Patents

Literature

399 results about "Water binding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Water binding capacity is the tendency of water to associate with hydrophilic substances whereas Water holding capacity is the ability of a matrix of molecules to entrap large amounts of water in a manner such that exudation is prevented. Bound water exists in the vicinity of solutes and other non-aqueous constituents,...

Nicotine containing stimulant unit

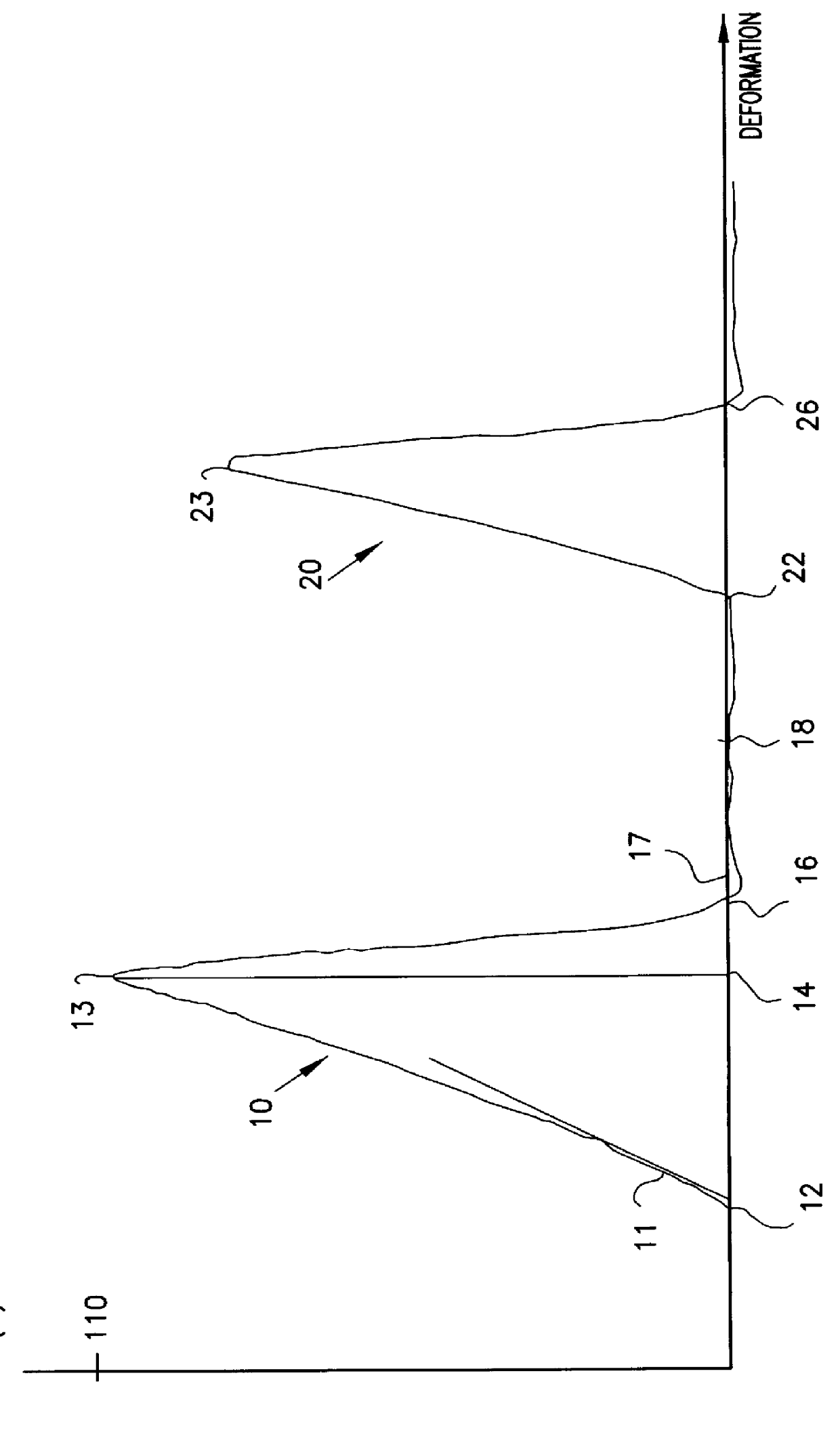

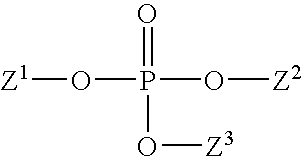

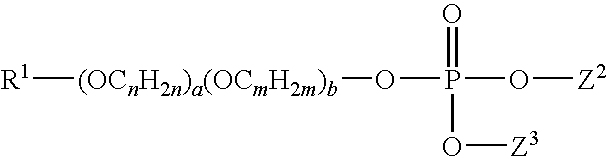

InactiveUS6110495AIncrease stimulationLarge deformationTobacco treatmentConfectioneryStimulantAdditive ingredient

A saliva-soluble stimulant unit comprising an active ingredient and optional ingredients comprising flavor and aroma additives incorporated in a gel prepared by gelling a water-binding gelling agent, in which the active ingredient comprises nicotine or other alkaloids with the same direction of activity, said unit having i) a texture profile, determined by texture profile analysis, with parameter values of firmness, hardness, brittleness, adhesiveness, elasticity, and cohesiveness within given ranges; (ii) a disintegration time within the range 5-60 minutes; and (iii) a nicotine content from 0.5 to 10 mg or a corresponding content of said alkaloids.

Owner:DAM ANDERS

Oral Care Compositions

InactiveUS20090269287A1Prevent significant water lossGood dispersionCosmetic preparationsToilet preparationsCarrageenanRelative humidity

Disclosed are oral care compositions, particularly thickened dentifrices in liquid, paste or gel form comprising a binding / thickening system that also function effectively as humectant agent thereby replacing a significant portion or all of traditional humectant components such as glycerin, sorbitol and other polyols. The binding / thickening system comprise select carrageenans that provide a water viscosity of at least about 20 mPa·s in a 1.5% solution at 25° C. and effective water-binding capacity to prevent significant water loss from the composition when exposed to air to cause unacceptable drying out. For example, the water-binding capacity of the carrageenan must be effective such that there is no more than about 0.75% water loss from a dentifrice composition when exposed to air for 30 minutes at room temperature conditions and 50% relative humidity. The present dentifrice compositions exhibit increased dispersibility in saliva during use, which provides for increased contact time of the composition with the user's teeth and oral cavity tissues such that the active dental agents contained therein are more rapidly available to effect their beneficial activity.

Owner:THE PROCTER & GAMBLE COMPANY

Reduced-carbohydrate and nutritionally-enhanced frozen desserts and other food products

InactiveUS20060286248A1Mitigate laxation effectReduce impactFrozen sweetsConfectioneryTagatoseMaltitol

A reduced carbohydrate ice cream or other frozen dessert product that contains a low-digestible sweetener system and a fermentable fiber material. The a low-digestible sweetener system consists of one or more low-digestible sweeteners having a molecular weight of from about 90 to about 190; and is typically a low molecular weight saccharide or a polyol. Typical low-digestible sweeteners include mannitol, maltitol, sorbitol, lactitol, erythritol, xylitol, isomalt, glycerin, talitol, mannose, tagatose, fructose, arabinose, fucose, lycose, ribose, sorbose, talose, and xylose, and mixtures thereof. The low-digestible sweetener replaces the digestible sugars to provide the appropriate freezing point depression of the product. The level of fermentable fiber is sufficient to mitigate a Taxation effect that can be caused by ingestion of the amount of the low-digestive sweetener. The fermentable fiber can be an inulin, a maltodextrin resistant to human digestion, an oligofructose, a fructooligosaccharide, a high water binding fermentable fiber, and a mixture thereof.

Owner:TECHCOM GRP LLC

Damp cleansing wipe

A disposable substantially damp cleansing article is disclosed having a cleansing composition impregnated onto a flexible substrate such as a non-woven cloth. The impregnated compositions include lathering surfactants and water, and a water-binding agent resulting in a composition having a water activity less than 0.977 but no lower than 0.001. Amounts of water range from greater than 15% to no higher than about 40% by weight of the total article. Speed of lather formation and foam volume increases within the window of the stated water activity and water range.

Owner:UNILEVER HOME & PERSONAL CARE USA DIV OF CONOPCO IN C

Water binding agent for lithium ionic cell electric pole material and preparation method thereof

ActiveCN101457131AStrong adhesionSufficient flexibility for processingElectrode manufacturing processesActive material electrodesLatex particleHigh voltage

The present invention relates to an aqueous binder used in lithium ionic cell electric pole material and the preparation method thereof, which belongs to lithium ionic cell electric pole material preparation field. The present invention aims to provide an aqueous binder for producing lithium ionic cell positive and negative plate with adjustable flexibility, and can meet all electric pole material aqueous binder requirements under various conditions of lithium ionic cell production and processing, storage and usage. The aqueouspolymer latex particle emulsion has an inside soft and outside hard core-shell structure with low polar polymer as core and high polar polymer as shell, and the solid content of the emulsion is 5-40 wt%, the mass percentage of low polar polymer is more than 0 and smaller than or equal to 95% in the core-shell structure. The lithium ionic cell produced according to the invention is provided with high capacity exertion of electroactive material, long battery periodic duty life and high voltage of discharge platform.

Owner:MEISHAN INDIGO TECH CO LTD

Compositions for improving flavor and safety of marinated meat products

A composition for improving the flavor and juiciness of marinated meats and inhibiting growth of pathogenic and spoilage microorganisms and a process for making the composition are described. Lemon juice and vinegar are neutralized, concentrated and blended with non-neutralized lemon juice and non-neutralized vinegar in appropriate proportions to achieve the desired water binding and antimicrobial effects.

