Battery cylindrical shell and cylindrical anti-explosion battery and its processing method and device

A technology for battery shells and processing equipment, applied in secondary batteries, battery pack parts, non-aqueous electrolyte batteries, etc., which can solve problems such as damage to the coating on the surface of the shell, doubts about the effect of sealing technology, and large fluctuations in sealing pressure. The fluctuation of sealing pressure is reduced, it is easy to popularize and implement, and the effect of simple implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

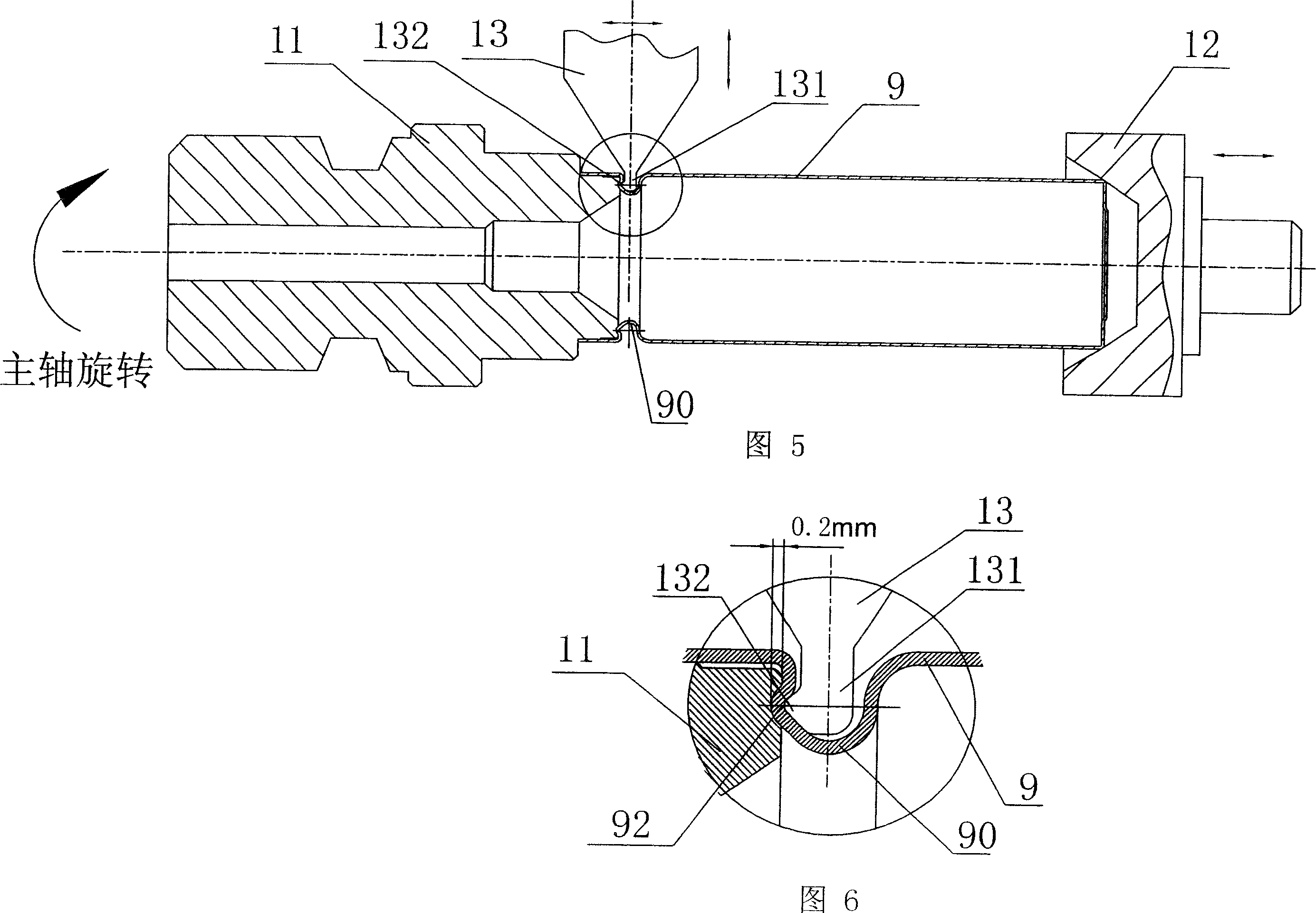

[0039] Processing equipment embodiment 1 and processing method:

