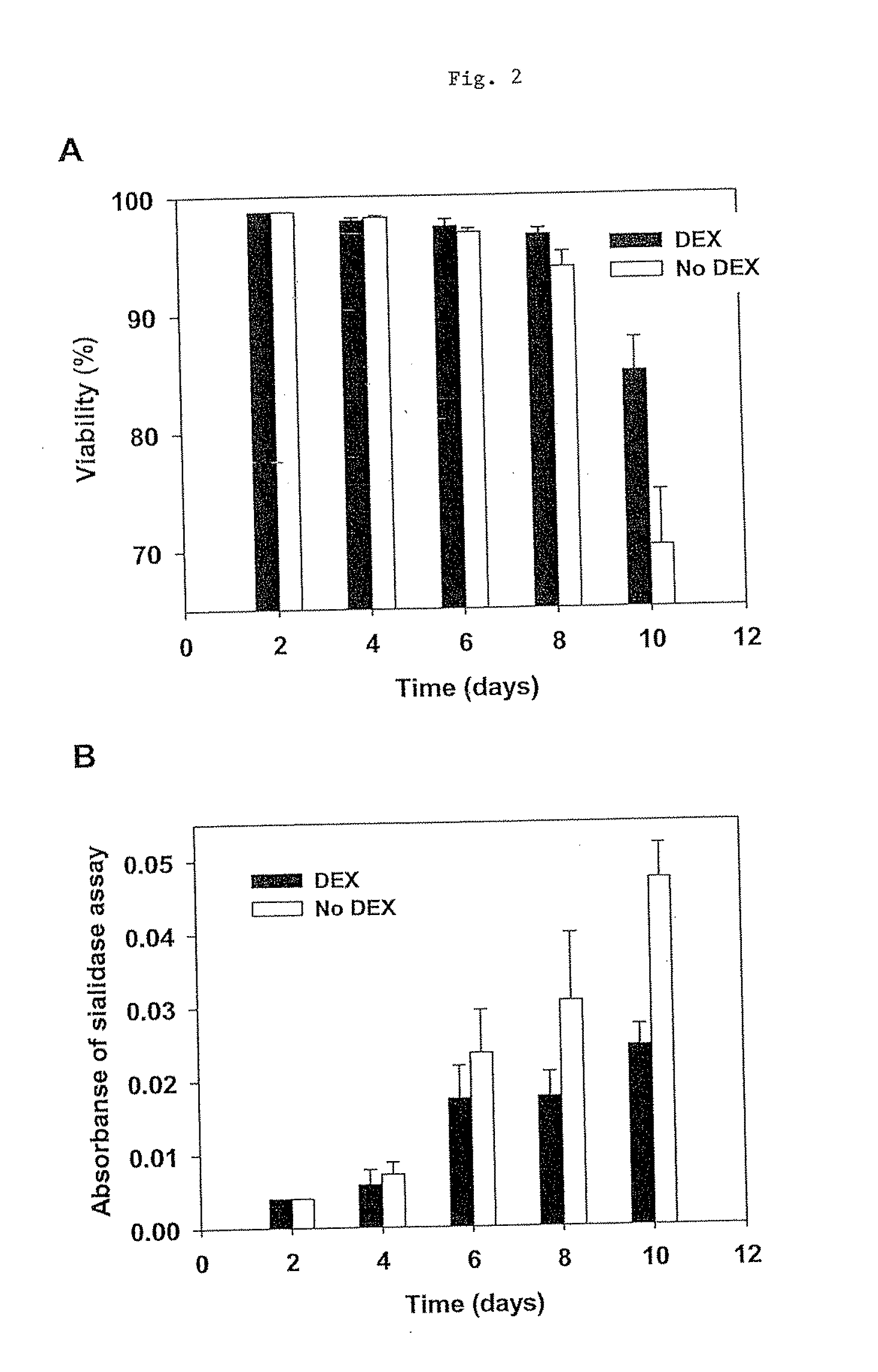

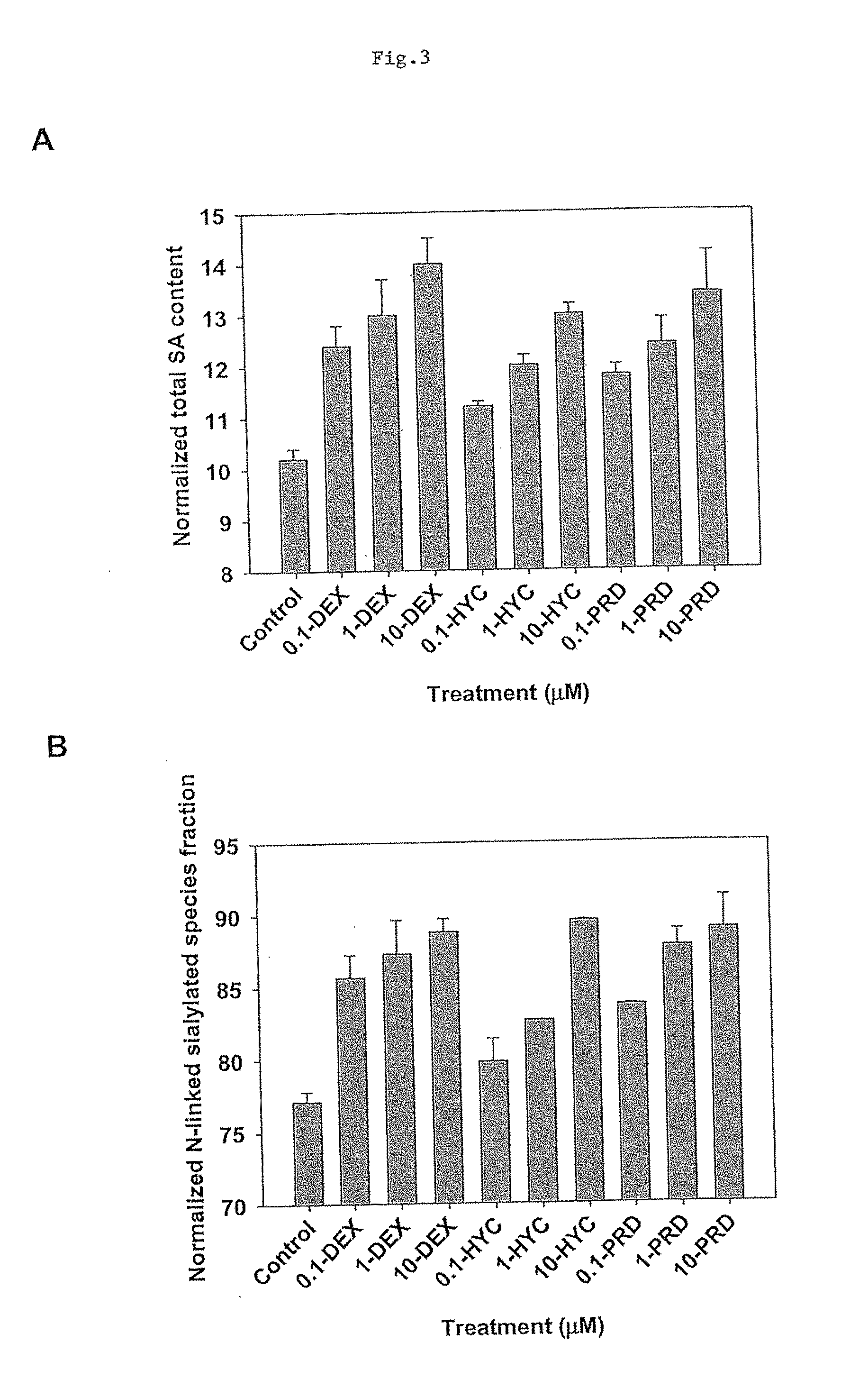

Mammalian cell culture processes for protein production

ActiveUS20110081679A1High densityReduce aggregationPolypeptide with localisation/targeting motifAntibody mimetics/scaffoldsBiotechnologyGlucocorticoid

The present invention describes methods and processes for the production of proteins, particularly glycoproteins, by animal cell or mammalian cell culture, preferably, but not limited to, fed-batch cell cultures. In one aspect, the methods comprise the addition of glucocorticoid compound during the culturing period. The addition of glucocorticoid compound sustain a high viability of the cultured cells, and can yield an increased end titer of protein product, and a high quality of protein product, as determined, e.g., by sialic acid content of the produced protein.

