Patents

Literature

240 results about "High amylose" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-Amylose Foods. Some foods high in amylose include: (44) Seeds, nuts and legumes (soak before cooking to remove harmful antinutrients like lectin) Some bread products (stick to sprouted or whole grain options) Corn products (be careful to only eat only organic, non-GMO corn) Oats and barley.

Probiotic compositions

PCT No. PCT / AU95 / 00613 Sec. 371 Date Jun. 17, 1997 Sec. 102(e) Date Jun. 17, 1997 PCT Filed Sep. 18, 1995 PCT Pub. No. WO96 / 08261 PCT Pub. Date Mar. 21, 1996A probiotic composition is disclosed which is particularly useful for inclusion in food products to enhance their nutritional value. The composition comprises one or more probiotic microorganisms such as Bifidobacterium and a carrier to transport the microorganisms to the large bowel or other regions of the gastrointestinal tract. The carrier is a modified or unmodified resistant starch, particularly a high amylose starch, which acts as a growth or maintenance medium for microorganisms in the large bowel or other regions of the gastrointestinal tact.

Owner:PENFORD HLDG +1

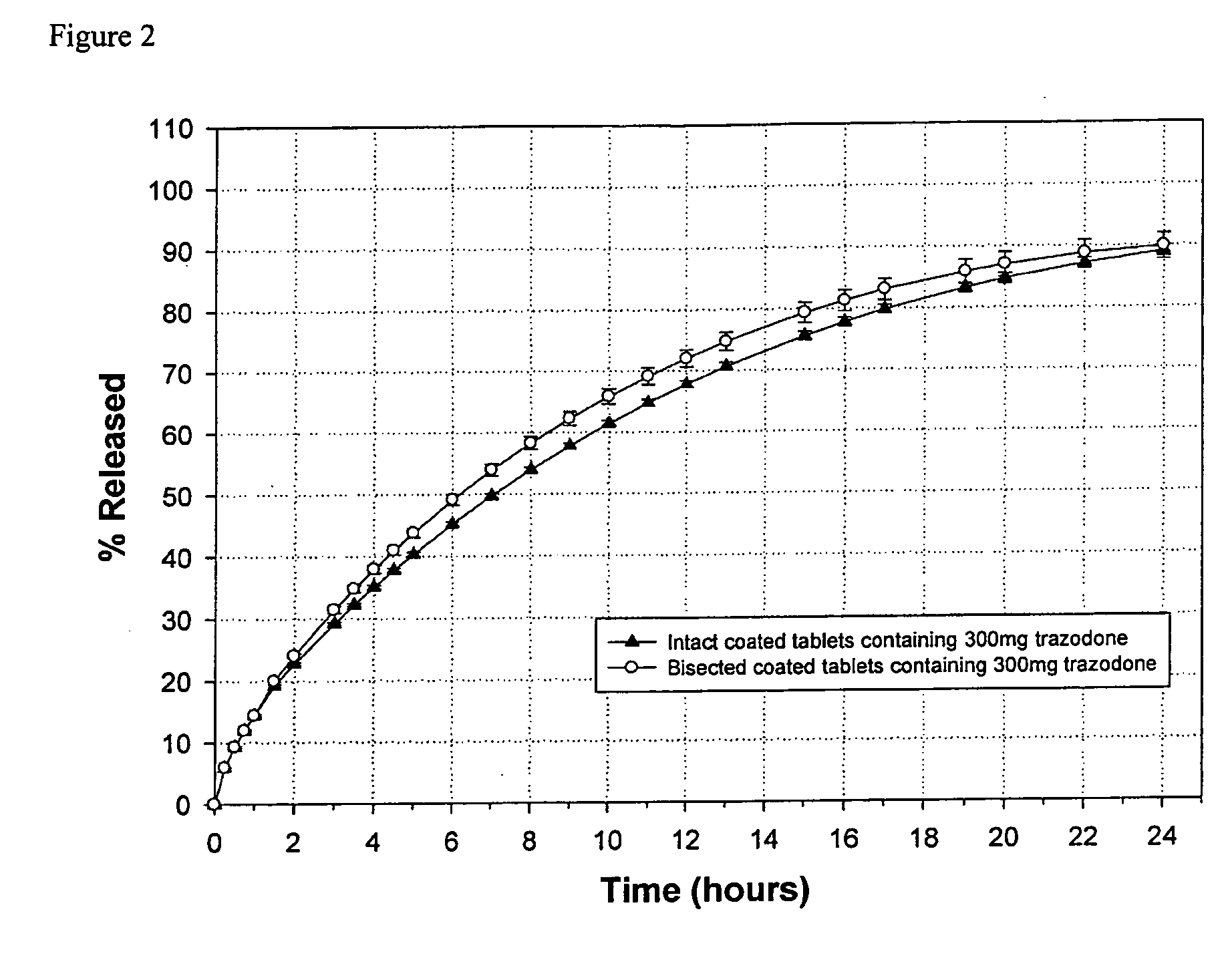

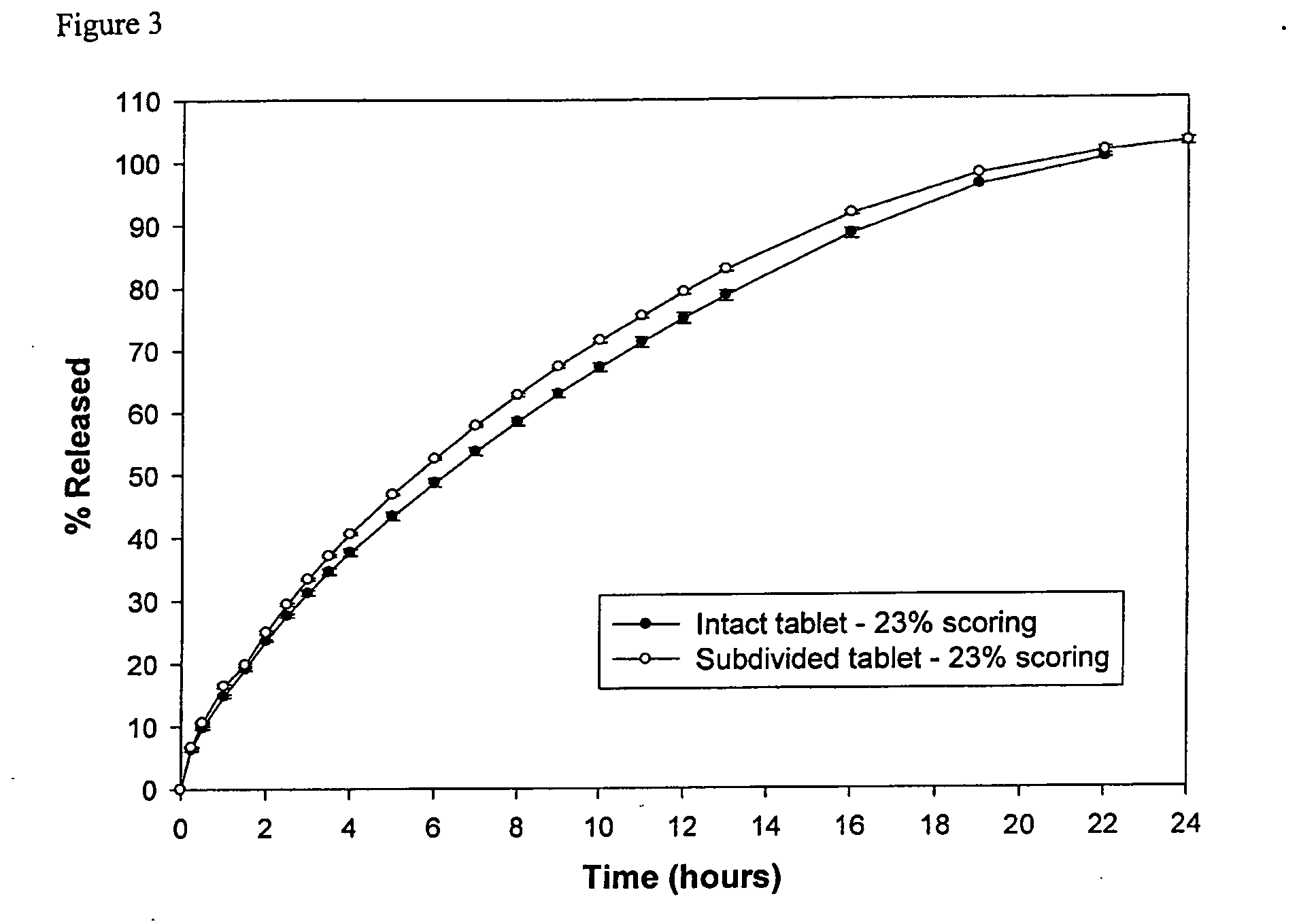

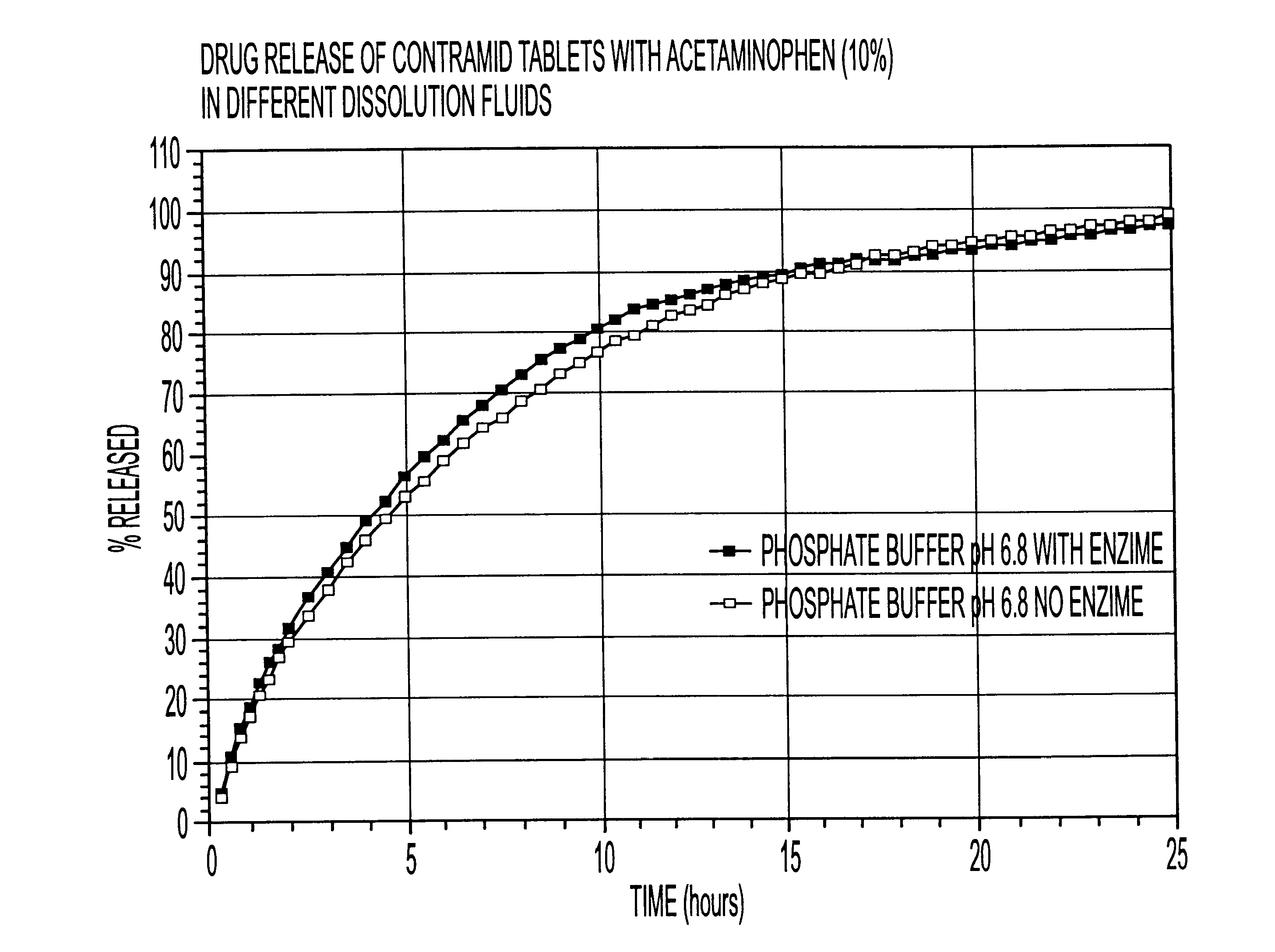

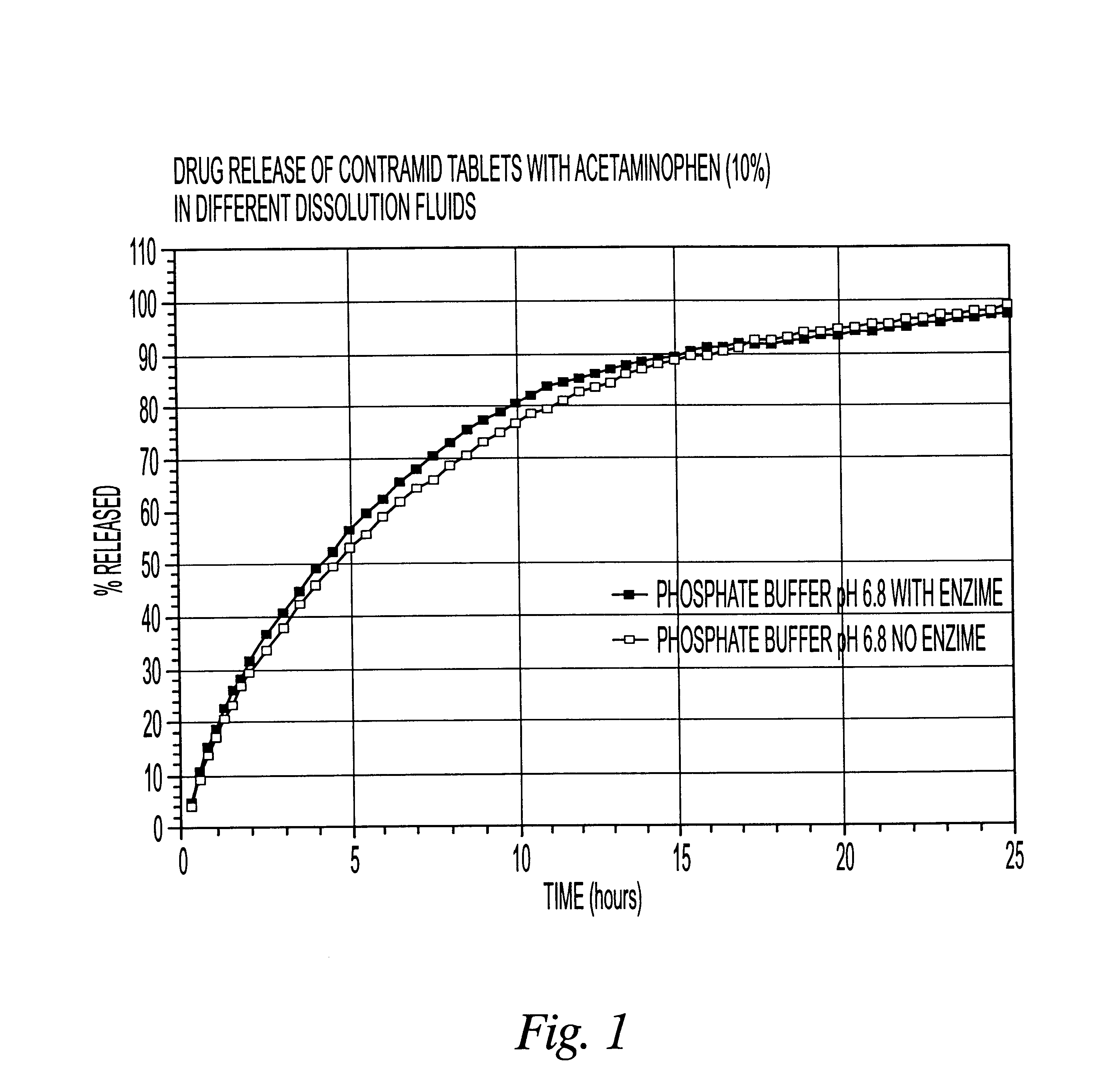

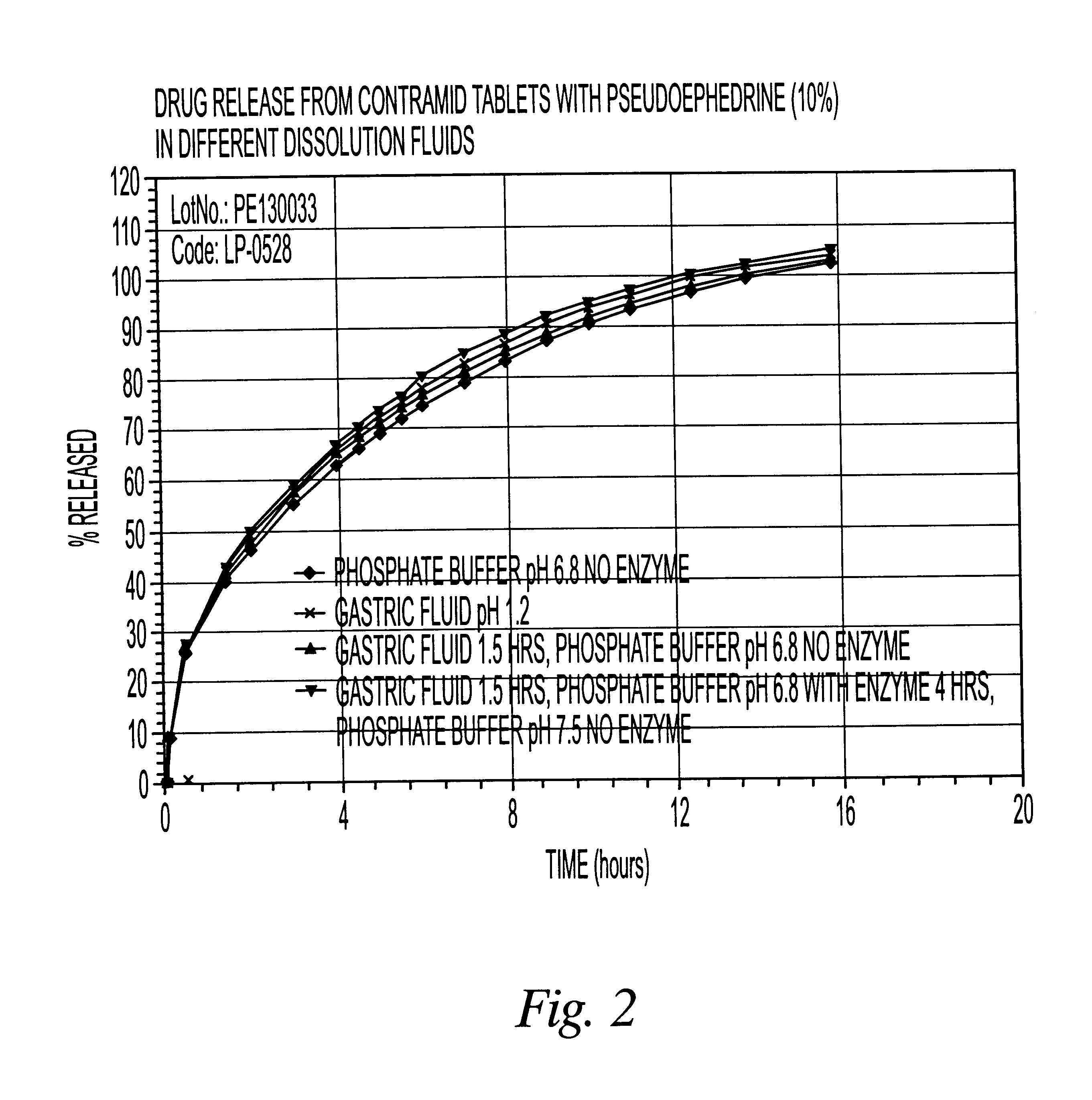

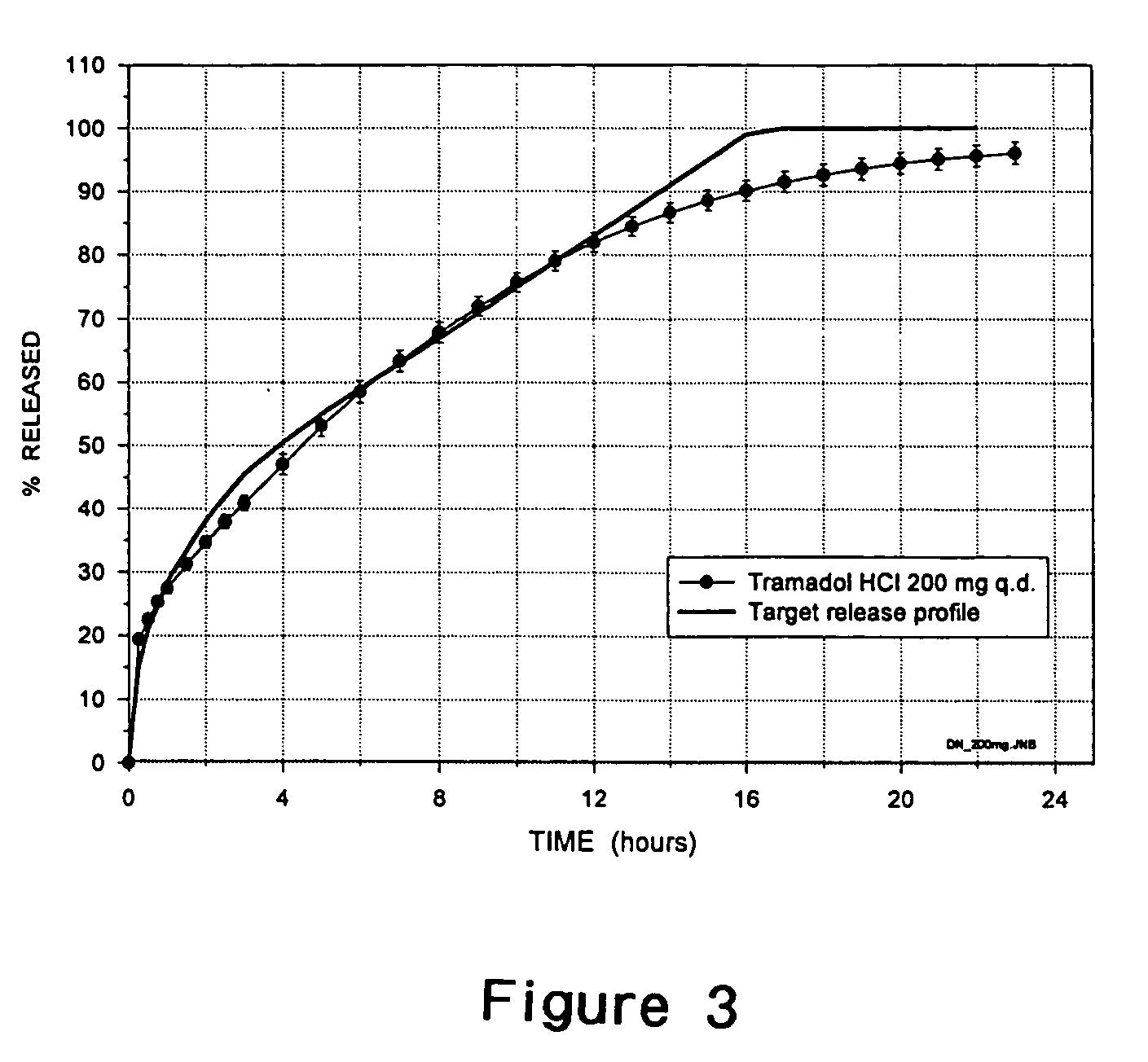

Sustained drug release compositions

ActiveUS20070128269A1Accurately and precisely deliver the appropriate amount of drugBiocideNervous disorderCross-linkActive agent

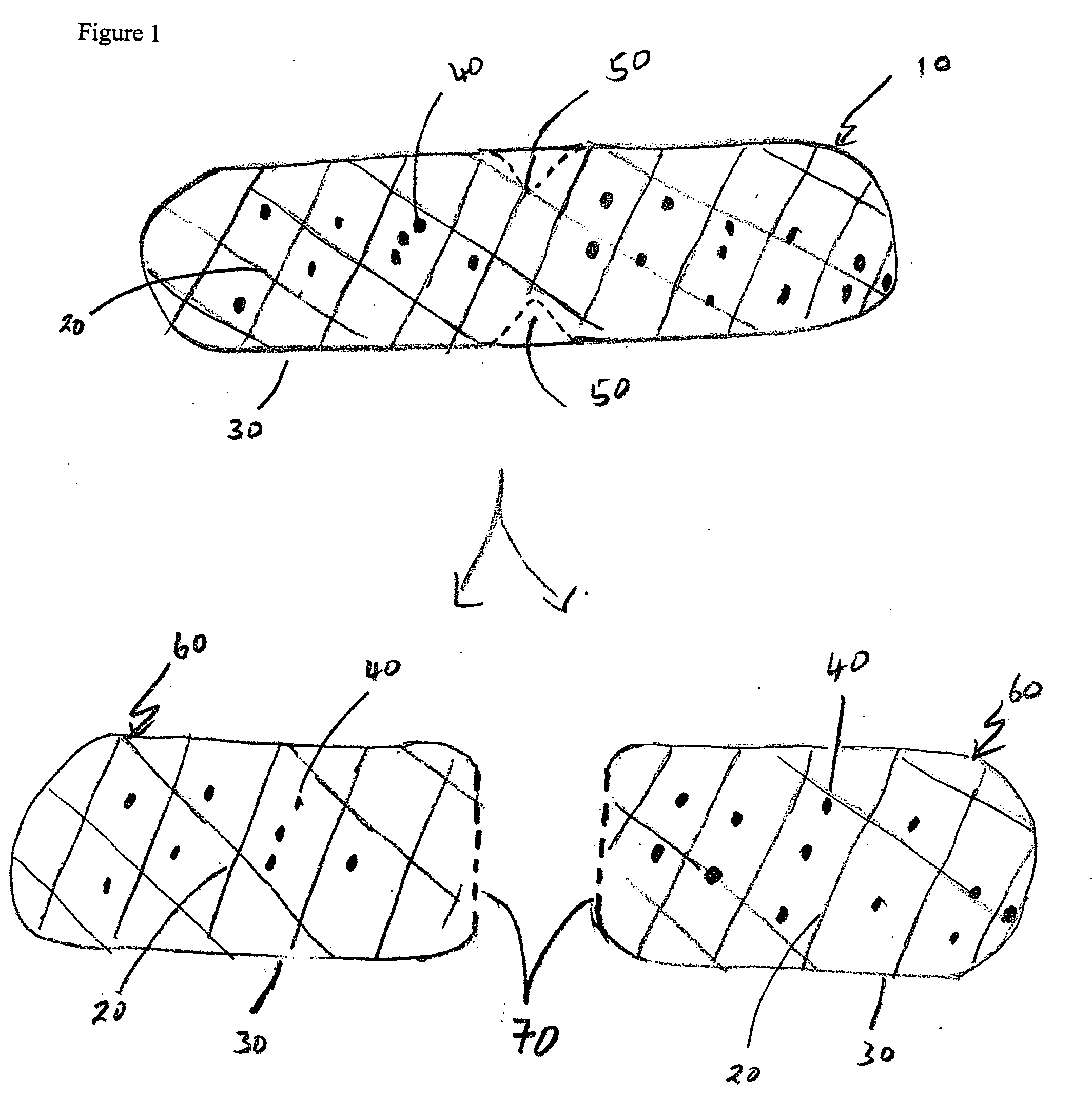

The invention relates to a sustained release formulation for delivering one or more pharmaceutically active agents. The formulation comprises cross-linked high amylose starch and at least one pharmaceutically active agent, and optionally can be subdivided into smaller dosage forms where the smaller dosage forms have substantially the same sustained release properties as the formulation from which they were derived. The formulations can provide sustained release for up to at least 24 hours, and because of their divisability permits a recipient of the active agent or the person administering the active agent to titrate the dosage of the agent.

