Patents

Literature

169results about How to "Large processing area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Metal surface treatment agent

InactiveCN102787310AReduce corrosion rateReduce surface tensionMetallic material coating processesNitrogenous heterocyclic compoundIonic liquid

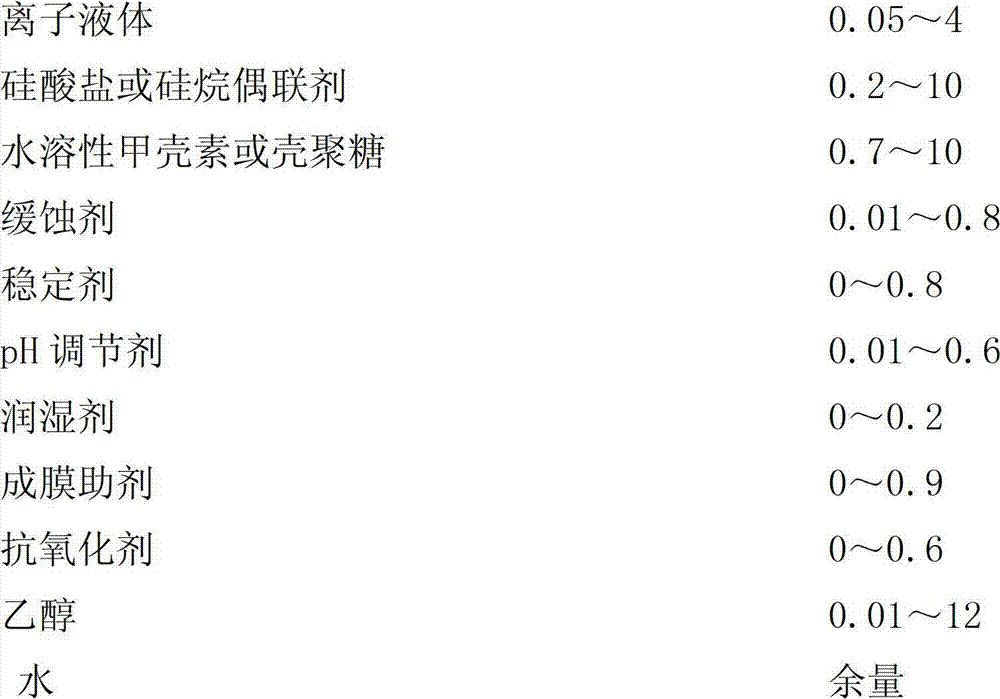

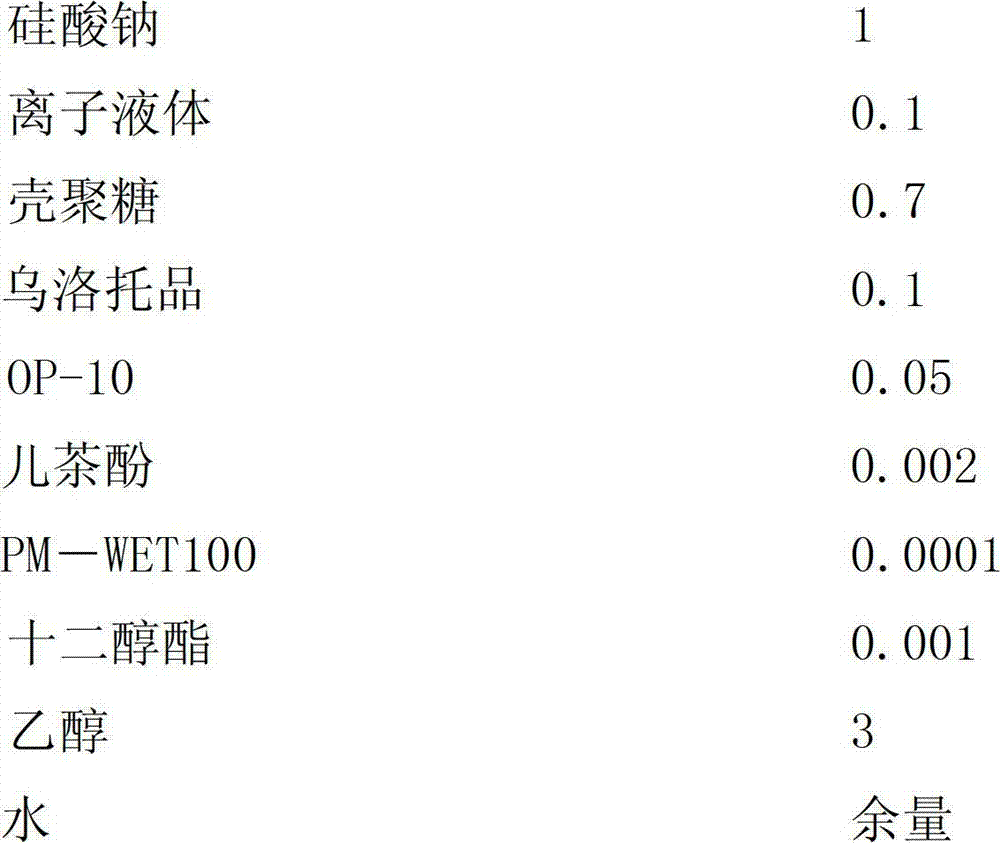

The invention provides a metal surface treatment agent composed of aqueous solution or aqueous emulsion containing ionic liquid. The metal surface treatment agent comprises the ionic liquid, silicate or silane coupling agent, water-soluble chitin or chitosan, corrosion inhibitor, stabilizer, pH modifier, wetter, coalescing agent, antioxidant, ethanol and water, the ionic liquid is room-temperature ionic liquid consisting of nitrogenous heterocyclic compound cations and inorganic or organic anions, one or more of nanoscale titanium dioxide, zirconium oxide or zirconium fluoride is uniformly mixed into the silicate or silane coupling agent by the weight equivalently accounting for 3%-25% of that of the silicate or silane coupling agent. A chemical conversion coating is formed on a metal surface by the metal surface treatment agent, can inhibit corrosion of the metal surface, and has a fine coating performance. The metal surface treatment agent is used for treating cold-rolled plates, galvanized plates and aluminum plates, and the metal surface treated by the metal surface treatment agent has the coating adhesion force equivalent to that of a metal surface treated by a phosphorus-containing metal surface treatment agent.

Owner:DALIAN POLYTECHNIC UNIVERSITY

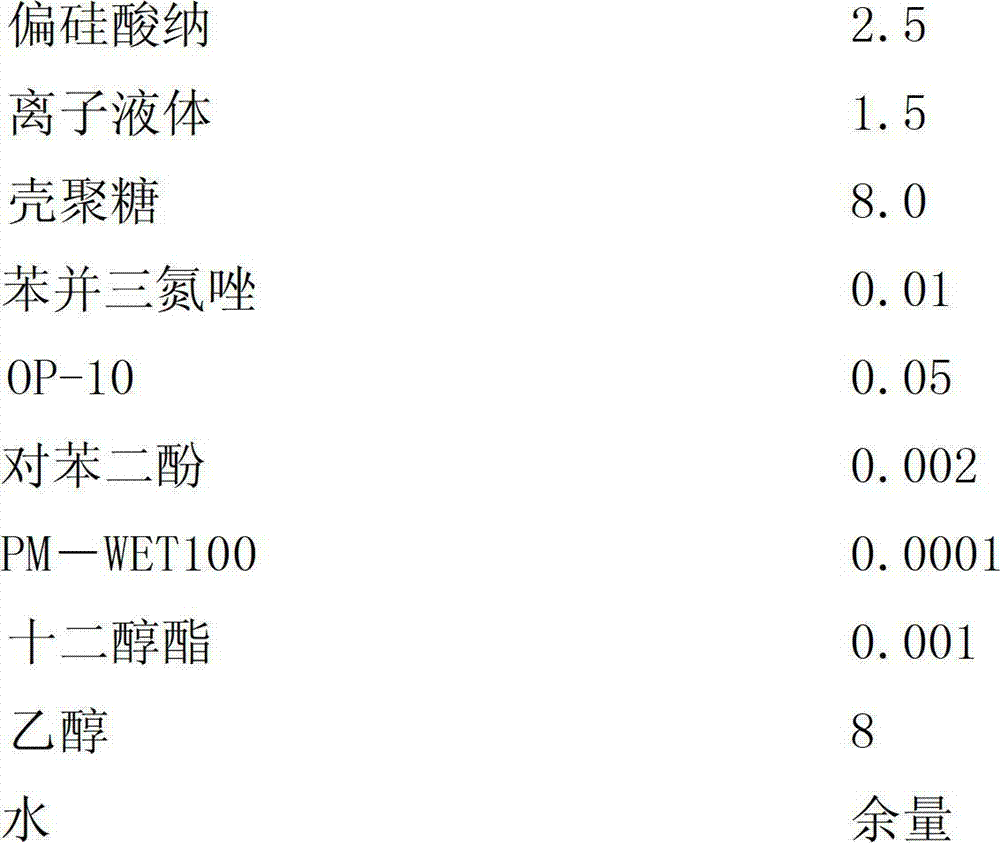

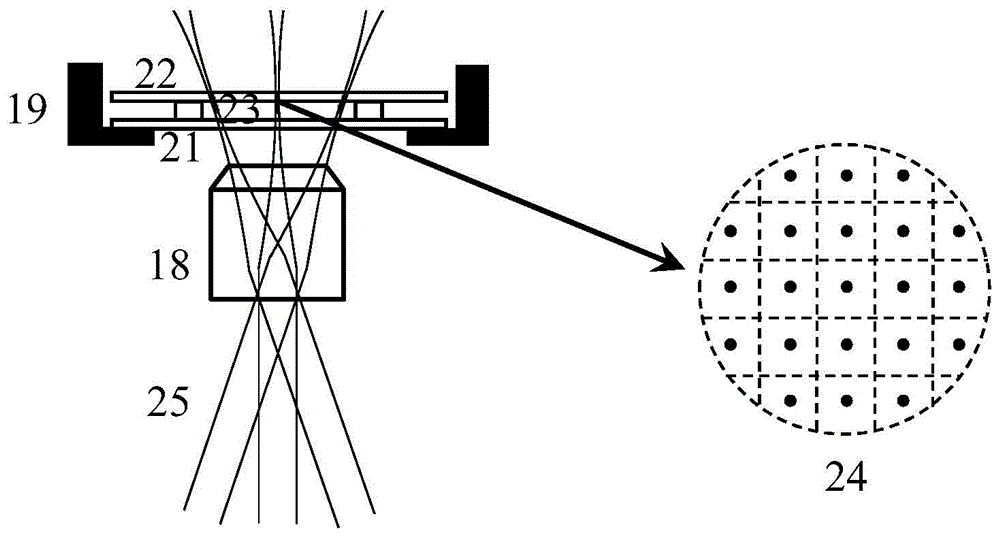

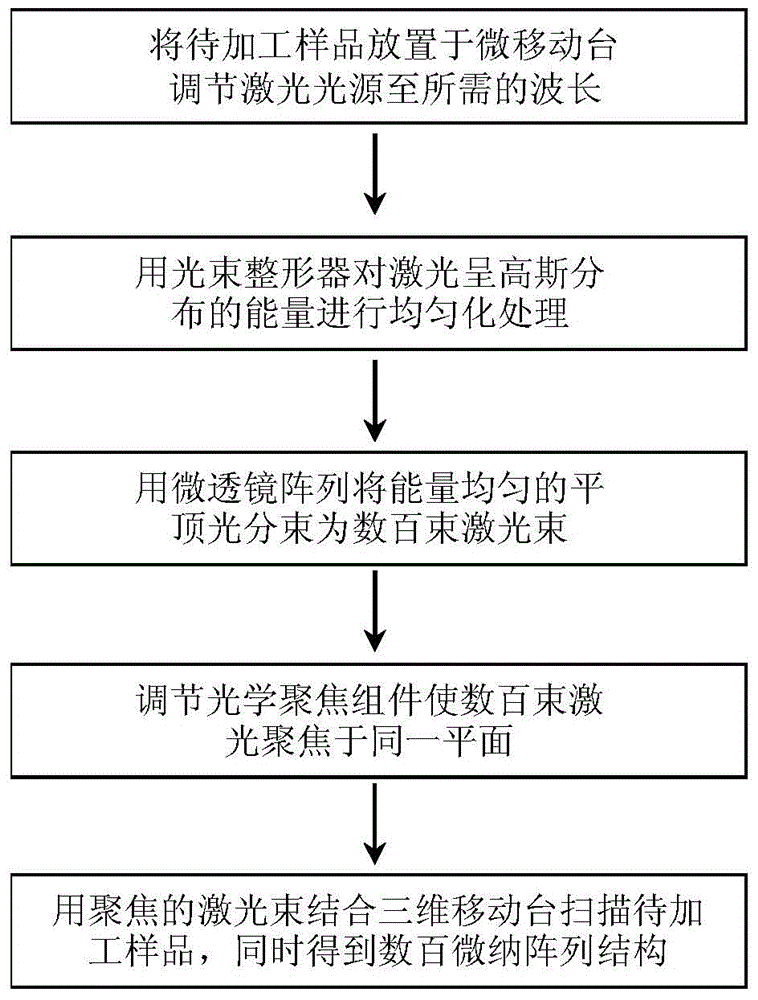

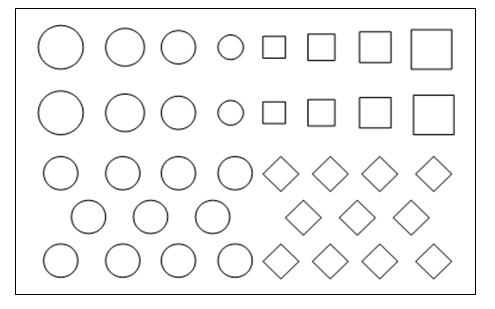

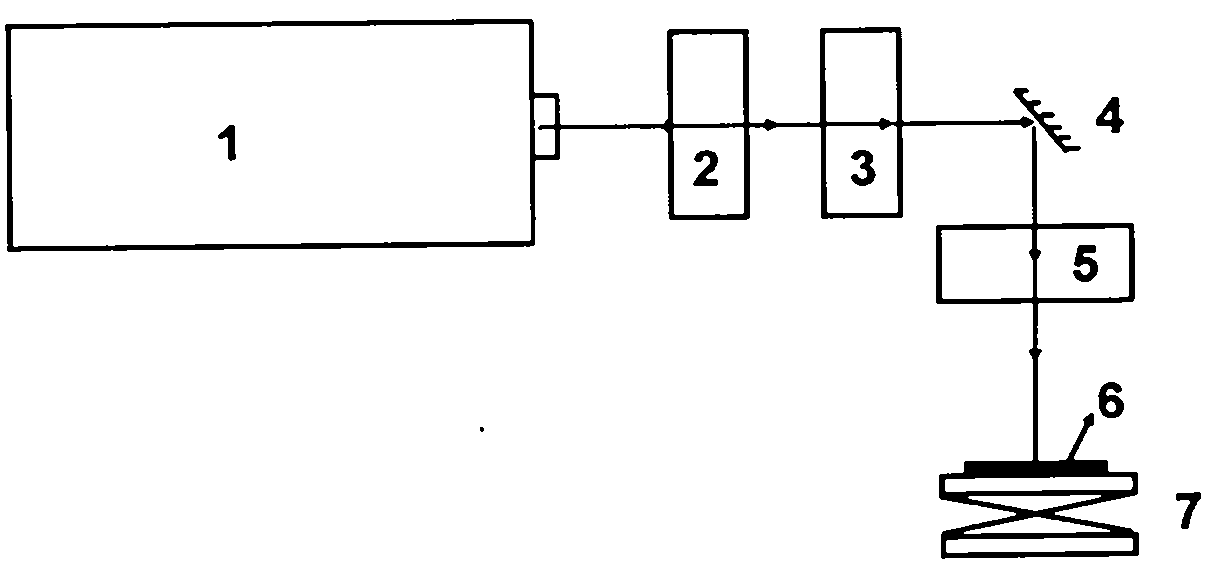

System and method for preparing micro-nano array structure by means of laser light

ActiveCN104439699AImprove consistencyFast preparationLaser beam welding apparatusMicro nanoLight beam

The invention discloses a system and method for preparing a micro-nano array structure by means of laser light. The method for preparing the micro-nano array structure by means of laser light comprises the steps that a first laser beam with the wavelength enabling a material to be processed to generate the multiphoton absorption effect is provided; homogenization treatment is conducted on the first laser beam in Gaussian distribution, so that a first flat beam with energy evenly distributed is obtained; the first flat beam is split into multiple laser beams arranged in an array mode by means of a microlens array component; the multiple laser beams arranged in the array mode are focused to beam focusing components located on the same plane respectively; a metal ion solution placed on a minitype movable table controlled by a computer is scanned, so that hundreds of micro-nano periodical array structures are obtained, wherein the beam spot area of the first flat beam is equal to or smaller than the effective array area of the microlens array component. According to the method for preparing the micro-nano array structure by means of laser light, the micro-nano array structures of the same structure and in controllable dimensions can be prepared in a large-scale mode rapidly.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

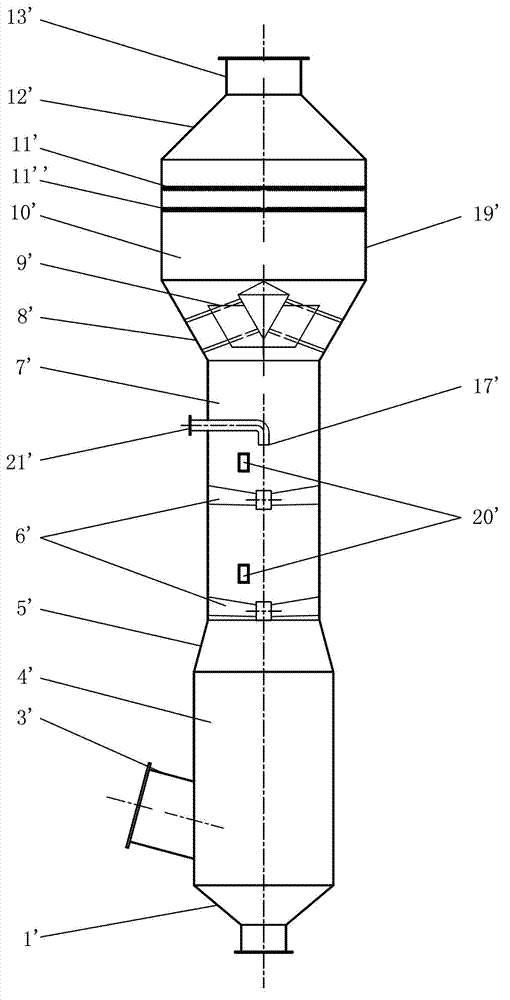

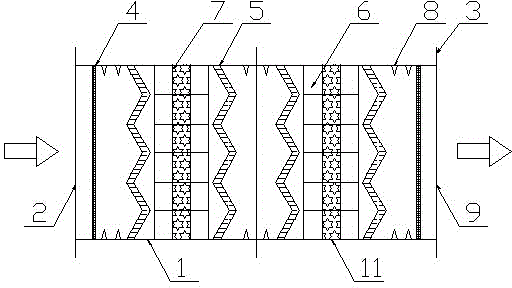

Flue-gas cleaner

InactiveCN103203170AAchieve complete cleanlinessImprove purification effectCombination devicesDraining tubeFlue gas

The invention discloses a flue-gas cleaner, comprising a liquid storage tank, a water spray chamber, an alkali liquor spraying chamber, an oxidized spraying chamber, a gas-liquid separating chamber, an active carbon adsorption chamber and a purified gas outlet, wherein the liquid storage tank is partitioned into at least three sub-tanks; each sub-tank is respectively connected to a sewage master pipe through a sewage branch pipe; the water spray chamber, the alkali liquor spraying chamber, the oxidized spraying chamber and the gas-liquid separating chamber are orderly communicated end to end through a flue-gas pipe, so as to form transverse channels which are connected in series in a reciprocating manner; the inner top part of each chamber is provided with the spraying pipe; and the side is communicated with corresponding sub-tank through a drain tube. The flue-gas cleaner is long in flue-gas flow, large in processing area, high in efficiency, and wide in adaptability, and can comprehensively process various toxic and harmful gases.

Owner:周勇定

Metal surface cleaning solution

The invention relates to a metal surface cleaning solution which is prepared by following raw materials of, by weight percentage, sulfuric acid, hydrochloric acid, a high polymer composite enhanced active agent, sodium dodecyl benzene sulfonate, urotropin, sodium silicate, citric acid, urea, industrial salt, triethanolamine and water. The cleaning solution can completely clean up various greasy dirt, rust and scale cinder attached on a metal surface effectively, and protective film can forms on the metal surface after being cleaned so as to prevent metal from rusting and oxidizing in a certain period. Waste water of a used cleaning solution can be reused after being recovered, precipitated and filtered.

Owner:杨恒春

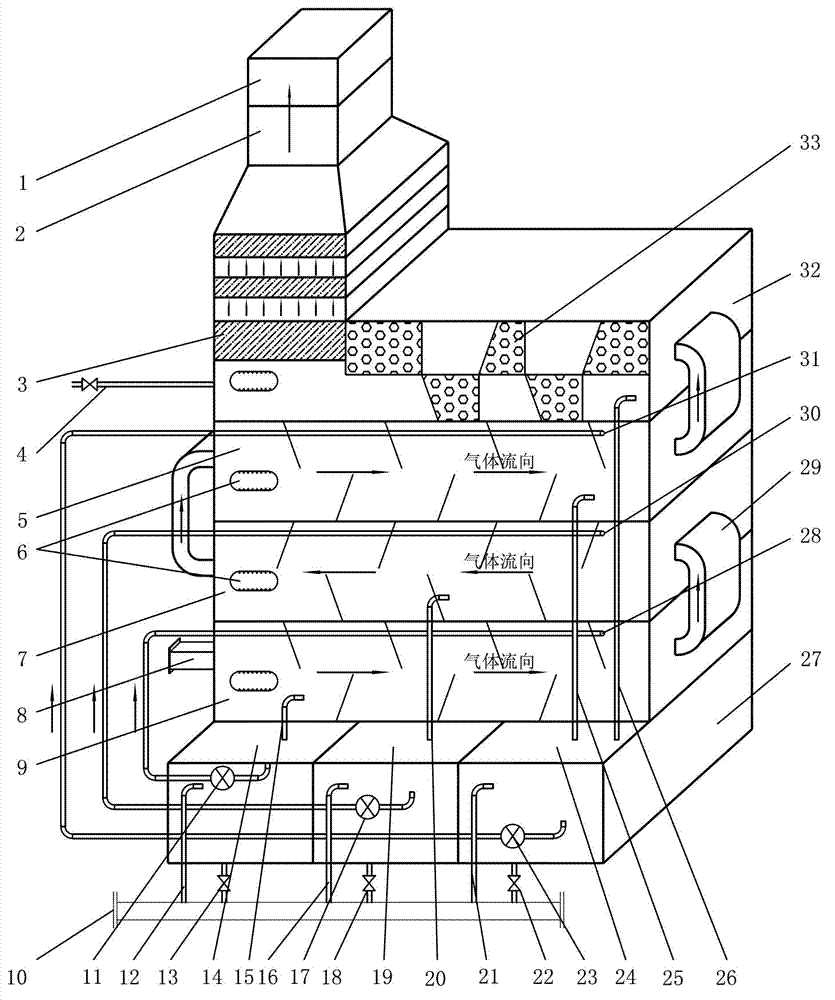

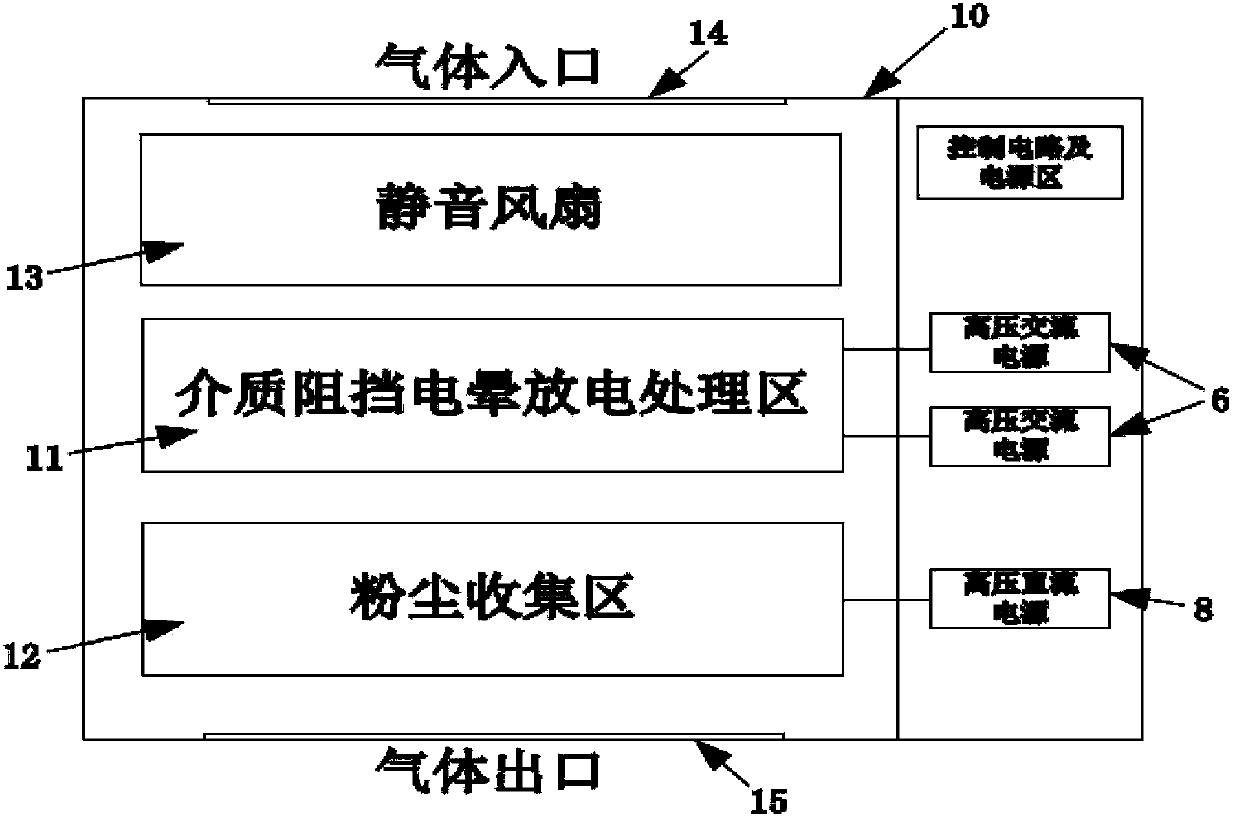

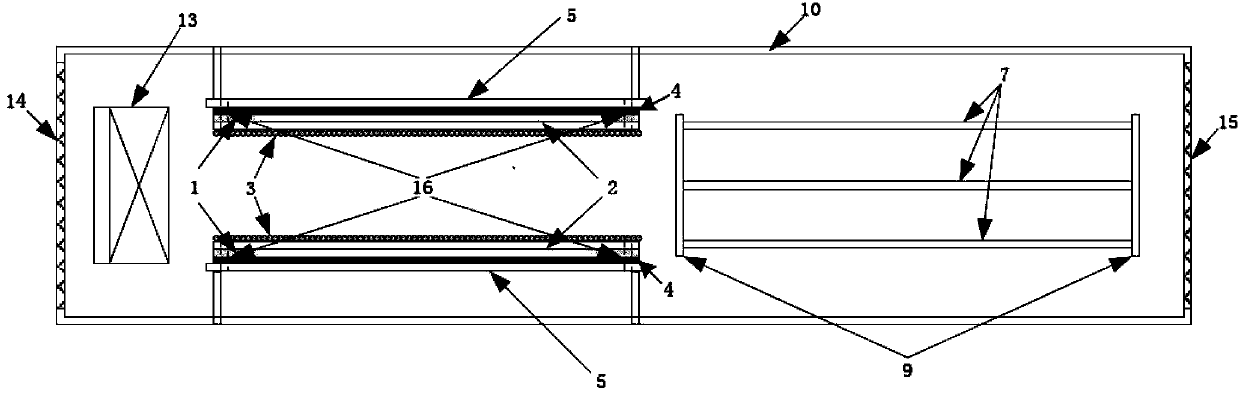

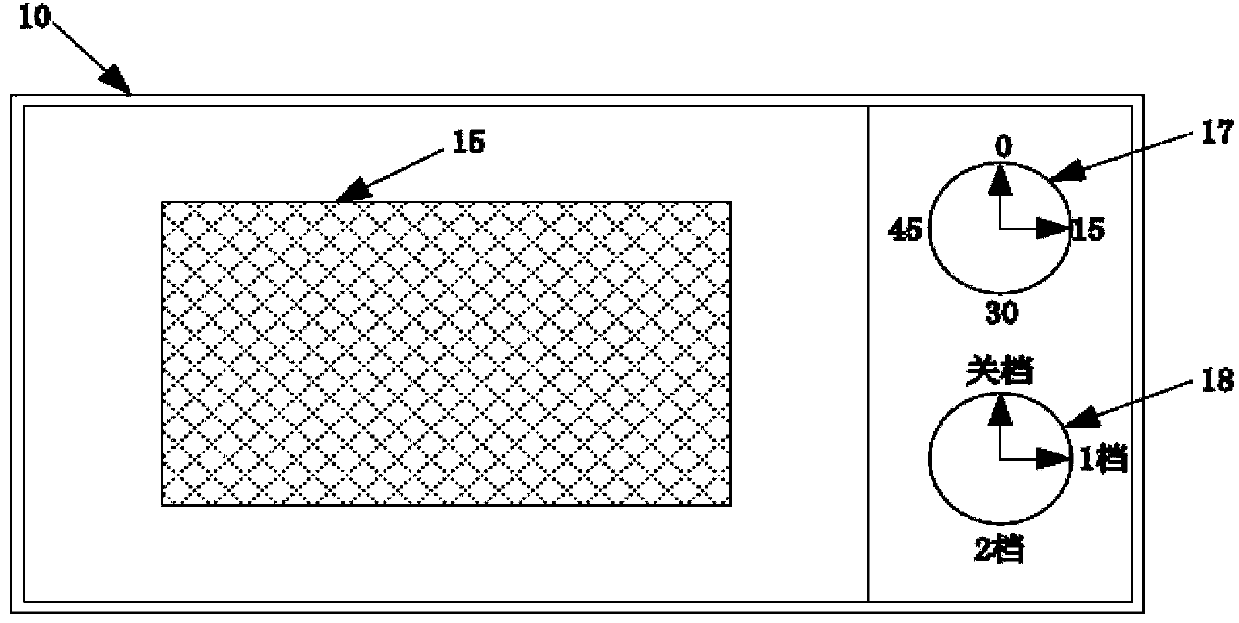

Indoor gas purification device based on discharge plasma

ActiveCN103388858AAchieving heteropolar chargingImprove adsorption capacityLighting and heating apparatusDeodrantsDielectricInhalable particles

The invention discloses an indoor gas purification device based on discharge plasma, comprising a shell provided with a gas inlet and a gas outlet, wherein a fan, a dielectric barrier corona discharge processing region and a dust collecting region are arranged in the shell between the gas inlet and the gas outlet. According to the indoor gas purification device, more uniform low-temperature plasma is generated by two discharge units which are arranged oppositely, oxidation processing is carried out on harmful gas in the dielectric barrier corona discharge processing region, heteropolarity charge electrocoagulation and processing are carried out on inhalable particles, the inhalable particles are collected in the dust collecting region, and the device has the advantages that no chemical agent and no physical additive are used, no special gas atmosphere exists, the energy consumption is low, indoor gas purification is realized under barometric pressure, and the effect is good.