Owner:KERRY GRP SERVICES INT

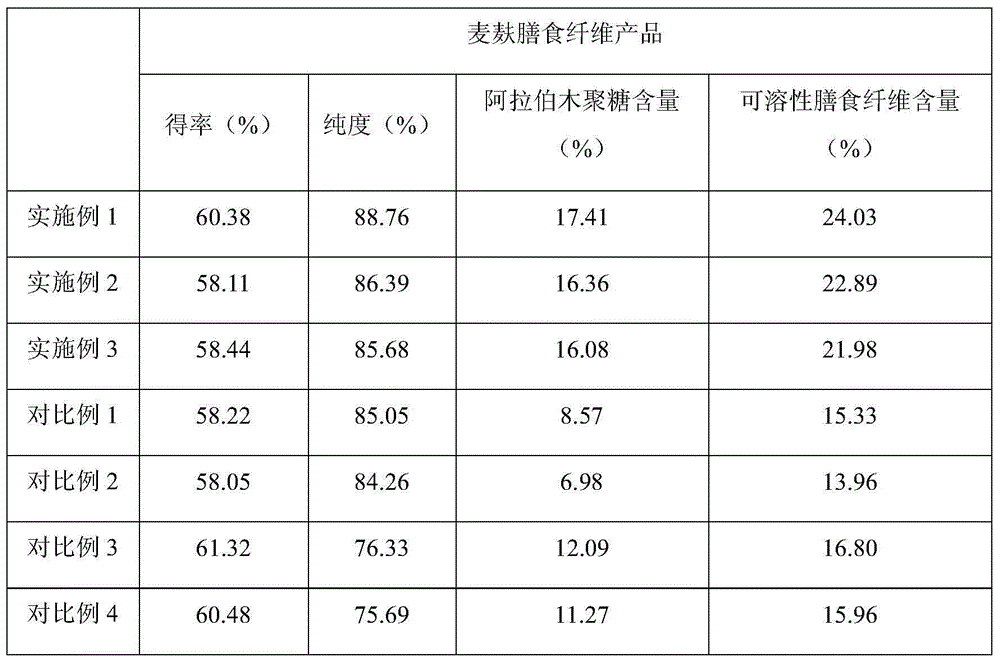

Novel method for preparing wheat bran dietary fibers by taking wheat bran as raw material

ActiveCN104544137AHigh yieldIncrease soluble dietary fiber contentFood preparationArabinoxylanEthanol precipitation

The invention discloses a novel method for preparing wheat bran dietary fibers by taking wheat bran as a raw material. The wheat bran dietary fibers are dietary fibers enriched with araboxylan and the content is more than 16.08%. The novel method takes the wheat bran as the raw material and sequentially comprises the following process steps: pre-treating the raw material; rapidly extracting with an alkaline solution; carrying out ethanol precipitation; adding water to suspend again and blasting by steam; hydrolyzing compound protease; hydrolyzing compound amylase; carrying out secondary alcohol precipitation; and sieving. The dietary fiber product has high wheat bran dietary fiber yield and dietary fiber purity, and also has high content of araboxylan and high content of soluble dietary fibers; the product has good functional properties including water binding capacity, viscosity and the like, and has a plurality of physiological functions of relaxing bowel, controlling blood glucose, lowering blood fat, adjusting human immunity and preventing colon cancer and the like, so that high-quality raw material guarantees are provided for widely applying the wheat bran dietary fibers to foods.

Owner:FARM PROD PROCESSING & NUCLEAR AGRI TECH INST HUBEI ACAD OF AGRI SCI

Cherry jam and preparation method thereof

The invention relates to a method for preparing jam, in particular to cherry jam and a preparation method thereof, and belongs to the technical field of food processing. The invention has the advantages that: cherry flesh is taken as a main raw material and is added with jelly powder, so that the jam has high water binding capacity; and a method of performing dipping treatment on the cherry flesh raw material by using a low temperature sugar solution is adopted, and the flavor and color of the flesh can be better maintained. The cherry jam processing technology has a positive effect and social benefit for promoting the re-innovation of a jam processing technology.

Owner:DALIAN ZHAOYANG SOFTWARE TECH

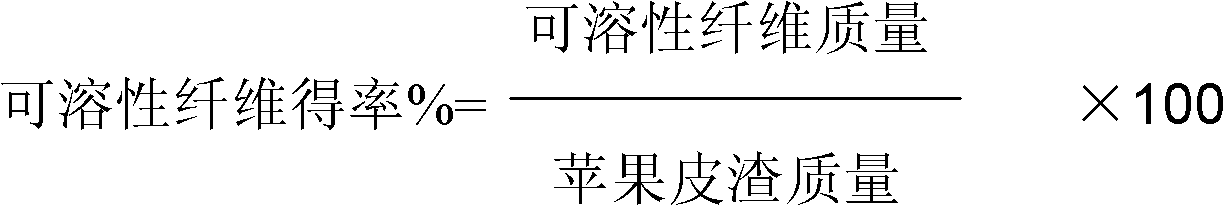

Preparation method for soluble dietary fiber with apple pomace as raw material

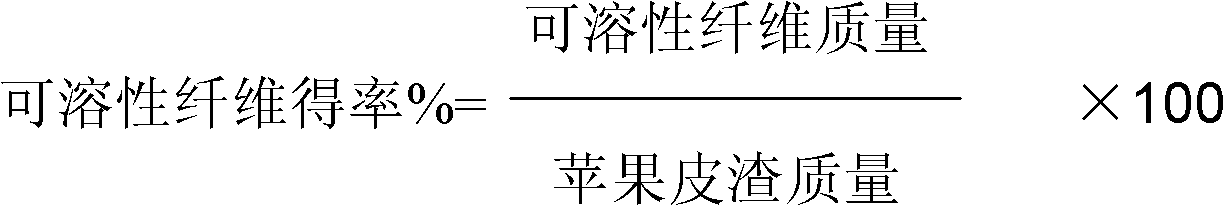

The invention discloses a preparation method for a soluble dietary fiber with apple pomace as a raw material. According to the method, an expanding method and an enzymatic hydrolysis method are combined. By the application of an expansion process, the structures of cellulose molecules become loose, and partial glycosidic bonds are broken, so that partial insoluble dietary fibers are transformed into soluble ones. After separation of the insoluble dietary fibers and the soluble dietary fibers, the expanded insoluble dietary fibers, which have the loose molecular structures, are hydrolyzed by utilizing a cellulase; and then the insoluble dietary fibers are further transformed into soluble dietary fibers. According to the invention, the modification of the insoluble dietary fibers in the apple pomace enables the insoluble dietary fibers to become high-quality soluble dietary fibers, so that an achievement rate of the soluble dietary fibers can substantially be enhanced as well as water binding capacity and expansibility of dietary fibers can also be improved. According to the test, the achieve rate of the soluble dietary fibers can reach 21.2%; the water binding capacity and expansibility can be enhanced by 110.3% and 7.0% respectively.

Owner:CHENGDU UNIV

Semi-Fluidic Composition for Lubricating, Moisture Retaining, Disinfecting, Sterilizing and Method Using the Same

InactiveUS20150264935A1Reduce liquidityHigh activityBiocideInorganic active ingredientsSubject matterFluid composition

A semi-fluid composition for lubricating, moisture retaining, disinfecting and sterilizing, which comprises of hypochlorous acid, thickening agent, emollient and water-binding agent, wherein the water and the thickening agent, emollient; and water-binding agent are mixed and stirred to form a hydrogel or a viscous substance, a method of using the semi-fluid composition for lubricating, moisture retaining, disinfecting and sterilizing, comprising following step: attaching the semi-fluid composition with effective amount to a subject-matter or applying the semi-fluid composition on the surface thereof, the subject is an adult intimacy product or a medical supply.

Owner:CHANG YI SHOU

Compositions for improving flavor and safety of marinated meat products

ActiveUS20120201950A1Meat/fish preservation using chemicalsMeat/fish preservation using acidsFlavorMicroorganism

Owner:KERRY GRP SERVICES INT

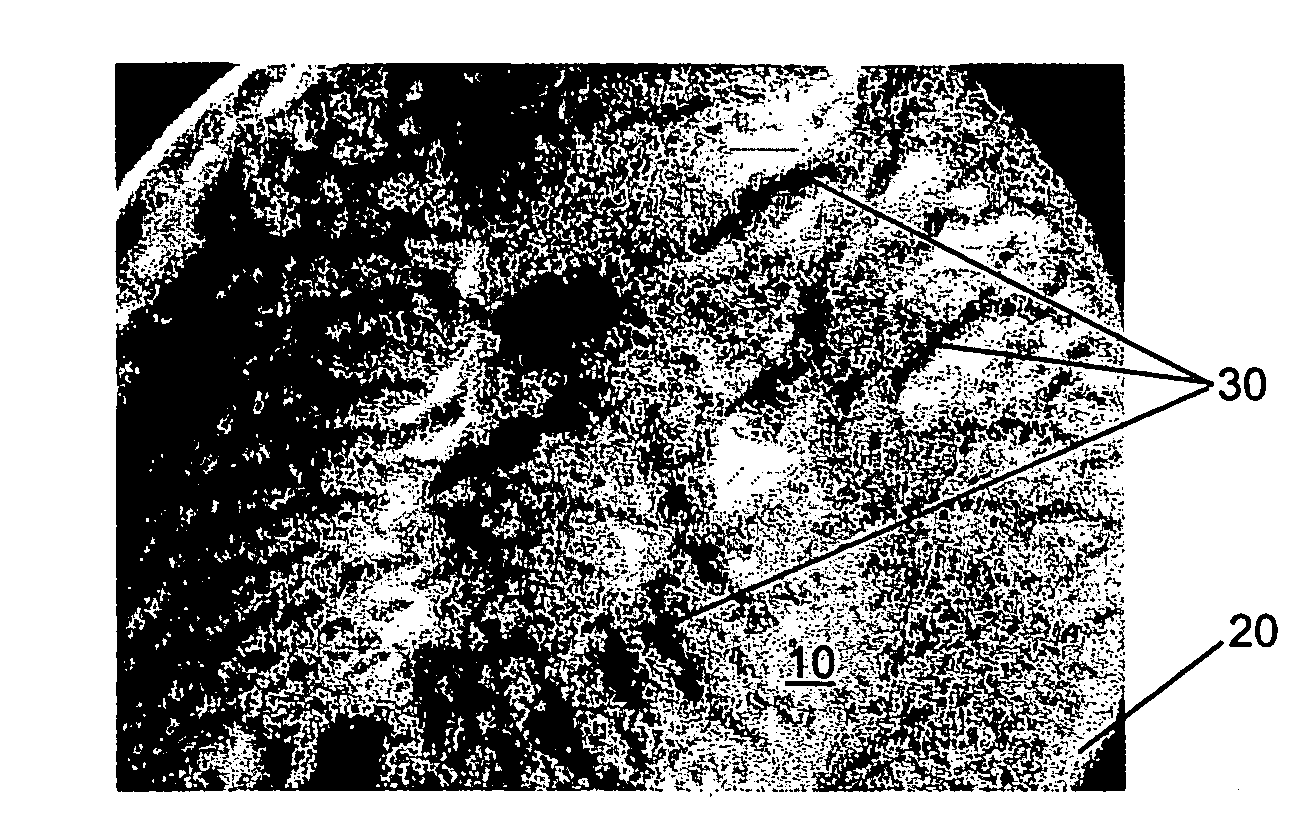

Bacterial cellulose/chitosan composite sponge dressing and preparation method thereof

ActiveCN103550817ANo scarHigh tensile strengthAdhesive dressingsAbsorbent padsPolymer scienceNonwoven fabric

