Mesoporous silica with yolk-shell structure and preparation method thereof

A technology of mesoporous silica and eggshell, which is applied in the field of mesoporous silica with egg yolk-eggshell structure and its preparation, can solve the problems of increased preparation cost, environmental pollution, high temperature heating, etc., and achieve low cost and environmental protection. Friendly, low-equipment-requiring effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Mix 1ml of concentrated ammonia water (the mass percent concentration of NH3 contained in the concentrated ammonia water is 25%) with 30ml of ethanol and 75ml of water, and then dissolve 0.16g of dodecyltrimethylammonium bromide in the mixed solution , 0.25ml tetraethyl orthosilicate and 0.25ml 1,2-bis(triethoxysilyl)ethane were added to the aqueous alcohol solution at 30°C and stirred at 500rpm, and reacted for 12h to obtain white di Silica precipitation;

[0032] (2) Centrifuge the silicon dioxide obtained in step (1), wash it with water, transfer it to water to prepare a silicon dioxide dispersion (2 mg / ml), and place it at 70°C for 20 hours;

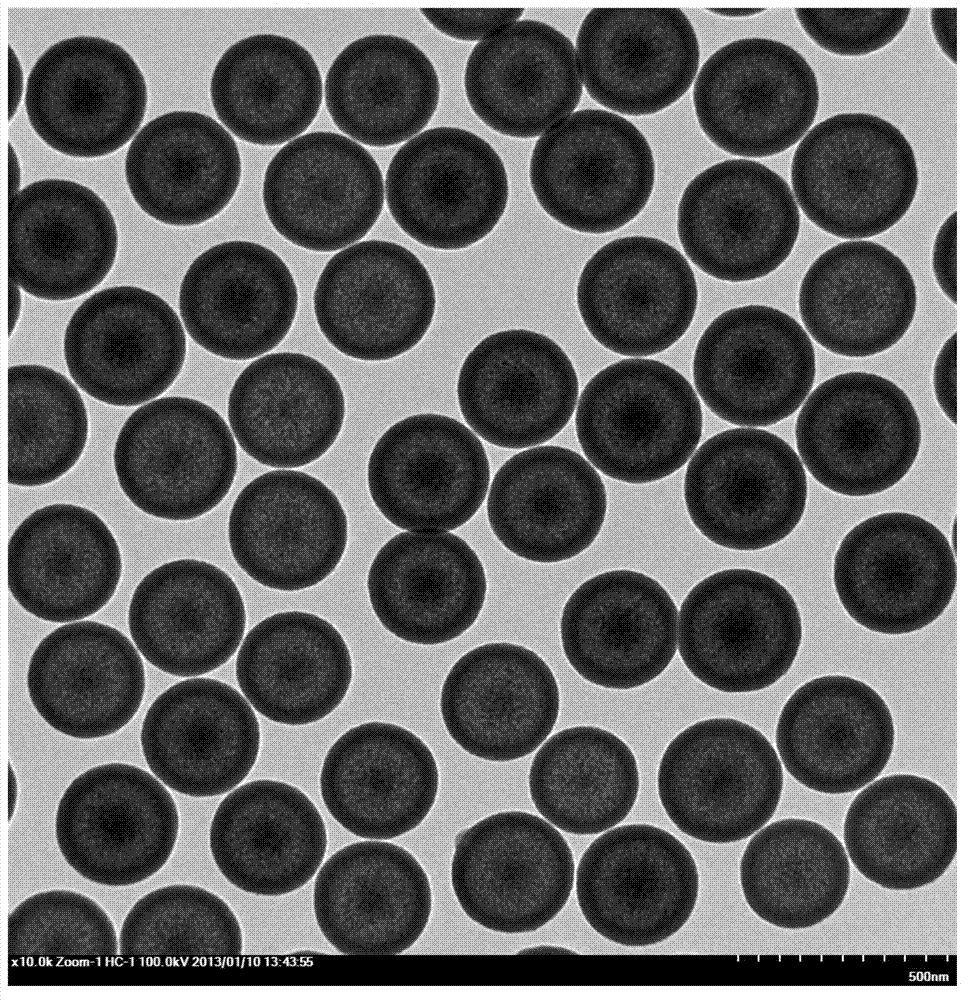

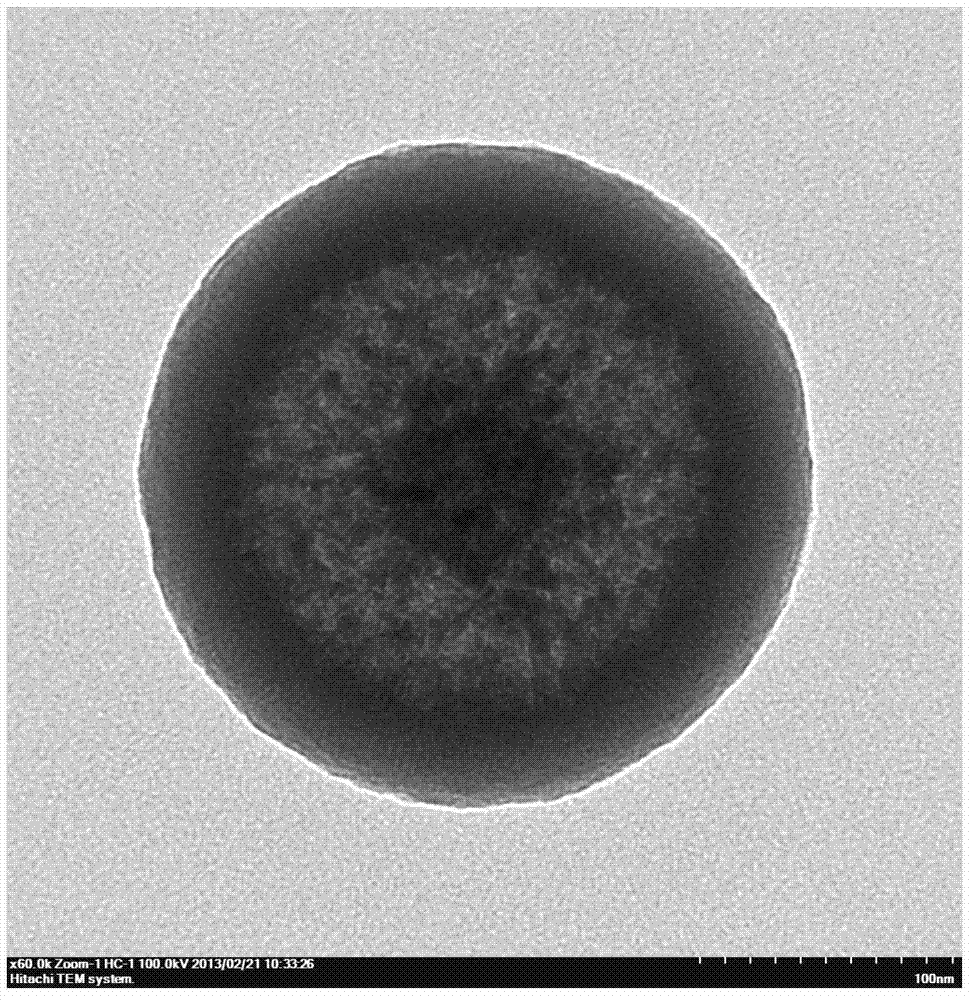