Owner:XI AN JIAOTONG UNIV

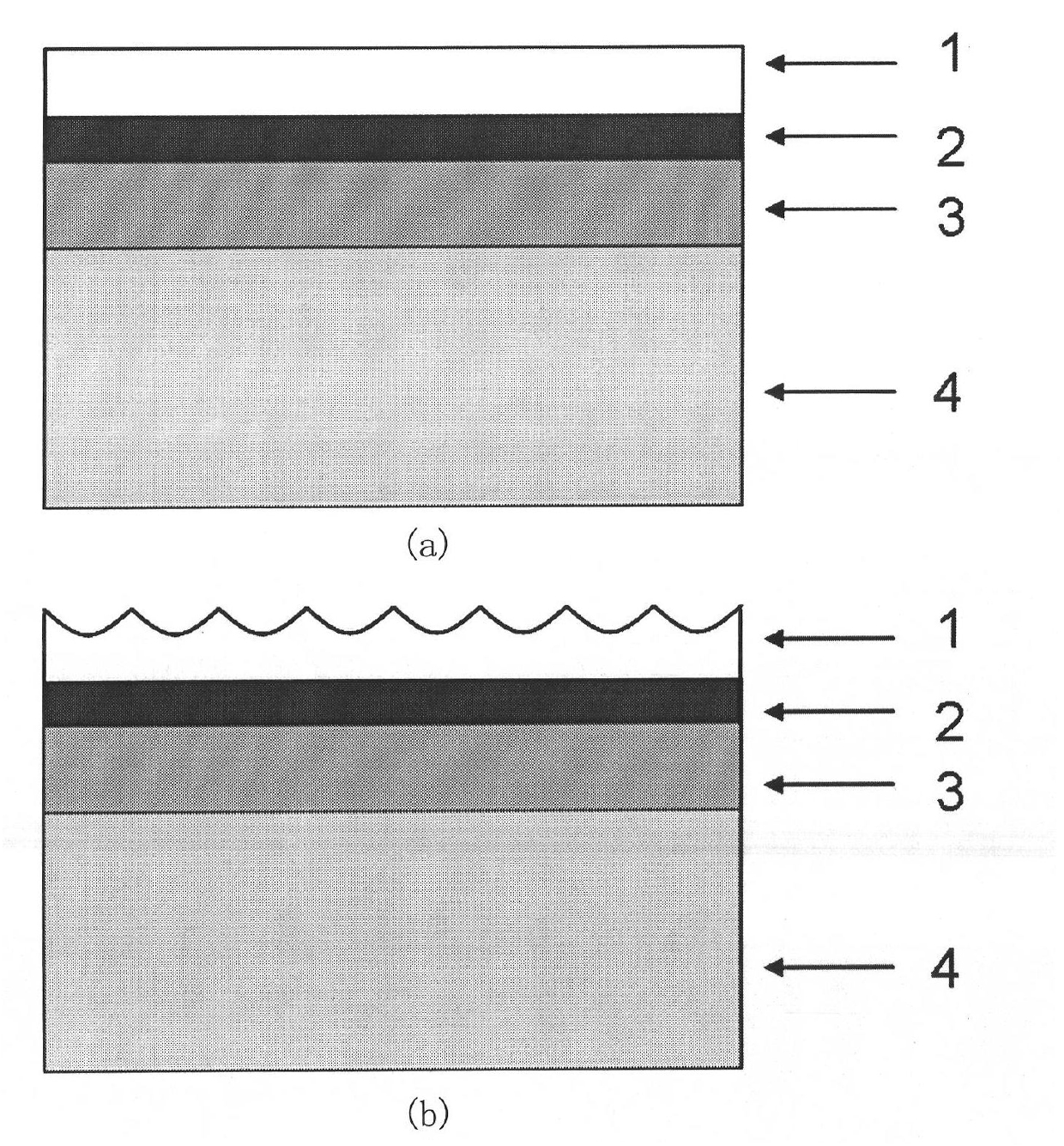

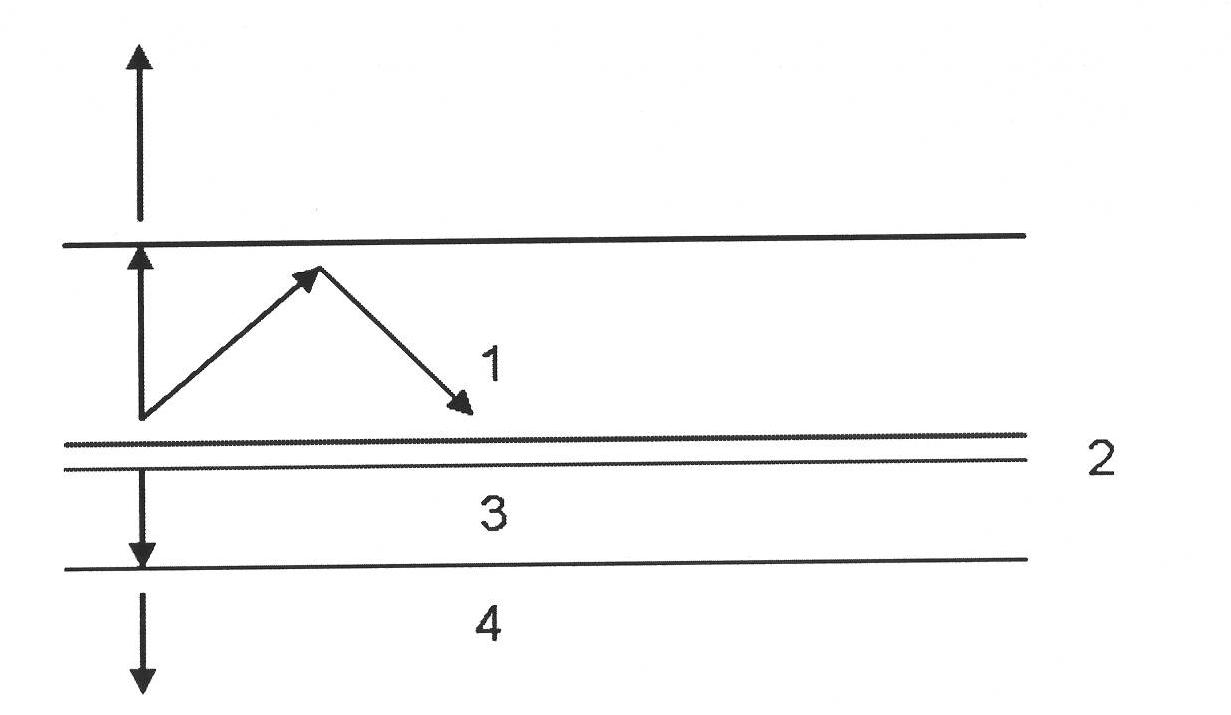

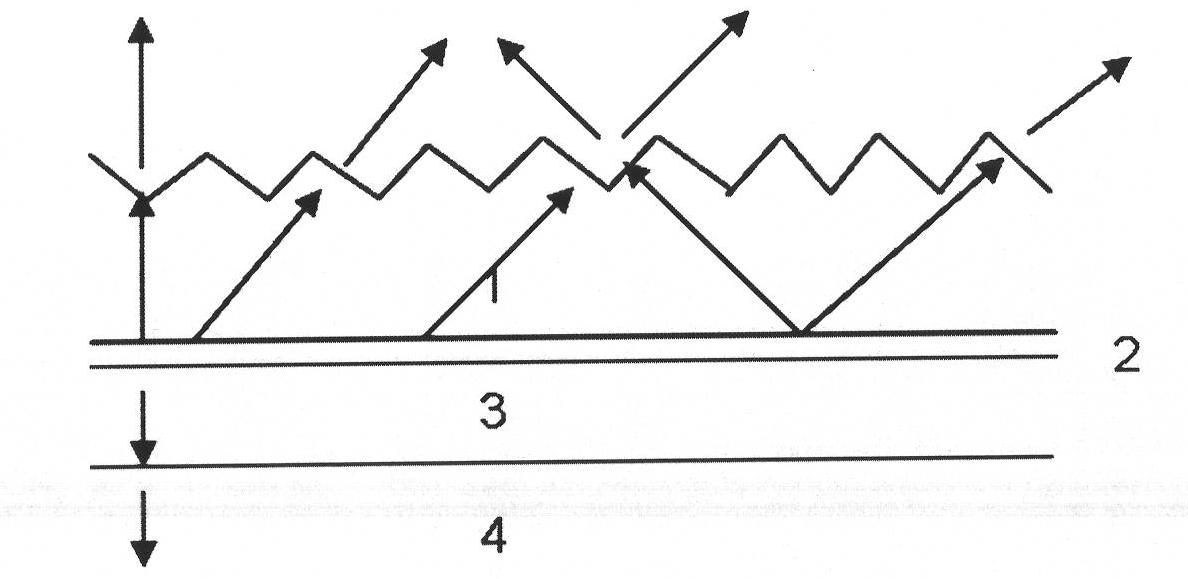

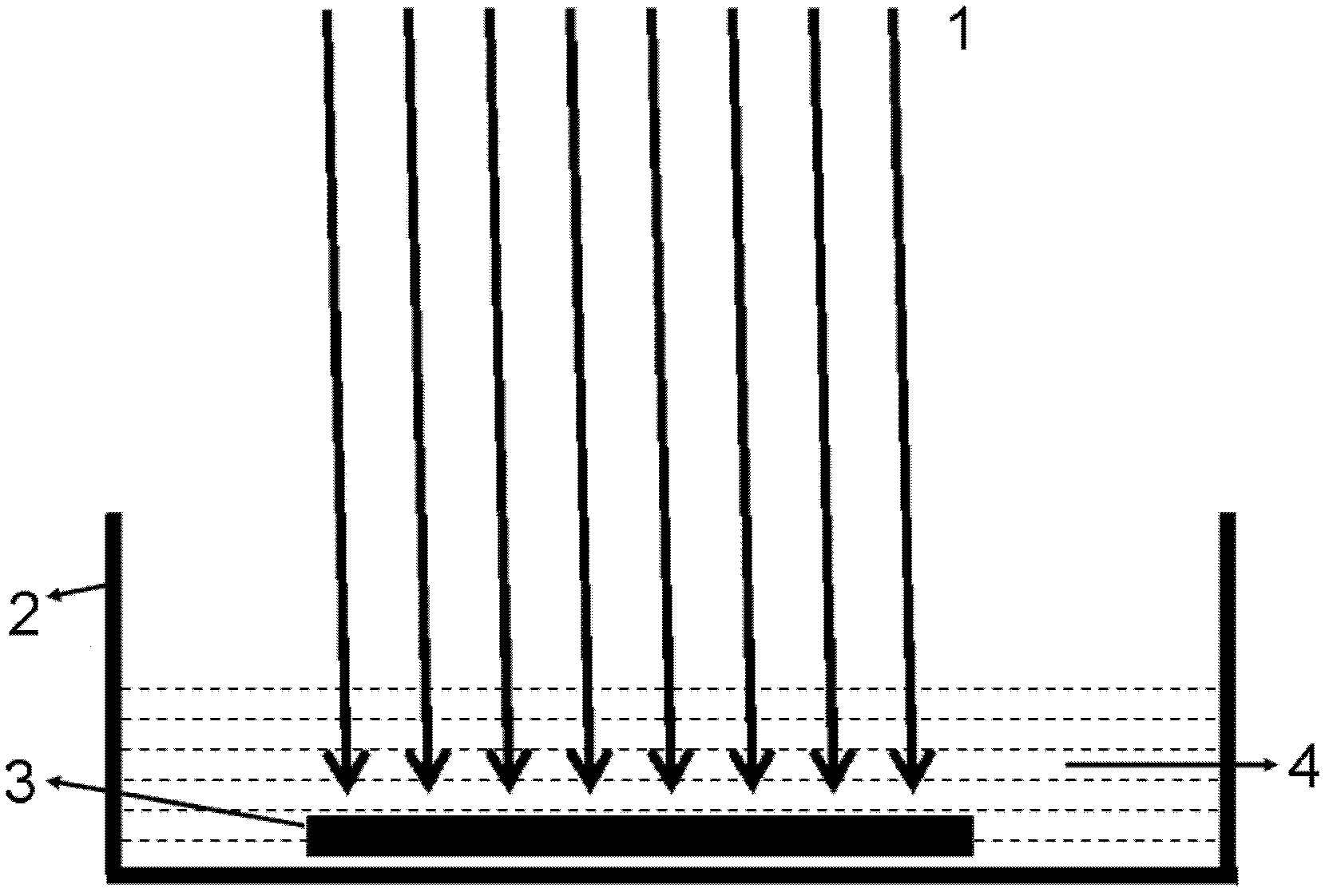

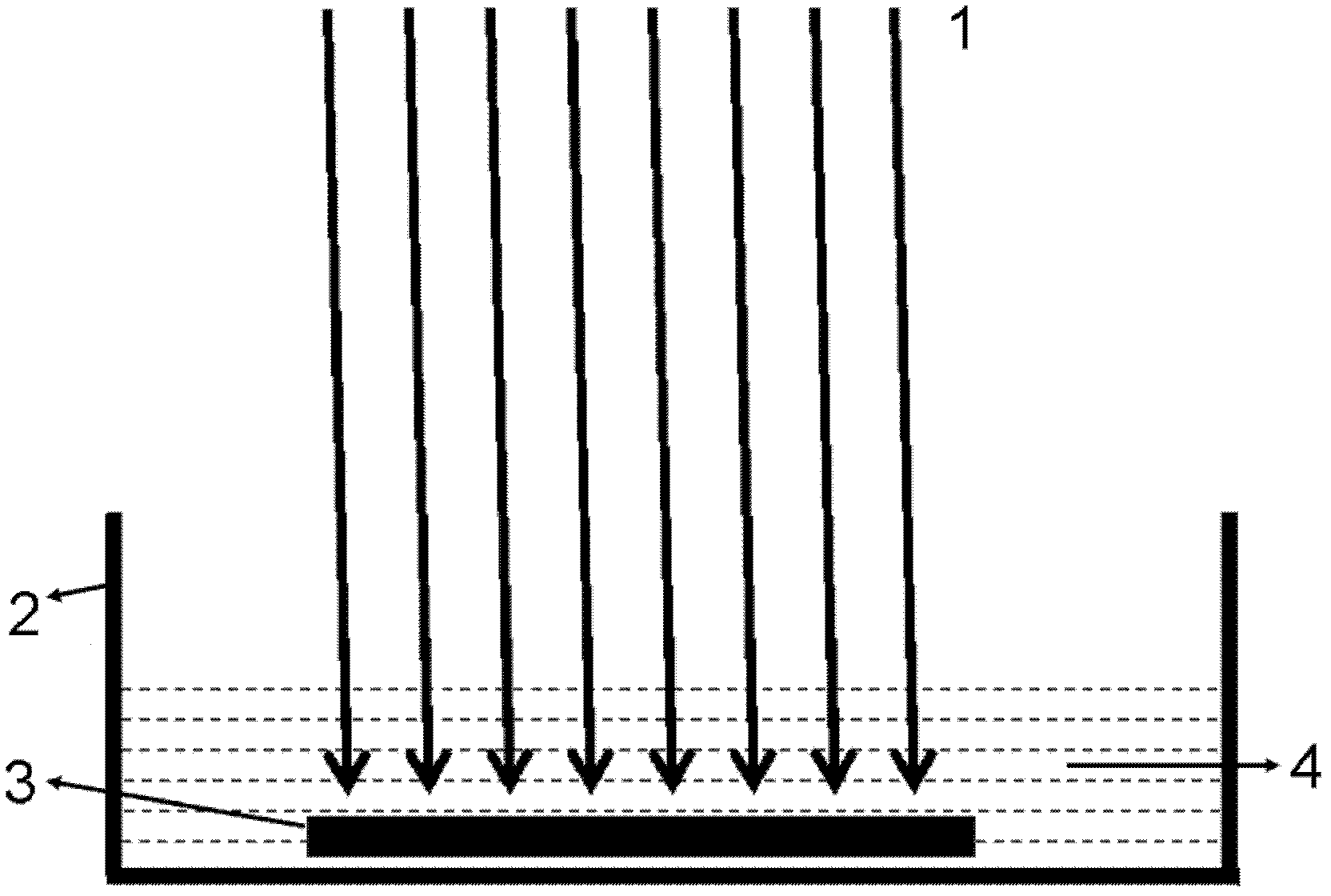

Method for coarsening surface of light-emitting diode (LED) with the aid of metal nanoparticles

InactiveCN102169930AReduce manufacturing costImprove extraction efficiencyLiquid/solution decomposition chemical coatingSemiconductor devicesSemiconductor materialsUltraviolet lights

The invention discloses a method for coarsening a surface of a light-emitting diode (LED) with the aid of metal nanoparticles, belonging to the technical field of manufacture of semiconductor optoelectronic materials and devices. The method comprises the steps: firstly, growing an LED epitaxial wafer on a semiconductor substrate, wherein the LED epitaxial wafer sequentially comprises an N-GaN film, a quantum well layer and a P-GaN layer; then depositing a layer of metal nanoparticles on the surface of the P-GaN layer with the aid of ultraviolet light in the solution of metal salts; placing the LED epitaxial wafer after being deposited with the metal nanoparticles in an etchant solution made from a certain proportion of hydrofluoric acid and oxidant; and performing wet etching with the aid of ultraviolet light. By depositing the metal nanoparticles on the N-GaN film, the electron distribution on the surface of the N-GaN film can be changed, the etching rate is increased, thereby being favorable to forming of a coarsened structure. The method disclosed by the invention is suitable for etching of different semiconductor materials and coarsening of the LED epitaxial wafer; and compared with the prior art, the cost is low, the coarsened area is large, the operation is simple, and an ideal coarsened effect can be obtained.

Owner:SHANDONG UNIV

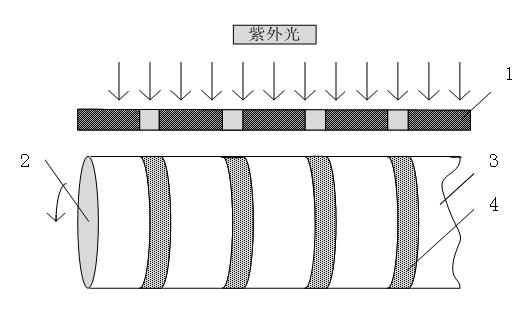

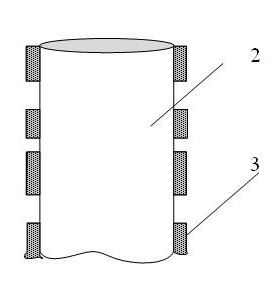

Processing method of cylindrical component with mask micro-structure on outer curved surface

InactiveCN101791726ASolving Manufacturing ChallengesHigh coaxiality requirementsMachining electrodesMachining working mediaProcessing accuracyMicrostructure

The invention discloses a processing method of a cylindrical component with a mask micro-structure on the outer curved surface, which belongs to the field of electrochemical machining. The method comprises the following steps: imaging the surface of a curved-surface part through dipping, glue coating and rolling lithography or processing a planar flexible insulation shielding thin film with laser and fixing the thin film on the surface of the curved-surface part, and carrying out micro electrolytic machining with a cylindrical part as the anode and a sleeve as a cathode, thereby forming a micro structure on the curved surface. The method solves the manufacturing problem of the curved-surface part with the outer surface of a complex fine microstructure, and can be used for processing large-area curved-surface microstructures, in particular microstructures with complex patterns and small sizes. The curved-surface microstructures processed by the invention have the advantages of large processing area and high processing accuracy. The invention has the advantages of capability of processing microstructures with complex patterns and small sizes, simple operation, high efficiency and low processing cost.

Owner:XI AN JIAOTONG UNIV

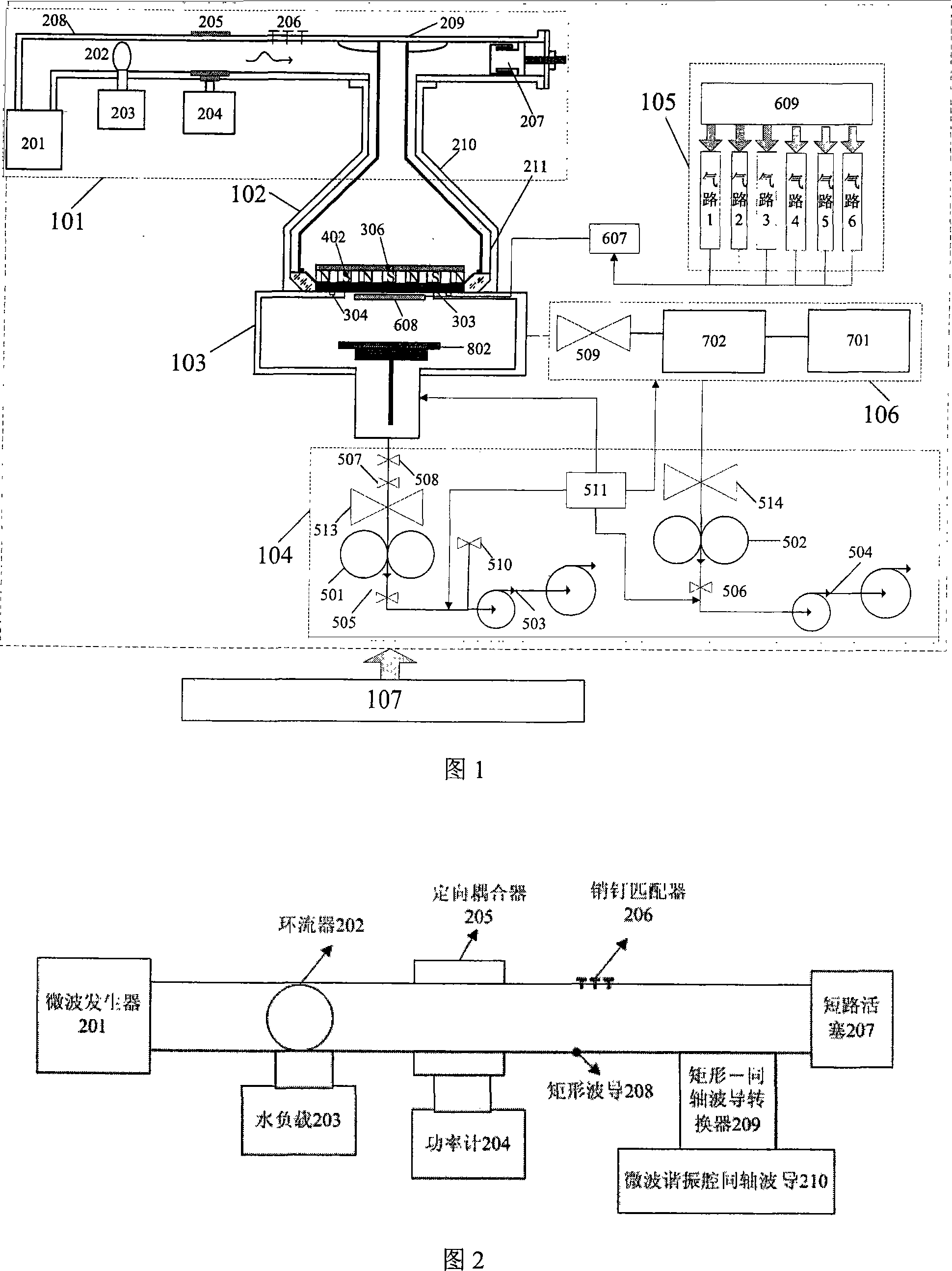

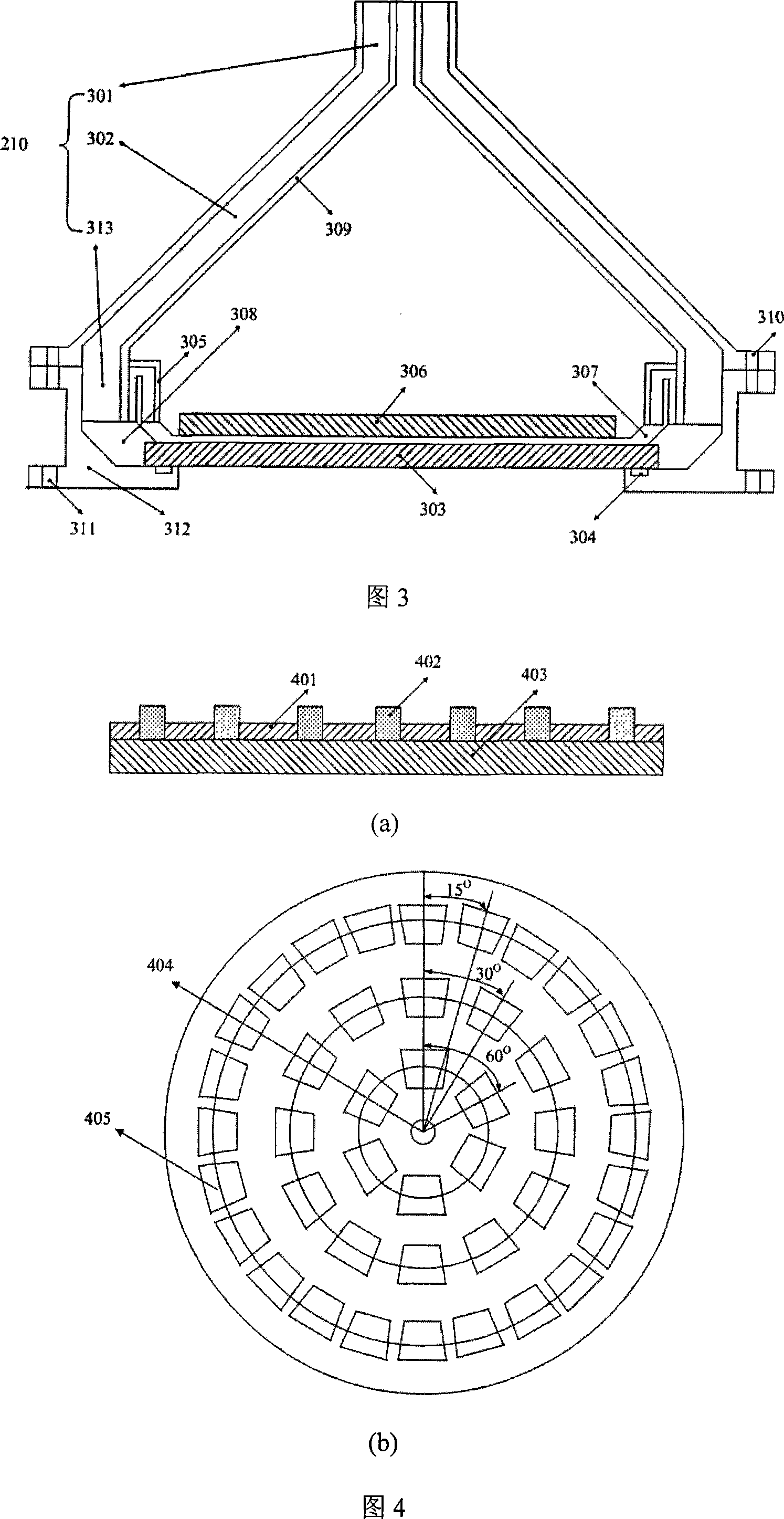

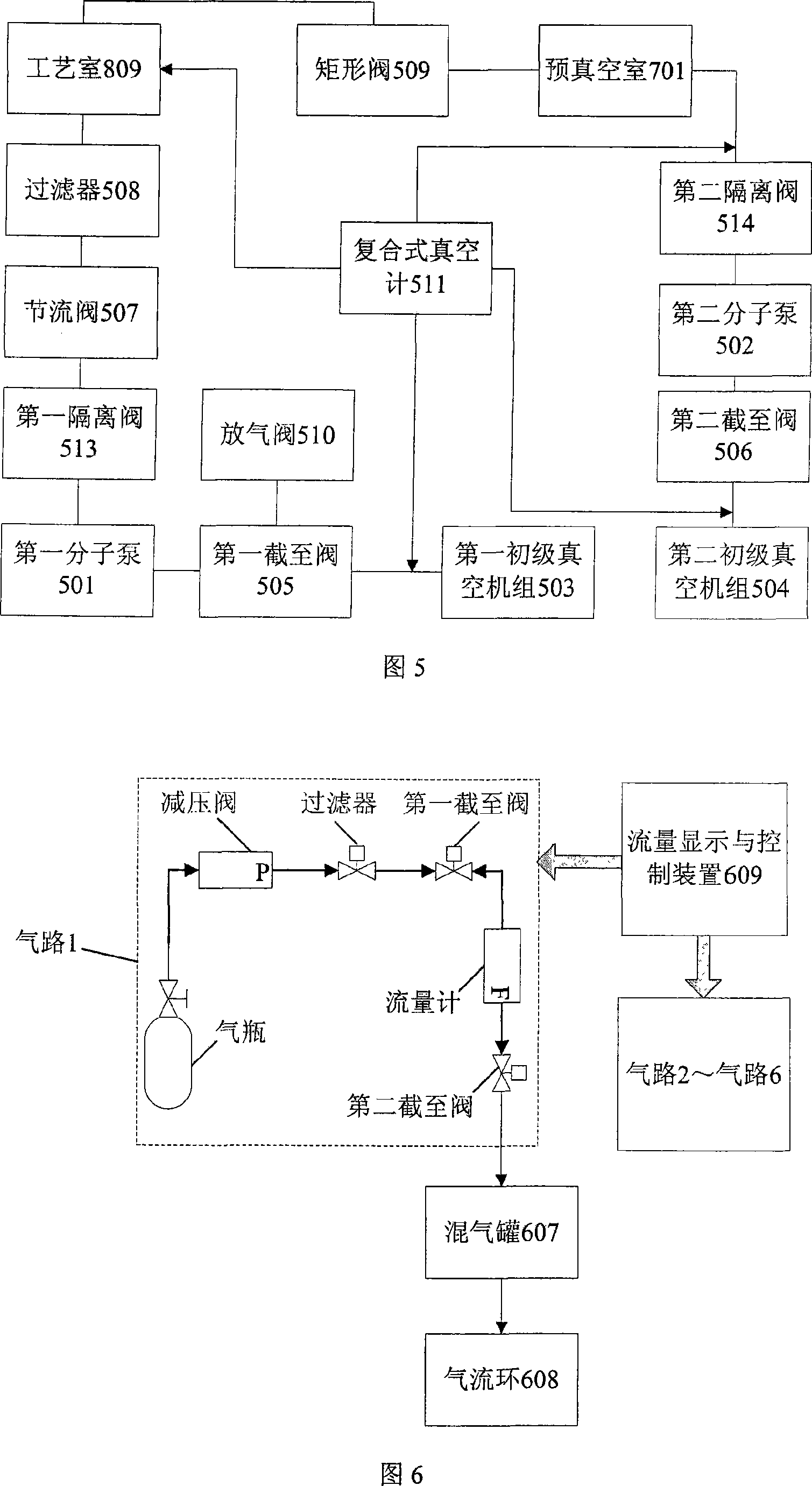

Microwave electron cyclotron resonance plasma chemistry gas phase sedimentation device

InactiveCN101144155AReduce volumeReduce power consumptionChemical vapor deposition coatingGas phaseMicrowave resonance

The present invention discloses microwave electron cyclotron resonance plasma body chemical vapor deposition equipment, which comprises a microwave power source and a transmission system 101, a microwave resonance cavity 102, a coating chamber and a specimen stage system 103, a vacuum system 104, a gas circuit system 105, an automatic sheet transmission system 106, and a controlling system 107, wherein, magnetic field devices 306 which are lined at equal intervals are arranged in the microwave resonance cavity; the specimen stage system is arranged inside the coating chamber; the microwave resonance cavity, the vacuum system, and the automatic sheet transmission system are respectively connected with a coating chamber 809, the microwave power source and the transmission system are connected with the microwave resonance cavity; a controlling software is solidified in the host computer of the controlling system; the working states of the microwave power source and the transmission system, the coating chamber and the specimen stage system, the vacuum system, and the gas circuit system are respectively controlled through interfaces, and thus the deposition technological process of a film is completed. The present invention has the advantages that the big area uniformity is good, the deposition rate is high, the automaticity and the production efficiency are high, the reliability is good, the power loss is small, and the stability and the repeatability are good.

