Preparation method for soluble dietary fiber with apple pomace as raw material

A technology for dietary fiber and apple pomace, which is applied in food preparation, food science, application and other directions, can solve the problems of environmental pollution, high degree of hydrolysis, low yield of soluble fiber, etc., and achieves reduction of production cost, simple preparation process, and environmental benefits. protective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] (1) Drying and puffing of apple pomace: put the apple pomace in a blast drying oven and dry until the water content is ≯7%, then take out the dried apple pomace and add water to stir, and after it is evenly stirred, use an extruder to puff it, and add water The weight is 20% of the weight of apple dry residue;

[0020] (2) soaking to extract soluble dietary fiber:

[0021] a. The puffed apple pomace is crushed to 50 meshes, then the apple pomace is dissolved in water at a weight ratio of 1:30 by the apple pomace and water, and 1.0% of the mass of the apple pomace is added simultaneously with α-amylase and 2.0% For papain, soak for 1 hour at 50°C and pH 6.8, then heat and boil for 5 minutes to inactivate protease and amylase;

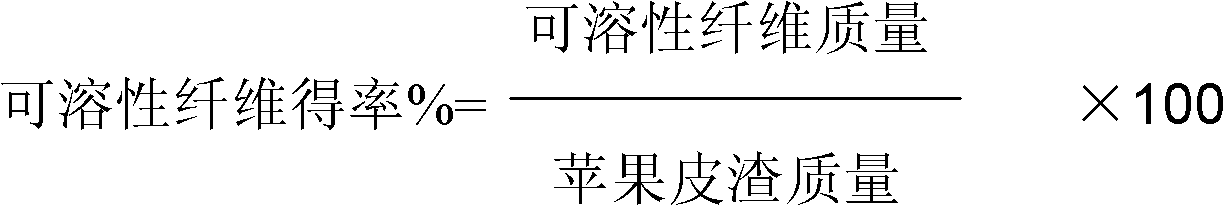

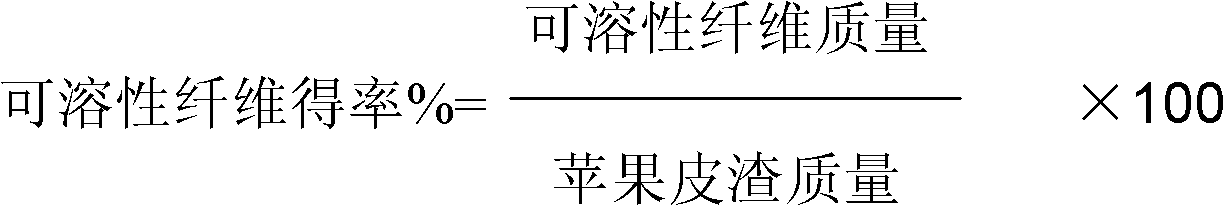

[0022] b. Filter the above soaking liquid to obtain the filtrate and filter residue, add 95% ethanol solution 4 times the volume of the filtrate to the filtrate, let it stand for 1 hour and then filter it with suction, and dry the obtained solubl...

Embodiment 2

[0029] (1) Drying and puffing of apple pomace: put the apple pomace in a blast drying oven and dry until the water content is ≯7%, then take out the dried apple pomace and add water to stir, and after it is evenly stirred, use an extruder to puff it, and add water The weight is 23% of apple dry residue weight;

[0030] (2) soaking to extract soluble dietary fiber:

[0031] a. The puffed apple pomace is crushed to 60 meshes, then the apple pomace is dissolved in water at a weight ratio of 1:40 by the apple pomace and water, and 1.0% of the mass of the apple pomace is added simultaneously with α-amylase and 2.0% For papain, soak for 1 hour at 55°C and pH 6.5, then heat and boil for 3 minutes to inactivate protease and amylase;

[0032] b. Filter the above soaking liquid to obtain the filtrate and filter residue, add 95% ethanol solution 4 times the volume of the filtrate to the filtrate, let it stand for 1 hour and then filter it with suction, and dry the obtained soluble cellu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Water holding capacity | aaaaa | aaaaa |

| Expansion force | aaaaa | aaaaa |

| Water holding capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com