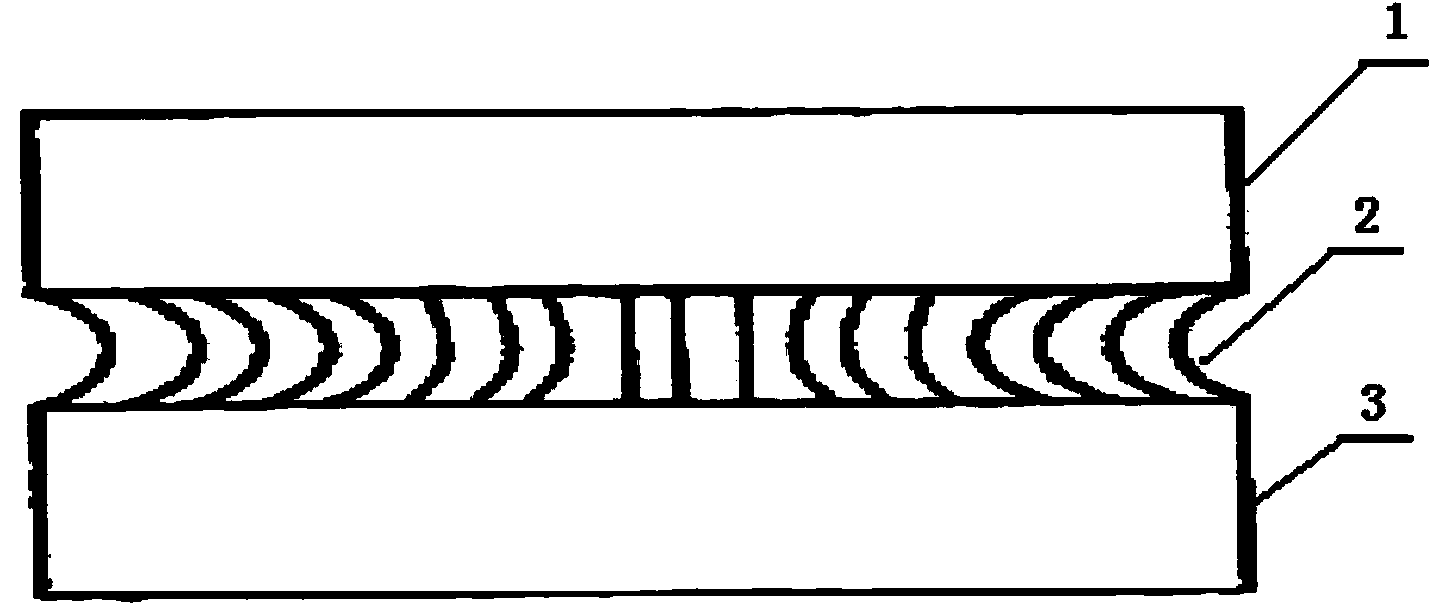

The invention relates to a bacterial cellulose / chitosan composite sponge dressing and preparation method thereof. The dressing comprises a cellulose / chitosan composite sponge layer (1), an adhering layer (2) and a nonwoven fabric layer (3) which are placed from top to bottom in sequence. The preparation method comprises the following steps of (1) boiling a bacterial cellulose membrane with an NaOH aqueous solution, fully washing with distilled water to reach neutral state, and then drying in vacuum to obtain bacterial cellulose fibrid; (2) preparing a chitosan solution, adding the bacterial cellulose fibrid, standing and defoaming, freezing, and finally freezing and drying to obtain bacterial cellulose / chitosan composite sponge; and (3) adhering the bacterial cellulose / chitosan composite sponge to a polypropylene nonwoven fabric with permeable micropores through an adhesive, a hot melt adhesive or a thermosensitive adhesive, thus obtaining the bacterial cellulose / chitosan composite sponge dressing. The dressing has the effects of stopping bleeding, diminishing inflammation, sterilizing, promoteing the wound healing, and has the advantages of no scar, high tensile strength, high water binding capacity and air and water permeability, high shape maintaining ability, etc. The preparation method is simple.

Owner:湖南仁馨生物技术有限公司

Tofu coagulator and preparation method therefor

PendingCN106538711AWith waste utilizationCompact structureCheese manufactureFood scienceFlavorLactobacillus rhamnosus

The invention provides a tofu coagulator. The tofu coagulator comprises the raw materials of a sterilized bean supernatant and activated compound lactobacillus, wherein the compound lactobacillus comprises lactobacillus casei, lactobacillus rhamnosus and lactobacillus zeae. The invention also provides a preparation method for the tofu coagulator. The preparation method comprises the steps of sterilizing the bean supernatant, and then inoculating the activated compound lactobacillus to the bean supernatant for fermenting. The coagulator is beneficial for intestinal health and capable of improving immunity of gastrointestinal tract; the coagulator is simple in preparation method, high in production efficiency, capable of utilizing waste materials and economic and environment friendly; and the tofu prepared by the coagulator is tender and smooth in taste, compact in structure, high in water binding capacity and elasticity, and has special flavor of bean supernatant fermenting liquid.

Owner:SHAOYANG UNIV +1

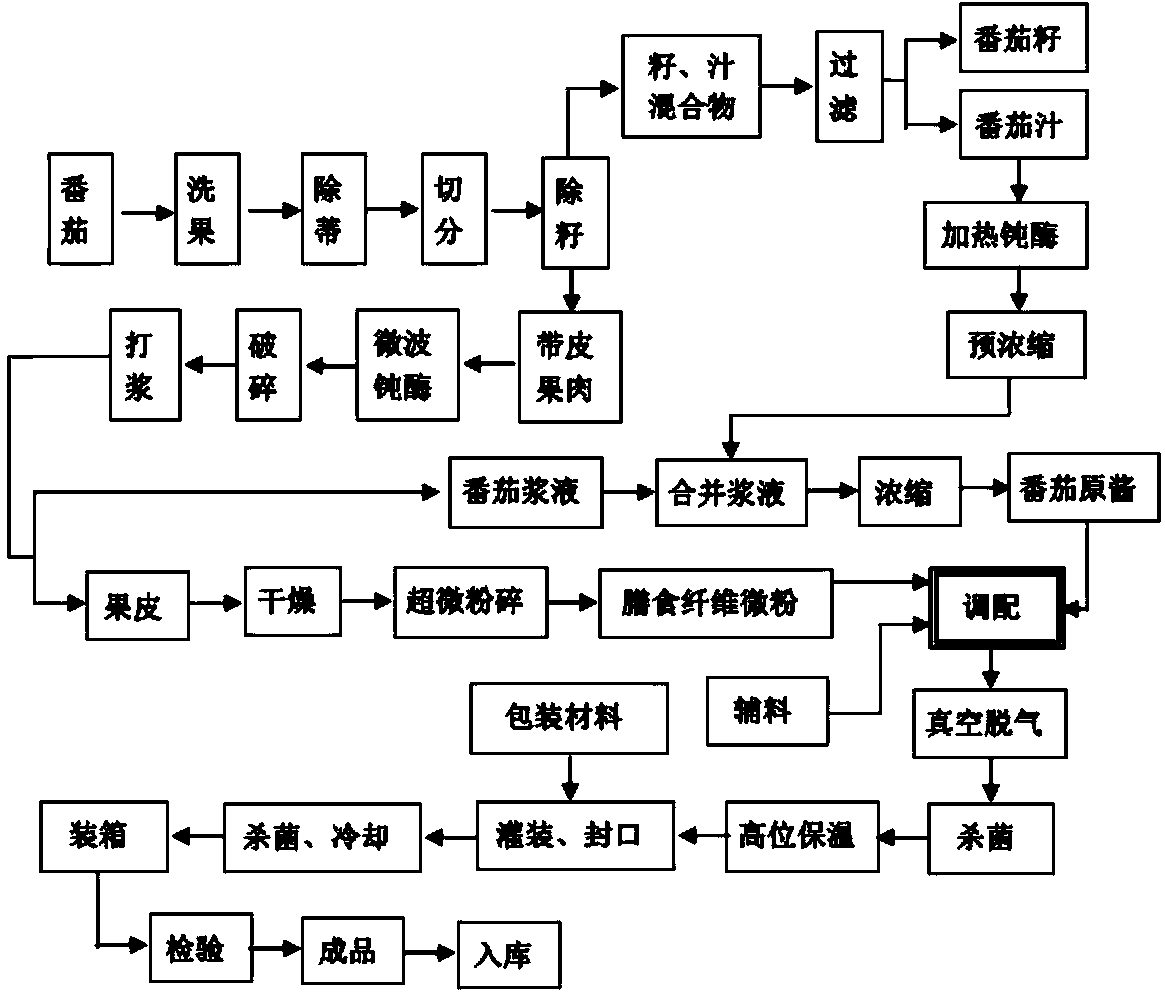

Tomato sauce with high dietary fiber and production method of tomato sauce

The invention discloses a tomato sauce with high dietary fiber and a production method of the tomato sauce, belonging to the field of processing technology of food seasonings. Tomato fruits are cut and seeds are removed, and the microwave enzyme passivating technology, the superfine grinding technology, the substep concentration technology and other technologies and processes are adopted to produce high-quality raw tomato sauce and tomato peel dietary fiber micro powder, and then the tomato sauce is prepared according to the formula; the formula is as follows in mass percentage: 55-60% of raw tomato sauce, 4-6% of tomato peel dietary fiber, 0.5-0.8% of edible salt, 2-4% of trehalose, 0.32-0.36% of citric acid, 2-2.2% of alimentary acetic acid, 0.008-0.01% of monascus red pigment, 0.01-0.02% of Nisin, 0.07-0.09% of xanthan gum and 28-32% of water. The nutrients of the tomato peel are fully utilized, and the enzyme passivating effect is good; the content of the dietary fiber of the tomato sauce is increased by 4.3-6.6 times and the content of the lycopene is increased by 1.3-2.2% compared with those of the prior art, and the tomato sauce has good water binding capacity, pure flavor, bright color and luster and good sensory quality.