Owner:BRISTOL MYERS SQUIBB CO

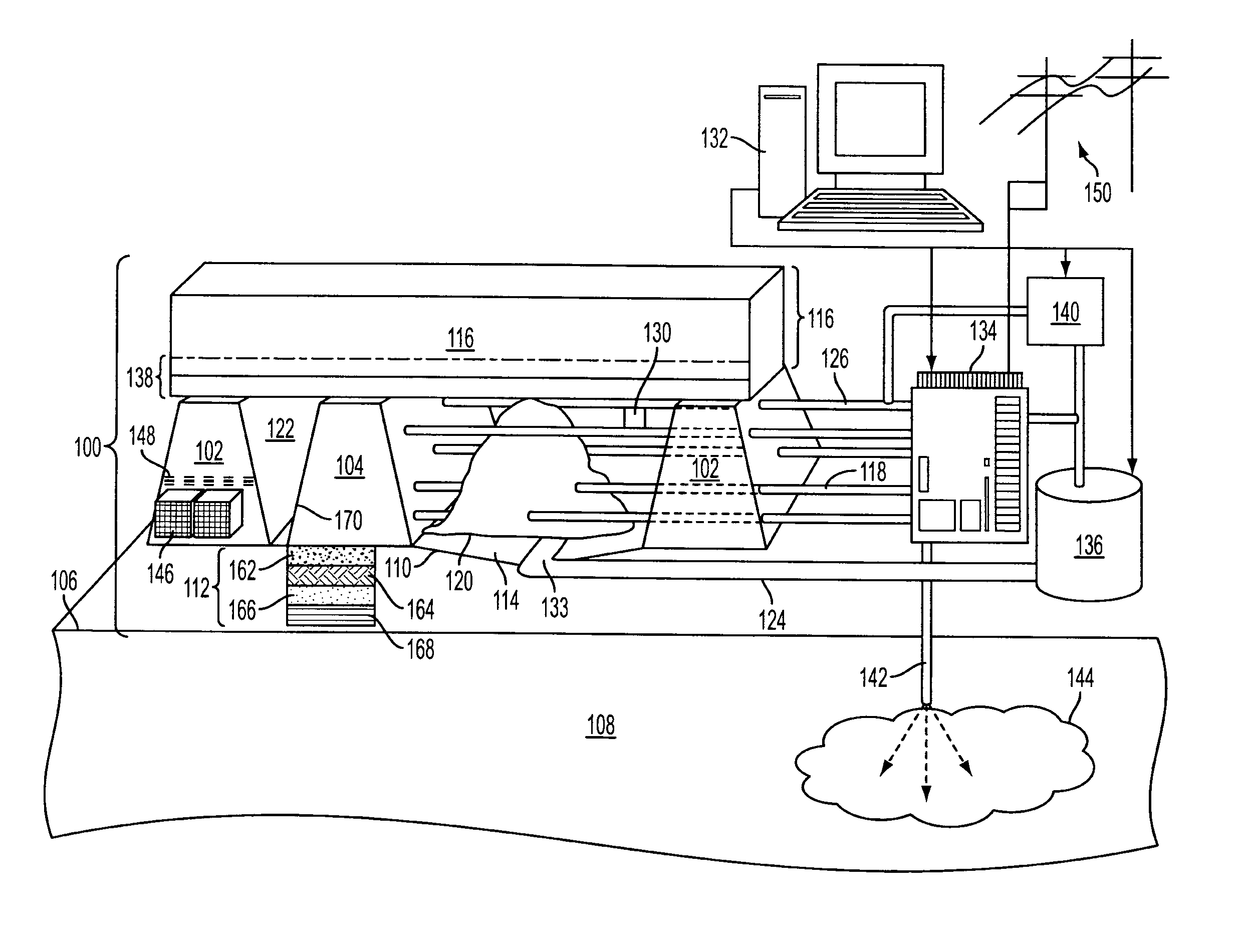

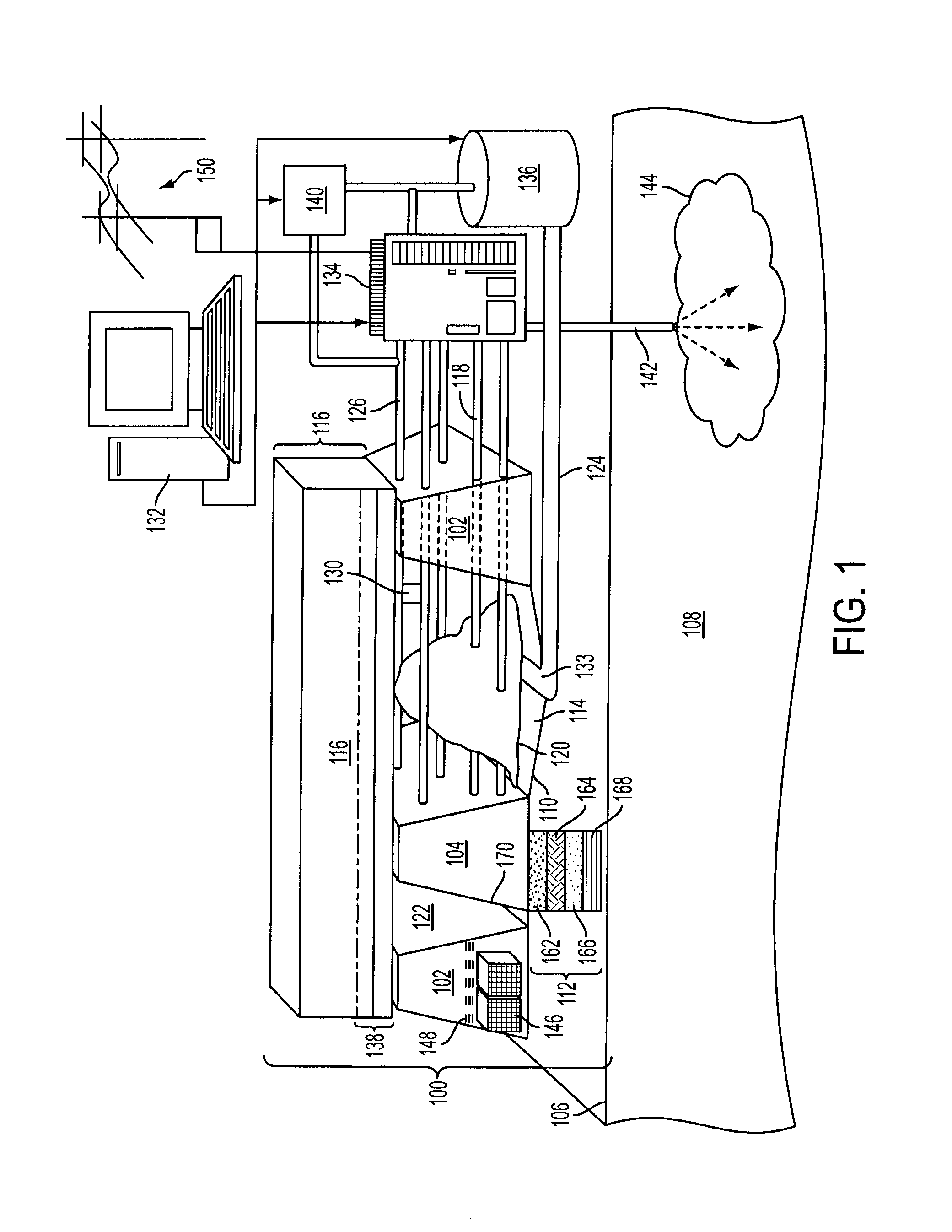

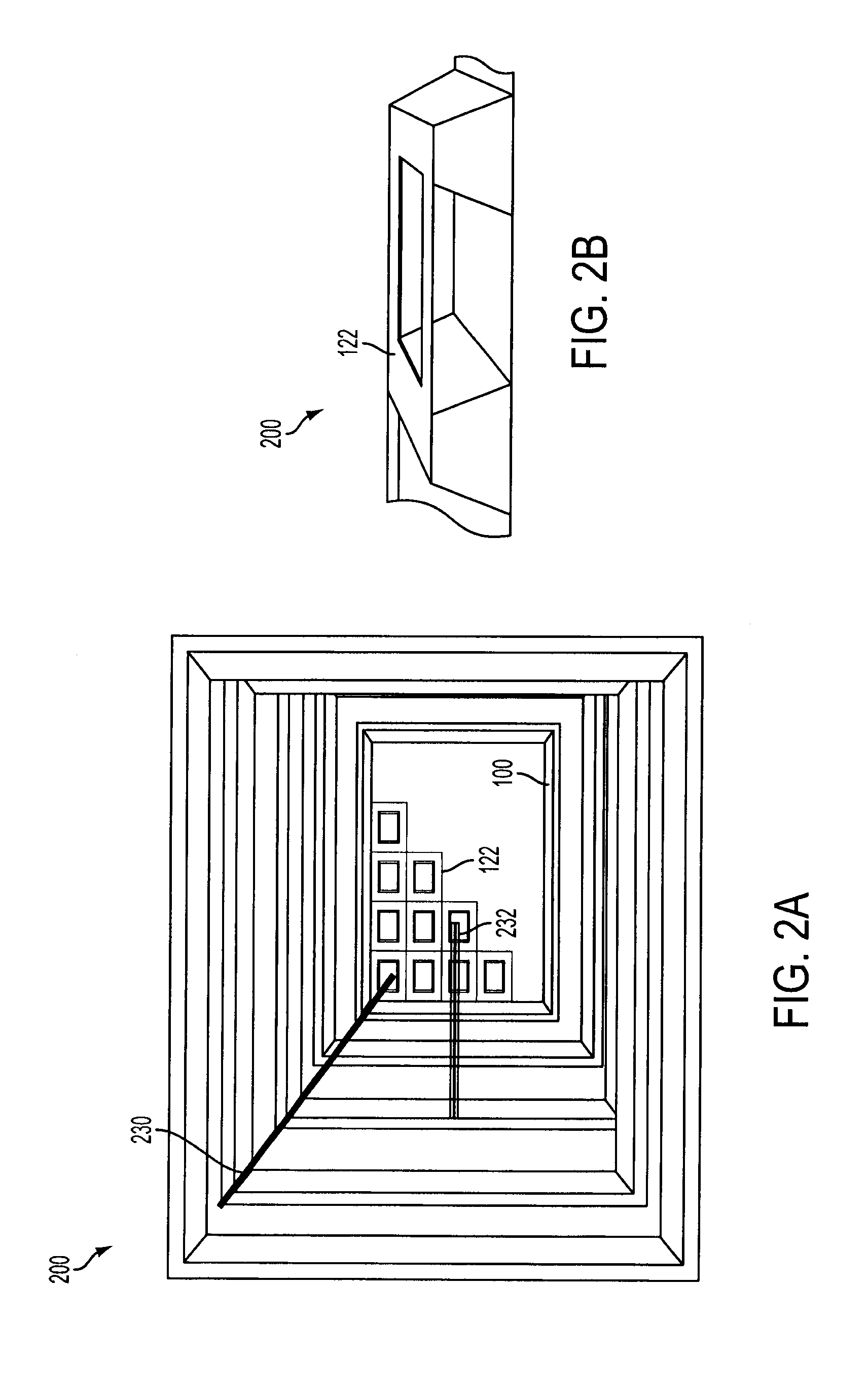

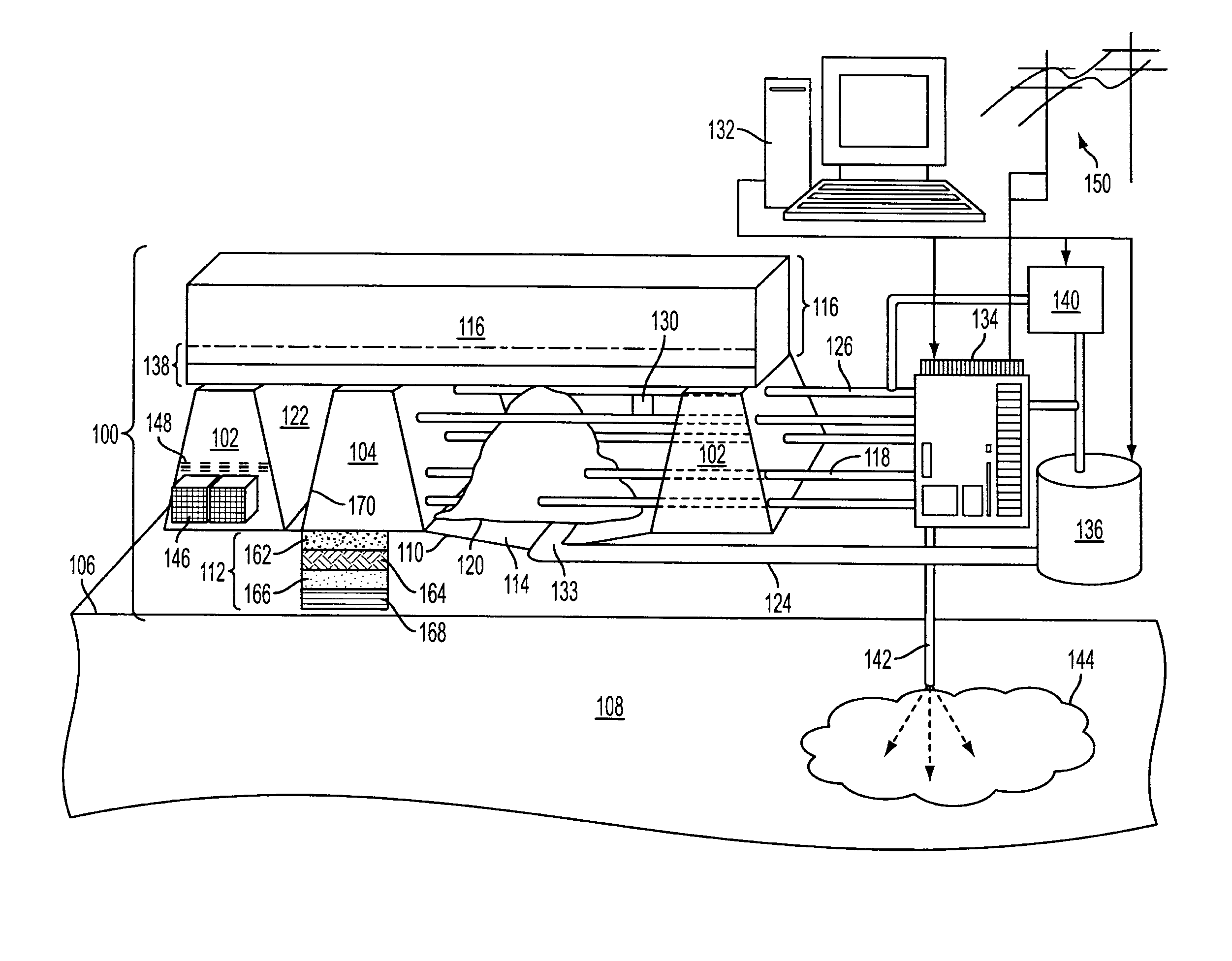

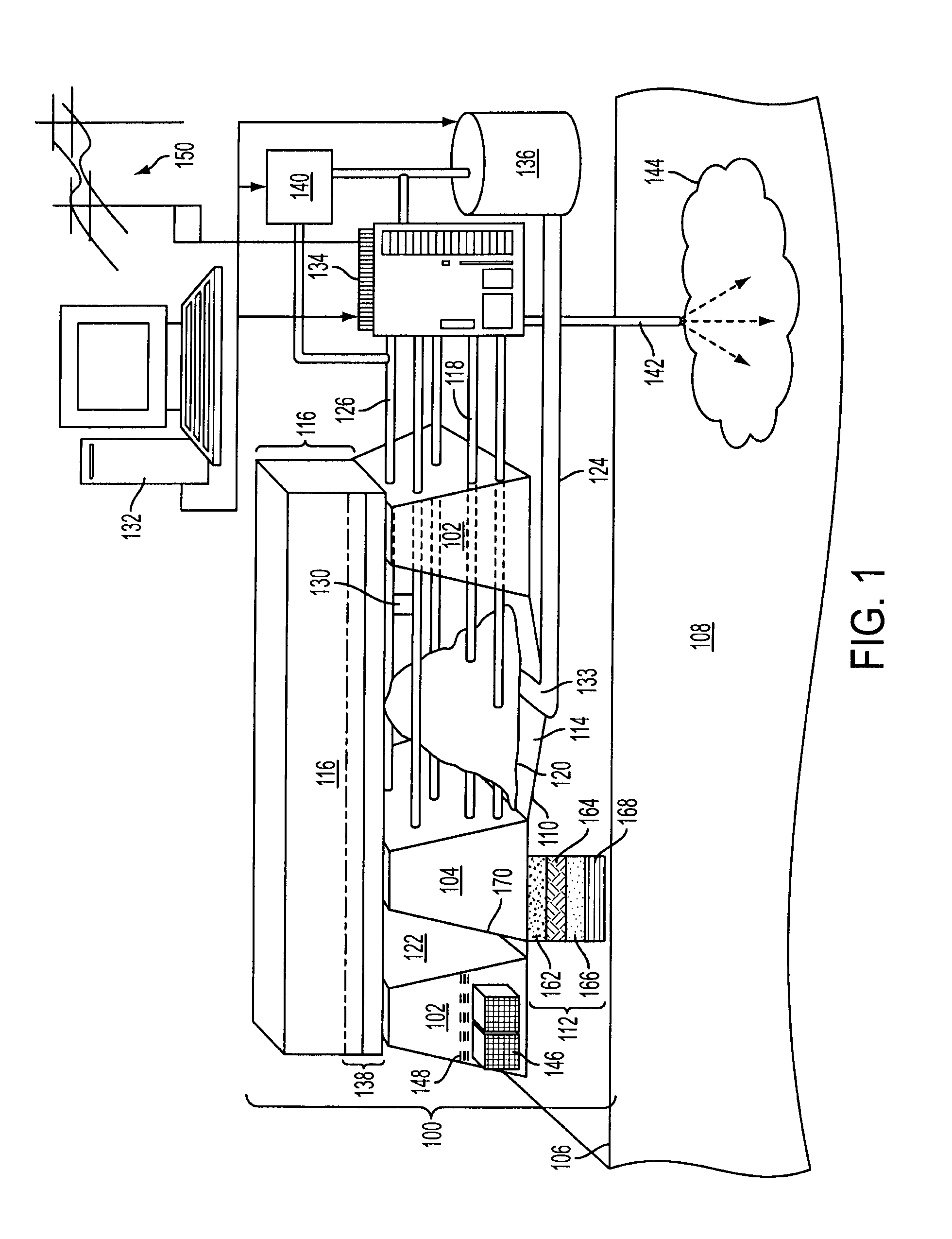

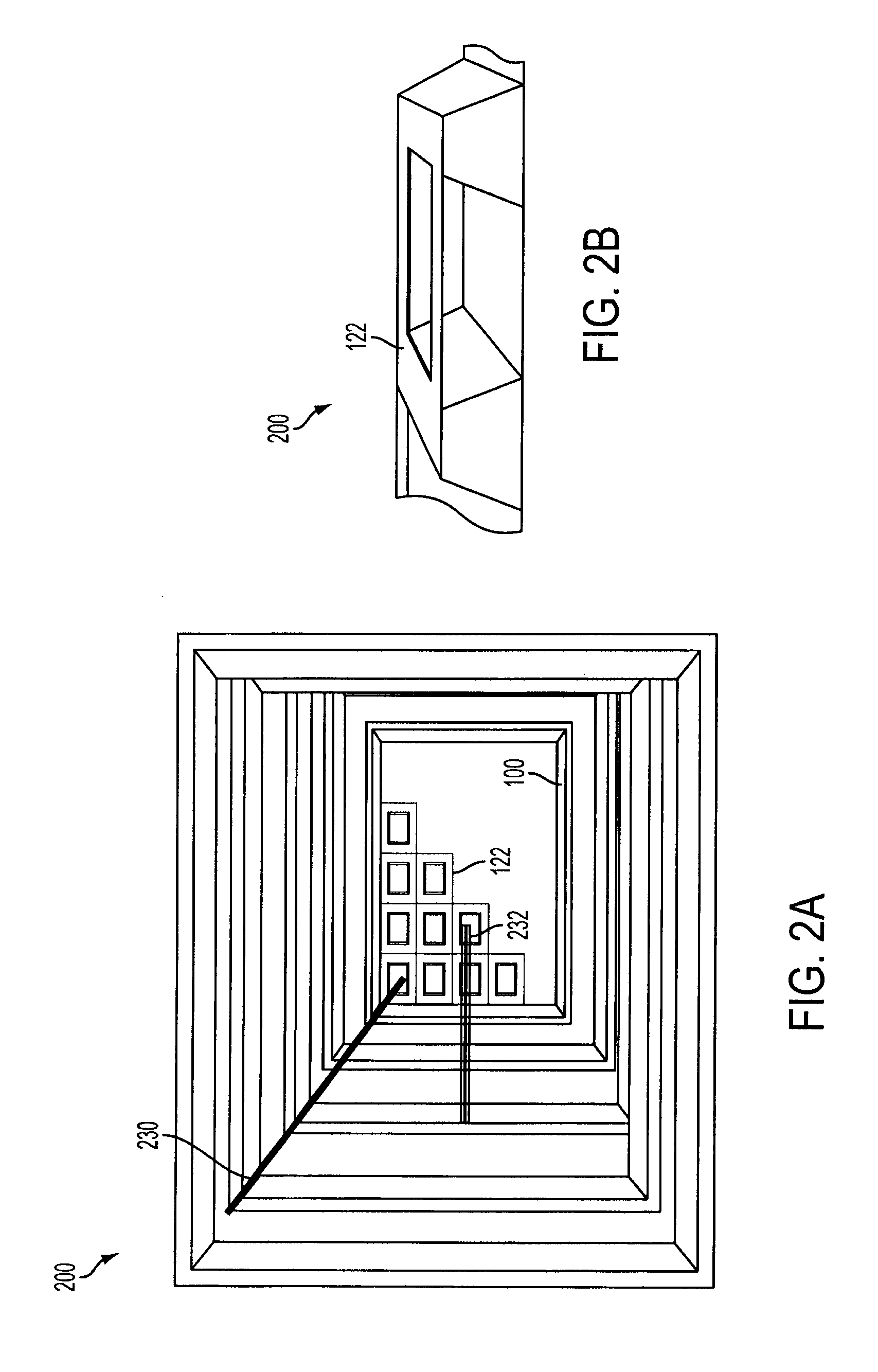

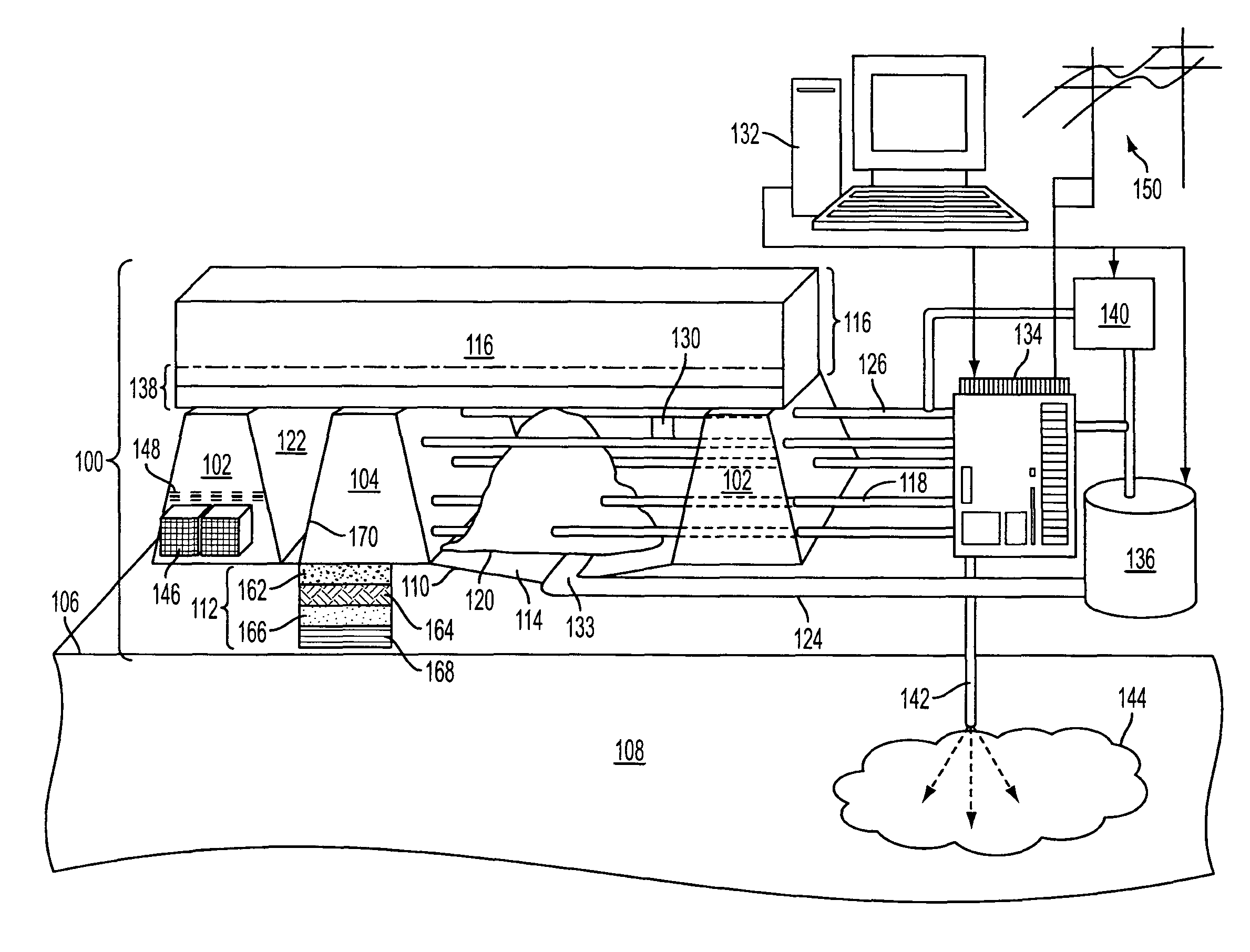

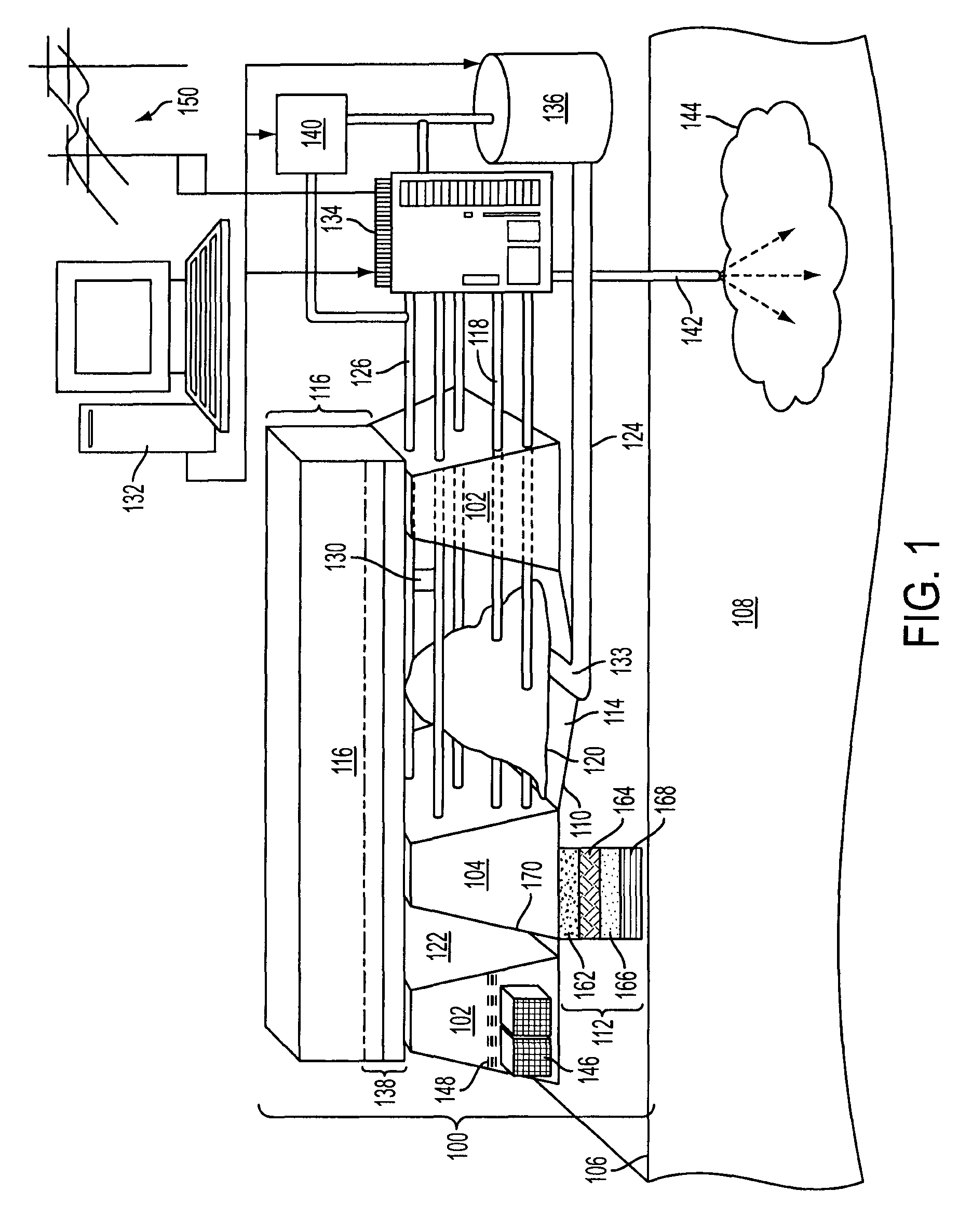

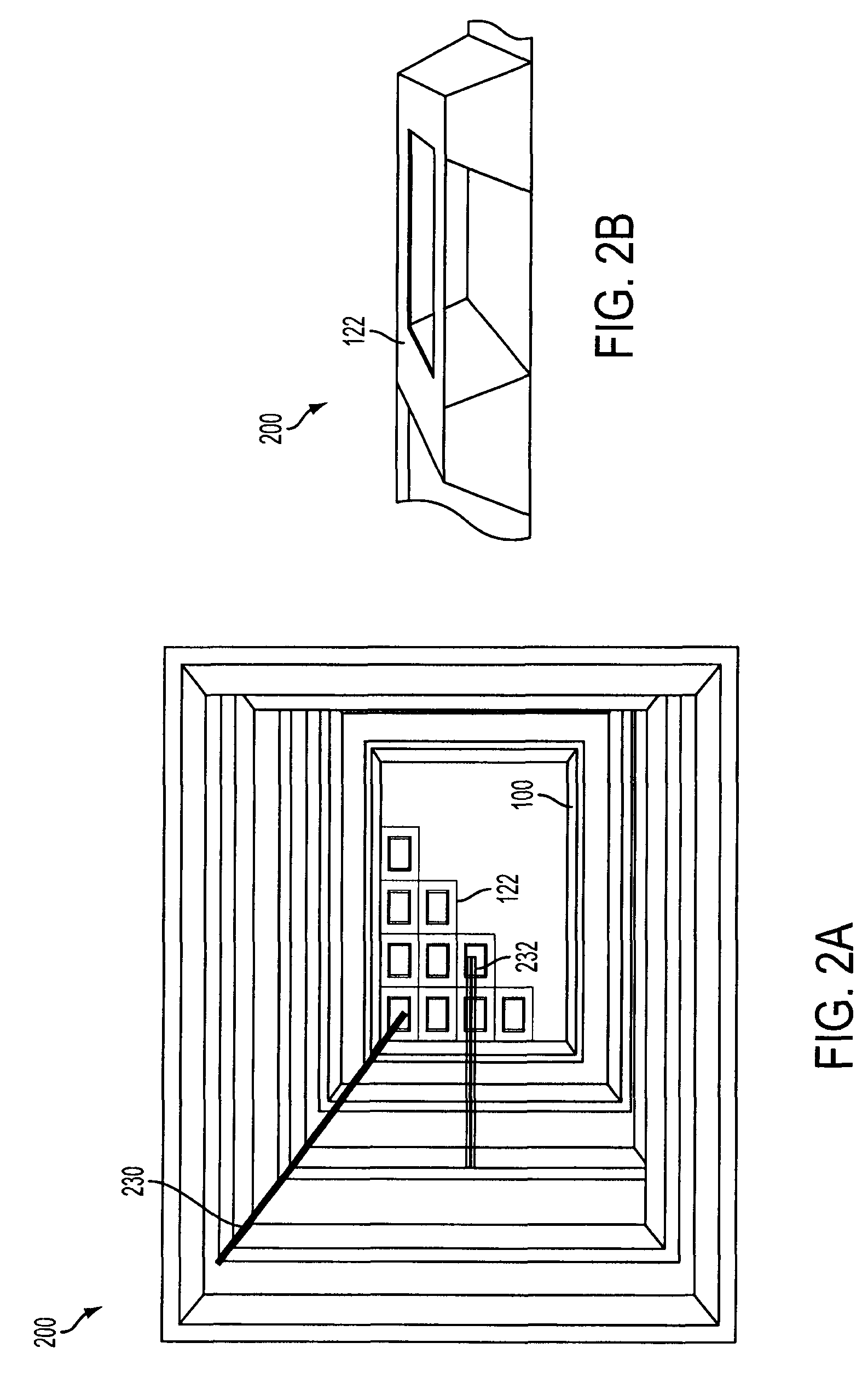

Methods of recovering hydrocarbons from hydrocarbonaceous material with reduced non-carbonaceous leachate and co2 and associated systems

ActiveUS20080190816A1Avoid insufficient heatingInhibition formationThermal non-catalytic crackingUnderground chambersLeachateMaterials science

A method of recovering hydrocarbons from hydrocarbonaceous materials can include forming a stationary permeability control infrastructure. This constructed infrastructure defines a substantially encapsulated volume. A comminuted hydrocarbonaceous material can be introduced into the control infrastructure to form a permeable body of hydrocarbonaceous material. The permeable body can be heated sufficient to remove hydrocarbons therefrom within a temperature range which is sufficient to substantially avoid formation of carbon dioxide or non-hydrocarbon leachates. During heating the hydrocarbonaceous material is substantially stationary as the constructed infrastructure is a fixed structure. Removed hydrocarbons can be collected for further processing, use in the process, and / or use as recovered.

Owner:RED LEAF RESOURCES

Methods of recovering hydrocarbons from hydrocarbonaceous material using a constructed infrastructure having permeable walls and associated systems

ActiveUS20080190815A1Easy to produceLarge movementThermal non-catalytic crackingUnderground chambersHydrocotyle bowlesioidesEngineering

A method of recovering hydrocarbons from hydrocarbonaceous materials can include forming a constructed permeability control infrastructure. This constructed infrastructure defines a substantially encapsulated volume having substantially permeable side walls and a substantially impermeable cap. A comminuted hydrocarbonaceous material can be introduced into the control infrastructure to form a permeable body of hydrocarbonaceous material. The permeable body can be heated sufficient to remove hydrocarbons therefrom without contamination or substantial leaching of materials outside of the impoundment. During heating the hydrocarbonaceous material is substantially stationary as the constructed infrastructure is a fixed structure. Removed hydrocarbons can be collected for further processing, use in the process, and / or use as recovered.

Owner:RED LEAF RESOURCES

Methods of recovering hydrocarbons from hydrocarbonaceous material using a constructed infrastructure and associated systems

ActiveUS7862705B2Low costHigh outputThermal non-catalytic crackingSolid waste disposalEngineeringHydrocarbon

A method of recovering hydrocarbons from hydrocarbonaceous materials can include forming a constructed permeability control infrastructure. This constructed infrastructure defines a substantially encapsulated volume. A comminuted hydrocarbonaceous material can be introduced into the control infrastructure to form a permeable body of hydrocarbonaceous material. The permeable body can be heated sufficient to remove hydrocarbons therefrom. During heating the hydrocarbonaceous material is substantially stationary as the constructed infrastructure is a fixed structure. Removed hydrocarbons can be collected for further processing, use in the process, and / or use as recovered.

Owner:RED LEAF RESOURCES

Method for the continuous production of alkyl(meth)acrylates with multiple catalyst recycling

ActiveUS20060211880A1Low costQuality productionPhysical/chemical process catalystsPreparation by ester-hydroxy reactionMeth-Quality level

The invention relates to an improved method for the continuous production of alkyl(methyl)acrylates by transesterification of methyl(meth)acrylate with alcohols that are heavy in comparison with methanol. A special processing technique makes it possible to obtain new levels of product quality. Very high space-time-overall yields can also be obtained. The invention is characterized by the multiple use of a homogeneous catalyst which thereby reduces the costs of auxiliary agents significantly.

Owner:EVONIK OPERATIONS GMBH

Steel bar with high weather resistance, low cost and seawater corrosion resistance and production process

ActiveCN108251746AGood weather resistanceLow costProcess efficiency improvementWeather resistanceRebar

The invention provides a steel bar with high weather resistance, low cost and seawater corrosion resistance and a production process. The steel bar comprises the following elementary compositions of,by weight, 0.04%-0.10% of C, 0.10%-0.50% of Si, 0.5%-1.6% of Mn, 0.03% or less of P, 0.02% or less of S, 2%-4% of Cr, 0.3%-0.5% of Cu, 0.2%-0.6% of Ni, and the balance Fe and inevitable impurities. According to the steel bar, the mechanical property meets the requirement of the steel bar for corrosion resistance, the aging strain is low, and the corrosion rate is lower than 70% that of common steel bars. The technical path of the process comprises a 70-ton ultrahigh-power electric furnace, LF ladle refining, deoxidation and alloying after steel discharging, argon blowing, continuous casting of165 square billets at four streams by four machines, a heat accumulating type stepping heating furnace, 18 non-twist tandem mills, controlled-rolling and controlled-cold cooling, finishing, packagingand storage.

Owner:福建三宝钢铁有限公司

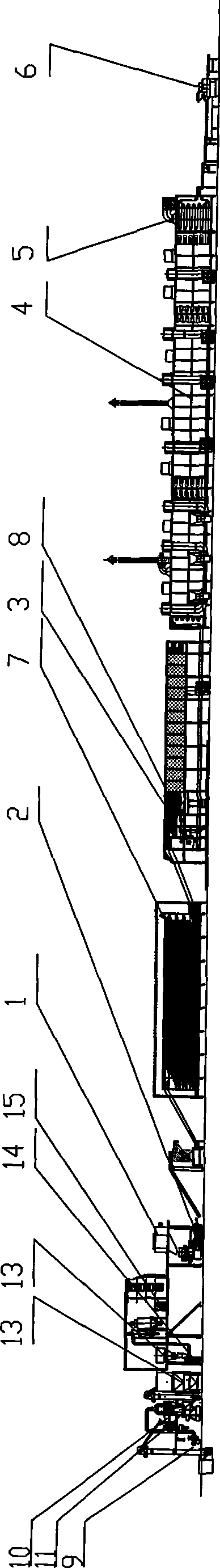

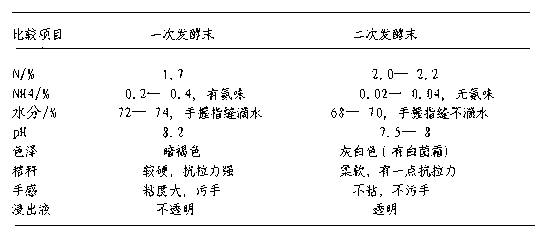

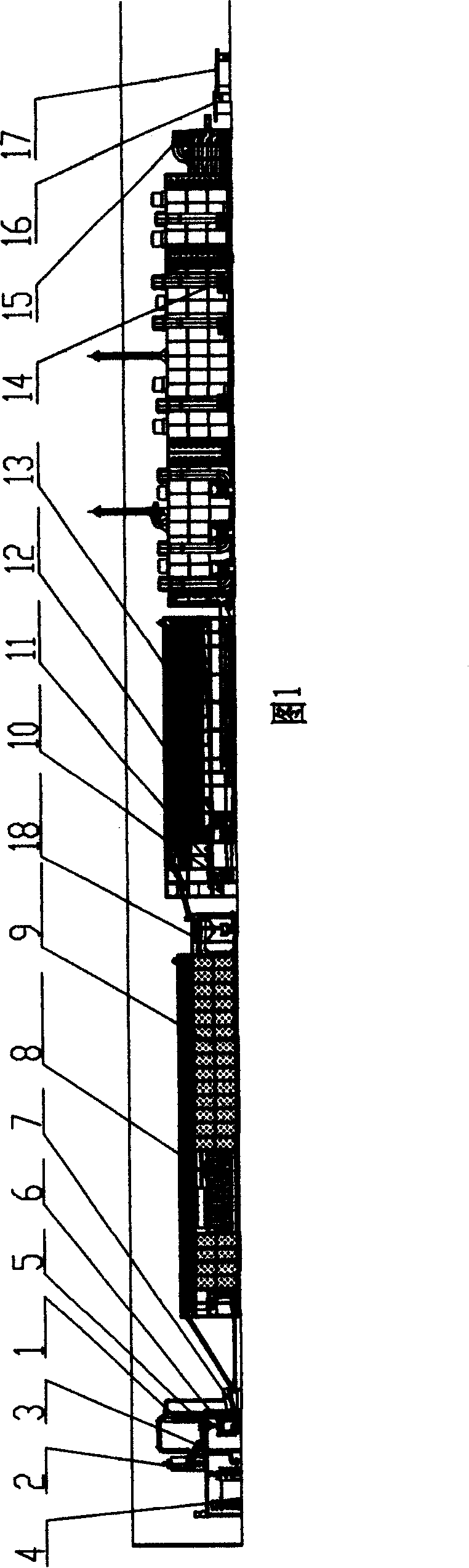

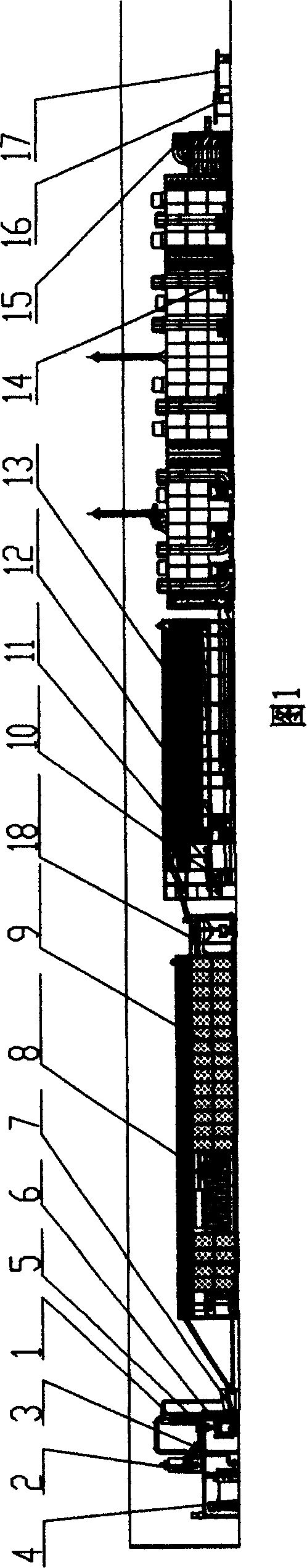

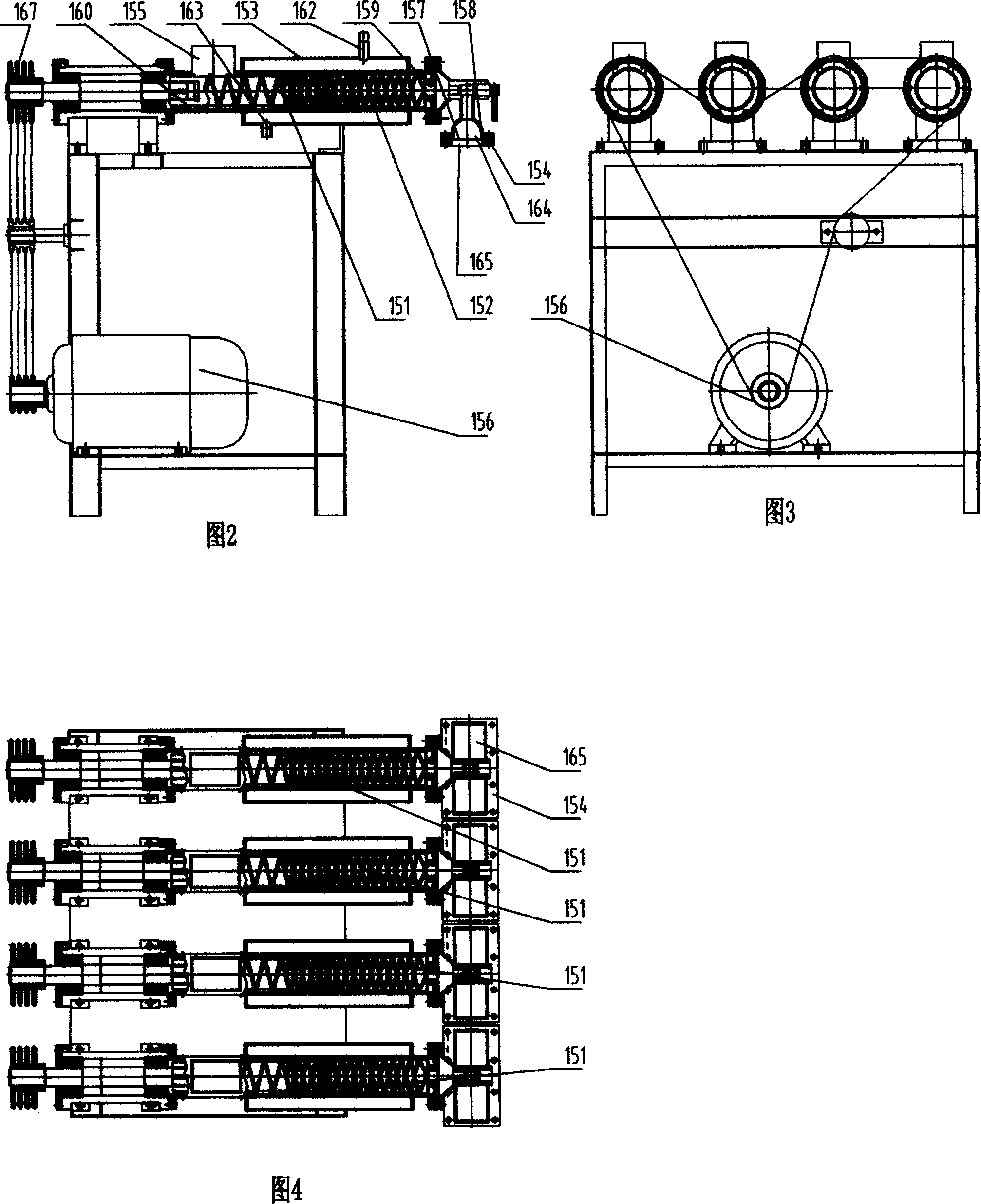

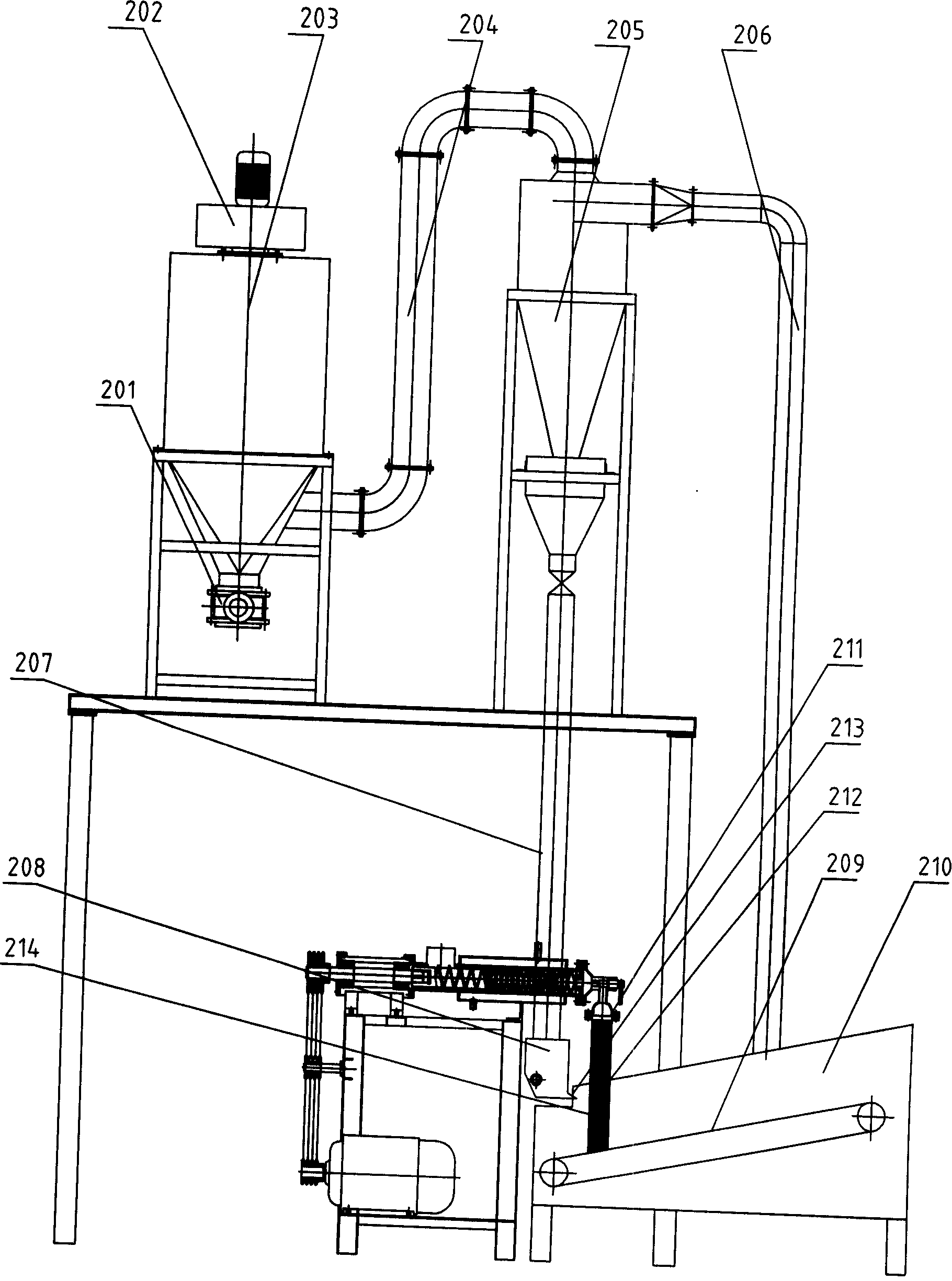

Fully-automatic convenient instant rice flour noodle production line and production technology thereof