Owner:ANGELINI PHARM INC

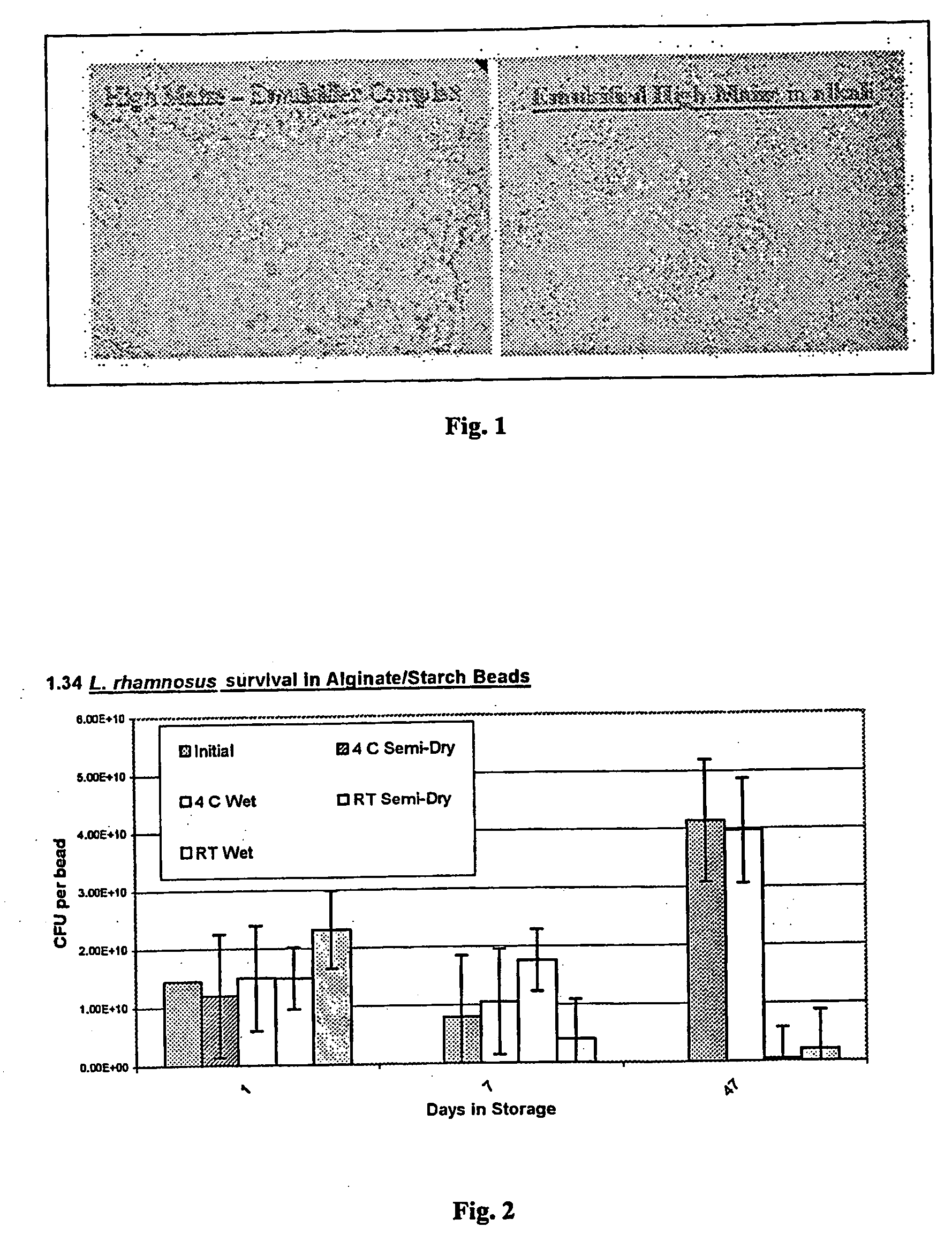

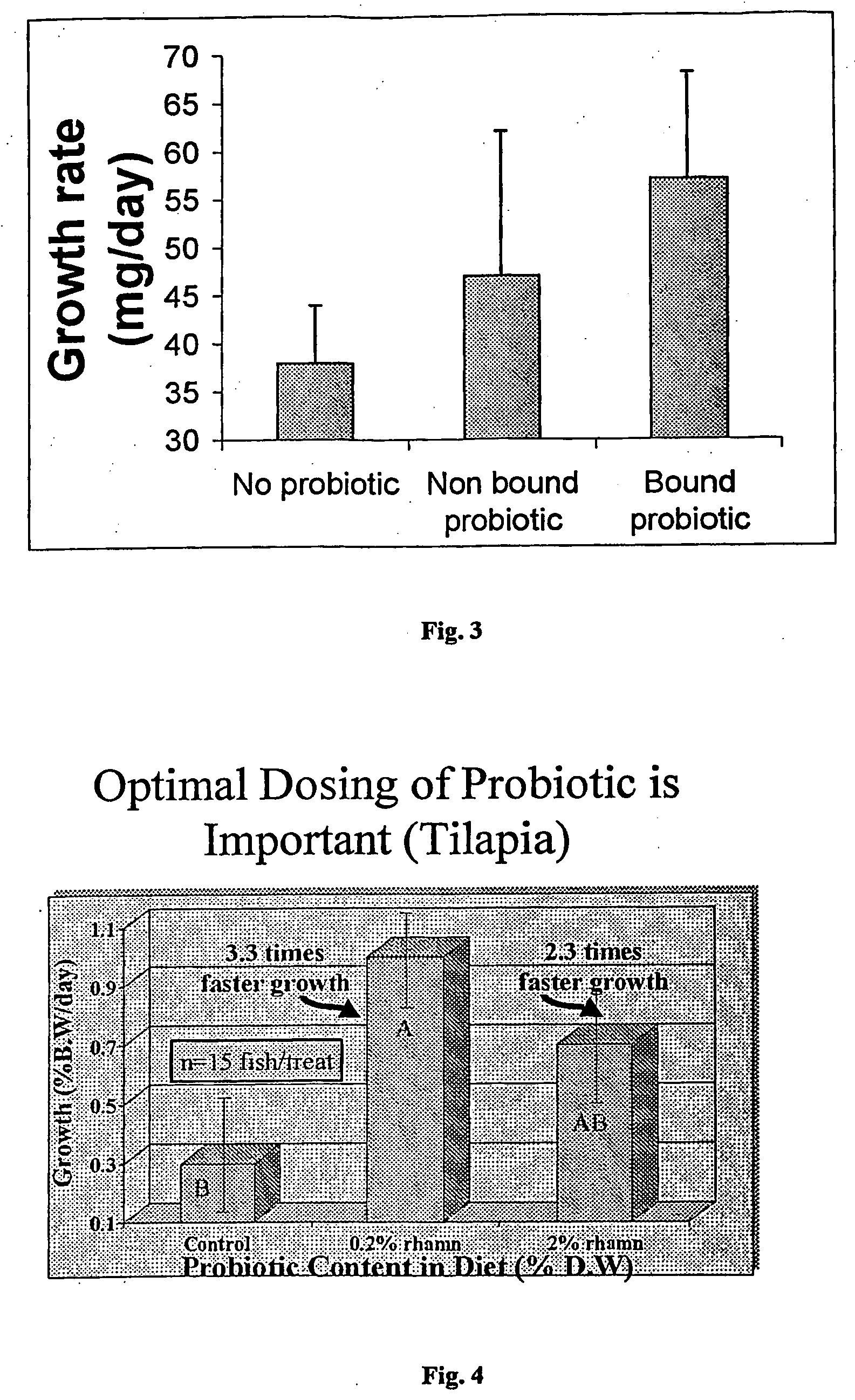

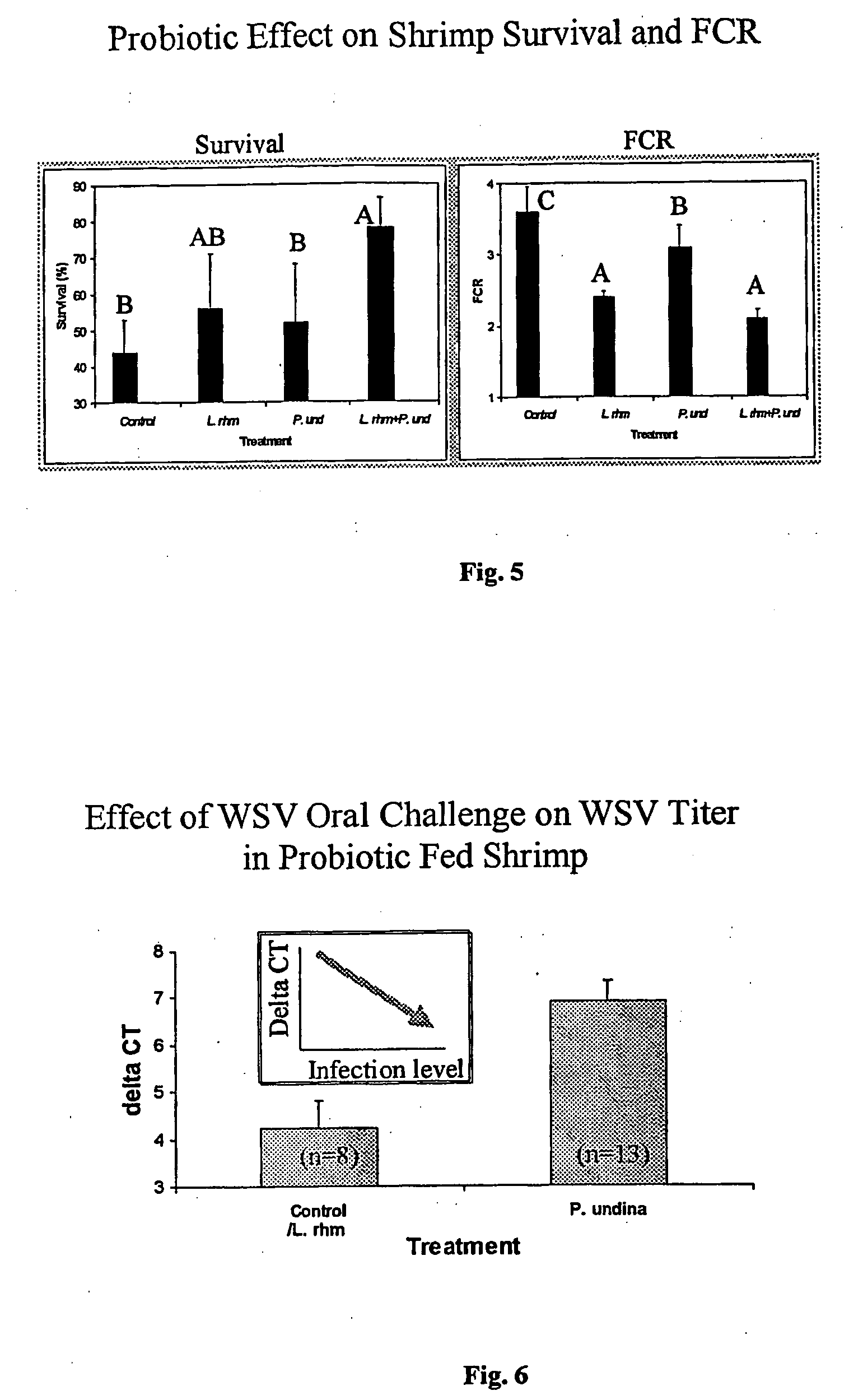

Nutraceuticals and method of feeding aquatic animals

A delivery vehicle for bioactive agents and live probiotic microbes to aquatic animals protects the bioactive compounds and microbes from digestion and destruction in the animal stomach. It provides for controlled release of bioactive agents and live probiotic microbes to aquatic animals in the form of dry or wet beadlets with essential nutrients and attractants bound with soluble starch and cross-linked alginate. The bioactive agents and live probiotic microbes can be bound with emulsified high-amylose starch and embedded in the beadlets in the form of microparticles.

Owner:INTERVET INC

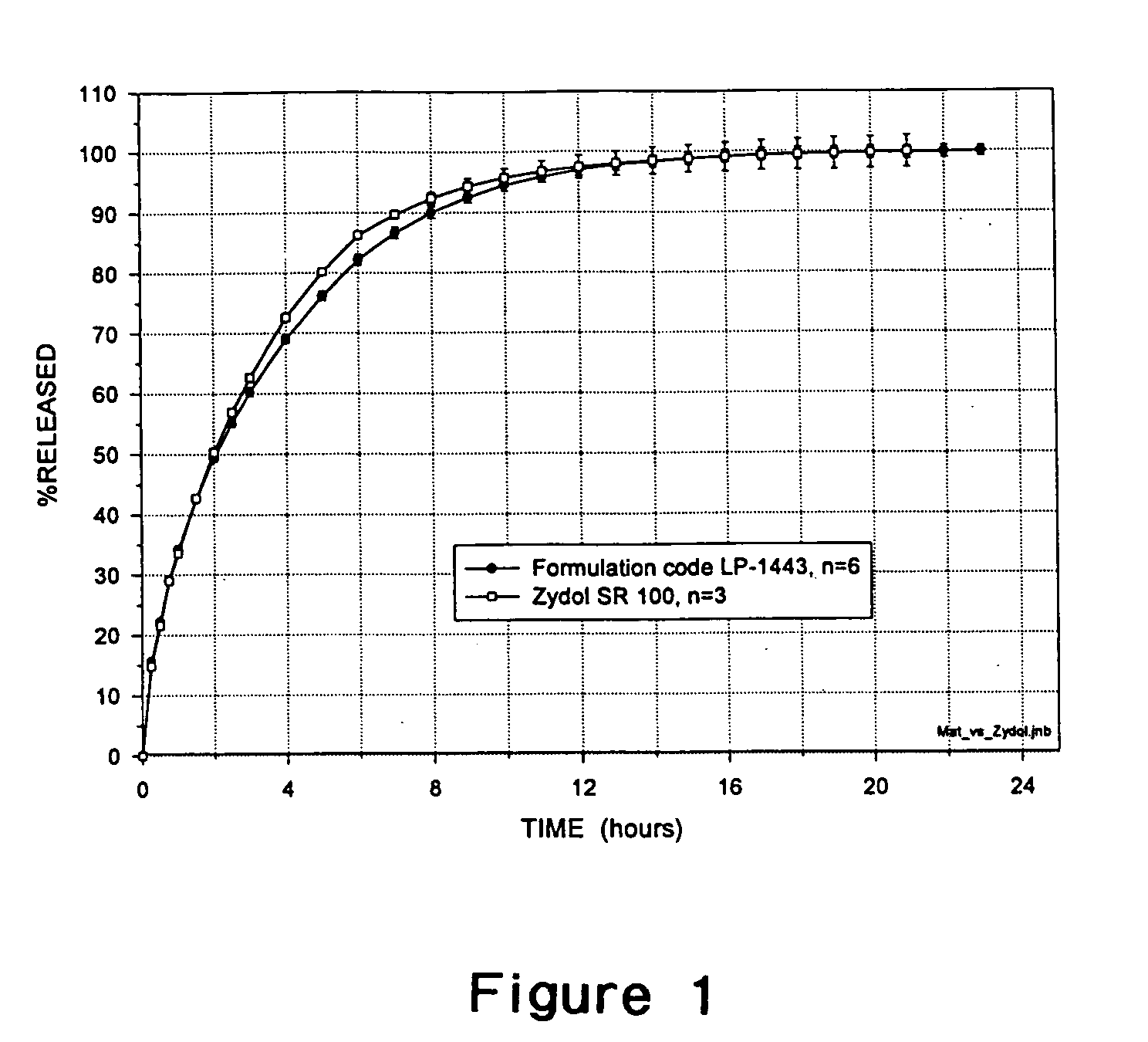

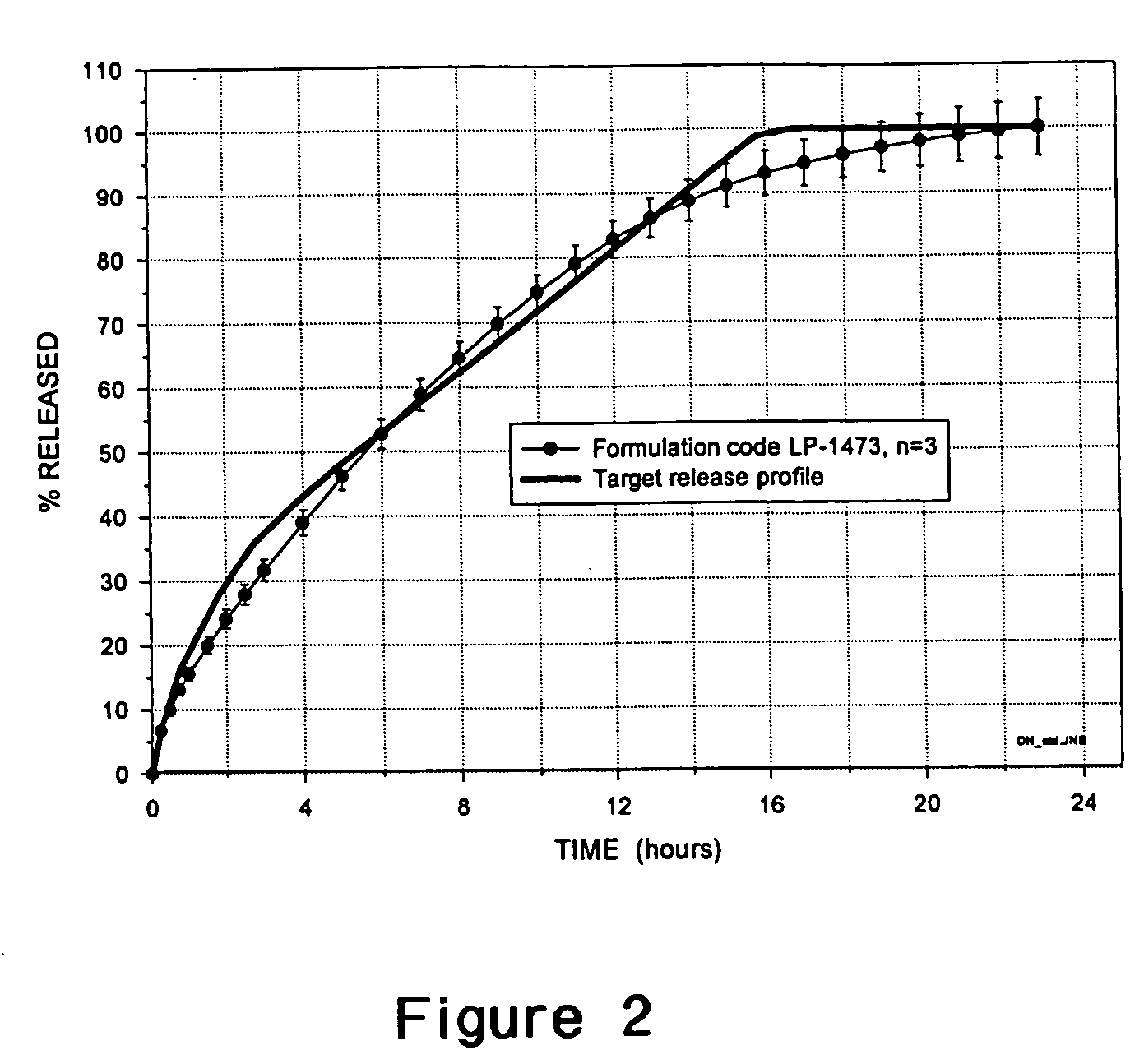

Cross-linked high amylose starch resistant to amylase as a matrix for the slow release of biologically active compounds

The present invention is concerned with a solid slow release oral pharmaceutical dosage unit resistant to amylase which comprises a solid dosage unit made up of an admixture of a therapeutic dosage of an orally effective pharmaceutical product, an optional polysaccharide or polyol, and cross-linked high amylose starch, wherein the cross-linking of the high amylose starch has been carried out with a covalent or non-covalent cross-linking agent with from about 0.1 g to about 30 g of cross-linking agent per 100 g of high amylose starch.

Owner:LABOPHARM INC

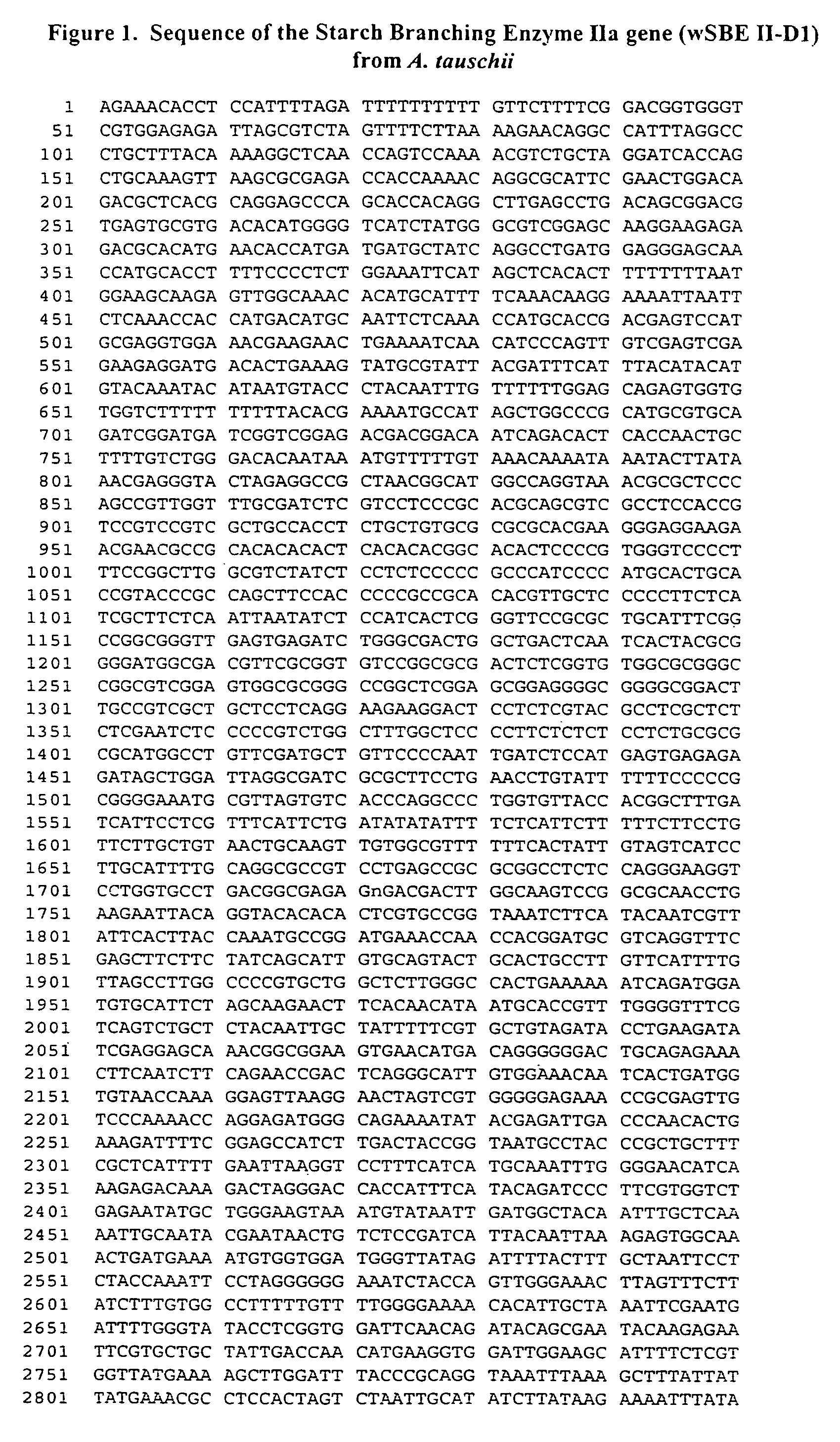

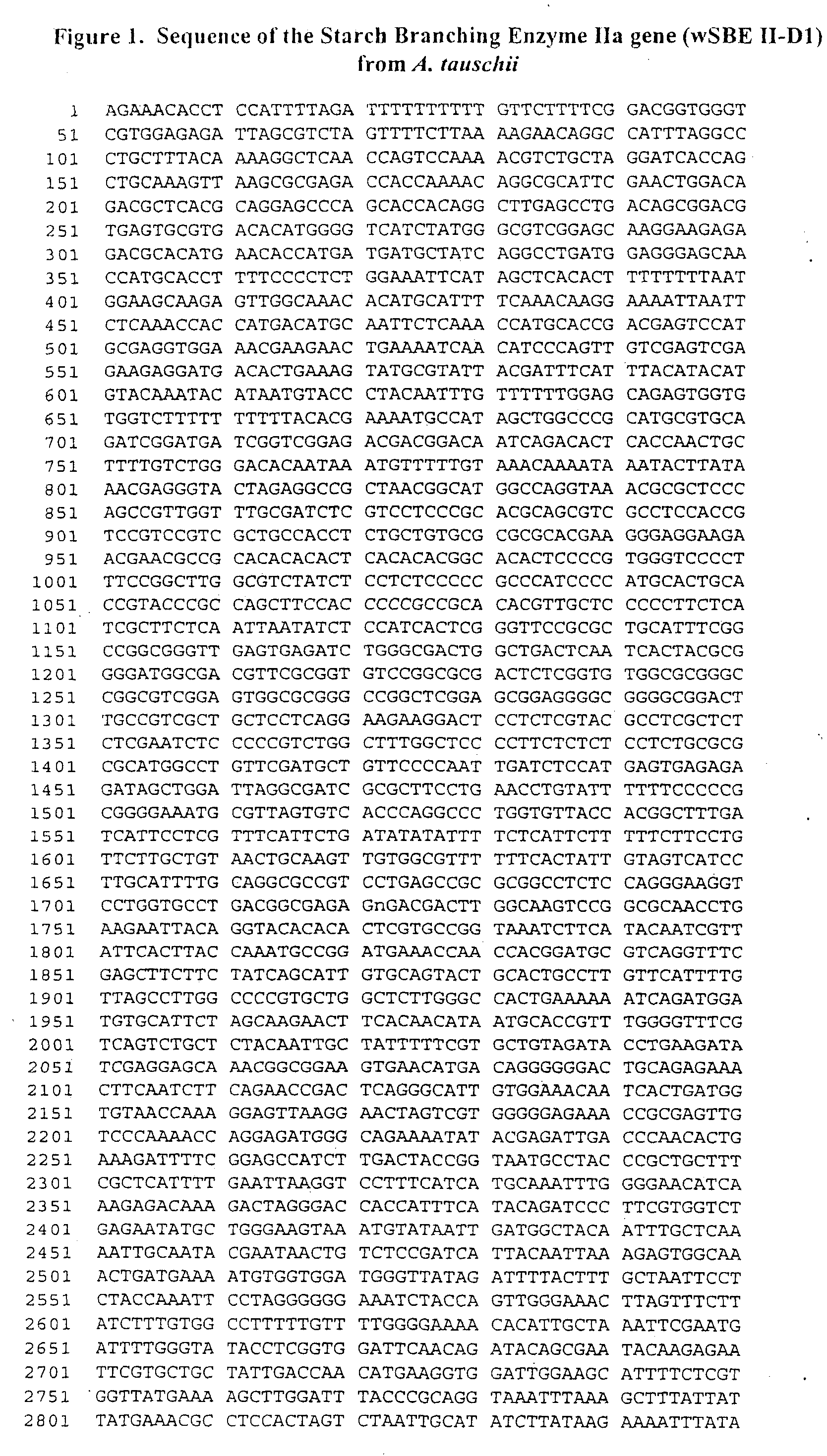

Wheat with altered branching enzyme activity and starch and starch containing products derived therefrom

Wheat having a reduced level of SBEIIa activity, that may have a relative high amylose content. Wheat having a mutant SBEIIa gene in the A genome. The wheat might additionally have reduced levels of SBEIIb activity. The wheat grain of this invention can be of a non-shrunken phenotype despite a lesion in the amylopectin synthesis pathway, and may also have a high relative amylose content.