Owner:GUANGDONG JIALONG FOOD

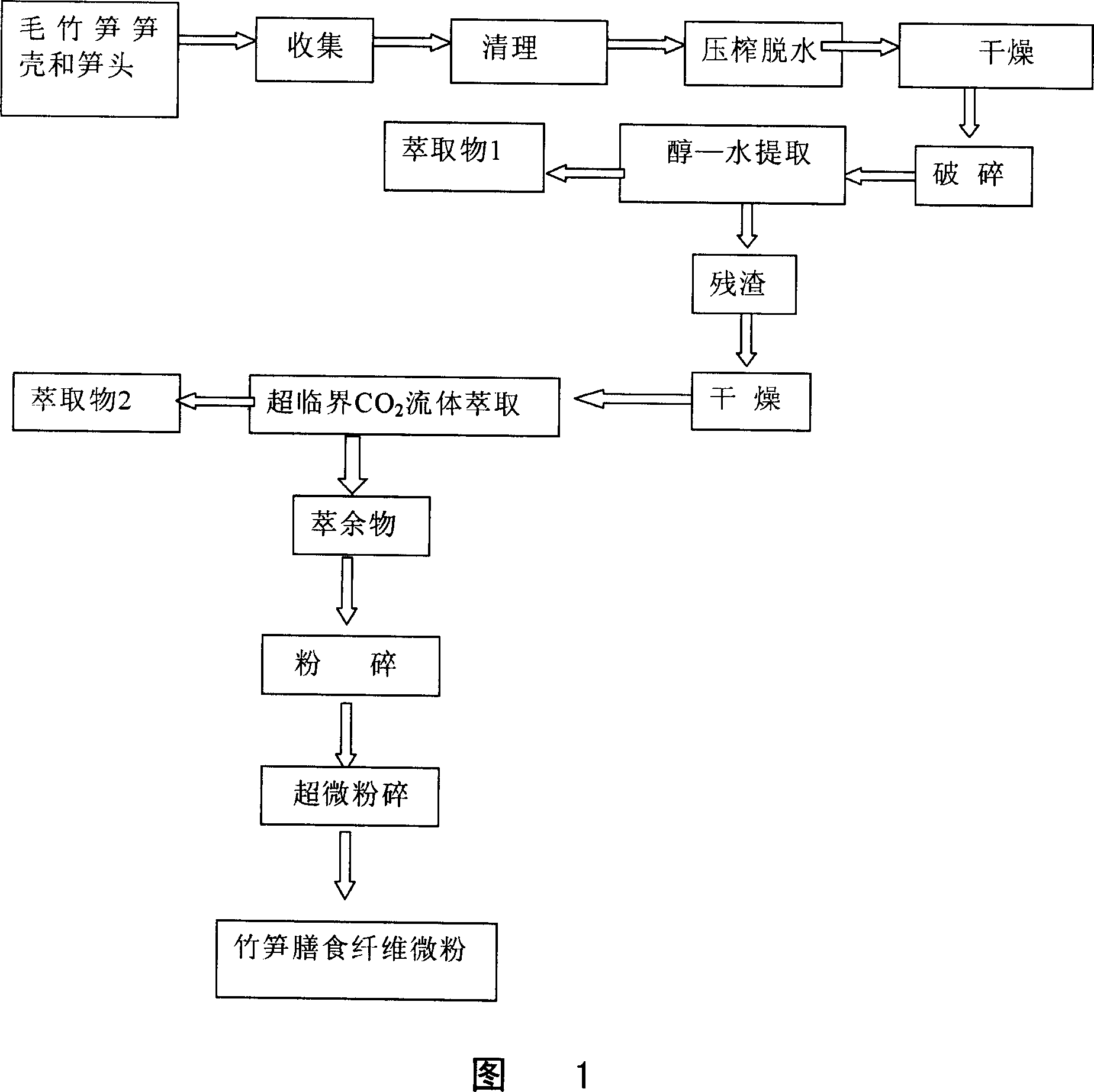

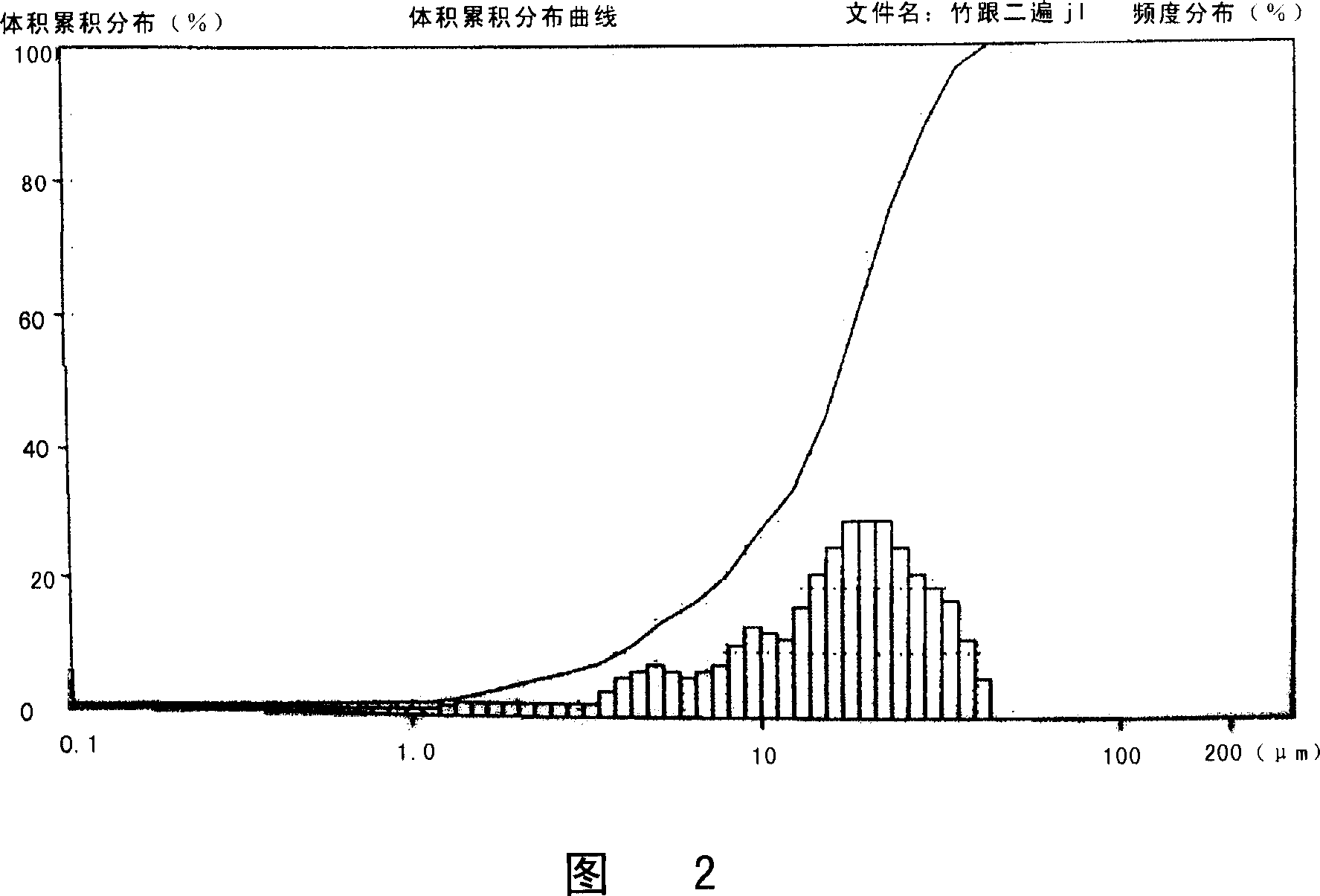

High-quality insoluble plant edible fiber micropowder and preparation method and application thereof

InactiveCN101142979ASmall particle sizeLarge specific surface areaFood preparationFiberDietary fiber

The invention discloses high-quality insoluble plant dietary fiber powder, and the particle size of more than 90 percent of dietary fiber powder is less than 30 mum and dietary fiber powder has the capacity of strong water binding, swelling, fat (oil) absorbency and chelating metal ion. The invention also discloses a preparation method for fine powder. Fine powder is widely used in health care (functional) food with the function of weight loss, purge, detoxification, etc., and is used for fiber reinforcing in the process of baking and expanding food, moreover, fine powder can also be used as fill material of drug. Fine fiber powder provided by the invention has low integrated production cost, high quality of product and long shelf life, and meanwhile, the powder is friendly to the environment in the production process and is suitable for large-scale industrial production.

Owner:城步锦龙农林科技开发有限责任公司

Processing method of fruit-flavor dried goose slices

InactiveCN103315321AUniform tasteImprove water holding capacityFood preparationNutritive valuesPhosphate

The invention relates to a processing method of fruit-flavor dried goose slices. The processing method comprises the following steps of: (1) finishing; (2) freezing; (3) slicing; (4) preparing a pickling liquid; (5) vacuum tumbling; (6) tedding; (7) roasting; (8) curing by adopting a juice; (9) baking obtained slices; and (10) packaging. According to the invention, during preparation of the pickling liquid, composite phosphate and papain are added as a composite tenderness agent, the effect is obviously superior to the effect obtained after one tenderness agent is abundantly and independently used; the added Arabic gum can form a gel system with goose egg white, so that taste molecules and smell molecules in the dried goose slices can be reserved to the maximum, and the dried goose slices have good flavor; the vacuum tumbling is adopted, therefore, compared with the prior art, the processing method has the advantages that the curing time is reduced, the technological period is shortened, the pickling liquid is absorbed to the maximum, the dried goose slices are uniformly pickled, the water binding capacity and tenderness are improved, and the mouthfeel is smooth; after being cured by adopting juice, the dried goose slices are increased in content of vitamin, and improved in nutritive values, and different juices can attach different flavors.