Owner:XIDIAN UNIV

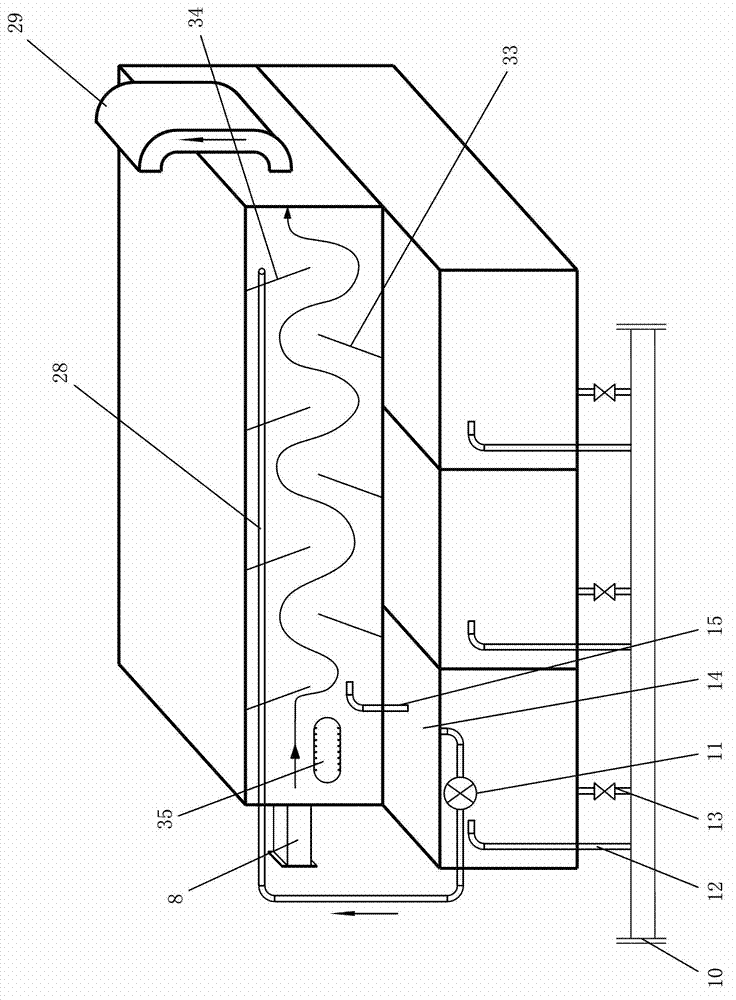

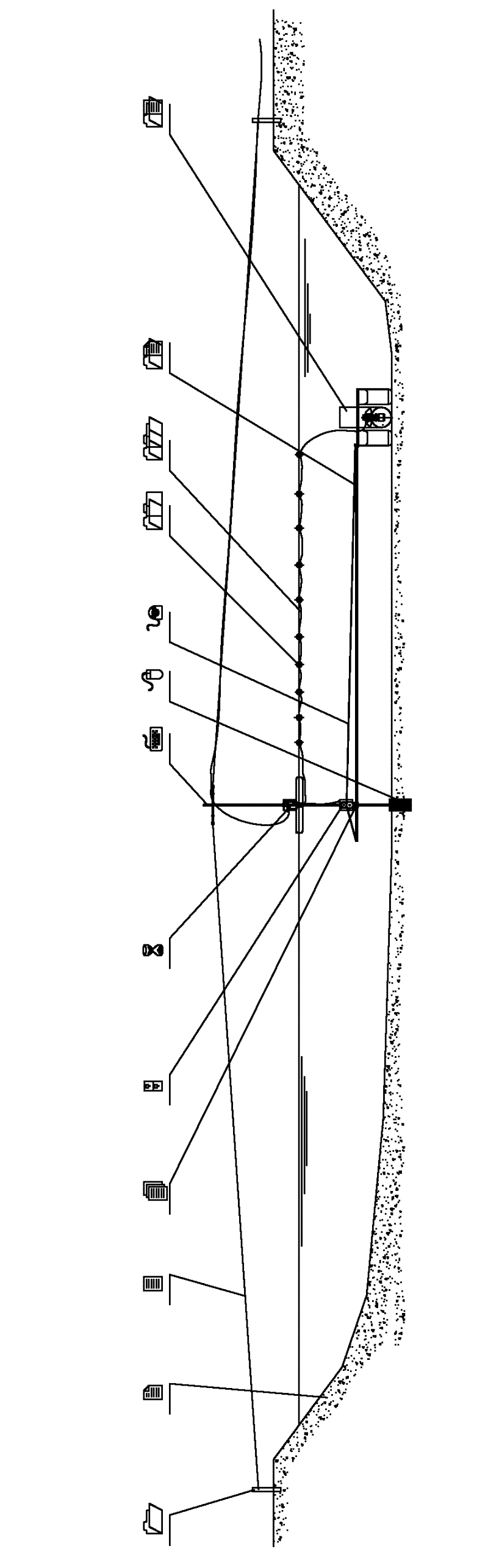

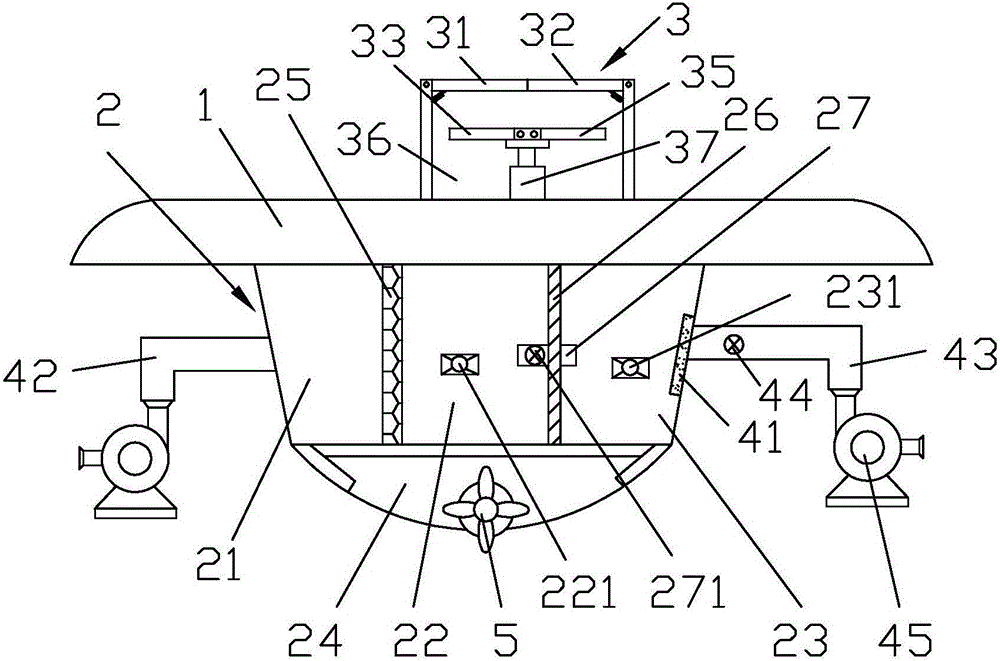

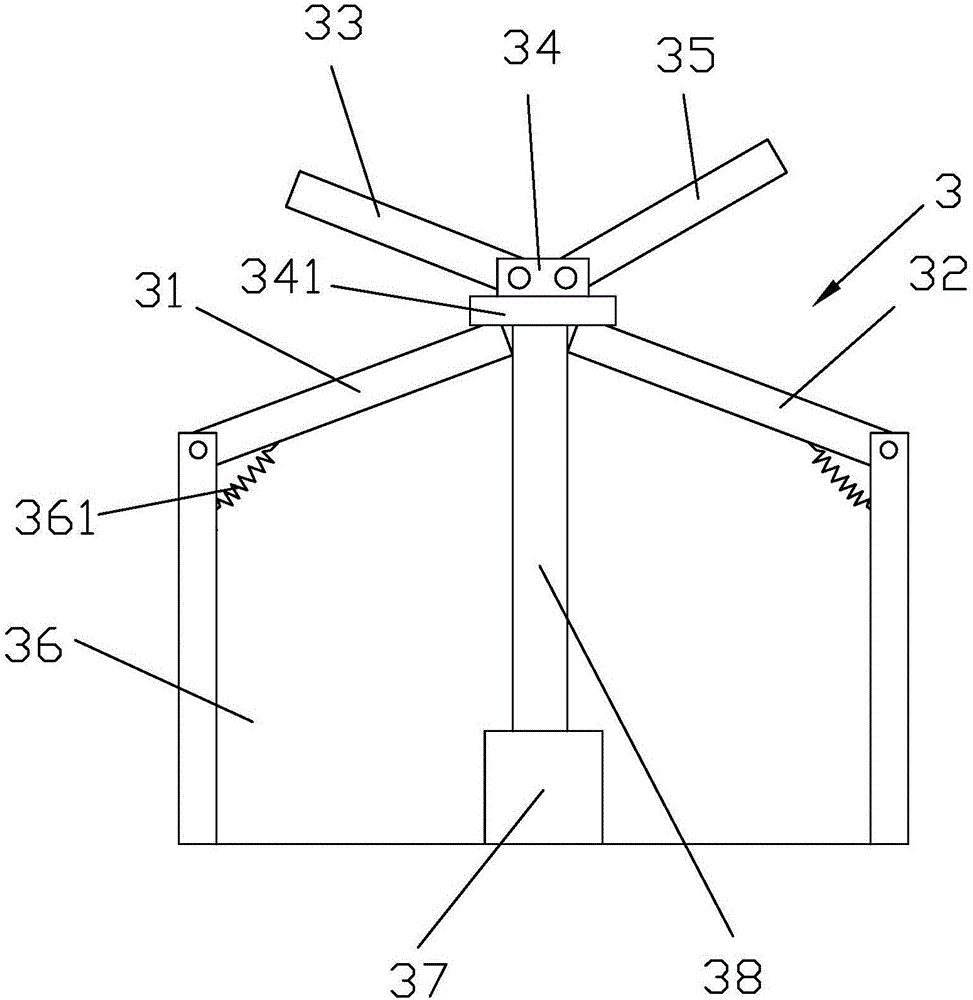

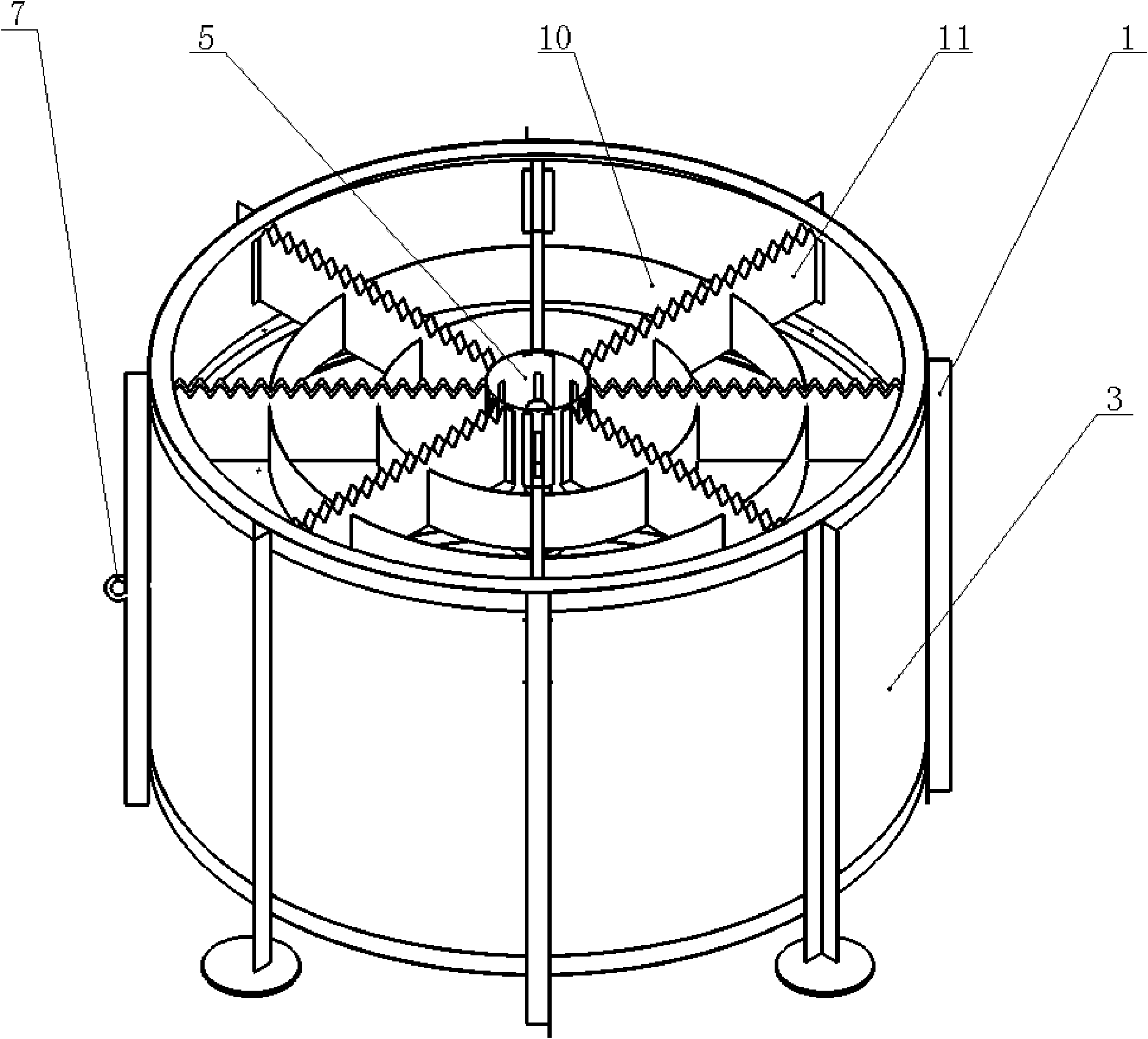

Resourceful treatment system of pond sediments

InactiveCN102246718AAvoid depositionGive full play to the buffer capacitySludge treatmentWater aerationDecompositionWater quality

The invention relates to a treatment system of water for aquaculture, in particular to a resourceful treatment system of pond sediments. The system is characterized in that a cement pile (8) is embedded at the bottom in the center of a pond (2); a central support pillar (7) is fixed on the cement pile; at the upper end of the central support pillar, at least three ropes (3) are pulled and fixed on cement columns (1) embedded on the periphery of the pond; one end of a guide rod (12) horizontally arranged in the pond water is sleeved on the central support pillar (7) by a sliding sleeve (4) andthe other end of the guide rod is connected with a sediment agitator (13); driven by a radial movement mechanism, the sediment agitator (13) radially moves toward or away from the central support pillar (7) along with or along the guide rod (12) while moving along the circumferential direction of the bottom surface of the pond (2). The resourceful treatment system has the following advantages: the organic floccule on the surface layer of the sediments in the whole pond is lifted through mechanical moving adsorption and the digestion capability and cenobium energy of the organic matters are improved by utilizing the dissolved oxygen and alkalinity on the photosynthesis layer to promote organic matter decomposition and phosphorus release and reduce accumulation of the organic matters, thus reducing culture pollution and improving the productivity and culture efficiency of the water body in the pond.