InactiveCN101167541AQuality productionGreat tasteSeed preservation by freezing/coolingFood shapingEngineeringFully automatic

The invention relates to a production line of convenient instant rice flour and process technology, wherein the production line of the convenient instant rice flour comprises a rice treatment device, a cooking flour-mixing machine, a self-mature wire-extruding device, an aging device, a quantitative disconnecting device, a boxing shaping device, a powder block drying device, a powder block cooling device, and a packaging conveying device, which are orderly arranged according to the transfer direction of materials. The aging device comprises a rice vermicelli refrigerator, an aging machine and a continuous fluffer. The invention has the advantages of excellent product quality, wide adaptability, high performance, automaticity, low consumption, energy saving, high yield, health and environmental protection.

Owner:广州尧先机械有限公司

Freshwater chlorella and application thereof in fixation of CO2 and production of microalgae oil

InactiveCN103215190AGreat application potentialPromote growthUnicellular algaeBiofuelsBiodieselDry weight

The invention provides freshwater chlorella sorokiniana XJ02 and application thereof in fixation of CO2 and production of microalgae oil. The preservation number of the chlorella is CCTCC (China Center For Type Culture Collection) NO: M2013104. The chlorella disclosed by the invention can be used for fixing 0.03-20% of CO2 at high efficiency, the CO2 fixation efficiency of chlorella is 130-343mg / L / d, the biomass (dry weight) concentration of the chlorella is 720-2250mg / L, the oil content of chlorella is 29.2-41%, the oil fatty acid of the chlorella is mainly composed of C16 and C18 short-chain fatty acids, and the chlorella is suitable for production of biodiesel. Compared with the reported microalgae, the chlorella has higher CO2 fixation efficiency and biomass yield; and the chlorella can be used for obtaining the microalgae oil at high yield by selecting an appropriate culture condition, thus the production cost of the microalgae oil can be greatly reduced. An excellent production algae is provided for high-efficient fixation of CO2 in the environment and preparation of biodiesel by the microalgae oil.

Owner:CENT SOUTH UNIV

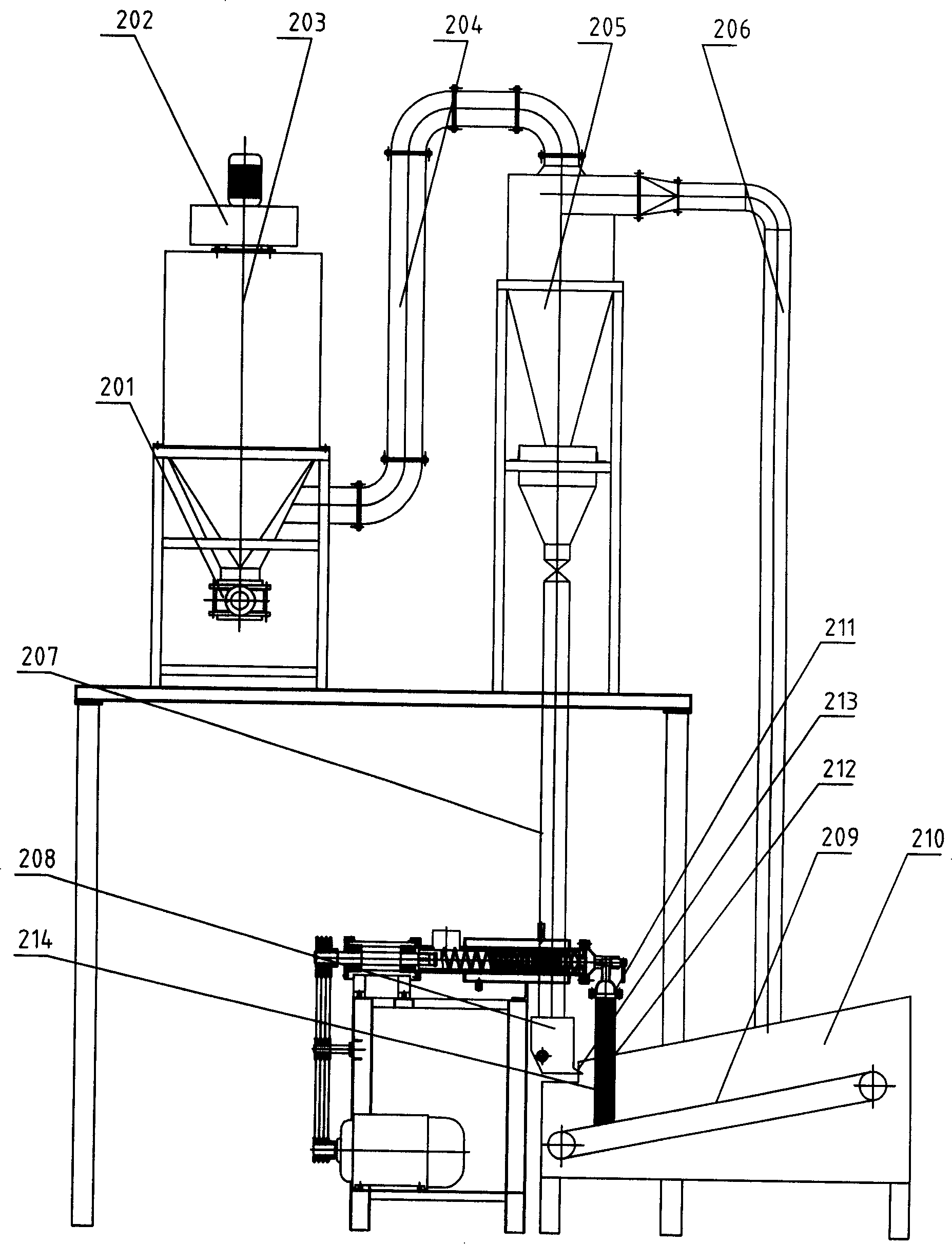

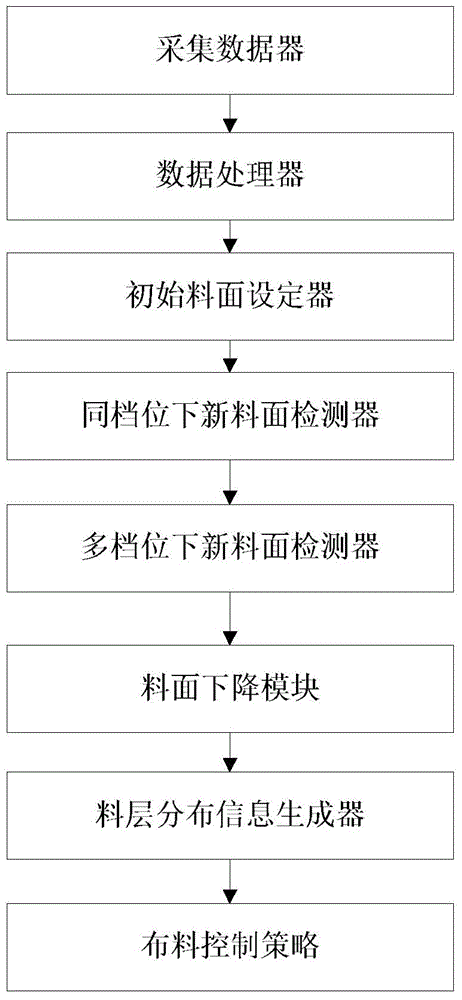

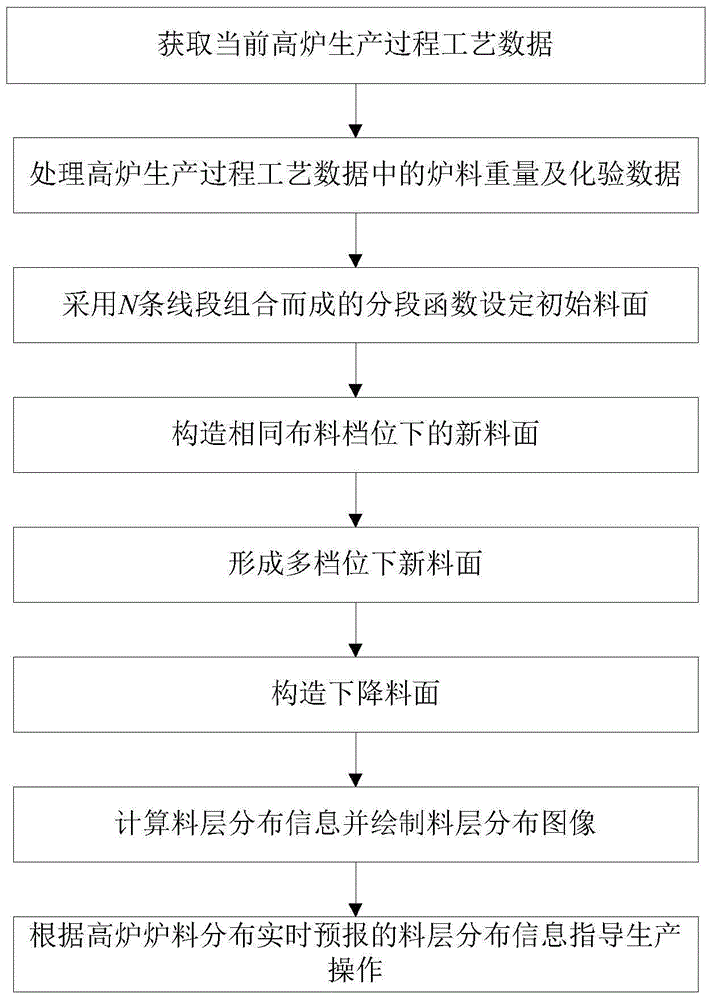

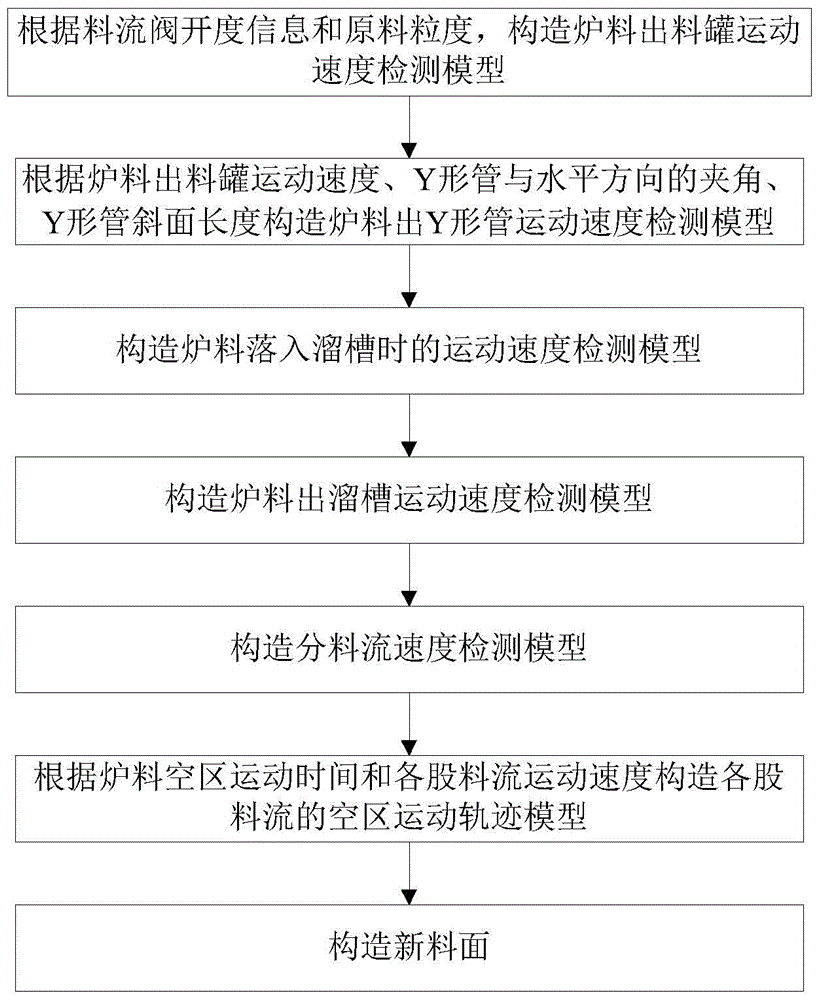

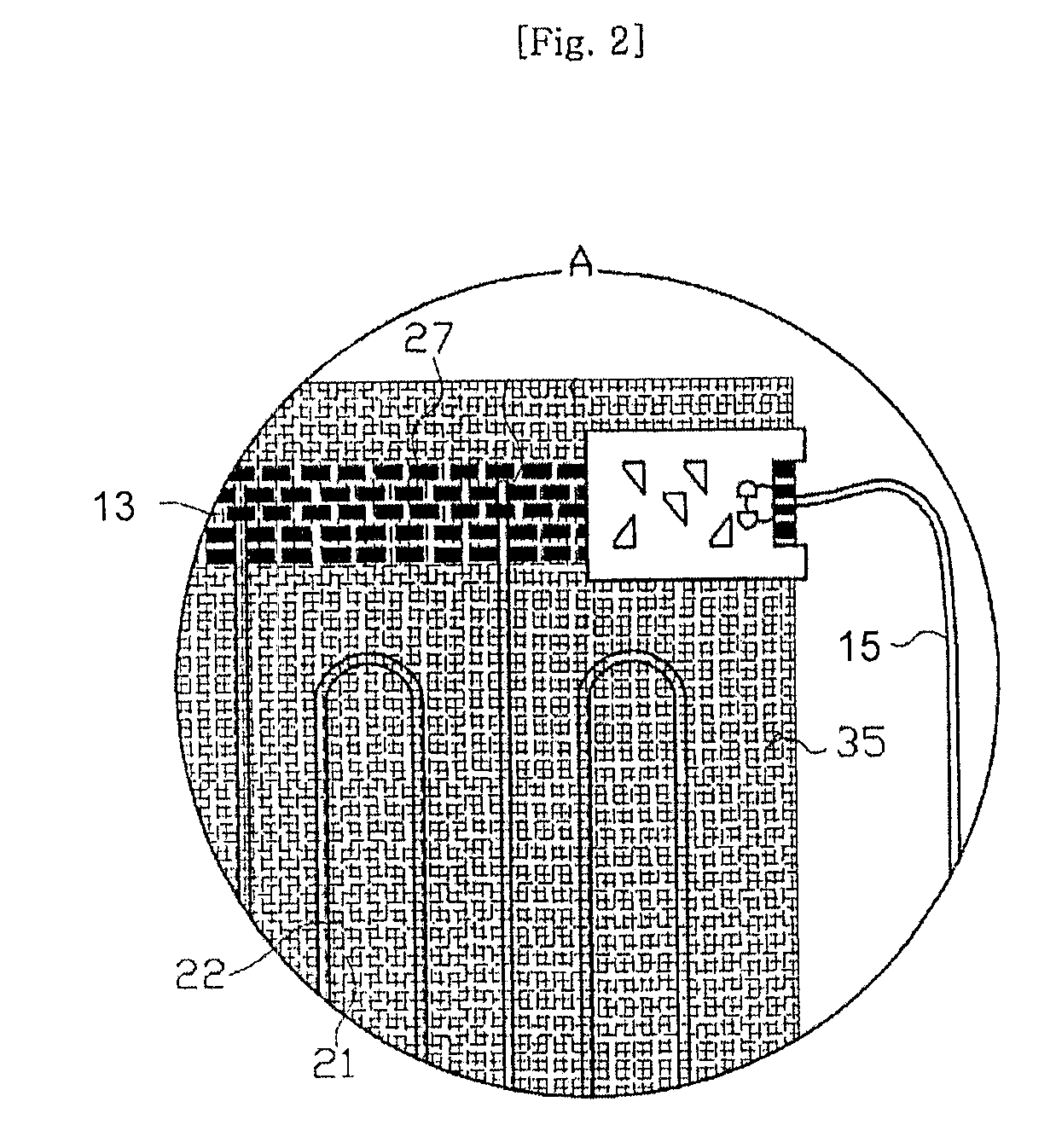

Blast furnace charge distribution real-time forecasting system and blast furnace charge distribution real-time forecasting method

ActiveCN104531924AStable productionQuality productionBlast furnace detailsChecking devicesDowntimeCharge layer

The invention provides a blast furnace charge distribution real-time forecasting system and a blast furnace charge distribution real-time forecasting method. The blast furnace charge distribution real-time forecasting system comprises a data acquisition device, a data processor, an initial charge level setter, an identical-level new charge level detector, a multi-level new charge level detector, a charge level descending module, a charge level distribution information generator and a distribution controller. The method comprises the steps of acquiring process data of a blast furnace in the production process; processing furnace charge weight and test data in the process data of the blast furnace in the production process; setting an initial charge level; establishing a new charge level under a same distribution level; forming a multi-level new charge level; establishing a descending charge level; calculating the distribution information of a charge layer, and drawing a charge layer distribution image; instructing the production and operation according to the charge layer distribution information forecasted according to the distribution of the blast furnace charge in real time. The method for combining a mechanism model and data drive is adopted, the distribution of blast furnace ore coke can be reasonably adjusted according to the judgment of the ore coke distribution furnace condition and the output result of the distribution model, the fluctuation of the furnace condition can be prevented, and the downtime ratio caused by the abnormality of the furnace situation can be reduced.

Owner:NORTHEASTERN UNIV

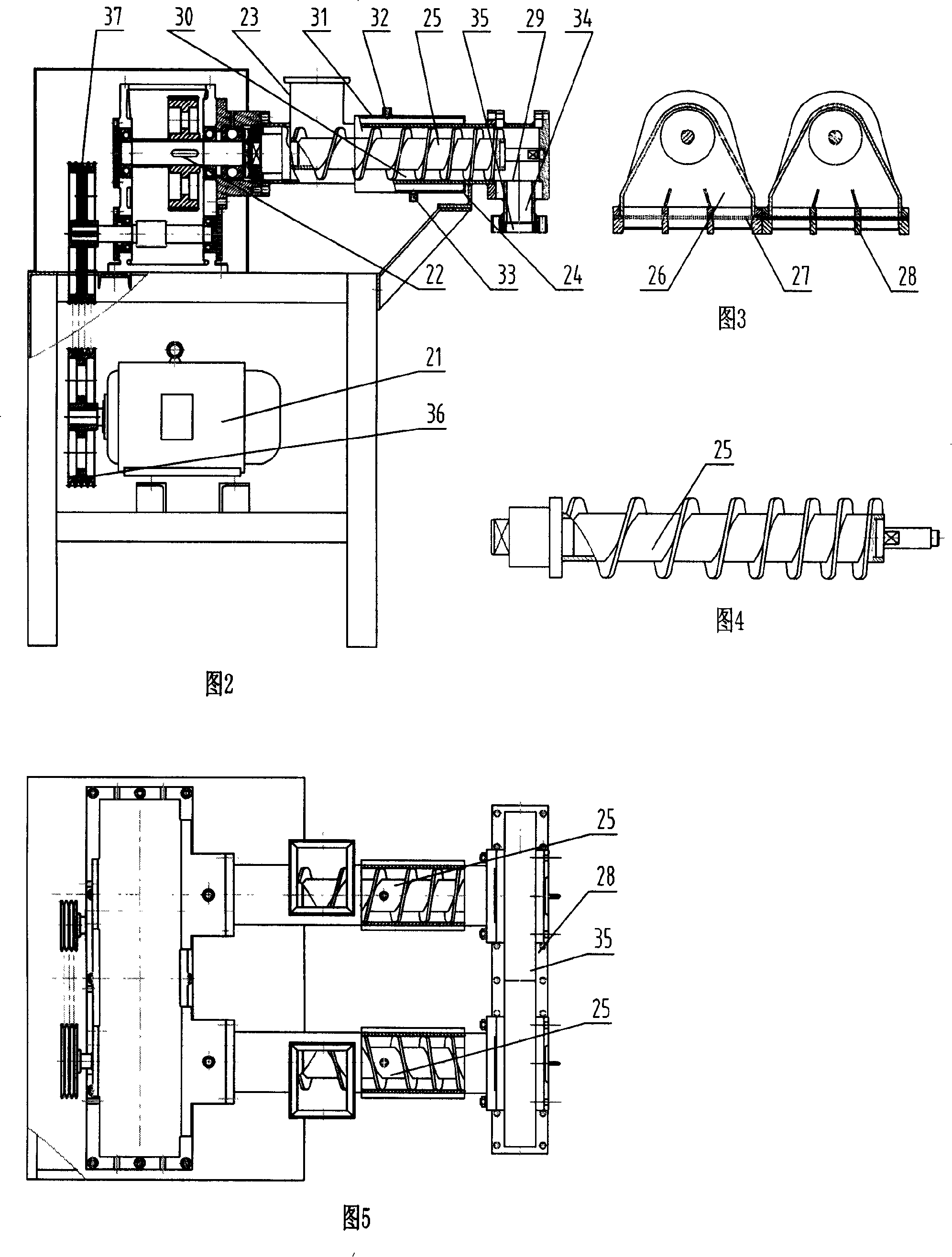

Full automatic production line of convenient and instant rice-flour and production technology thereof

InactiveCN101518311AIncrease production capacitySimple processFood preparationProduction lineMaterial transfer

The invention discloses a production line of convenient and instant rice-flour and a production technology thereof. The production line comprises a rice processing device, a stewing mill, a self-ripe scrooping device, an aging device, a quantitative disconnecting device, an entry-box shaping device, a powder block drying device, a powder block cooling device and a package conveying device which are arranged in sequence in accordance with material transferring direction. The aging device comprises a ricevermicelli refrigerator, an aging machine and a continuous fluffer. The production line and the production technology have the advantages of good product quality, broad suitability, high efficiency and automation, lower energy consumption, high yield, hygiene and environment protection.

Owner:BUHLER GUANGZHOU FOOD MACHINERY

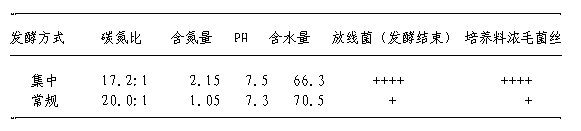

Centralized secondary fermentation method for agaricus bisporus

InactiveCN103319219AQuality productionHigh yield productionBio-organic fraction processingOrganic fertiliser preparationBiotechnologyAnimal Foraging

The invention discloses a centralized secondary fermentation method for agaricus bisporus. The culture medium comprises the following raw materials in parts by weight: 45-60 parts of forage, 35-50 parts of chicken manure, 2-8 parts of gypsum and 3-10 parts of oil cakes. The method comprises the following steps of: uniformly spreading forage in a pre-wetting pool for pre-wetting for 2-5 days; adding chicken manure, gypsum and oil cakes and uniformly and adequately mixing; filling the mixed fermentation material in a ventilating floor in a primary fermentation tunnel, and conveying fresh air to the fermentation material through a fan; fermenting for 4-6 days and transferring the fermentation material to another primary fermentation tunnel. The base material of the primary tunnel fermentation is uniformly stacked on the ventilating floor in a secondary fermentation tunnel, and the temperature of the fermentation material is controlled by operation of the fan. Secondary fermentation comprises the following steps: a balancing stage, a heating stage, pasteurization, cultivation at constant temperature and discharge at low temperature. According to the method, local wheat straw hoods, straws, chicken manure and the like are used as main raw materials to form the culture medium. Centralized scaled production cultivation materials are formed by the technology of pre-treatment of the raw materials, primary fermentation and secondary fermentation.