Owner:ZHEJIANG ZHUOWANG AGRI SCI & TECH

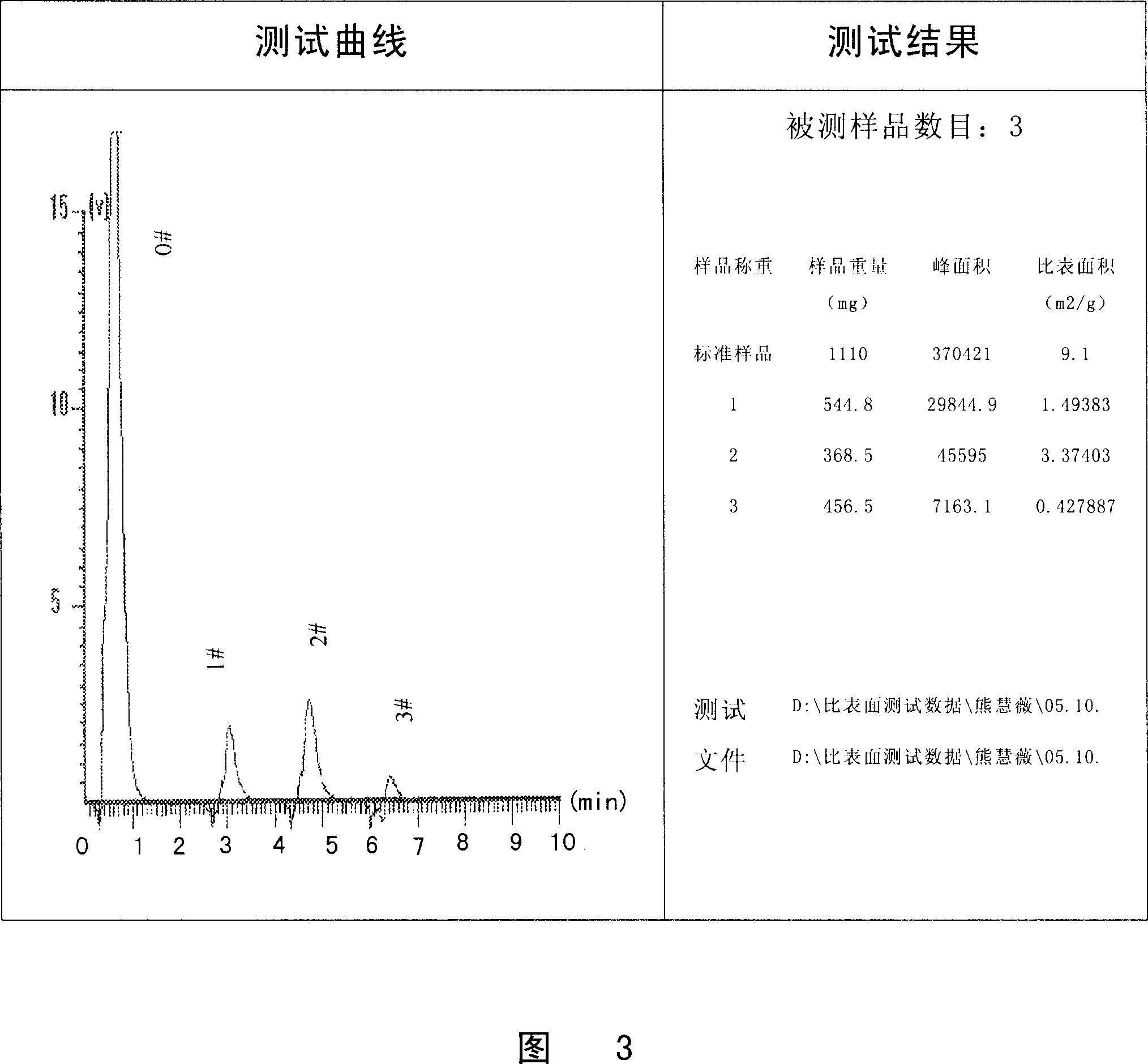

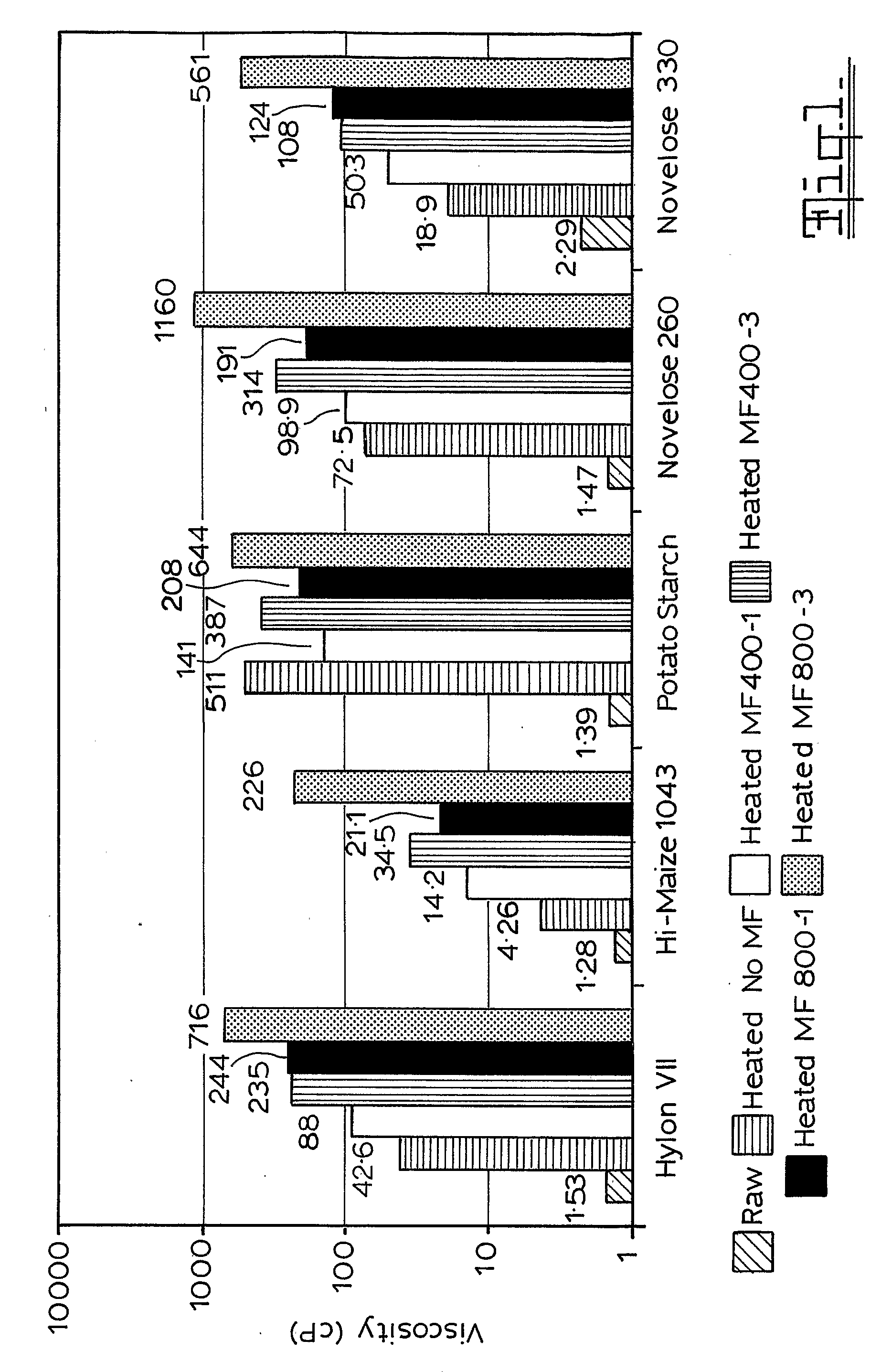

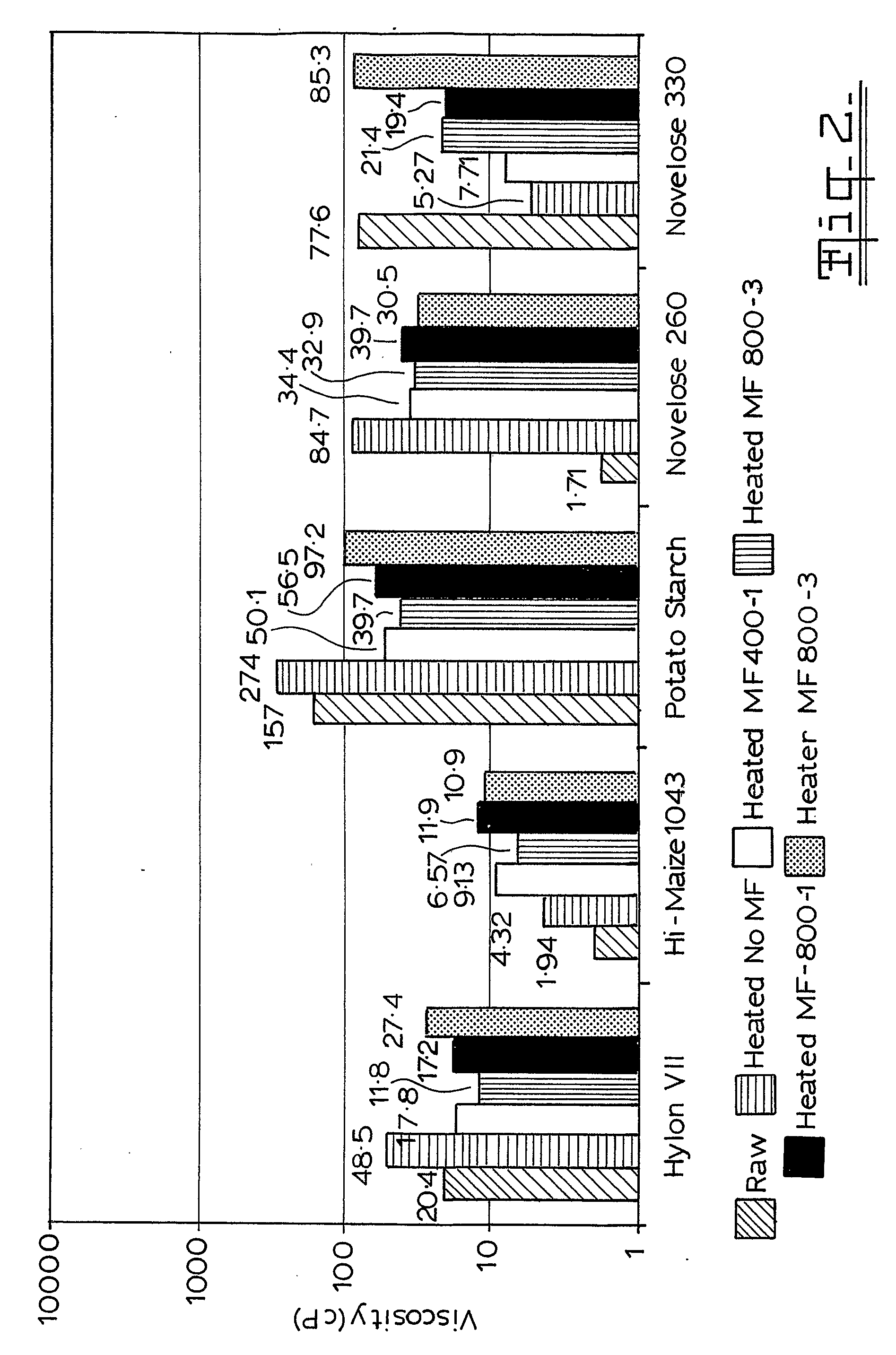

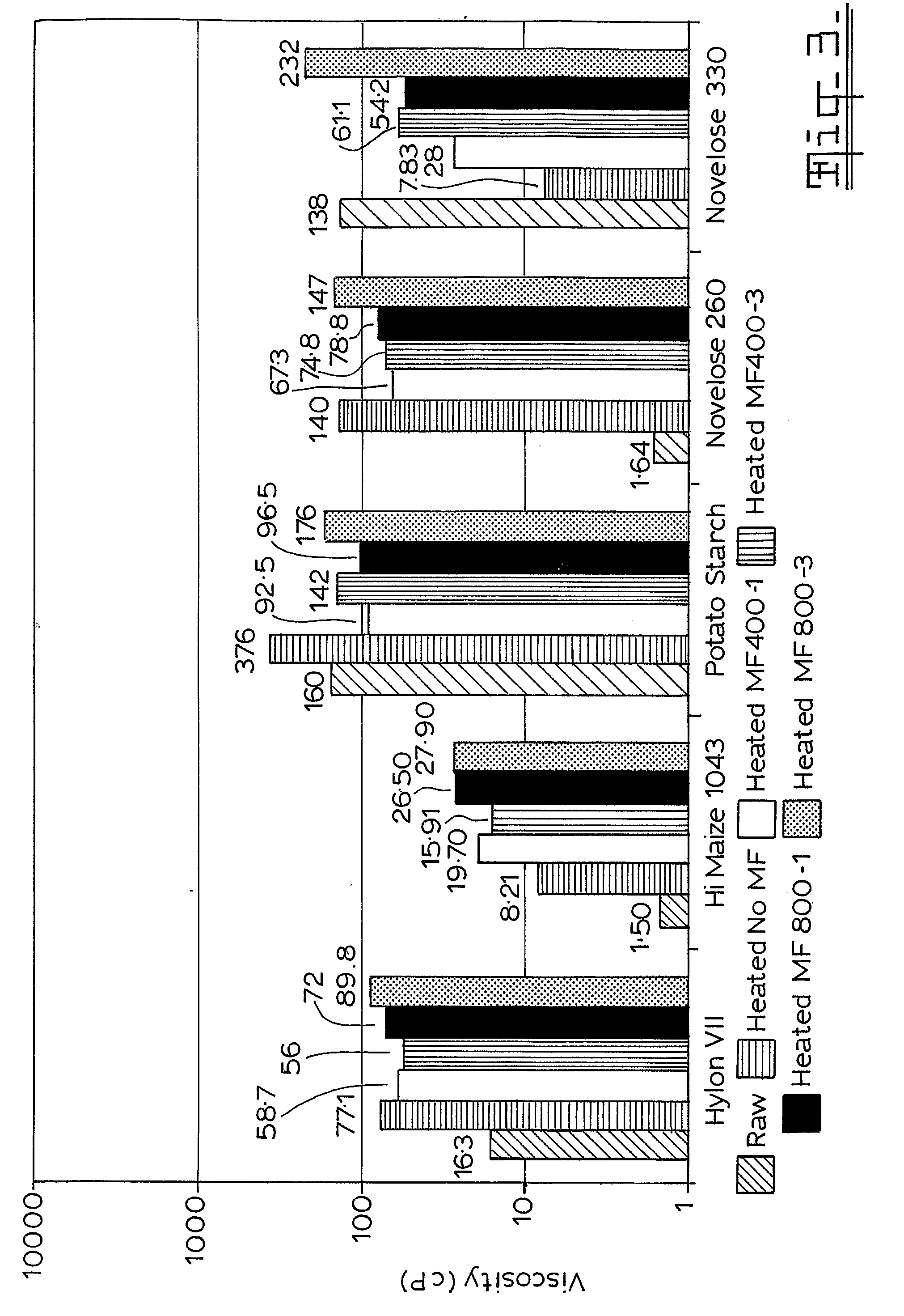

Starch Treatment Process

InactiveUS20070212475A1Alter performance characteristicReduced additiveConfectionerySweetmeatsFood gradeAdditive ingredient

High amylose starches are treated to retain resistance while improving water binding properties. Starch functionality is varied by pre-processing of starches by heating and microfluidisation, to create changes in product viscosity, resistant starch content, particle size and molecular weight. The treated starches produce food grade resistant starches which have the ability to bind water, build viscosity, gel and form films. They can be used as fat replacement ingredients.

Owner:COMMONWEALTH SCI & IND RES ORG

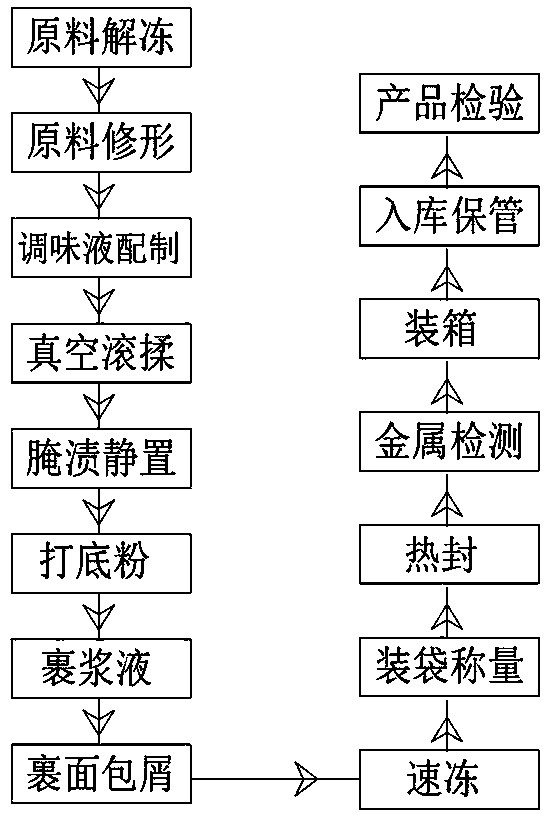

Rattan pepper-flavor quick-frozen chicken breast seasoning formula and using method thereof

ActiveCN103976324ARemove the sour tasteGreat tasteFood coatingFood preparationBiotechnologySodium bicarbonate

The invention discloses a rattan pepper-flavor quick-frozen chicken breast seasoning formula and a using method thereof. The seasoning formula comprises the following components by weight percent: 10%-30% of water, 1%-3% of isolated soybean protein, 0.5%-3% of starch, 1%-2% of edible salt, 0.5%-1.5% of white granulated sugar, 0.1%-1% of fermented soya bean powder, 0.1%-1% of glucose, 0.1%-1% of sodium glutamate, 0.1%-0.5% of sodium bicarbonate, 0.1%-0.4% of composite phosphate, 0.02%-0.2% of edible essence and 0.02%-3% of spice. The using method is as follows: using the seasoning formula to prepare a quick-frozen chicken breast product with better mouthfeel. By combining the medicated food materials such as rattan pepper, and the like, the chicken breast has refreshing and thick spicy flavor and is free of acor of the chicken breast, so that the meat is improved better on water binding capacity and meat tendering, and therefore, problems that the chicken breast is acerb in aftertaste, hard in meat, and not good in mouthfeel are solved.

Owner:辽宁禾丰食品有限公司

Method for producing aquatic granulated feed adhesive modified starch

InactiveCN101962414AWide adaptabilitySimple and fast operationClimate change adaptationAnimal feeding stuffSolubilityAdhesive

The invention discloses a method for producing aquatic granulated feed adhesive modified starch. Starch is taken as a raw material; an esterifying agent, a composite catalyst and an adhesion agent are added into the starch; and the mixture is subjected to dry-method high-temperature reaction, cooling and screening to prepare a finished product. By performing one-step catalytic esterification, catalytic degradation and adhesion action on the starch, the product has the advantages of cold water solubility, cohesiveness, water-binding capacity, stability and other comprehensive performance superior to those of the conventional natural plant starch adhesives, and capacities of overcoming defects of plant starch serving as a granulated feed adhesive, improving the feed stability in water, reducing the loss of nutrient components of the feed and improving the utilization rate of the feed. A process of dry-method chemical modification is adopted in the production process of the product and the method has the advantages of simple and convenient operation, high reaction efficiency, short period, no wastewater, environmental protection and light pollution.

Owner:广西农垦明阳生化有限公司

Stable unit dose compositions with high water content

