Full automatic production line of convenient and instant rice-flour and production technology thereof

A fully automatic, production line technology, applied in food preparation, food science, applications, etc., can solve problems such as unautomated production and poor sanitation conditions, and achieve the effects of avoiding food pollution, high product quality, and wide adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

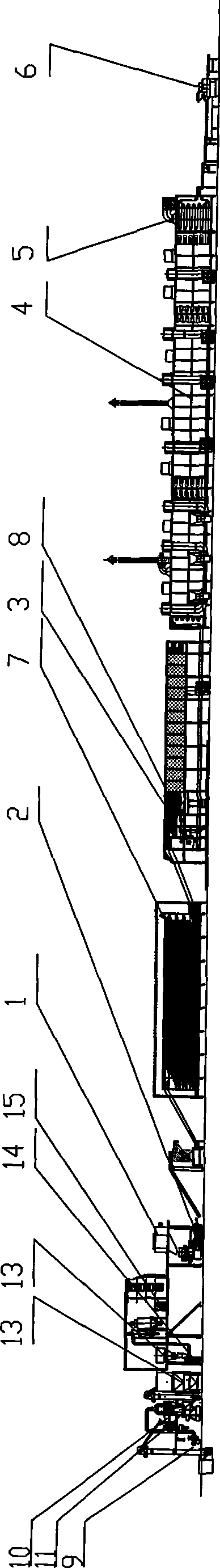

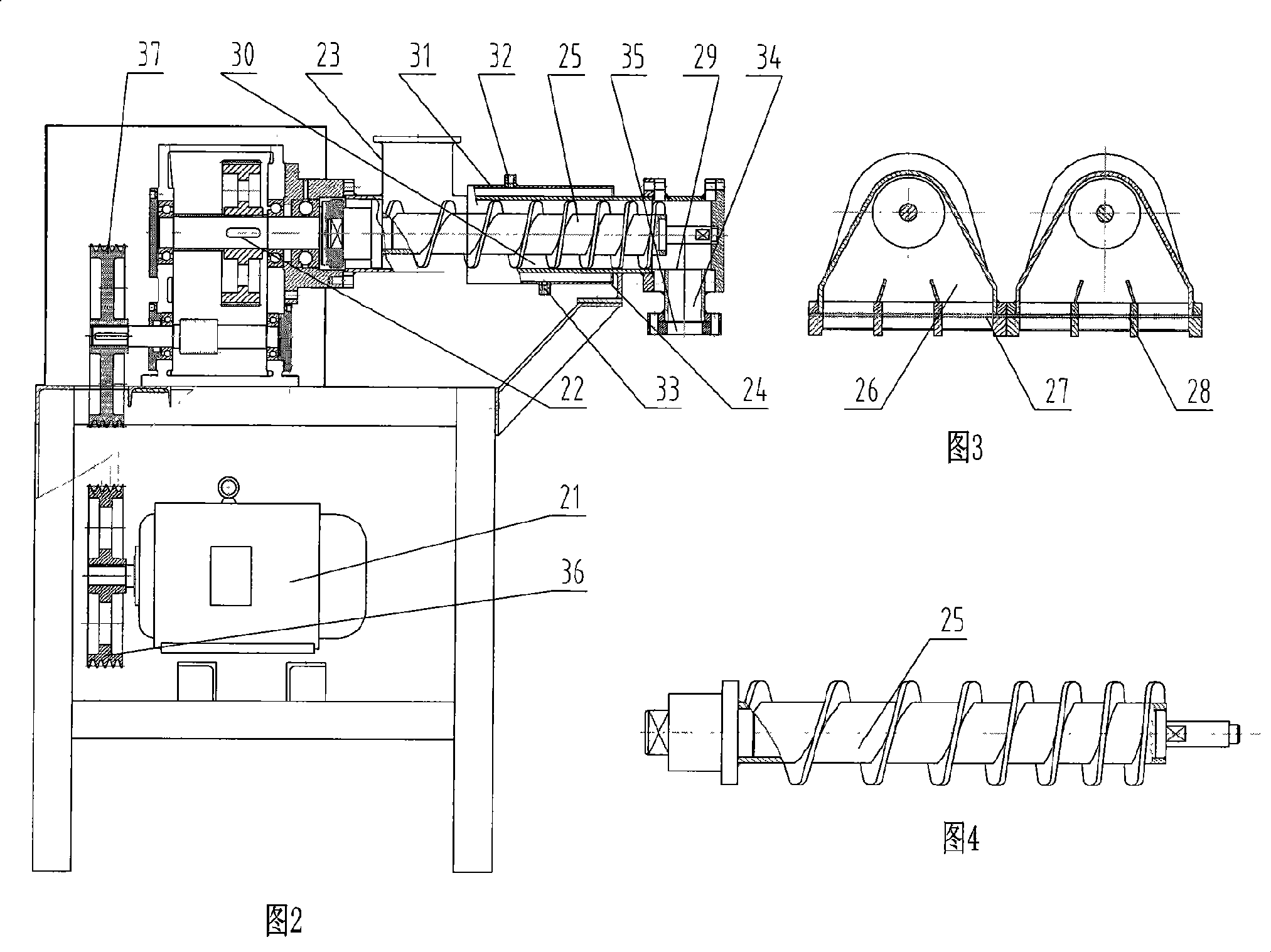

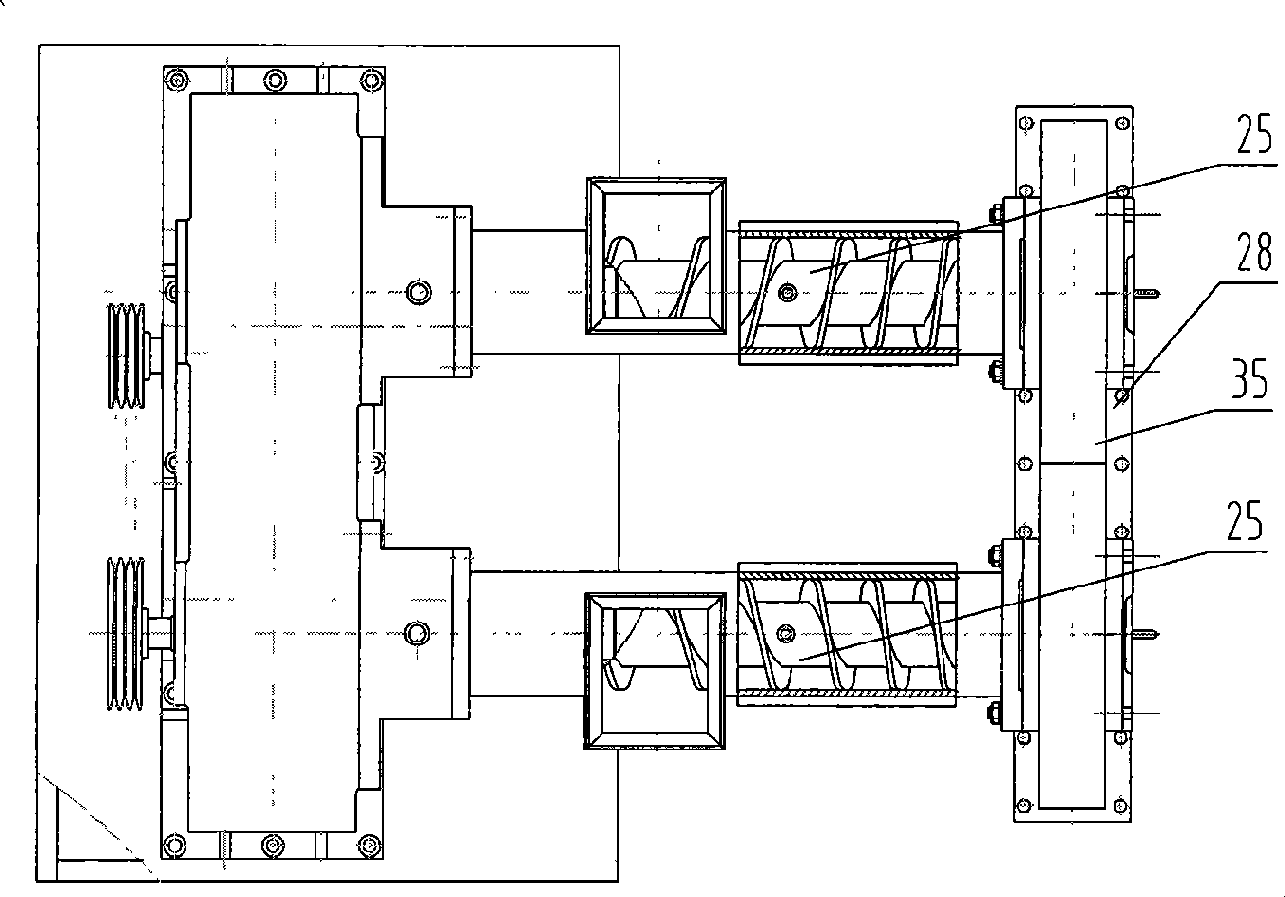

[0038] Such as figure 1 As shown, a convenient instant rice noodle production line includes a rice processing device for processing rice into a slurry, a steaming and beating machine 1 that mixes and heats the rice slurry and starch, and extrudes the vermicelli into silk. Rice vermicelli self-cooking extruding device 2, aging aging device for processing rice vermicelli, quantitative cutting device 3 for quantitatively cutting rice vermicelli, box-putting and shaping device for putting cut rice vermicelli into powder box, powder box A powder block drying device 4 for drying the powder blocks inside, a powder block cooling device 5 for cooling the powder blocks, and a packaging conveying device 6 for sending the powder blocks to packaging. The aging aging device includes a rice vermicelli freezer 7 for freezing and anti-sticking the freshly extruded rice vermicelli, an aging aging machine for freezing and thawing aging, and a continuous silk loosening machine 8 for performing a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com