Owner:ARISTA CEREAL TECH

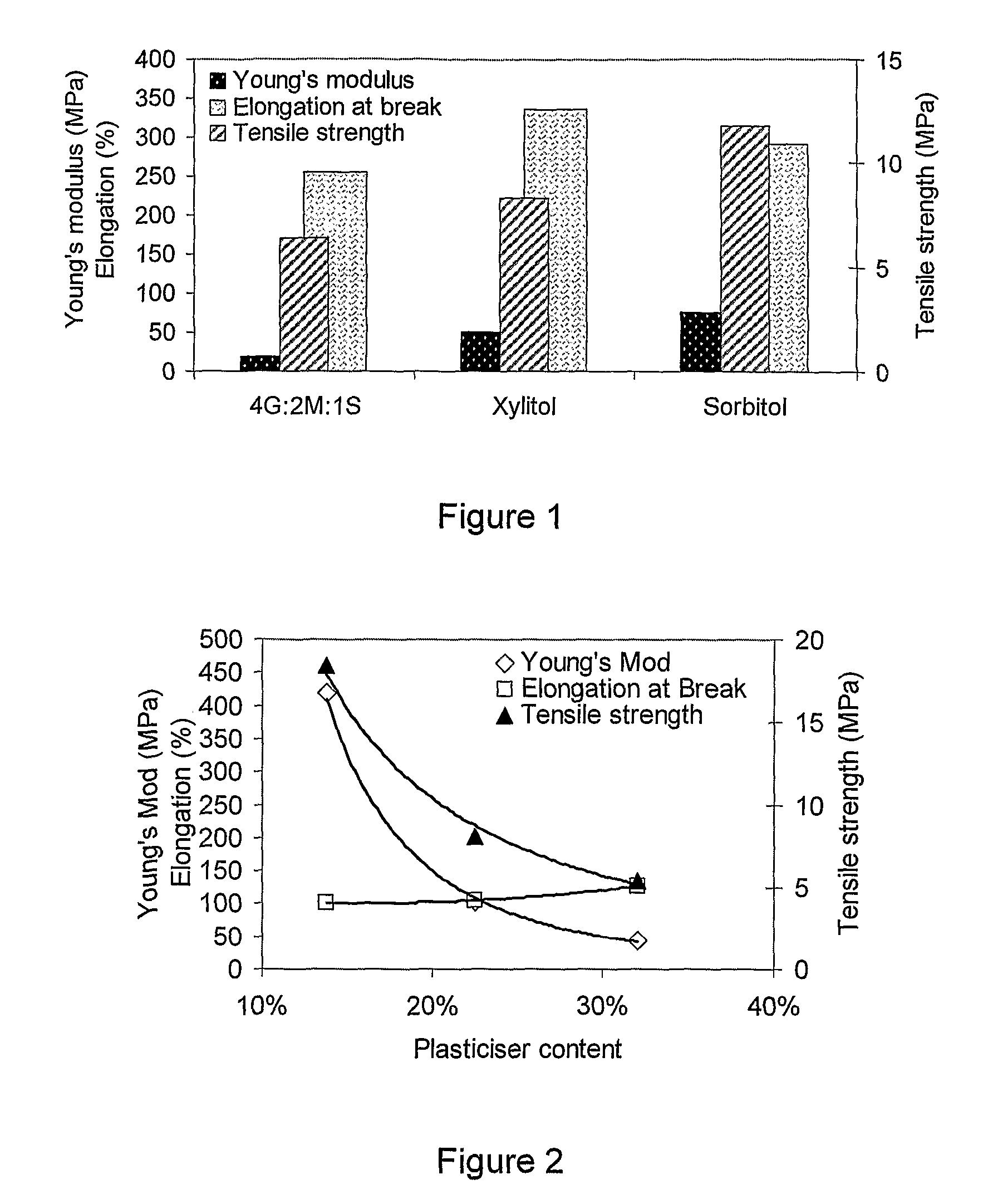

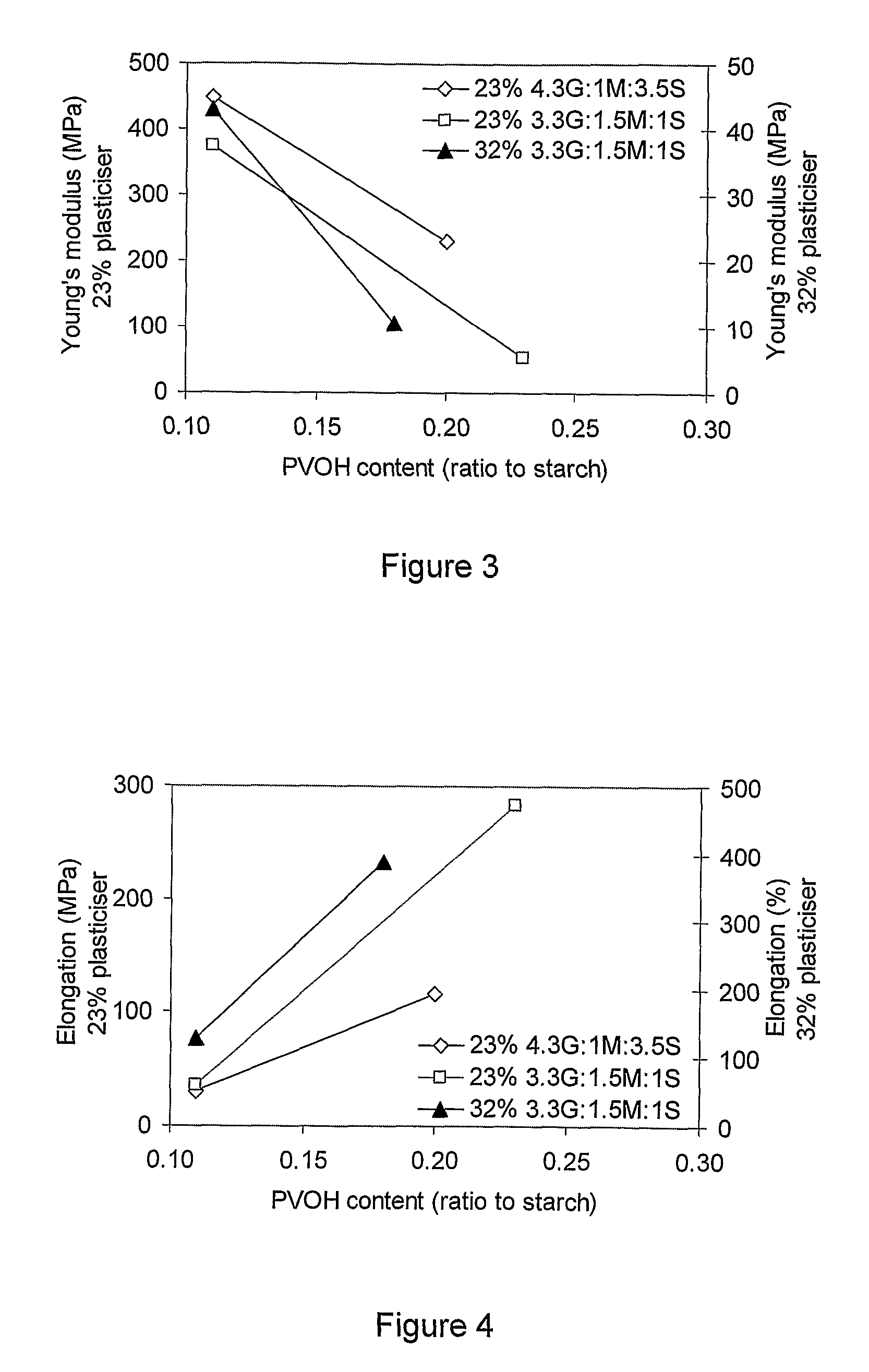

Mouldable Biodegradable Polymer

ActiveUS20070276317A1Improve the level ofImprove hydrophobicityFireproof paintsSynthetic resin layered productsMolten statePolymer science

Owner:PLANTIC TECH

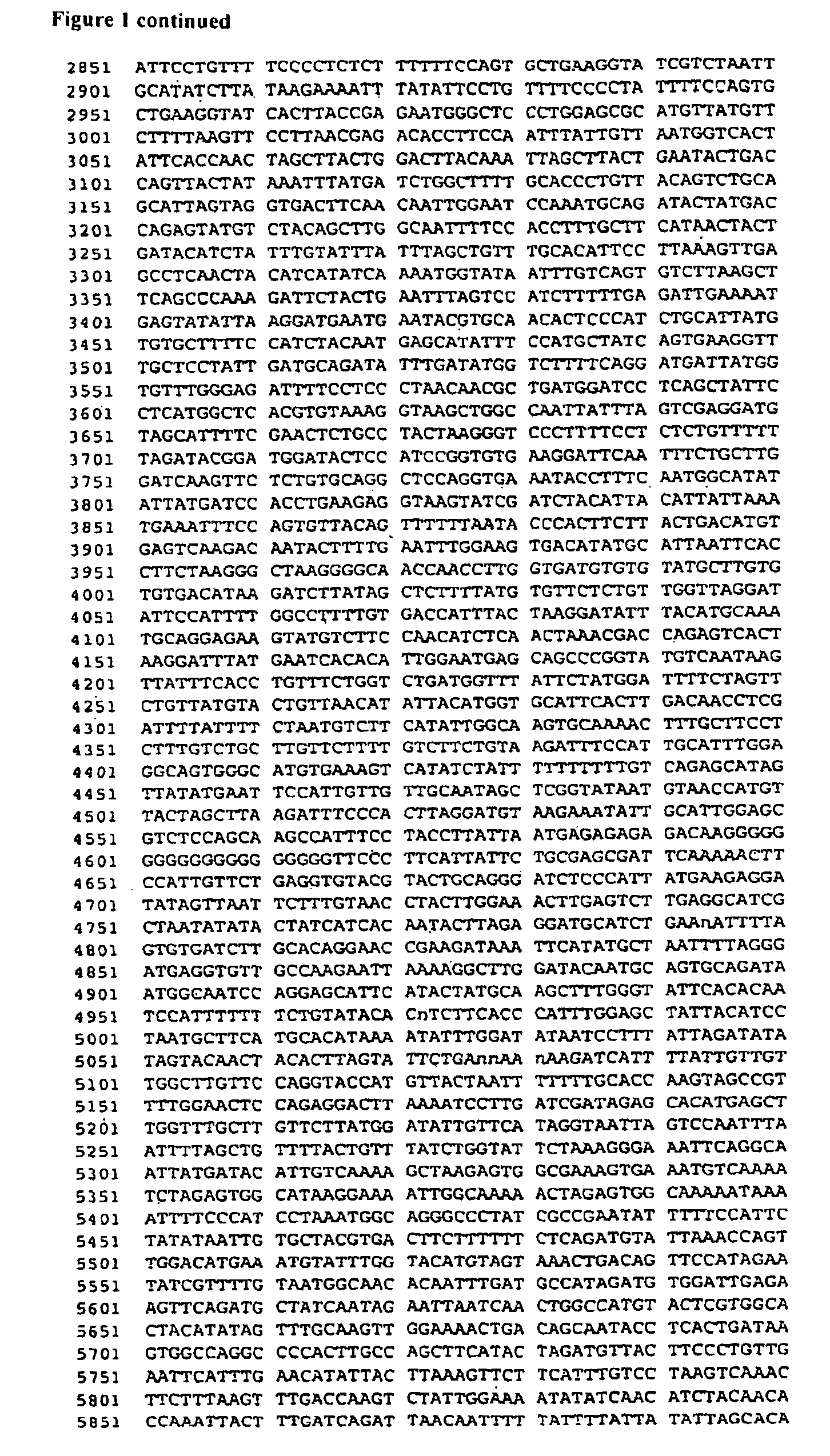

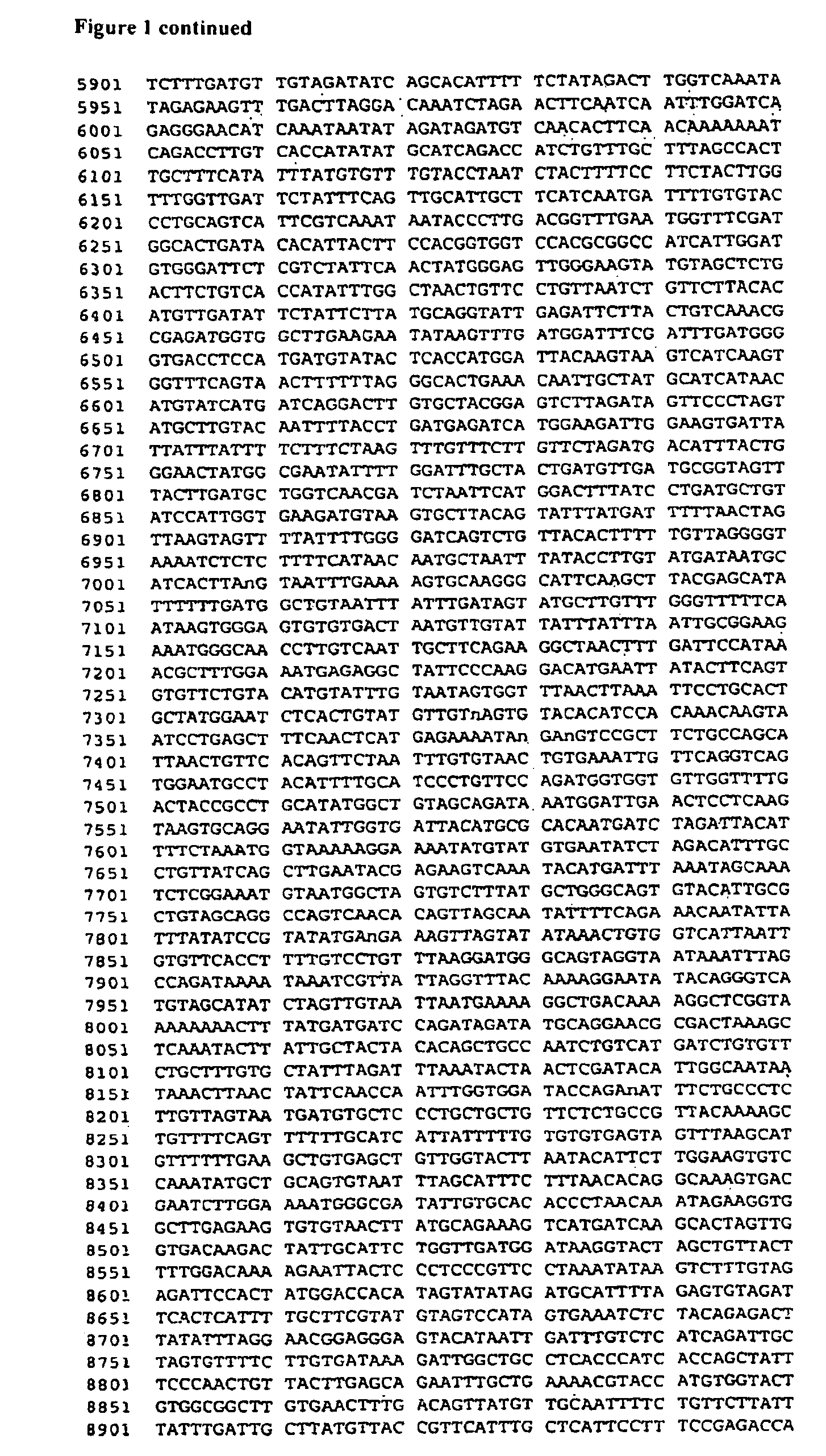

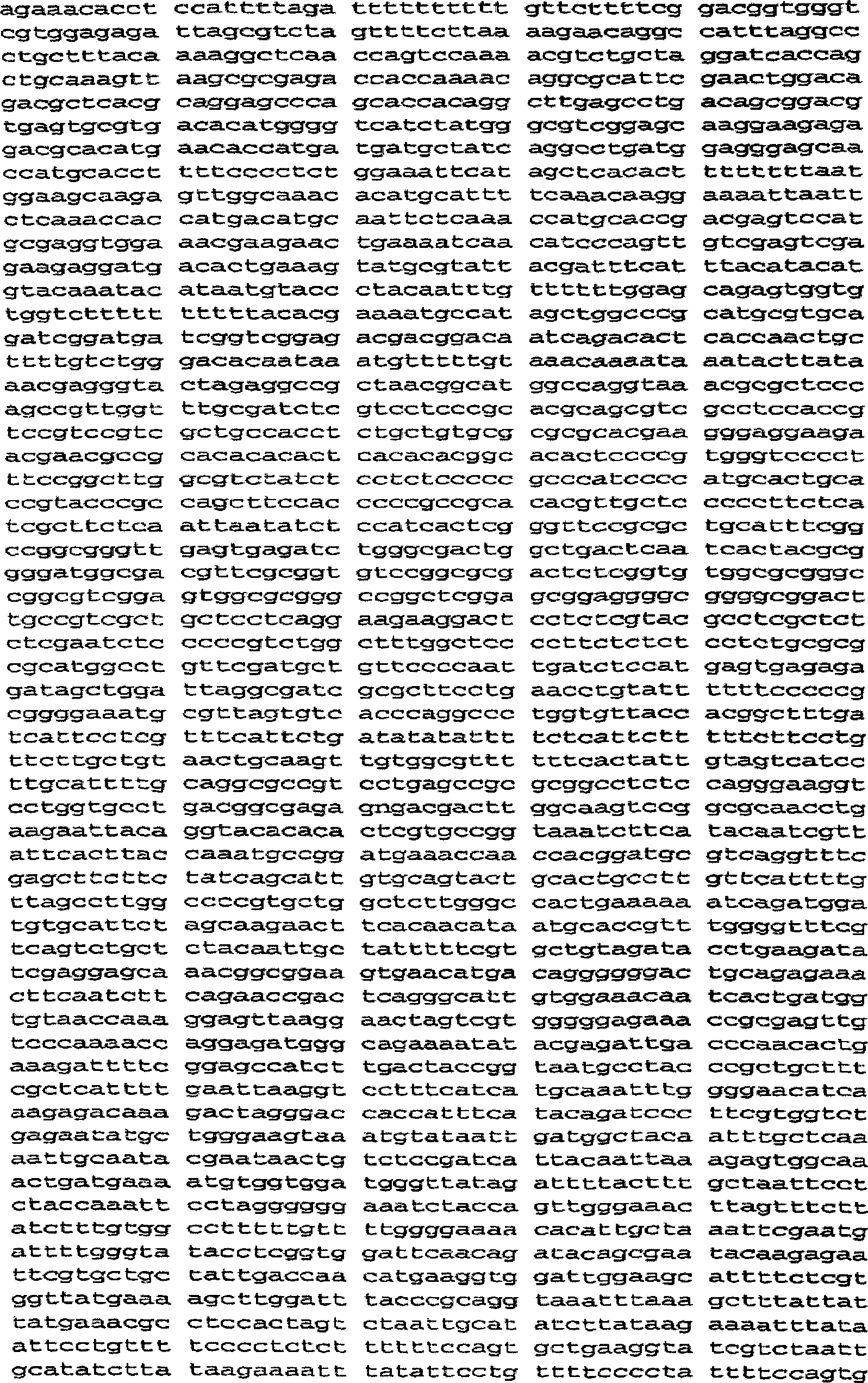

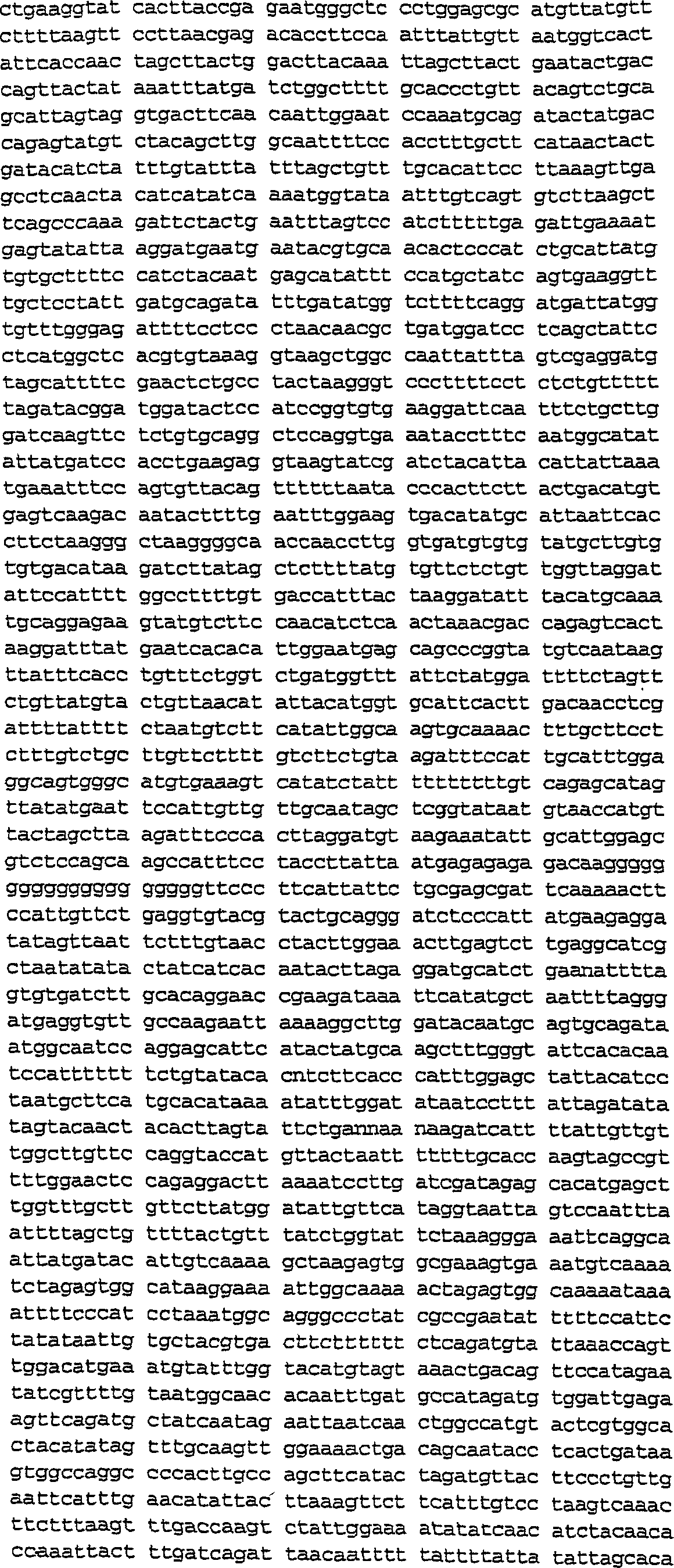

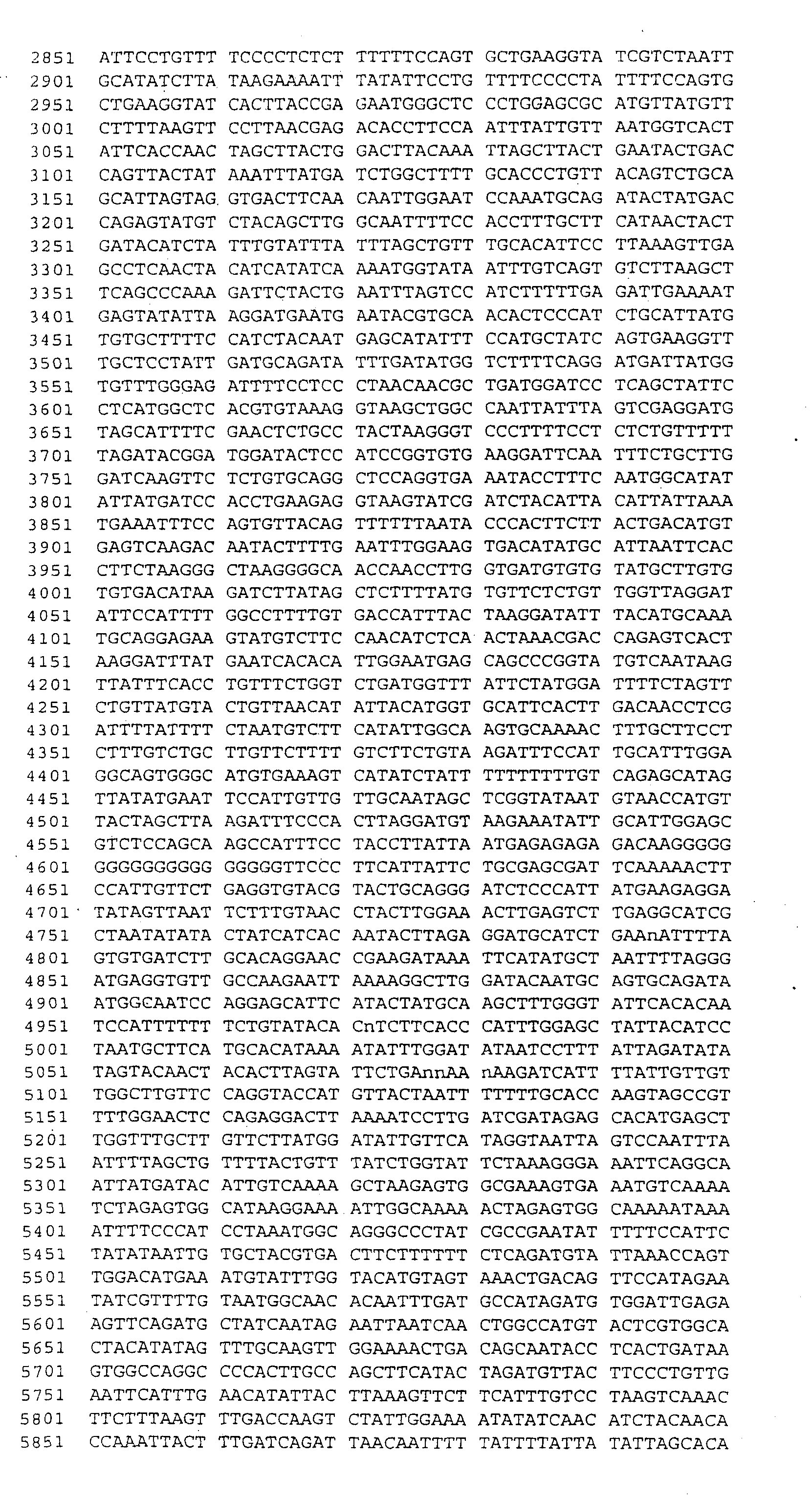

Rice and products thereof having starch with an increased proportion of amylose

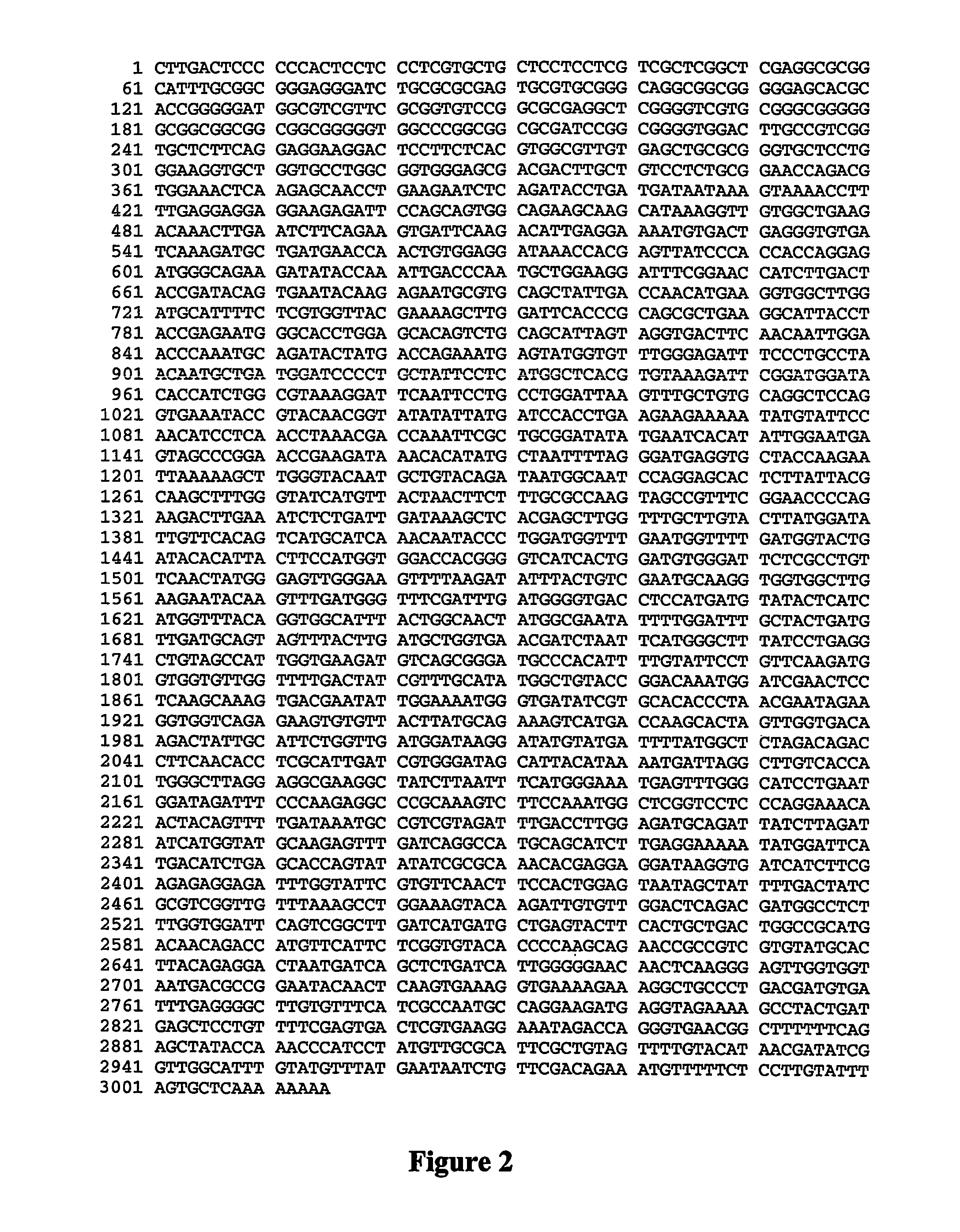

InactiveUS7790955B2Reduced activityLower Level RequirementsFood genetic modificationTransferasesRice grainTransgene