Owner:FISHERY MACHINERY & INSTR RES INST CHINESE ACADEMY OF FISHERY SCI

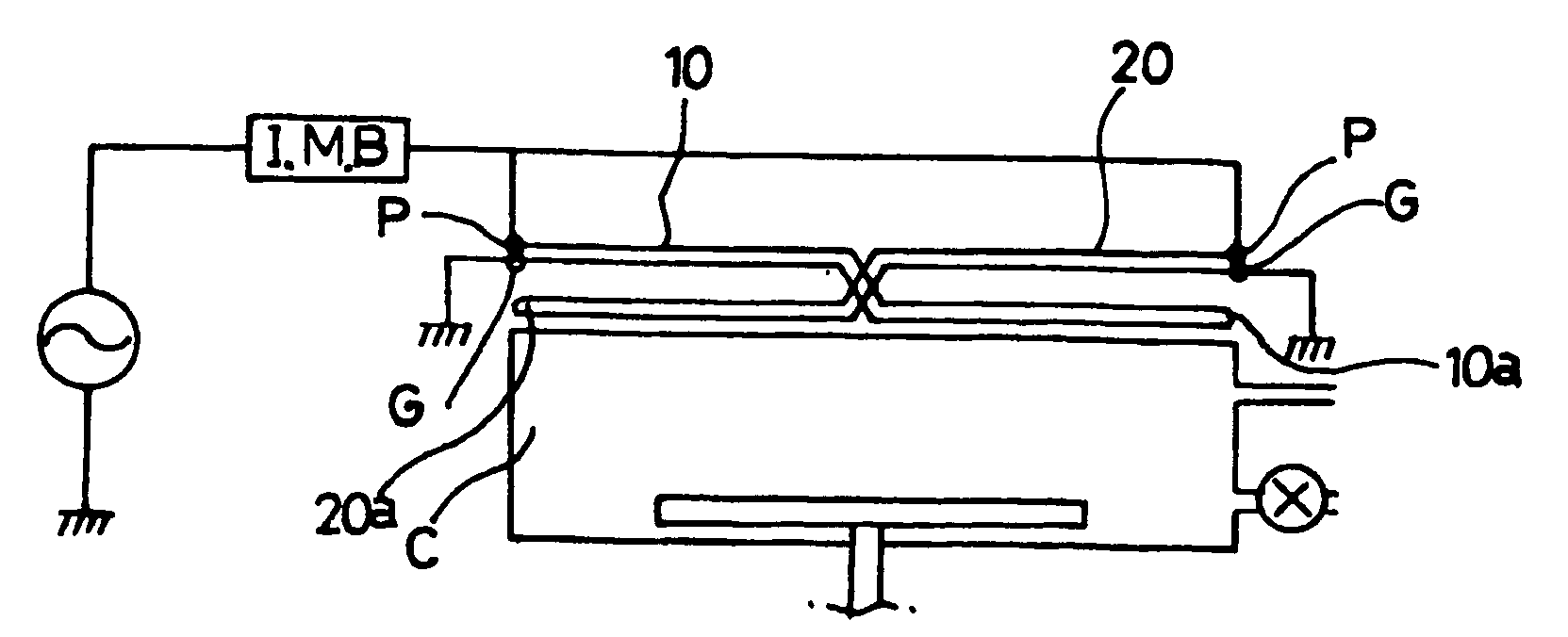

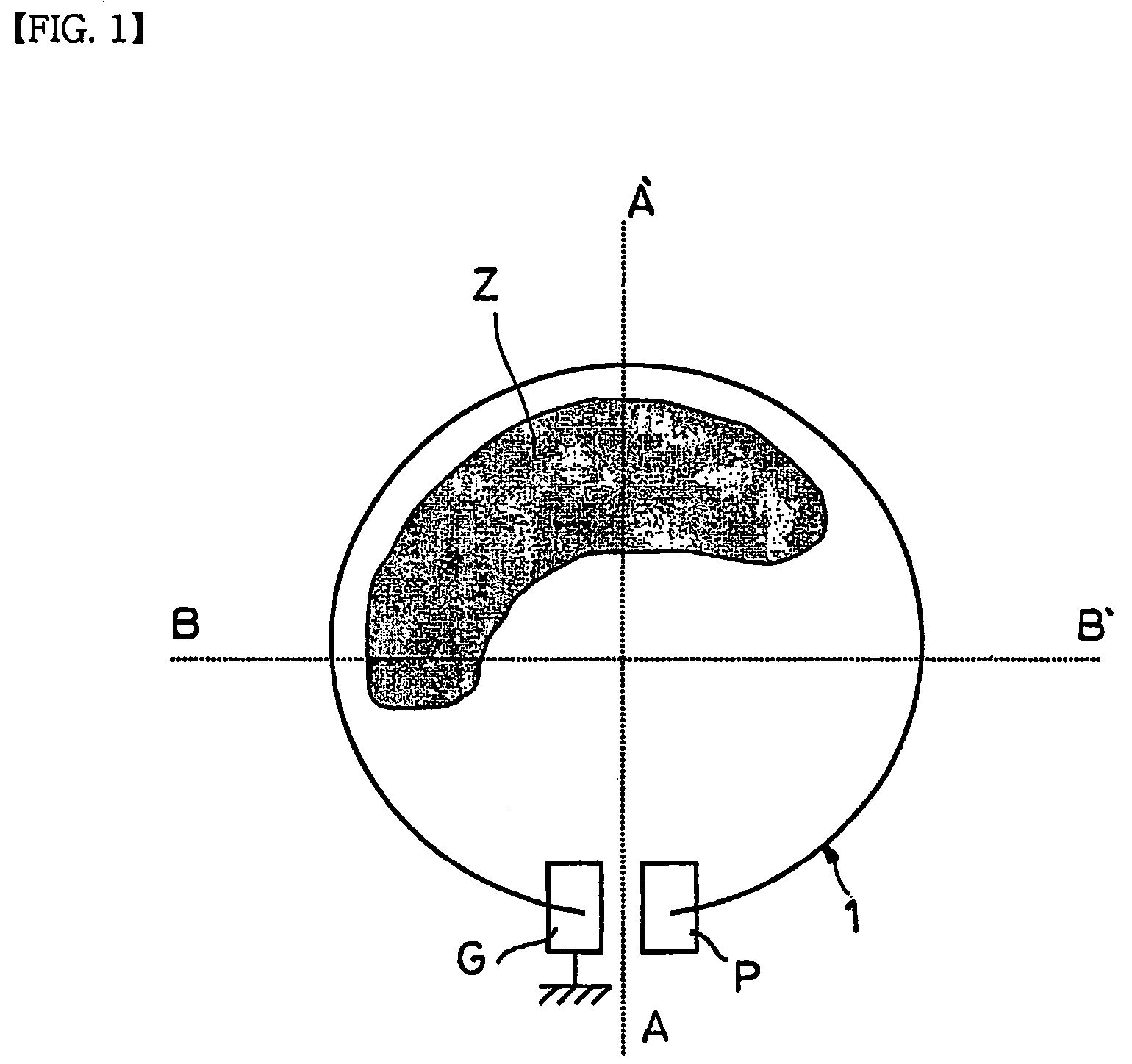

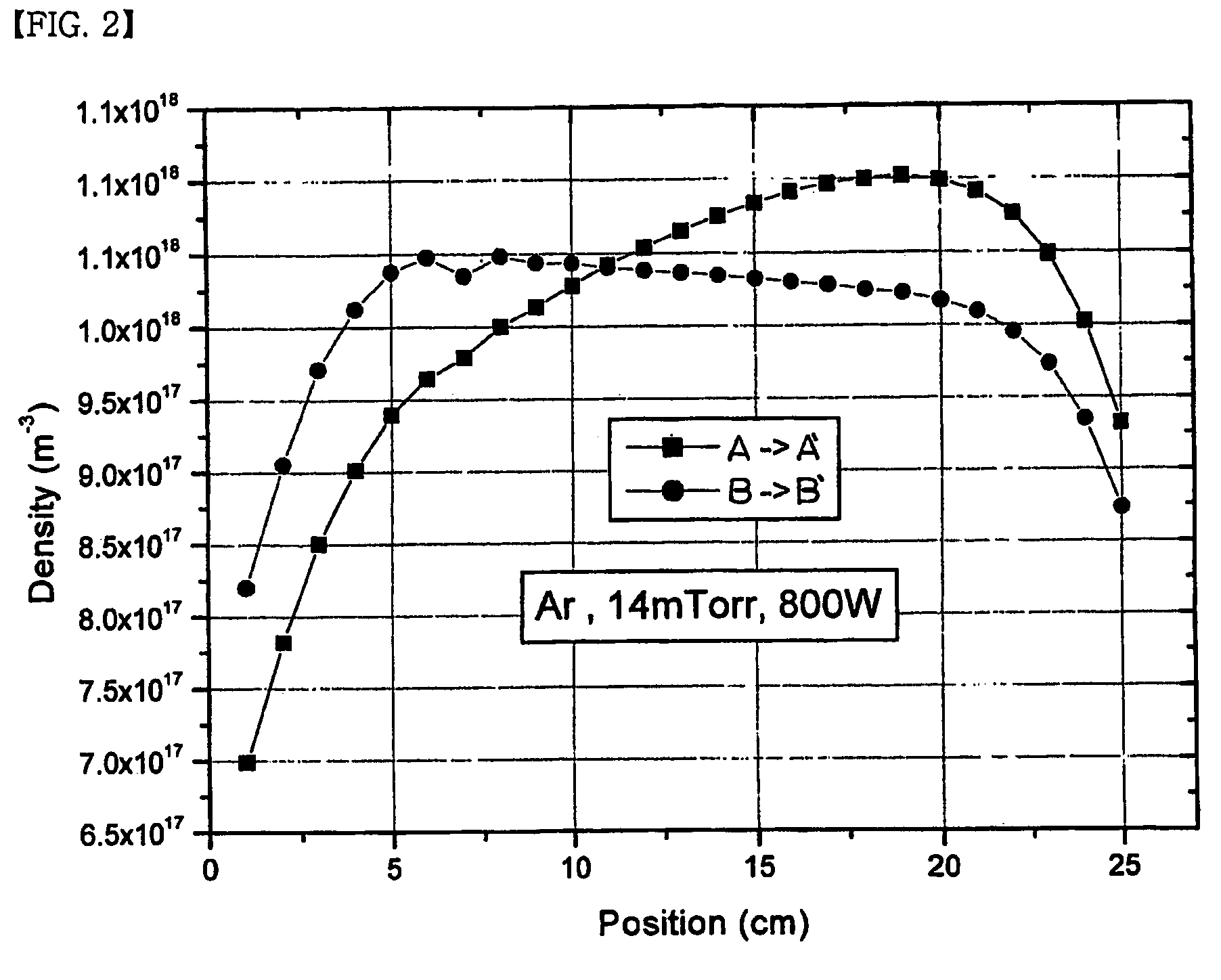

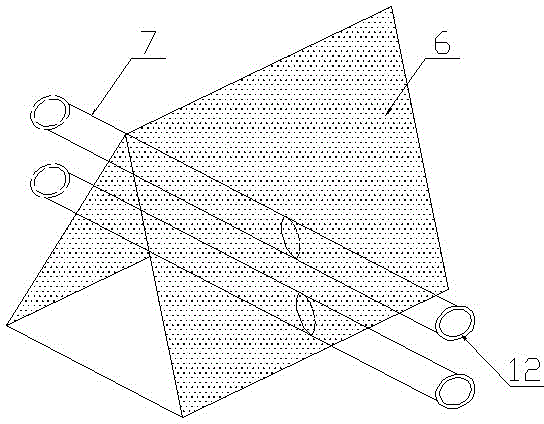

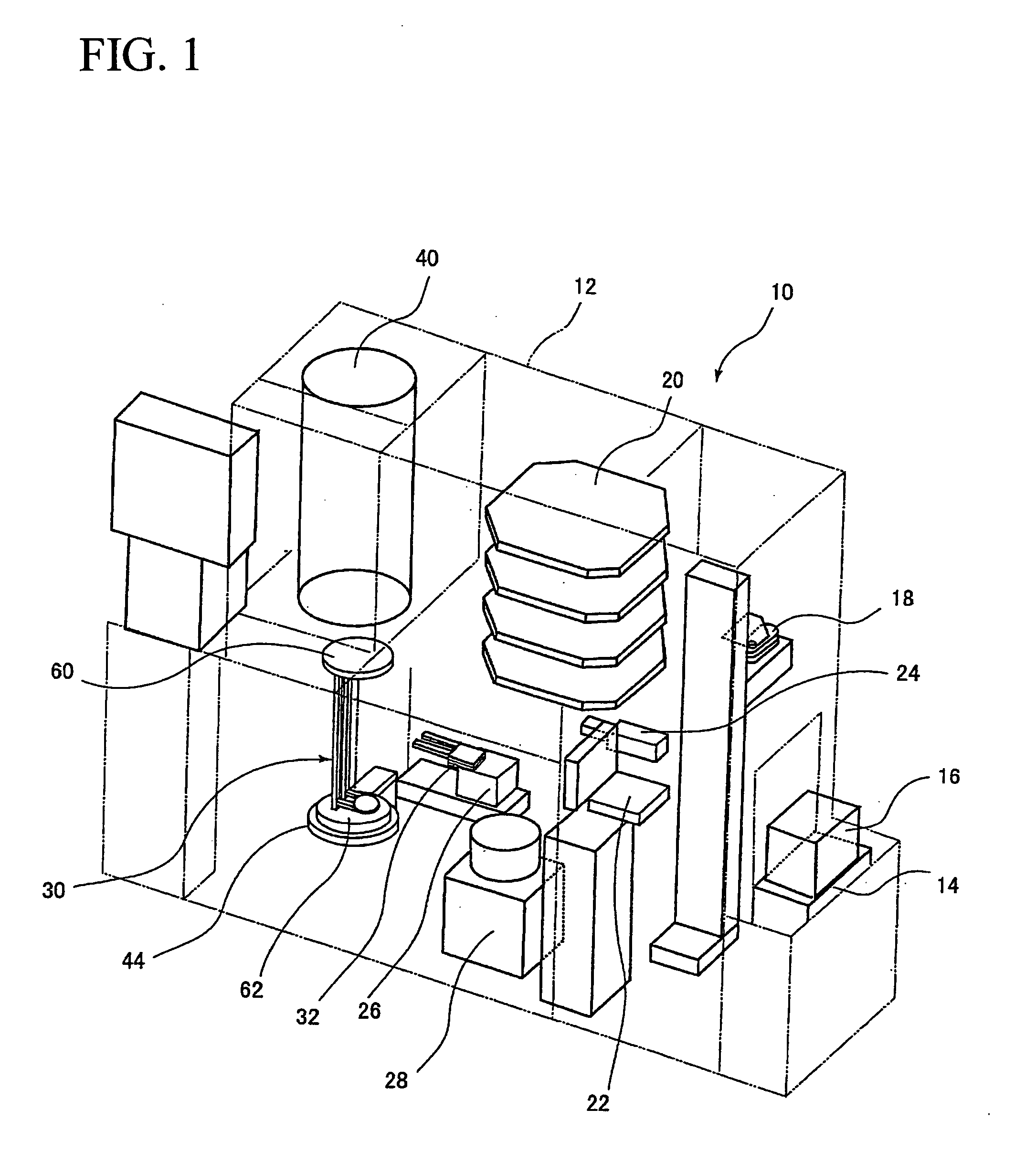

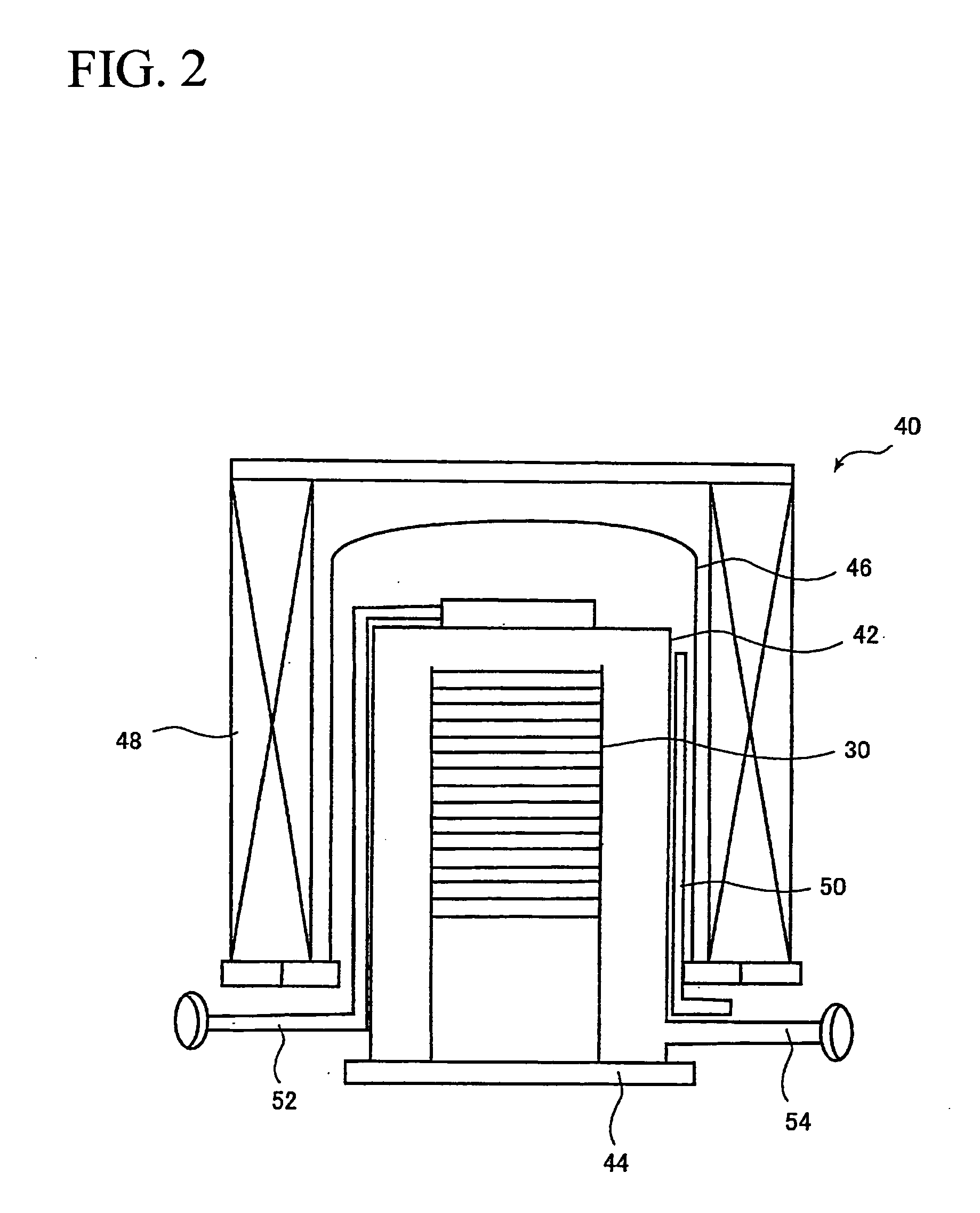

Antenna structure for inductively coupled plasma generator

InactiveUS7079085B2Simple structureAvoid it happening againResonant long antennasAntenna arraysDisplay deviceEngineering

An antenna structure for an inductively coupled plasma generator suitable for processing large-diameter wafers or large, flat-panel display devices by making a plasma density distribution uniform and symmetrical with respect to a rotating direction inside a circular or rectangular chamber in which a wafer is processed. In the antenna structure having a powered end to which RF power is applied and a ground end connected to the ground, at least two loop antenna elements are disposed electrically in parallel with each other, the powered ends and ground ends of the respective antennas are disposed symmetrically with respect to the center of the antennas, and the antennas crossing each other such that the powered ends and ground ends thereof are disposed at a part far from a chamber and central parts thereof are disposed at a part close to the chamber.

Owner:PLASMART CO LTD

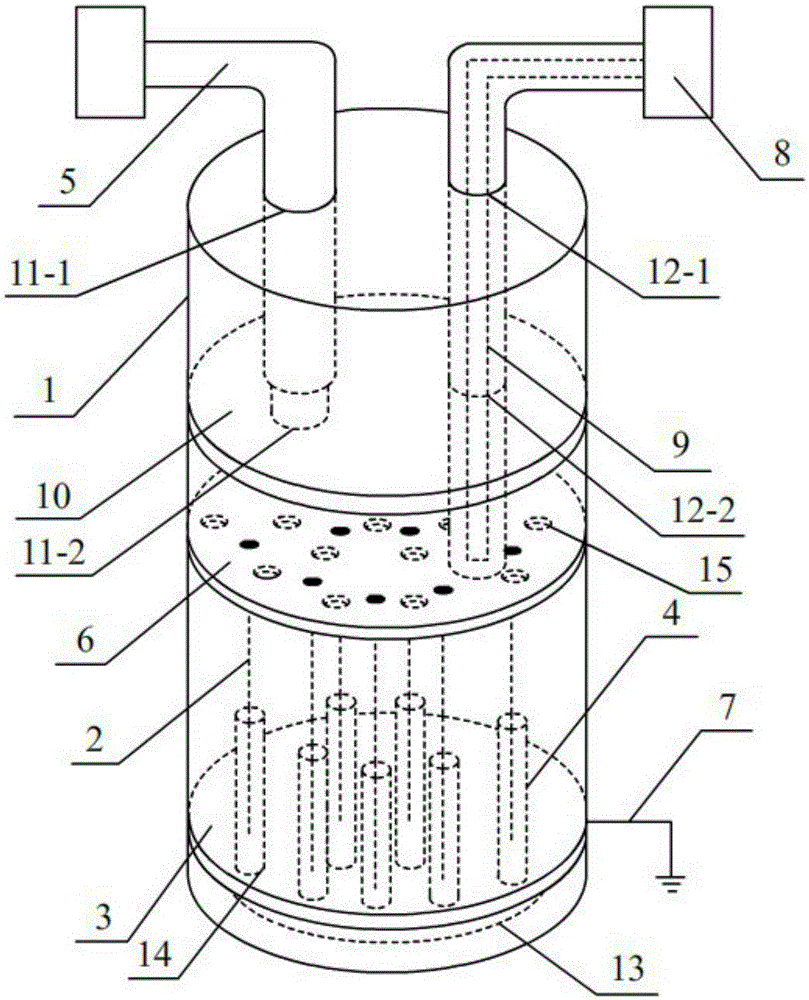

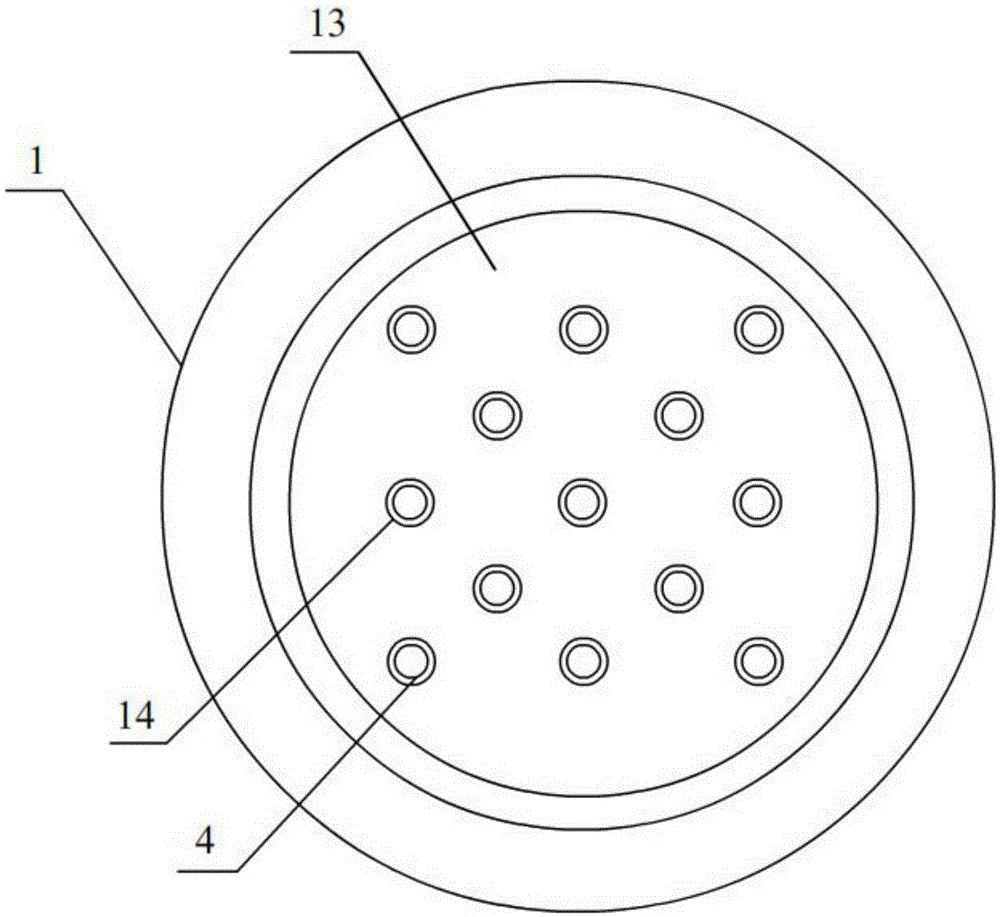

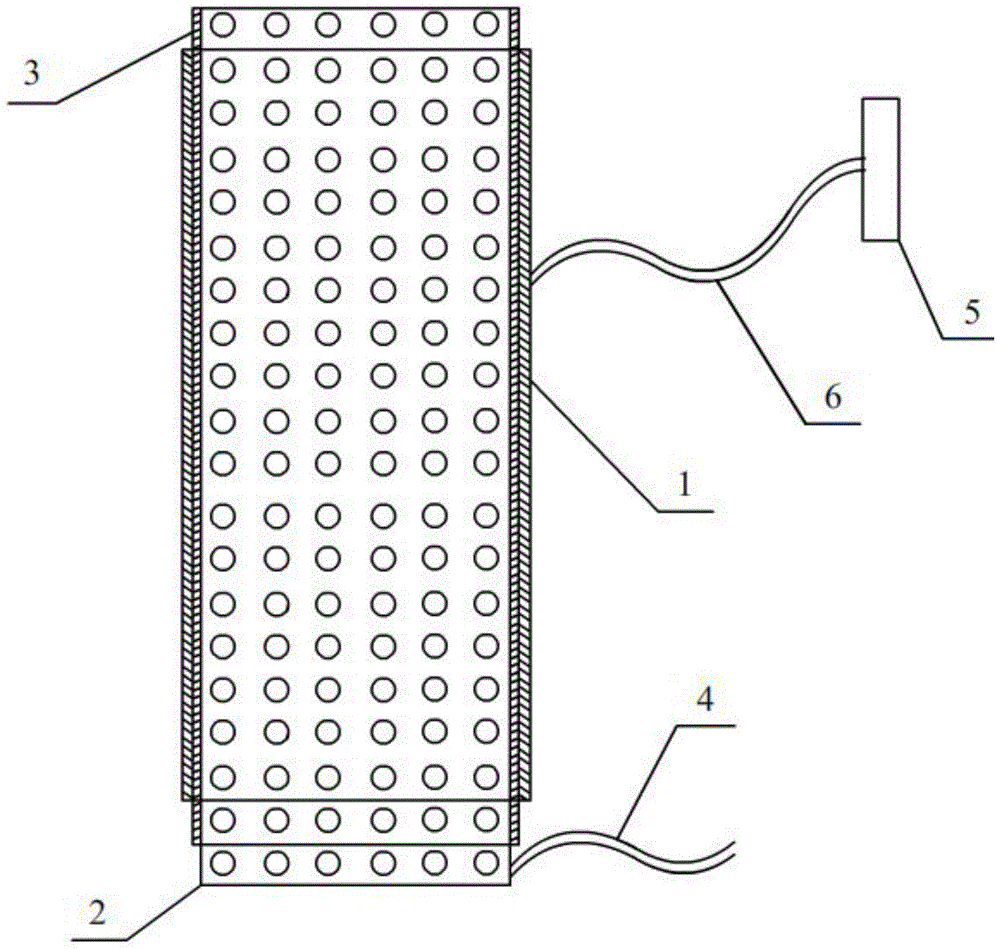

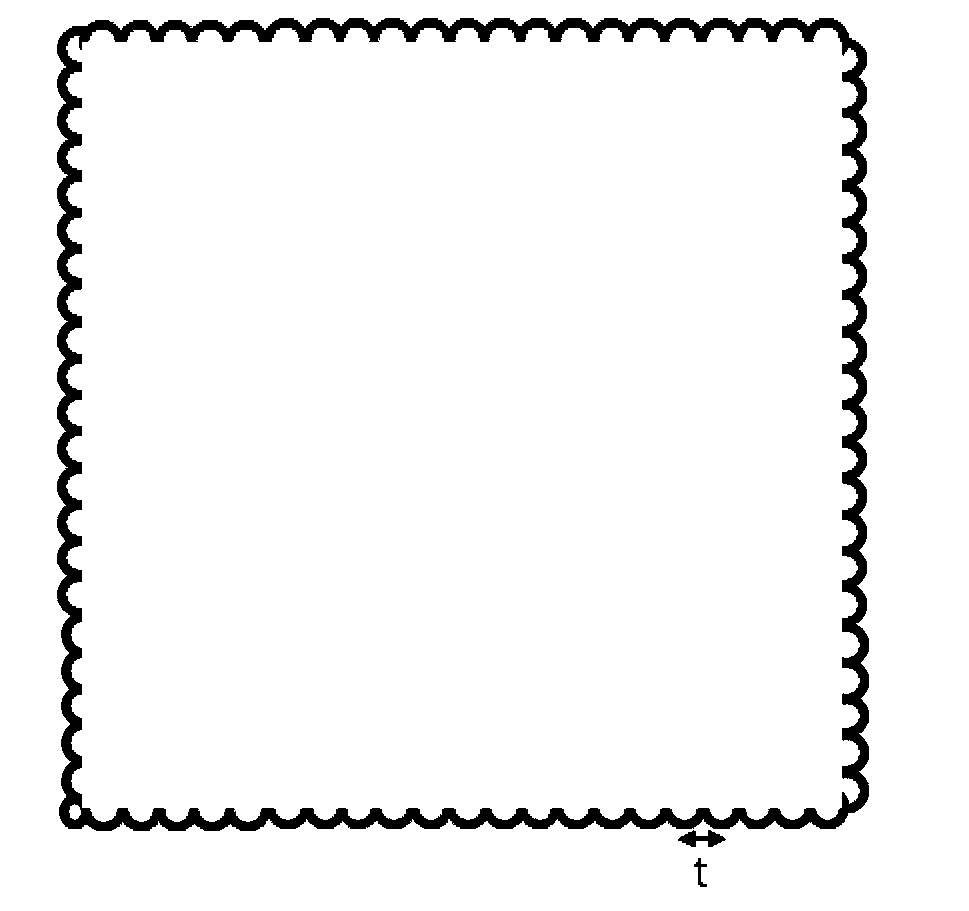

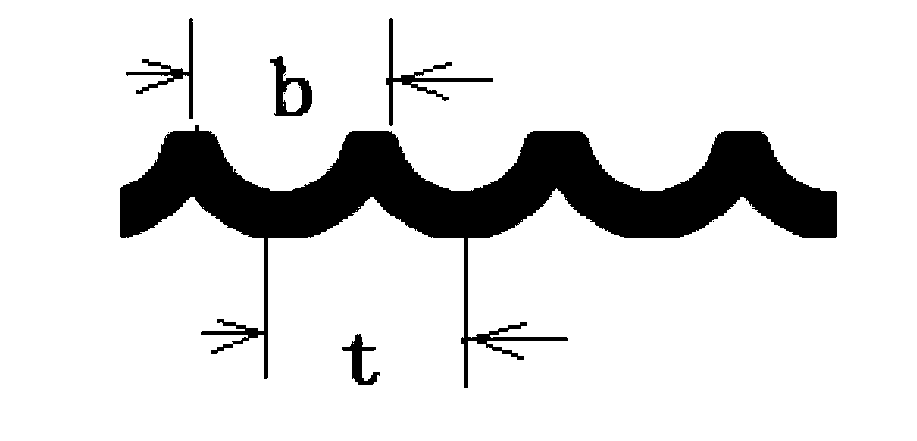

Medical array type micro-plasma skin treatment device

ActiveCN105396227ASimple structureEasy to useX-ray/gamma-ray/particle-irradiation therapySkin treatmentsEngineering

The invention provides a medical array type micro-plasma skin treatment device comprising a shell, high voltage electrodes, a ground electrode, insulation medium tubes, an air inlet tube, a PCB, a high voltage power supply and a high voltage line. The shell is a cylindrical shell, and the internal part is provided with a separating plate of which the surface is provided with an air inlet A and a line penetrating port A. The sealing end of the shell is provided with an air inlet B and a line penetrating port B. The air inlet tube is communicated with the air inlet A through the air inlet B. The PCB, the ground electrode and a sealing cap are installed below the separating plate in turn. The sealing cap is connected with the shell in a threaded way. The ground electrode and the surface of the sealing cap are uniformly provided with through holes. The insulation medium tubes are arranged in the through holes. The high voltage electrodes are installed in the internal parts of the insulation medium tubes. The top ends of the high voltage electrodes are welded on the PCB. The surface of the PCB is uniformly provided with ventilation holes. The high voltage line is connected on the PCB. The high voltage line penetrates through the line penetrating port A and the line penetrating port B to be connected with the external high voltage power supply. The medical array type micro-plasma skin treatment device has advantages of being simple in structure, convenient to use and flexible in operation.

Owner:DALIAN NATIONALITIES UNIVERSITY

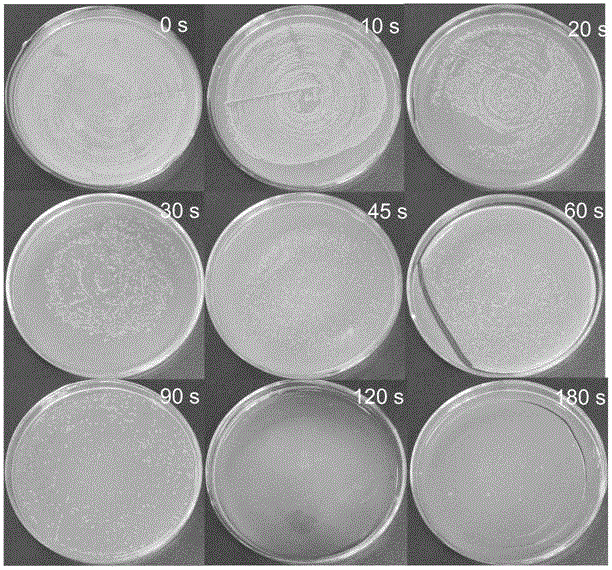

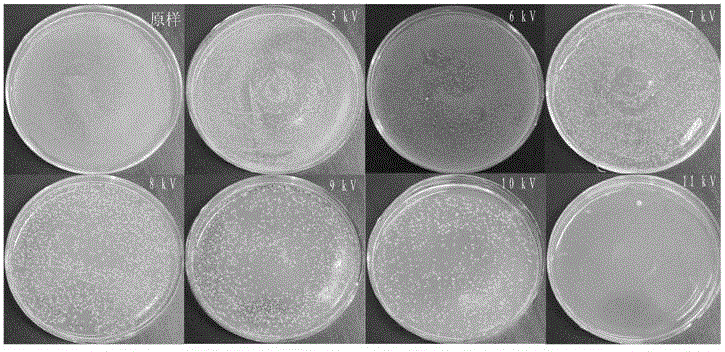

Device for sterilizing and disinfecting surface of endoscope through plasma

The invention discloses a device for sterilizing and disinfecting the surface of an endoscope through plasma. The device comprises a high-voltage electrode, a ground electrode, an insulating medium tube, a lead, a power supply and a high-voltage wire, wherein the ground electrode is made of a conductive metal net; the ground electrode is tightly adhered to the inner wall of the insulating medium tube; the top end of the ground electrode is flush with the top of the insulating medium tube; the bottom end of the ground electrode extends out from the bottom end of the insulating medium tube; the ground electrode is grounded through the lead; the high-voltage electrode is a copper foil or an aluminum foil; the high-voltage electrode is tightly wound on the surface of the outer wall of the insulating medium tube; the upper end and the lower end of the high-voltage electrode are both lower than the opening the insulating medium tube; the high-voltage electrode is connected with the power supply through the high-voltage wire. The device is sleeved by an insulating shell, the shell is of a single-opening tube structure, a screw cap is connected with the top opening of the insulating shell in a sleeve manner, three layers of concentric baffle rings are arranged at the bottom of the insulating shell; the inner diameters of the three layers of the baffle rings are reduced in sequence from top to bottom. The device has the advantages of being simple in structure, convenient to use, low in cost, small in energy consumption, high in efficiency, free of endoscope damage, and the like.

Owner:DALIAN DONGDA CLEANING TECH CO LTD

Reverse-polarity AlGaInP-based LED side wall coarsening method

InactiveCN104078535AAchieve sidewall rougheningImprove light extraction efficiencySemiconductor devicesQuantum efficiencyEngineering

The invention relates to a reverse-polarity AlGaInP-based LED side wall coarsening method. The method includes the following steps that (1) exposure and development are conducted on a mesa image epitaxial wafer of a reverse-polarity AlGaInP-based LED through an existing photolithographic process, and a constant periodicity edge figure is formed at the periphery of the mesa image epitaxial wafer; (2) the mesa image epitaxial wafer obtained after development in the step (1) is corroded through deionized water containing saturation Br2; (3) cleaning and photoresist removing are conducted on the mesa image epitaxial wafer after being corroded through the step (2) according to the conventional process, and coarsening side wall corresponding to the periodicity edge figure shape is formed. According to the reverse-polarity AlGaInP-based LED side wall coarsening method, the mode that coarsening of the side wall of the LED chip is achieved through the photolithographic technology is first proposed, the light extraction efficiency of the LED, especially the LED chip side face, is improved greatly compared with the prior art, the external quantum efficiency of LED devices is improved, internal heat is reduced, and the service life of the LED is prolonged.

Owner:SHANDONG INSPUR HUAGUANG OPTOELECTRONICS

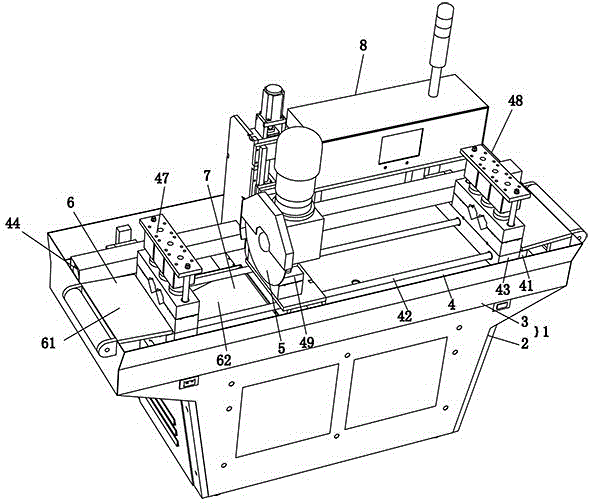

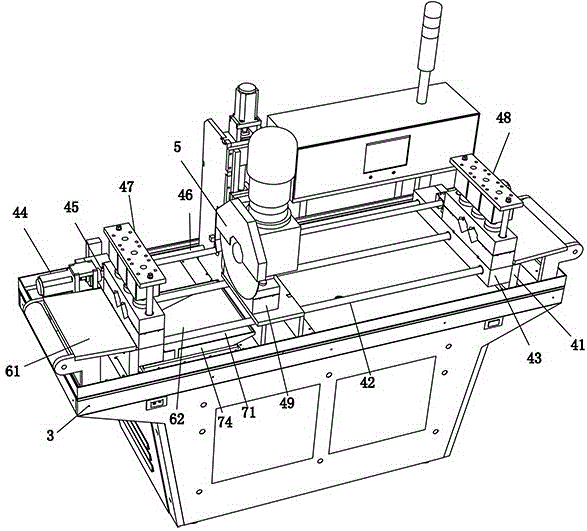

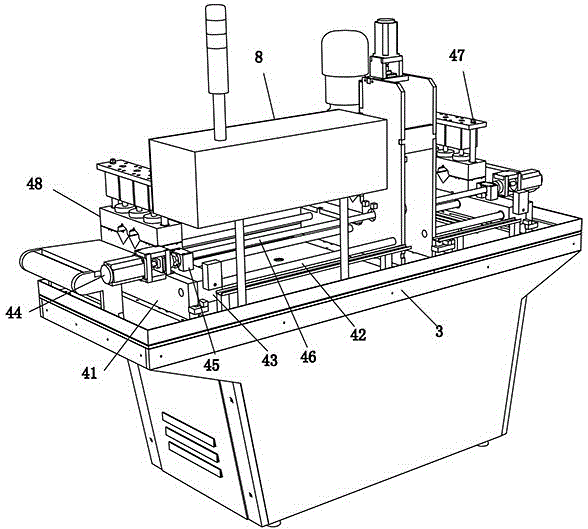

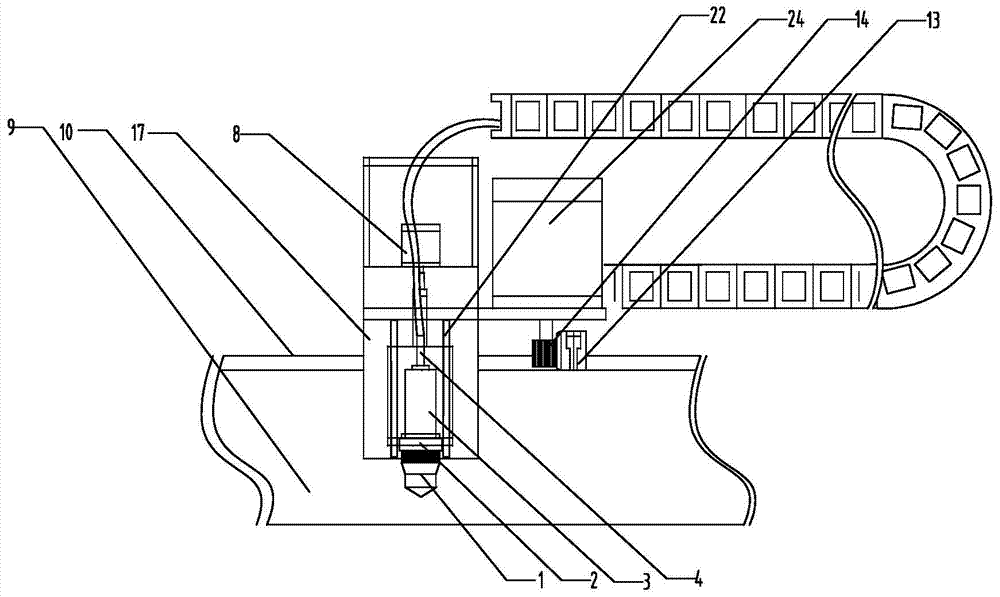

Automatic pipe cutting machine

ActiveCN105057762ALarge processing areaLarge working spaceTube shearing machinesShearing machine accessoriesEngineeringMachining

The invention discloses an automatic pipe cutting machine which comprises a rack. The rack comprises a base and a table face arranged on the top of the base. The rack is provided with a clamping mechanism, an up-down moving cutting roller, a long and short material feeding mechanism and a material-water separation mechanism. The clamping mechanism is distributed in a left-right offset mode, the up-down moving cutting roller is matched with the clamping mechanism, the long and short material feeding mechanism can feed long materials and short materials, and the material-water separation mechanism is matched with the long and short material feeding mechanism. A pipe cutting area can be fully avoided, larger work space is provided for workpieces, it is guaranteed that the whole structure is more compact and reasonable in layout, and the defect that a screw rod of an existing pipe cutting machine is arranged in the middle and accordingly the whole machine is too long is avoided. The long materials and the short materials which are cut can be output from different discharge openings, classification and collection are convenient, cleanliness of the machining environment is improved, and labor intensity of workers is reduced. Materials and water of the cut materials are effectively separated in the feeding process through the material-water separation structure, a machining site can be kept clean, and the dryness degree of the materials is improved.

