Freshwater chlorella and application thereof in fixation of CO2 and production of microalgae oil

A technology of microalgae oil and chlorella, which is applied in microorganism-based methods, microorganisms, biofuels, etc., can solve the problem of high production cost of microalgae oil, and achieve the effects of good application potential, high yield and short growth cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

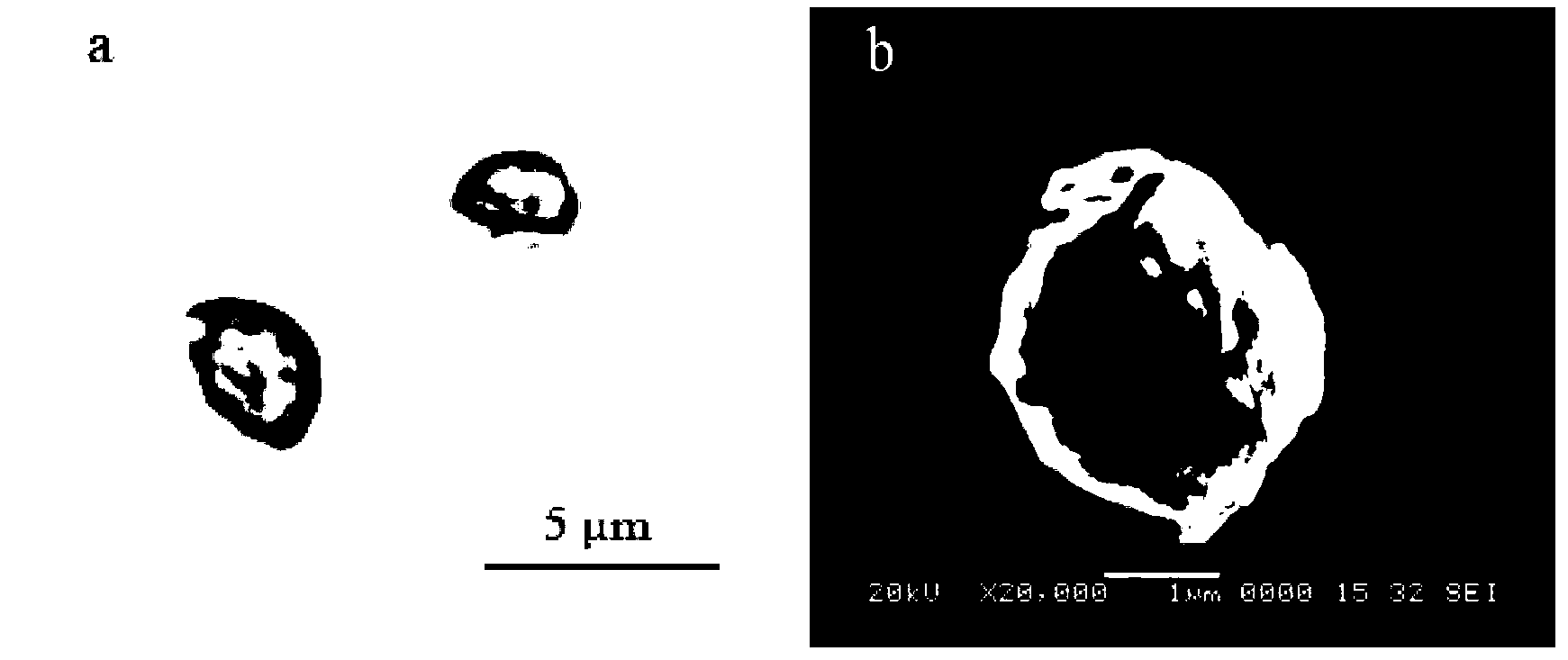

Image

Examples

Embodiment 1

[0031] Pick a single algae on a solid plate under sterile conditions and drop it into a small test tube containing 10ml of BG-11 sterilized culture solution, and culture it in a light incubator at 28°C and 3500lux light intensity, and grow to the end of the index. The inoculation ratio of 1:10 is used to expand the culture. The specific operation is: transfer the 10ml microalgae culture solution to the Erlenmeyer flask containing 100ml BG-11 sterilized culture solution, and place it in a light incubator at 28°C and 3500lux light intensity. When it grows to the end of the index, it will be the microalgae cell fluid that has been expanded and cultured.

[0032] Prepare 1 L of BG-11 medium in an airlift photosynthetic bioreactor, insert the expanded cultured microalgae cell liquid, so that the cell density in the medium is 6×10 7 pieces / ml. The initial pH is 8.0, the temperature is 28°C, and the light intensity is 3500lux, the air of 0.23vvm (CO 2 The content is 0.03% (CO2 volu...

Embodiment 2

[0035] According to the method of Example 1, the microalgae cell fluid was expanded and cultivated.

[0036] Prepare 1 L of BG-11 medium in an airlift photosynthetic bioreactor, insert the expanded cultured microalgae cell liquid, so that the cell density in the medium is 6×10 7 pieces / ml. The initial pH is 8.0, the temperature is 28°C, and the light intensity is 3500lux, the air of 0.23vvm (CO 2 Content is 5%), cultivated for 12 days.

[0037] The algal cells were collected by centrifugation, dried at a constant temperature of 60-80°C, and the dry weight of the algal powder was weighed and calculated. The biomass concentration of algae powder is 2250mg / L, the biomass production rate is 187mg / L / d, CO 2 The fixation efficiency is 343mg / L / d, and the oil content determined by the chloroform-methanol method is 30%. The fatty acid composition of oil is mainly short-chain fatty acids of C16 and C18.

Embodiment 3

[0039] According to the method of Example 1, the microalgae cell fluid was expanded and cultivated.

[0040] Prepare 1 L of BG-11 medium in an airlift photosynthetic bioreactor, insert the expanded cultured microalgae cell liquid, so that the cell density in the medium is 6×10 7 pieces / ml. The initial pH is 8.0, the temperature is 28°C, and the light intensity is 3500lux, the air of 0.23vvm (CO 2 Content is 20%), cultivated for 12 days.

[0041] The algal cells were collected by centrifugation, dried at a constant temperature of 60-80°C, and the dry weight of the algal powder was weighed and calculated. The biomass concentration of algae powder is 1520mg / L, the biomass production rate is 127mg / L / d, CO 2 The fixing efficiency is 240mg / L / d, and the oil content is 41% as determined by the chloroform-methanol method. The fatty acid composition of oil is mainly short-chain fatty acids of C16 and C18.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com