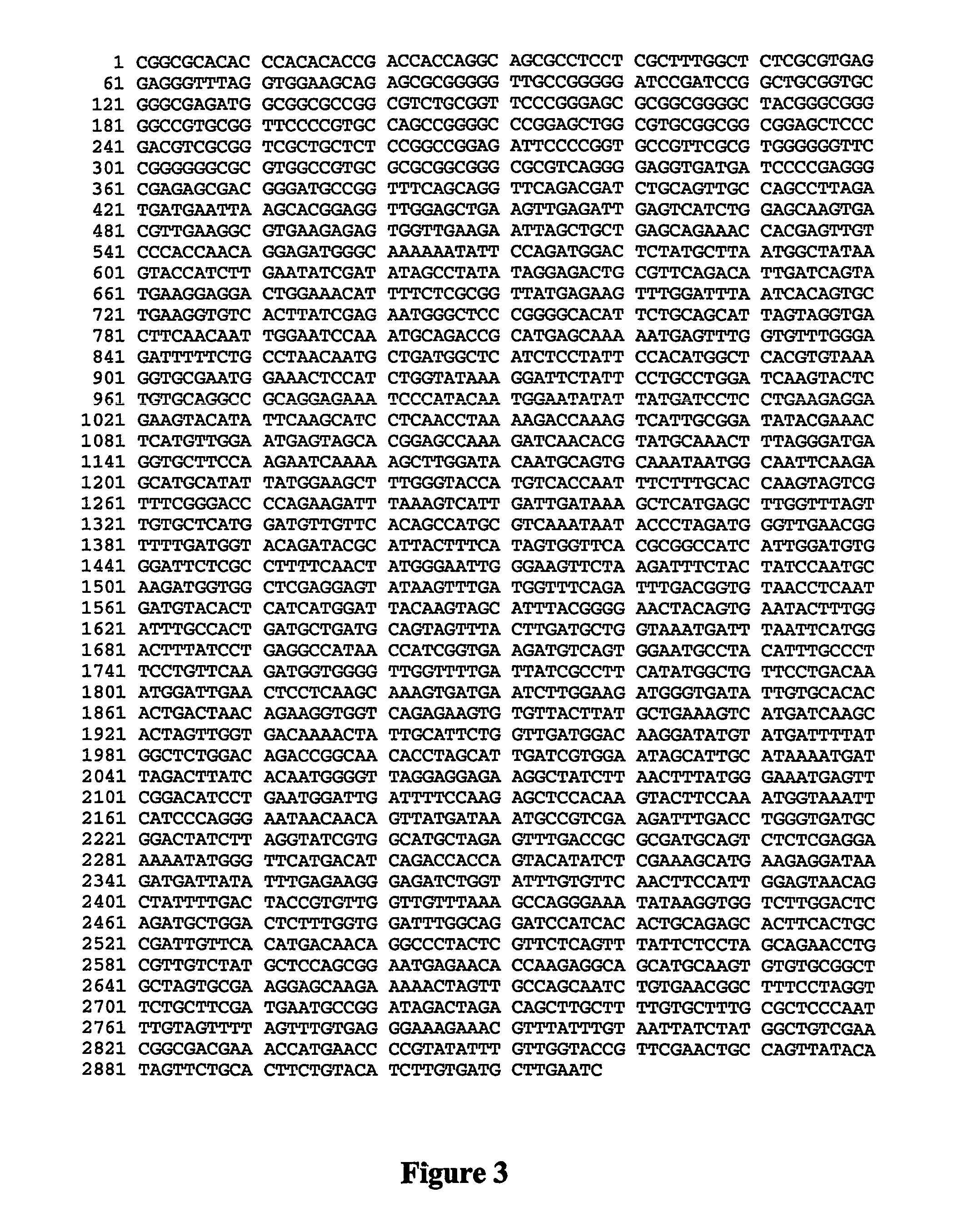

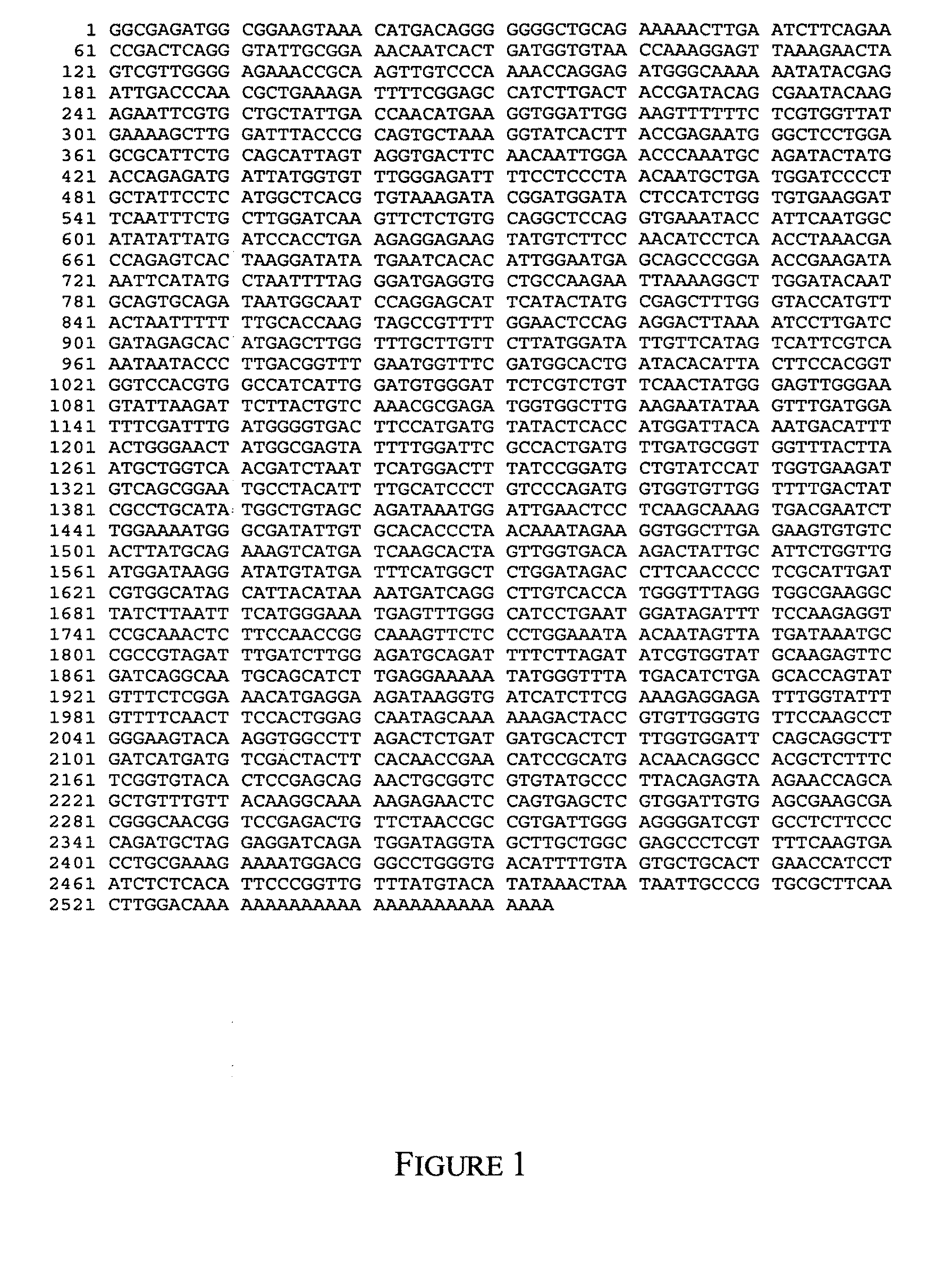

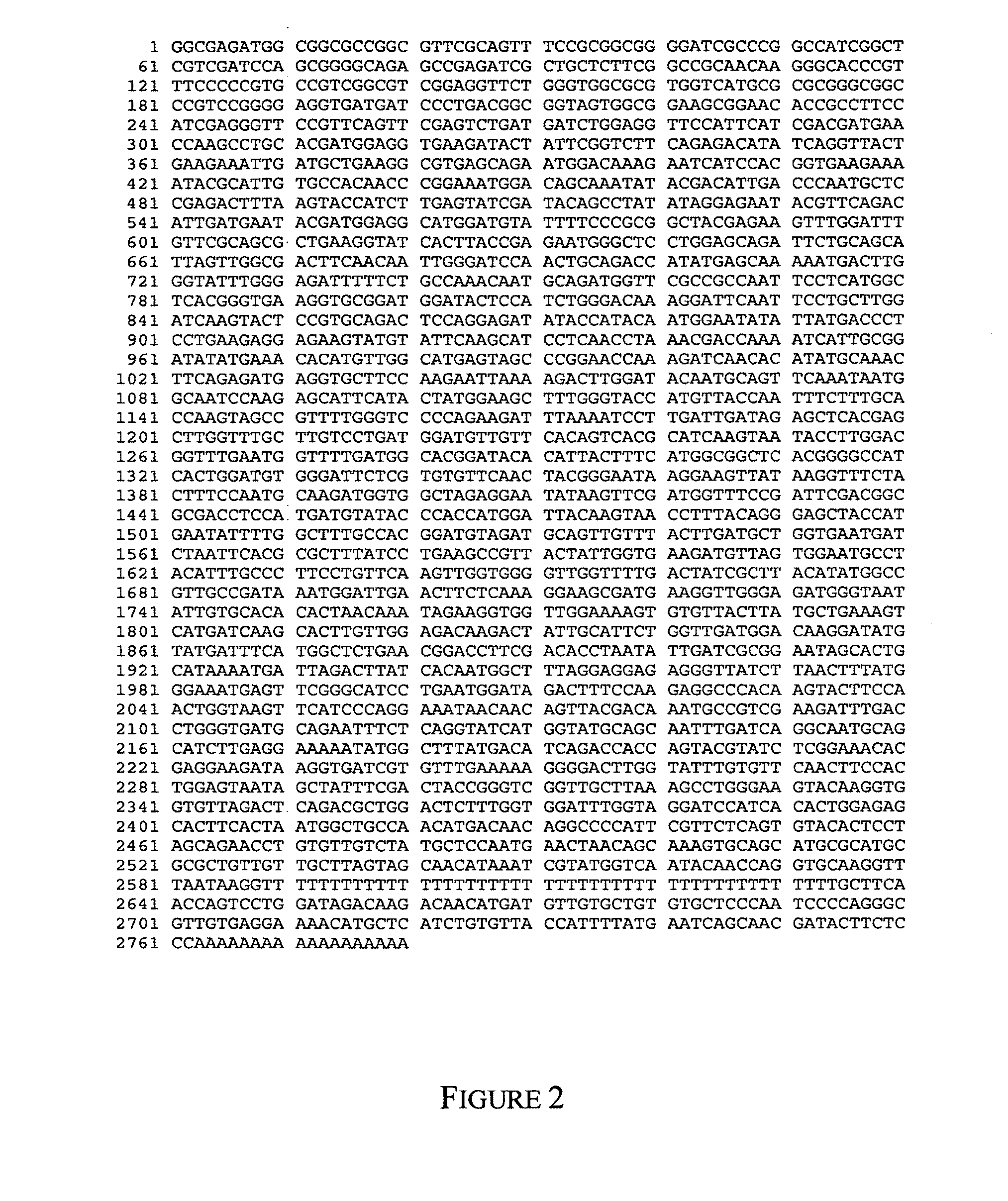

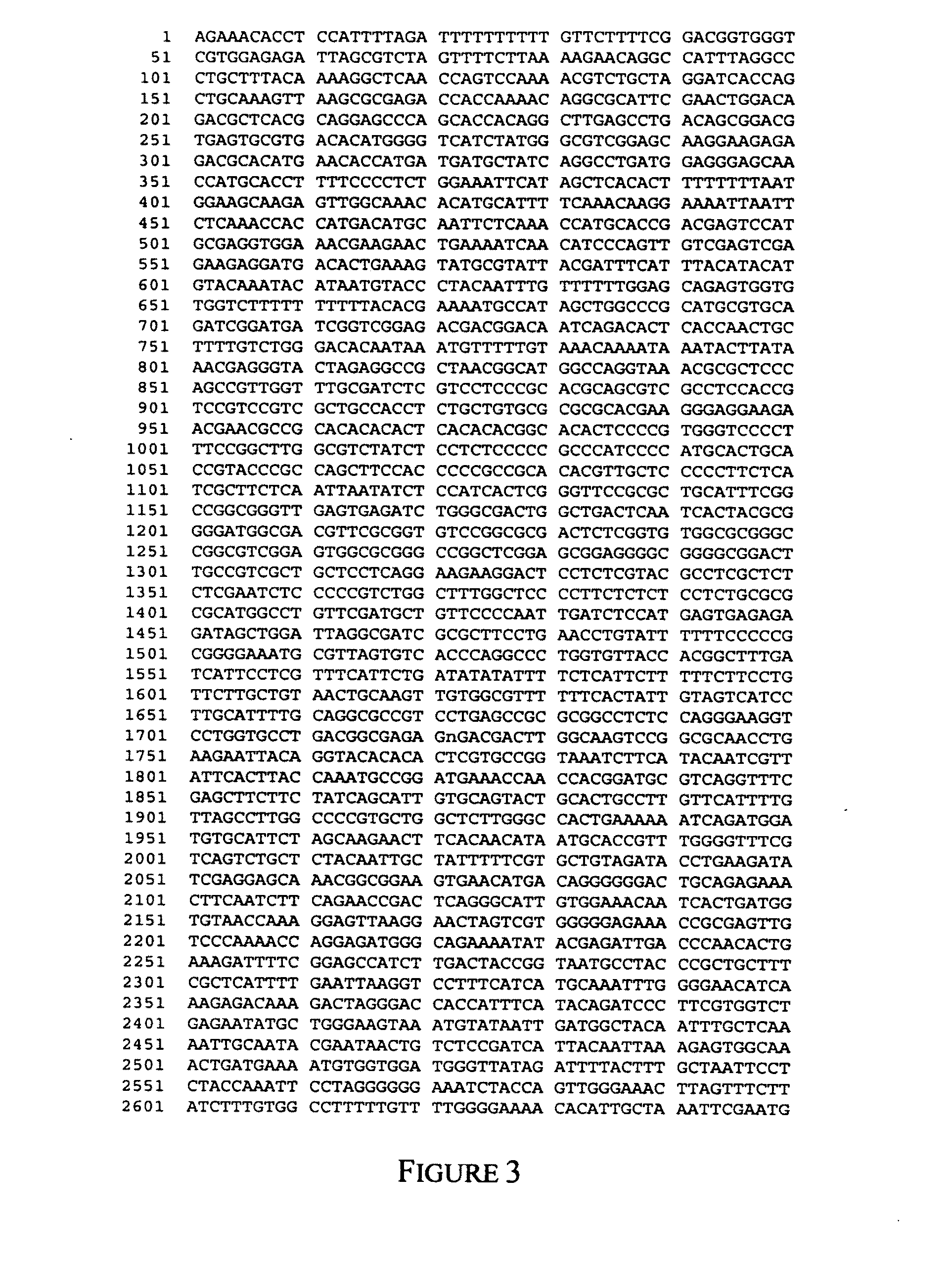

Rice having reduced levels of starch branching enzymes produce grain having a high relative amylose content in the endosperm. The rice grain of this invention can be of a non-shrunken phenotype despite a lesion in the amylopectin synthesis pathway and may be transgenic or nontransgenic. 1 GCCACCGACA TCCGCCGCAA TGCTGTGTCT CACCTCCTCTTCCTCCTCCG CGCCCGCTCC 61 GCTCCTTCCC TCTCTCGCTG ATCGACCGAG CCCGGGAATCGCGGGCGGGG GTGGCAATGT 121 TCGCCTGAGC GTGGTTTCTT CGCCGCGCCG GTCGTGGCCTGGAAAGGTCA AGACCAATTT 181 CTCAGTTCCT GCGACTGCGC GAAAAAACAA AACCATGGTGACTGTTGTGG AGGAGGTCGA 241 CCACCTTCCT ATATATGATC TGGACCCTAA GTTGGAGGAATTCAAGGATC ACTTCAACTA 301 TAGGATAAAA AGATACCTCG ACCAGAAATG CCTGATTGAAAAACATGAGG GGGGCCTTGA 361 AGAATTTTCT AAAGGCTATT TGAAGTTTGG GATTAATACAGTTGATGGTG CCACAATATA 421 TCGTGAATGG GCGCCTGCTG CACAAGAAGC ACAGCTCATTGGTGAGTTCA ATAACTGGAA 481 TGGTGCAAAA CACAAGATGG AGAAGGATAA ATTTGGCATTTGGTCAATCA AGATTTCACA 541 TGTCAATGGG AAGCCTGCCA TCCCTCACAA TTCCAAGGTTAAATTTCGCT TTAGGCATGG 601 GGGTGGAGCA TGGGTTGATC GTATTCCCGC ATGGATTCGTTATGCAACTT TTGATGCCTC 661 TAAATTTGGA GCTCCATATG ATGGTGTACA CTGGGATCCTCCAGCCTGTG AAAGGTACGT 721 GTTTAAGCAT CCTCGACCTC CAAAACCTGA TGCTCCACGCATCTATGAGG CTCATGTGGG 781 GATGAGTGGT GAAGAGCCAG AAGTAAGCAC ATACAGAGAATTTGCAGACA ATGTGTTACC 841 ACGCATACGG GCAAATAACT ACAACACAGT TCAGTTAATGGCAATCATGG AACATTCCTA 901 CTATGCTTCT TTTGGGTATC ACGTGACAAA TTTTTTCGCAGTCAGCAGCA GATCAGGAAC 961 ACCAGAGGAT CTGAAATATC TTGTTGACAA GGCACATAGTTTAGGATTAC GAGTTCTGAT1021 GGATGTTGTC CATAGCCATG CGAGTAATAA TGTGACCGATGGTCTAAATG GCTATGACGT1081 TGGACAAAAC ACTCATGAGT CTTATTTTCA TACAGGAGATAGGGGCTACC ATAAACTCTG1141 GGATAGTCGT CTGTTCAACT ATGCCAATTG GGAGGTCTTAAGATTTCTTC TTTCTAATTT1201 GAGATATTGG ATGGACGAAT TCATGTTTGA TGGCTTCCGATTTGATGGGG TTACATCAAT1261 GCTATACCAT CACCATGGTA TCAATAAGGG ATTTACTGGAAACTACAAGG AGTATTTCAG1321 TTTGGATACC GATGTGGATG CAATTGTTTA CATGATGCTCGCAAACCATT TAATGCATAA1381 ACTCTTGCCG GAAGCAACTA TTGTTGCTGA AGATGTTTCGGGCATGCCAG TGCTTTGTCG1441 GCCAGTTGAT GAAGGTGGAG TAGGGTTTGA CTTCCGCCTGGCAATGGCCA TTCCTGATAG1501 ATGGATTGAC TACCTGAAGA ACAAAGAGGA CCGCAAATGGTCAATGAGTG AAATAGTGCA1561 AACTTTGACT AACAGGAGAT ATACAGAAAA ATGCATTGCCTATGCCGAGA GCCATGATCA1621 GTCCATTGTT GGTGACAAGA CTATAGCATT TCTCTTGATGGACAAGGAAA TGTACACTGG1681 CATGTCAGAC TTGCAGCCTG CTTCACCTAC CATCAACCGTGGCATTGCAC TCCAAAAGAT1741 GATTCACTTC ATTACGATGG CCCTTGGAGG TGATGGCTACTTAAATTTTA TGGGCAATGA1801 GTTTGGCCAT CCAGAATGGA TTGACTTTCC AAGAGAAGGCAACAACTGGA GCTATGATAA1861 ATGCAGACGT CAGTGGAGCC TTGTCGACAC TGATCACCTTCGATACAAGT ATATGAATGC1921 ATTTGATCAA GCAATGAATG CACTCGAGGA GGAATTTTCCTTCCTGTCAT CATCAAAGCA1981 GATTGTTAGC GACATGAACG AGAAAGATAA GGTTATTGTCTTTGAACGTG GAGATTTGGT2041 TTTTGTTTTC AATTTTCATC CCAACAAAAC TTATAAGGGTTACAAAGTCG GATGTGACTT2101 GCCCGGGAAG TACAGAGTAG CTCTGGACTG TGATGCTTTGGTCTTTGGTG GCCATGGAAG2161 AGTTGGCCAT GATGTGGATC ACTTCACGTC TCCCGAGGGAATGCCAGGAG TACCAGAAAC2221 AAATTTCAAC AACCGCCCTA ACTCATTCAA AGTCCTTTCCCCGCCCCGTA CCTGTGTGGC2281 TTACTATCGC GTTGATGAAG ATCGTGAAGA GCTCAGGAGGGGTGGAGCAG TTGCTTCTGG2341 AAAGATTGTT ACAGAGTATA TCGATGTTGA AGCAACAAGTGGGGAGACTA TCTCTGGTGG2401 CTGGAAGGGC TCCGAGAAGG ACGATTGTGG CAAGAAAGGGATGAAGTTTG TGTTTCGGTC2461 TTCTGACGAA GACTGCAAAT GAAGCATCAG ATTTCTTGATCAGGAGCAAC TGTTGGTGCC2521 CTTGTAATCT GGAGATCCTG GCTTGCCTTG GACTTGGTTGTGGTTCTTTA GCAGTTGCTA2581 TGTACCTATC TATGATATGA ACTTTATGTA TAGTTCGCCTTAAAGAAAGA ATAAGCAGTG2641 ATGATGTGGC CTTAAACCTG AGCTGCACAA GCCTAATGTAAAAATAAAGT TTCAGGCTTT2701 CATCCAGAAT AAAACAGCTG TTCATTTACC ATCTCAAAA

Owner:COMMONWEALTH SCI & IND RES ORG

Flour composition with increased total dietary fiber, process of making, and uses thereof

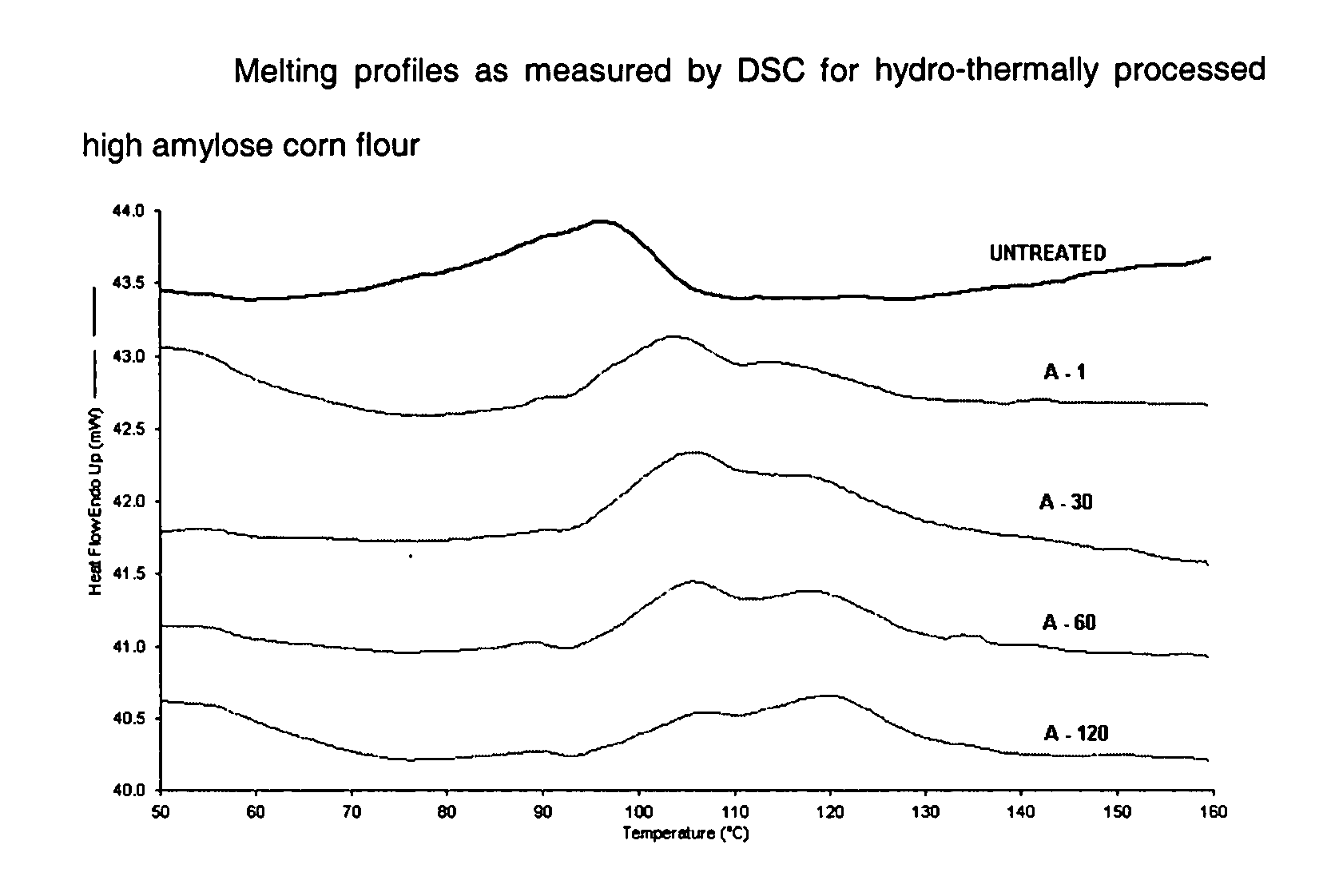

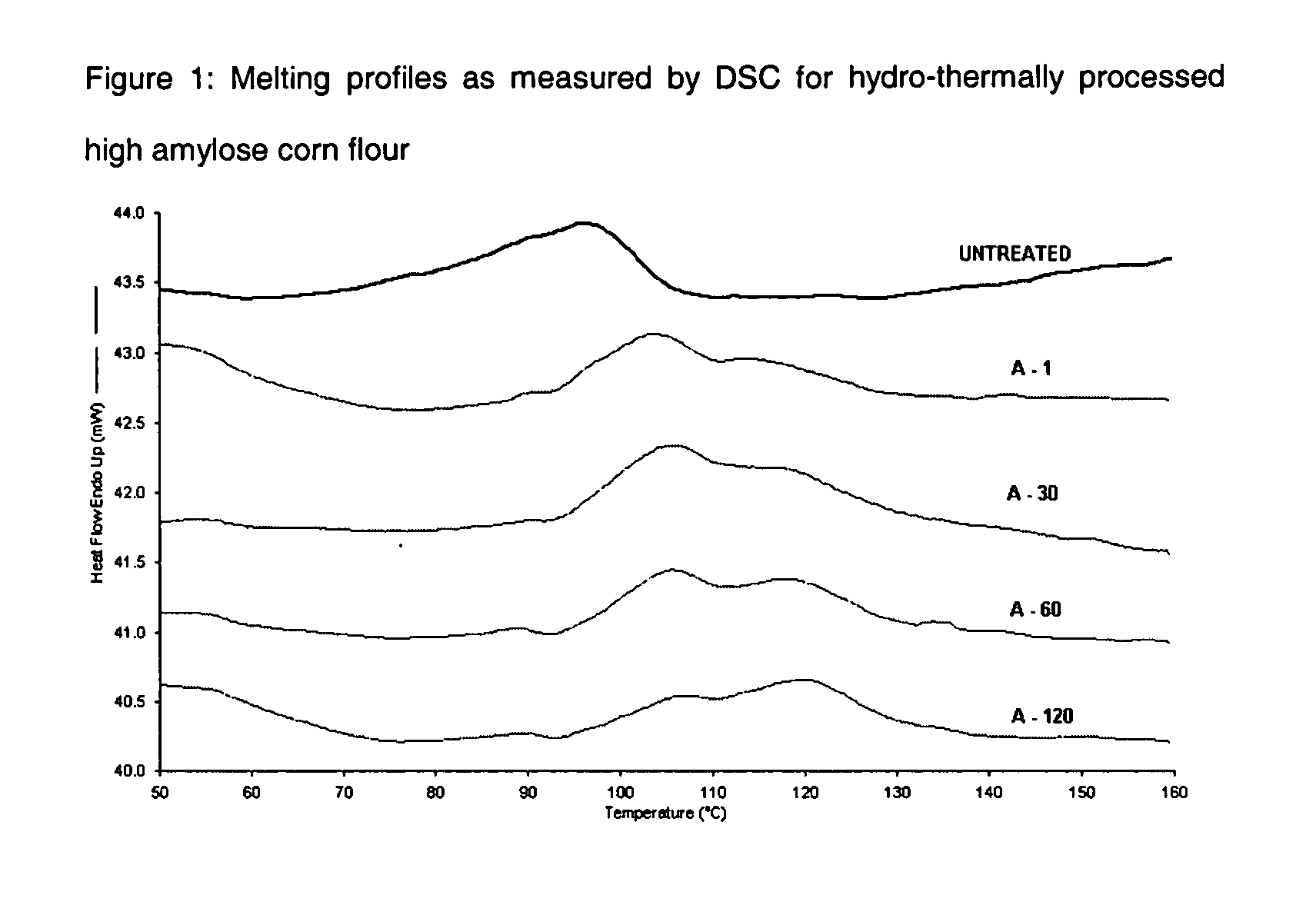

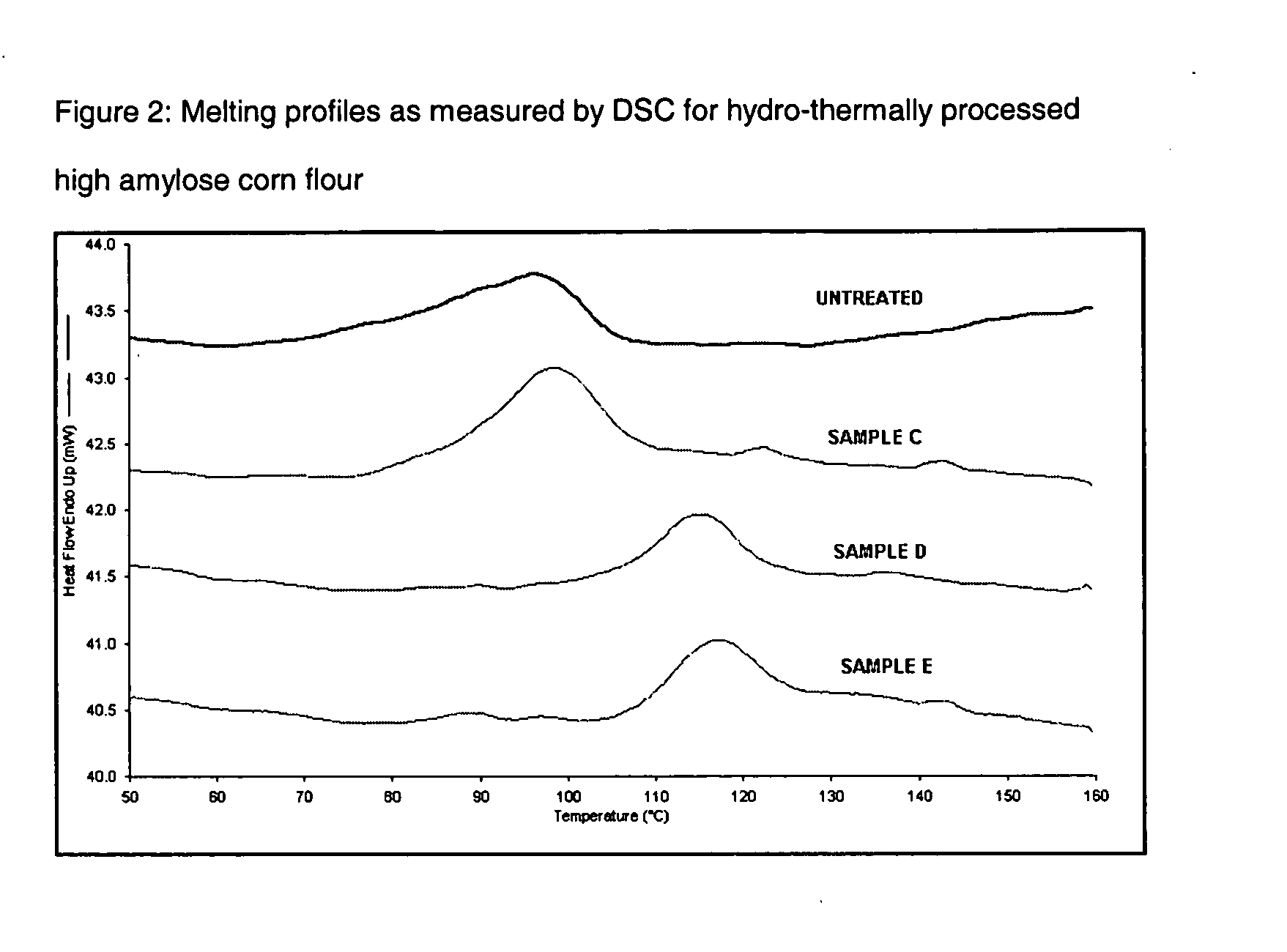

High amylose flour may be processed by a short hydrothermal treatment to increase its total dietary fiber (TDF) content. These flours may be prepared by heating a high amylose flour at a total water content of from about 10 to 50% by weight at a temperature of from about 80 to 160° C., for about 0.5 to 15 minutes at target temperature. This invention further relates to products which contain the high TDF flour, including food products.