Owner:欧奔智能设备科技(杭州)股份有限公司

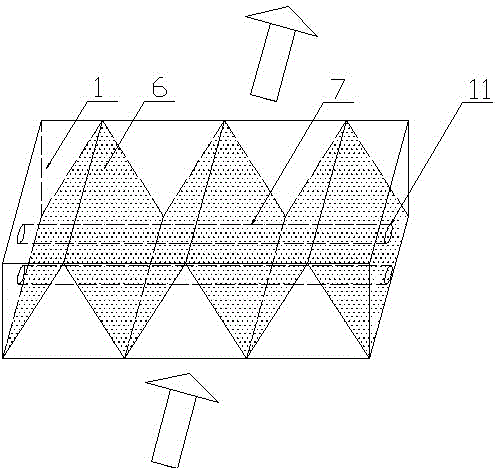

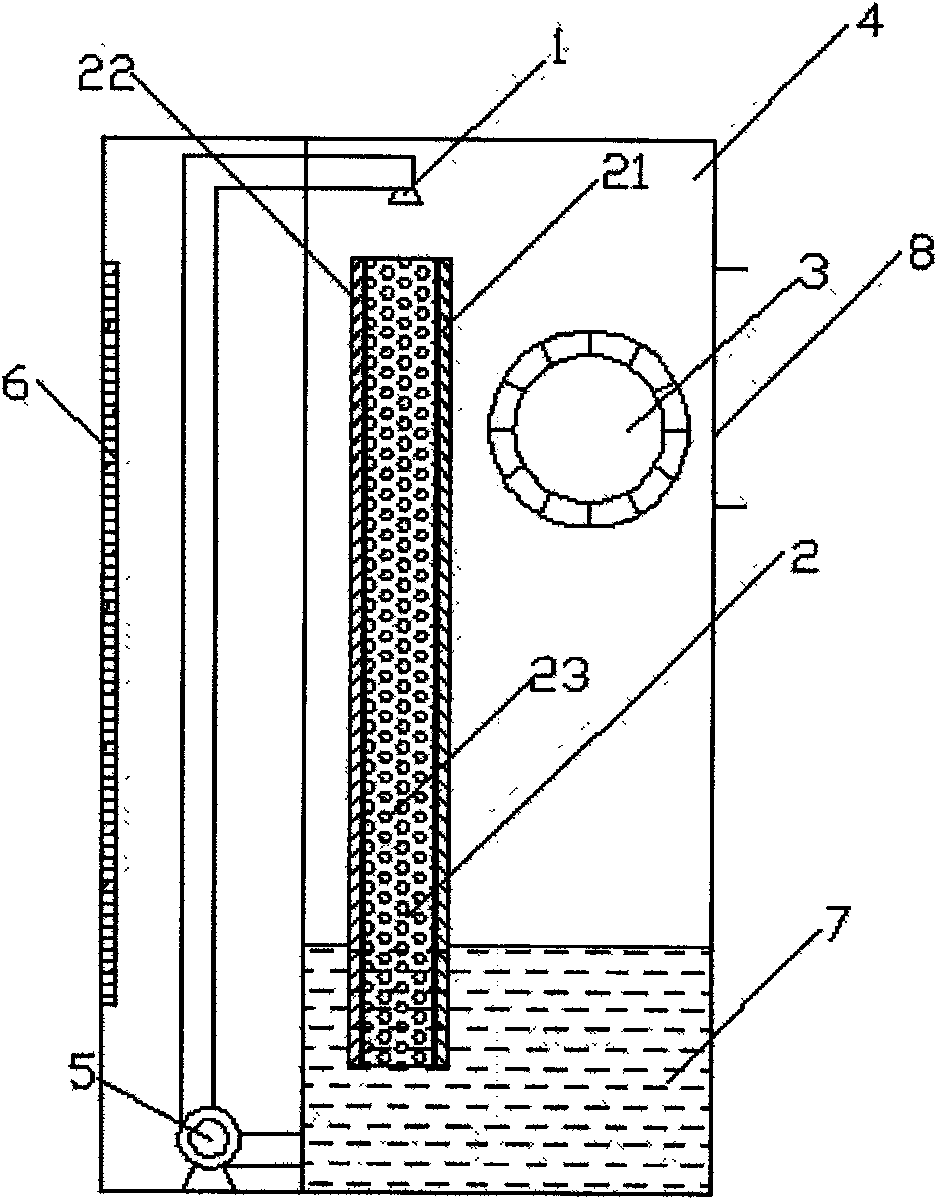

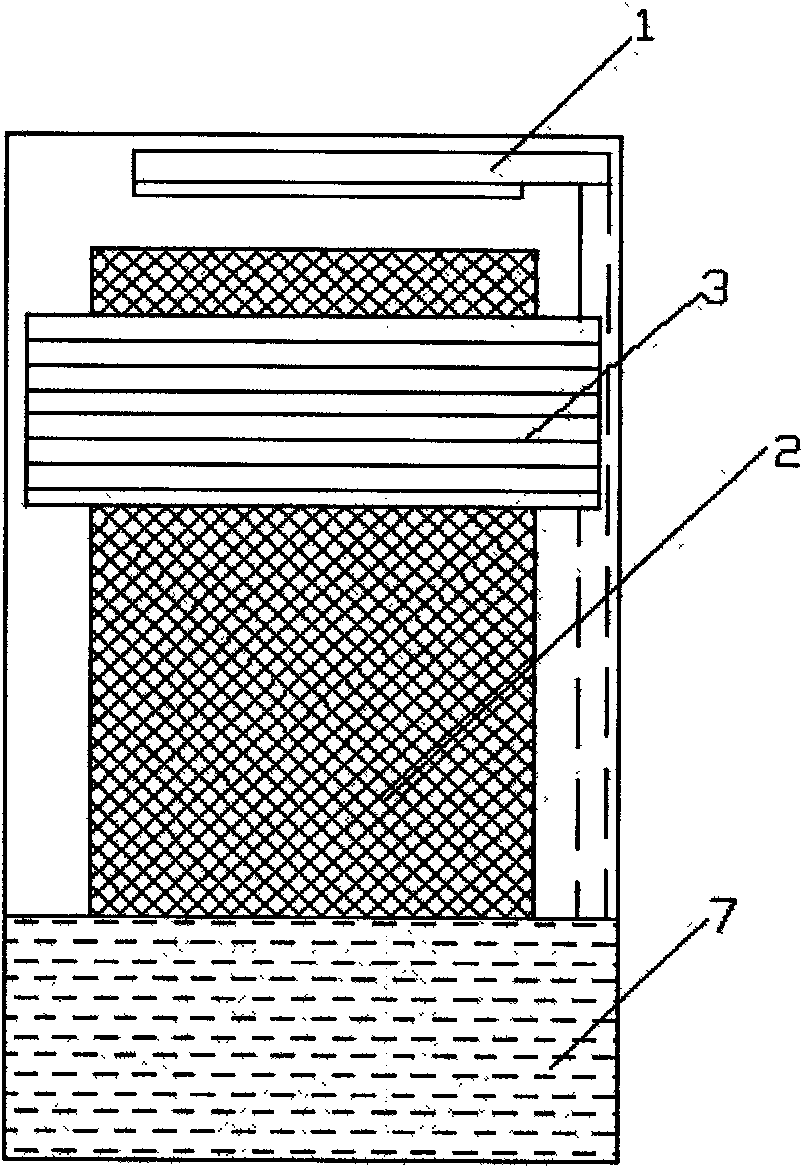

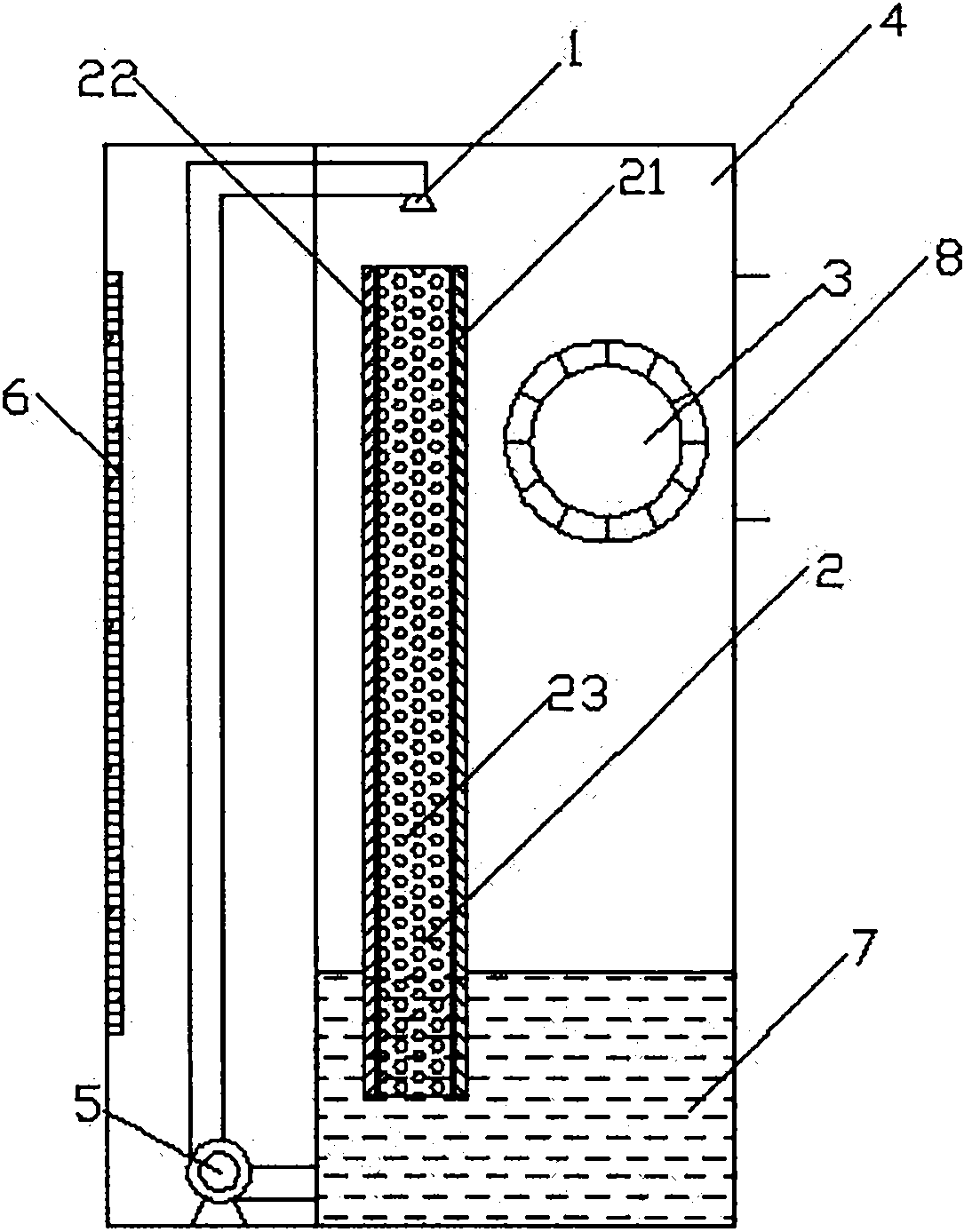

Air flue type photocatalysis air purifier

ActiveCN104089348ALarge processing areaIncrease the areaLighting and heating apparatusDispersed particle separationEngineeringAir purifier

The invention discloses an air flue type photocatalysis air purifier which comprises a shell. At least one photocatalysis structure is arranged inside the shell, and photocatalysis filter screens and an ultraviolet source are arranged in the photocatalysis structure. The air flue type photocatalysis air purifier is characterized in that, in the photocatalysis structure, the number of the photocatalysis filter screens is two, and the whole photocatalysis filter screens are in a back-and-forth zigzag W shape, a fin is arranged between the two photocatalysis filter screens, the fin is in a W shape in the length direction and is transversely connected to the interior of the shell, the width direction of the rib is coincident with the longitudinal direction of the shell, a transparent sleeve arranged in the transverse direction of the shell is installed in the middle of the fin in a penetrated mode, and the ultraviolet source is arranged in the transparent sleeve. The photocatalysis filter screens, the fin and the inner surface of the shell are all coated with photocatalysts. The air flue type photocatalysis air purifier can be installed in an air flue, and extra occupied space is not needed; meanwhile, the effective reaction area of the air flue type photocatalysis air purifier is large, the using efficiency of the ultraviolet source is high, the reaction-mass transferring capacity of the surface of the photocatalysts is high, energy consumption is small, the structure is simple, the reaction efficiency is high, and the air flue type photocatalysis air purifier is convenient to use and install.

Owner:CHONGQING UNIV

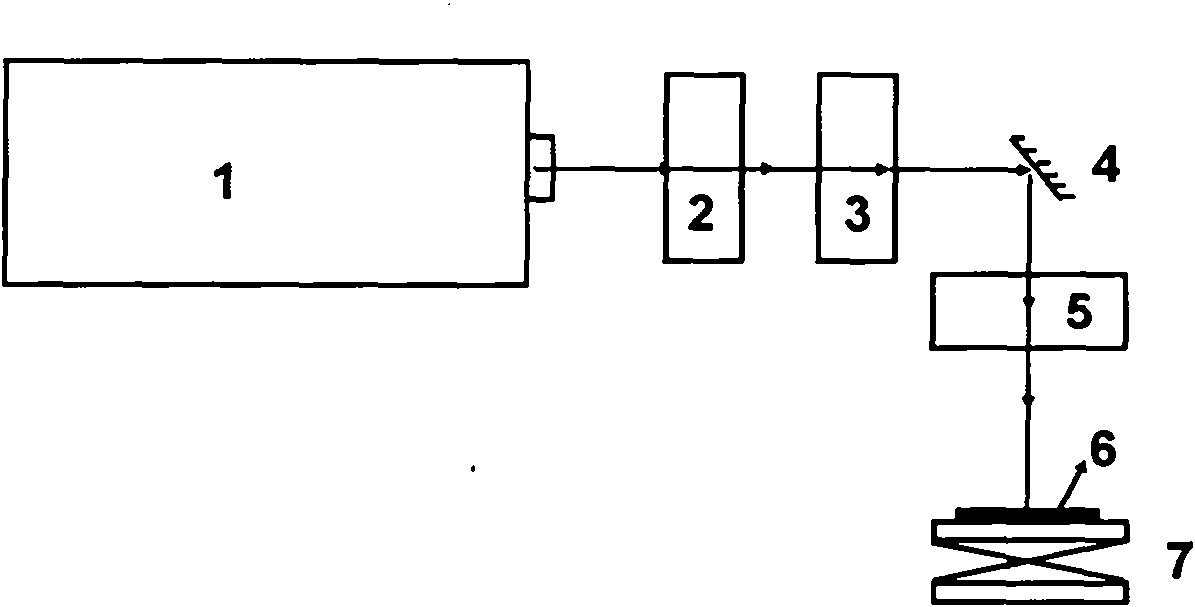

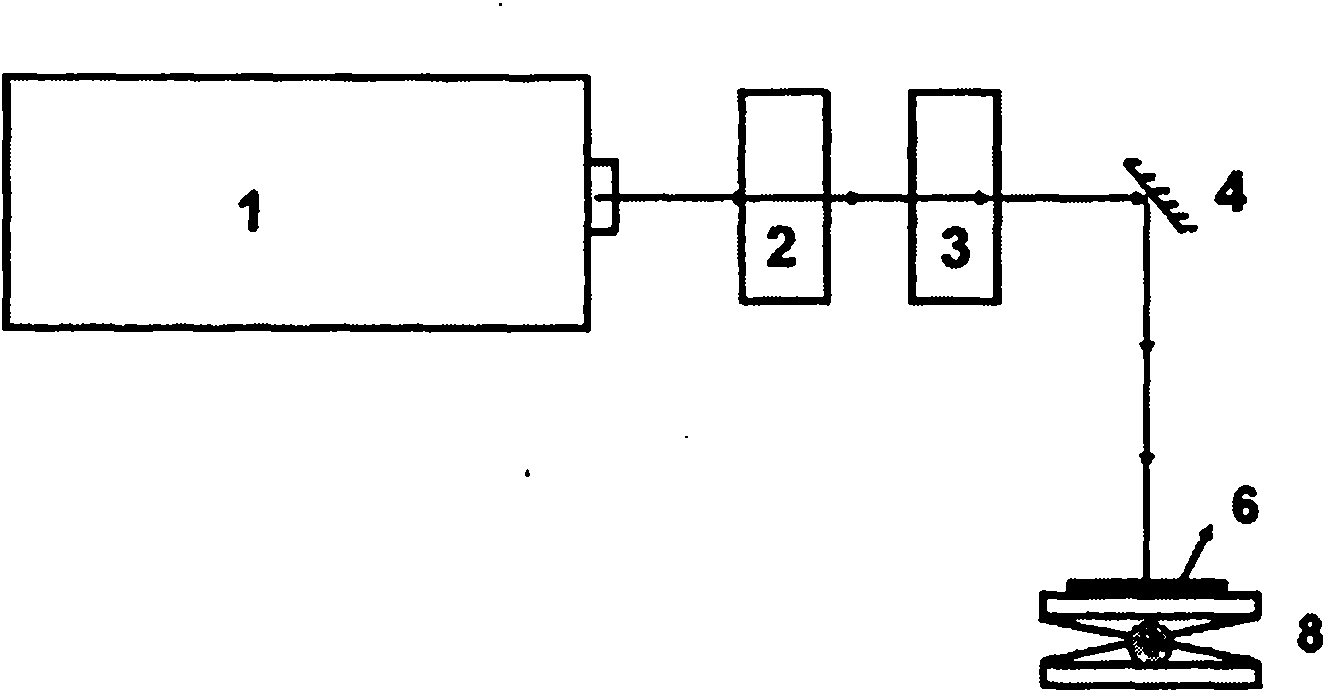

LED large-area controllable surface coarsening and etching method based on laser

InactiveCN101866996AImprove light extraction efficiencySimple production processSemiconductor devicesGalvanometerHigh power lasers

The invention relates to an LED large-area controllable surface coarsening and etching method based on a laser, belonging to the technical field of an LED. The method utilizes semiconductor material for carrying out strong absorption generating gasification on high-power laser with the wavelength less than the band edge absorption wavelength of the semiconductor material, thus realizing surface coarsening for the semiconductor material on the surface of the LED. A high-speed galvanometer or a precise displacement platform is used for controlling the laser processing area or pattern, and can be used for controlling the laser power and the processing line width and depth of focus level adjustment. The LED large-area controllable surface coarsening and etching method can be applied to surface coarsening and etching of the GaAs-based LED and the GaN-based LED of various structures. The laser takes the wavelength less than the band edge absorption wavelength of the processed semiconductor material as reference. The method has the advantages of wide applicable material, rapid processing speed, large area, low cost, good coarsening effect, low damage for the semiconductor material, high controllability of system processing parameters and the like, can effectively solve the problem of p-GaN layer coarsening, and has great application potential in the production of the high-brightness LED.