Owner:SICHUAN MAOSEN BIOLOGICAL SCI & TECH

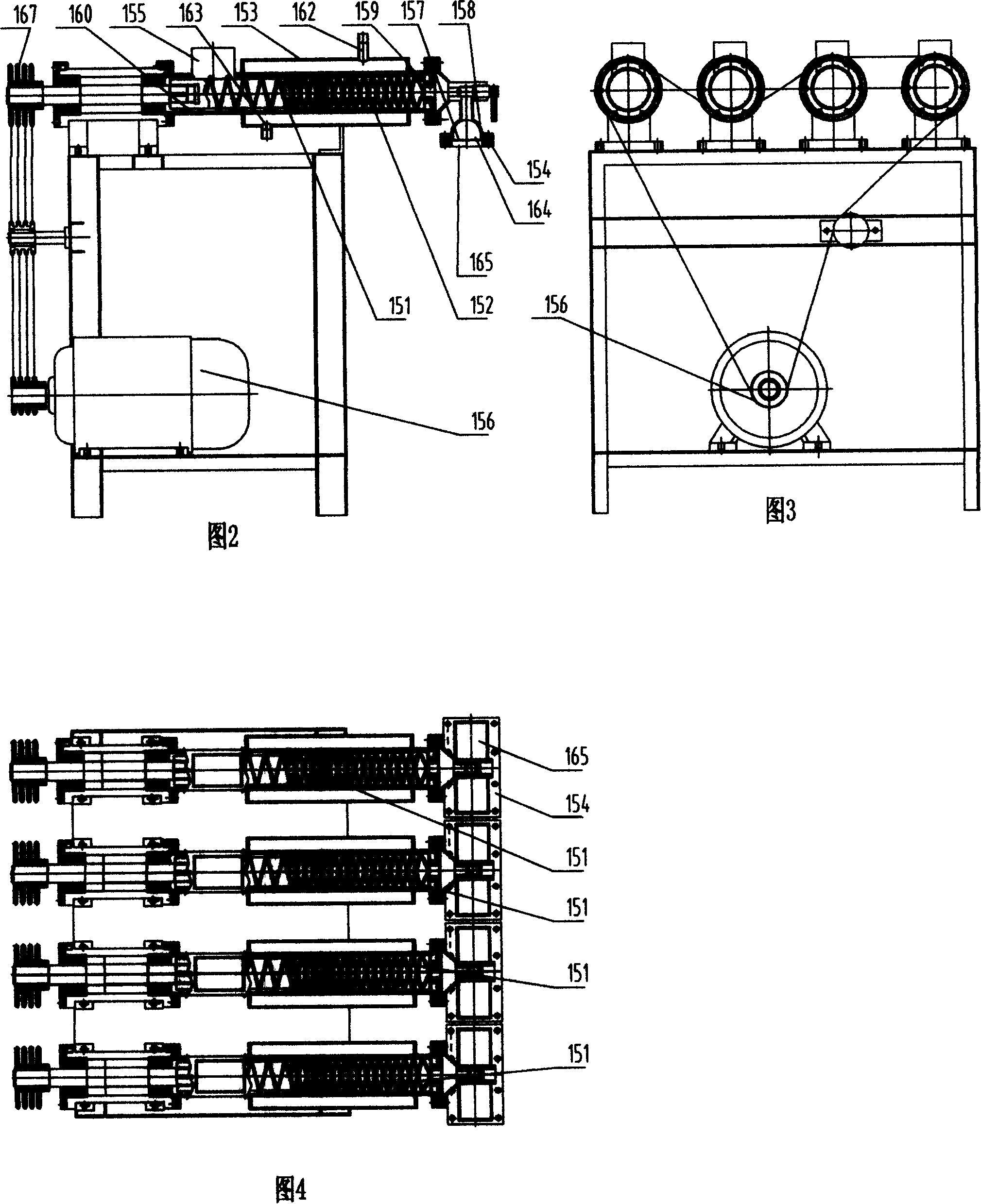

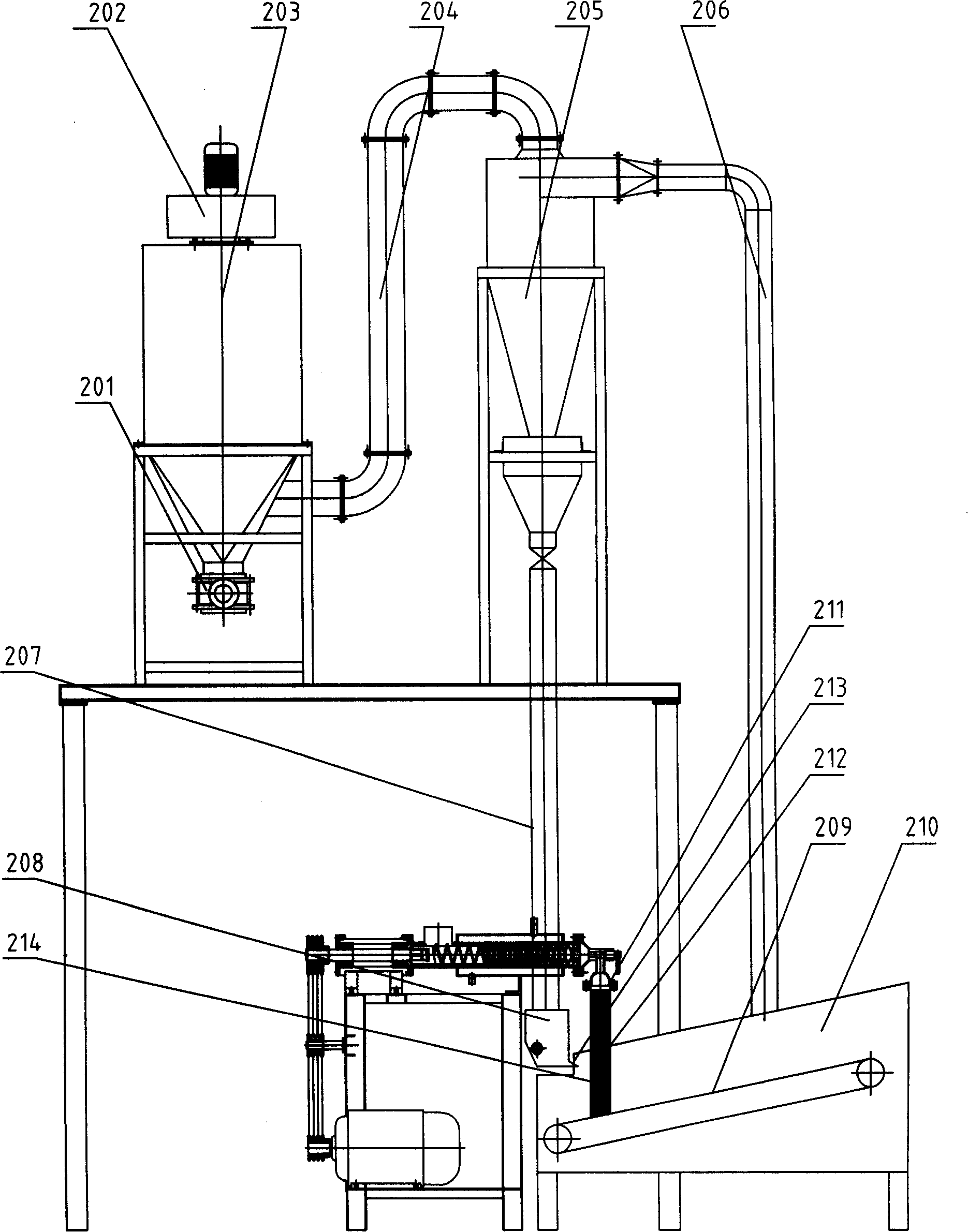

Fully automatic convenient vermicelli production line and its producing technology

InactiveCN101167599AIncrease production capacitySimple processFood shapingFood preparationFlavorProduction line

The invention relates to a full-automatic instant vermicelli production line, and comprises a starch agitating device, a self-curing scroop machine which can produce instant vermicelli only by one time curing, a time-effect aging device, a washing fluffer device, a quantitative cutting device, a powder agglomate drying device, a powder agglomate cooling device, and a package conveying device which are all sequentially arranged along the direction of transmitting materials. The time-effect aging device comprises a first natural time-effect aging machine, a vermicelli refrigerating machine, a washing fluffer machine, and a washing bean jelly machine for the secondary natural time-effect aging. The producing process sequentially comprises the starch agitating, the self-curing scroop, the time-effect aging, the quantitative cutting, the powder agglomate drying, the powder agglomate cooling, and the package conveying, and also comprises the merely primary self-curing scroop. The time-effect aging comprises the first natural time-effect aging, the vermicelli refrigerating, the washing fluffer, and the secondary natural time-effect aging which can lead the self-curing scroop machine which can produce instant vermicelli only by one time curing to extrude the vermicelli, and the vermicelli is not adhesive. The instant vermicelli cannot become burnt when the instant vermicelli is placed in the boiled water, and the flavor is good.

Owner:BUHLER GUANGZHOU FOOD MACHINERY

Novel maize culture technology

InactiveCN103947324AHigh yield productionQuality productionFertilising methodsSeed coating/dressingBiotechnologyMechanical equipment

The invention discloses a novel maize culture technology. The implementation method of the novel maize culture technology comprises the following steps: selection and preparation of land, selection and treatment of seeds, treatment before sowing, sowing, field management, in-time herbicide spraying, and harvesting. The novel maize culture technology has the characteristics that novel mechanical equipment is adopted for reasonable planting, and the traditional maize cultivation technology is broken through, and high-yield, high-quality and high-efficiency maize production is realized.

Owner:黎雁欣

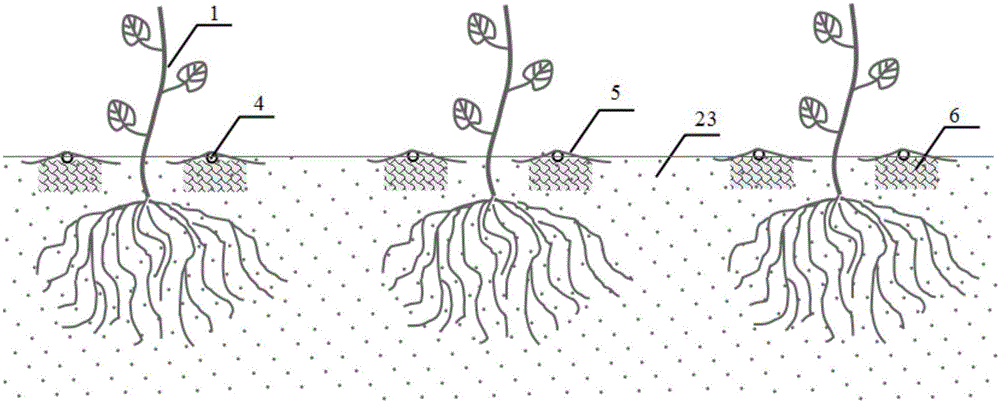

Corn stubble-remaining ridge side planting method

InactiveCN101233811ASustained high productionQuality productionClimate change adaptationFertilising methodsLand resourcesSoil organic matter

The invention relates to a stubble-leaving ridge side planting method pertaining to a technical field of corn planting and cultivation. A stubble of 5-15cm is left in even ridges of the existing tillage method after corn harvest, and seeds are sowed at a side of the ridge containing the stubble in the next year. One plough is shallowly processed on the side of a stubble belt of the last year, and then base fertilizer is applied. The seeds in precision quantity are manually sowed by using a disseminator and then grain fertilizer is applied. Soil is covered on the seeds and compacted to conserve soil moisture. The stubble-leaving ridge side planting method for corn of the invention realizes safely returning of straws, little move of soil, soil moisture conservation and seedling protection. Combined with dressing, subsoiling is used for breaking plough pans to create soil reservoir of plough layers, improve the use efficiency of natural rainfall, realize natural decay and returning of high stubbles, increase soil organic matters and cultivate fertility, thus ensuring the sustainable use of land resource.

Owner:JILIN ACAD OF AGRI SCI

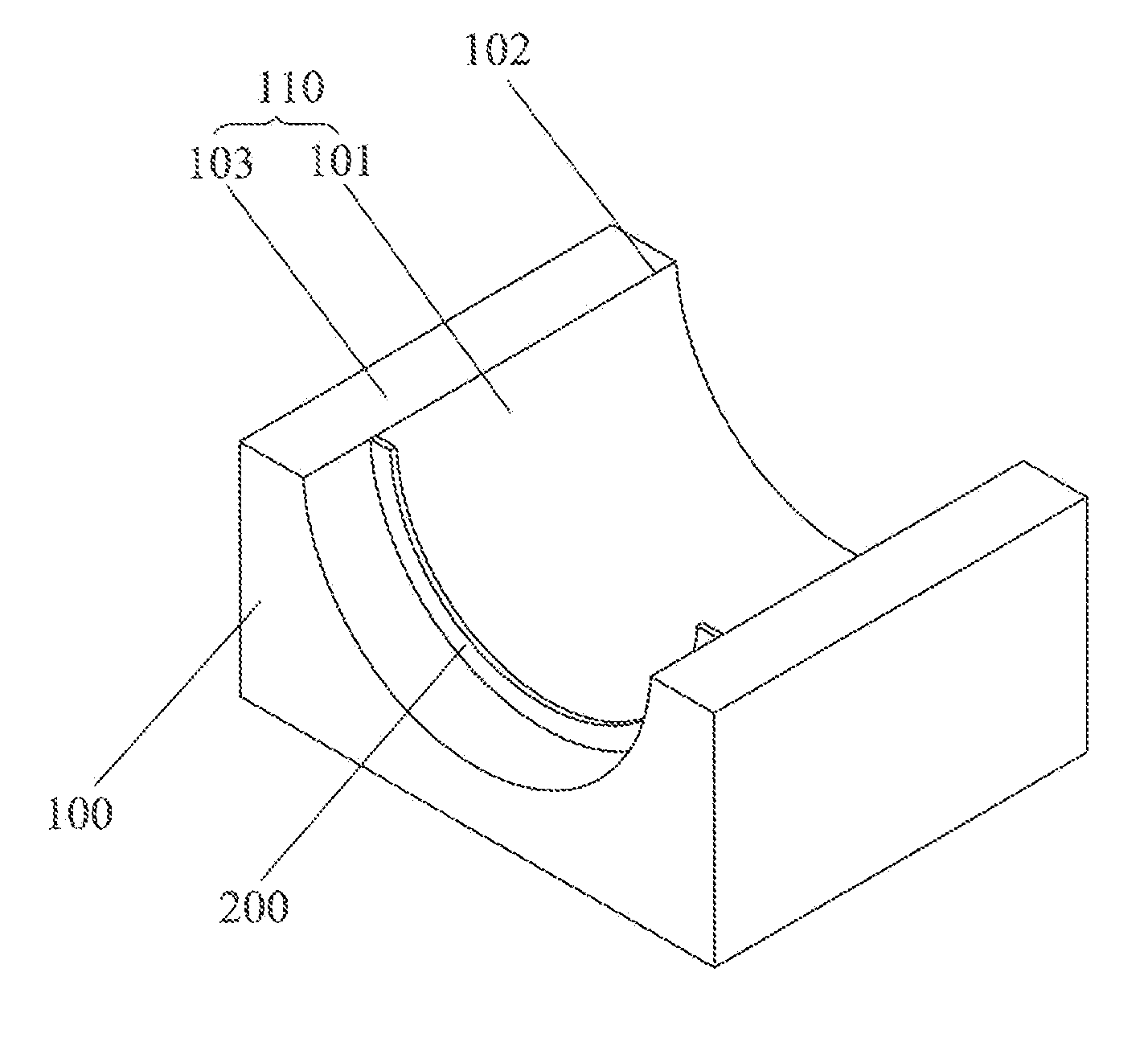

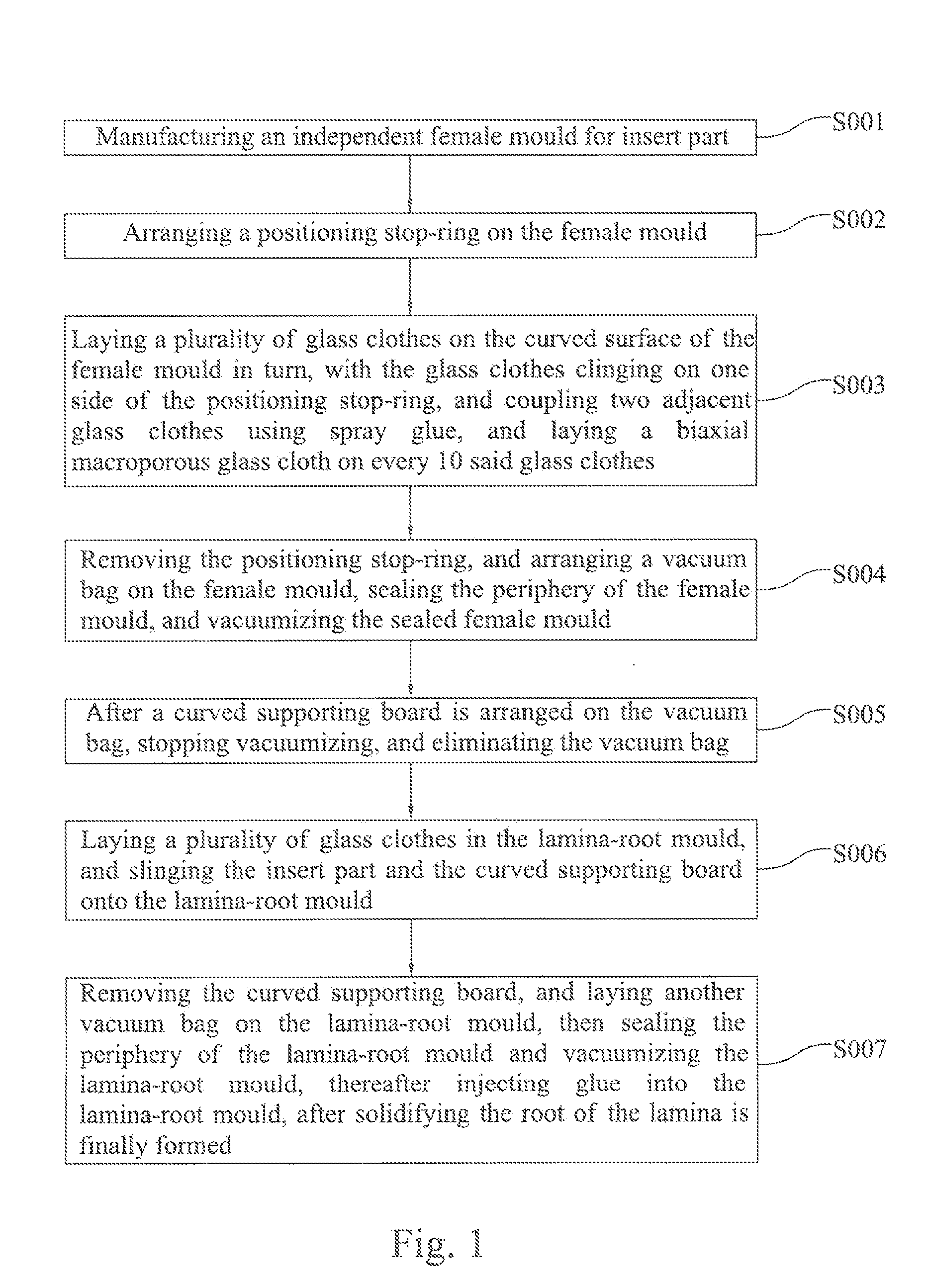

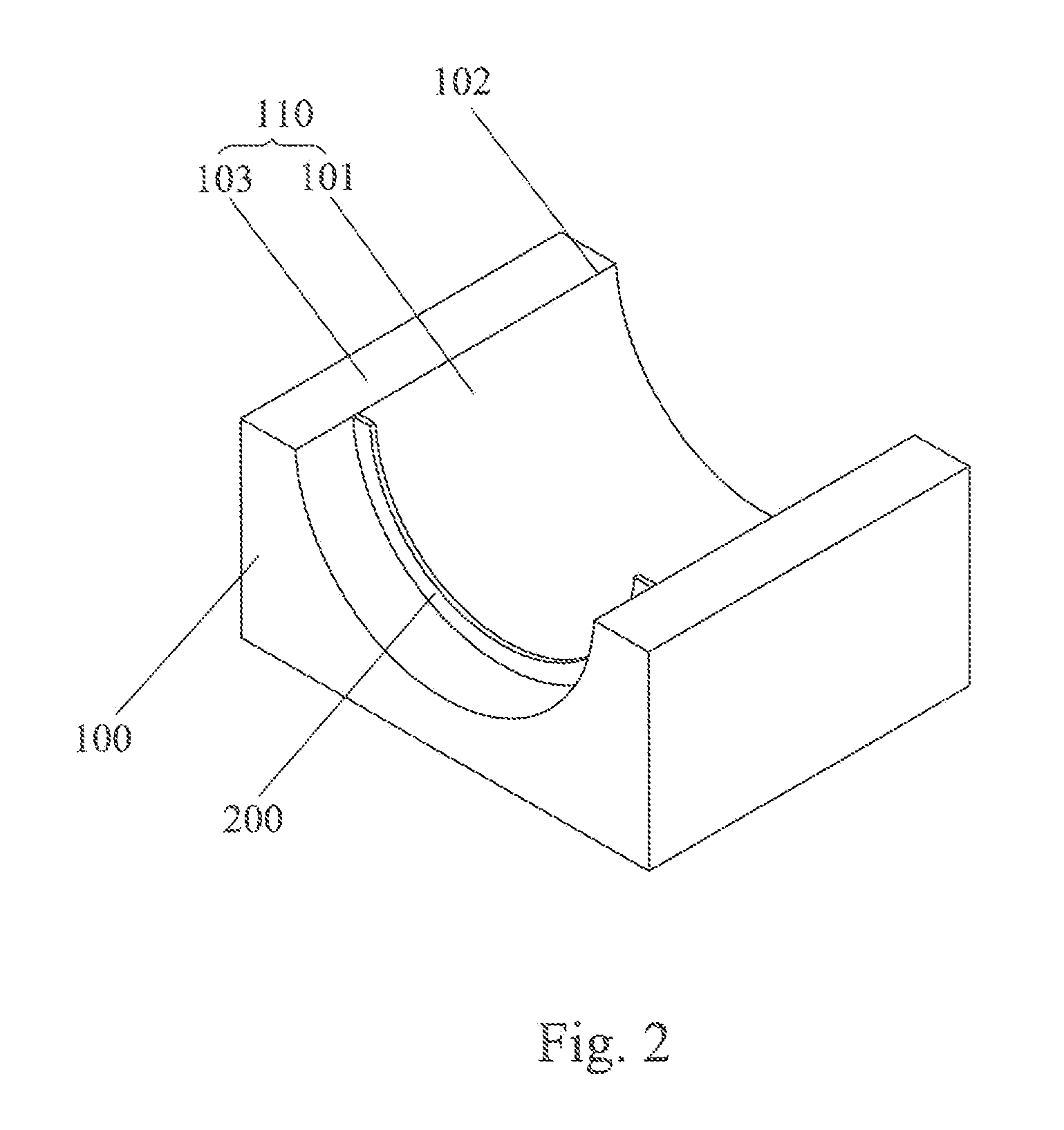

Method of manufacturing root of megawatt wind-turbine blade

InactiveUS20120006473A1High production efficiencyLong operate lifeFinal product manufactureConfectioneryTurbine bladeLeaf blade

A method of manufacturing root of megawatt wind-turbine blade includes the following steps: (1) manufacturing an independent female mould, and arranging a positioning stop-ring on the female mould; (2) clinging on one side of the positioning stop-ring, a plurality of glass fabrics and macroporous glass fabrics are laid on the curved surface of the female mould; (3) after laying the glass fabrics, sealing the female mould using a vacuum bag, and vacuumizing the female mould after a curved supporting board is arranged on the vacuum bag; (4) after laying a plurality of glass fabrics in the blade mould, slinging the prefabricated part and the curved supporting board to arrange them in the blade mould; (5) sealing the blade mould using another vacuum bag, vacuumizing the blade mould, thereafter infusing resin into the blade mould, after curing the root of the blade is finally formed. The method of manufacturing root of megawatt wind-turbine blade increases the production efficiency and production quality of the blade root, and prolongs the operation life of the blade root.