Owner:CORN PROD DEV INC

Biodegradable polymer

InactiveUS20040242732A1Reduce thicknessReduce congestionGroup 4/14 element organic compoundsFlexible coversCarboxylic acidStearic acid

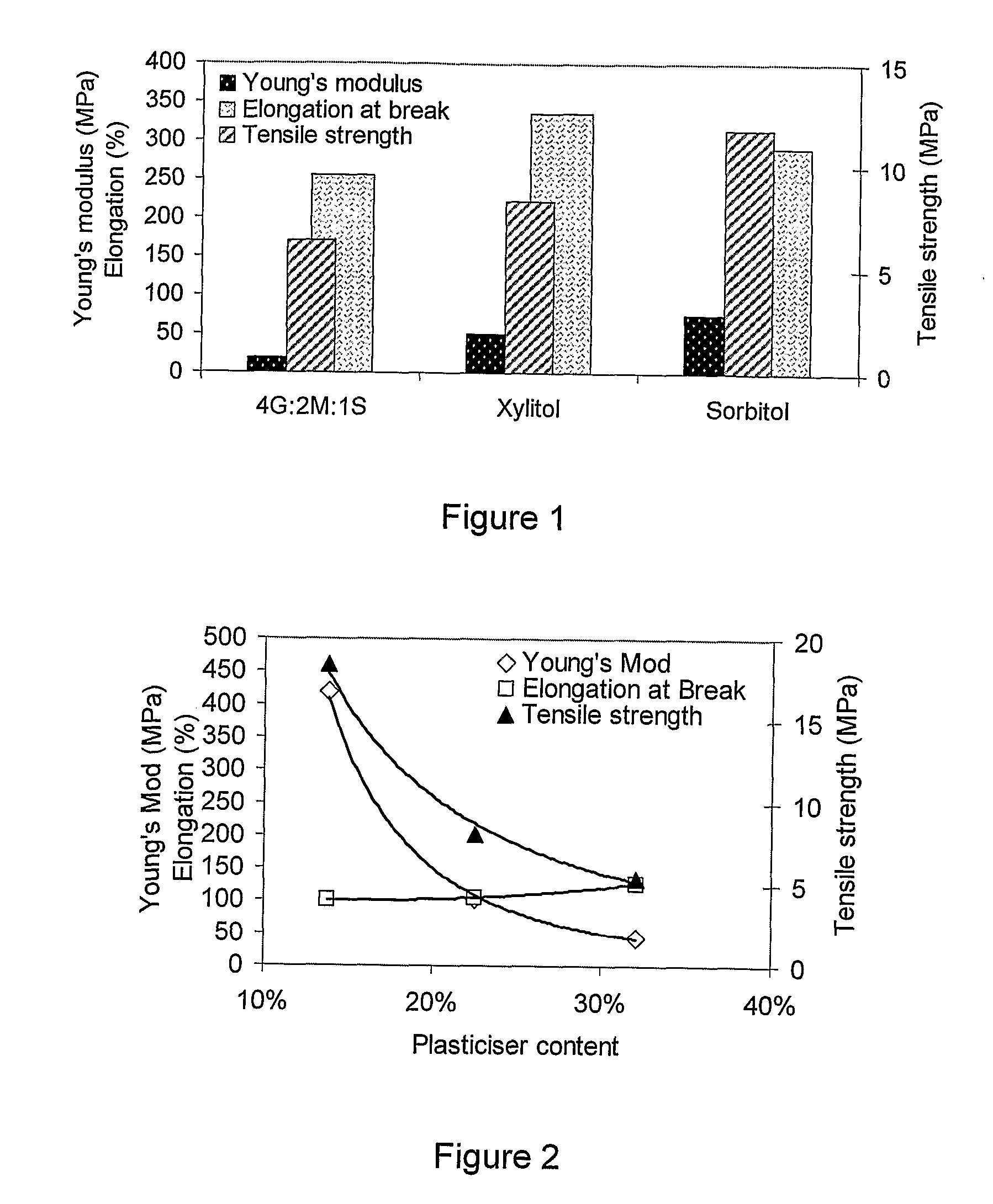

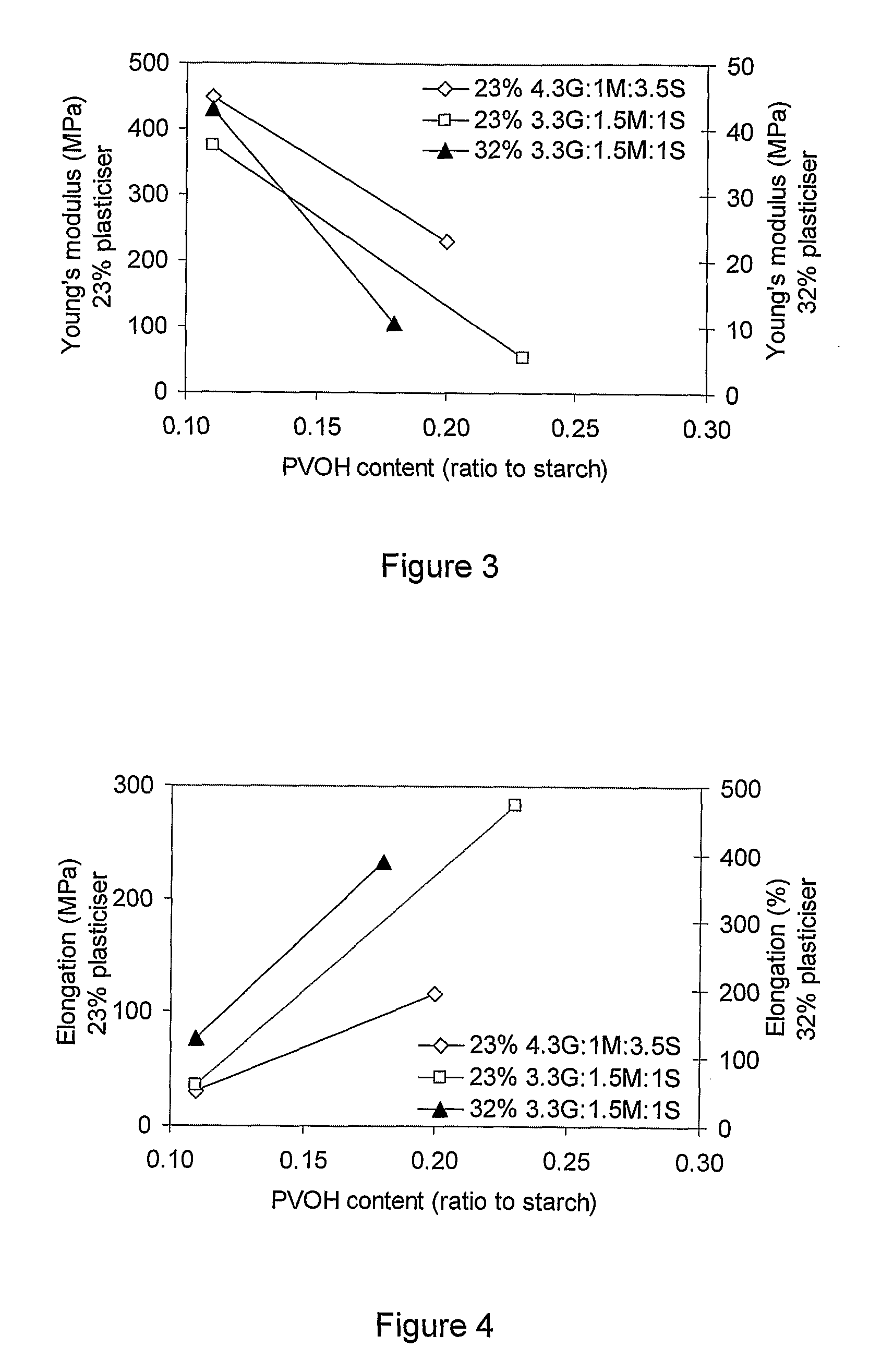

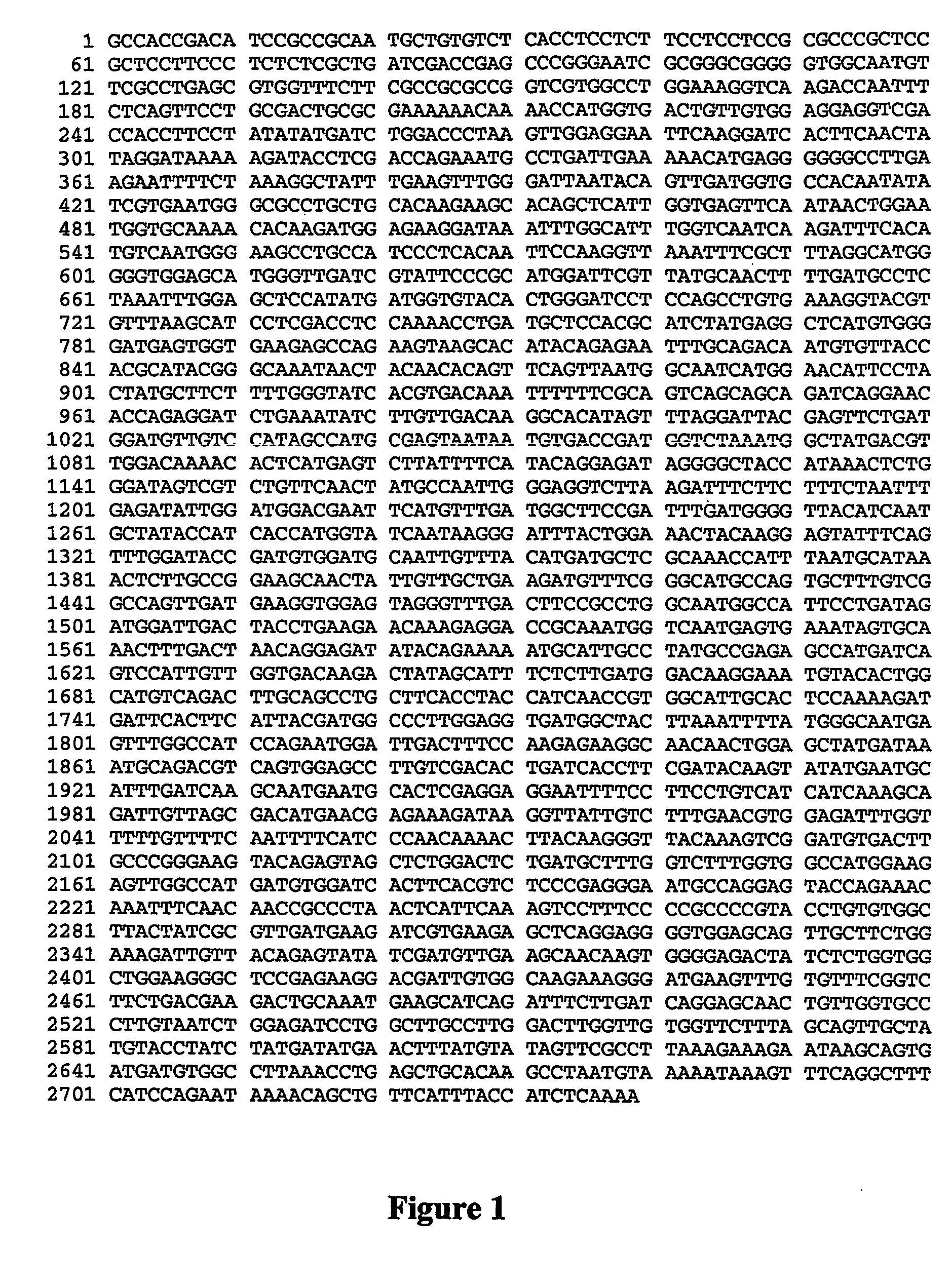

A biodegradable polymer is disclosed having the composition g) from 8 to 80% by weight of a starch modified to include an hydroxyalkyl C2-6 group or modified by reaction with an anhydride of a dicarboxylic acid, preferably hydroxypropylated high amylose starch, a) from 0 to 87.9% of starch, b) from 4 to 11% by weight of a water soluble polymer selected from polyvinylacetate, polyvinyl alcohol and copolymers of ethylene and vinylalcohol which have a melting point compatible with the molten stat of the starch components, c) from 0 to 20% by weight of a polyol plasticiser, preferably glycerol, d) from 0.1 to 1.5% by weight of a C12-22 fatty acid or salt, preferably stearic acid and, e) 0 to 12% added water. The polymers are suitable as biodegradable rigid sheet or flexible film materials for use in packaging foodstuffs.

Owner:PLANTIC TECH

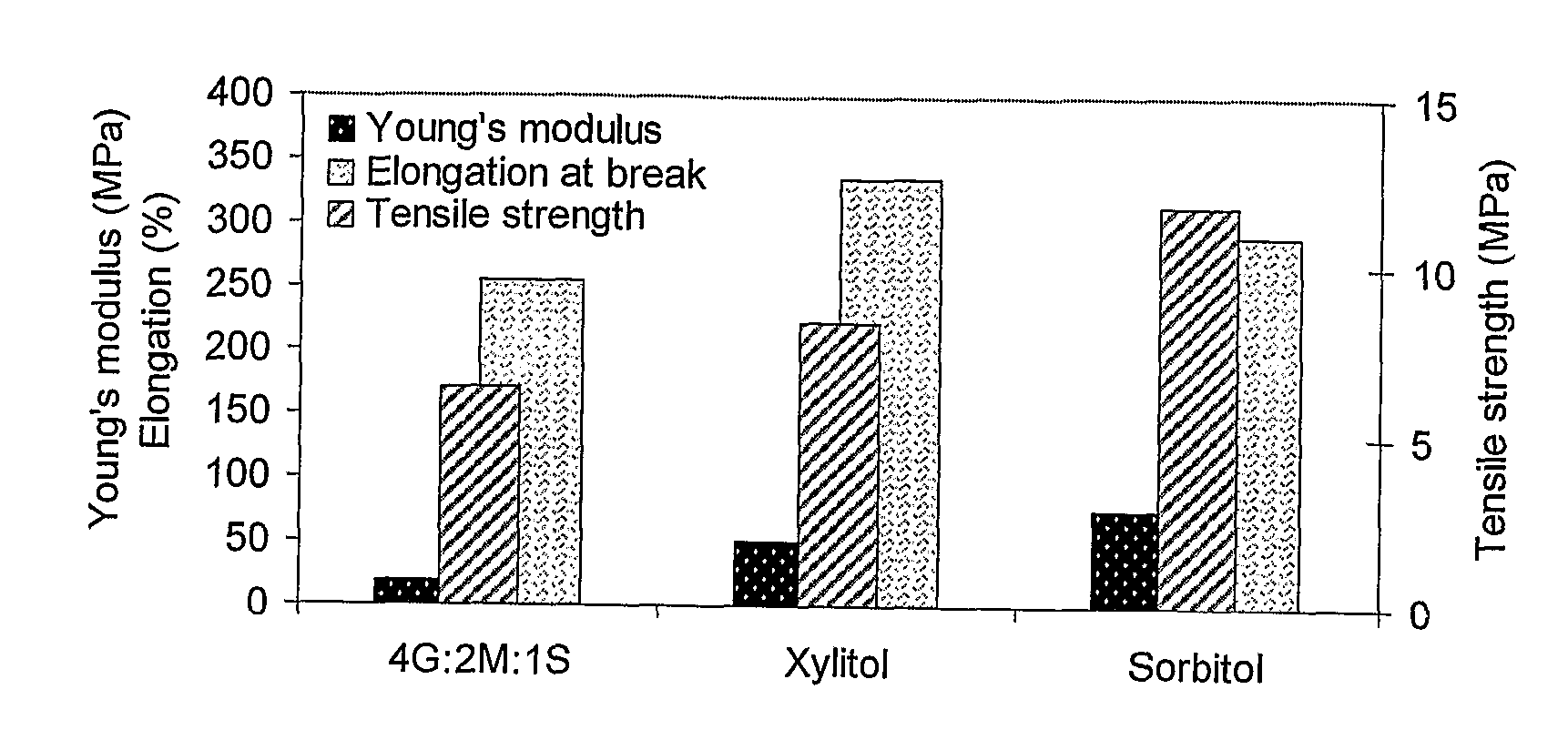

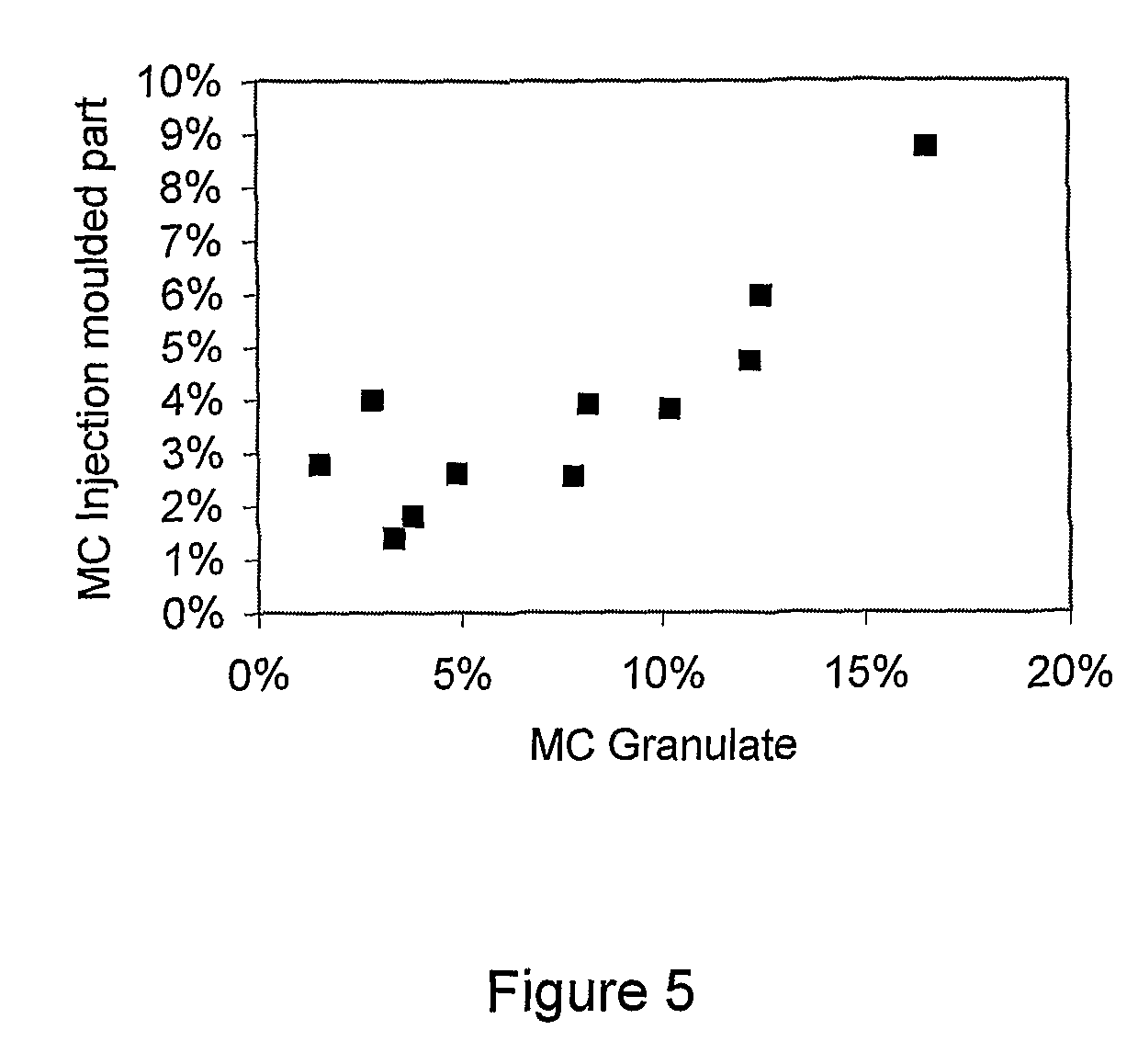

Mouldable Biodegradable Polymer

InactiveUS20100297458A1Synthetic resin layered productsCellulosic plastic layered productsMolten statePolyethylene oxide

A biodegradable injection mouldable polymer composition including on a dry weight basis from 45-85% w / w by weight of a starch and / or a modified high amylose starch, from 2-15% w / w by weight of a water soluble polymer preferably selected from polyvinyl alcohol, polyvinyl acetate and copolymers of ethylene and vinyl alcohol which have a melting point compatible with the molten state of the starch components, and from 5-45% w / w by weight of one or more polyol plasticizers having a molecular weight in the range of 50-6000, more preferably 50-2500, and still more preferably 100-400 and preferably selected from the group consisting of sorbitol, glycerol, maltitol, xylitol, mannitol, erythritol, polyglycerol, glycerol trioleate, tributyl citrate, acetyl tri-ethyl citrate, glyceryl triacetate, 2,2,4-trimethyl-1,3-pentanediol diisobutyrate, polyethylene oxide, ethylene glycol, diethylene glycol or polyethylene glycol; more preferably glycerol, maltitol, sorbitol, erythritol and xylitol. The composition is preferably substantially soluble in water.

Owner:PLANTIC TECH

Biological tuberous starch degradable plastic master batch, preparing method and application thereof

InactiveCN101724178AIncrease polarityIncrease amylose contentFlexible coversWrappersThermoplasticPolymer science

The invention relates to a biological tuberous starch degradable plastic master batch. The plastic mater batch is prepared from the following components by weight percentage: 70-80% of fine tuberous starch, 7-10% of flexibilizer, 0.5-2% of initiator, 4-7% of modifier, 1-3% of plasticizer and 3-6% of lubricating processing aid. The method for producing the biological tuberous starch degradable plastic master batch comprises the following steps of: tuberous starch refining procedure, starch high-speed mixing procedure and reaction extrusion procedure. The tuberous starch is a natural polymer substance with high polymerization degree, and has the advantages of high polarization, high amylose content, low cost and easy purchase. In addition, the tuberous starch is easy to perform graft reaction with the polymer, and is easy to perform esterification reaction with the modifier; and the natural starch with high rigidity and high crystallinity is converted into a plastic master batch with plastic property through microfining, modification and reaction extrusion. As the master batch has a certain strength and thermoplastic processing property, the master batch can be used for processing various film products, blow molding products and injection molding products according to different adding amounts.

