Bacterial cellulose/chitosan composite sponge dressing and preparation method thereof

A bacterial cellulose and composite sponge technology, applied in dressings, viscous dressings, medical science and other directions, can solve the problems of limited liquid absorption capacity, easy deformation, insufficient strength, etc., and achieves strong shape maintenance ability, high tensile strength, and preparation Simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

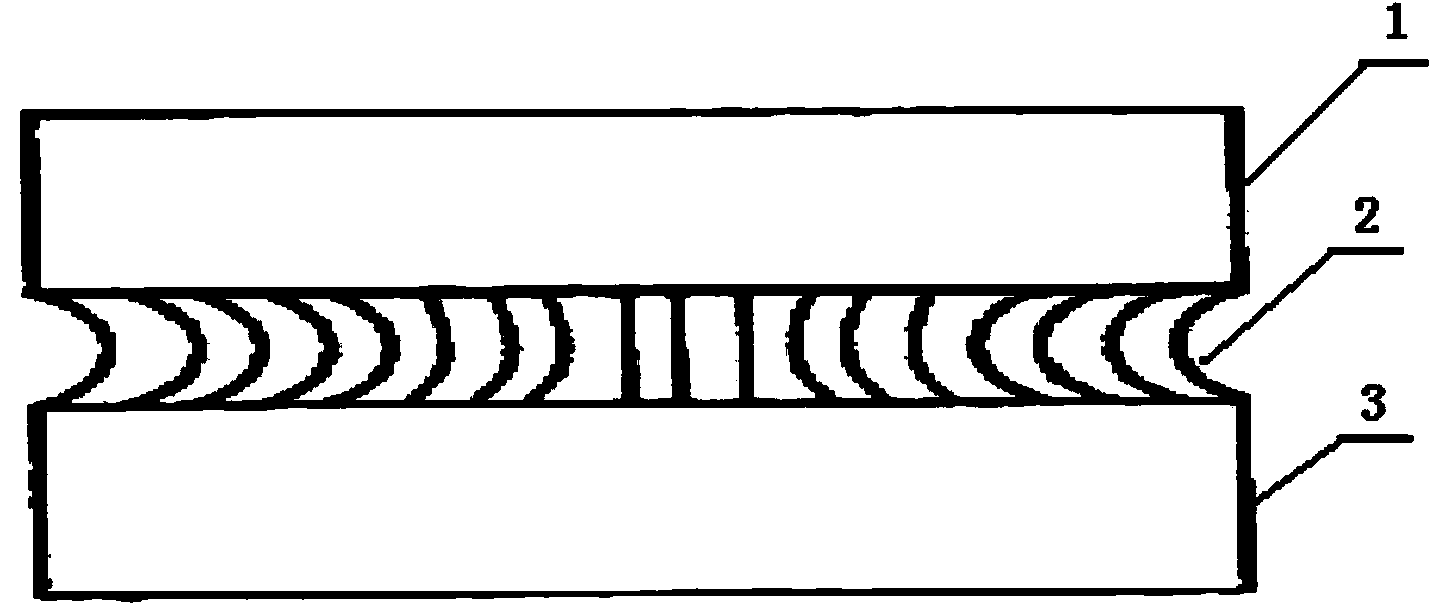

Image

Examples

Embodiment 1

[0030] The bacterial cellulose membrane with a degree of polymerization of 800 was boiled with 1% NaOH aqueous solution at 80 °C for 45 min, then fully washed with distilled water until neutral (pH=7.0), and vacuum-dried at 75 °C for 12 h. Use a ball mill to grind to a length of 6.5mm and a specific surface area of 500m 2 / g of fibrids.

[0031] Chitosan sheet is placed in 2% (mass fraction) acetic acid, let stand for more than 4 hours, then add glacial acetic acid and make wherein acetic acid content reaches 4%, be dubbed as the shell that content is 3% (mass fraction) through stirring polysaccharide solution. The bacterial cellulose fibrids are added to the chitosan solution in an amount of 15% of the dry weight of the chitosan, and left to stand for defoaming.

[0032] The above-mentioned chitosan solution added with bacterial cellulose fibrids was poured into a flat-bottomed shallow dish, frozen in a refrigerator at -20°C for 7-9 hours, and then freeze-dried to obtain ...

Embodiment 2

[0035] The bacterial cellulose membrane with a degree of polymerization of 1000 was boiled with 1% NaOH aqueous solution at 80 °C for 45 min, then washed with distilled water until neutral (pH = 7.0), and vacuum-dried at 75 °C for 12 h. Use a ball mill to grind to a length of 5.5mm and a specific surface area of 600m 2 / g of fibrids.

[0036] The chitosan sheet was placed in 3% (mass fraction) acetic acid, left to stand for more than 4 hours, and then stirred to form a chitosan solution with a content of 3% (mass fraction). The bacterial cellulose fibrids are added to the chitosan solution in an amount of 10% of the dry weight of the chitosan, and left standing for defoaming.

[0037] The above-mentioned chitosan solution added with bacterial cellulose fibrids was poured into a flat-bottomed shallow dish, frozen in a refrigerator at -20°C for 7-9 hours, and then freeze-dried to obtain a bacterial cellulose / chitosan composite sponge.

[0038] The bacterial cellulose / chitosa...

Embodiment 3

[0040] The bacterial cellulose membrane with a degree of polymerization of 3000 was boiled with 1% NaOH aqueous solution at 80 °C for 45 min, then washed with distilled water until neutral (pH = 7.0), and vacuum-dried at 75 °C for 12 h. Use a ball mill to grind to a length of 9.5mm and a specific surface area of 400m 2 / g of fibrids.

[0041] Chitosan tablets were placed in 1-butyl-3-methylimidazolium chloride [C 4 In MIM]Cl, let stand more than 8 hours, be made into the chitosan solution that content is 9% (mass fraction) through stirring. The bacterial cellulose fibrids are added to the chitosan solution in an amount of 20% of the dry weight of the chitosan, and left to stand for defoaming.

[0042] The above-mentioned chitosan solution added with bacterial cellulose fibrids was poured into a flat-bottomed shallow dish, frozen in a refrigerator at -20°C for 7-9 hours, and then freeze-dried to obtain a bacterial cellulose / chitosan composite sponge.

[0043] The bacterial c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com