Owner:SHANDONG UNIV

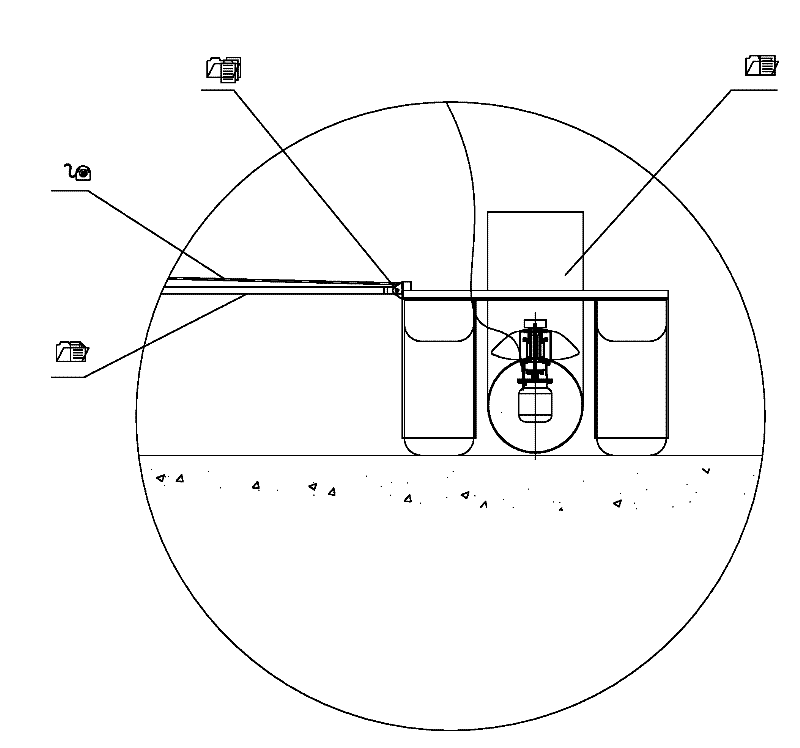

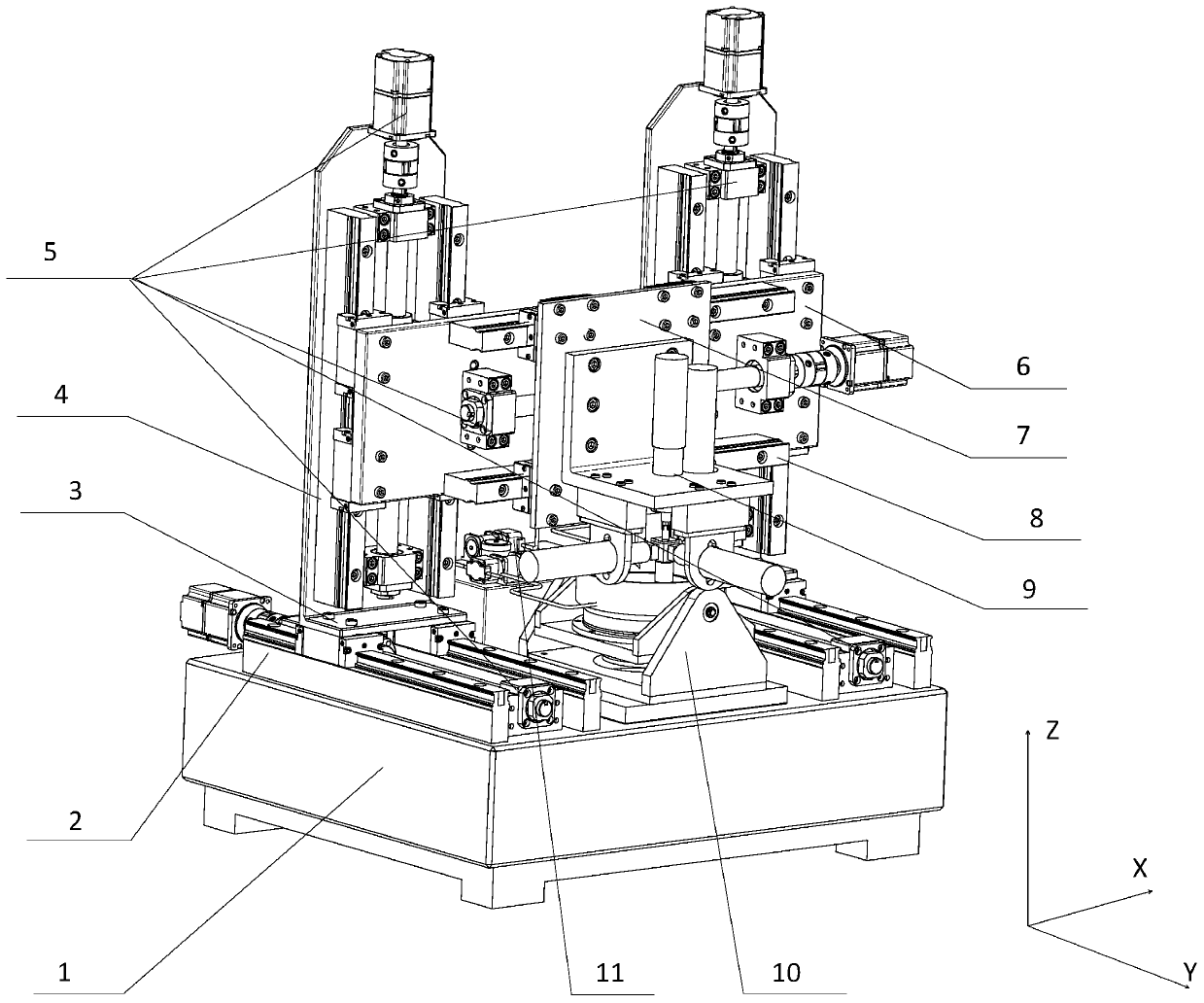

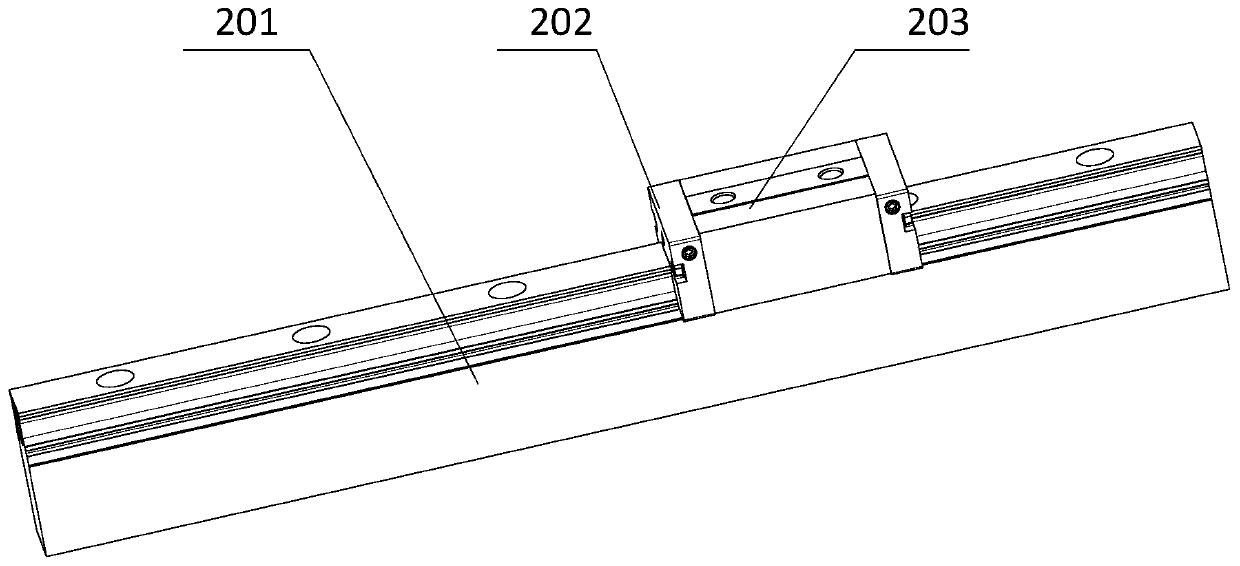

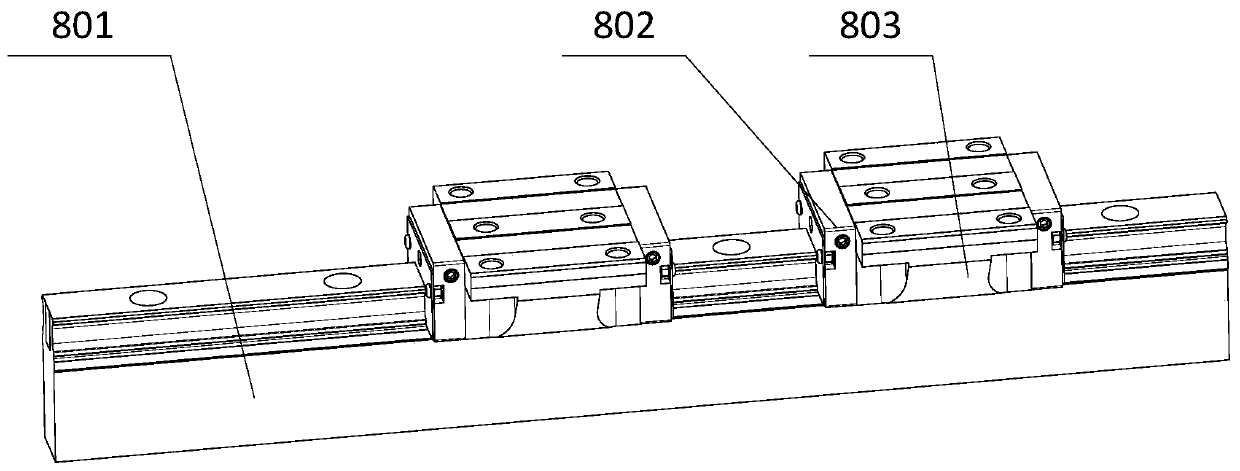

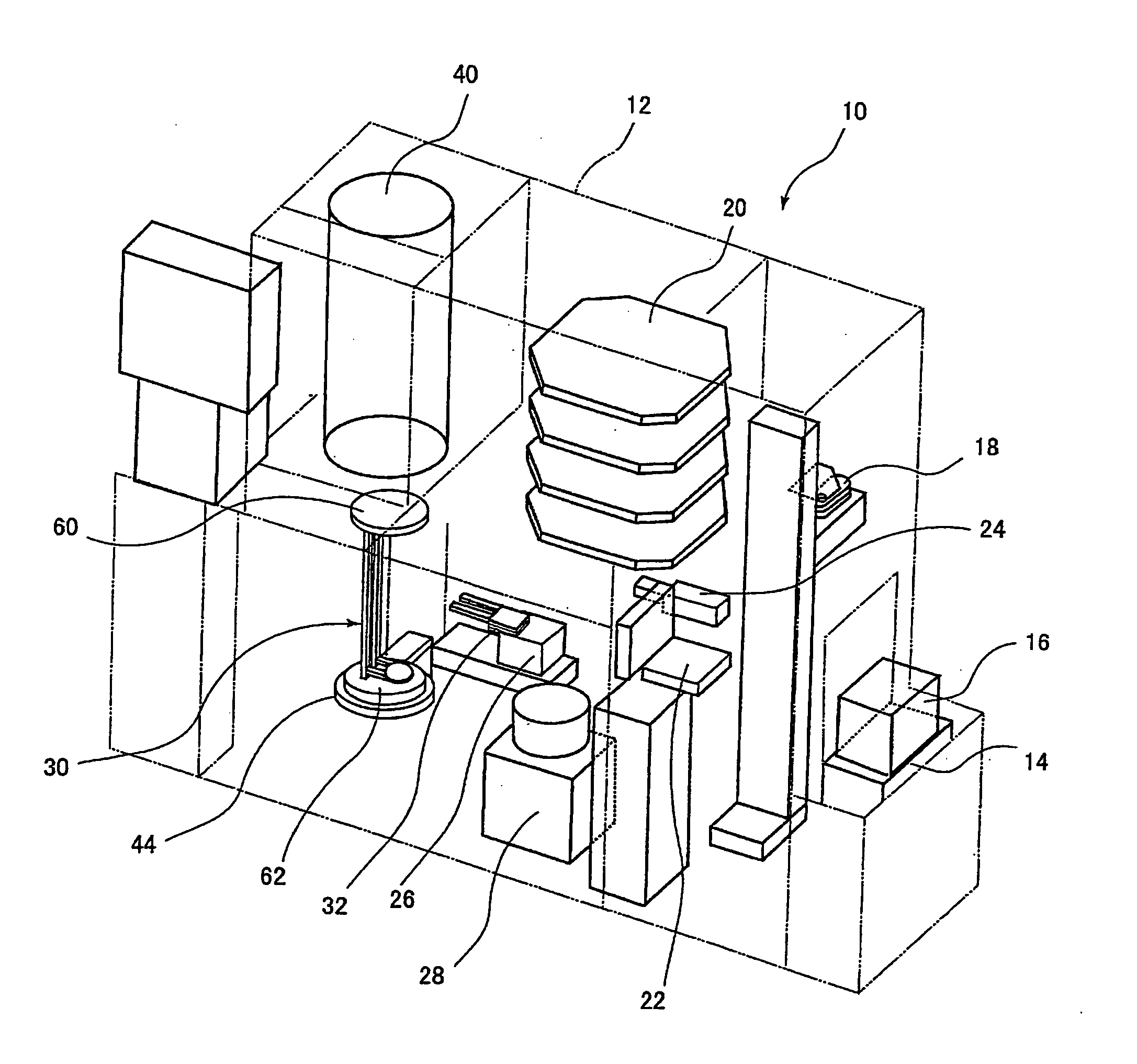

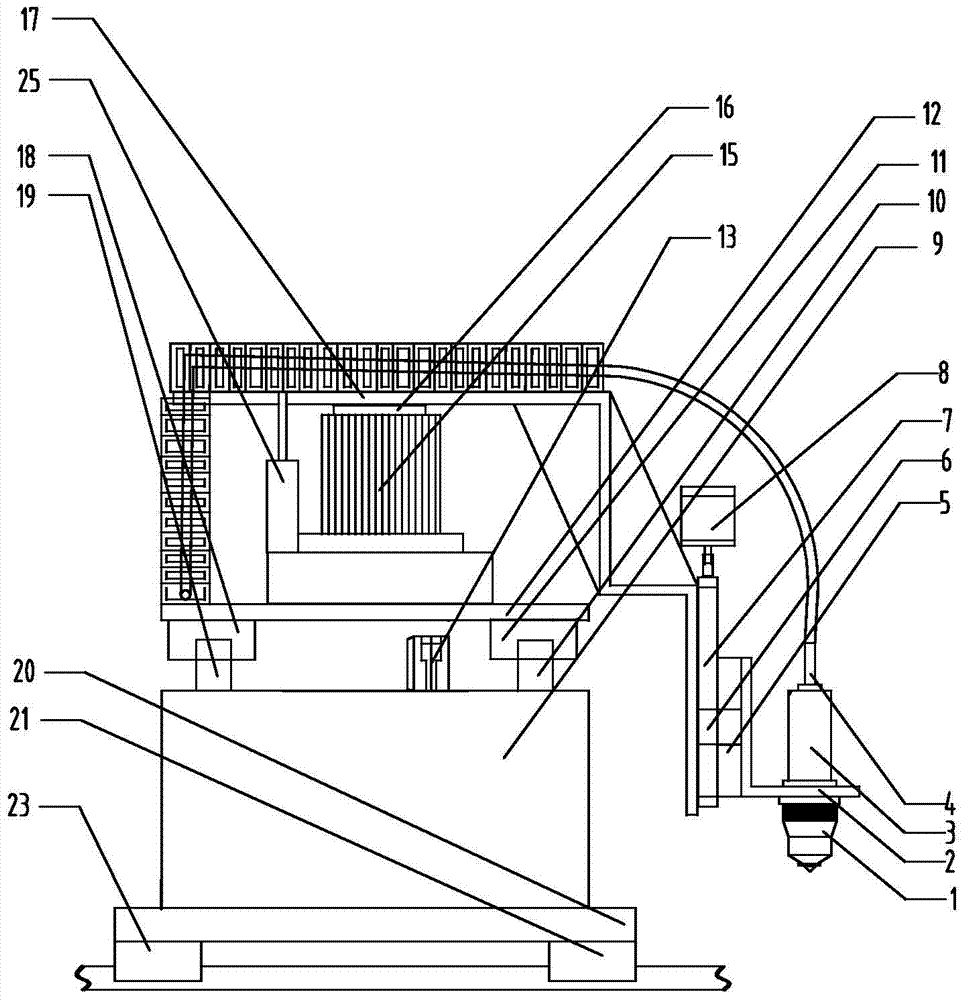

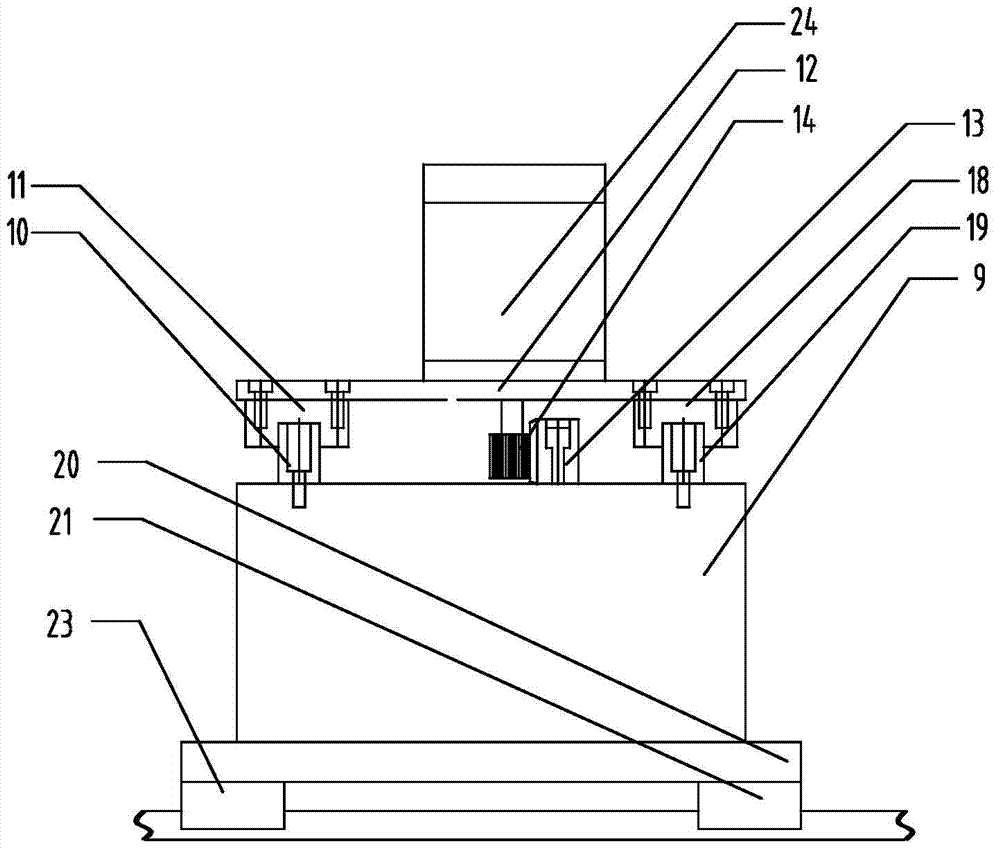

Multi-dimensional ultrasonic assisted magneto-rheological precision polishing machine tool and machining method

PendingCN110561202ALarge processing areaThorough polishingOptical surface grinding machinesGrinding/polishing safety devicesUltrasonic assistedMagnetorheological fluid

The invention relates to a multi-dimensional ultrasonic assisted magneto-rheological precision polishing machine tool and a machining method, and belongs to the technical field of polishing machine tools. Two sets of Y-direction moving rails are separately fixed on the left side and the right side of a machine tool base 1, two Z-direction fixing bottom plates are separately fixed on the Y-direction moving rails arranged on the left side and the right side of the machine tool base 1, two Z-direction moving rails are separately fixed on the Z-direction fixing bottom plates, X-direction fixing bottom plates are separately fixed on the two Z-direction moving rails, and X-direction moving rails are fixed on the upper sides and the lower sides of the X-direction fixing bottom plates; and a magnetorheological fluid circulating device is fixedly arranged behind the middle of the machine tool base, a rotating workbench is fixedly arranged in front of the middle of the machine tool base, tool head mounting bottom plates are fixed on the X-direction moving rails, and tool heads are fixed on the tool head mounting bottom plates. The polishing machine has the advantages that polishing machiningis carried out at the same time in three different directions, so that the machining area at the same time is larger, the rotation motion of a grinding head enables the polishing machining to be morecomprehensive and thorough, and the polishing machining efficiency and the machining precision are improved.

Owner:JILIN UNIV

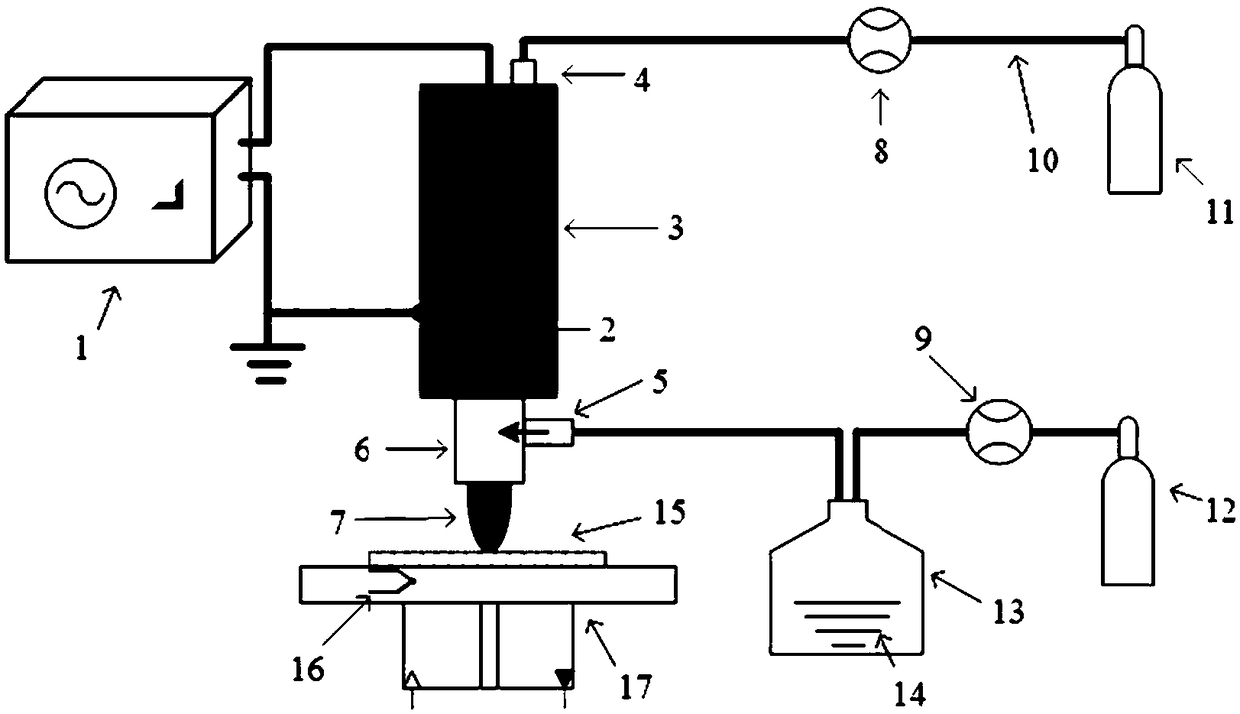

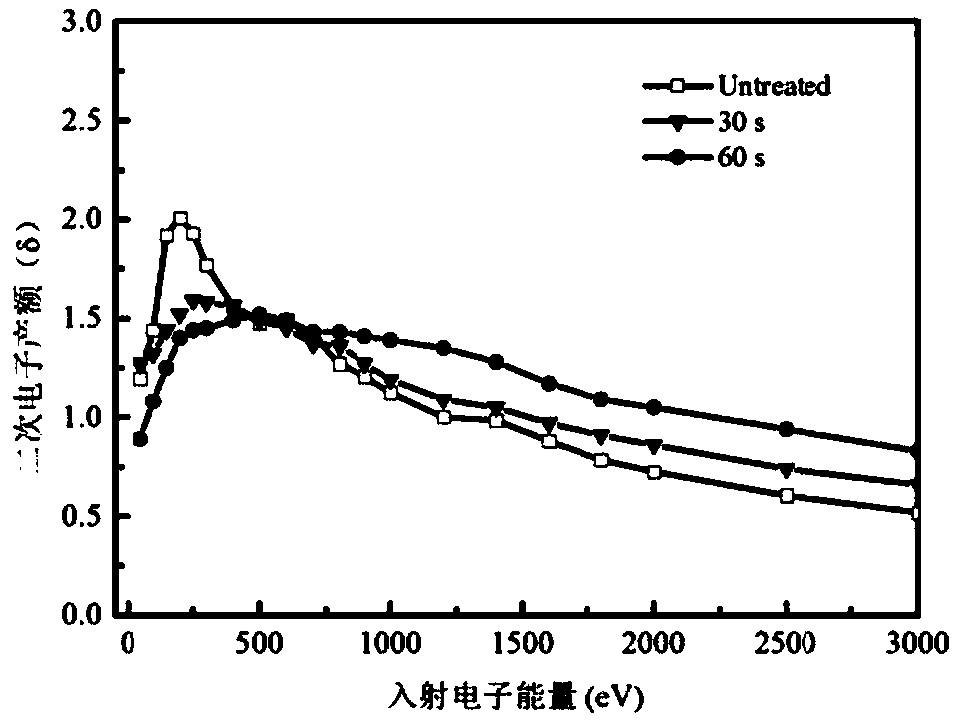

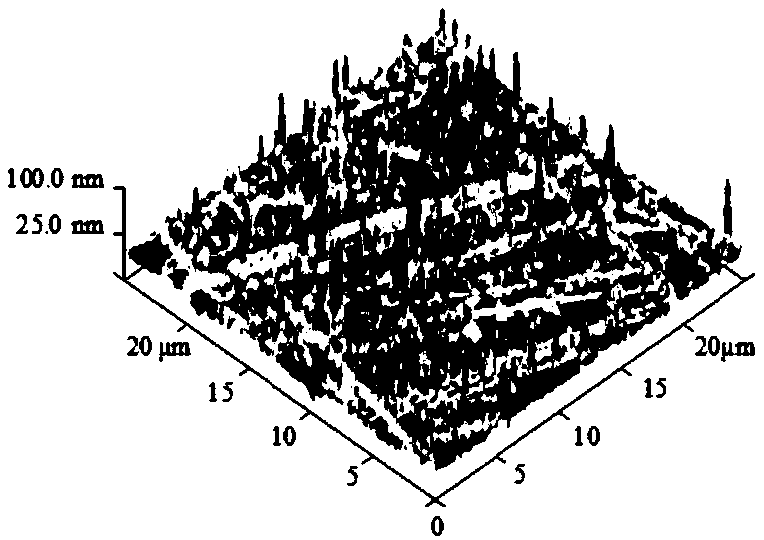

Spray-coating device and method for restraining secondary electron yield of solid dielectric material

ActiveCN108611623AAchieve modificationSimple structureChemical vapor deposition coatingDielectricDecomposition

The invention relates to a spray-coating device and a spray-coating method for restraining secondary electron yield of a solid dielectric material and belongs to the technical field of plasma. The spray-coating method comprises the following steps of: washing and drying a to-be-treated sample; building the spray-coating device for restraining the secondary electron yield of the solid dielectric material; carrying out an atmospheric plasma torch spray-coating experience; and carrying out a secondary electron yield test and material surface physical shape observation. According to the spray-coating device and the spray-coating method provided by the invention, by utilizing plasma torches generated by an atmospheric plasma spray gun, a reaction precursor reacts to generate a Ti-containing group and an N-containing group; a compact and uniform TiN film is deposited on the surface of a dielectric; specifically, a gas-carrying precursor has decomposition and polymerization reaction; polymerization, grafting and crosslinking effects are realized on the surface of the dielectric so that the deposited film forms a 'micro-trap' structure, the surface roughness is reduced, the secondary electron yield of the solid dielectric is restrained, and the surface insulation property of the dielectric is improved.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

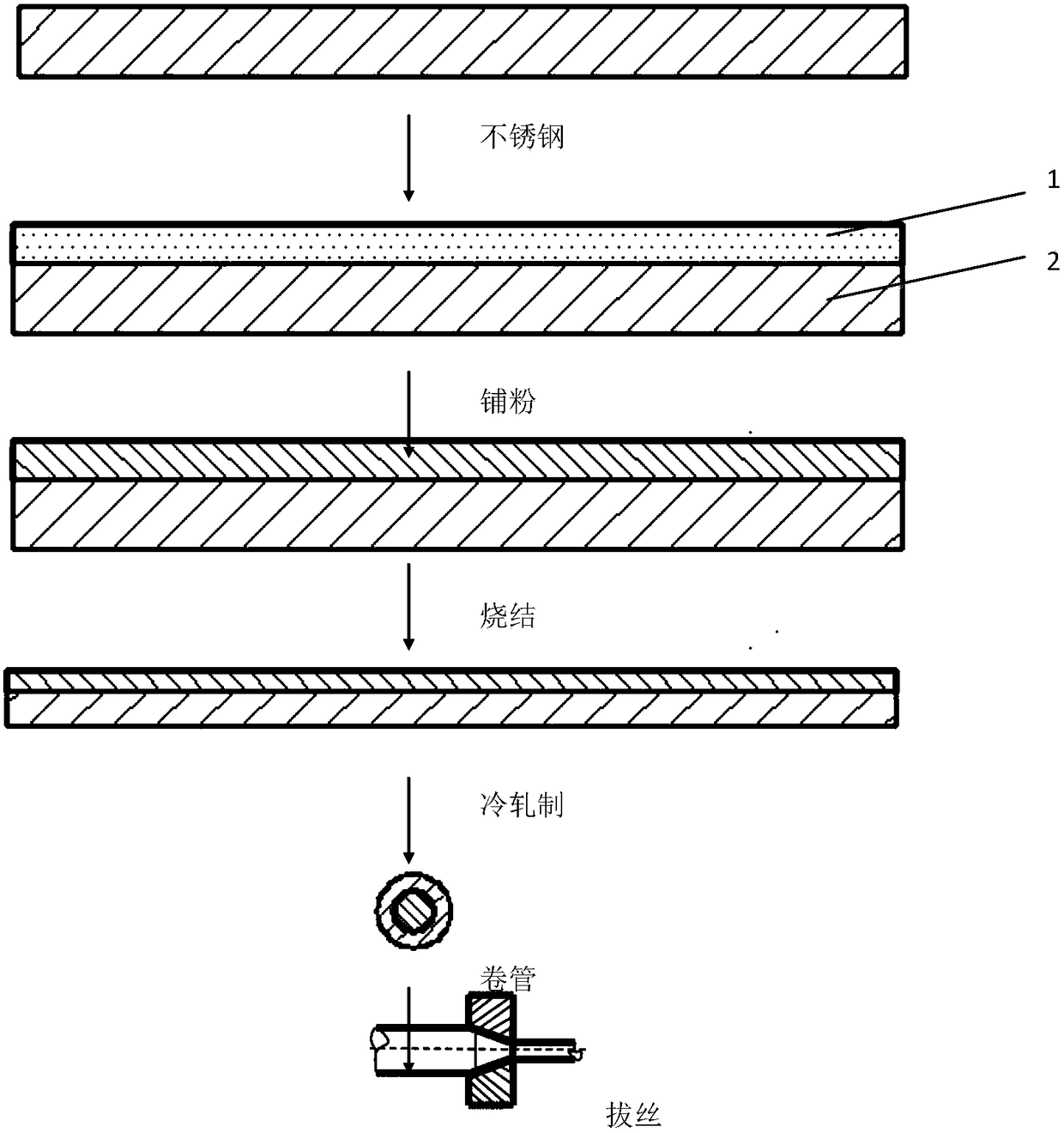

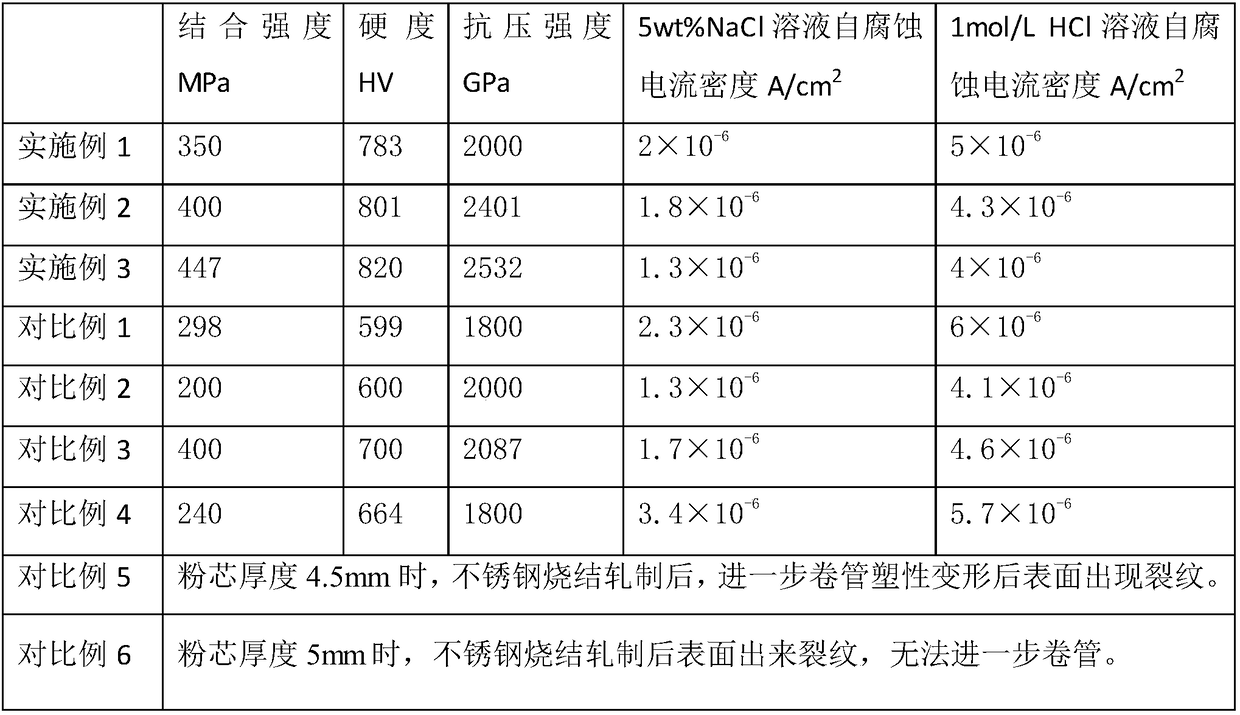

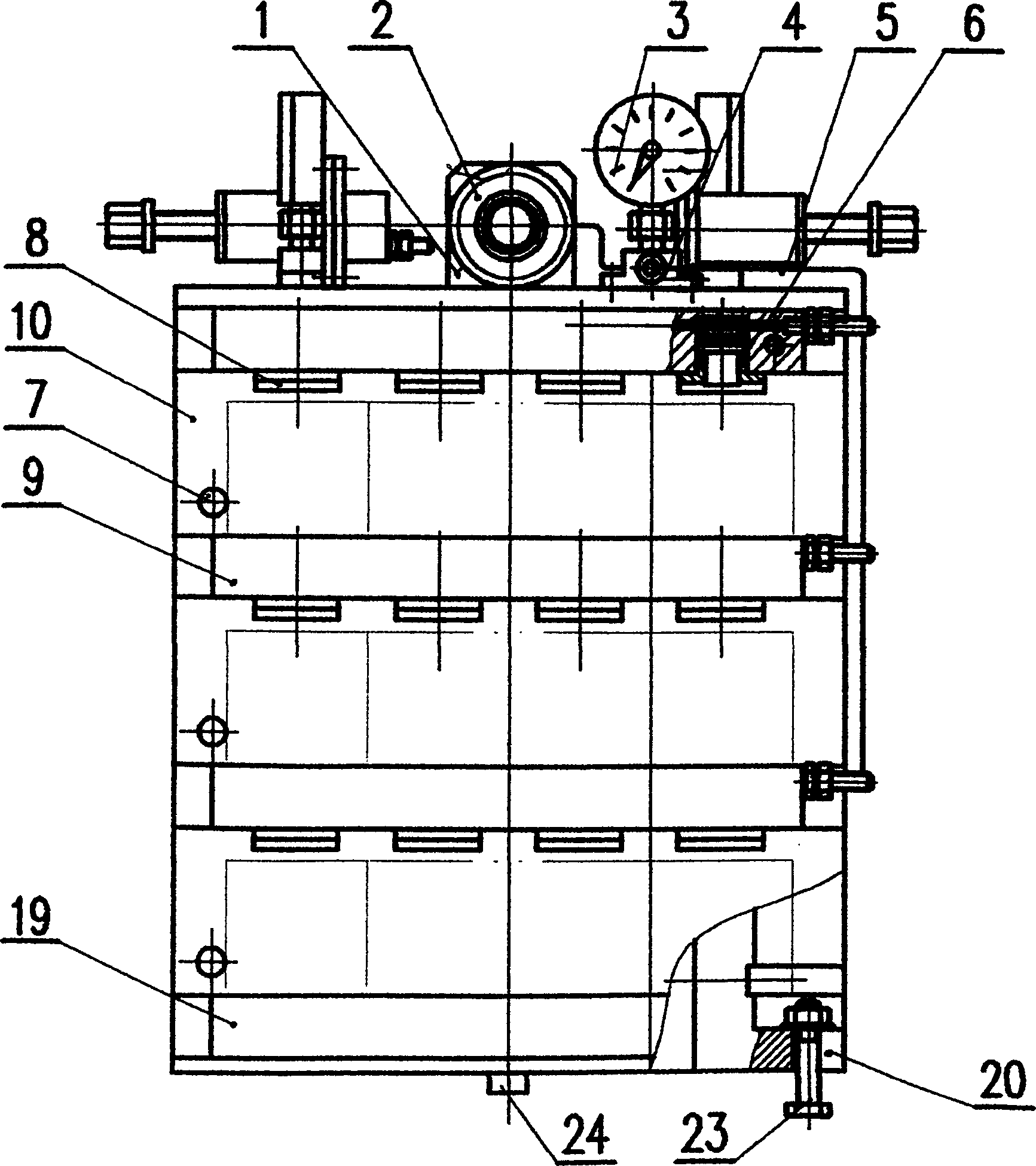

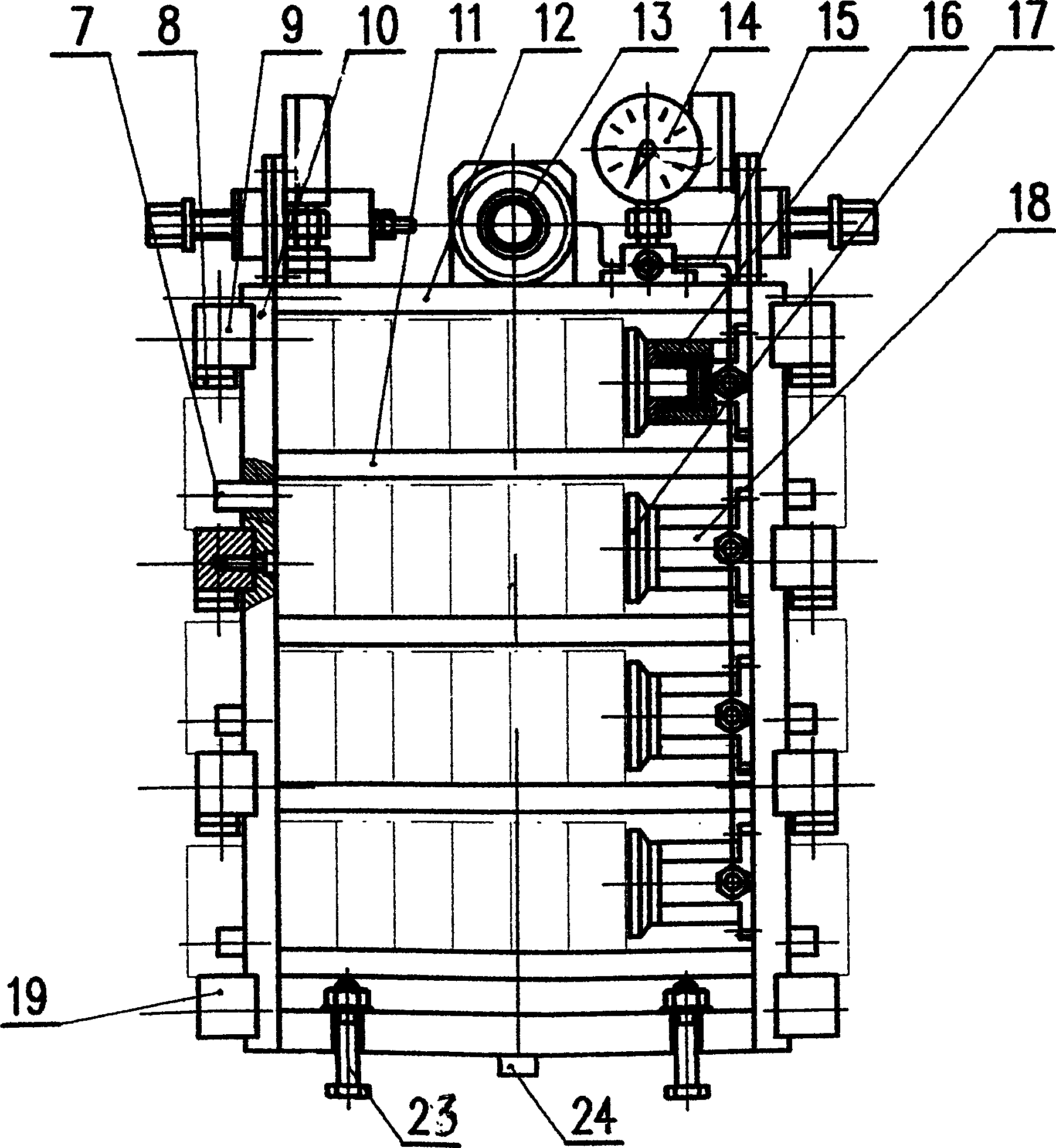

Electric-arc fusion-cladding powder core wire, and preparation method of high-entropy alloy coating