Owner:梁雄辉

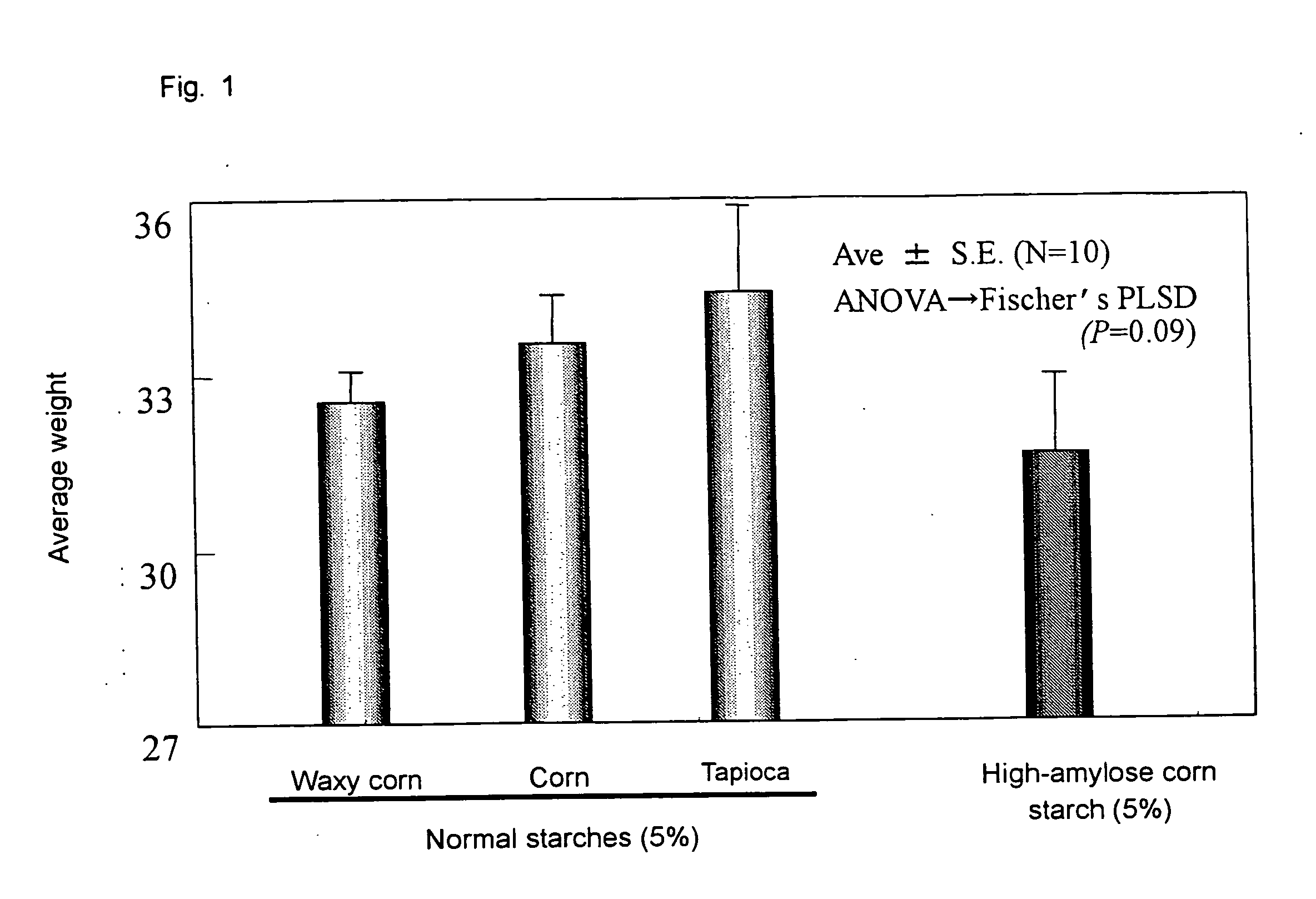

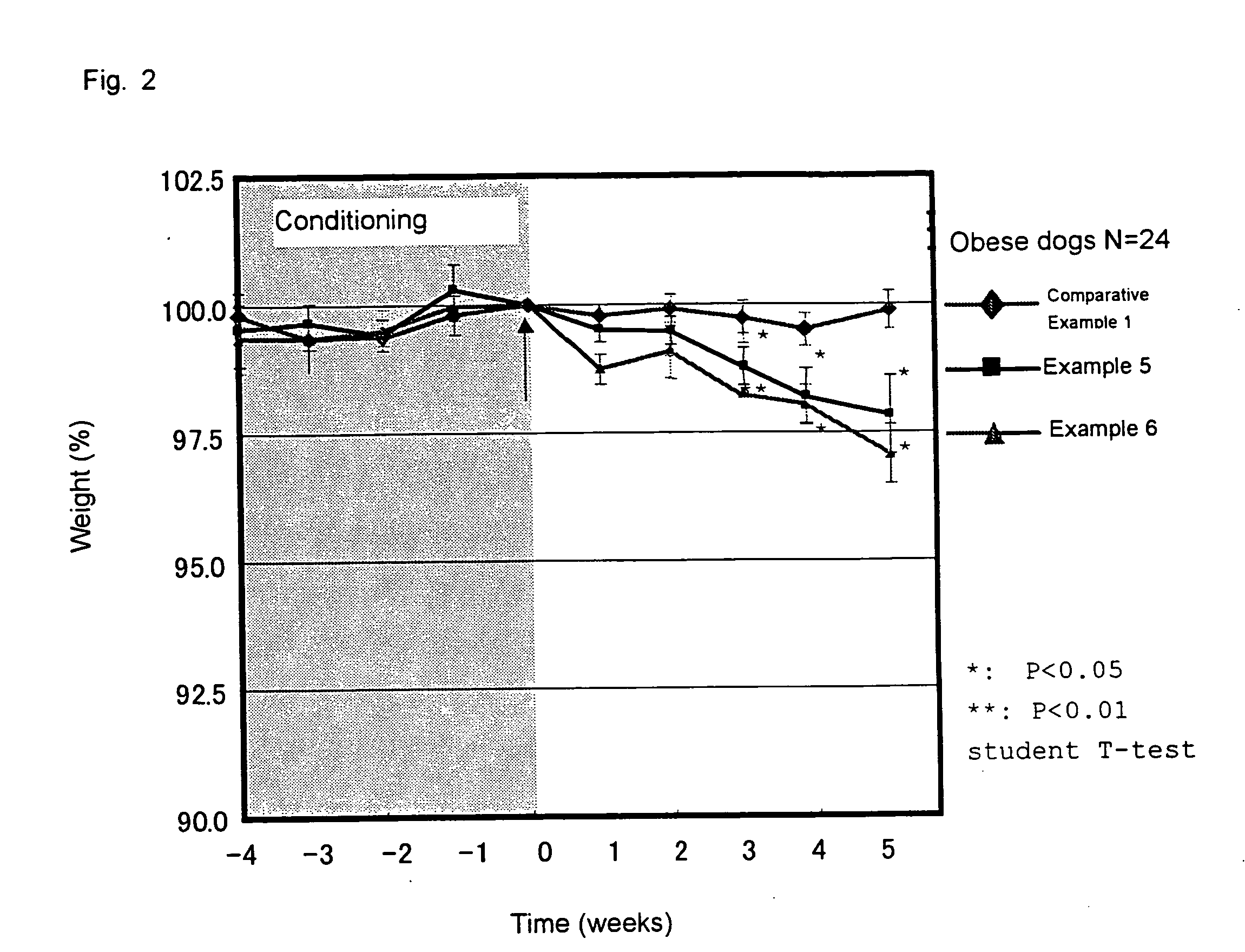

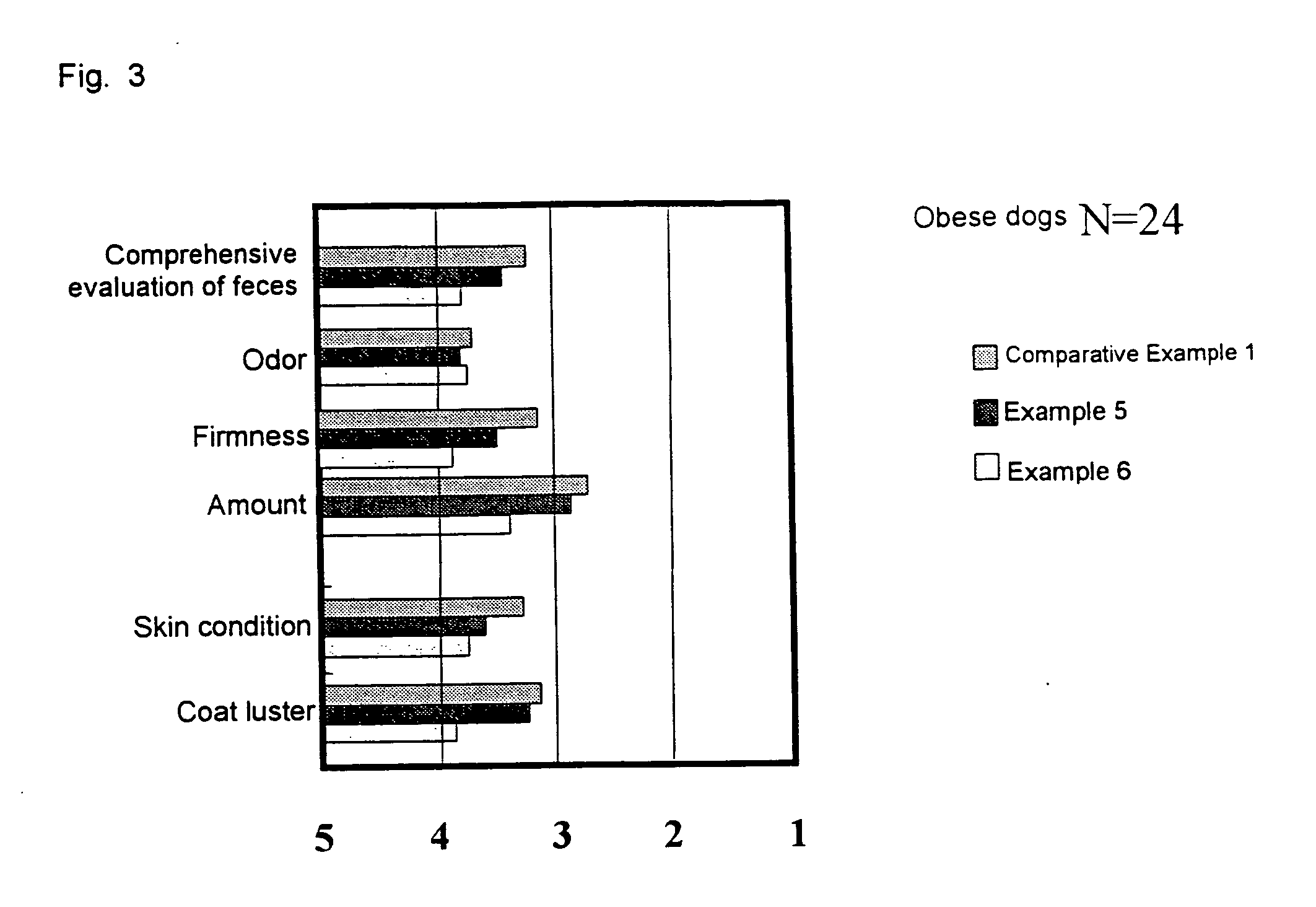

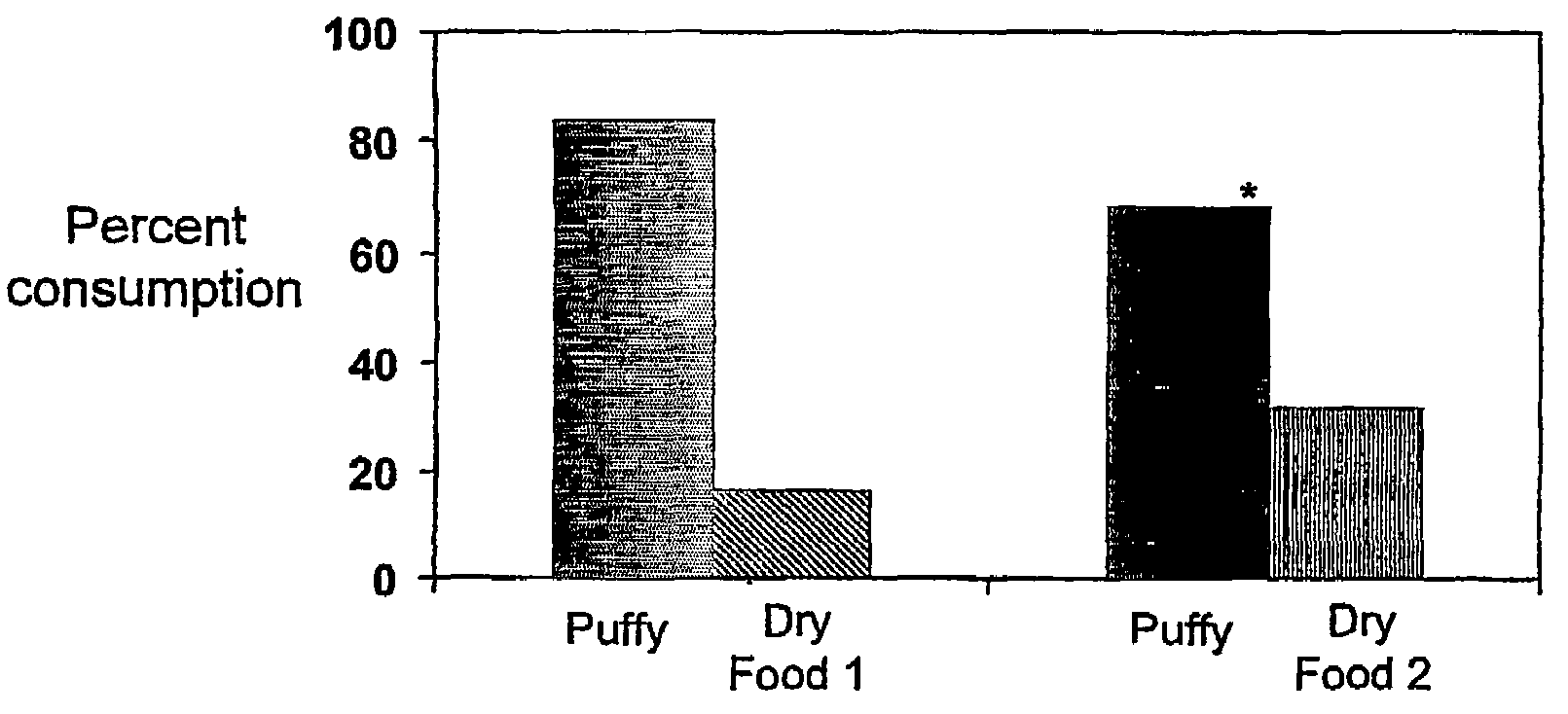

Pet foods

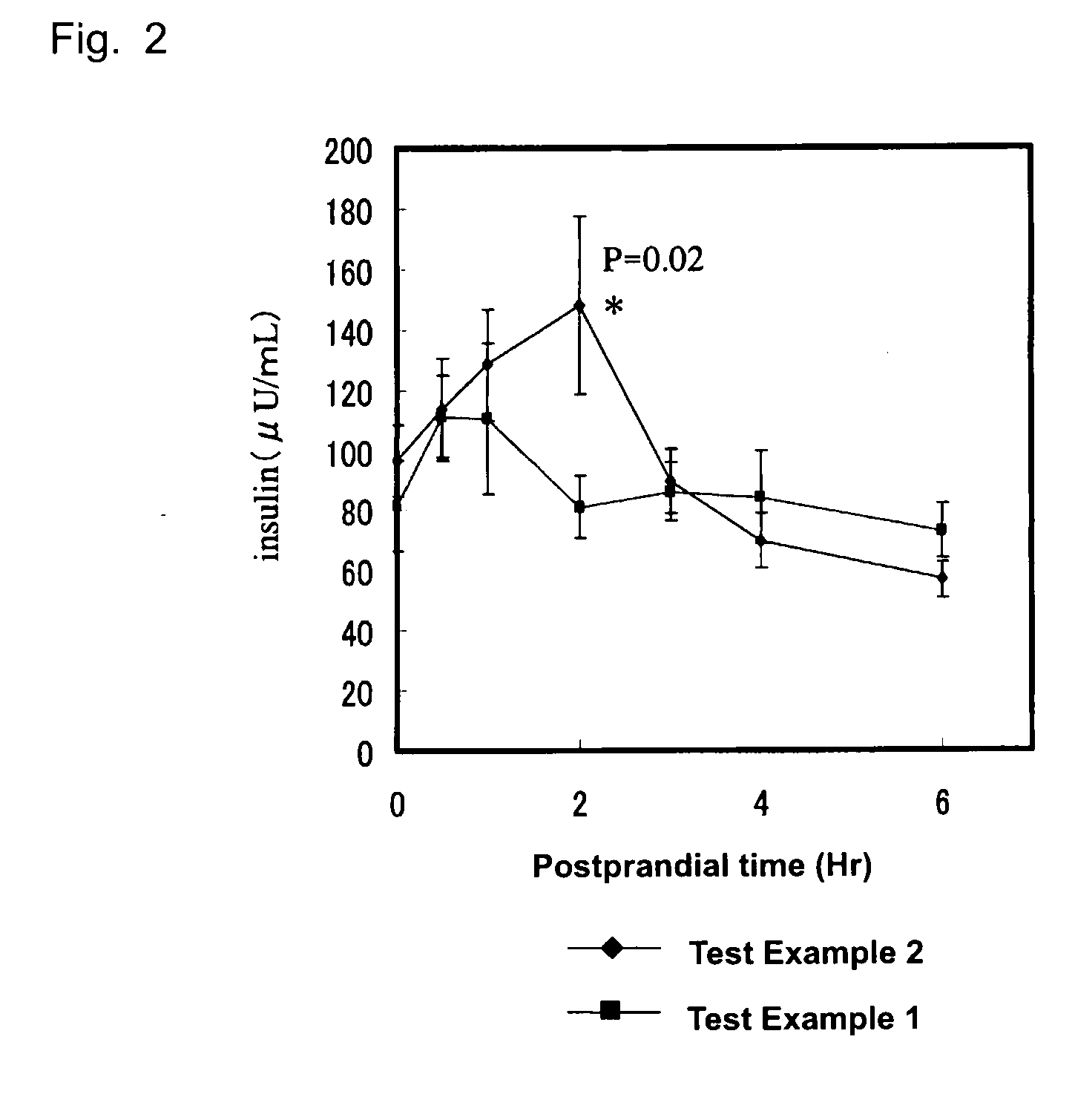

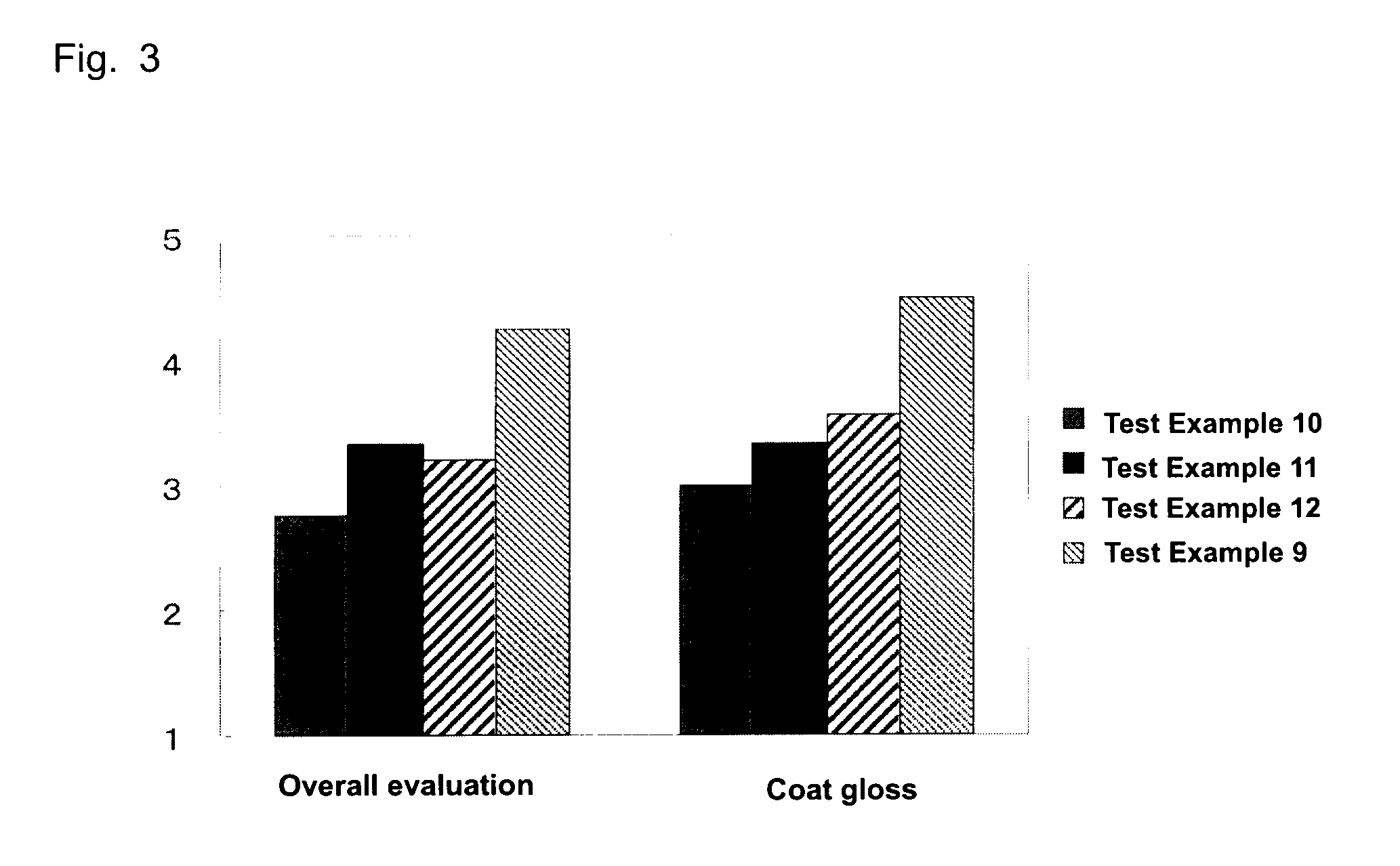

InactiveUS20090148560A1Improving pet ' appearanceHigh purityMilk preparationFatty substance preservation using additivesSorghumCompanion animal

A pet food containing (A) an oil or fat and (B) one or more carbohydrate sources selected from the group consisting of modified starch, barley, sorghum, corn and high-amylose starch, wherein a content of diacylglycerol in the whole oil or fat is 20 wt % or higher.The pet food according to the present invention is excellent in the preventing or controlling effect on obesity, is not reduced in ingestion capacity, and does not affect stool conditions.

Owner:KAO CORP

Wheat with altered branching enzyme activity and starch and starch containing products derived therefrom

Wheat having a reduced level of SBEIIa activity, that may have a relative high amylose content. Wheat having a mutant SBEIIa gene in the A genome. The wheat might additionally have reduced levels of SBEIIb activity. The wheat grain of this invention can be of a non-shrunken phenotype despite a lesion in the amylopectin synthesis pathway, and may also have a high relative amylose content.