ActiveUS20180216033A1Increase moisture contentHigh activityNon-ionic surface-active compoundsDetergent solventsWater dispersibleLinear alkylbenzene sulfonate

Stable unit dose compositions with high water content are provided. Such unit dose compositions include an aqueous composition having a water activity of from about 0.65 to about 0.95 and a water-soluble container formed from a water-soluble or water-dispersible film material. In one embodiment, the aqueous composition includes water in an amount of 25% to 70% by weight, a surfactant system, and a water binding agent. The surfactant system may include: (1) a linear alkylbenzene sulfonate (LAS) and / or an alcohol ethoxylsulfate (AES), (2) a non-ionic surfactant, and (3) a fatty acid. The unit dose compositions can prevent the enclosed liquid detergent composition with a high level of water content from dissolving or pre-maturely dispersing the water-soluble container.

Owner:HENKEL KGAA

Method for improving cereal dietary fiber solubility

The invention discloses a method for improving cereal dietary fiber solubility. The method utilizes lactobacillus fermentation treatment to replace traditional acid-alkali treatment, utilizes superhigh-pressure homogenization treatment to replace traditional processing treatment and finally prepares the finished product by spray drying. The method has the advantages that 1, lactic acid is produced by lactobacillus fermentation and dietary fibers are modified by the simulative chemical treatment method so that a dietary fiber structure is loose and the loose dietary fiber structure is conducive to follow-up processes; and the method has mild treatment conditions so that a water-binding capacity and functions of the dietary fibers are kept well; 2, a fragrance of metabolites such as lactic acid produced by lactobacillus fermentation covers a bad smell of raw materials such as bean dregs so that the fragrance of the product can be easily accepted by consumers; 3, the dietary fiber production method comprises the superhigh-pressure homogenization treatment based on fermentation treatment so that the particle size of the dietary fibers is reduced to less than 40 micrometers and roughness of the dietary fibers is not felt by consumers; and 4, the method has simple processes and can be industrialized easily.

Owner:朱琴

Edible fungus culture medium using tea resources as main materials and preparation method and application for edible fungus culture medium

ActiveCN102875232AIncrease added valueEfficient use ofFertilizer mixturesBiotechnologyBiological activation

The invention discloses an edible fungus culture medium using tea resources as main materials. The edible fungus culture medium consists of the following raw materials in percentage by weight: 60 to 80 percent of tea resource, 10 to 30 percent of quick nutrient source, 1 to 8 percent of pH value regulator, and 2 to 8 percent of functional water binding agent. The invention also discloses a preparation method for the edible fungus culture medium. According to the method, the activation of antigrowth factors and a sterilization process of base stock are used as key technologies, and the tea resources such as autumn and summer tea which is not harvested, trimmed branches and leaves in waste tea gardens, and a great amount of tea deep processing byproducts are treated. The invention also discloses the application of the edible fungus culture medium; and the edible fungus culture medium is mainly applied to the culturing of edible fungi such as mushrooms, agaric, and glossy ganoderma, so that the resources in different industries are efficiently integrated, the environment stress is relieved, and the low-carbon, high-efficiency and practical effects are achieved.

