Tomato sauce with high dietary fiber and production method of tomato sauce

A tomato sauce, high dietary fiber technology, applied in food preparation, food science, application and other directions, can solve the problems of difficult to maintain lycopene and other nutrients, insufficient resource utilization, low viscosity, etc., to improve equipment utilization, The effect of improving food safety and increasing the content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

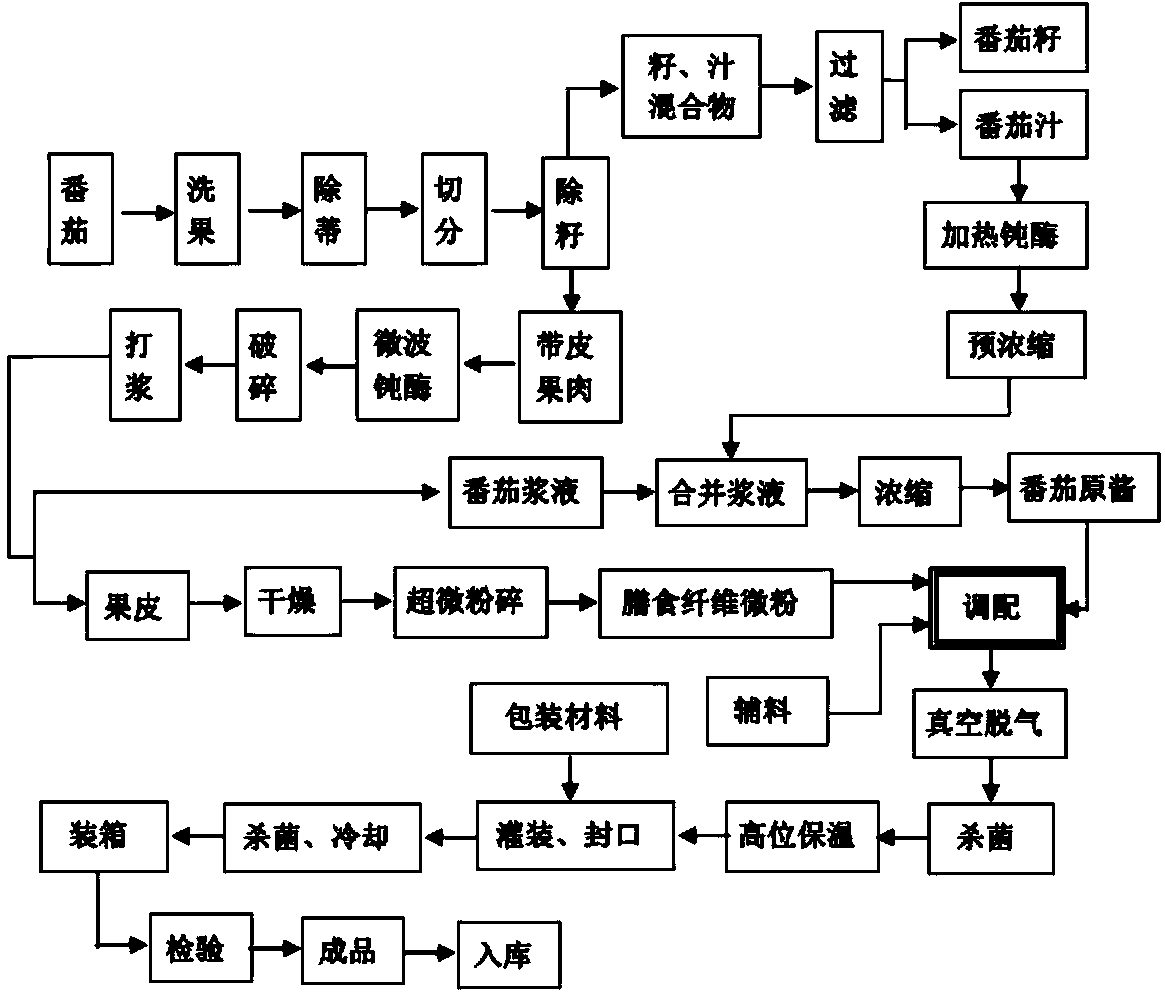

Method used

Image

Examples

Embodiment 1

[0088] (1) The formula (by mass percentage) of tomato sauce is: tomato sauce 55%–60%, tomato skin dietary fiber 4%–6%, edible salt 0.5%–0.8%, trehalose 2%–4% , citric acid 0.32%–0.36%, edible acetic acid 2%–2.2%, monascus red pigment 0.008%–0.01%, nisin (Nisin) 0.01%–0.02%, xanthan gum 0.07%–0.09%, water 28%–32%.

[0089] (2) The production process is as follows:

[0090] ① Wash the ripe tomatoes with clean water, remove the stems, and drain the residual water.

[0091] ② Cut the cleaned tomato in half from the midline of the fruit, take out the tomato seeds, and separate the skinned pulp from the seeds.

[0092] ③ Process the pulp with skin at 6 Kw for 30 s with microwave degreening equipment, then send it to the crusher for thermal crushing while it is hot, and then use three beating and refining machines with sieve holes of Ф0.8mm, Ф0.6mm and Ф0.4mm Beating and refining are carried out to obtain tomato pulp and tomato skin respectively.

[0093] ④ A small amount of toma...

Embodiment 2

[0100] (1) The formula (by mass percentage) of tomato sauce is: 60% tomato sauce, 4% dietary fiber from tomato skin, 0.5% edible salt, 2% trehalose, 0.32% citric acid, 2% edible acetic acid, red Aspergillus 0.008%, nisin 0.01%, xanthan gum 0.07%, water 31.092%.

[0101] (2) The production process is as follows:

[0102] ① Wash the ripe tomatoes with clean water, remove the stems, and drain the residual water.

[0103] ② Cut the cleaned tomato in half from the midline of the fruit, take out the tomato seeds, and separate the skinned pulp from the seeds.

[0104] ③ Process the pulp with skin at 6 Kw for 30 s with microwave degreening equipment, then send it to the crusher for thermal crushing while it is still hot, and then use three sieves with sieve holes of Ф0.8 mm, Ф0.6 mm and Ф0.4 mm The beating and refining machine performs beating and refining to obtain tomato pulp and tomato skin.

[0105] ④ A small amount of tomato juice brought out during the seed removal process is...

Embodiment 3

[0112] (1) The formula (by mass percentage) of tomato sauce is: 58% tomato sauce, 5% dietary fiber from tomato skin, 0.7% edible salt, 3% trehalose, 0.34% citric acid, 2.1% edible acetic acid, red Aspergillus 0.01%, nisin 0.015%, xanthan gum 0.08%, water 30.755%.

[0113] (2) The production process is as follows:

[0114] ① Wash the ripe tomatoes with clean water, remove the stems, and drain the residual water.

[0115] ② Cut the cleaned tomato in half from the midline of the fruit, take out the tomato seeds, and separate the skinned pulp from the seeds.

[0116] ③ Process the pulp with skin at 6 Kw for 30 s with microwave degreening equipment, then send it to the crusher for thermal crushing while it is still hot, and then use three sieves with sieve holes of Ф0.8 mm, Ф0.6 mm and Ф0.4 mm The beating and refining machine performs beating and refining to obtain tomato pulp and tomato skin.

[0117] ④ A small amount of tomato juice brought out during the seed removal process ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com