ActiveCN108998716AAvoid powder leakageLarge processing areaMolten spray coatingPower flowHigh entropy alloys

The invention provides an electric-arc fusion-cladding powder core wire, and a preparation method of a high-entropy alloy coating. The powder core wire is composed of a stainless steel strip and a powder core, wherein the thickness of the stainless steel strip is 0.8mm, and the powder core is powder of Mn, Cr, Fe, Ni, and Cu in a molar ratio of 2:2:2:2:1. A preparation method of the powder core wire comprises the following steps: (1) preparing the powder core; (2) paving powder and sintering; (3) performing cold rolling; and (4) coiling, drawing wires, reeling, installing coiled wires on a wire feeder, and spraying-deposing fused core wires on the surfaces of base materials by setting the electric-arc welding voltage to be 14 V, current to be 150A, and speed to be 8cm2 / min under the actionof 0.9MP high-pressure argon to form the high-entropy alloy coating.

Owner:JIANGSU UNIV OF TECH

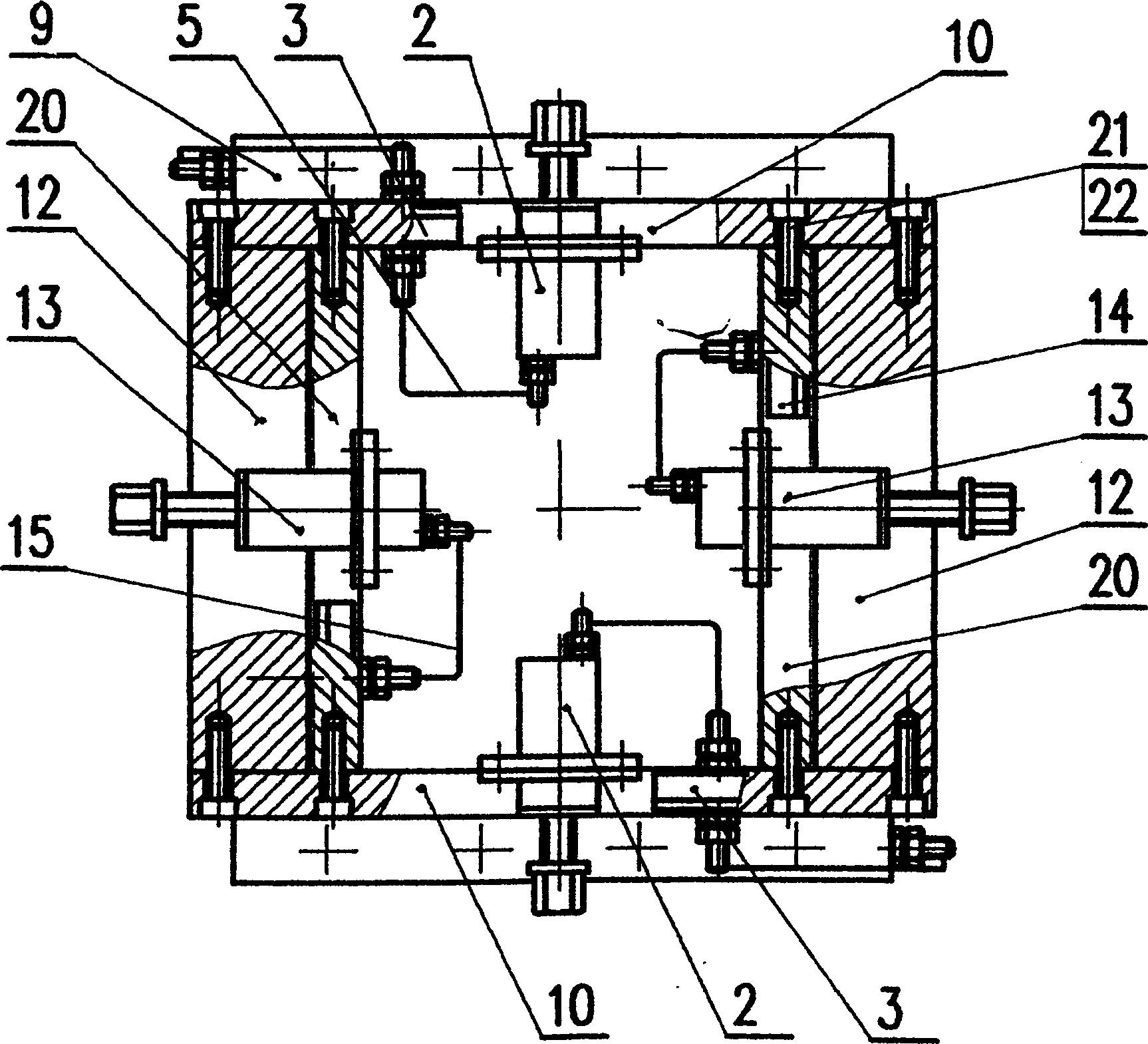

Processing method for hexahedral valve assembling block parts and clamp thereof

InactiveCN1593842AExpand clampingLarge processing areaPositioning apparatusMetal-working holdersEngineeringSwitching time

The invention relates to process for blocking accessory of cubic valves and the clump, which both belongs to the field of processing blocking accessory of cubic valves for hydraulic pressure controlling valve. The sets vertical quadrate clump box that has four faces on two revolving workbench of the chief horizontal processing table. Then set the six faces of the cubic valves to the four faces of the clump box. To finish the horizontal process and hole process of the six faces of the cubic valves through the revolving of quadrate clump box and the atomically tool switching of horizontal processing table. Processing, setting up and using of the invention are simple, so it needs only one step and lesser tool switching time to finish the horizontal process and hole process of the six faces of the cubic valves so that to product with high efficiency and high quality.

Owner:ZHEJIANG CHUNHUI INTELLIGENT CONTROL

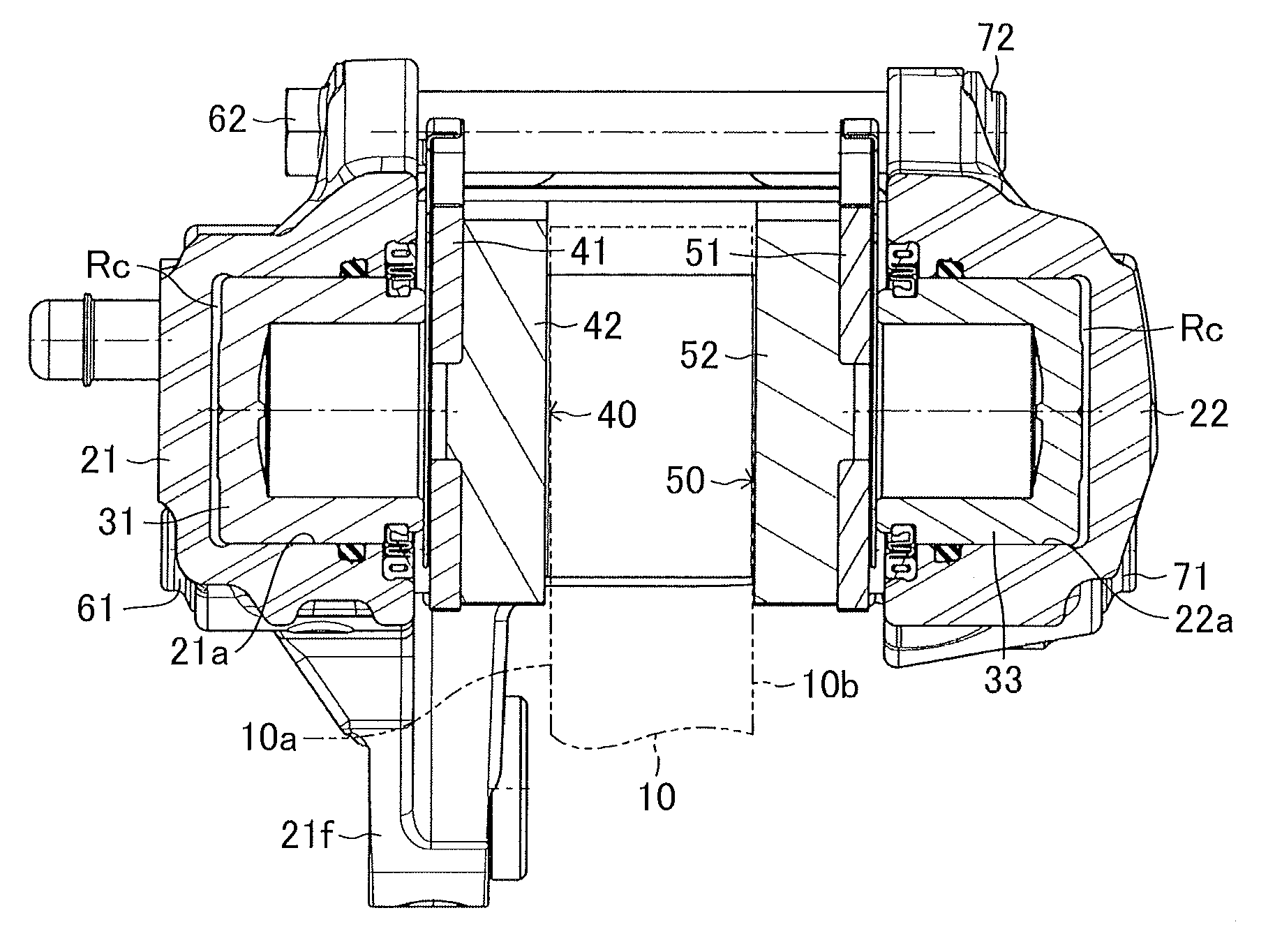

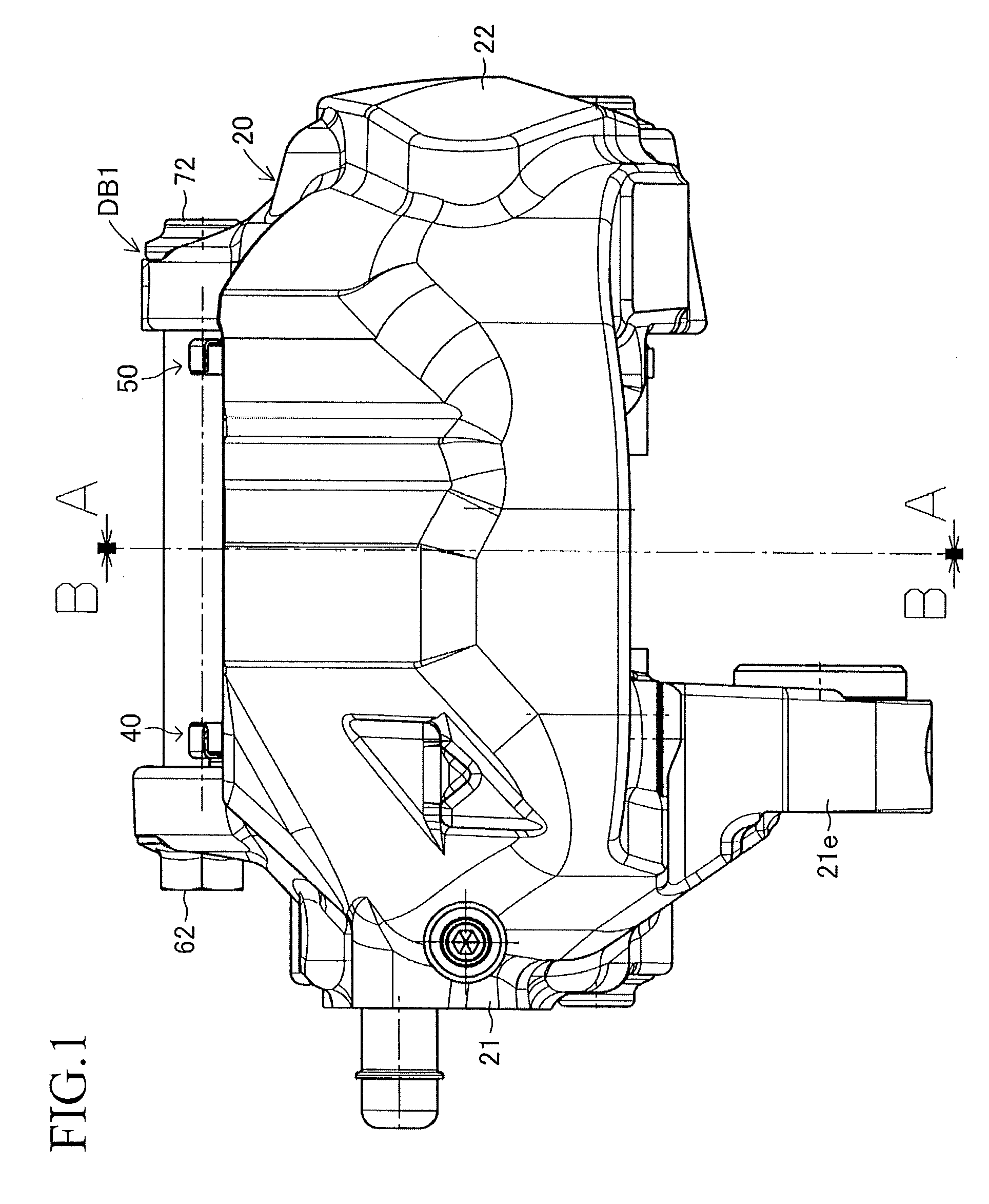

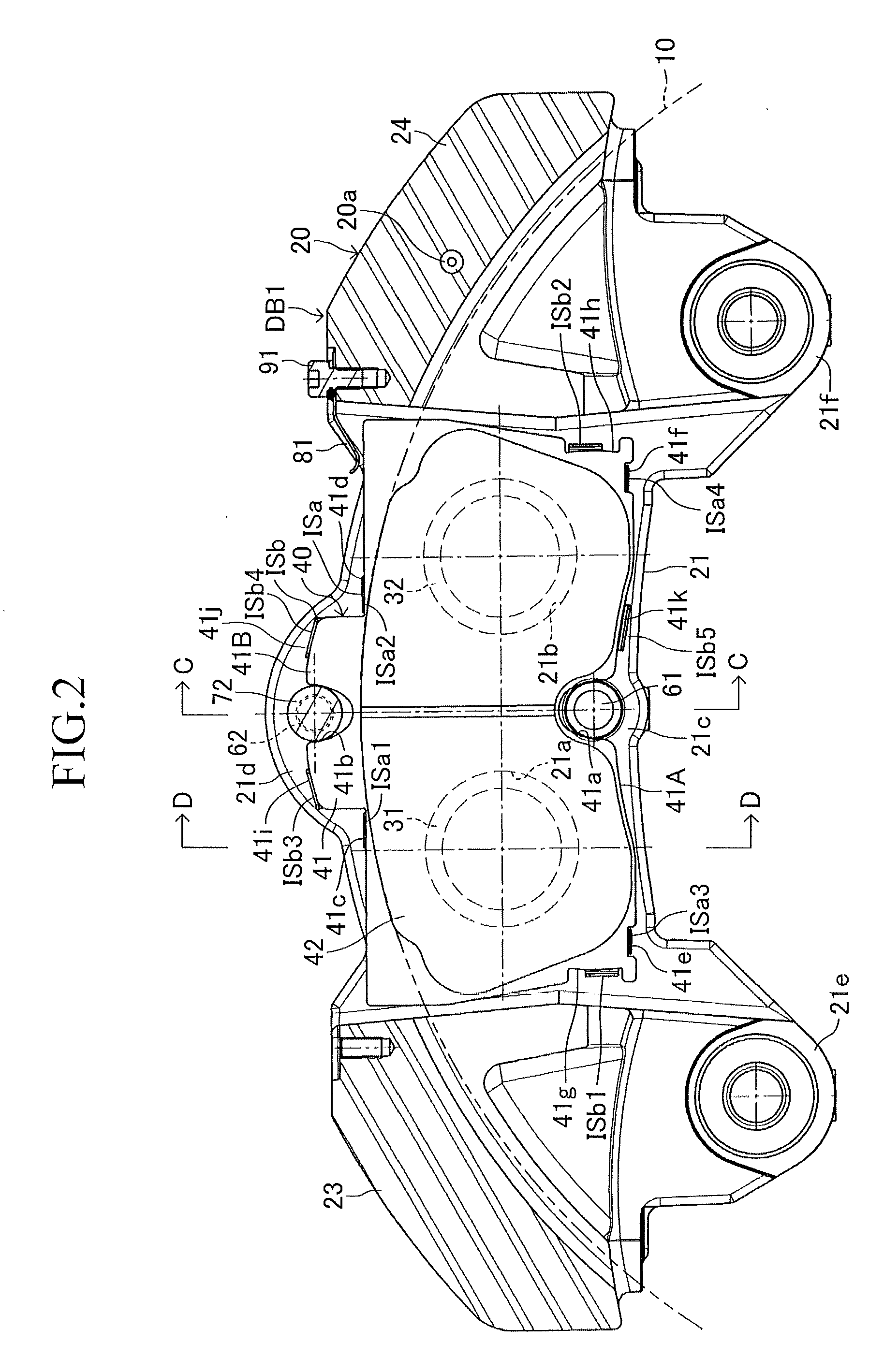

Disc brake apparatus

InactiveUS20120298457A1Easy to changeLarge processing areaFluid actuated brakesBraking element arrangementsEngineeringCalipers

Owner:ADVICS CO LTD

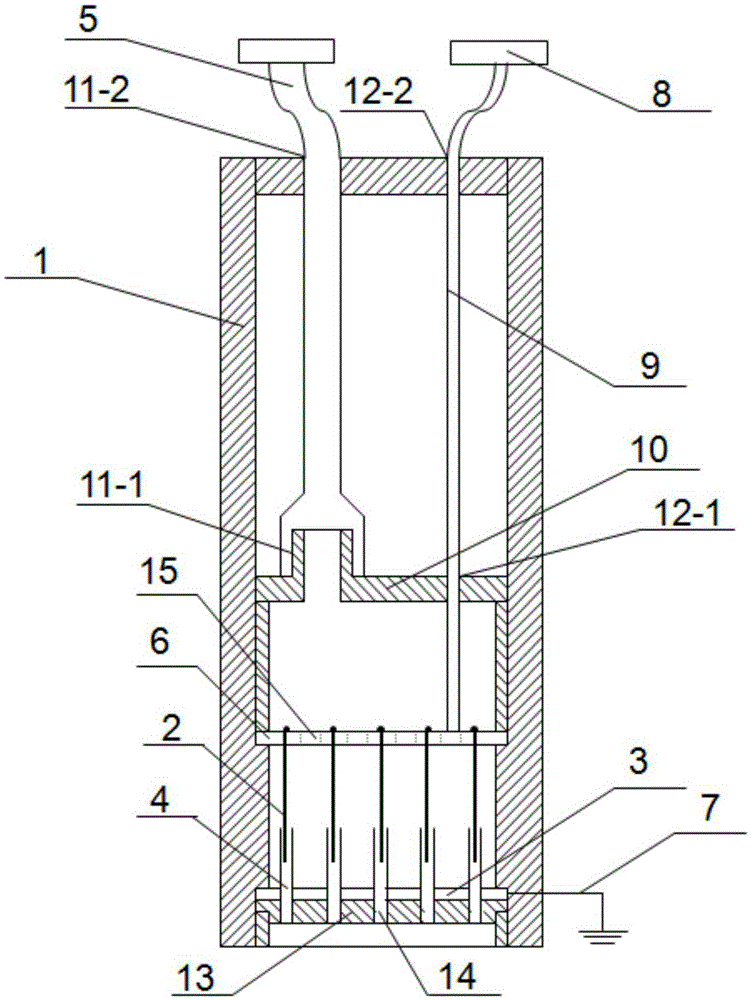

Heat Treatment Apparatus

InactiveUS20070275570A1Avoid it happening againSmall diameterSemiconductor/solid-state device manufacturingPressure vessels for chemical processMechanical engineeringHeat treated

Owner:KOKUSA ELECTRIC CO LTD

Microorganism utilizing park water purifying device and purifying method thereof

ActiveCN106006964AImprove performanceLow costGeneral water supply conservationTreatment with aerobic and anaerobic processesMicroorganismEcological environment

The invention mainly discloses a microorganism utilizing park water purifying device and a purifying method thereof. The technical scheme is as follows: the microorganism utilizing park water purifying device comprises a bed body, a treatment bin positioned below the bed body and a solar energy supply device positioned above the bed body, wherein the solar energy supply device comprises a protection cover, a photovoltaic panel and a containing bin; a filter area, an aerobic area and an anaerobic area are sequentially arranged in the treatment bin from left to right; a precipitation area is arranged below the filter area, the aerobic area and the anaerobic area; and a power device is arranged on the outer side of the treatment bin and connected with the solar energy supply device. The water purifying device is put on the water surface, and aquatic plants are grown on the bed body; and the sewage enters the aerobic area from the filter area and then goes into the anaerobic area and is finally discharged through a water-out pipe. In the invention, original ecological environment is not damaged, the solar energy supply device supplies energy, and thus the operation cost is low; the water quality is treated by the treatment bin, the treatment efficiency is high, and the effect is good; and the power device drives the water purifying device to move freely, the treatment area is wide, and the popularization and application are facilitated.

Owner:杭州市城市土地发展有限公司

Integrated laser cutting machine for large-format gantry fiber optic conducting tube plate

InactiveCN103692088AImprove cutting efficiencyLarge processing areaLaser beam welding apparatusLaser cuttingMachine tool

The invention relates to an integrated laser cutting machine for a large-format gantry fiber optic conducting tube plate. The integrated laser cutting machine comprises a cutting workbench, wherein the two ends of the cutting workbench are respectively and fixedly provided with a first Y-axis guide rail and a second Y-axis guide rail, and a first beam mounting plate and a second beam mounting plate are respectively and fixedly arranged on the first Y-axis guide rail and the second Y-axis guide rail in a sliding way, and are fixedly connected by a beam; a first X-axis guide rail and a second X-axis guide rail are fixedly arranged on the beam, and an A-axis rotation DDR motor is fixedly arranged on the first X-axis guide rail and the second X-axis guide rail in a sliding way; an L-shaped rotation supporting plate is arranged on an output shaft of the A-axis rotation DDR motor, and a Z-axis movement assembly capable of making vertical up-and-down movement is arranged on the L-shaped rotation supporting plate; a laser cutting component is arranged on the Z-axis movement assembly. The machining can be carried out at both sides of the beam and the side of a machine tool, and the machining, loading and unloading can be simultaneously realized.