Owner:LIANYUNGANG ZHONGFU LIANZHONG COMPOSITES GRP

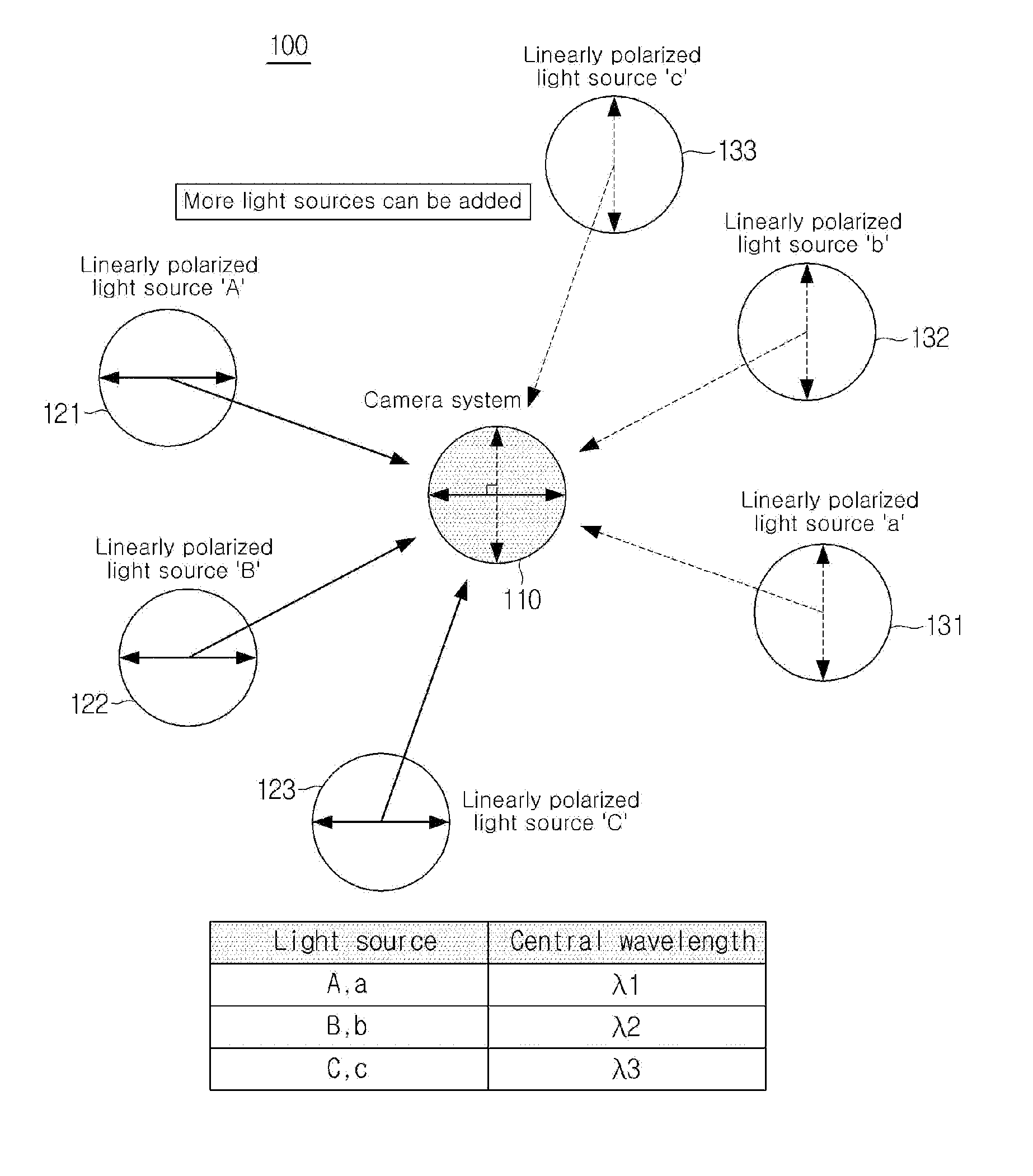

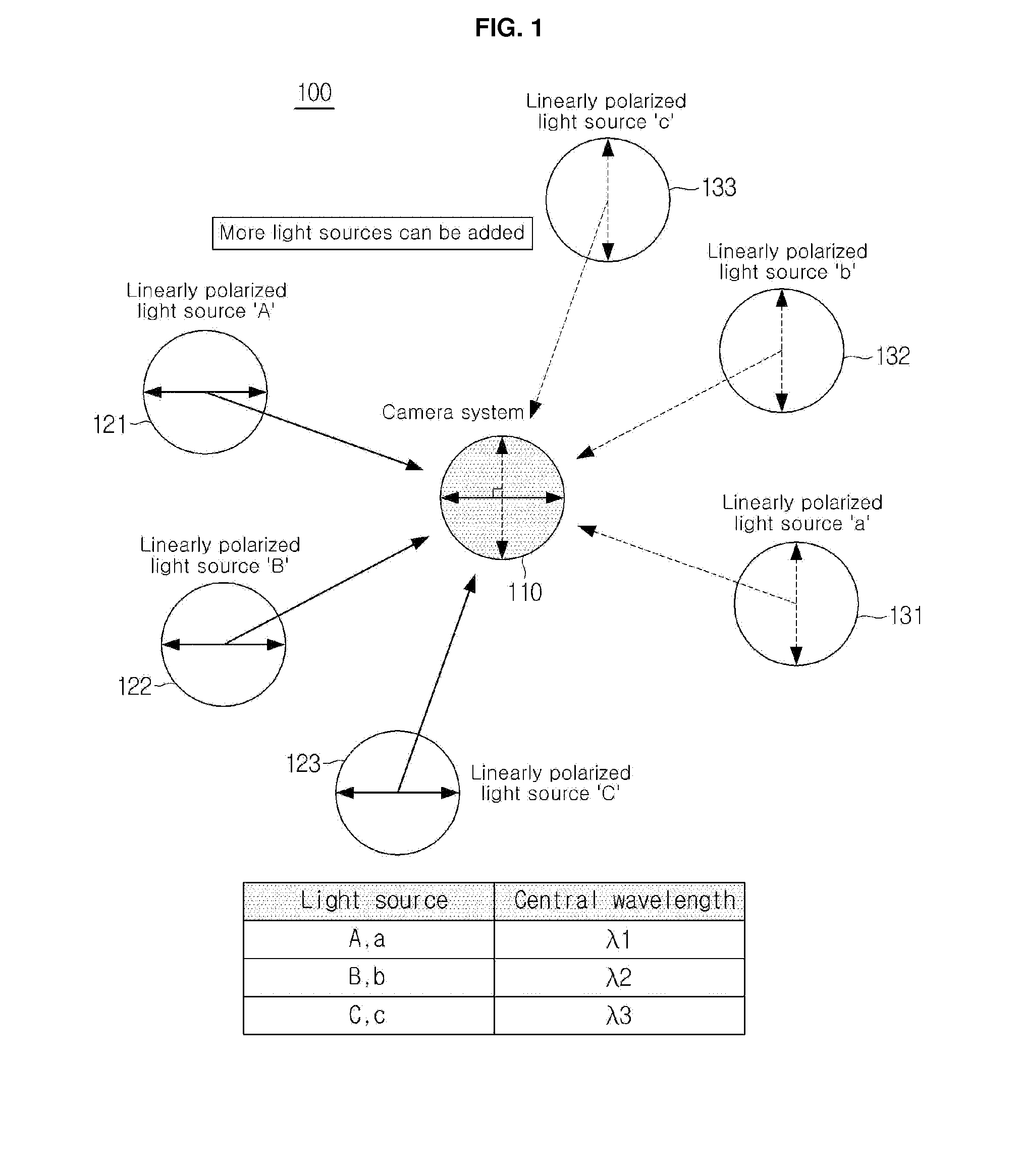

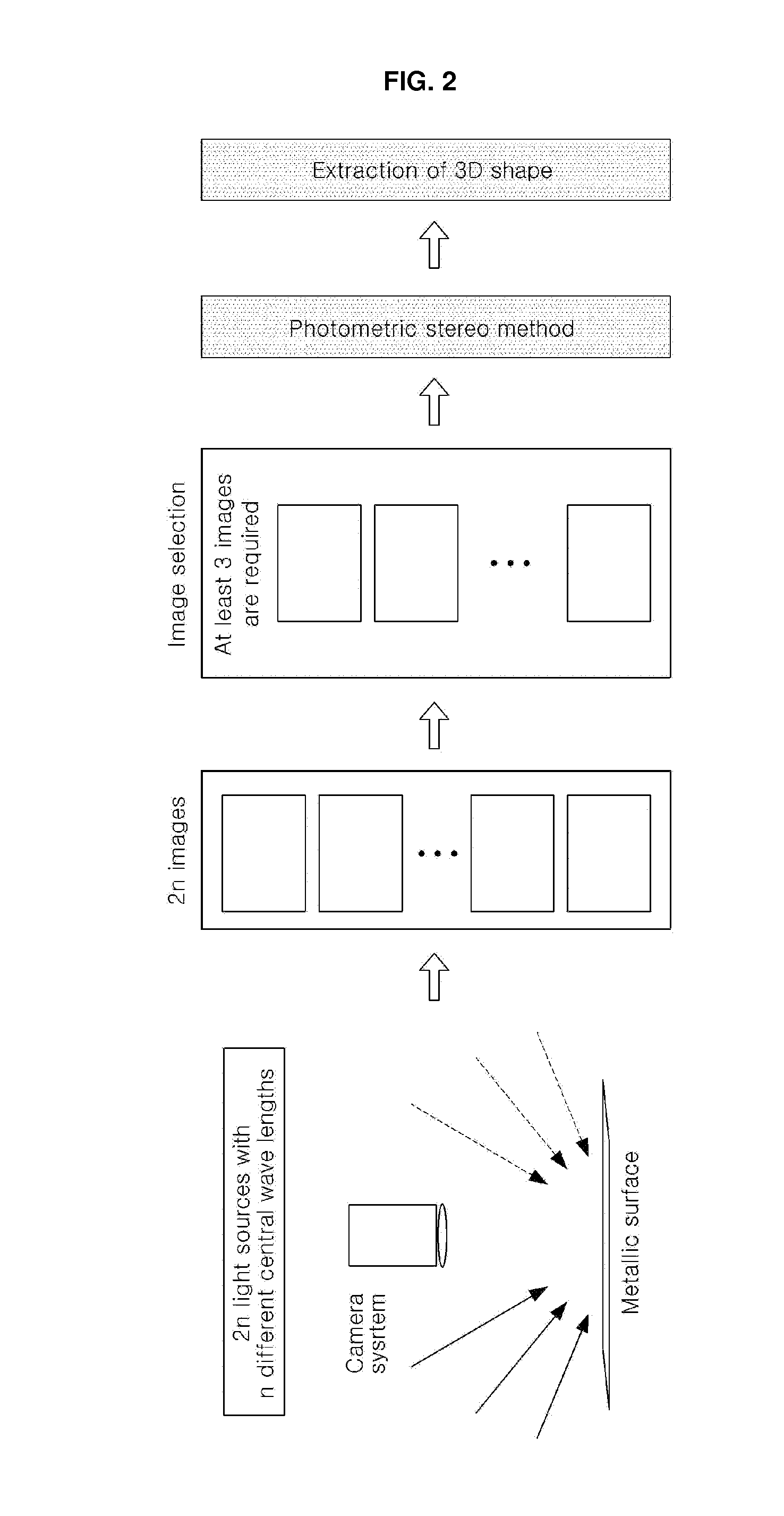

Method and system for reliable 3D shape extraction of metal surface

ActiveUS20140168382A1Improve qualityCost savingUsing optical meansSteroscopic systemsImage based3d shapes

The present invention relates to a method and system for reliable 3D shape extraction of a metal surface. In this method, images are acquired at the same time by simultaneously irradiating interference-free polarized lights to a metal object. A photometric stereo method is then applied based on the images except for images which make the extraction of a 3D shape of the metal object inaccurate.

Owner:DONGGUK UNIV GYEONGJU CAMPUS IND ACAD COOPERATION FOUND

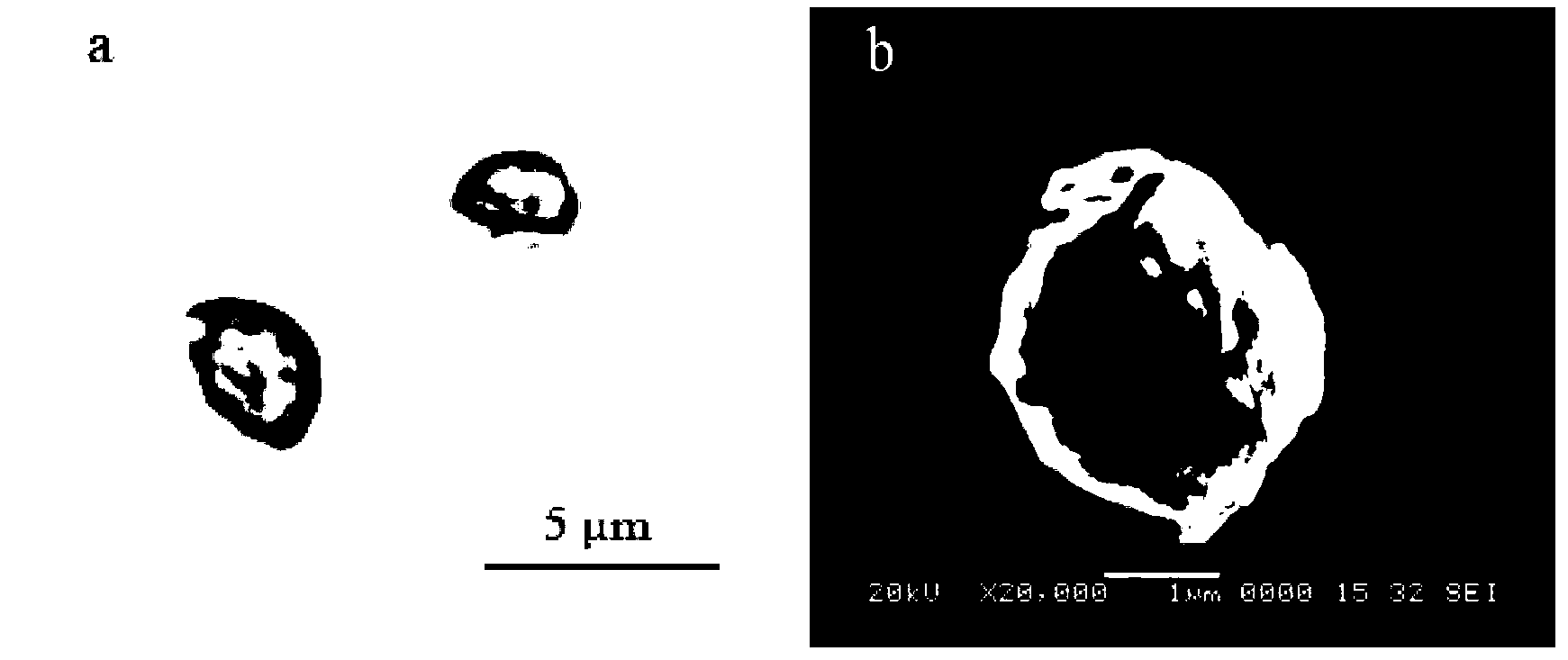

Method for testing fresh cocoon raw silk by adopting polarizing microscope

InactiveCN103175833AQuality productionEasy to operateMaterial analysis by optical meansCover glassBiology

The invention relates to a method for testing fresh cocoon raw silk, and specifically discloses a method for testing appearance of fresh cocoon raw silk by adopting a polarizing microscope for distinguishing fresh cocoon raw silk from dry cocoon raw silk. The method for testing the fresh cocoon raw silk by adopting the polarizing microscope comprises the following steps of: cutting out a section of raw silk of about 3cm from the raw silk of an unknown sample, placing the cut raw silk on a glass slide, dropping a drop of glycerol, and covering the glass slide with cover glass to form a raw silk slide; and placing the raw silk slide under the polarizing microscope for observation, finding the raw silk fiber under a low-power objective (10x), and then, changing to a high-power objective (40x) for observation. In the method provided by the invention, the polarizing microscope is used for observing and photographing the raw silk, and the fresh cocoon raw silk is distinguished from the dry cocoon raw silk according to the smoothness of the fiber surface in a raw silk polarized image and the amount of sericin particles. The method has the advantages of being simple, easy and efficient, convenient to operate, low in cost and high in efficiency, and so on, is beneficial for selection of high-quality raw silk raw materials by silk weaving enterprises, and promotes high-quality and high-efficiency production of the silk weaving enterprises.

Owner:ZHEJIANG UNIV

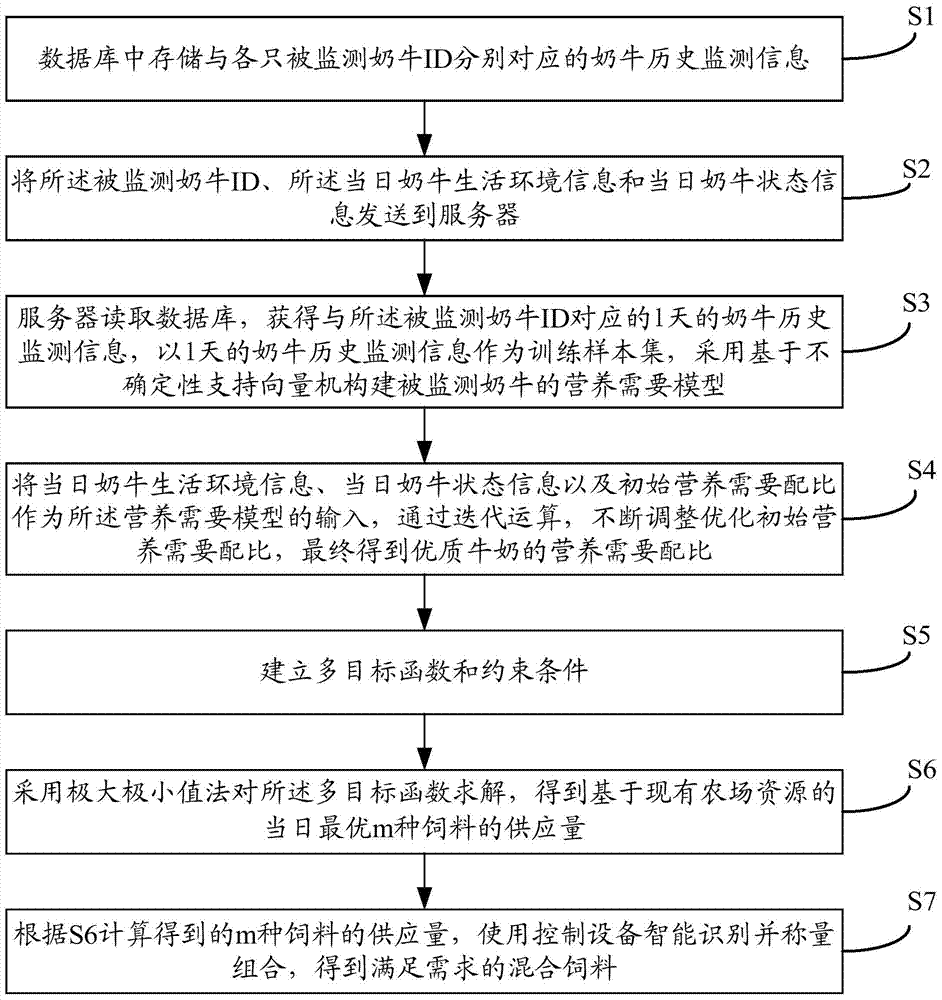

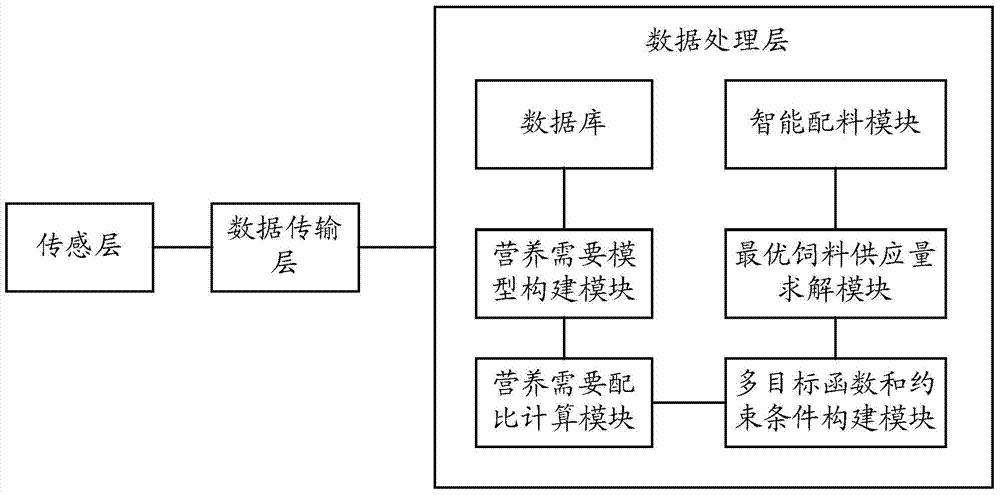

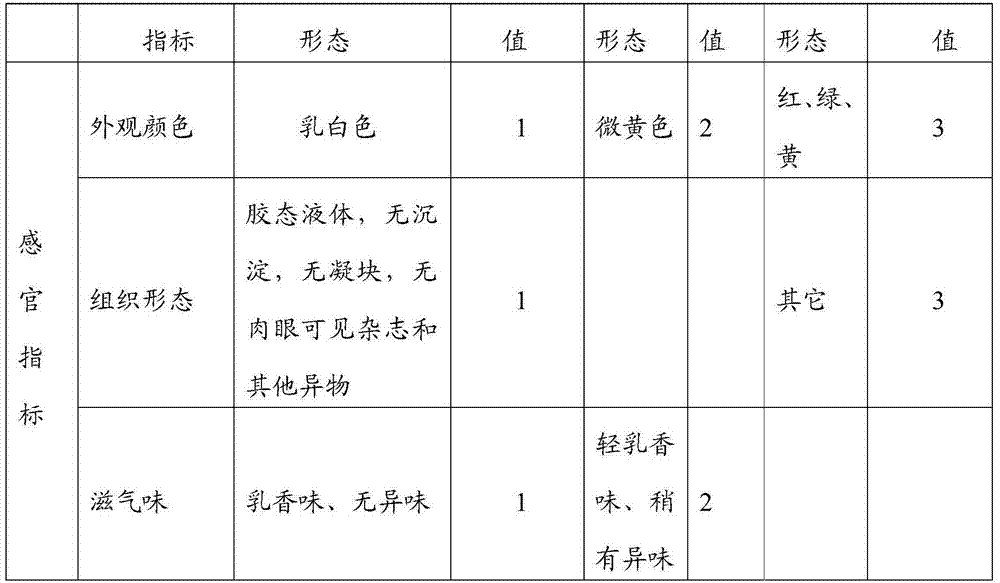

Intelligent nutrition proportioning method and system based on uncertainty support vector classification

InactiveCN104778625AQuality productionEfficient productionData processing applicationsCharacter and pattern recognitionRequirements modelAdditive ingredient

The invention provides an intelligent nutrition proportioning method and system based on uncertainty support vector classification. The system comprises a database, a nutrition requirement model construction module, a nutrition requirement proportion calculation module, a multi-target function and constraint condition construction module, an optimal feed supply amount solving module and an intelligent dosing module, wherein the database is used for storing historical dairy cow monitoring information independently corresponding to an ID (Identity) of each monitored dairy cow. According to the basic information and different daily food intake and milk yield of the dairy cows, a proper quantity of different ingredients is blended duly, an optimal proportion of mixed feed which conforms to traditional farm resources can be intelligently obtained, and therefore, the high-quality and efficient production of the dairy cows can be realized. Meanwhile, feed use efficiency is improved, and the fine cultivation of a dairy cow cultivation process is realized.

Owner:BEIJING WISDOM AGRI

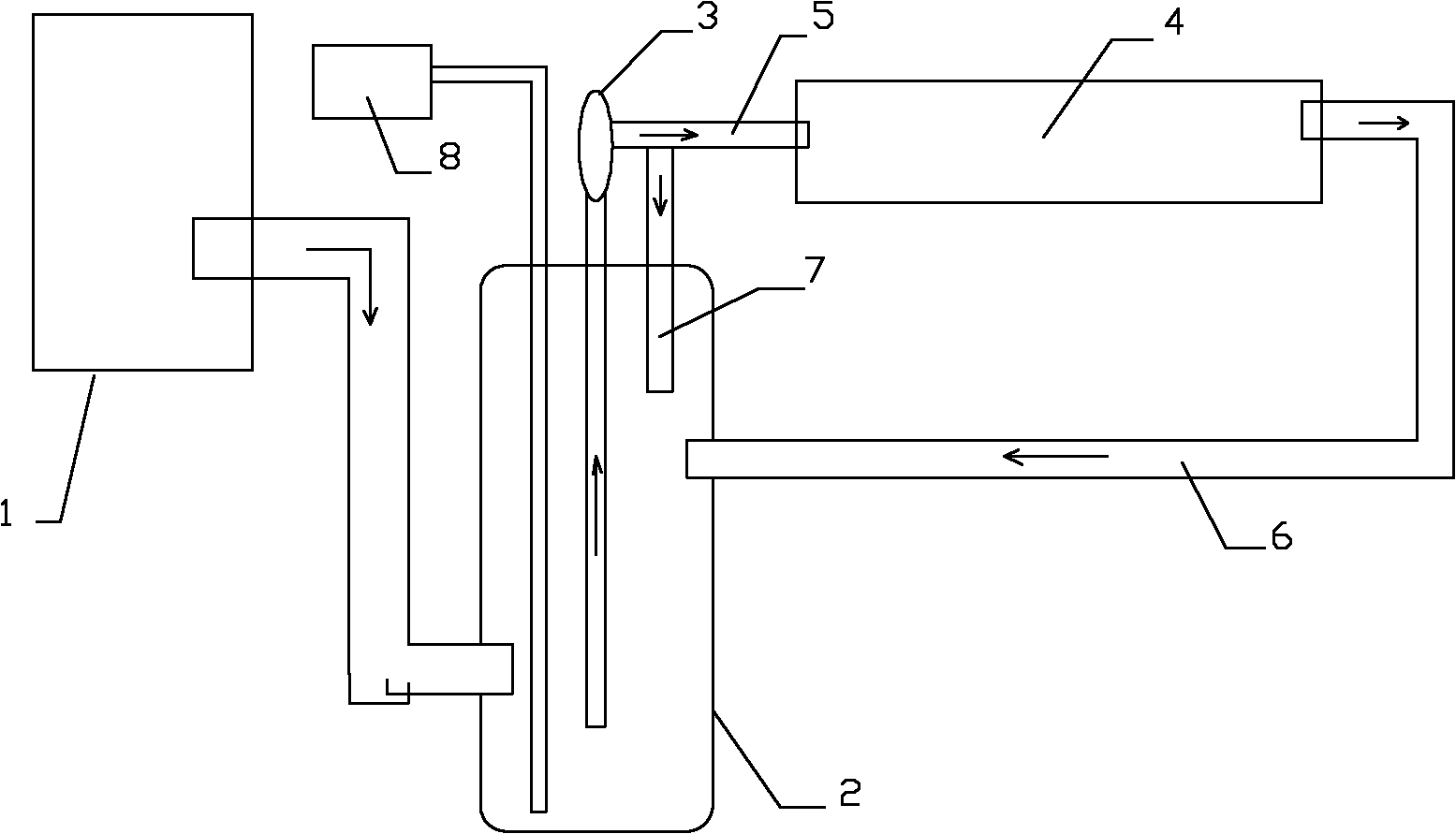

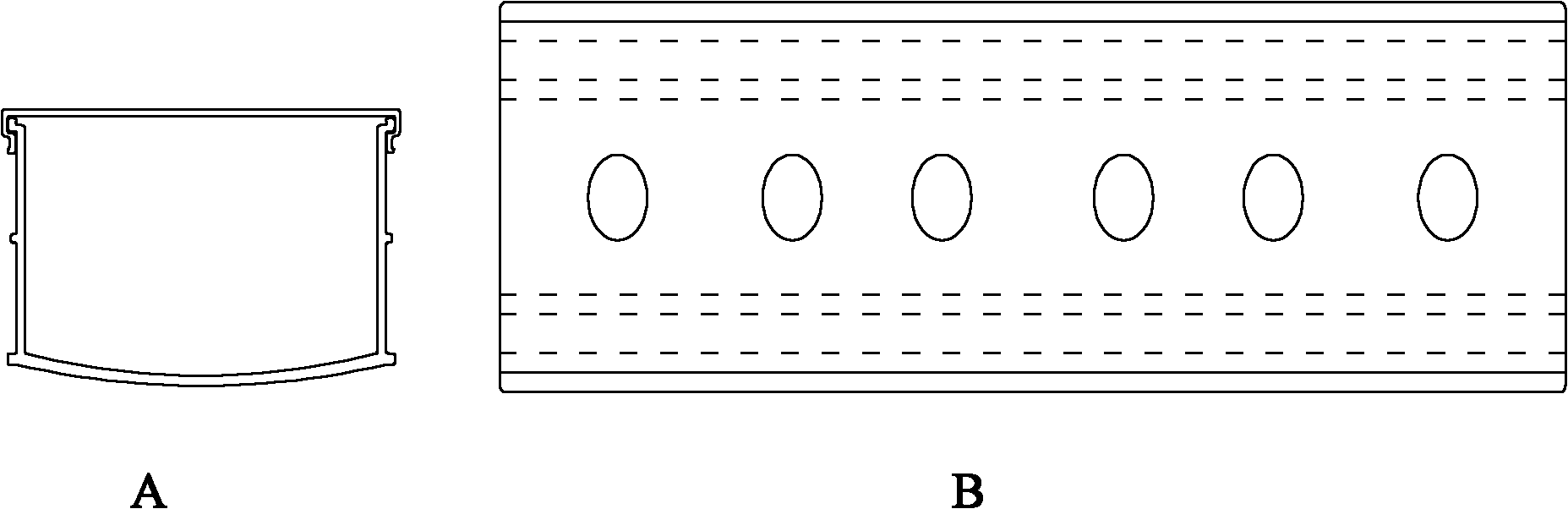

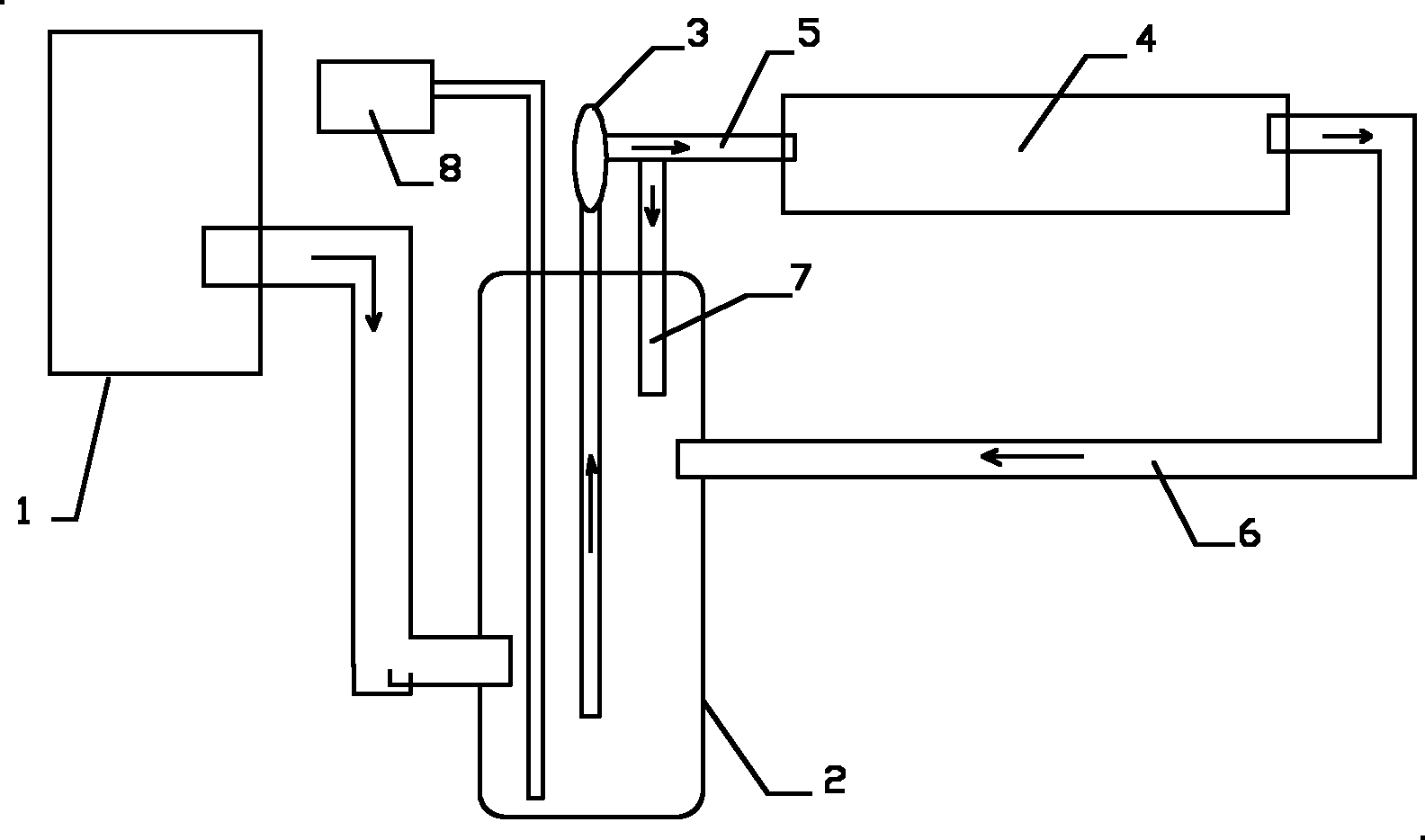

Water ploughing system for culturing vegetable and application thereof

ActiveCN101803560AEfficiently regulate the circulation temperatureRegulating cycle temperatureAgriculture gas emission reductionCultivating equipmentsAir compressionNutrient solution

The invention discloses a water ploughing system for culturing vegetables and applicant thereof. The water ploughing system comprises a liquid storing system, a nutrient solution circulating system, a planting platform system and a protection system, wherein the liquid storing system mainly comprises a water reservoir, a liquid storing well and an oxygen increasing device; the water reservoir is connected with the liquid storing well by a pipeline; the liquid storing well is arranged under the earth surface; the elevation position of the water reservoir is higher than that of the liquid storing well; the oxygen increasing device comprises a return pipe and an air pressure pump; the nutrient solution circulating system mainly comprises a suction pump, a liquid feeding pipeline and a liquid returning pipeline; the planting platform system comprises a planting groove and a bedstead; the planting groove comprises a groove body and a groove cover; the groove cover and the groove body are movably connected; and the bottom of the groove body has the radian; the protection system mainly comprises a sunshade net, the minimum cover range of which is the planting platform system. The system overcomes the technical problem that the temperature of the nutrient solution in the traditional water ploughing culture is difficult to control, the dissolved oxygen is not enough and the production cost is overhigh; therefore, the system is suitable for the cultivation of various leaf vegetables and can realize the high-quality efficiency production of vegetables.

