High-quality insoluble plant edible fiber micropowder and preparation method and application thereof

A dietary fiber and micropowder technology, applied in the field of dietary fiber, can solve the problems of serious environmental pollution, affecting the quality and performance of dietary fiber, and high production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

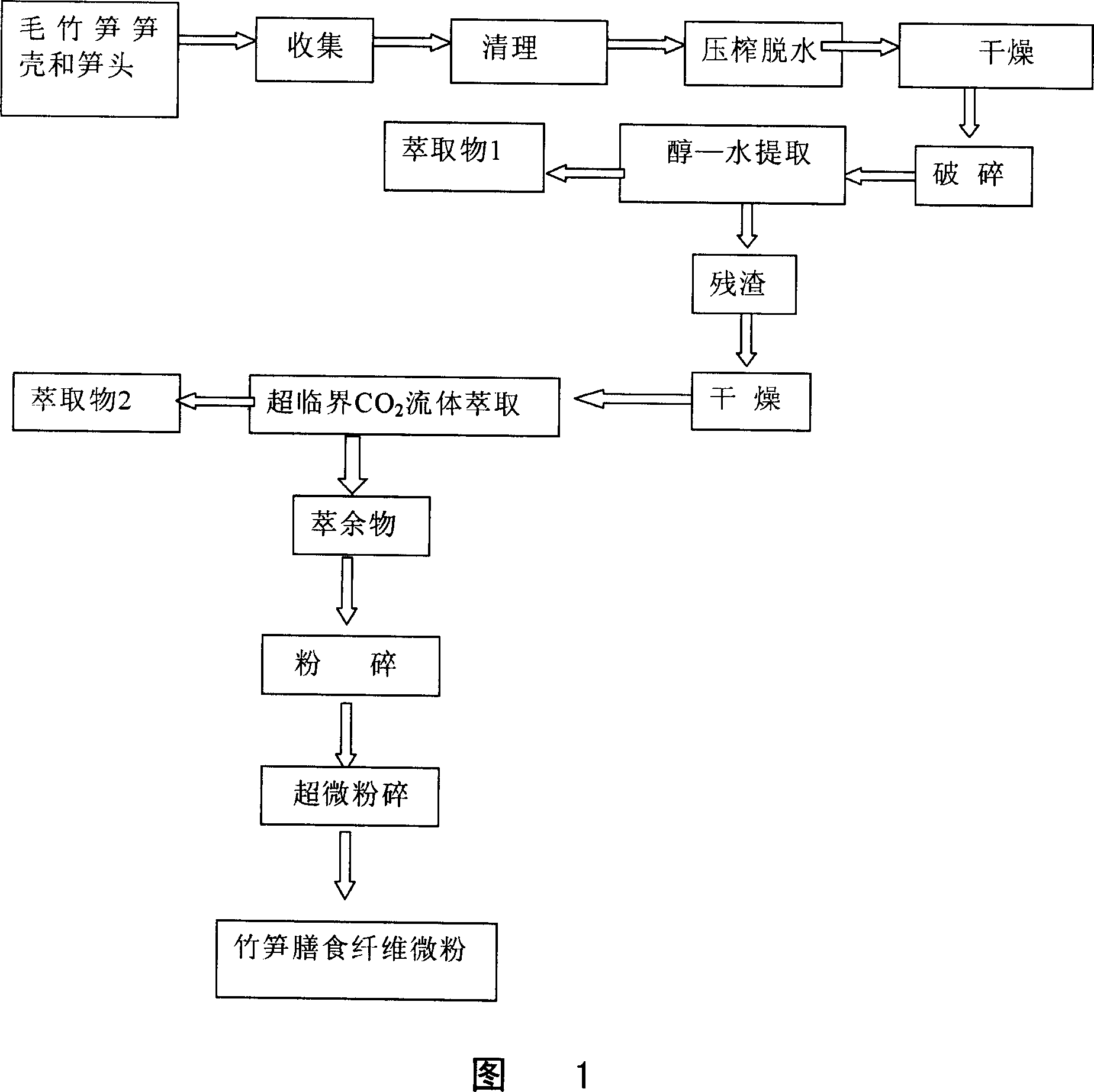

Method used

Image

Examples

Embodiment 1

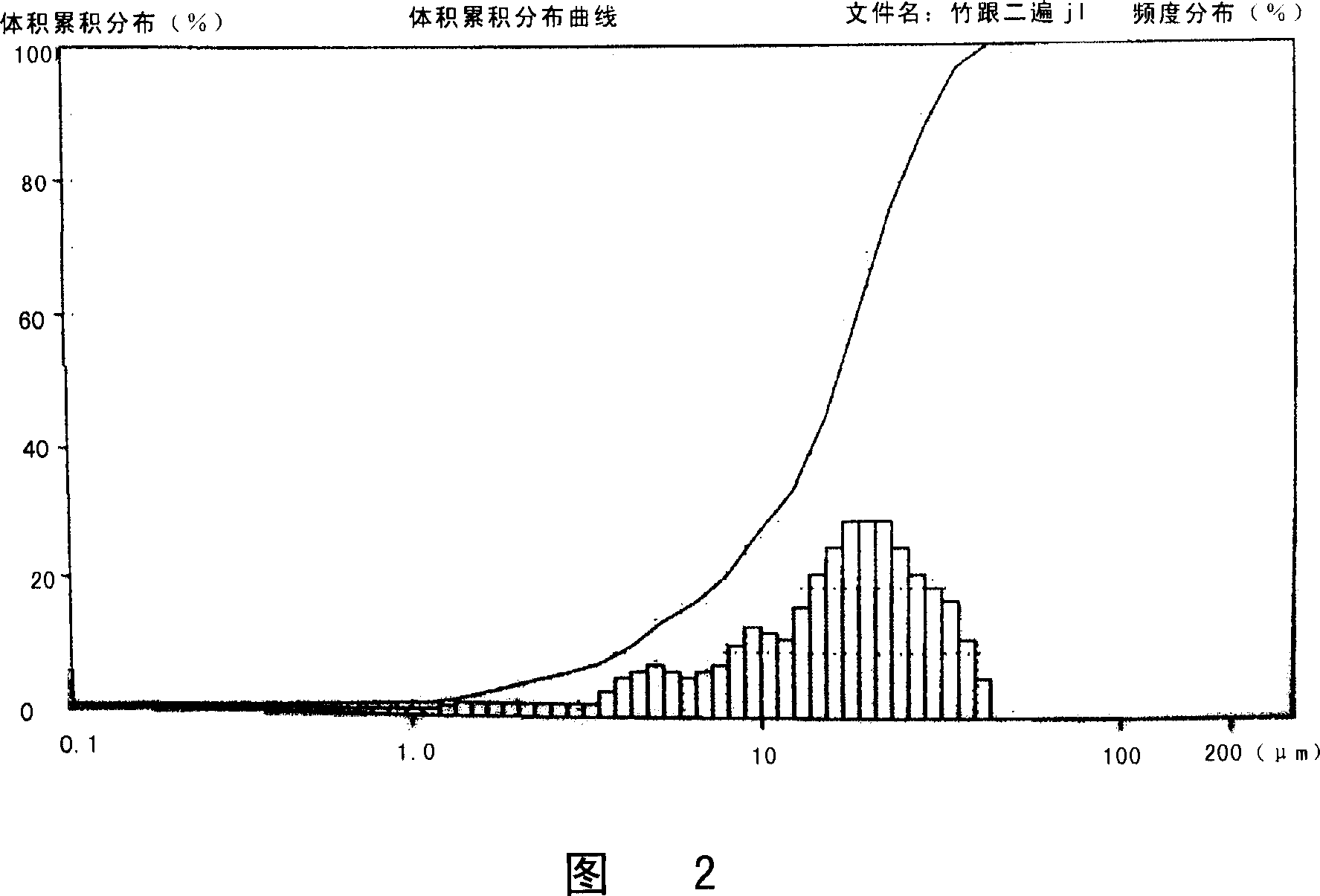

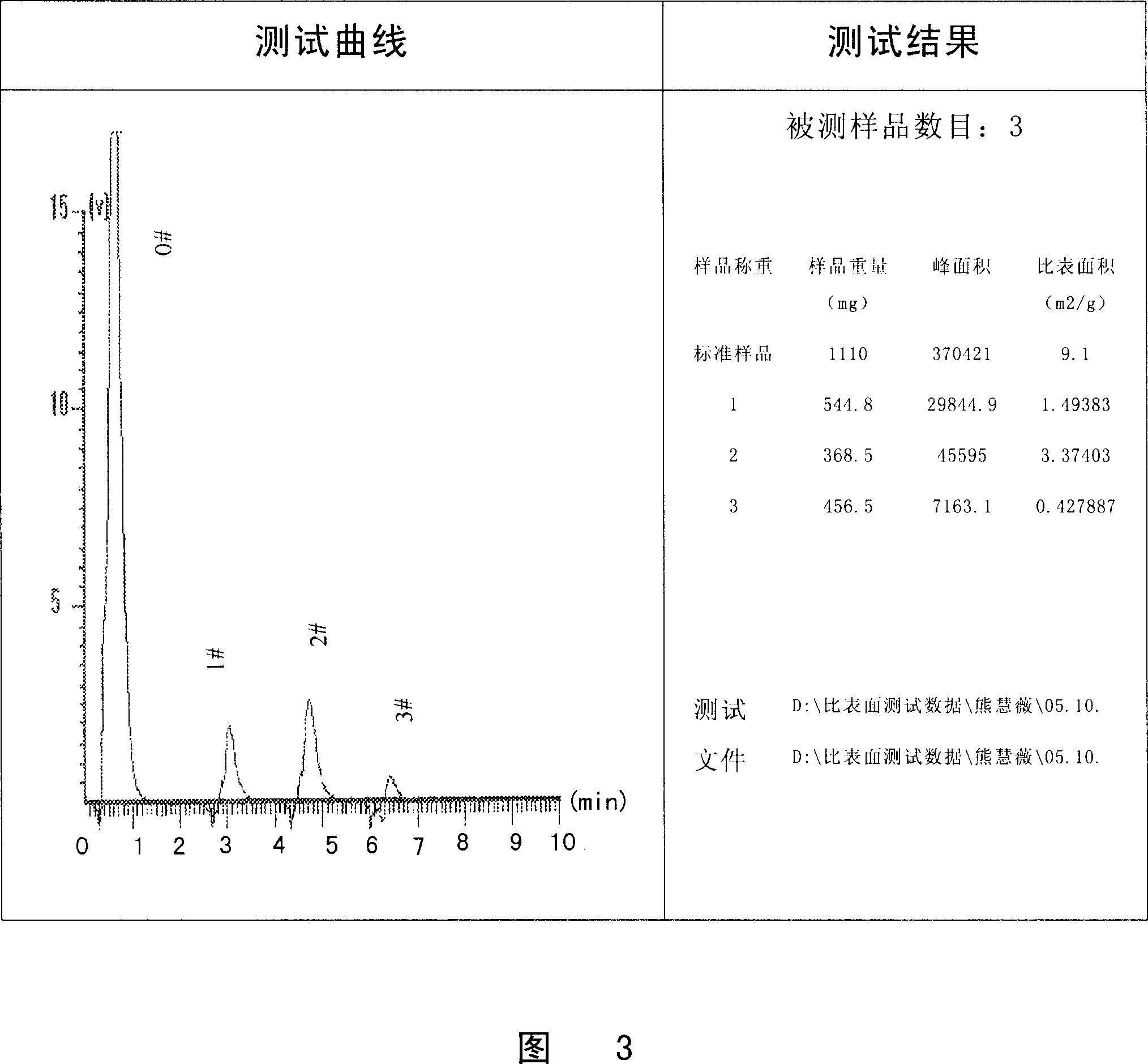

[0103] Preparation of insoluble dietary fiber micropowder I

[0104] Collect moso bamboo shoots and boiled bamboo shoots in large pots, and then make small package seasoning bamboo shoots. After cleaning, press and dehydrate, dry with hot air until the moisture content is below 10%, and grind the raw materials to 20 mesh in a traditional Chinese medicine grinder. about. Then take 5kg Phyllostachys pubescens powder, put it in an extraction tank, add 50L of 30% (v / v) ethanol aqueous solution, heat reflux extraction, extraction temperature 60 ℃, extraction time 2h. The extract is treated separately. After the residue is centrifuged and dehydrated, it is dried with hot air until the water content is below 10%. 