[0033] (3) The reaction product obtained in step (2) was centrifuged, washed with water, transferred to a mixed solution of 50 μl concentrated hydrochloric acid and 100ml ethanol, heated at 40°C for 1 hour to remove the surfactant, and finally obtained the egg yolk-eggshell structure medium Porous silica, such as figure 1 ...

Embodiment 2

[0036] (1) Mix 1ml of concentrated ammonia water (the NH contained in the concentrated ammonia water 3 The mass percentage concentration is 28%) mixed with 30ml ethanol and 75ml water, then 0.16g tetradecyltrimethylammonium bromide was dissolved in the mixed solution, and 0.5ml orthosilicon Acetate tetraethyl ester and 0.5ml 1,2-bis(triethoxysilyl)ethane were added to the mixed solution, reacted for 24h, and white silica precipitate was obtained;

[0037] (2) Centrifuge and wash the silica obtained in step (1), transfer it to water to prepare a silica dispersion (0.1 mg / ml), and place it at 50°C for 12 hours;

[0038] (3) The reaction product obtained in step (2) was centrifuged, washed with water, transferred to a mixed solution of 100 μl concentrated hydrochloric acid and 200ml ethanol, heated at 50°C for 10 hours to remove the surfactant, and finally obtained the egg yolk-eggshell structure medium Porous silica.