Owner:HANGZHOU TEA RES INST CHINA COOP

Wrapper for sesame balls, sesame balls, and method for making sesame balls

The invention discloses a wrapper for sesame balls, which is made of water, glutinous rice flour, deepfreeze oil, white sugar, glucose, wheat starch, food improver, dietary alkali and purple potatoes. The glucose in the wrapper causes fast coloration of the sesame balls in frying. The food improver is capable of effectively improving machining property and water binding capacity of the sesame balls and enables the coat of each sesame ball to be crisp, each sesame ball to be expanded and dough to be soft and glutinous, and the food improver also enables the sesame balls to less apt to crack in deepfreezing and storage. The deepfreeze oil enables tissue and gloss of the sesame balls to be improved, flavor and taste of the sesame balls to be improved, and shelf life of the deepfreezed sesame balls to be prolonged. In addition, a purple potato filling is made to lead the sesame balls to be more nutrient and delicious. The sesame balls are full, pure in coloration and good in taste, sesame seeds are evenly inlaid onto the outside of each sesame ball, the fried sesame balls taste soft, cool and smooth, the sesame balls are non-sticky to teeth when eaten, and the sesame balls belong to a delicious daily snack popular with young and old.

Owner:云鹤食品有限公司

Moulded body containing plastic and reinforced by natural fibres

InactiveUS20060258783A1Minimize further water absorptionSave time-consuming and expensive conditioningCosmetic preparationsToilet preparationsBiopolymerNatural fiber

The invention relates to a moulded body containing plastic and reinforced by natural fibres. Said moulded body is produced from fibrous plant or animal material containing residual water, at least one thermoplastic or duroplastic material, and at least one water-binding biopolymer and / or biomonomer, by means of plastic or thermoplastic deformation at a high temperature and / or high pressure, and then by shaping, preferably by means of extrusion. In spite of a residual water content of between 0.3 and 8 wt. %, the inventive moulded body is in an unexpanded form. The invention also relates to a method for producing said moulded body.

Owner:RETTENBACHER MARKUS

Stuffing modifier, dumpling and preparation methods thereof

InactiveCN107594323AKeep the clumping performancePreserve tendernessFood coatingGellan gumMonoglyceride

The invention relates to the technical field of food processing and specifically relates to a stuffing modifier, a dumpling and preparation methods thereof. The modifier is prepared from gellan gum, calcium hydrophosphate, xanthan gum, composite phosphate, monoglyceride and corn starch, wherein the gellan gum and the calcium hydrophsphate interact with each other to form gel; thus, under the situation that diced meat is utilized as a stuffing raw material, stuffing huddling performance can be still well kept, and granular sensation of meat stuffing is enhanced; the composite phosphate, the corn starch and the monoglyceride are added to effectively improve water binding capacity; thus, meat tenderness is kept, meat stuffing taste is prevented from being dry and skinny; meanwhile, product texture is improved, granular sensation is obvious when the meat stuffing is eaten, and the meat stuffing has elasticity; the xanthan gum is utilized as a thickener and can absorb moisture precipitatedfrom the meat stuffing, meat stuffing thickness is improved, and production operation is facilitated.