Owner:COMMONWEALTH SCI & IND RES ORG +1

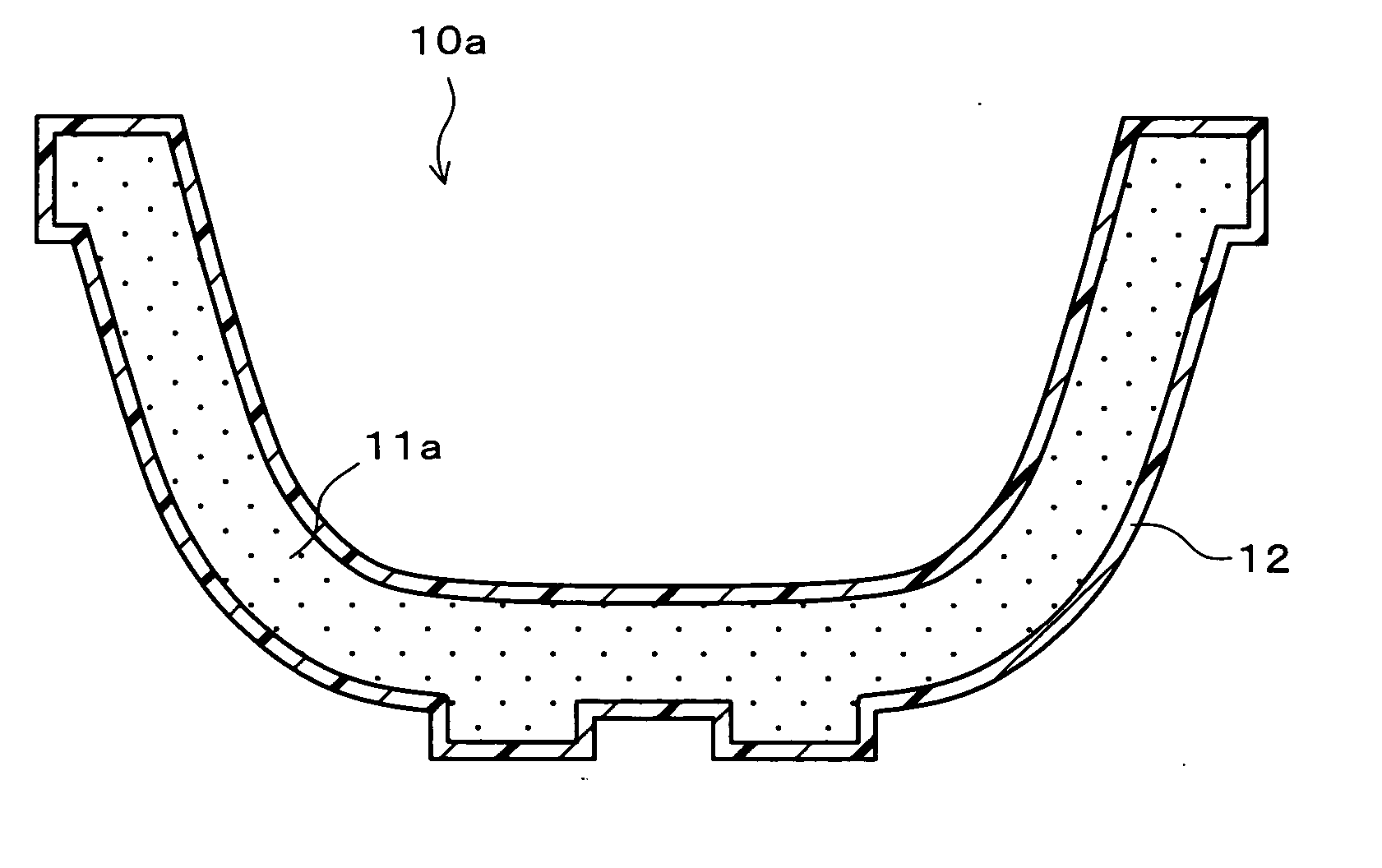

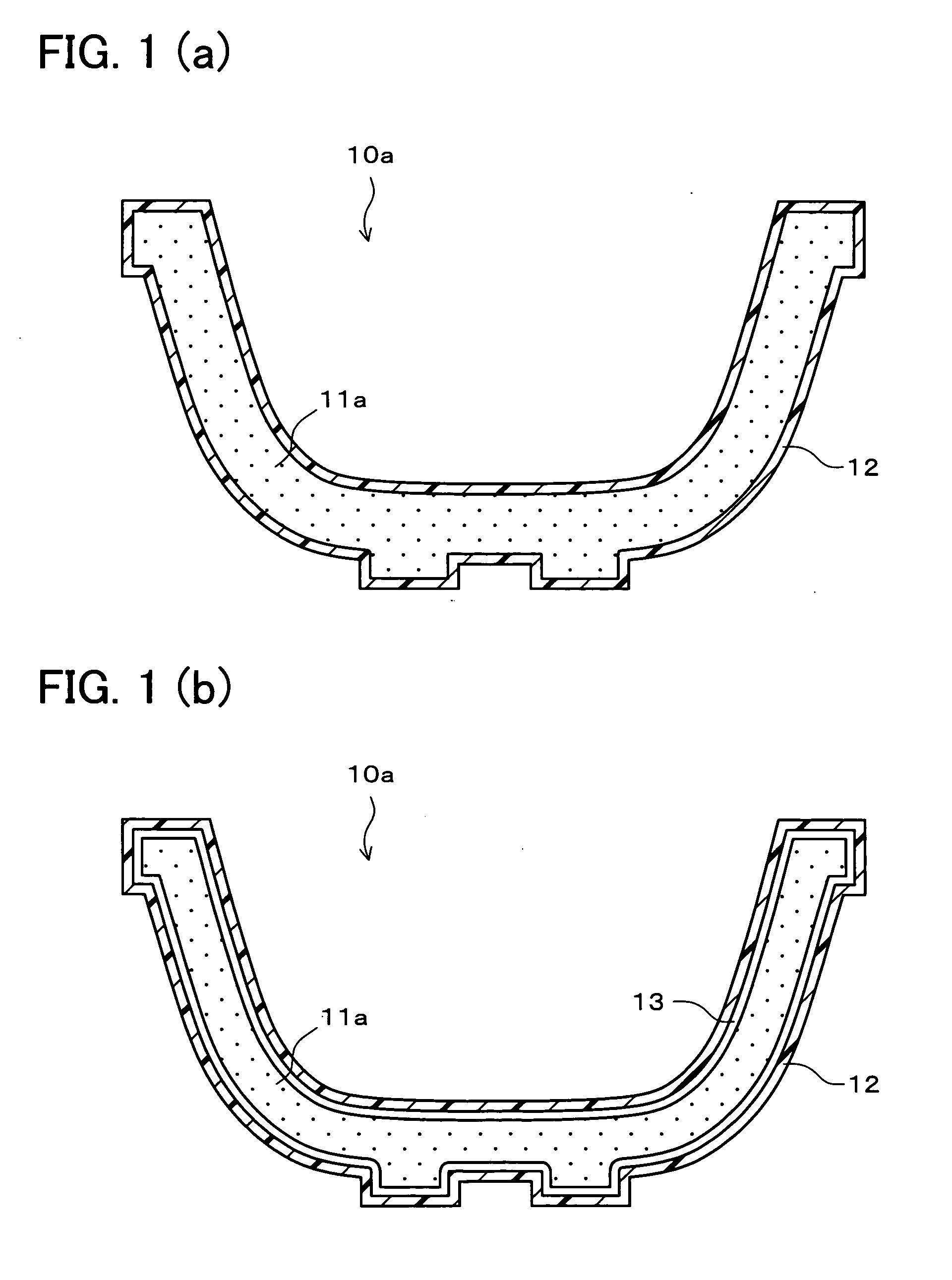

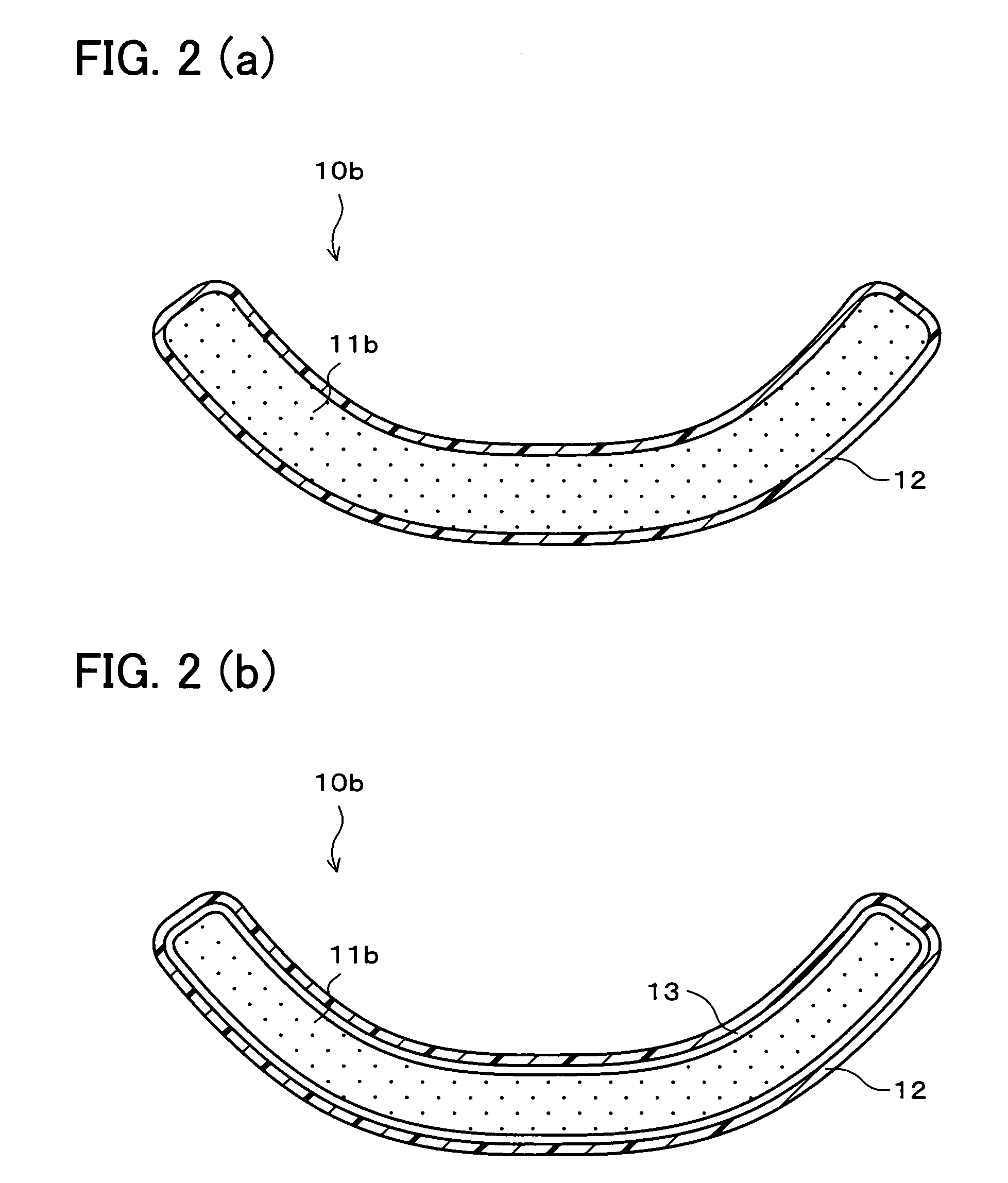

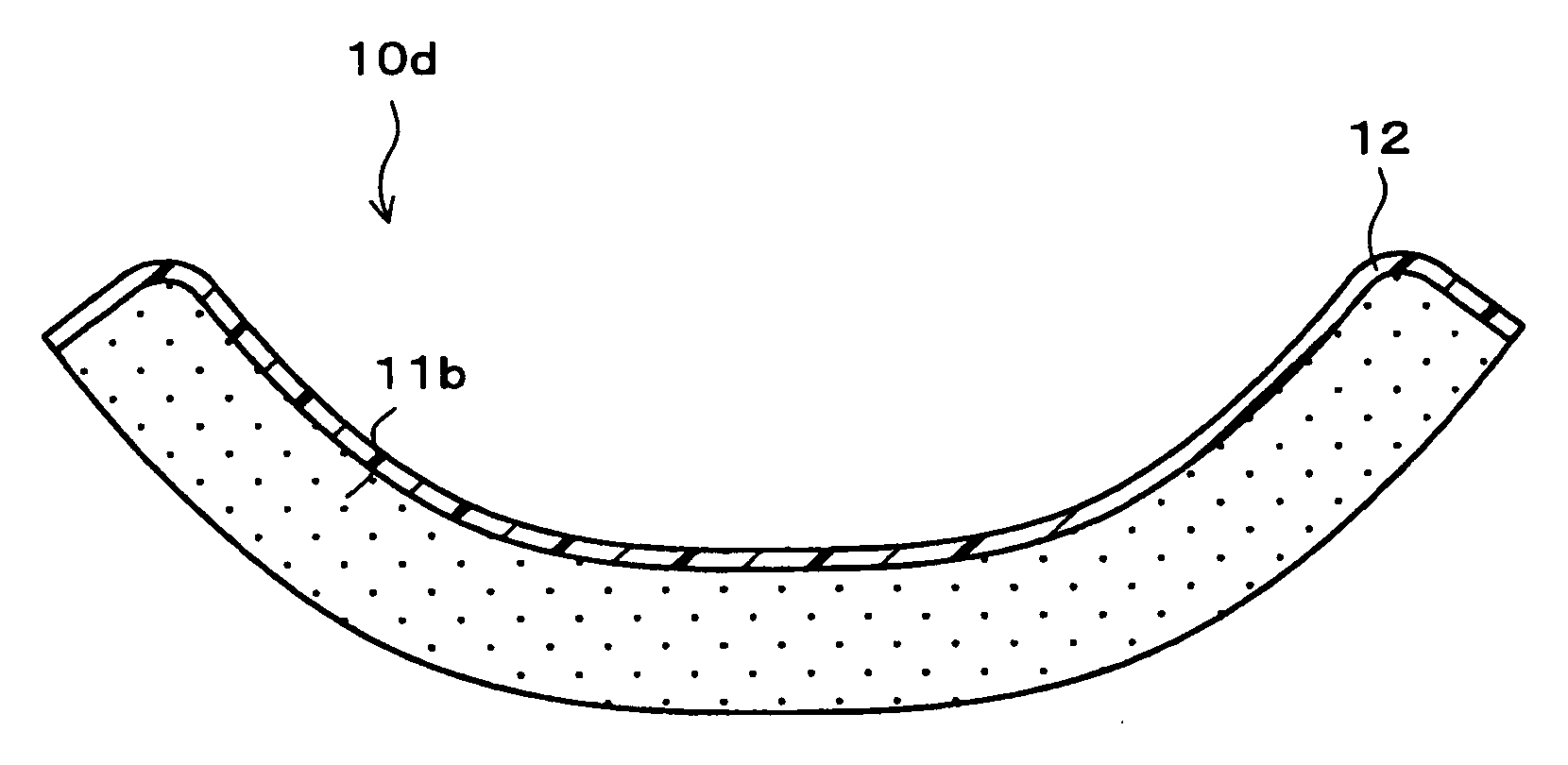

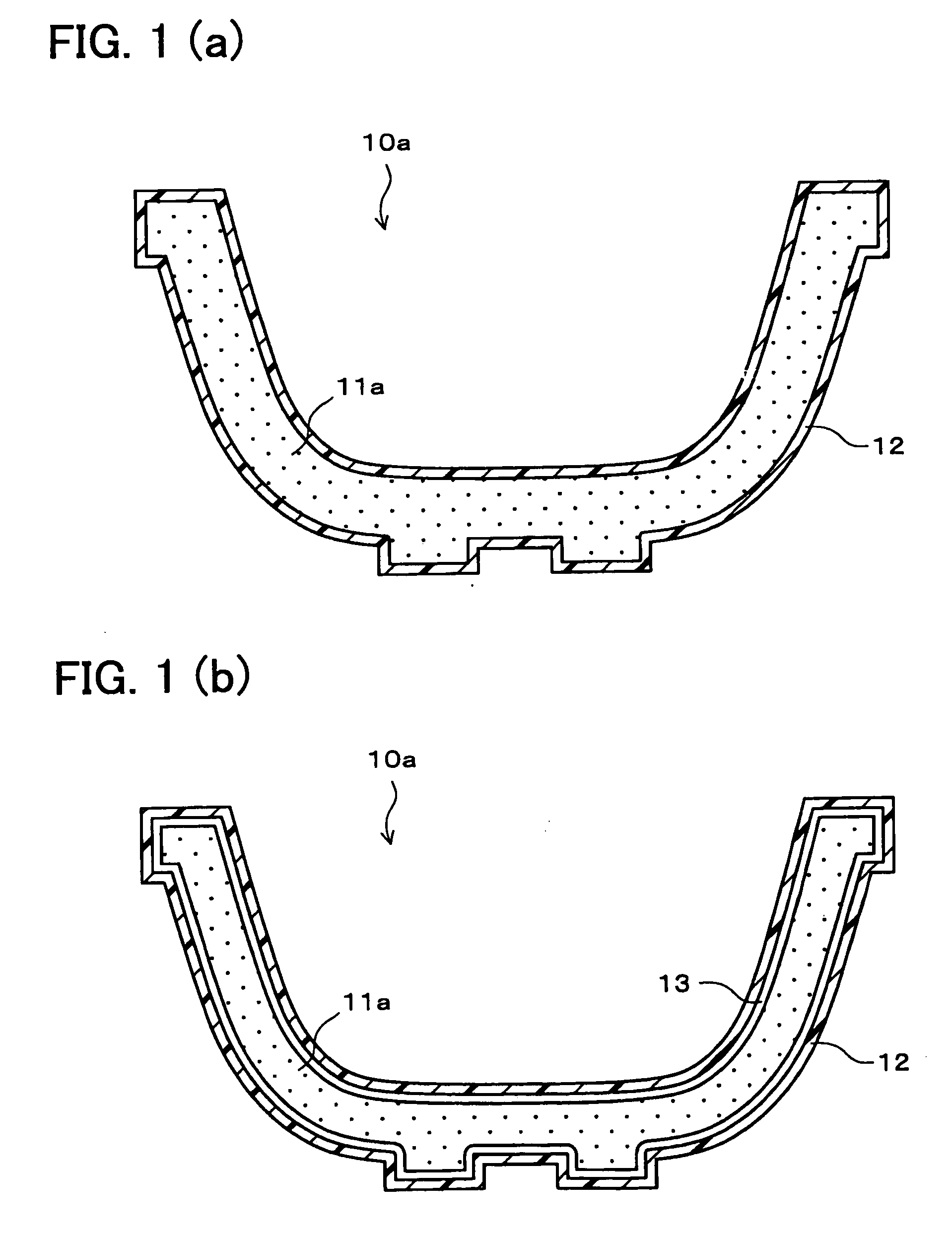

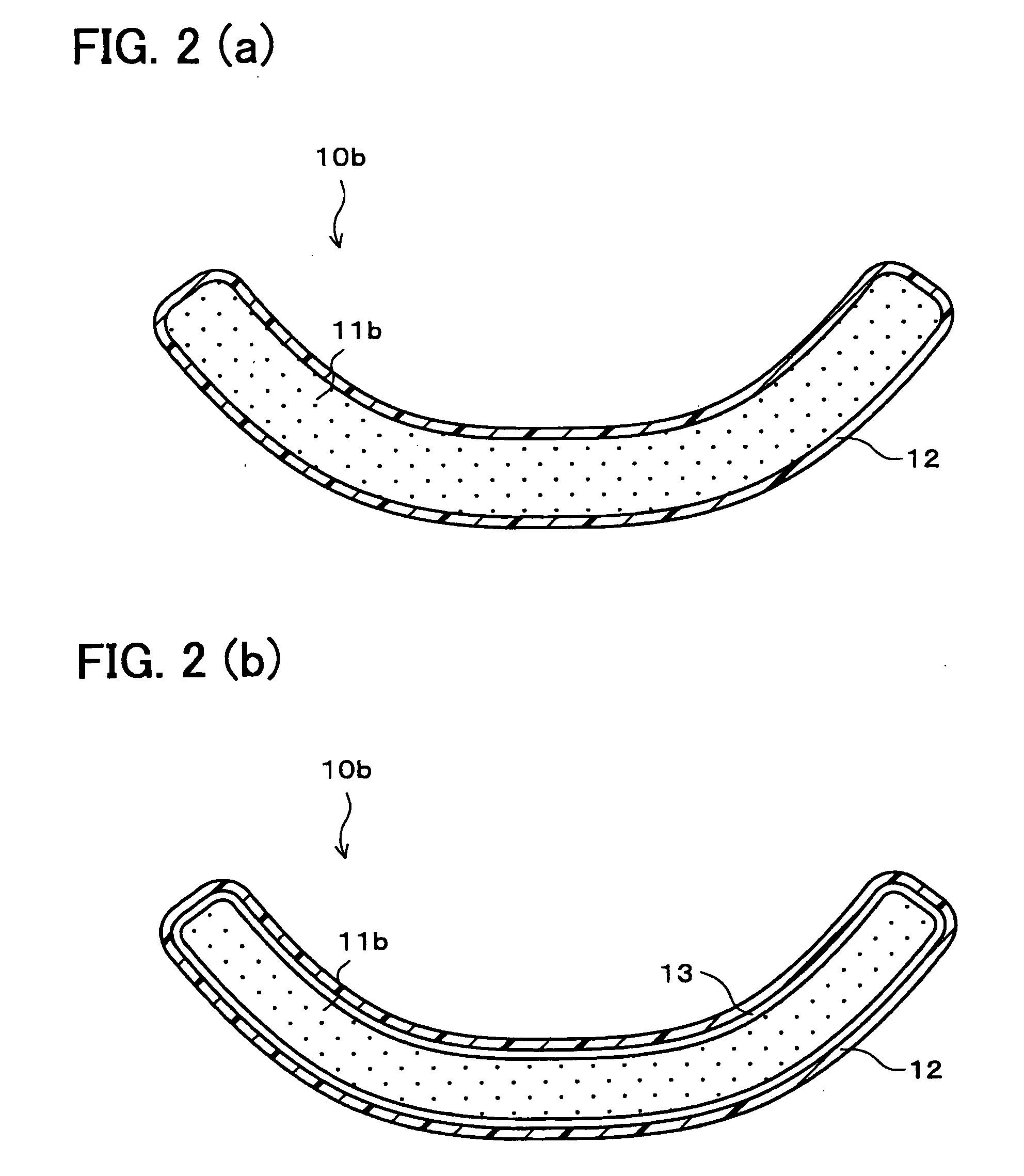

Biodegradable molding

InactiveUS20050202229A1Increased intensityIncrease physical strengthFlexible coversWrappersPolymer sciencePolyvinyl alcohol

A bowl-shaped container (10a) which is as a biodegradable molded article adheres a coating film (12) mainly made of biodegradable plastic and having at least hydrophobicity to the surface of the main body (11a) of the container mainly made of starch. The main body (11a) is molded through steam expansion of a slurry or dough molding material containing high-amylose starch and water, or a slurry or dough molding material containing starch, polyvinyl alcohol and water. For these reasons, it is possible to accomplish sufficient strength and at least sufficient water resistance, to exert a very excellent biodegradability and further to provide a biodegradable molded article having excellent moisture absorption strength mainly made of starch even if the biodegradable molded article has a complicated shape.

Owner:NISSEI CO LTD

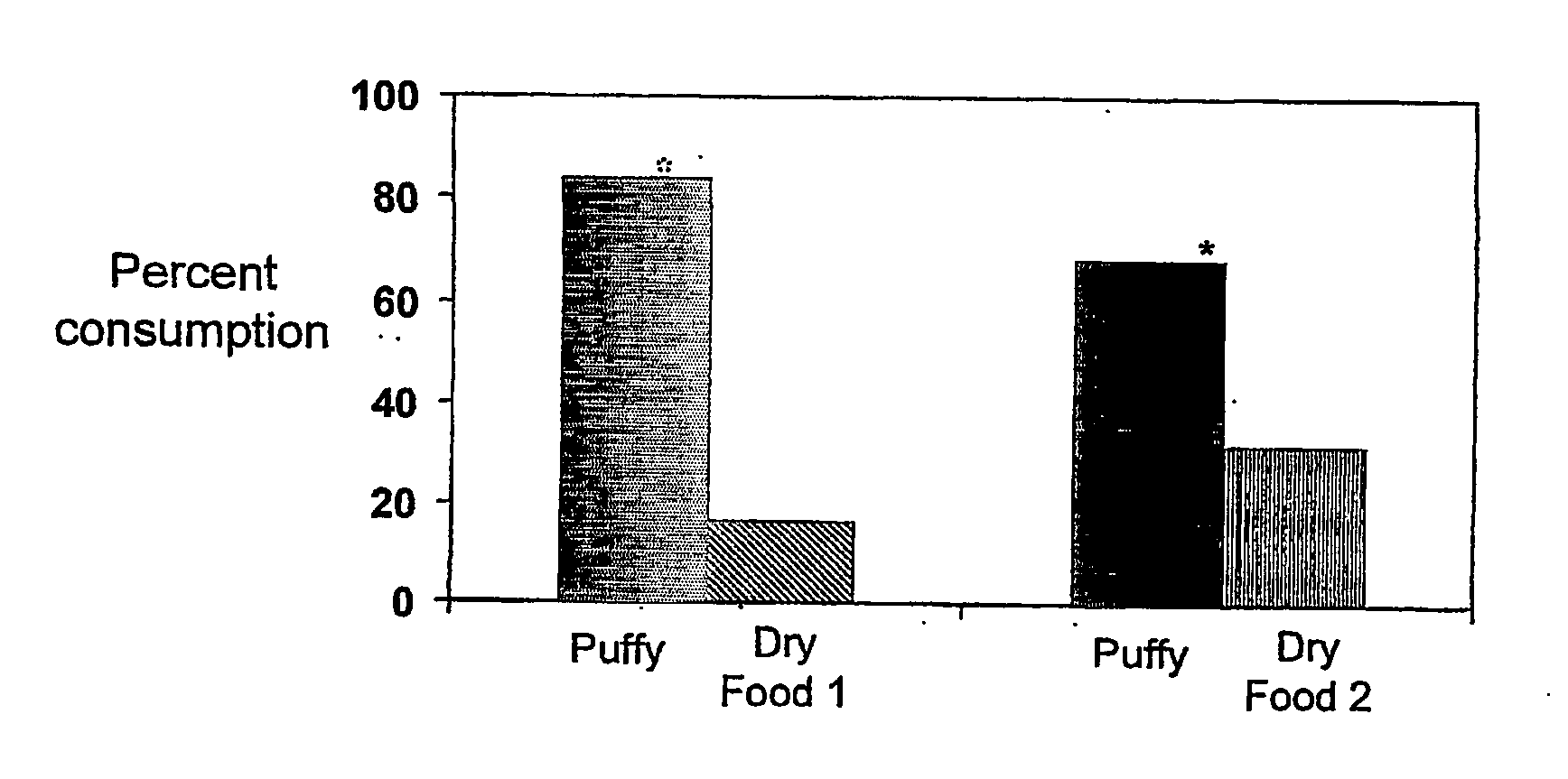

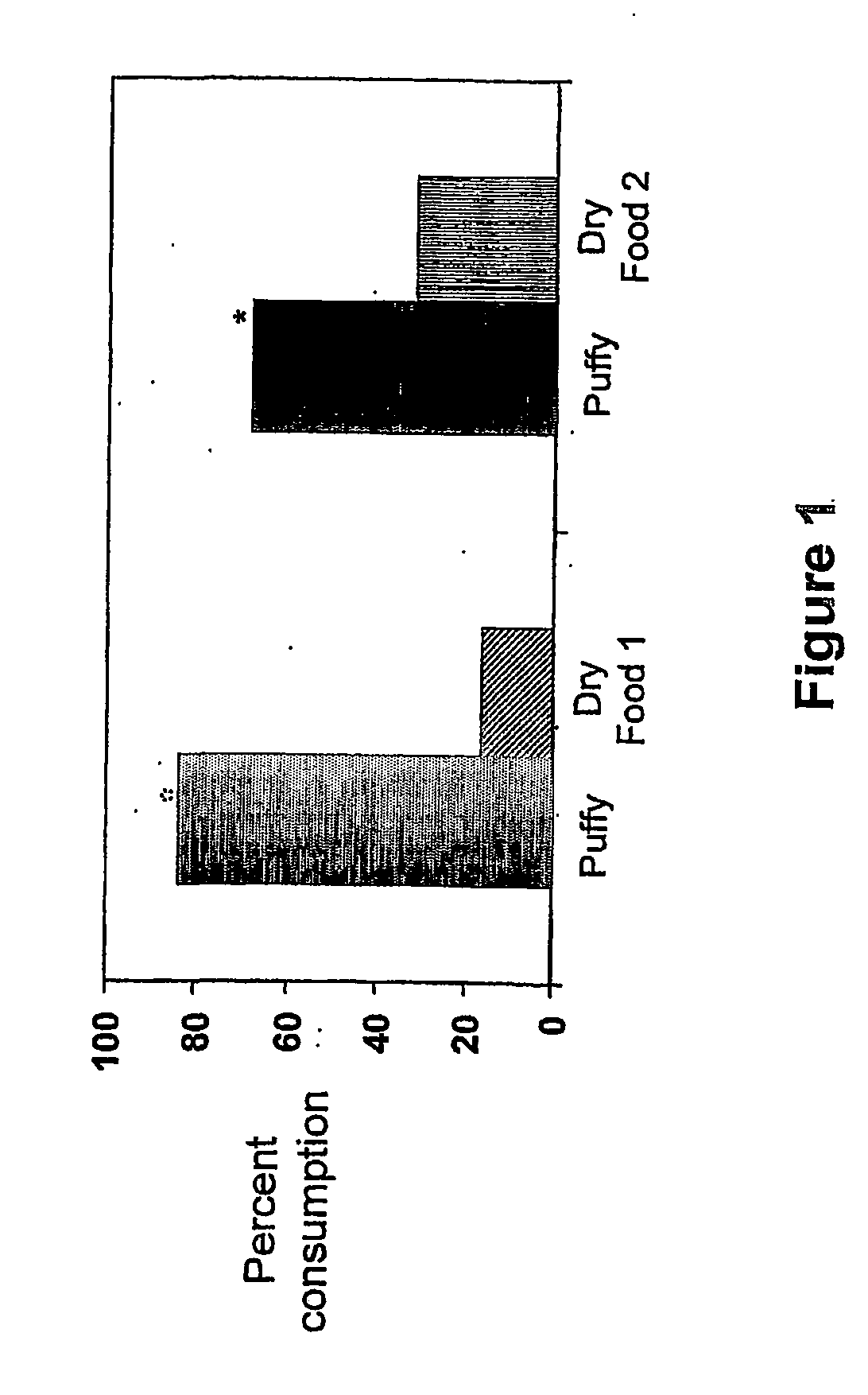

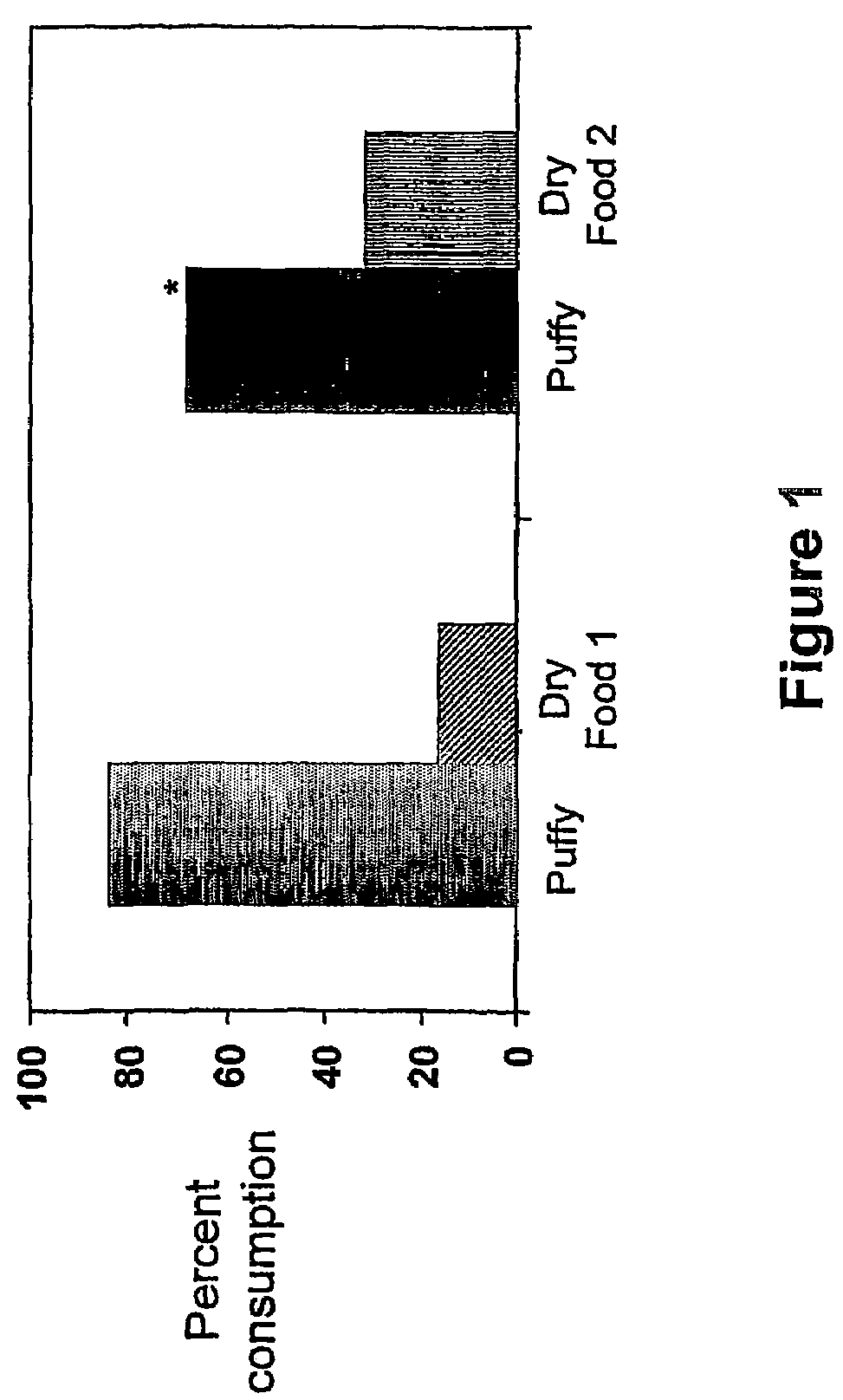

Puffed pet food for diet control

InactiveUS20060240169A1Few calorieLose weightConfectioneryAnimal feeding stuffDiet controlledEnergy dense food

Low energy-dense food products and methods of making low energy-dense food products are provided. Illustrative examples have a bulk density of less than 240 kg / m3 (about 15 lb / ft3) and comprise a high amylose starch and a starch comprising long chain amylose.

Owner:NESTEC SA

Preparation method for completely biodegraded high amylose starches base thin film

The invention relates to a preparation method of a fully biodegraded high-amylose based film. The invention resolves the problem that the present plastic film cannot be fully biodegraded. The preparation method of the fully biodegraded high-amylose based film includes following steps: (1) Gelatinization; (2) Blending; (3) Plasticization and Crosslinking; (4) Degasification and Drying, and the fully biodegraded high-amylose based film can be obtained by the preparation method. The products produced by the invention are characterized in safety, nontoxicity, full biodegradation, etc., thus having good use performance and degradation performance.