Owner:GUANGZHOU ZHUOLI AGRI TECH

Method of maximising utilisation of egg albumen

ActiveUS20090263561A1Increase profitabilityGreat massDough treatmentBakery productsAnimal scienceFood products

A food product formulation which includes dried hen egg albumen (white), wherein the level of said albumen in said formulation is based on the water absorption or water binding (gelling) capacity of said albumen.

Owner:SOUTHSIDE COLDSTORES

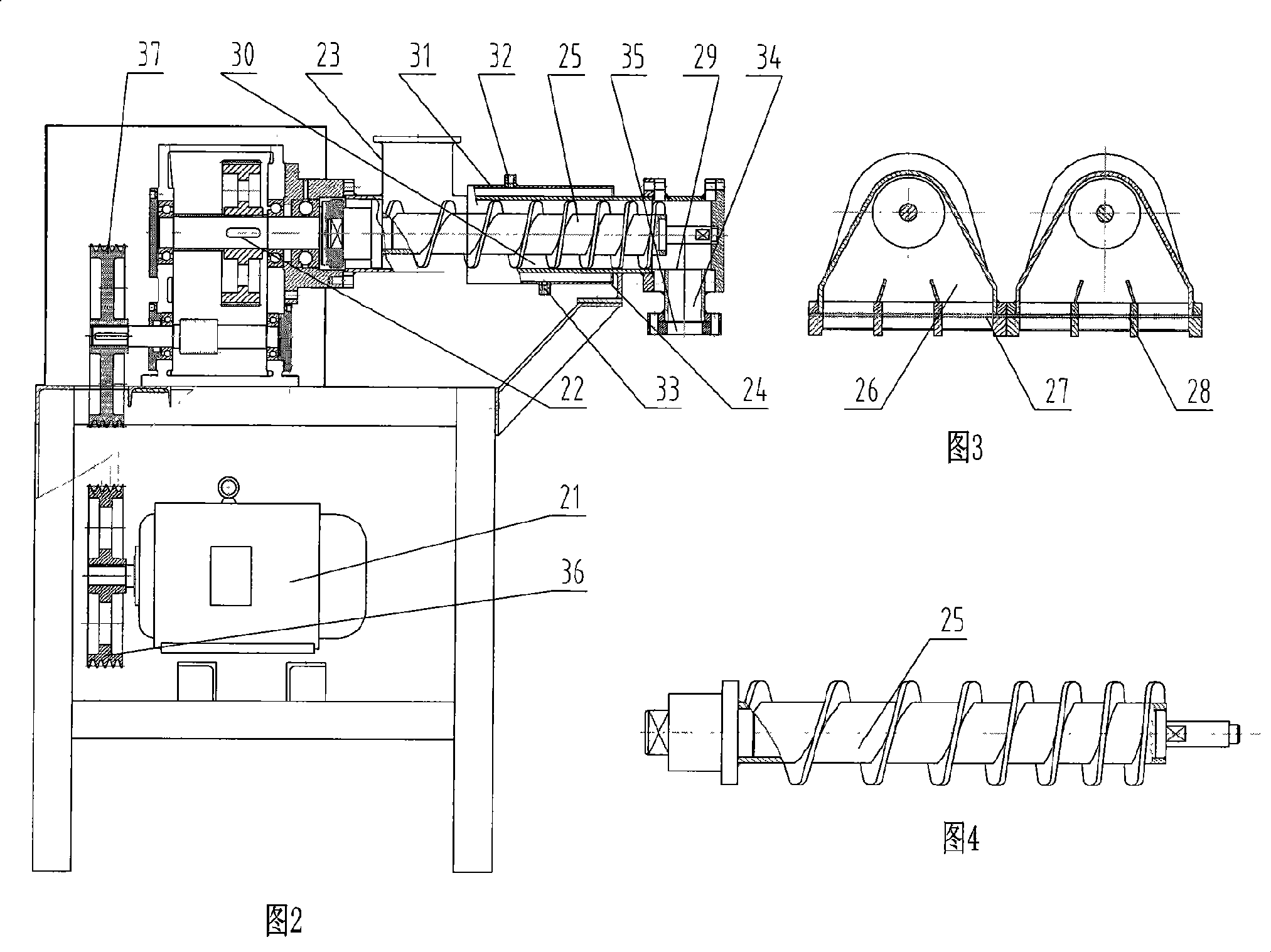

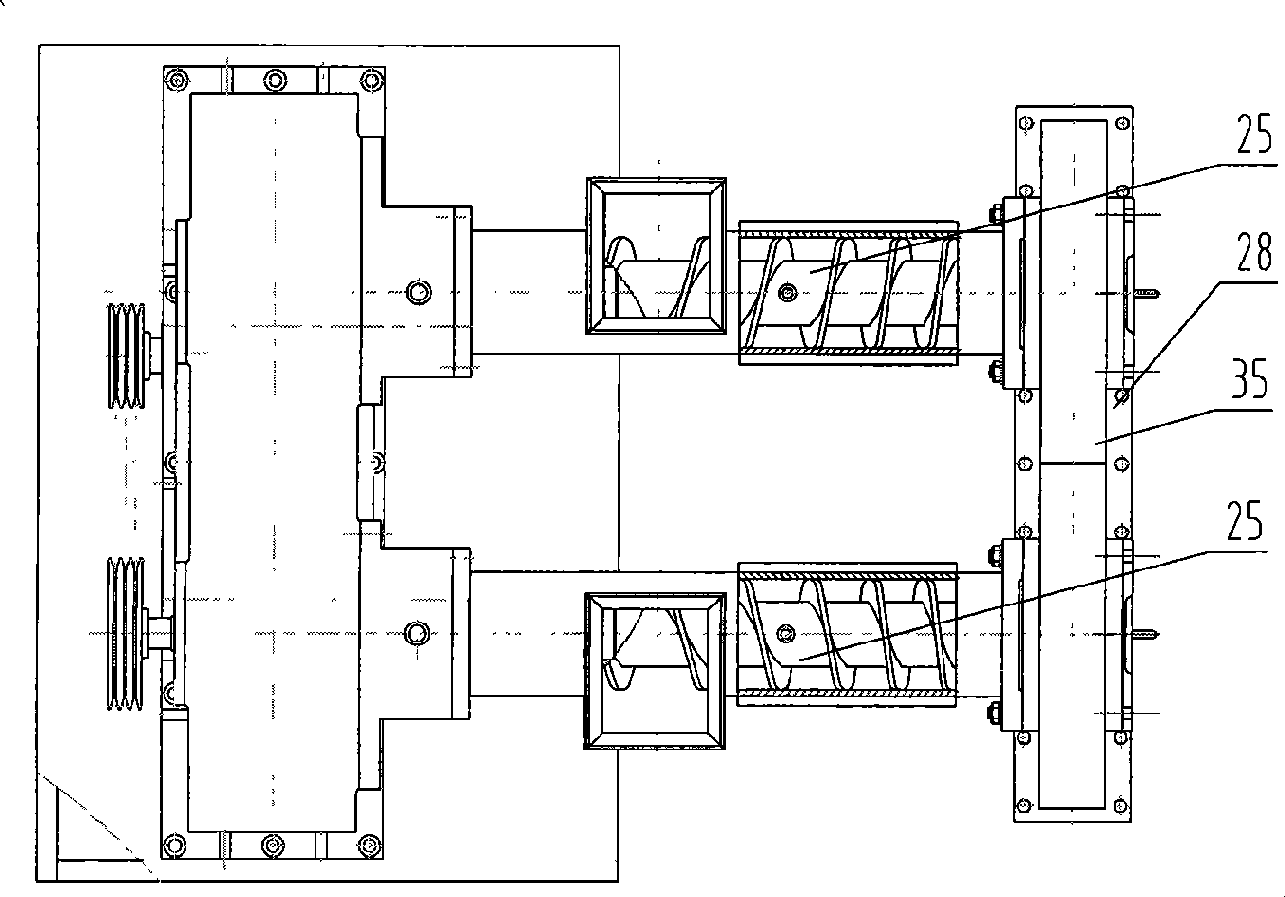

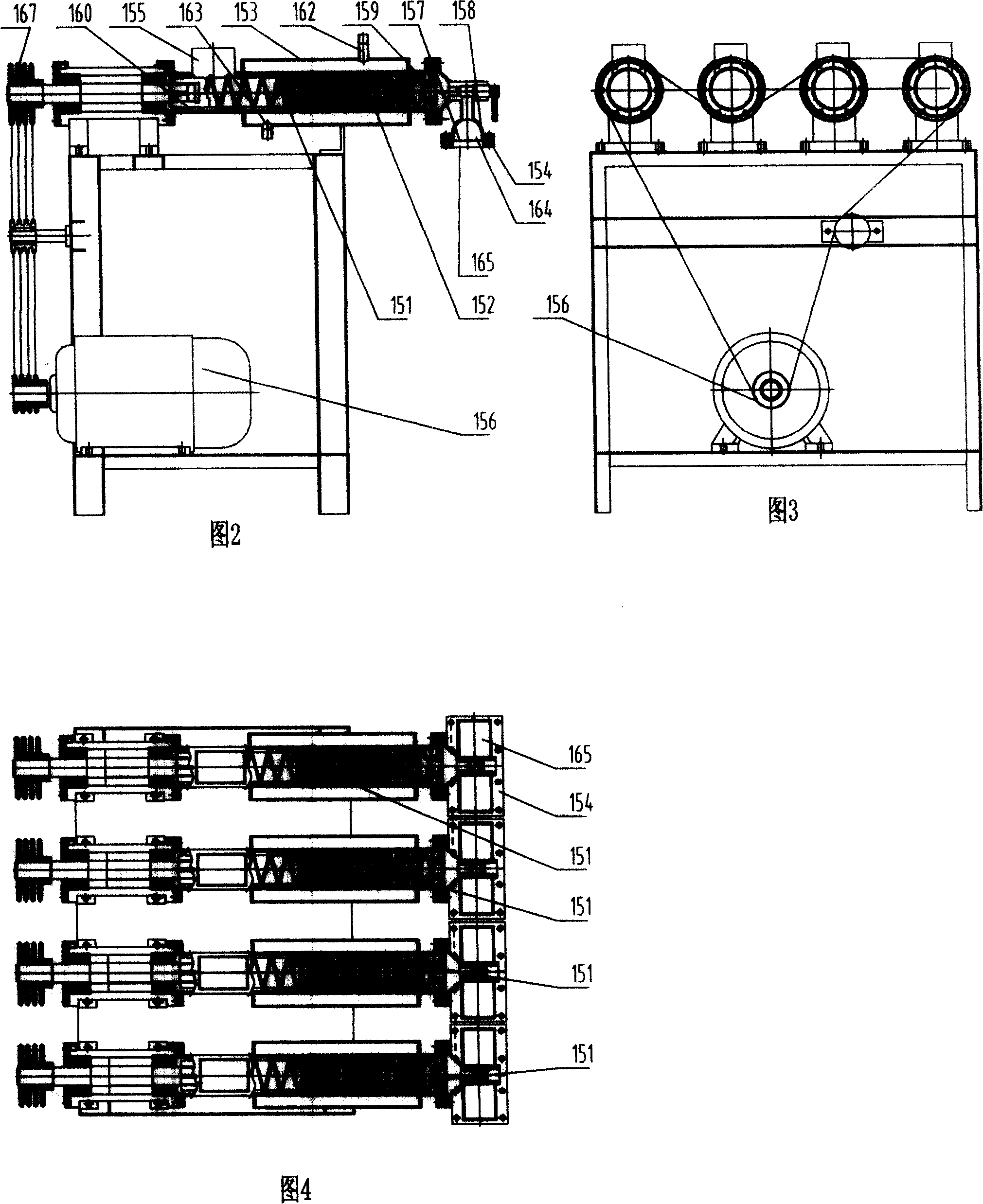

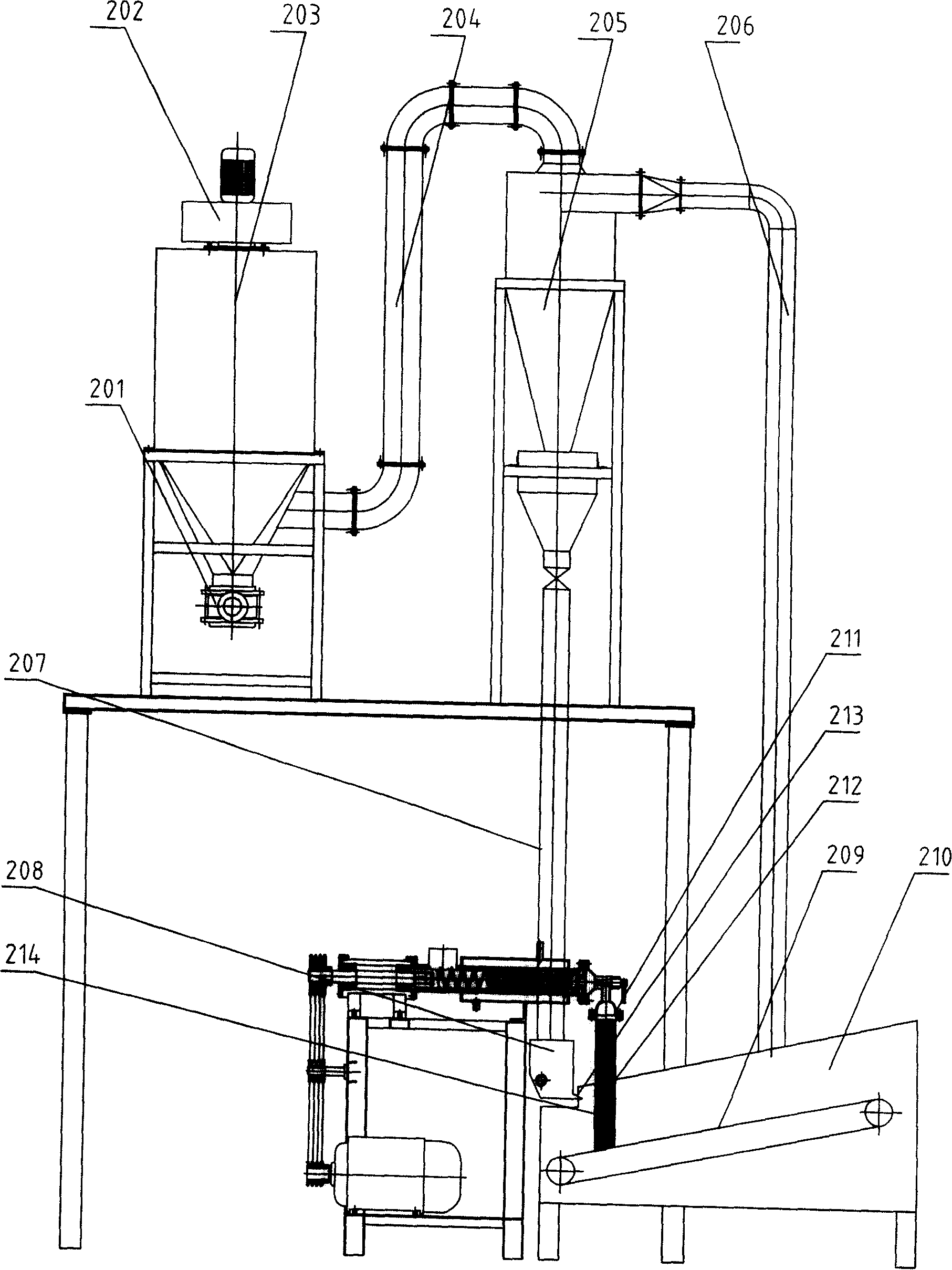

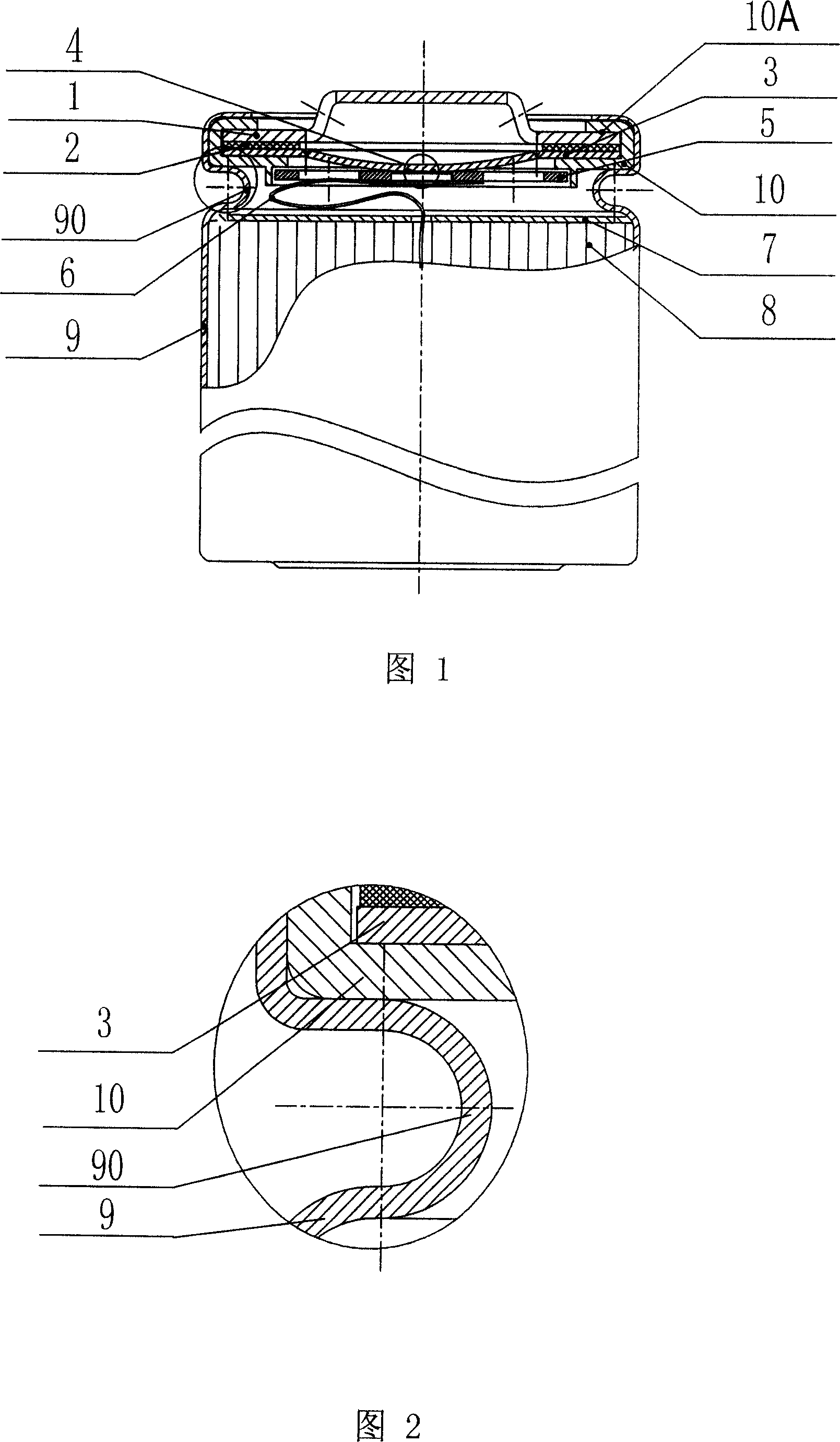

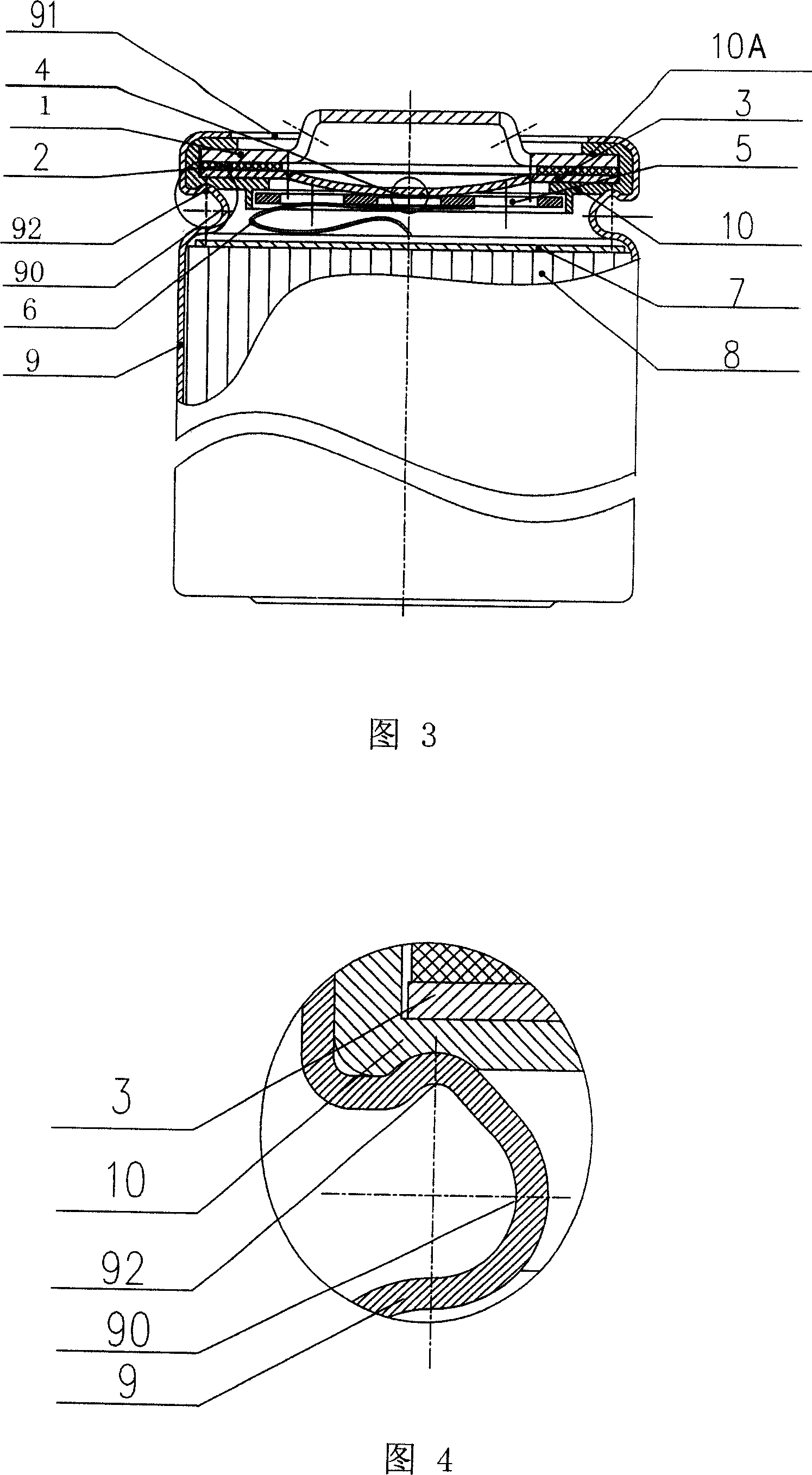

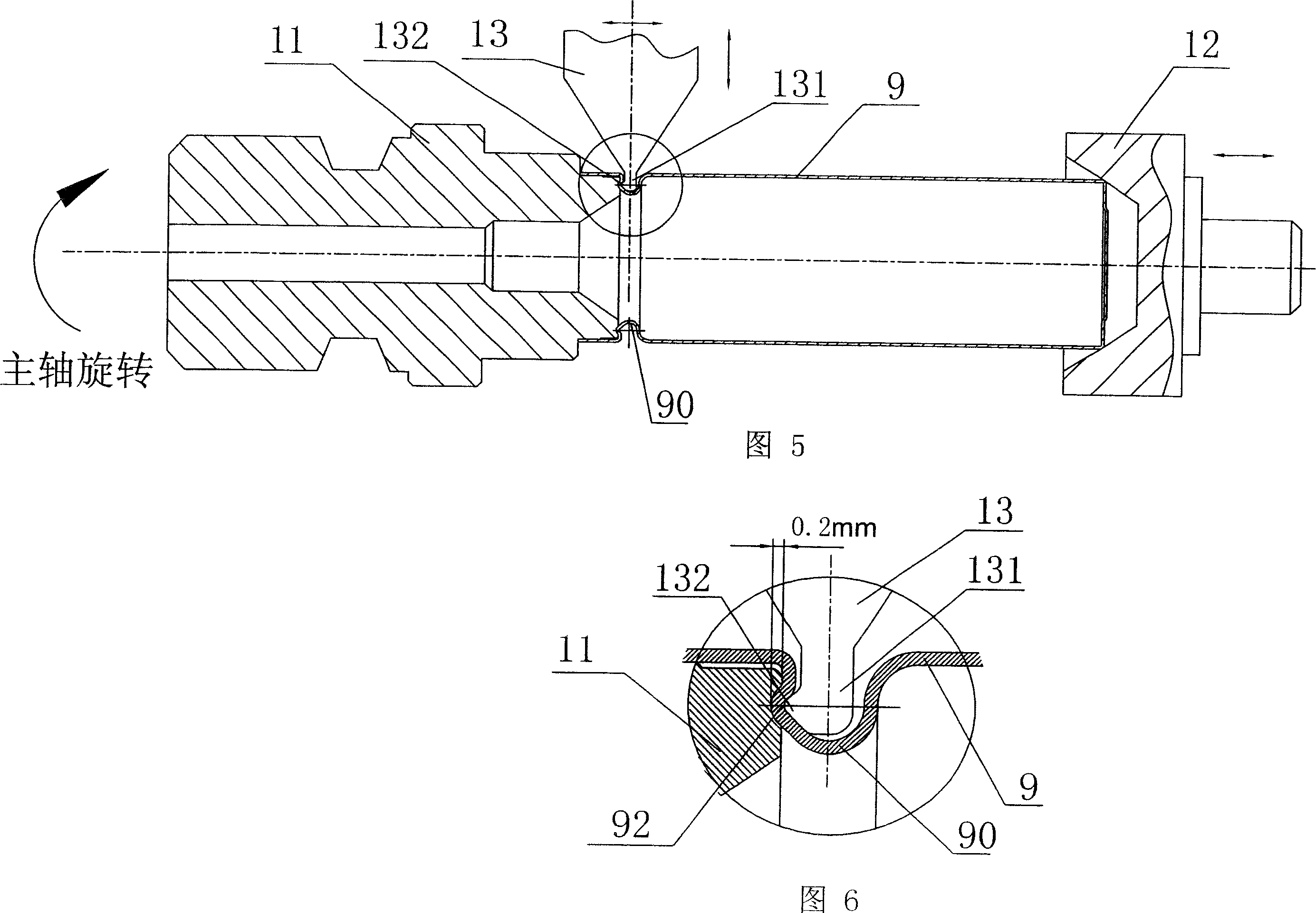

Battery cylindrical shell and cylindrical anti-explosion battery and its processing method and device

InactiveCN1988211APrevent liquid leakageImprove stress conditionFinal product manufactureSmall-sized cells cases/jacketsEngineeringElectrical battery

This invention relates to a cell cylinder shell and a cylinder explosion-proof cell, its processing method and a device, in which, the shell includes a cylindrical side and a bottom molded at one run, a circle of concave cannelure is formed on the shoulder of the side and an upward convex ring on the upper edge of it. Advantage: the molding of the shell is more reasonable, the stress of the shell and airtight packing is improved and sealing of the seal is increased.