Owner:郑州研霖生物科技有限公司

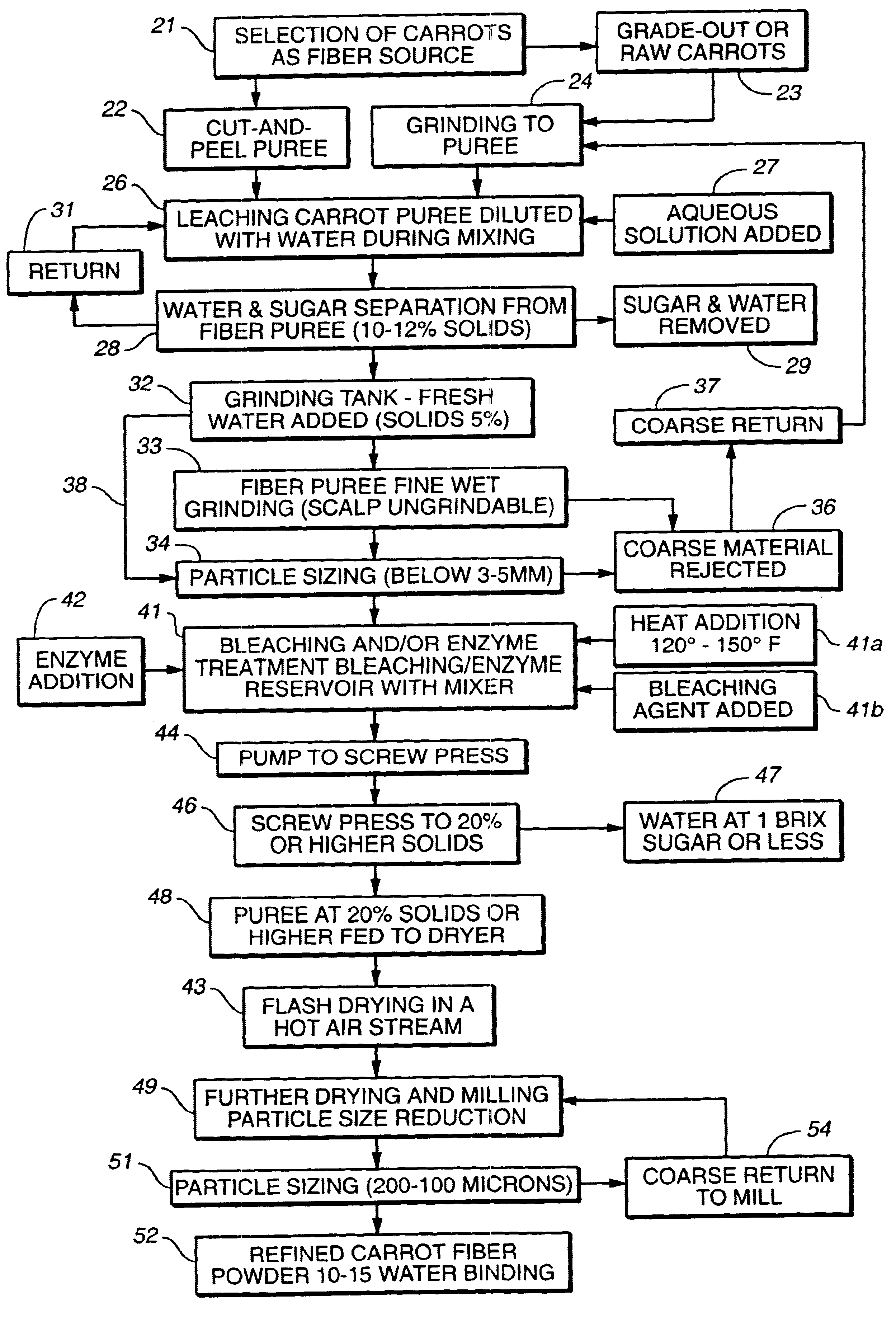

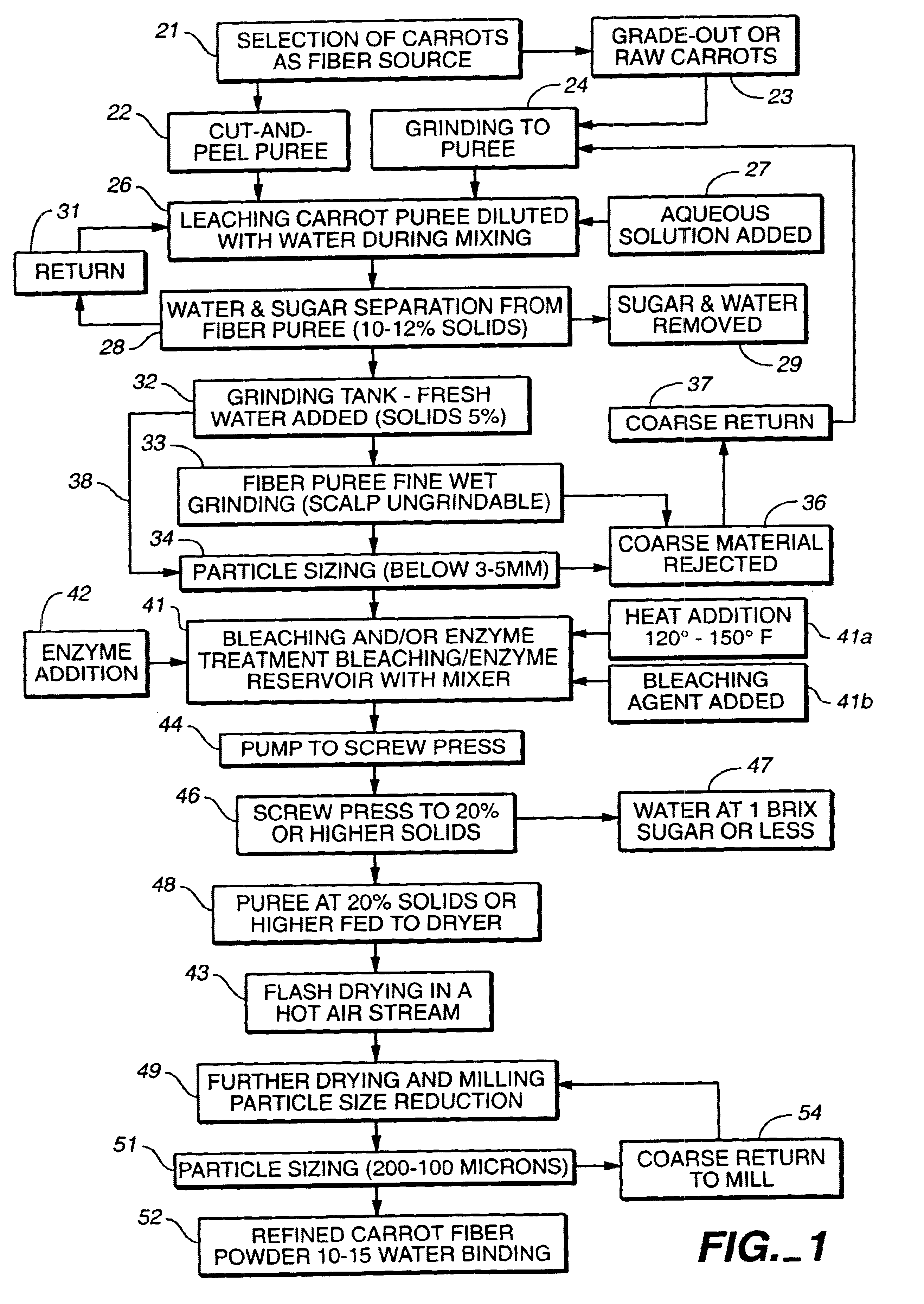

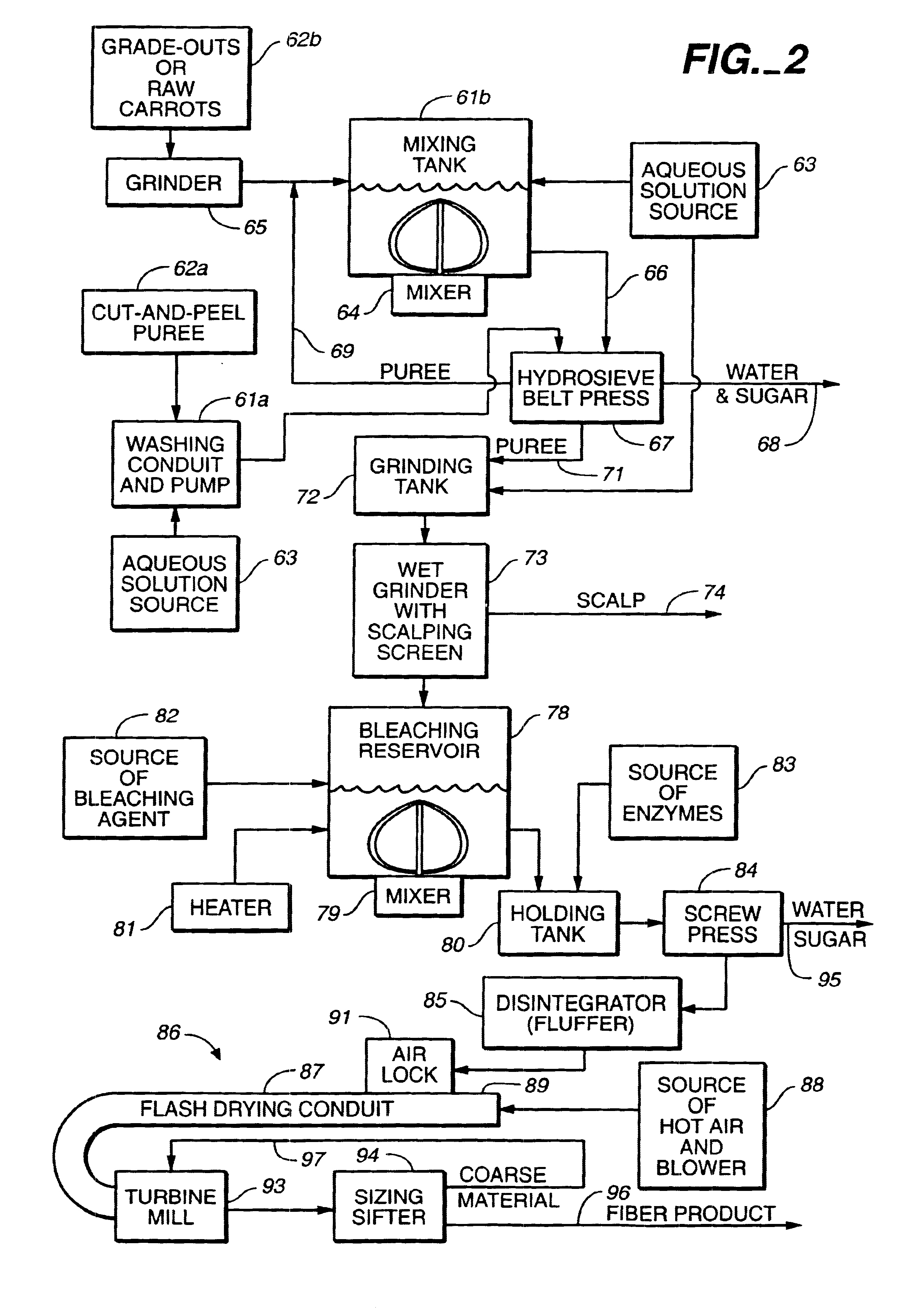

Process and apparatus for producing fiber product with high water-binding capacity and food product made therefrom

A dietary fiber product having a water absorption capacity of 8 to 15 times its weight and process for producing the same. The process includes the steps of selecting carrot material as the source for the fiber product (21), leaching a puree of the carrot material with an aqueous solution to remove the sugars from the carrot material (26), sizing the particles in the carrot material (34), bleaching the sized carrot material (41), reducing the moisture content of the bleached carrot material (46), flash drying the carrot material (43) and milling the dried carrot material to produce the dietary fiber product (49). A product produced by the process and apparatus for performing the process are disclosed, as are food products made from the carrot-based dietary fiber.

Owner:WM BOLTHOUSE FARMS

Seedling growing feeding block and preparation method thereof

InactiveCN106613488ANo pollution in the processAvoid pollutionSelf-acting watering devicesGrowth substratesSludgeBiology

The invention relates to the technical field of plant seedling growing instruments, in particular to a seedling growing feeding block. A feeding block body is prepare from, by weight, 30-45 parts of sludge, 15-25 parts of crop straw, 10-20 parts of excrements of livestocks, 8-18 parts of suaeda salsa, 5-15 parts of hawthorn residues, 5-15 parts of shiitake fungus residues, 5-15 parts of a water retention synergist, 5-13 parts of chitosan and 10-20 parts of Chinese medicine residues. The invention further relates to a preparation method of the feeding block. The method comprises the steps of material preparation, fermentation and compression molding. Various biological resources such as Chinese medicine residues and edible fungus residues are adopted as raw materials to be pressed into the feeding block, the feeding block contains enriched organic materials, humus and microelements, is abundant in nutrient and easy to degrade, and has the good water binding capacity.

Owner:WEIFANG YOURONG IND

Tender and crisp fish ball and making method thereof

The invention discloses a tender and crisp fish ball. The tender and crisp fish ball comprises the following components in parts by weight: 45-60 parts of minced fillet of frozen nemipterus virgatus, 0.5-2 parts of tender and crisp agent, 3-8 parts of pig fat, 20-30 parts of ice water, 0.1-0.5 part of composite phosphate, 1-3 parts of table salt, 0.1-1.0 part of aginomoto, 0.1-1.0 part of glucose, 0.1-1.0 part of seafood flavor and 5-20 parts of accessories. The invention also relates to a method for making the fish balls; the method has the following advantages: (1) the high-quality minced fillet of nemipterus virgatus is adopted so that the protein content is rich, the accessories of the product are simple, and the water binding capacity and freezing resistance of the product can be guaranteed without any starch and colloid; (2) the tender and crisp agent comprises protein as a major component, and is nutritive, healthy and harmless to a human body, and capable of keeping better tender and crisp taste of the product while supplementing the protein; and (3) a simple steaming process is adopted, so that the production cost of an enterprise is saved and the productive profit of the enterprise is increased.

Owner:SHANDONG HUIFA FOODS

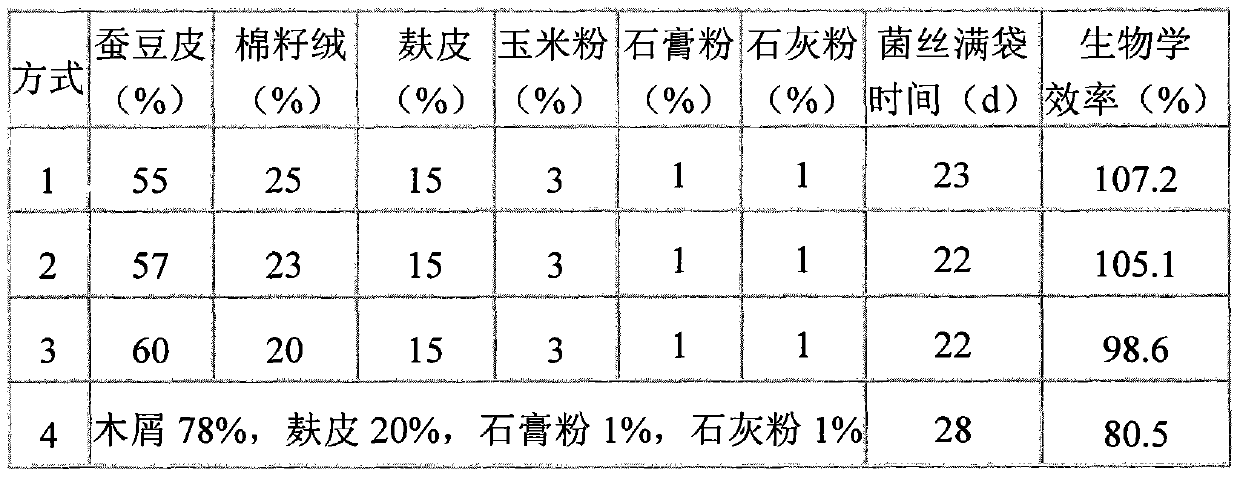

Pholiota nameko cultivation material compatibility and method for preparing cultivation material

InactiveCN103420723AIncrease carbon to nitrogen ratioNutritional balanceFertilizer mixturesPholiotaBroad beans

The invention relates to a pholiota nameko cultivation material which is characterized in that broad bean hulls are used as a main raw material, cotton linters, bran, corn flour, gypsum powder and the like are used as auxiliary materials, and the water content of the cultivation material is 65-66 percent. The invention also relates to a method for preparing the cultivation material. Compared with a saw dust cultivation material, the pholiota nameko cultivation material has the advantages that 1, the cultivation material is reasonable in matching of coarse sand fine grains, and the air permeability and water binding capacity of the cultivation material are increased, so that the growth rate of pholiota namekohypha is increased, and the bagful time is shortened; 2, the cultivation material has a reasonable carbon nitrogen ratio and balanced nutrition and promotes the growing development of sporocarp, and the yield is increased by 20-30 percent; 3, the cultivation raw-material channel is broadened, and the production cost is greatly reduced. The pholiota nameko cultivation material compatibility and the method have the social benefits that a broad bean hull substitution is used for cultivating pholiota nameko, one part of fungus-forest contradiction can be eased, waste is turned into wealth, and energy conservation and emission reduction are facilitated.

Owner:邬金飞

Plant-based fermented yogurt stabilizer and application thereof

InactiveCN110074193AImprove water holding capacityMaintain textureMilk substitutesFood sciencePhosphateFermentation

The invention provides a plant-based fermented yogurt stabilizer and application thereof, and belongs to the technical field of processing of fermented yogurt. The plant-based fermented yogurt stabilizer is prepared by compounding hydroxy propyl distarch phosphate, acetylated distarch phosphate, xanthan gum, gelatin, pectin, gellan gum and agar. The plant-based fermented yogurt stabilizer is addedbefore fermentation, thus the stability of the structure of fermented soybean milk is maintained under low-temperature cold storage conditions, precipitation of whey is avoided, good water binding capacity and the texture and taste of the fermented soybean milk are maintained, the rough texture of ordinary fermented soybean milk is improved, the fermented soybean milk tastes delicate and smooth,and not only is special bean flavor of soybeans maintained, but also unpleasant beany flavor is removed.

Owner:郑州康晖食品科技有限公司

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com