2 The fluid is the extraction agent. After starting up, adjust the extraction pressure to 25MPa, the extraction temperature to 50°C; the separation temperature to 35°C, and the separation pressure to 6Mpa. After the conditions are stable, the dynamic extraction will be circ...

Embodiment 2

[0108] Preparation of Insoluble Dietary Fiber Micropowder II

[0109] Collect soybean dregs, press and dehydrate after cleaning, and dry with hot air until the moisture content is below 10% (about 20 mesh). Take 5kg of okara powder, put it in the material tank of microwave extraction equipment (model: WCD2S-1), add 75L of pure water preheated to 70°C, and use microwave-assisted extraction for 0.5h. The extract is treated separately, the residue is taken, dehydrated by pressing, and then dried with hot air until the moisture content is below 10%, and the raw material is put into CO 2 In the supercritical fluid extraction kettle, add 400mL of ethanol as an entrainer. After starting up, adjust the extraction pressure to 20MPa, the extraction temperature to 45°C; the separation temperature to 30°C, the separation pressure to 4Mpa, and cycle the dynamic extraction for 5 hours when the conditions are stable. Take out the extract from the separation kettle for other use, and reclaim...

Embodiment 3

[0113] Preparation of Insoluble Dietary Fiber Micropowder III

[0114] The corn hulls are collected, dehydrated by centrifugation, and dried with hot air until the moisture content is below 10%. Finally, take 5kg of dried corn dregs and place them in the material tank of the ultrasonic extraction equipment, add 25L of food-grade ethanol, and use ultrasonic-assisted extraction. The extraction temperature is 40°C, the extraction time is 40min, and the extract is treated separately. Take the above extraction residue, press and dehydrate, then dry with hot air until the moisture content is below 10%, put the raw material into CO 2 In the supercritical fluid extraction kettle, add 250mL acetone as an entrainer. After starting up, adjust the extraction pressure to 35MPa, the extraction temperature to 60°C; the separation temperature to 25°C, and the separation pressure to 8Mpa. The extract is taken out from the separation kettle and treated separately, and the entrainer is recovere...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com