BCT-BZT-BST (Barium calcium titanate-barium zirconate titanate-barium stannate titanate) ternary system lead-free piezoelectric ceramic

A barium zirconate titanate and lead-free piezoelectric technology, applied in the field of lead-free piezoelectric materials, can solve the problems of poor piezoelectric performance of lead-free piezoelectric ceramics, and achieve high-voltage constant, good application prospects, and great application potential Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

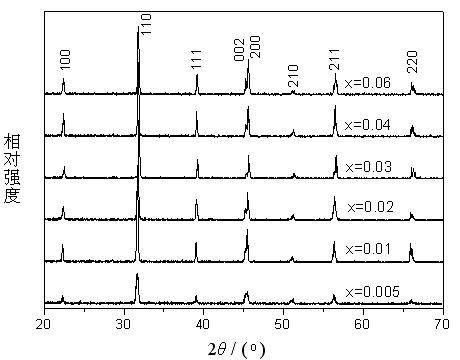

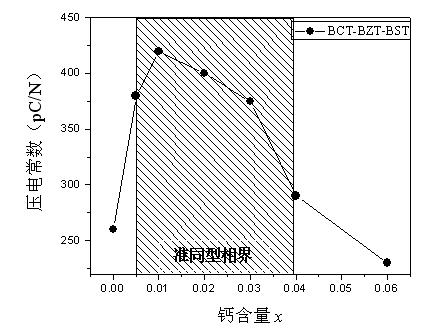

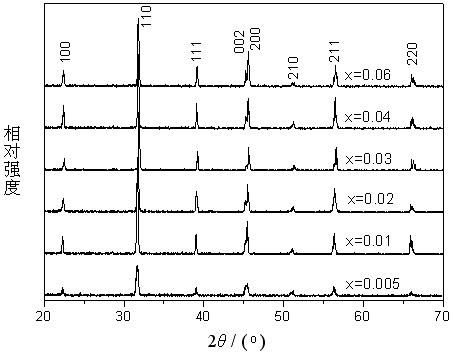

[0019] The formula of this embodiment is Ba 0.8-x Ca x Ti 0.8 o 3 -0.1BaTi 0.9 sn0.1 o 3 -0.1BaTi 0.8 Zr 0.2 o 3 ,in x =0.005.

[0020] Weigh raw materials according to the stoichiometric ratio of the formula: BaCO 3 , CaCO 3 , SnO 2 , ZrO 2 、TiO 2 , the so-called raw material powder was ball milled with absolute ethanol as the medium for 10 hours, and the slurry obtained by ball milling was kept at 80°C for 10 hours. After drying the powder, it was pre-calcined at 1200°C for 6 hours to obtain Ba 0.795 Ca 0.005 Ti 0.8 o 3 -0.1BaTi 0.9 sn 0.1 o 3 -0.1BaTi 0.8 Zr 0.2 o 3 Powder; add 5 wt% PVB to granulate, and press it into a disc with a diameter of 10mm and a thickness of 1mm under a pressure of 100MPa; after the ceramics are fully debonded, they are sintered at 1350°C in air for 6h to prepare BCT-BZT- BST ternary ceramics.

[0021] The obtained BCT-BZT-BST ternary system lead-free piezoelectric ceramics are finely ground, ultrasonically cleaned and then...

Embodiment 2

[0024] The formula of this embodiment is Ba 0.8-x Ca x Ti 0.8 o 3 -0.1BaTi 0.9 sn 0.1 o 3 -0.1BaTi 0.8 Zr 0.2 o 3 ,in x =0.01.

[0025] Weigh raw materials according to the stoichiometric ratio of the formula: BaCO 3 , CaCO 3 , SnO 2 , ZrO 2 、TiO 2 , the so-called raw material powder was ball milled with absolute ethanol as the medium for 12 hours, and the slurry obtained by ball milling was kept at 80°C for 12 hours. After drying the powder, it was pre-calcined at 1250°C for 5 hours to obtain Ba 0.79 Ca 0.01 Ti 0.8 o 3 -0.1BaTi 0.9 sn 0.1 o 3 -0.1BaTi 0.8 Zr 0.2 o 3 Powder; add 6wt% PVB to granulate, and press it into a disc with a diameter of 10mm and a thickness of 1mm under a pressure of 200MPa; after the ceramic is fully debonded, it is sintered at 1400°C in air for 5h to prepare BCT-BZT-BST Ternary ceramics.

[0026] The obtained BCT-BZT-BST ternary system lead-free piezoelectric ceramics are finely ground, ultrasonically cleaned and then polariz...

Embodiment 3

[0029] The formula of this embodiment is Ba 0.8-x Ca x Ti 0.8 o 3 -0.1BaTi 0.9 sn 0.1 o 3 -0.1BaTi 0.8 Zr 0.2 o 3 ,in x =0.02.

[0030] Weigh raw materials according to the stoichiometric ratio of the formula: BaCO 3 , CaCO 3 , SnO 2 , ZrO 2 、TiO 2 , the so-called raw material powder was ball milled with absolute ethanol as the medium for 14 hours, and the slurry obtained by ball milling was kept at 80°C for 12 hours. After drying the powder, it was pre-calcined at 1300°C for 4 hours to obtain Ba 0.78 Ca 0.02 Ti 0.8 o 3 -0.1BaTi 0.9 sn 0.1 o 3 -0.1BaTi 0.8 Zr 0.2 o 3 Powder; add 6 wt% PVB to granulate, and press to form under a pressure of 150MPa; after the ceramics are fully debonded, they are sintered at 1450°C in air for 6 hours to prepare BCT-BZT-BST ternary ceramics.

[0031] The obtained BCT-BZT-BST ternary system lead-free piezoelectric ceramics are finely ground, ultrasonically cleaned and then polarized by a silver electrode at room temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| piezoelectric charge coefficient | aaaaa | aaaaa |

| piezoelectric charge coefficient | aaaaa | aaaaa |

| piezoelectric charge coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com