Convenient vermicelli production line and its producing technology

A technology that is convenient for fans and production processes. It is used in food preparation, food forming, food science and other directions. It can solve the problems of long time, energy consumption, energy consumption, etc., and achieve high yield, high product quality, and good taste. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

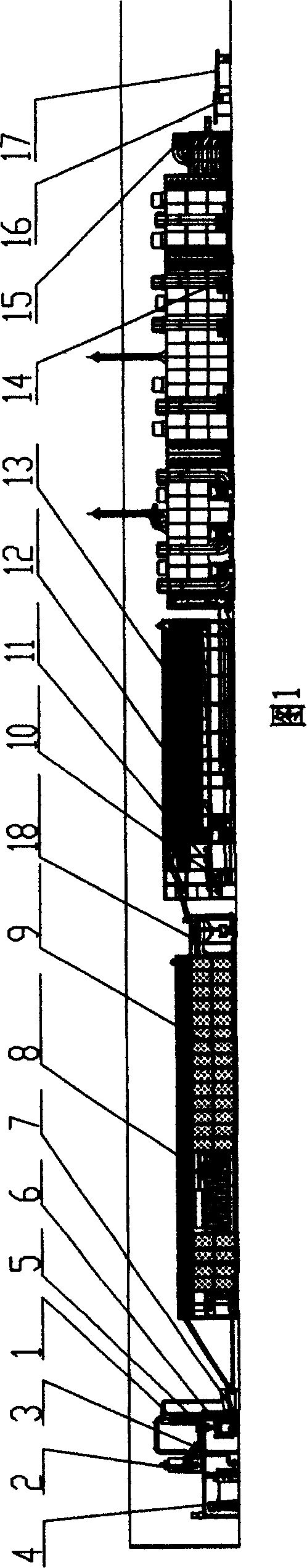

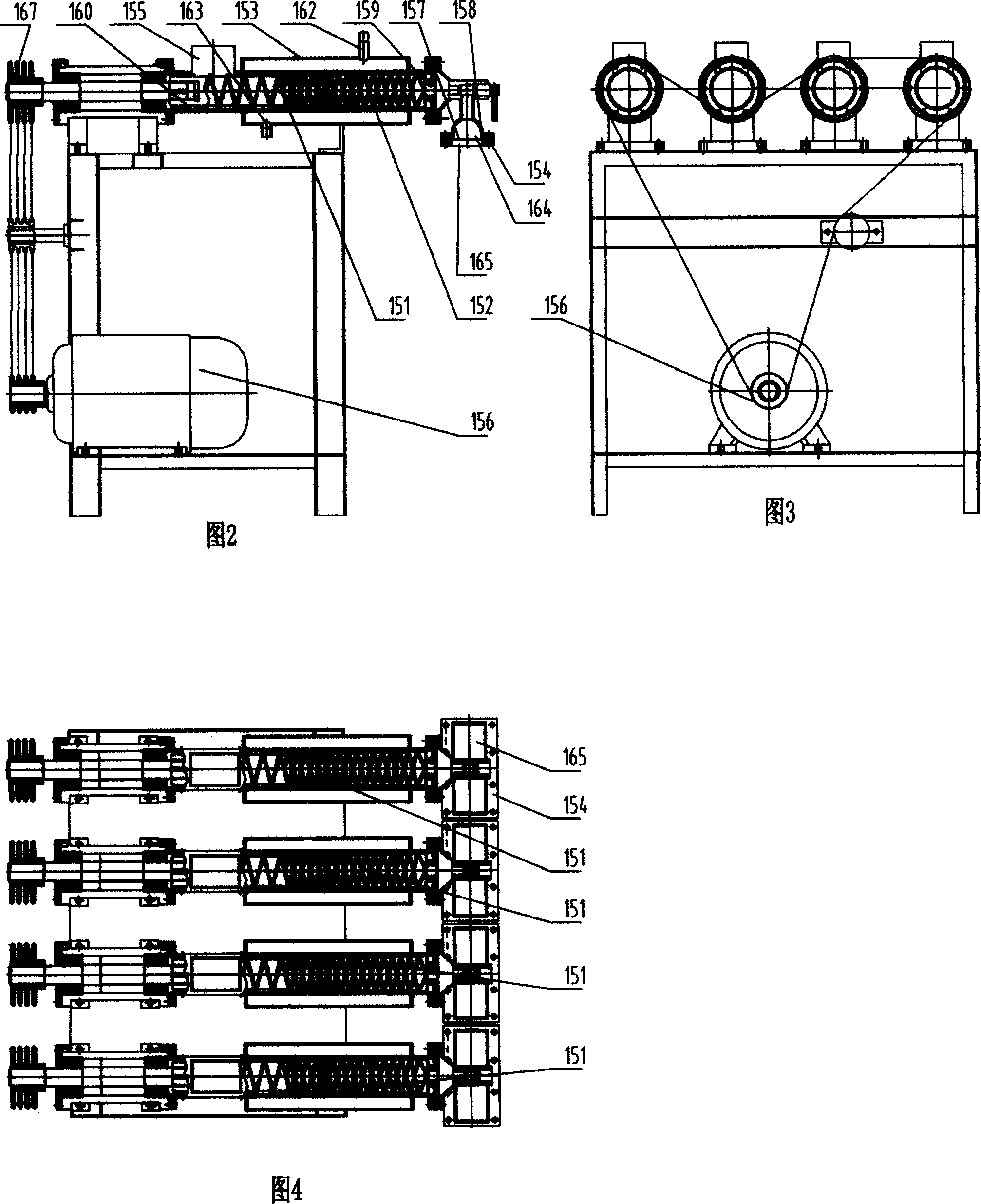

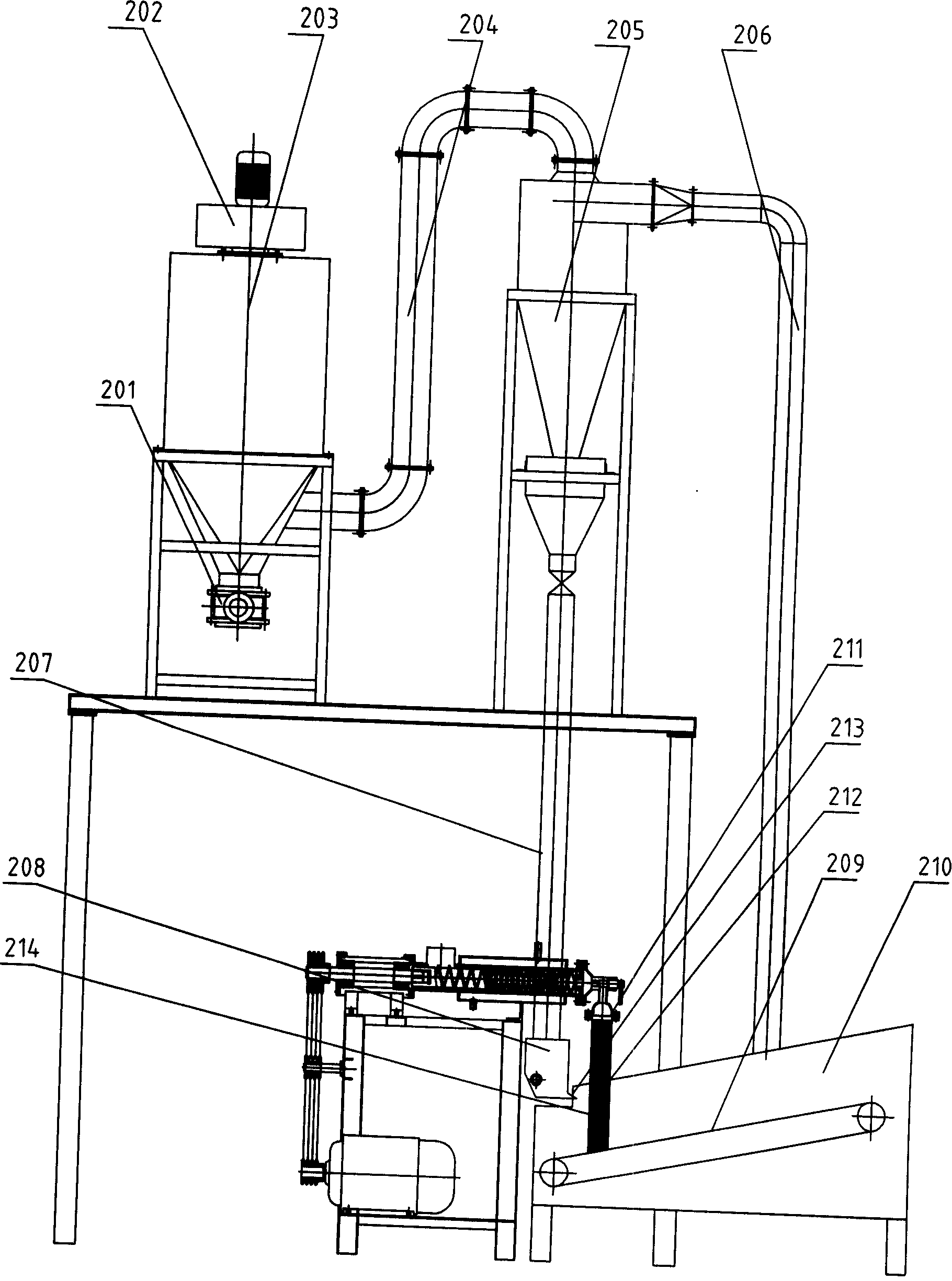

[0034]As shown in Figure 1, a convenient vermicelli production line includes an air suction system that removes the dirt in the starch through the action of centrifugal force connected in sequence according to the material conveying direction. Slurry mixing tank 2. Sieving machine for removing granular matter in the slurry 3. Hot water tank for heating and stirring the slurry 4. Dividing the slurry into two strands and entering the multi-screw slurry self-cooking extruder 6 Sizing barrel 5, multi-screw powder slurry self-cooking extruder 6 which matures the powder slurry and extrudes it into wire, and anti-sticking machine 7 for spraying dry powder to vermicelli extruded from the multi-screw powder slurry self-cooking wire extrusion machine 6 , the vermicelli primary aging machine that makes the vermicelli age naturally for the first time 8, the vermicelli freezer that makes the vermicelli hanging and freezing 9, the washing and loosening machine that makes the frozen vermicell...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com