Owner:HYB BATTERY

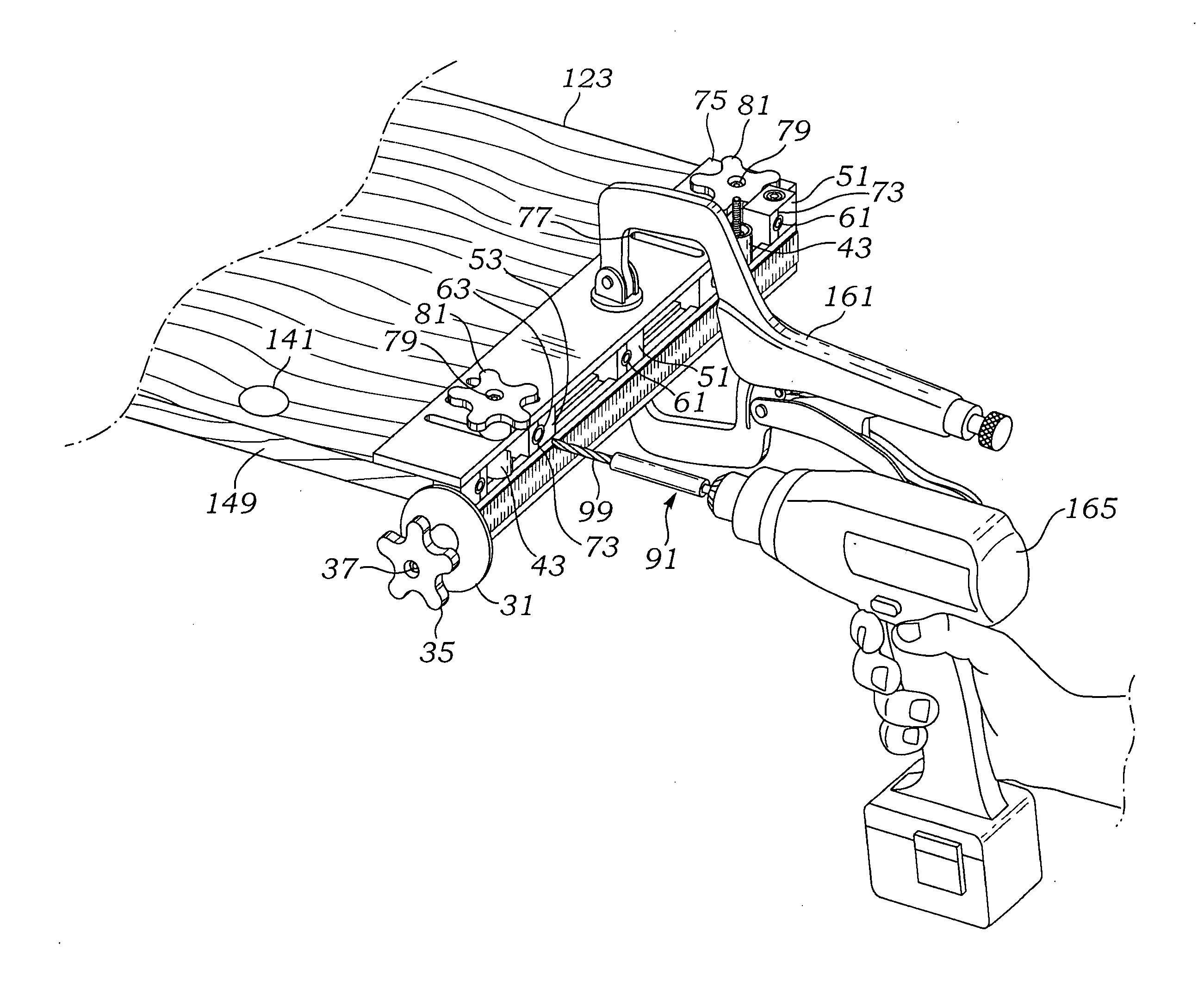

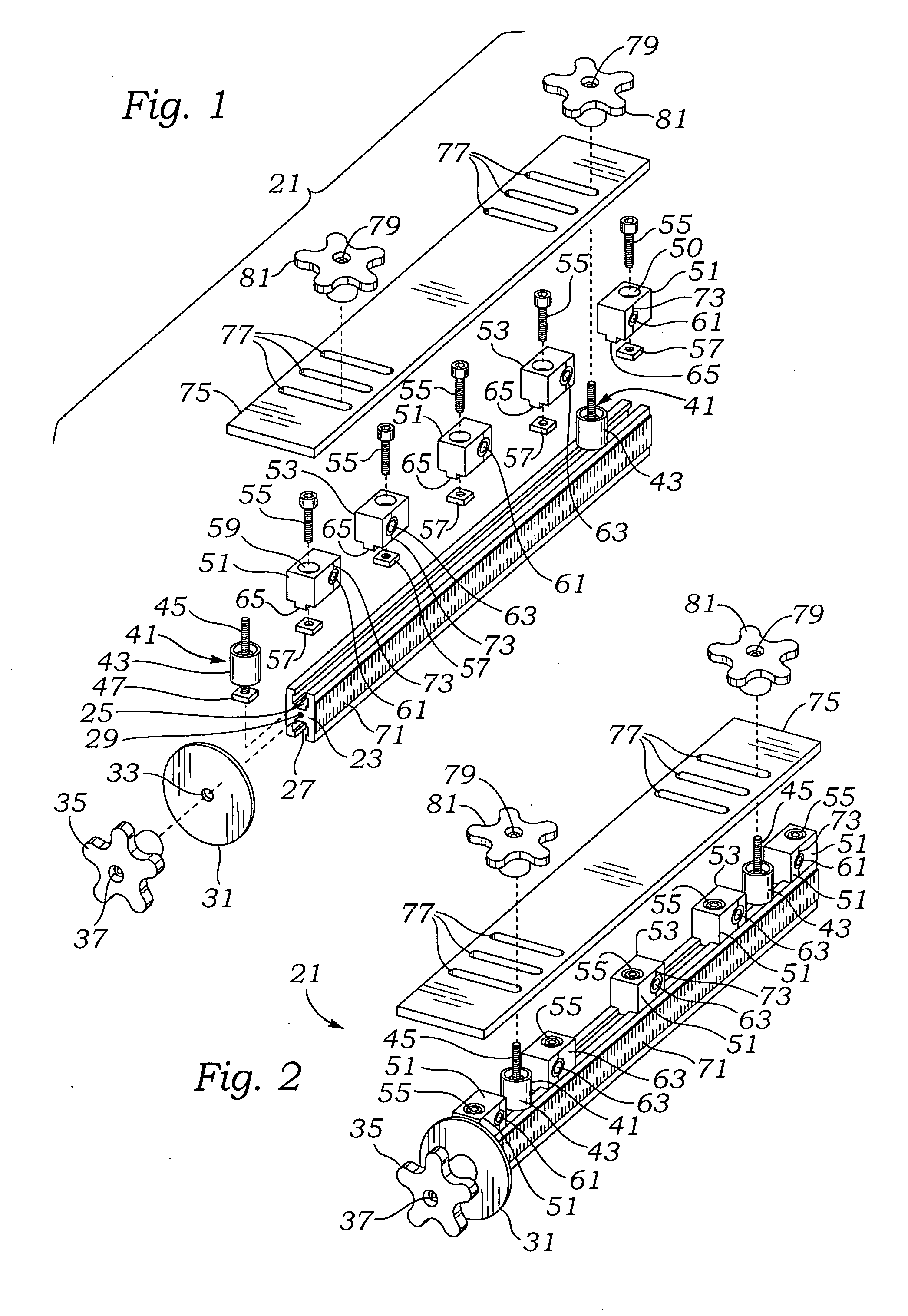

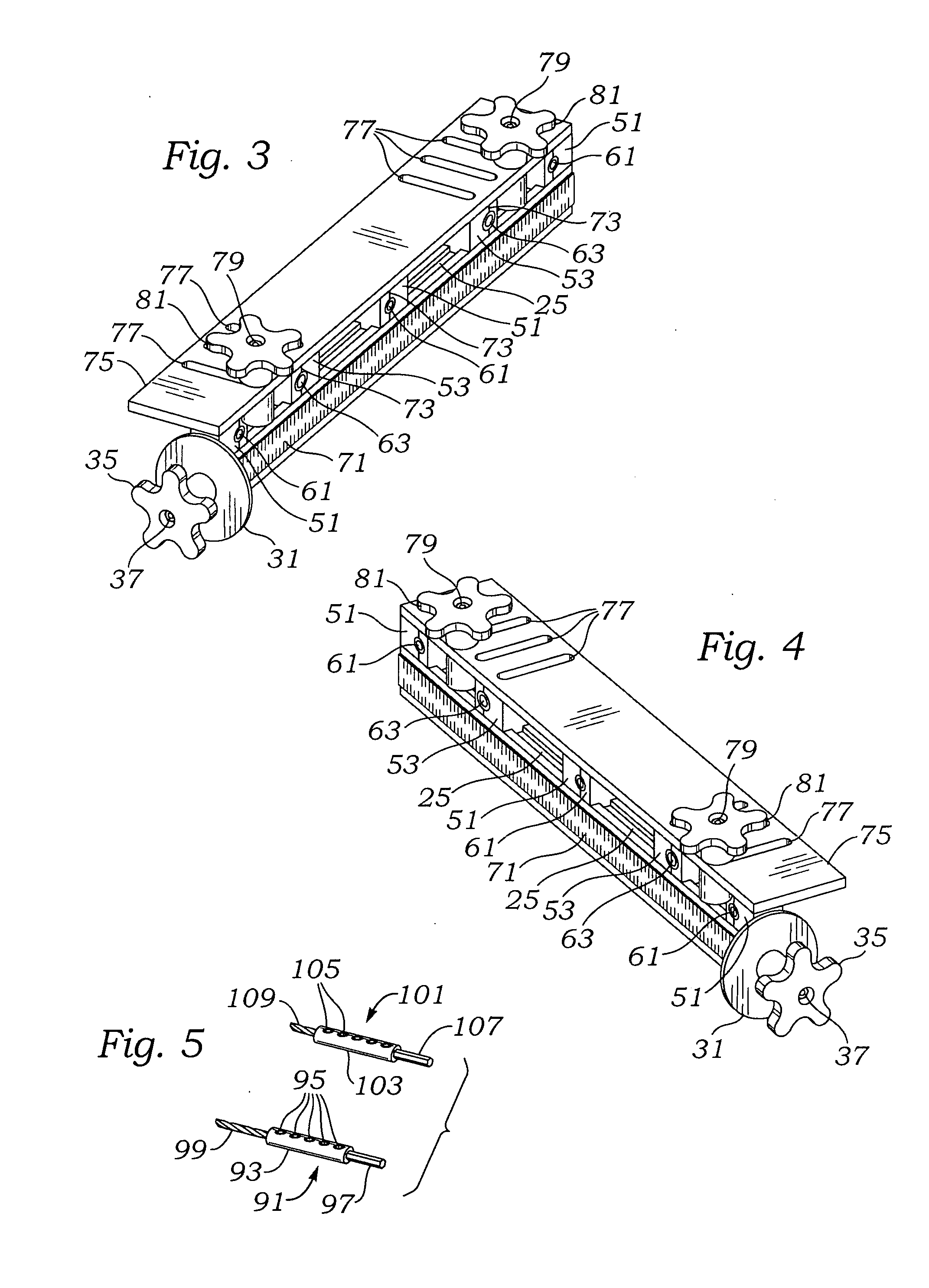

Cabinet assembly bore indexing tool and method

ActiveUS20120051866A1Control depthPrecise alignmentSleeve/socket jointsDrilling/boring measurement devicesEngineeringMechanical engineering

A cabinet assembly bore indexing tool and method provides facilitated bore indexing and guided drilling, while an assembly method helps to make the tool almost foolproof while reducing overall cabinet construction time and raising cabinet quality. The tool uses approximate or nominal material thickness blocks referred to as drill bushing blocks and adjustable axial length spacer sleeves in a floating spacer assembly to locate the drilled bores at the nominal center of the horizontal members and correspondingly in the reciprocal location on the internal surface near the edge of the vertical members so that when assembled they go together in perfect alignment. The cabinet assembly bore indexing tool indexes from an edge or surface to ensure front exterior matching upon assembly of a resulting rectangular annular shaped member as the basic unit upon which cabinet construction is based.

Owner:BLICK JOHN

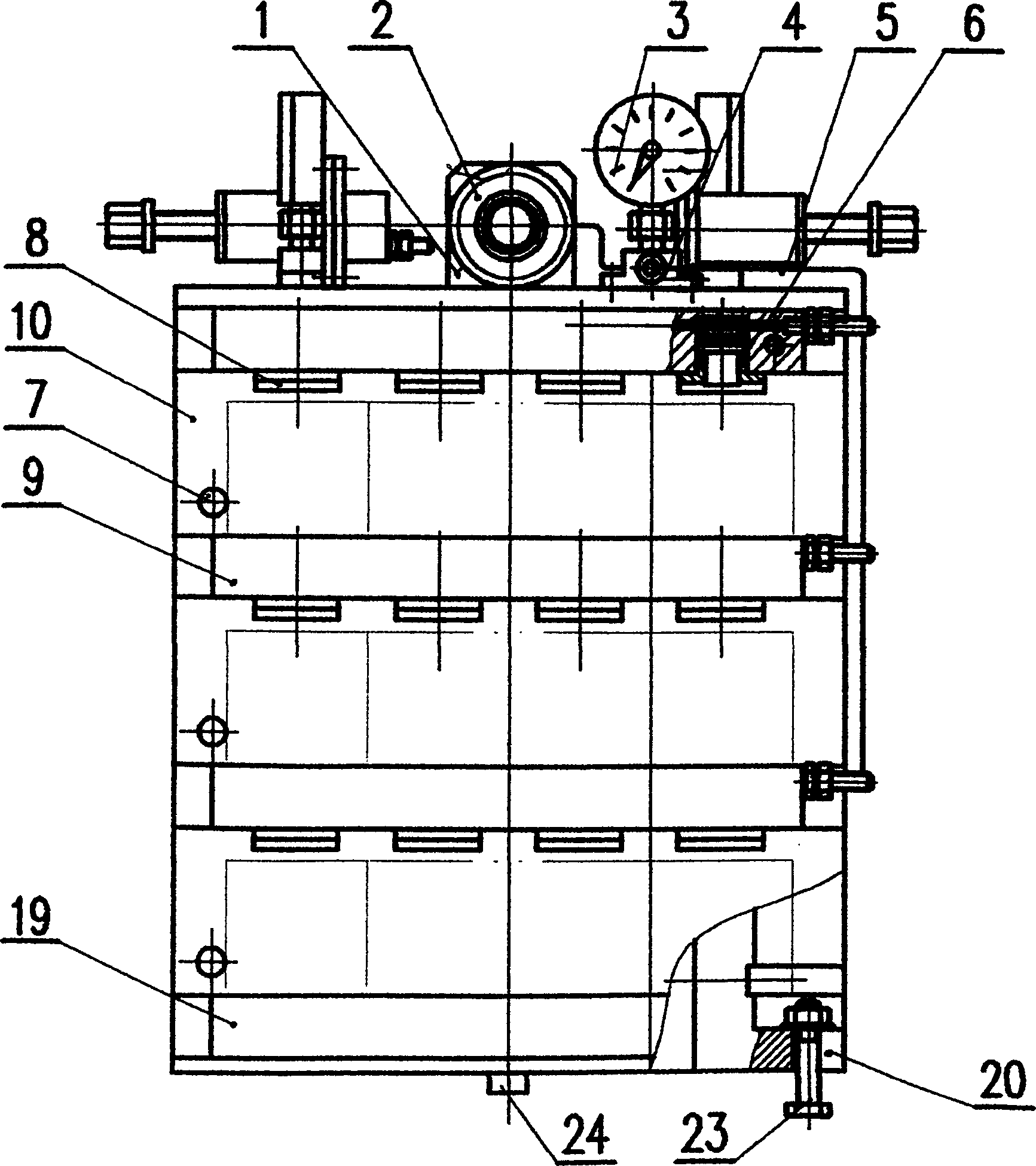

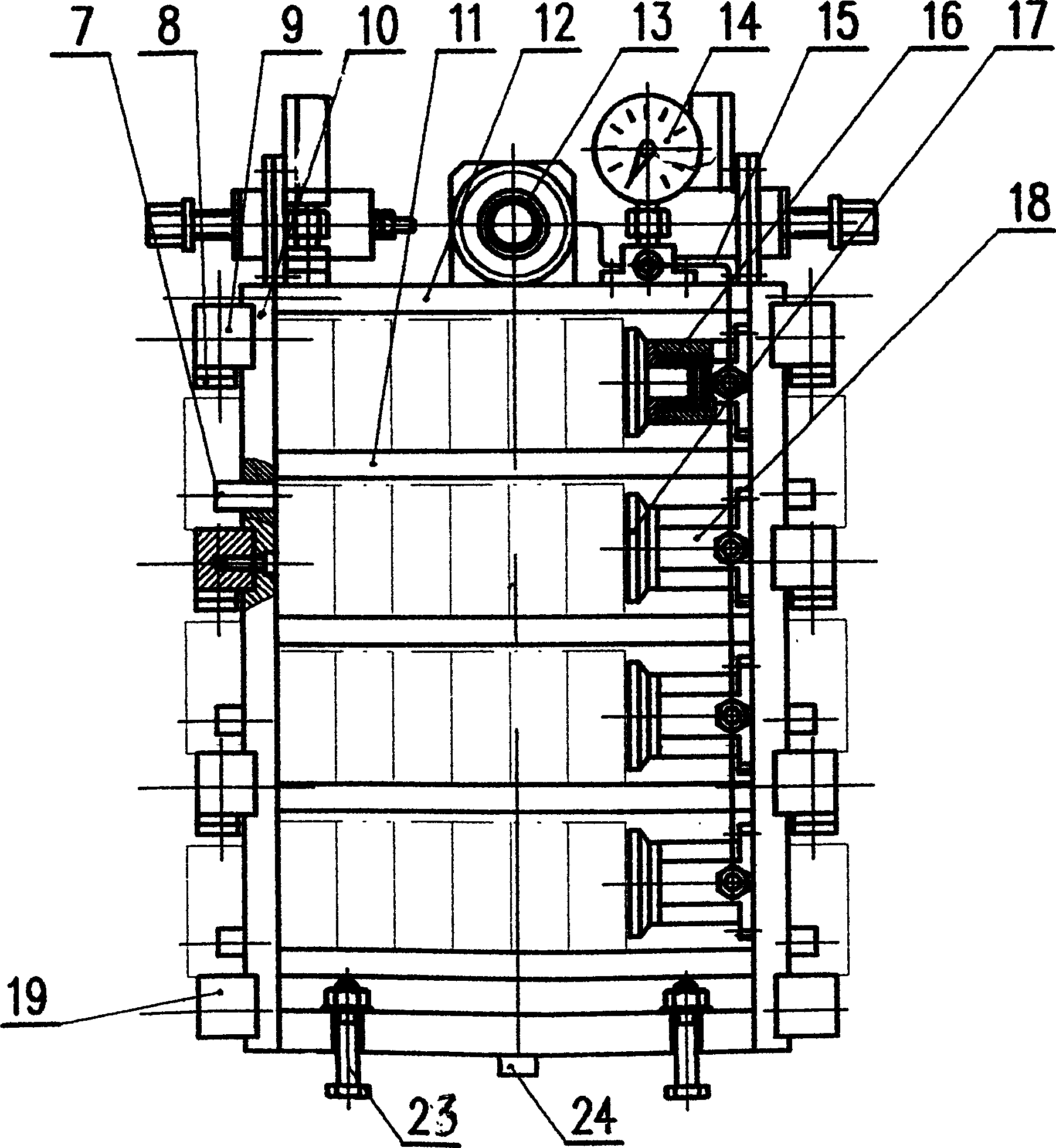

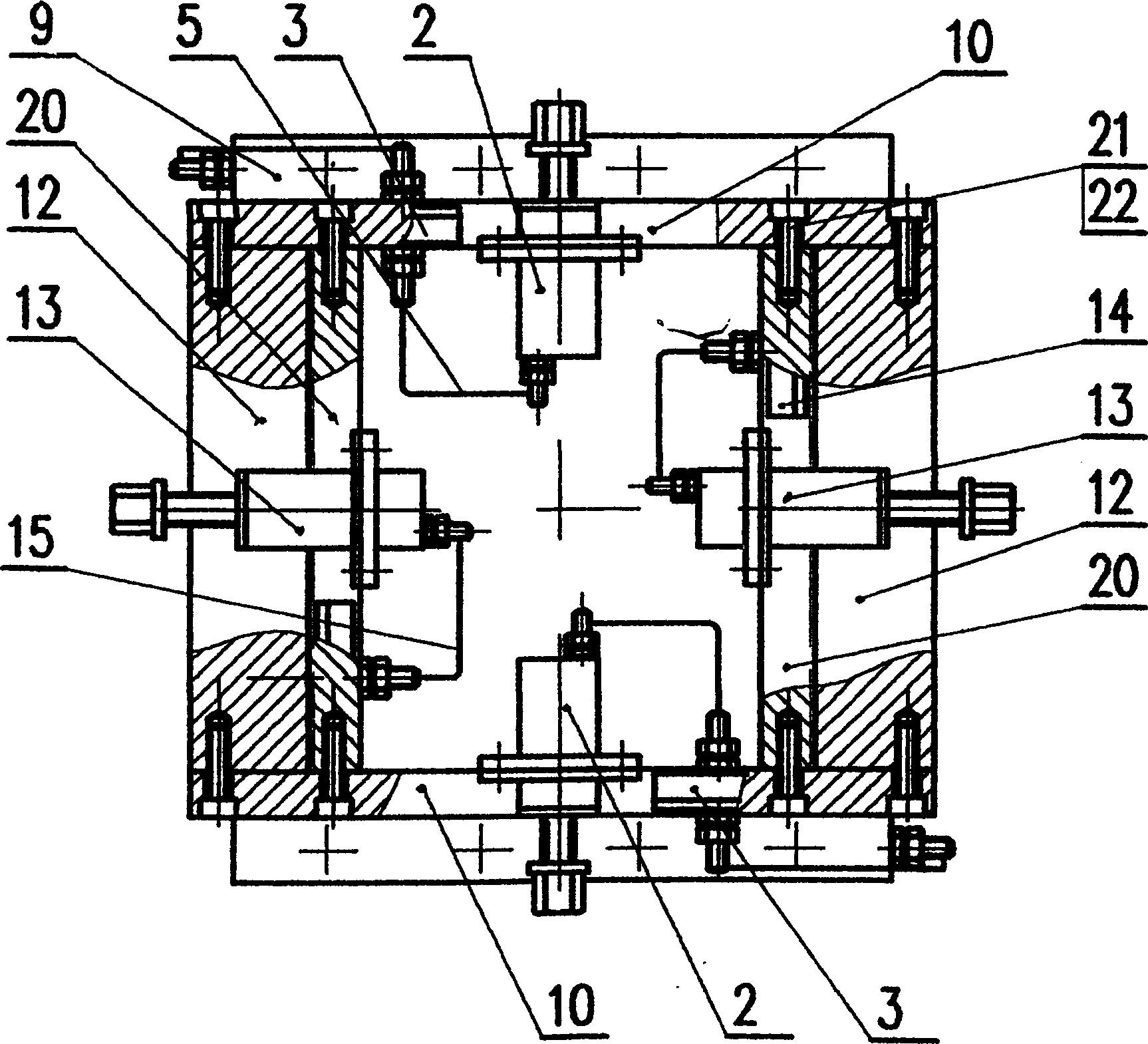

Processing method for hexahedral valve assembling block parts and clamp thereof

InactiveCN1593842AExpand clampingLarge processing areaPositioning apparatusMetal-working holdersEngineeringSwitching time

The invention relates to process for blocking accessory of cubic valves and the clump, which both belongs to the field of processing blocking accessory of cubic valves for hydraulic pressure controlling valve. The sets vertical quadrate clump box that has four faces on two revolving workbench of the chief horizontal processing table. Then set the six faces of the cubic valves to the four faces of the clump box. To finish the horizontal process and hole process of the six faces of the cubic valves through the revolving of quadrate clump box and the atomically tool switching of horizontal processing table. Processing, setting up and using of the invention are simple, so it needs only one step and lesser tool switching time to finish the horizontal process and hole process of the six faces of the cubic valves so that to product with high efficiency and high quality.