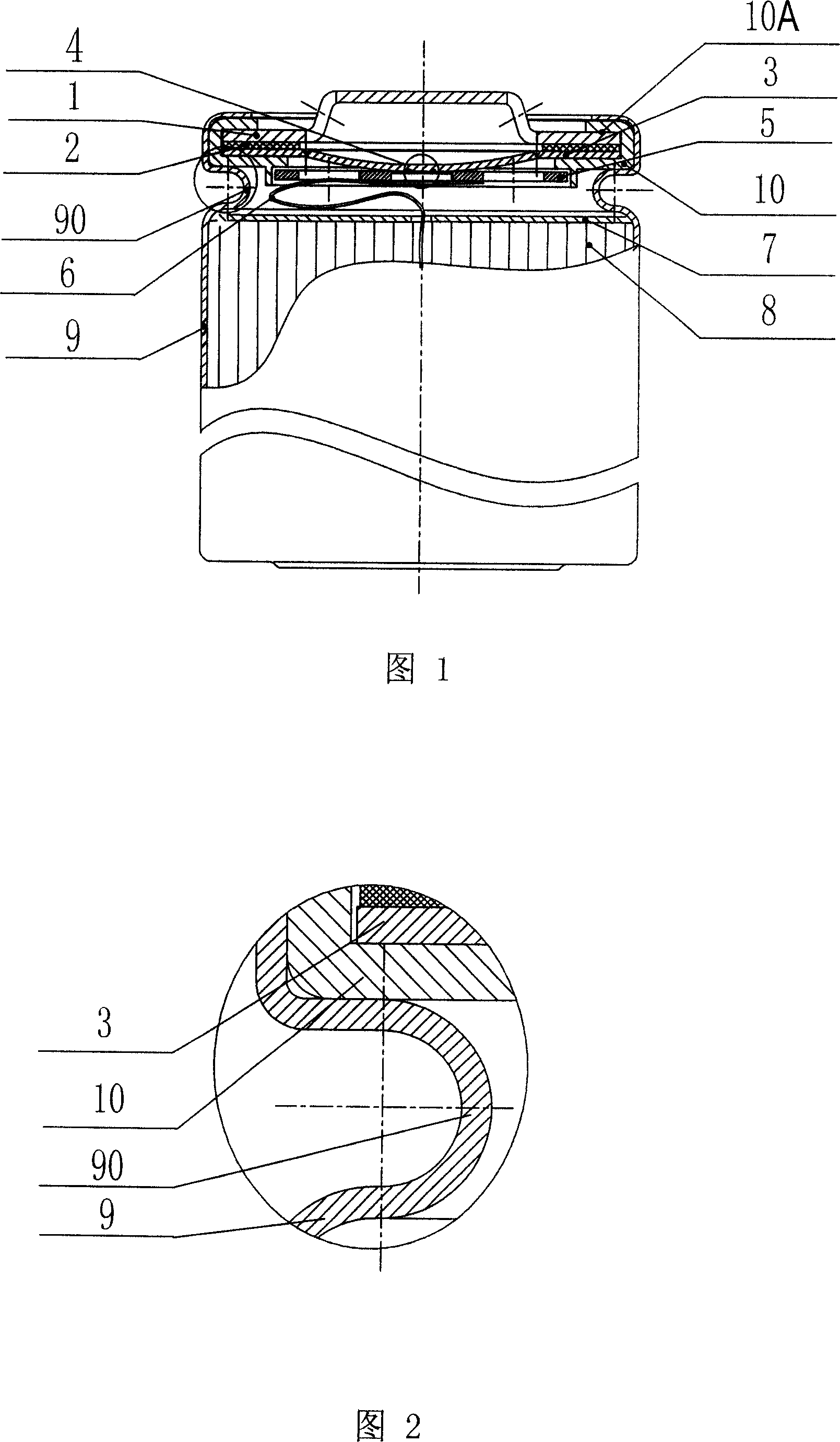

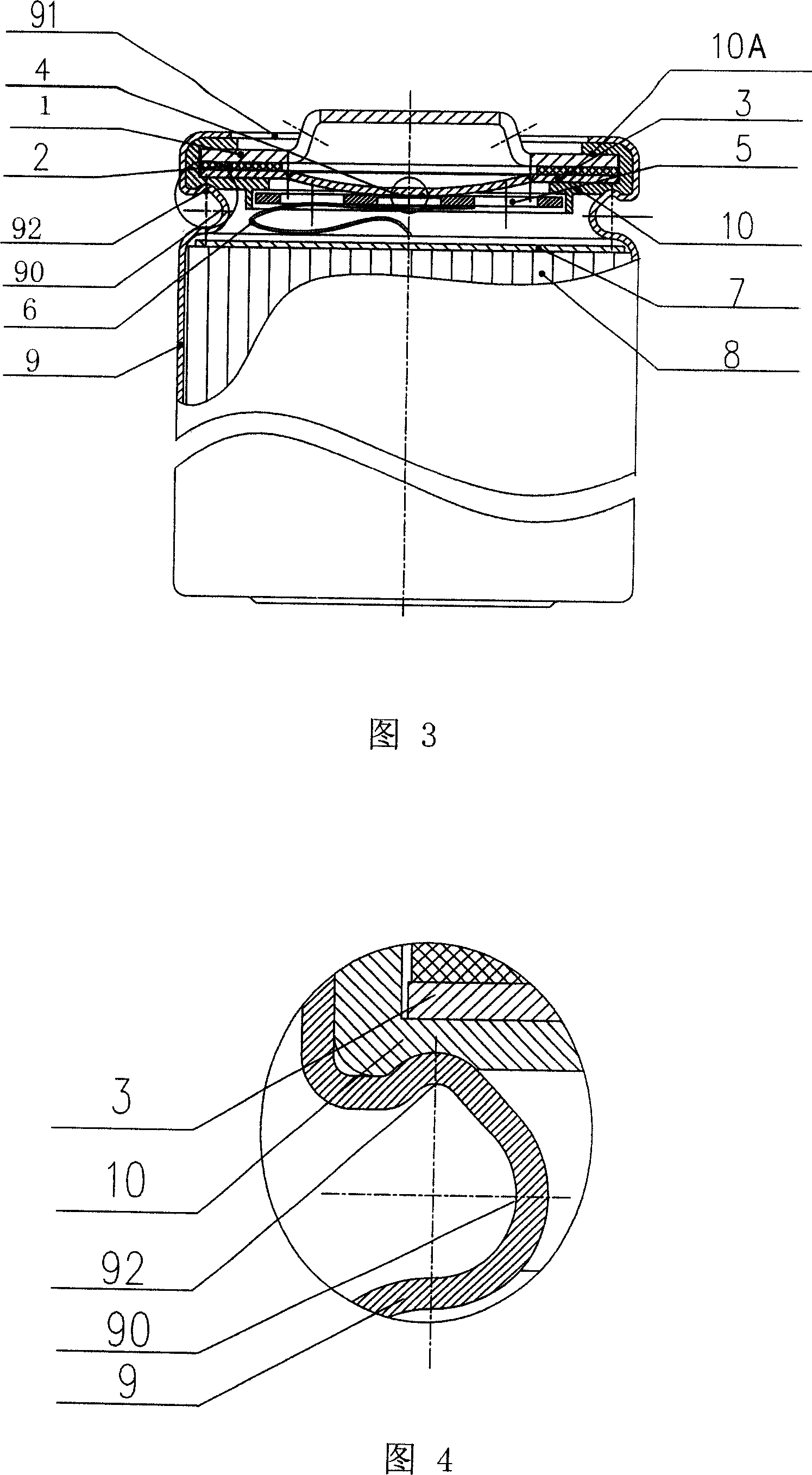

[0040] Figures 5 and 6 are schematic diagrams of processing the convex ring of the casing by using Embodiment 1 of the processing equipment of the present invention. Embodiment 1 of the processing equipment includes a mandrel 11 and a rear ejector rod 12 for pressing and positioning the battery casing 9 from both ends in the axial direction, and the processing equipment also includes a hook die 13, which includes a probe The hook head 131 inserted into the rolling groove is formed with a smooth convex body 132 in a hook shape on the end side of the hook head 131 . The processing method includes the following steps: A) forming a circle of rolling grooves 90 by rolling on the shoulder of the battery case 9, and at the same time, applying an axial extrusion thrust in the axial direction of the battery case 9; B) after the rolling grooves 90 are formed, using The convex body 132 of the hook die 13 forms a circle of...

Embodiment 2

[0042] Processing equipment embodiment 2 and processing method:

[0043] Figures 7 and 8 are schematic diagrams of processing the convex ring of the shell by using the equipment embodiment 2 of the present invention. The processing equipment embodiment 2 includes a lower die 14, and the processing equipment also includes a stamping upper die 15. The lower end of the stamping upper die 15 includes a stepped surface 150, and a small head downwards is formed below the stepped surface 150. Tapered die head 151, the outer diameter of the small head of the tapered die head 151 is equivalent to the inner diameter of the battery case 9; the inner diameter of the opening 140 of the lower die 14 is equivalent to the outer diameter of the battery case 9, and the lower The clamping mold 14 has a depth-adjusting mechanism (not shown in detail) for adjusting the depth of the hole, and the depth-adjusting mechanism can make the outer bottom surface of the upper edge of the rolling groove 90 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com