Owner:HARBIN INST OF TECH

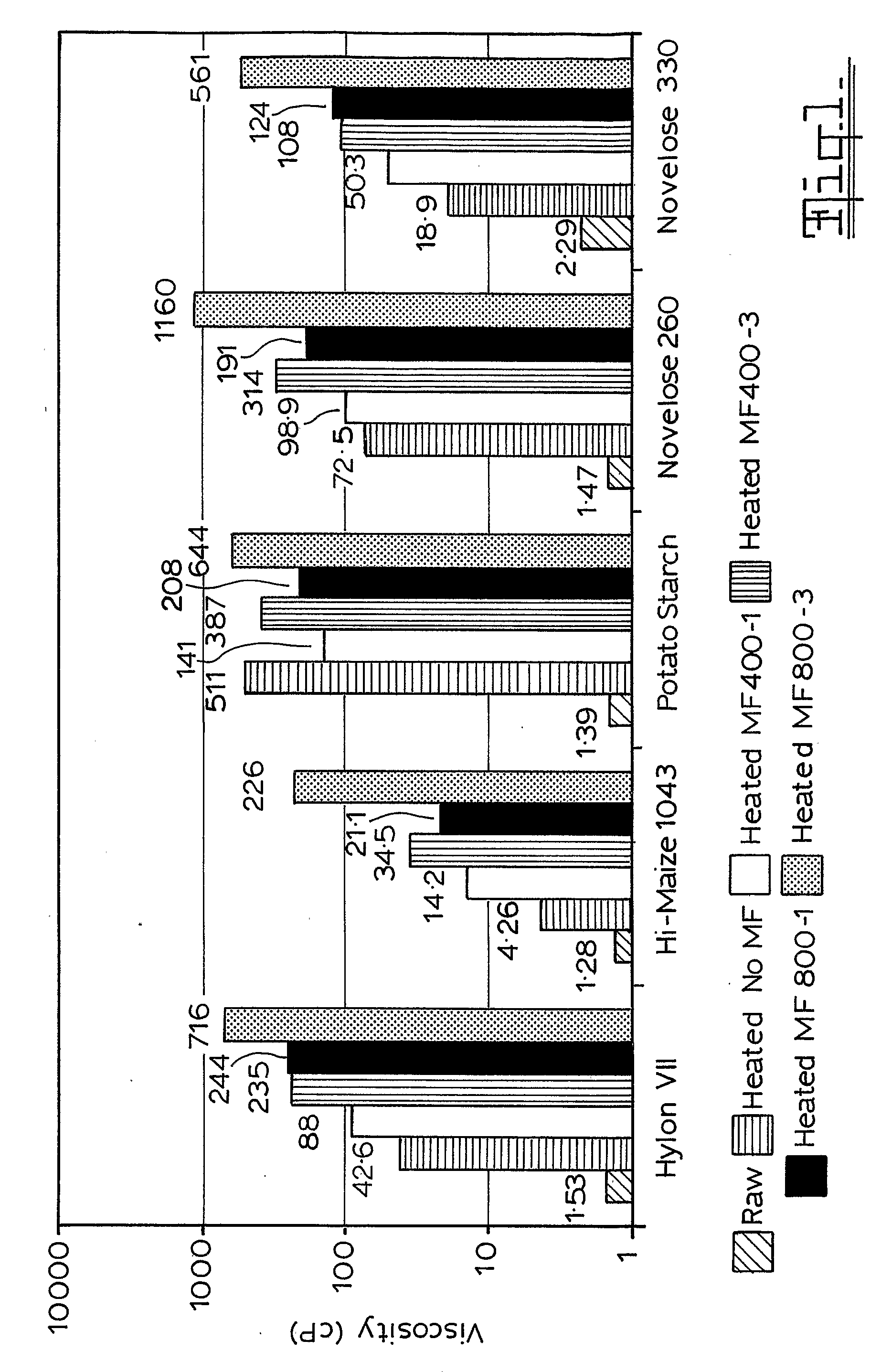

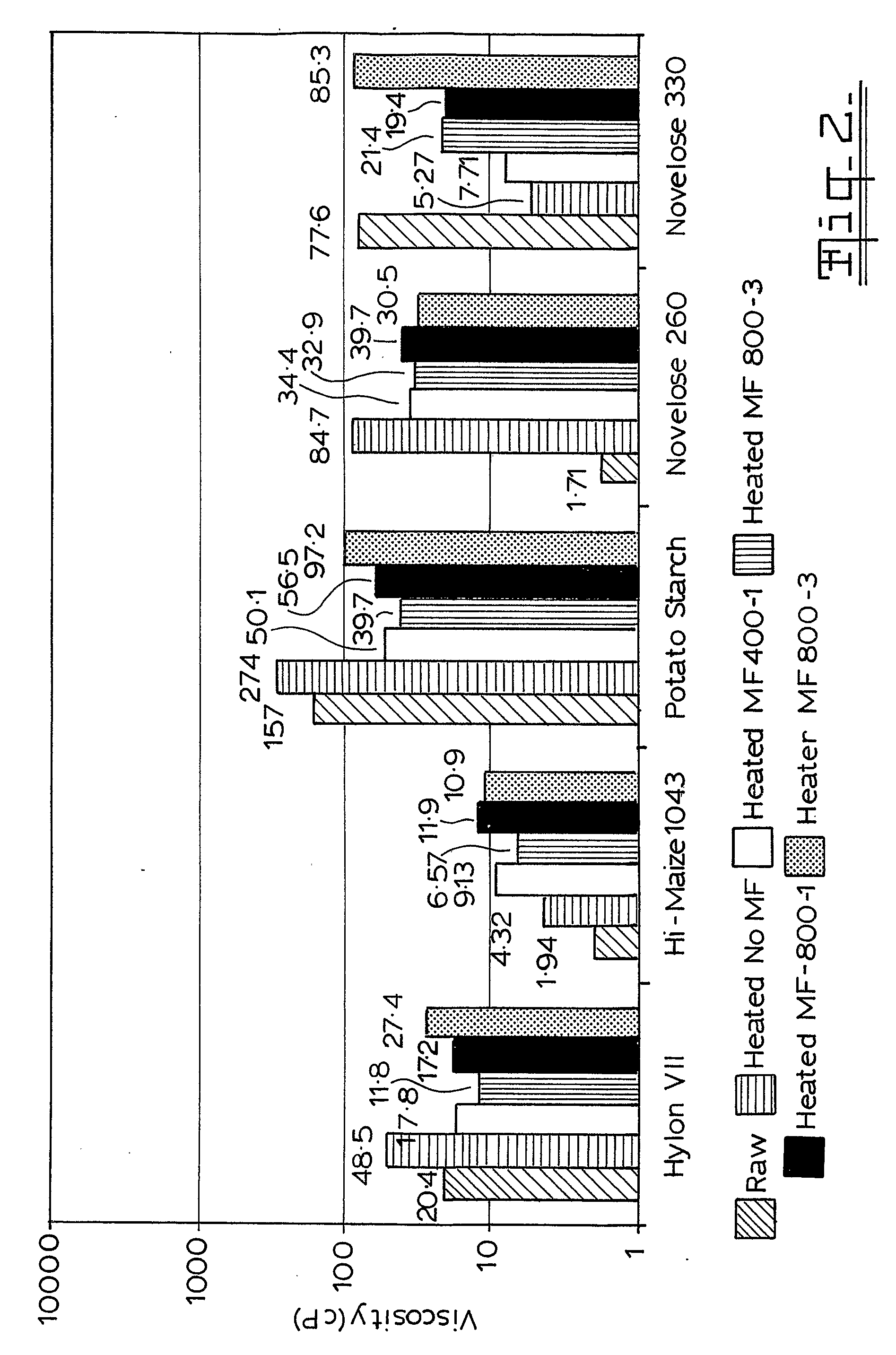

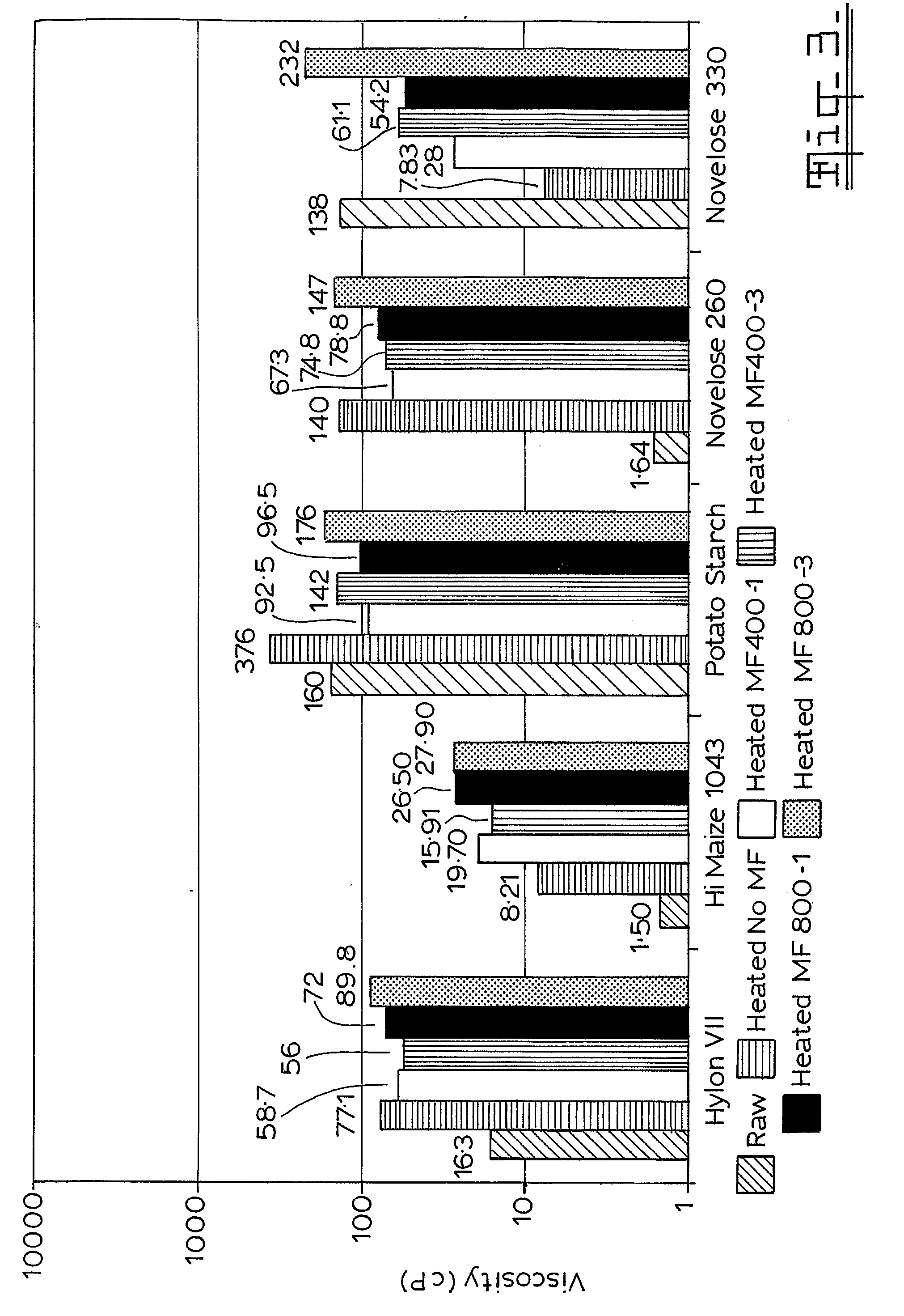

Starch Treatment Process

InactiveUS20070212475A1Alter performance characteristicReduced additiveConfectionerySweetmeatsFood gradeAdditive ingredient

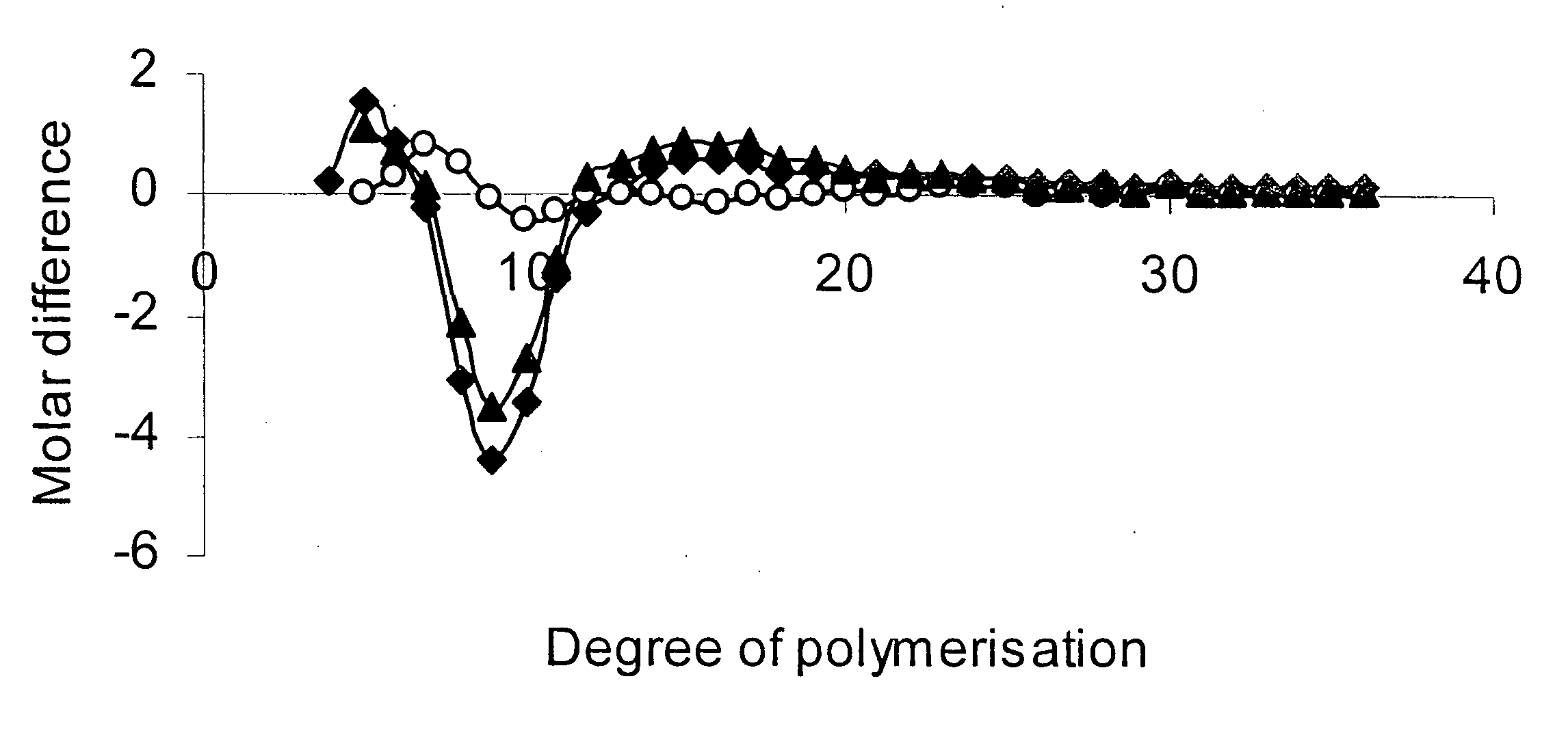

High amylose starches are treated to retain resistance while improving water binding properties. Starch functionality is varied by pre-processing of starches by heating and microfluidisation, to create changes in product viscosity, resistant starch content, particle size and molecular weight. The treated starches produce food grade resistant starches which have the ability to bind water, build viscosity, gel and form films. They can be used as fat replacement ingredients.

Owner:COMMONWEALTH SCI & IND RES ORG

Starch hollow capsule and preparation method thereof

ActiveCN103070845ALow priceQuality improvementPharmaceutical non-active ingredientsCapsule deliverySODIUM METAPHOSPHATECross-link

The invention provides a starch hollow capsule and a preparation method thereof. The starch hollow capsule comprises components in parts by weight as follows: 60 parts to 90 parts of cross-linking high amylose, 3 parts to 15 parts of tributyl citrate, 5 parts to 15 parts of guar gum, 1 part to 5 parts of span-80 and 1 part to 5 parts of inulin. The cross-linking high amylose is prepared by cross-linking natural high direct connection starch through a cross-linking agent consisting of sodium metaphosphate and adipic acid. The starch hollow capsule has the advantages that the price is low, the quality is good, and the strength is high, standards of Chinese Pharmacopoeia are achieved, the friability is 5%, the disintegration time is five minutes, and obvious effects are achieved in practical application.

Owner:北京爱特康医疗科技有限公司

Cross-linked high amylose starch for use in controlled-release pharmaceutical formulations and processes for its manufacture

InactiveUS20040013726A1Ability to obtainEasy to processAntibacterial agentsNervous disorderCross-linkControlled release

The present invention relates to a novel form of cross-linked high amylose starch and processes for its manufacture. Such cross-linked high amylose starch is useful as an excipient in a controlled-release pharmaceutical formulation when compressed with pharmaceutical agent(s) in a tablet. Such cross-linked high amylose starch is prepared by (a) cross-linking and chemical modification of high amylose starch, (b) gelatinization, and (c) drying to obtain a powder of said controlled release excipient. In a preferred embodiment, such cross-linked high amylose starch is prepared in the following steps: (1) granular cross-linking and additional chemical modification (e.g., hydroxypropylation) of high-amylose starch; (2) thermal gelatinization of the starch from step (1); and (3) drying the starch from step (2) to yield a powder capable of being used as a controlled release excipient.

Owner:LABOPHARM INC

Method for preparing resistant starch of corn

InactiveCN101427741AGood physical and chemical propertiesDelicate tasteFood preparationFatty acidFermentation

The invention relates to a preparation method of corn resistant starch, which uses common corn starch as raw material to produce corn resistant starch with multiple physiological functions and characteristics by combined treatment of microbial fermentation and hot pressing and cooling. The resistant starch has physiologic functions of effectively controlling body weight, preventing constipation, appendicitis, hemorrhoids and colon cancer, controlling diabetes, increasing lipid discharge, improving lipid composition, promoting absorption of zinc, calcium and magnesium ions, increasing removal of cholesterol and cholic acid, and reducing cholesterol biosynthesis, lipid absorption and fatty acid biosynthesis. The resistant starch used in food processing industry has better physicochemical properties than those of dietary fiber, low water retention capacity, good mouthfeel, no influence on food, and improve food texture. The invention solves the problems in production of resistant starch, including low yield and lack of high amylase starch in China.

Owner:JILIN AGRICULTURAL UNIV

Puffed pet food for diet control

InactiveUS7678406B2Few calorieRisk minimizationConfectioneryAnimal feeding stuffDiet controlledEnergy dense food

Low energy-dense food products and methods of making low energy-dense food products are provided. Illustrative examples have a bulk density of less than 240 kg / m3 (about 15 lb / ft3) and comprise a high amylose starch and a starch comprising long chain amylose.

Owner:NESTEC SA

Mouldable biodegradable polymer

ActiveUS8569402B2Improve hydrophobicityImprove water resistanceFireproof paintsSynthetic resin layered productsMolten statePolyethylene oxide

A biodegradable injection moldable polymer having the composition a) from 50 to 85% by weight of a starch and or a modified high amylose starch b) from 4 to 13% by weight of a water soluble polymer selected from polyvinylacetate, polyvinyl alcohol and copolymers of ethylene and vinylalcohol which have a melting point compatible with the molten state of the starch components c) from 10 to 35% by weight of a polyol plasticizer d) from 0.5 to 10% of a polyethylene oxide or polyethylene glycol e) from 0 to 1.5% by weight of a C12-22 fatty acid or salt and f) from 0.25% to 3% of a food grade emulsifier. The polymers are suitable for biodegradable, flushable tampon applicators and other medical or industrial products where flushability and bio degradability are desirable.

Owner:PLANTIC TECH

Barley with altered branching enzyme activity and starch and starch containing products with an increased amylose content

InactiveUS20090226592A1Reduced activityReduce enzyme activityDough treatmentTransferasesHordeum vulgareStarch synthesis

Barley having a reduced level of SBEIIa activity produces grain having a high relative amylose content. The barley might additionally have reduced levels of SBEIIb activity. The barley grain of this invention can be of a non-shrunken phenotype despite a lesion in the amylopectin synthesis pathway.

Owner:COMMONWEALTH SCI & IND RES ORG

Wheat with altered branching enzyme activity and starch and starch containing products derived therefrom

ActiveUS20110070352A1Reduce the ratioDough treatmentFood genetic modificationStarch synthesisBulgur wheat

Wheat having a reduced level of SBEIIa activity, that may have a relative high amylose content. Wheat having a mutant SBEIIa gene in the A genome. The wheat might additionally have reduced levels of SBEIIb activity. The wheat grain of this invention can be of a non-shrunken phenotype despite a lesion in the amylopectin synthesis pathway, and may also have a high relative amylose content.

Owner:ARISTA CEREAL TECH

High amylose dog chew formulation

InactiveUS7722911B2Resist formationReducing of choking and intestinal blockageBaking mixturesFrozen sweetsThermoplasticPlasticizer

Owner:B&S PLASTICS

Preparation method of corn starch-fatty acid compound having V-shaped crystal structure

InactiveCN104757369AImprove hydrophobicityImprove acid resistanceFood preparationWater bathsFreeze-drying

Owner:QINGDAO AGRI UNIV

Biodegradable polymer

InactiveUS20060293419A1Reduce the temperatureEasily plasticised and extrudedGroup 4/14 element organic compoundsOrganic compound preparationMolten statePolyvinyl alcohol

A biodegradable polymer is disclosed having the composition g) from 8 to 80% by weight of a starch modified to include an hydroxyalkyl C2-6 group or modified by reaction with an anhydride of a dicarboxylic acid, preferably hydroxypropylated high amylose starch, a) from 0 to 87.9% of starch, b) from 4 to 11% by weight of a water soluble polymer selected from polyvinylacetate, polyvinyl alcohol and copolymers of ehtylene and vinylalcohol which have a melting point compatible with the molten state of the starch components, c) from 0 to 20% by weight of a polyol plasticiser, preferably glycerol, d) from 0.1 to 1.5% by weight of a C12-22 fatty acid or salt, preferably stearic acid and, e) 0 to 12% added water. The polymers are suitable as biodegradable rigid sheet or flexible film materials for use in packaging foodstuffs.

Owner:PLANTIC TECH

Biodegradable molded article

InactiveUS20090008819A1Satisfaction intensityPromote biodegradationFlexible coversWrappersPolymer sciencePolyvinyl alcohol

A bowl-shaped container (10a) which is as a biodegradable molded article adheres a coating film (12) mainly made of biodegradable plastic and having at least hydrophobicity to the surface of the main body (11a) of the container mainly made of starch. The main body (11a) is molded through steam expansion of a slurry or dough molding material containing high-amylose starch and water, or a slurry or dough molding material containing starch, polyvinyl alcohol and water. For these reasons, it is possible to accomplish sufficient strength and at least sufficient water resistance, to exert a very excellent biodegradability and further to provide a biodegradable molded article having excellent moisture absorption strength mainly made of starch even if the biodegradable molded article has a complicated shape.

Owner:NISSEI CO LTD

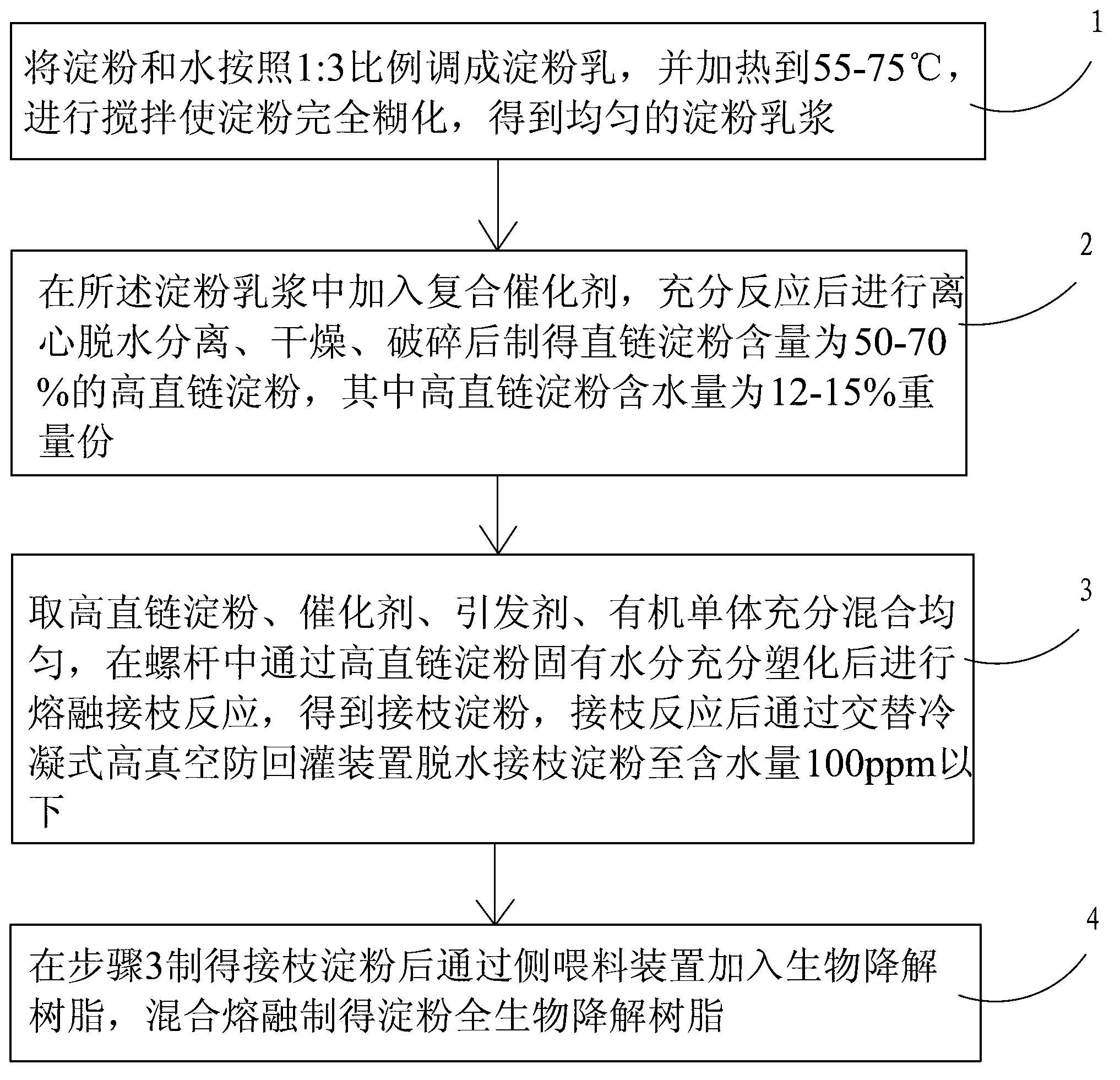

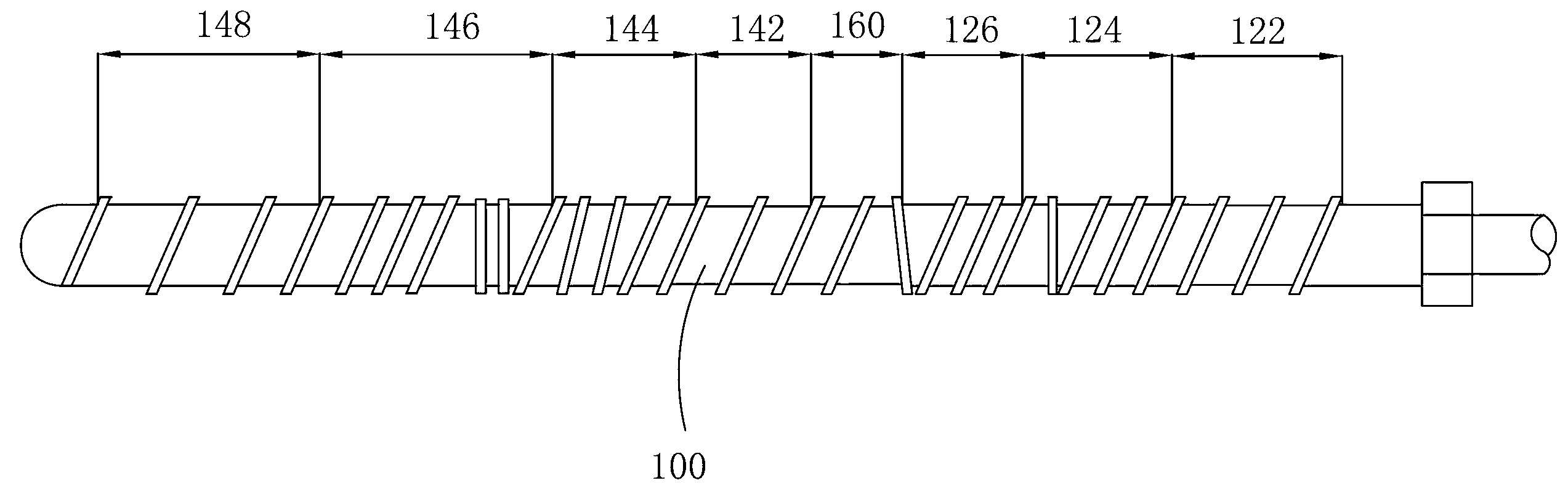

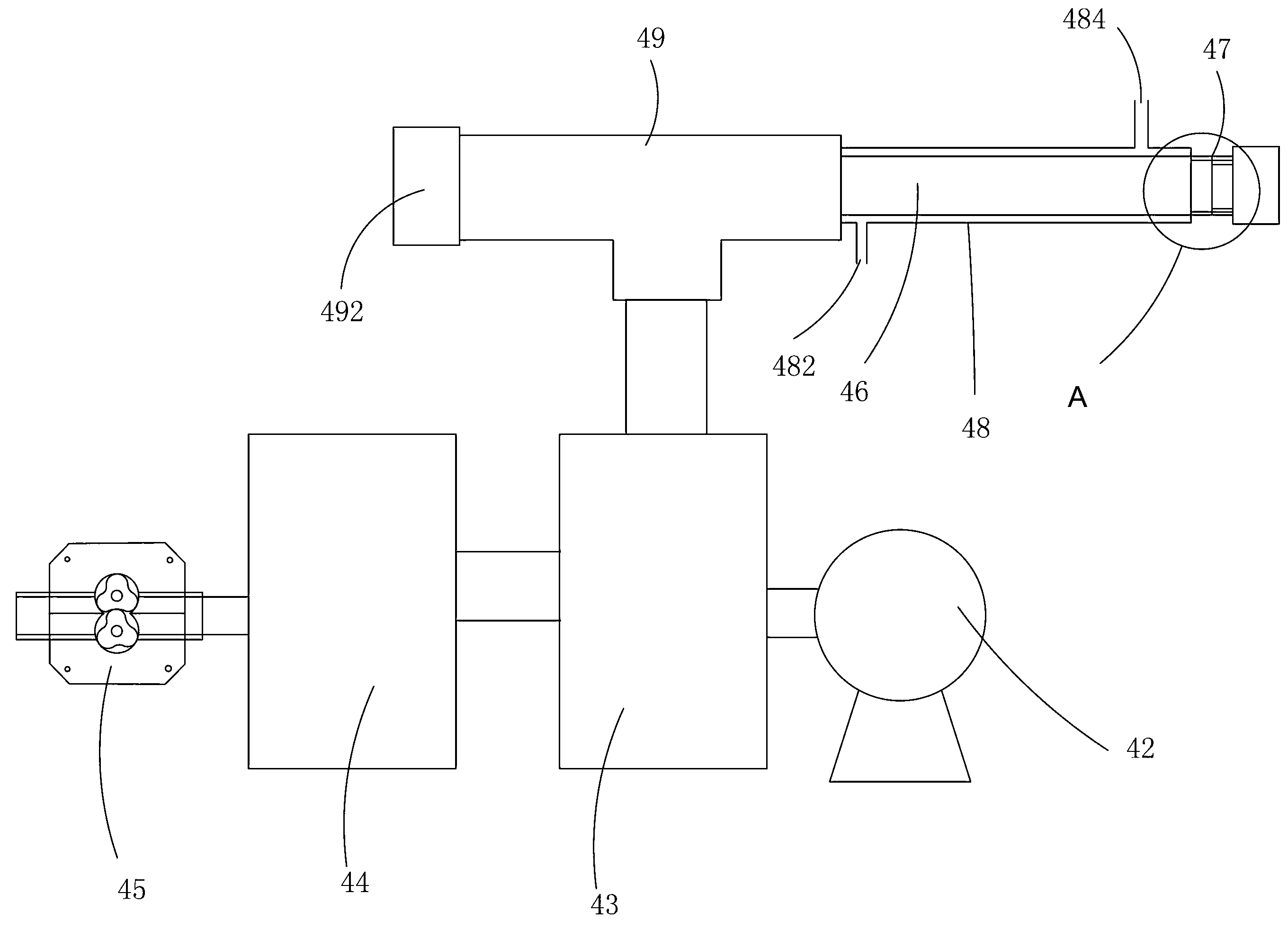

Starch full-biodegradable resin and continuous preparation method thereof

The invention provides a starch full-biodegradable resin and a continuous preparation method thereof. The starch full-biodegradable resin comprises the following components in parts by weight: 100 parts of high amylose, 0.05-0.10 part of catalyst, 0.1-0.15 part of initiator, 3-5 parts of organic monomer and 65-170 parts of biodegradable resin. The starch full-biodegradable resin is high in starch filling content and excellent in mechanical property and secondary processability, and can meet a stricter sanitary standard. According to the continuous preparation method of the starch full-biodegradable resin, the starch grafting and blending is carried out through continuous operation, the phenomena that the mechanical property and secondary processability of the products are lowered caused by migration of plasticizers and ordered reconfiguration of structures carried out spontaneously among chains are avoided, and a stricter sanitary standard can be met. The prepared starch full-biodegradable resin is high in starch content and excellent in mechanical property, and the cost is greatly reduced.

Owner:安徽华哲虹彩科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com