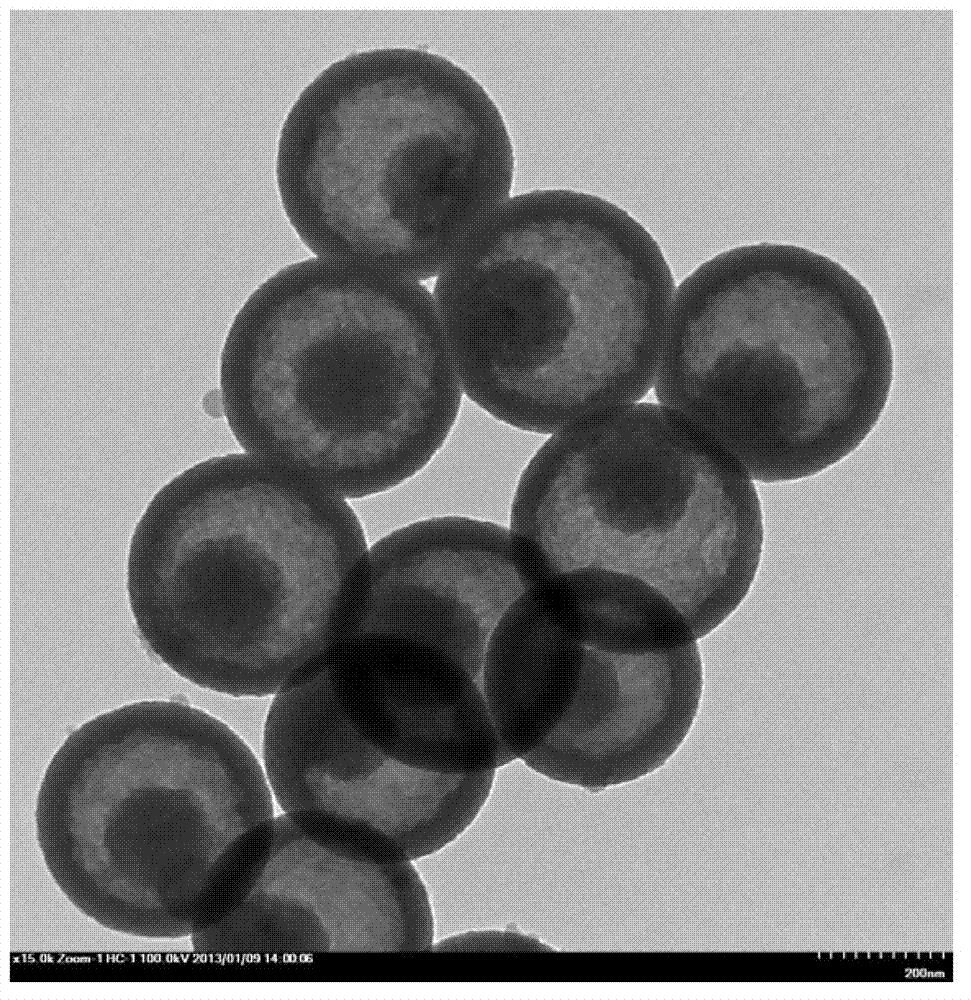

[0039] The mesoporous silica with egg yolk-eggshell struct...

Embodiment 3

[0041] (1) Mix 1ml of concentrated ammonia water (the NH contained in the concentrated ammonia water 3 The mass percent concentration is 26%) mixed with 30ml ethanol and 75ml water, then 0.64g hexadecyltrimethylammonium bromide was dissolved in the mixed solution, and 0.25ml orthosilicon Acetate tetraethyl ester and 0.25ml 1,2-bis(triethoxysilyl)ethane were added to the mixed solution, reacted for 3h, and white silica precipitate was obtained;

[0042] (2) Centrifuge and wash the silica obtained in step (1), transfer it to water to prepare a silica dispersion (5mg / ml), and place it at 20°C for 150h;

[0043] (3) The reaction product obtained in step (2) was centrifuged, washed with water, transferred to a mixed solution of 200 μl concentrated hydrochloric acid and 400ml ethanol, heated at 60°C for 5 hours to remove the surfactant, and finally obtained the egg yolk-eggshell structure medium Porous silica.

[0044] The mesoporous silica with egg yolk-eggshell structure obtaine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com