Owner:ZHEJIANG CHUNHUI INTELLIGENT CONTROL

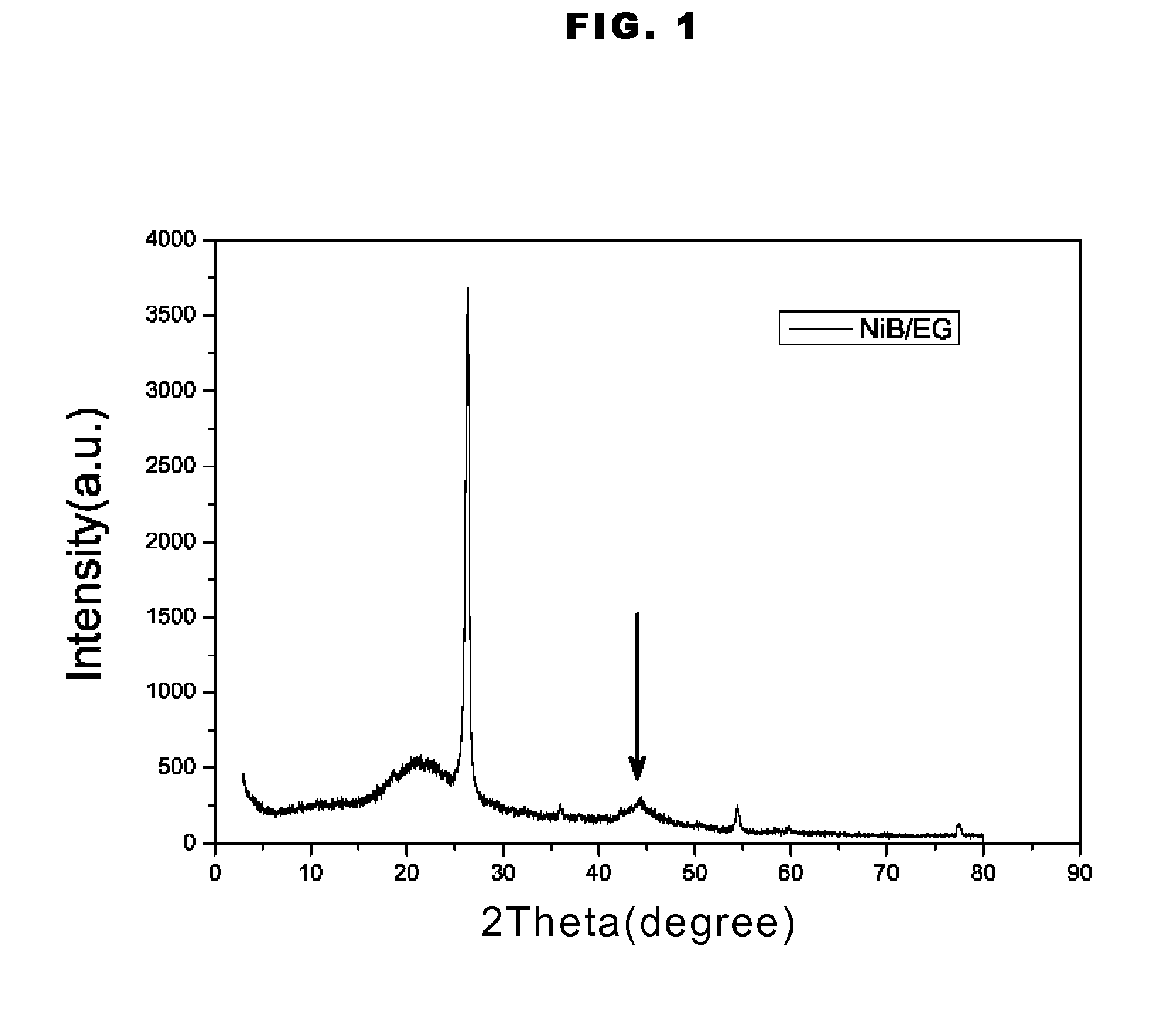

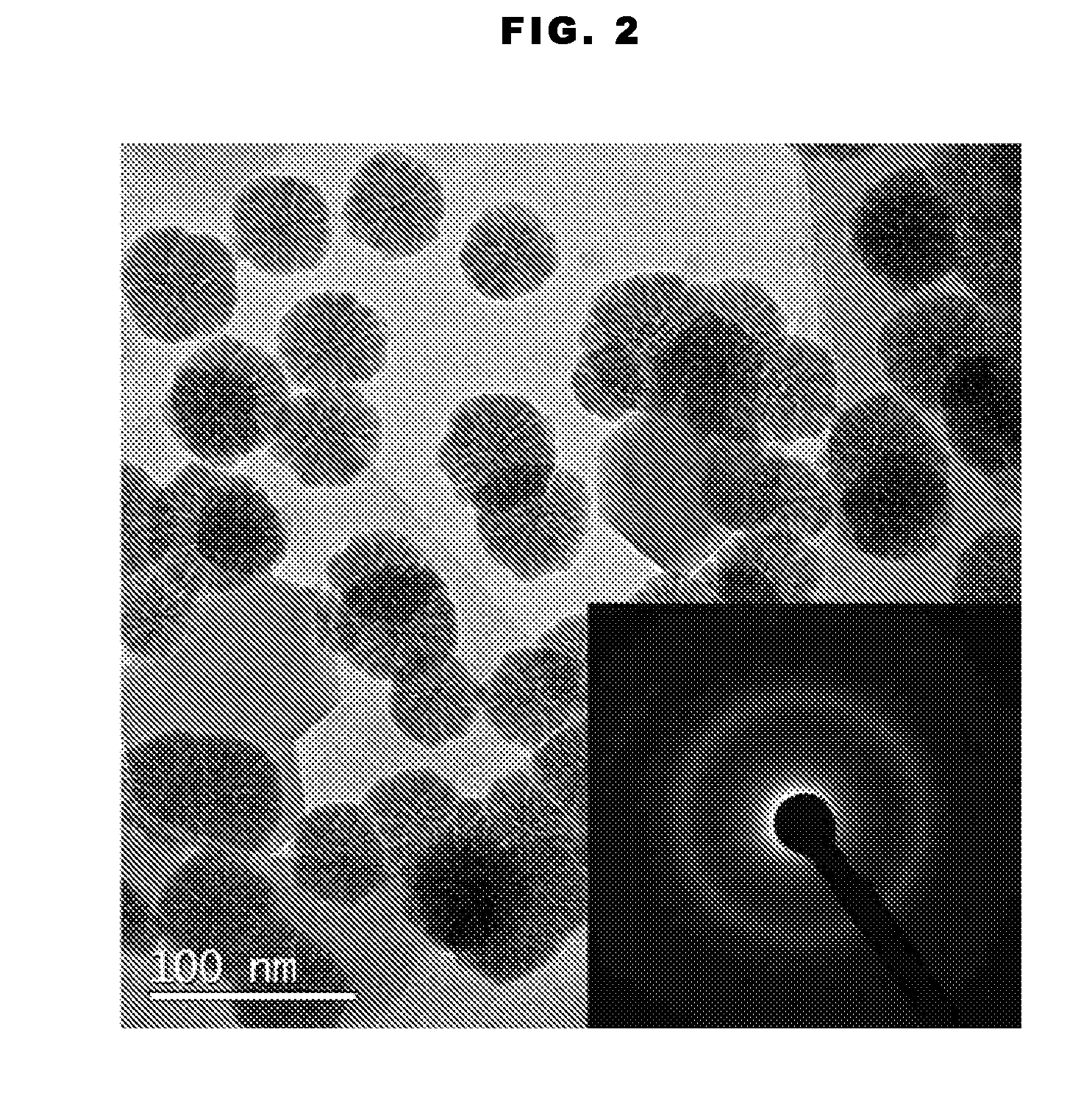

Supported amorphous ni-b alloy catalyst, its preparation and use

InactiveUS20080009640A1High catalytic activityImprove mechanical propertiesOrganic chemistryCatalyst activation/preparationAlloy catalystGraphite

A supported amorphous alloy catalyst, which is supported on a macroporous carrier-expanded graphite. The catalyst contains a Ni—B amorphous alloy (5 to 50% by weight) and a transit inductive metal (0.1 to 10% by weight). The diameter of expanded graphite carrier particles is 80-800 μm. Its BET specific surface area is 10-100 m2 / g. The catalyst is prepared by metal inductive electroless powder plating method which is easy to apply to industrial production. Ni—B clusters of prepared catalyst are well dispersed on the support. The catalyst shows high catalytic activity and good mechanical property, and is safe to use with low manufacturing costs.

Owner:TIANJIN UCAN SCL & TECH DEV +1

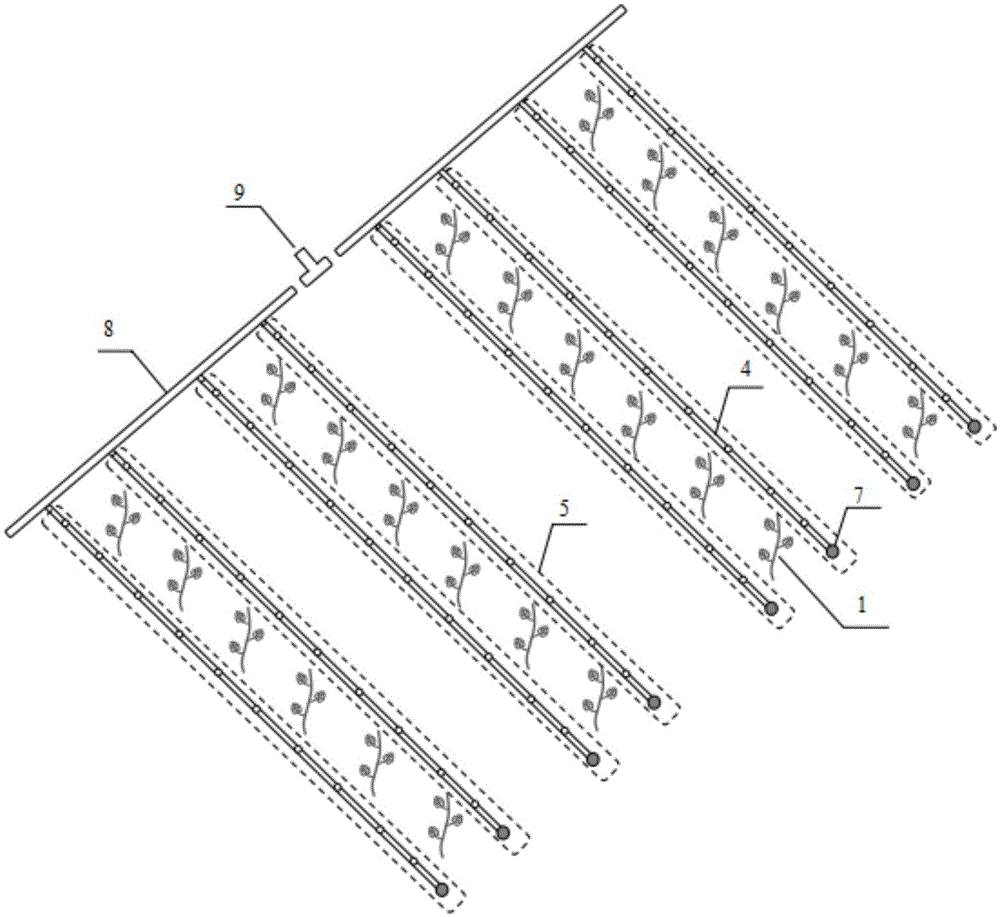

Facility cultivation method for grapes

InactiveCN105123425AAvoid spreadingAvoid breedingClimate change adaptationGreenhouse cultivationDiseaseViticulture

The invention discloses a facility cultivation method for grapes. The purpose is to solve the problems that in an existing cultivation technology for the grapes, the utilization efficiency of water and fertilizer is low, and the ventilation of rhizosphere soil is poor. The facility cultivation method for the grapes includes the steps that 1, a cultivation shed / greenhouse is prepared; 2, in seedling field planting, seedling field planting is suitable for being carried out at the spring, robust seedlings are selected for field planting, the height of the seedlings is larger than or equal to 50 cm, the thickness of the seedlings is larger than or equal to 0.6 cm, the number of plump buds is larger than or equal to four, the row spacing is set to be 0.8 m, and the line spacing is set to be 1.5 m; 3, in construction of an irrigation system, a heat pivot of the irrigation system is installed, and then a drop irrigation system is constructed inside the cultivation shed and connected with the head pivot of the irrigation system; 4, water and fertilizer management is performed; 5, in temperature management, the temperature at daytime inside the cultivation shed / greenhouse is 23-28 DEG C, and the temperature at night inside the cultivation shed / greenhouse is 15-20 DEG C, wherein during frosting, the surface layer of soil can be covered with a layer of straw or straw matting, and the thickness of the straw or the straw matting is 5 cm; 6, shaping and trimming are performed; 7, diseases and insect pests are prevented and treated; 8, corn straw matrixes are supplied.

Owner:JILIN AGRICULTURAL UNIV

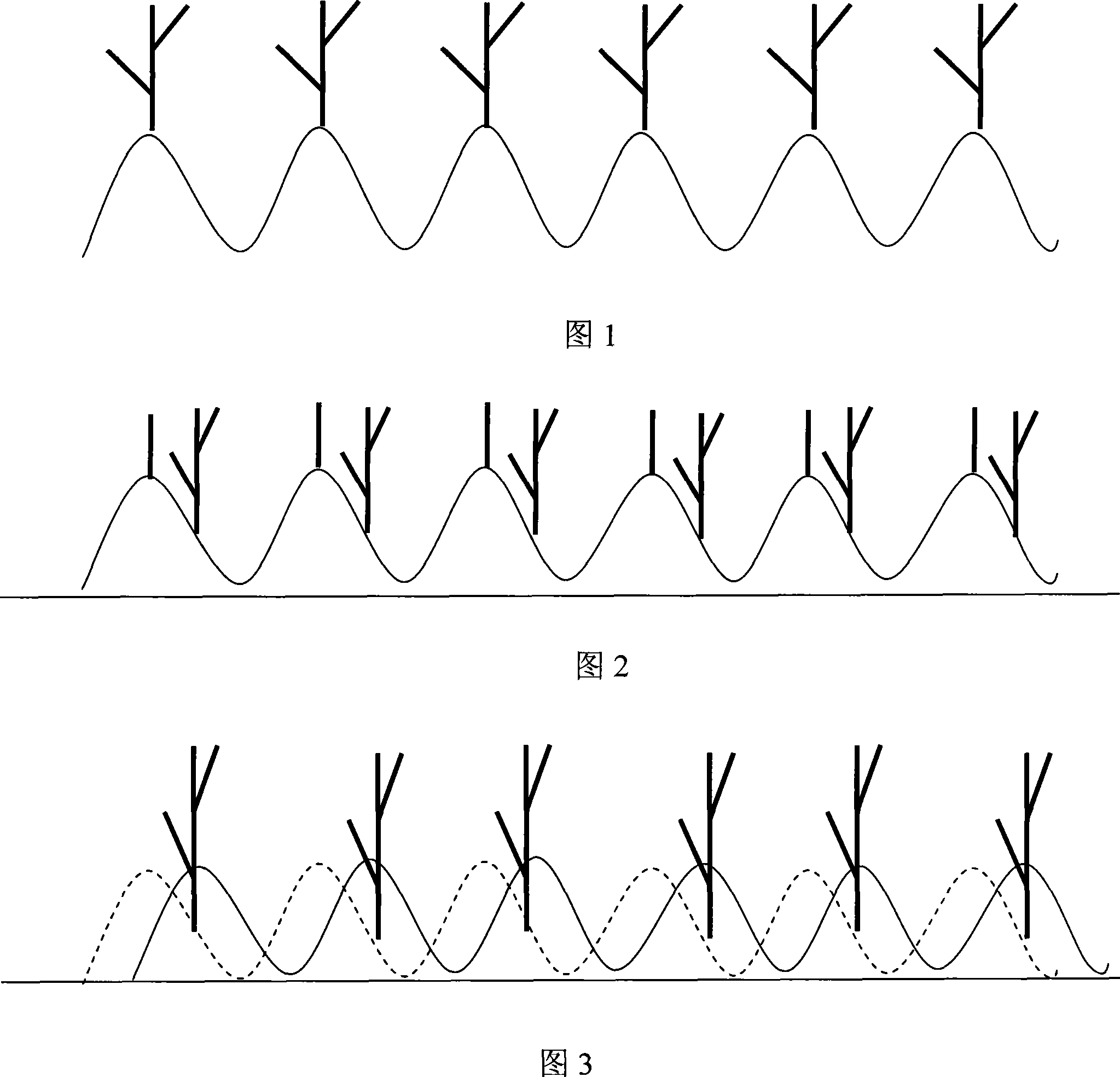

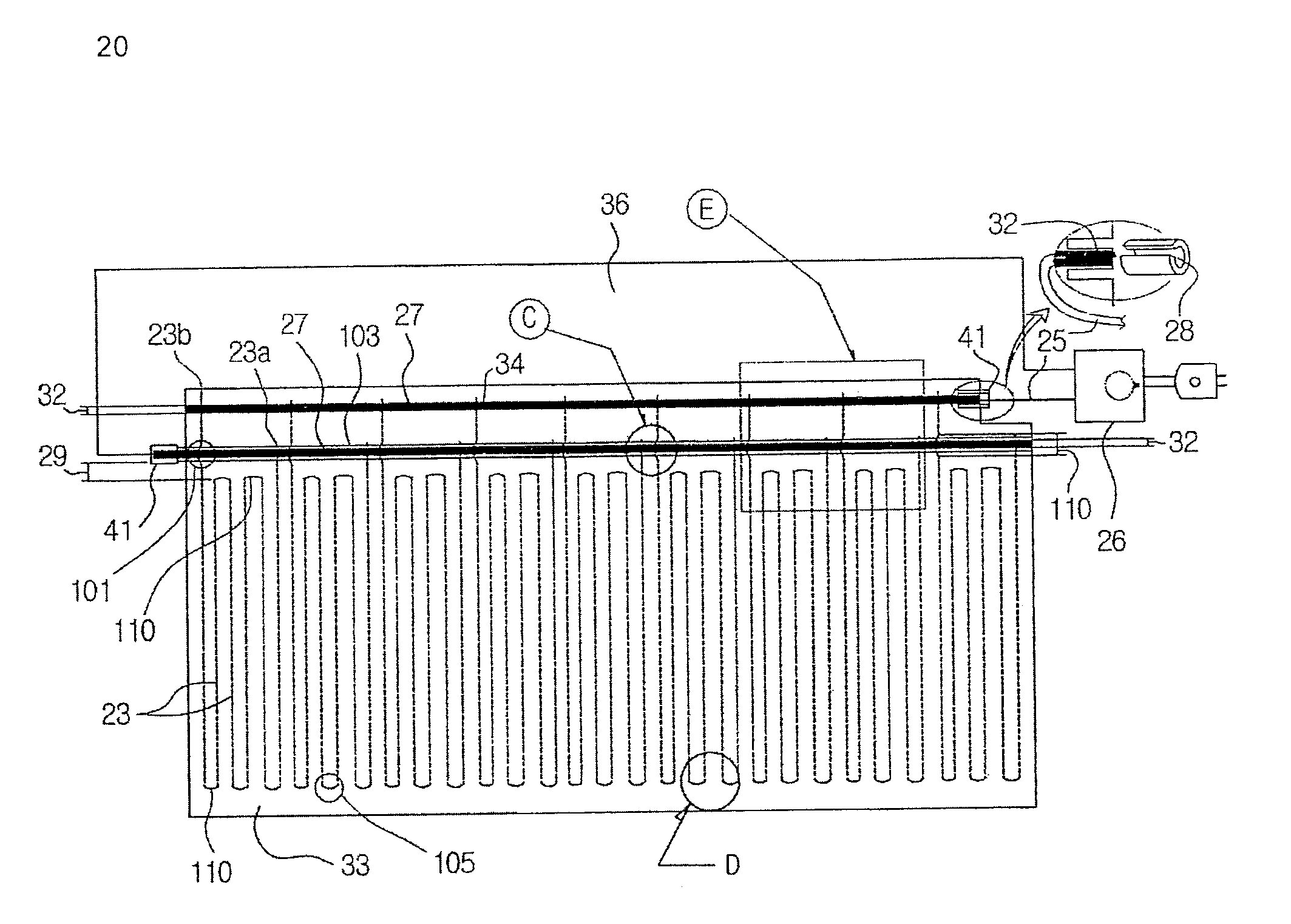

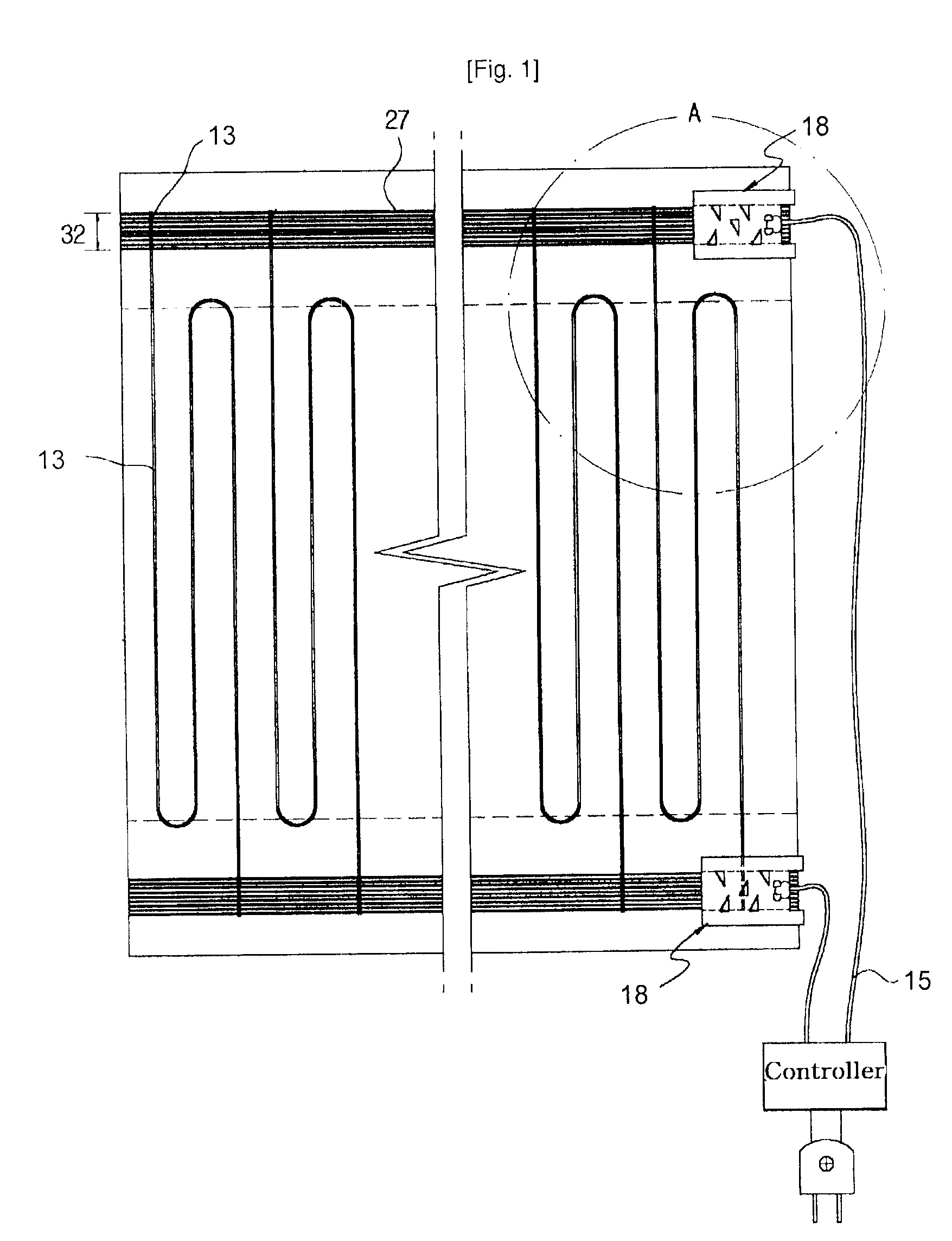

Heating fabric and manufacturing method thereof

InactiveUS7820945B2Firmly connectedImprove product reliabilityCrochetingOrnamental textile articlesFiberCarbon fibers

Disclosed is a heating fabric comprising a heating fabric element made by weaving woof fibers and warp fibers, a pair of conductive parts being a plain fabric made by a weaving method to extend from one side edge of the heating fabric element, for supplying electric power to the heating fabric element, wherein electrode fibers are woven in rows as warp threads in the conductive parts and a heating fiber is intermittently woven as woof threads at predetermined intervals so as to be conductive with the conductive parts, and wherein the heating fiber is woven in a zigzag pattern on the other side of the plain fabric of the conductive parts, in which one end of the heating fiber is woven into the conductive part, and a portion of the other end of the heating fiber is not woven into the conductive part, thereby forming a jumping portion having a length longer than a width of the conductive part, the jumping portion jumping over the conductive part so as not to be conductive with the conductive part. Due to the one-side arrangement of the conductive parts and the zigzag pattern of the carbon fibers, electromagnetic waves are reduced and offset. Accordingly, the heating fabric is advantageous for a user's health.

Owner:PACIFIC MEDICAL

Fully-automatic convenient vermicelli production line and production technology

InactiveCN101167485AQuality productionGreat tasteDough mixing/kneading machinesDough extruding machinesFully automaticSelf curing

An instant bean vermicelli production line comprises a starch stirring device, a self-curing vermicelli extruding device, an ageing effect aging device, a water scrubbing vermicelli loosing device, a quantitative shearing device, a flour agglomerate drying device, a flour agglomerate cooling device and a packing transporting device which are sequentially arranged according to material conveying direction. An antisticking machine is further arranged between the self-curing vermicelli extruding device and a first natural ageing machine, comprising a flour applying chamber, a flour applying device, an air-supply arrangement and a flour retracting device. An instant bean vermicelli manufacturing technique sequentially comprises starch stirring, self-curing vermicelli extruding, ageing effect aging, quantitative shearing, flour agglomerate drying, flour agglomerate cooling and packing transporting. Bean vermicelli antisticking is carried through between the self-curing vermicelli extruding and the ageing effect aging, and the bean vermicelli antisticking process comprises the air-supply arrangement for supplying air to the flour spouting device which spouts flour to the bean vermicelli under the function of wind from the air-supply arrangement. The instant bean vermicelli production line of the invention has the advantages of great antisticking effect and capability of meeting antisticking requirement of bean vermicelli with different proportion.

Owner:BUHLER GUANGZHOU FOOD MACHINERY

Method for promoting early cultivation and improving fertile fruit rate of giant rose grapes

ActiveCN103766188AMeet production needsHigh fruit rateCultivating equipmentsHorticulture methodsGreenhouseShoot

The invention discloses a method for promoting early cultivation and improving the fertile fruit rate of giant rose grapes. The method comprises the following steps: (1) during the period from sprouting to blossoming of the giant rose grapes, nitrogenous fertilizer is not applied and the soil humidity is 75-83%; (2) in the 7-10 days before first blossoming, pinching of main shoots is carried out, sub-shoots are processed and then inflorescence is managed; (3) in the 3-5 days before first blossoming, new shoots of vain growth are wrenched to enable the vertical new shoots of vain growth to maintain the horizontal state and the parallel new shoots of vain growth to grow downwards in an inclined mode, and the giant rose grapes are cultivated in the environment of greenhouse heat preservation. In the step (3), the new shoots of vain growth are more than 60cm in length, and wrenching of the shoots is carried out on the positions 2-3 joints below the inflorescence. According to method for promoting early cultivation and improving the fertile fruit rate of the giant rose grapes, the fertile fruit rate can be 30-40%, the production requirement can be met, and the rose grapes are full and sweet and can reach the standard of first-class products.

Owner:上海马陆葡萄公园有限公司

Convenient vermicelli production line and its producing technology

InactiveCN101167598AIncrease production capacitySimple processFood shapingFood preparationProduction lineEngineering

The invention relates to an instant vermicelli production line, and comprises a starch agitating device, a self-curing scroop device, a time-effect aging device, a quantitative cutting device, a powder agglomate drying device, a powder agglomate cooling device, and a package-conveying device which are all sequentially arranged along the direction of transmitting materials. A reshaping dehumidifier is further arranged between a quantitative cutting machine and a drying machine, and comprises a reshaping dehydration device which comprises one row or more than one rows of air ducts, the number of the air ducts at each row is corresponding to the number of powder boxes at each row of a drying box, blowing ports of the air ducts are correspondingly dead against the powder boxes along the vertical direction, the dehumidification method of the producing process comprises the powder box or a face box on a band carrier to be conveyed to the position just below the air duct, the air duct is arranged just above the corresponding powder box or the face box for blowing, water films and powder agglomates between the powder box and an eyelet of the face box or the water films on the face blocks are blown, the water on the surface of the powder agglomates or the face blocks is discharged from the eyelet of the power box or face box. The invention can save plenty of energy sources and time.

Owner:BUHLER GUANGZHOU FOOD MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com