Owner:武汉华俄激光工程有限公司

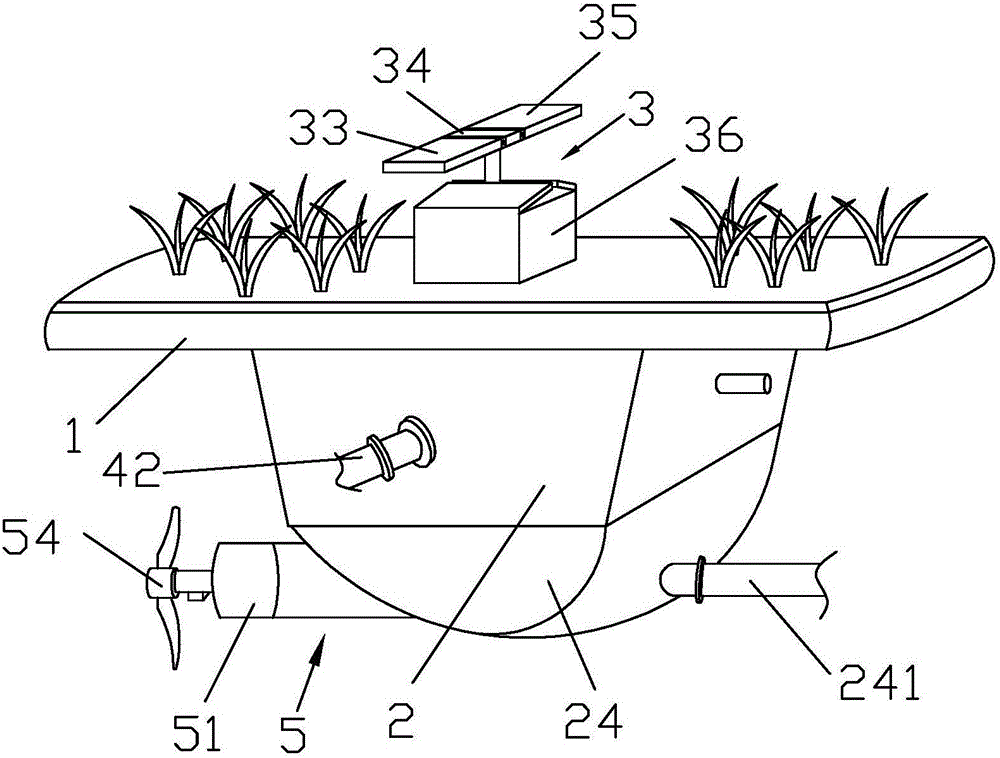

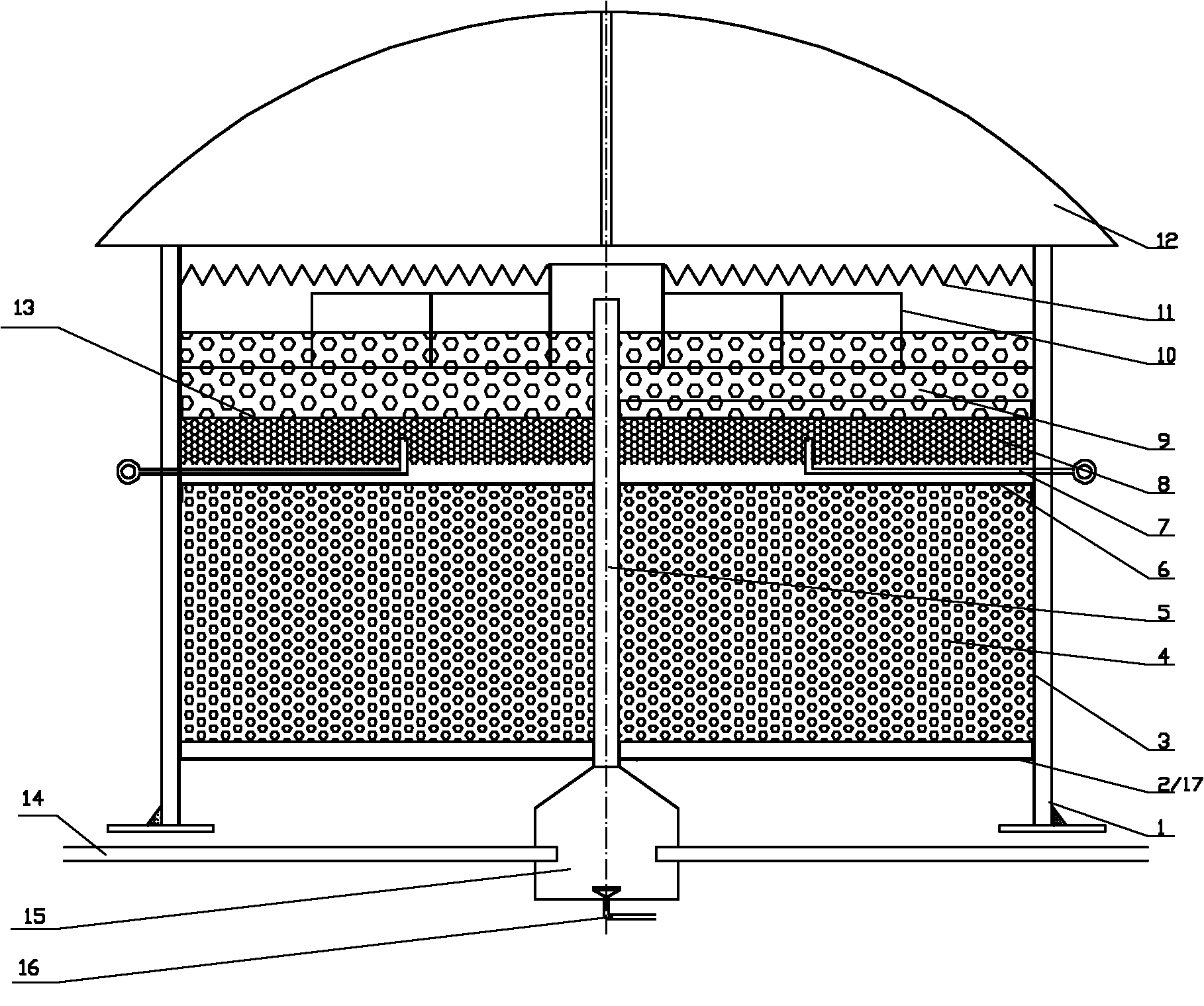

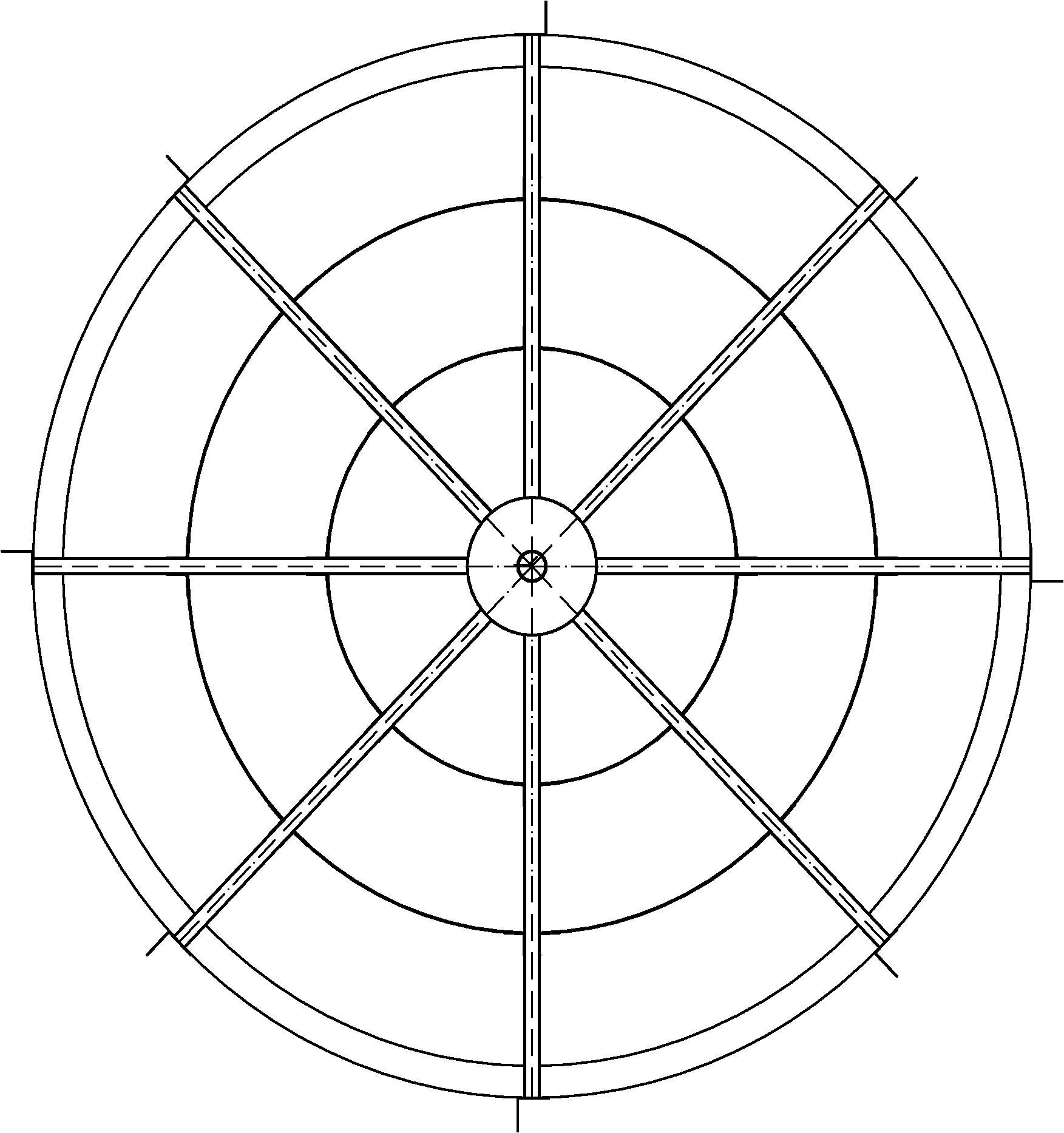

Multi-functional aquacultural biological floating island water purification device

InactiveCN102139962AReduce energy consumptionAvoid cloggingSustainable biological treatmentBiological water/sewage treatmentWater pipeFloating island

The invention relates to a water purification device for aquaculture, in particular to a multi-functional aquacultural biological floating island water purification device. An arc-shaped canopy (12) covers on the top of a cylindrical drum body (3); the drum body (3) is supported by a frame (1) and respectively provided with an A-shaped stainless steel net (2), a floating filter material layer (4), a B-shaped stainless steel net (6), a foam grain filter material (8), a C-shaped stainless steel net (13) and a heavy filter material (9) from bottom to top; a plurality of baffle rings (10) are configured in a heavy filter material (9) layer and uniformly and radially provided with water diversion channels (11) comprising water diversion weirs; the drum body (3) is internally provide with a water pumping pipe (5); a water outlet positioned on the upper part of the water pumping pipe (5) is positioned on the upper part of the heavy filter material (9) layer, a water inlet positioned on the lower end of the water pumping pipe (5) is connected with an air-water chamber (15) and a horizontal water inlet pipe (14); a pressure air pipe (16) is connected to the bottom of the air-water chamber (15); and aquatic plants are planted on the heavy filter material (9) layer. In the invention, an upper water layer and a lower water layer are exchanged by utilizing a water pumping technology, the dissolved oxygen of the water layers of a water body is provided and the water body is treated by utilizing the aquatic plants and various filter material components, thereby the treatment area of the water body is increased ; and in addition, the invention has little energy consumption.

Owner:FISHERY MACHINERY & INSTR RES INST CHINESE ACADEMY OF FISHERY SCI

A method for wet roughening of gallium phosphide window layer of light-assisted red LED

InactiveCN102280536ASimple and fast operationLow costSemiconductor devicesHydrofluoric acidPhoto assisted

The invention, which belongs to the LED technology field, relates to a coarsening method of a wet method of a gallium phosphide window layer of a photo-assisted red light LED. A mixed solution of hydrofluoric acid and an oxidizing agent is utilized and light irradiation is utilized; a gallium phosphide window layer can be corroded without a mask layer and a conical composition array is obtained, so that a surface coarsening of the red light LED is realized. A size and a height of the conical composition caused by corrosion can be controlled by controlling corrosion time and a concentration ofcorrosive liquid. According to the invention, a problem of coarsening of the gallium phosphide window layer of the red light LED can be effectively solved and an extraction efficiency of a red light LED chip can be improved more than double. The method has advantages of good coarsening effect, low cost and rapid speed and the like and thus has great application potential in production of a large power red light LED.

Owner:SHANDONG UNIV

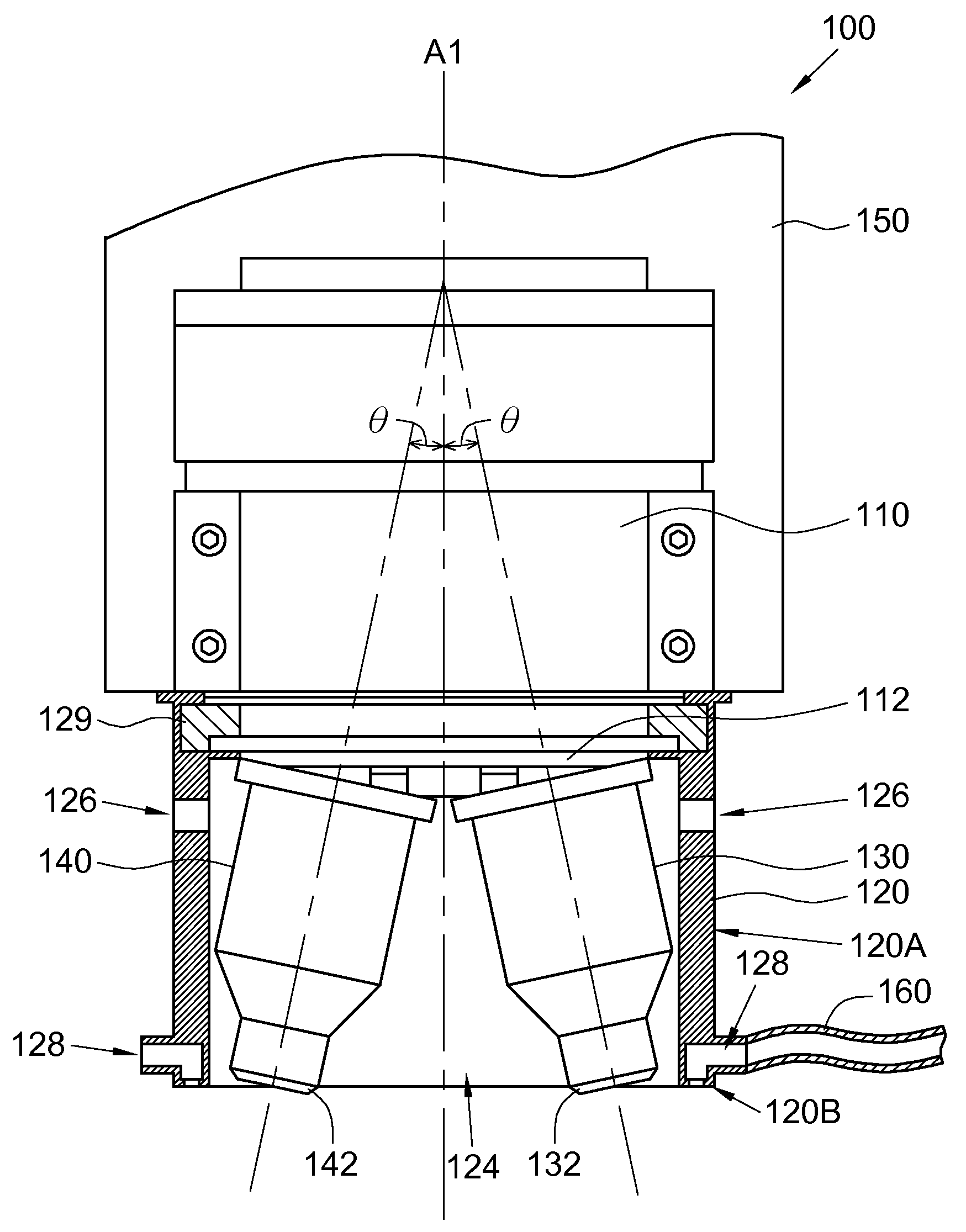

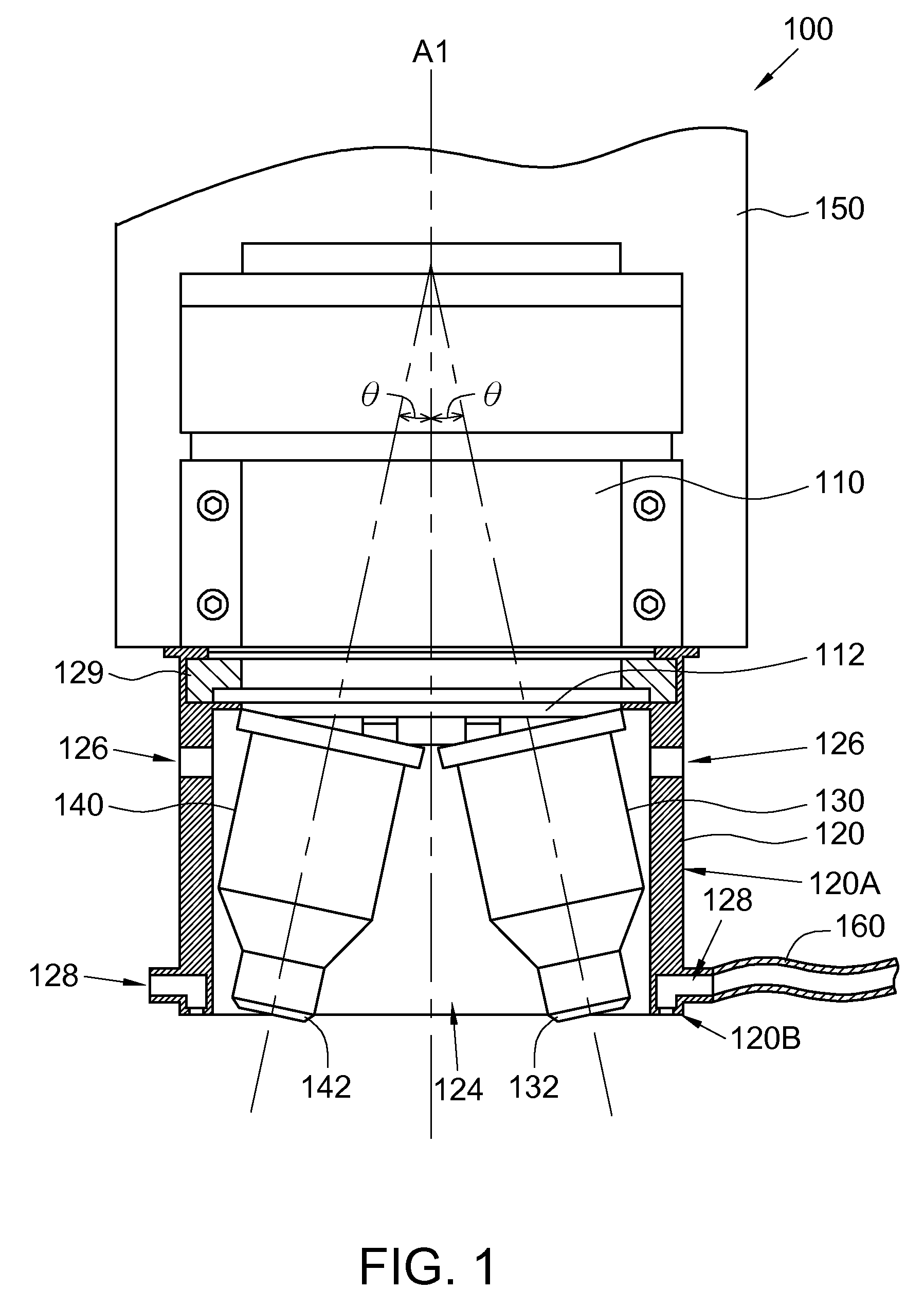

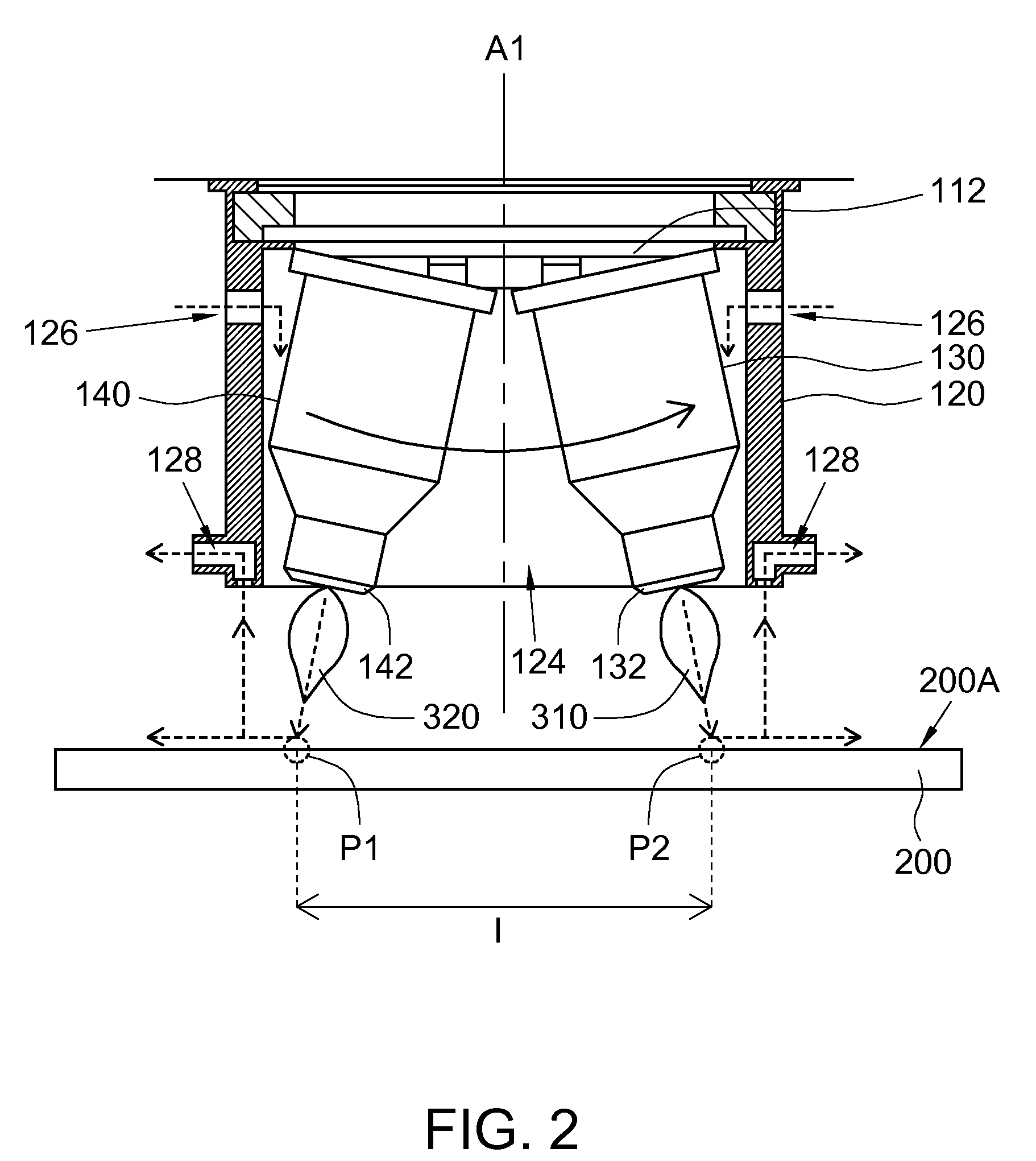

Wide area atmosphere pressure plasma jet apparatus

ActiveUS20100164353A1Avoid overall overheatingImprove product qualification rateElectric arc lampsSemiconductor/solid-state device manufacturingWide areaPlasma jet

A wide area atmospheric pressure plasma jet apparatus including a transmission mechanism, a plasma housing and two plasma-generating devices is provided. The transmission mechanism includes a rotation output end that has a center axis. The plasma housing has an opening. The plasma housing further has a air-attracting hole near the rotation output end and extended from an outer wall of the plasma housing to the interior of the plasma housing, so that the heat of the plasma housing can be dissipated due to the generated gas circulation. The plasma-generating devices are disposed within the plasma housing and connected with the rotation output end. Each of the plasma-generating devices has a plasma nozzle located at the opening and tilts from the center axis. When the rotation output end drives the plasma-generating devices to rotate, two plasma beams are obliquely ejected from the plasma nozzle and the plasma processing area is increased.

Owner:IND TECH RES INST

Method and device for treating pollutant and dust in gas

InactiveCN101804294AIncrease negative ionsAdd fragrance ingredientsUsing liquid separation agentElectrolysisProduct gas

The invention belongs to the environment protection field and discloses a method and a device for treating pollutant and dust in gas. The method is electrochemical means, solution-electrode is adopted as reaction system, gas is guided into the solution-electrode reaction system, and electrolysis reaction is carried out to degrade pollutant. The adopted electrode is a three-dimensional foam electrode with openings, and foam filler is filled between anode and cathode. The invention also provides a device applicable to the method, liquid cycle and effective distribution are adopted, so that gas and liquid can be effectively distributed and mixed on the surface of the three-dimensional electrode, effective area of reaction is greatly increased, and gas purification efficiency is improved.

Owner:SUN YAT SEN UNIV

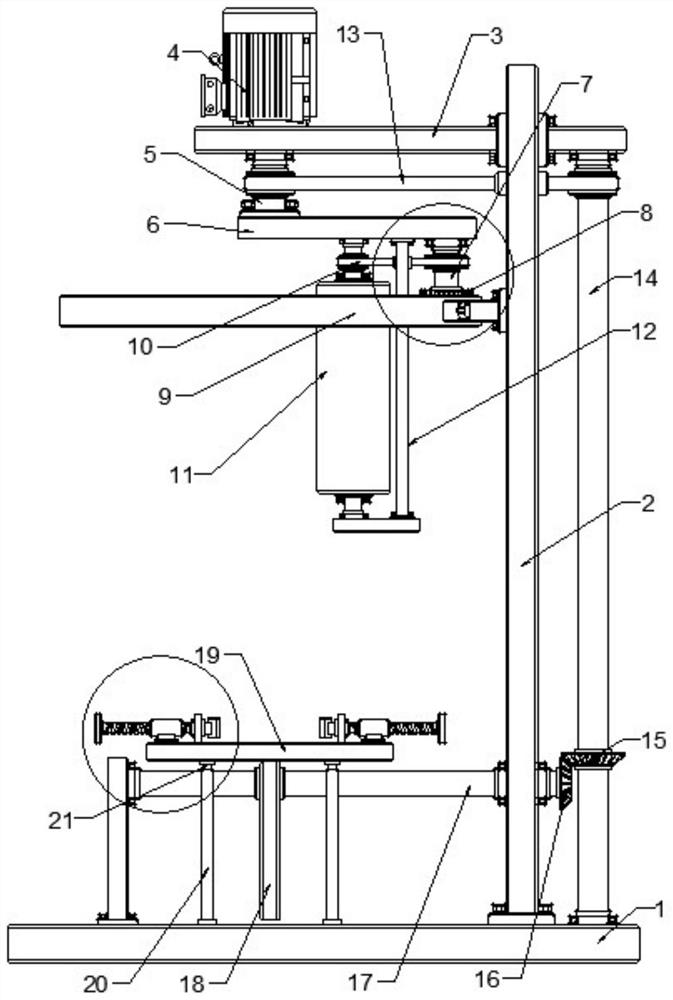

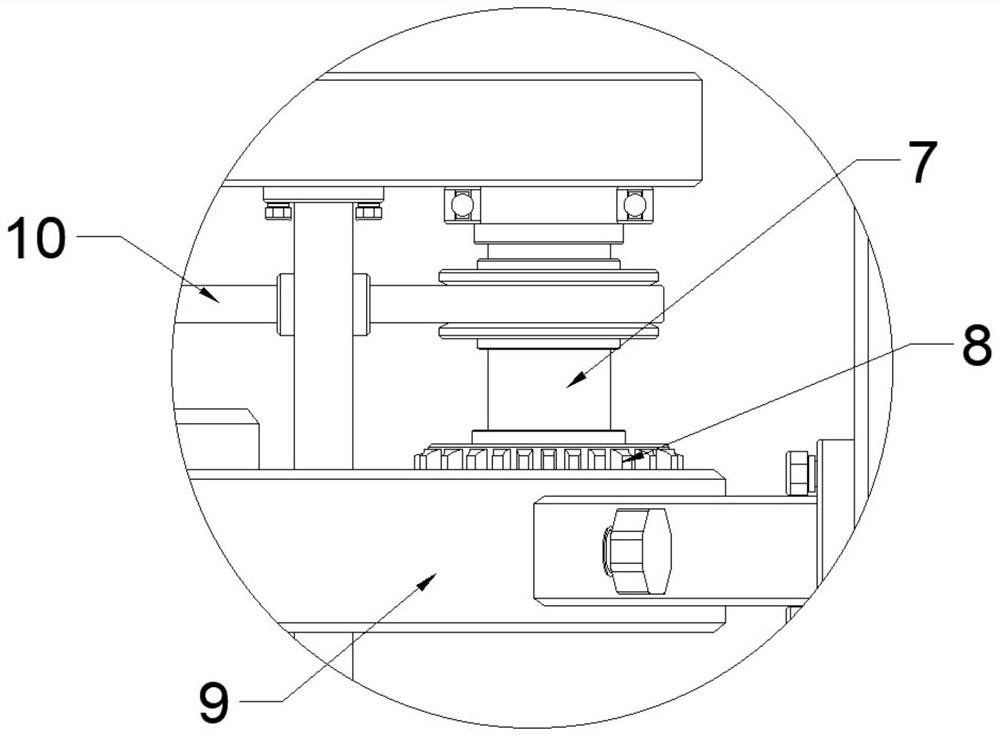

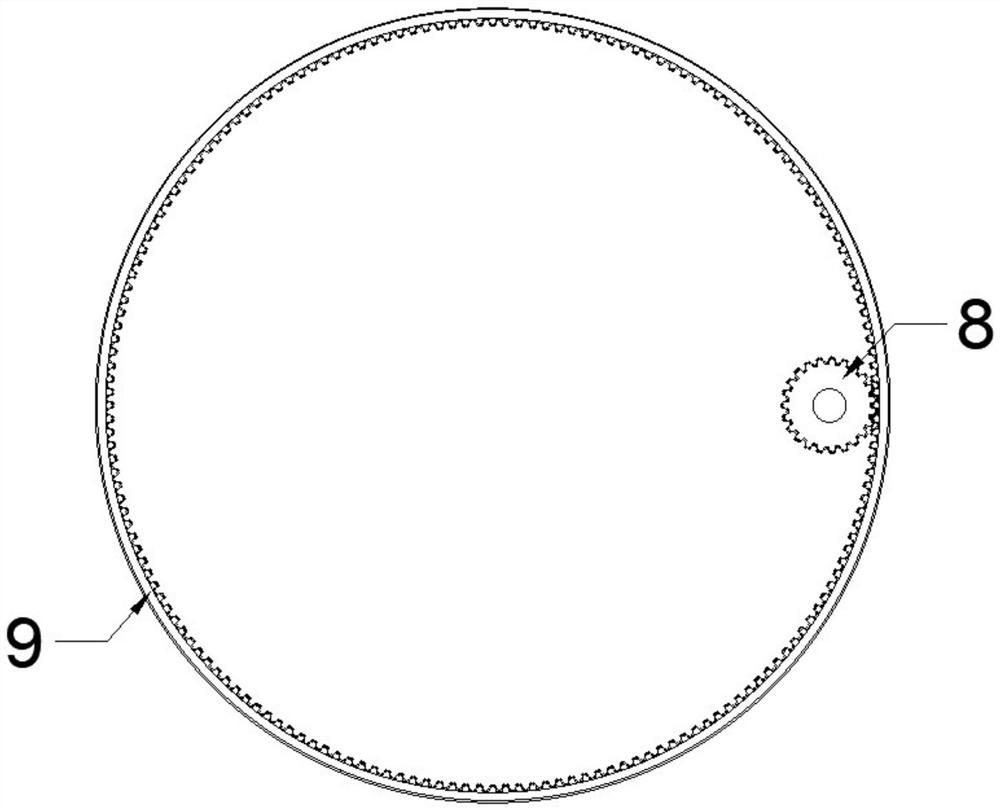

Oil cylinder body surface circumference finish machining device for machining

The invention discloses an oil cylinder body surface circumference finish machining device for machining. A mounting piece is horizontally and fixedly mounted at the upper part of a stand column; a circular motion mechanism is mounted on the mounting piece; a grinding roller for finely grinding the surface of an oil cylinder body is arranged at the lower part of the circular motion mechanism; thecircular motion mechanism is connected with an engagement module for driving the grinding roller to rotate when the grinding roller performs a circular motion; the oil cylinder body is fixed on a table plate through a clamping structure; the circular motion mechanism drives the grinding roller to perform the circular motion during acting; when the grinding roller performs the circular motion, theengagement module is used for driving the grinding roller to quickly rotate, so that the grinding roller performs the circular motion and rotates to finely grind the surface of the oil cylinder body;the circular motion mechanism drives an eccentric module to act through a transmission structure; and the eccentric module drives the table plate to perform a reciprocating up-down movement to drive the oil cylinder body to perform the reciprocating up-down movement to finely grind different depth positions of the surface of the oil cylinder.

Owner:湖南省宝满科技开发有限公司

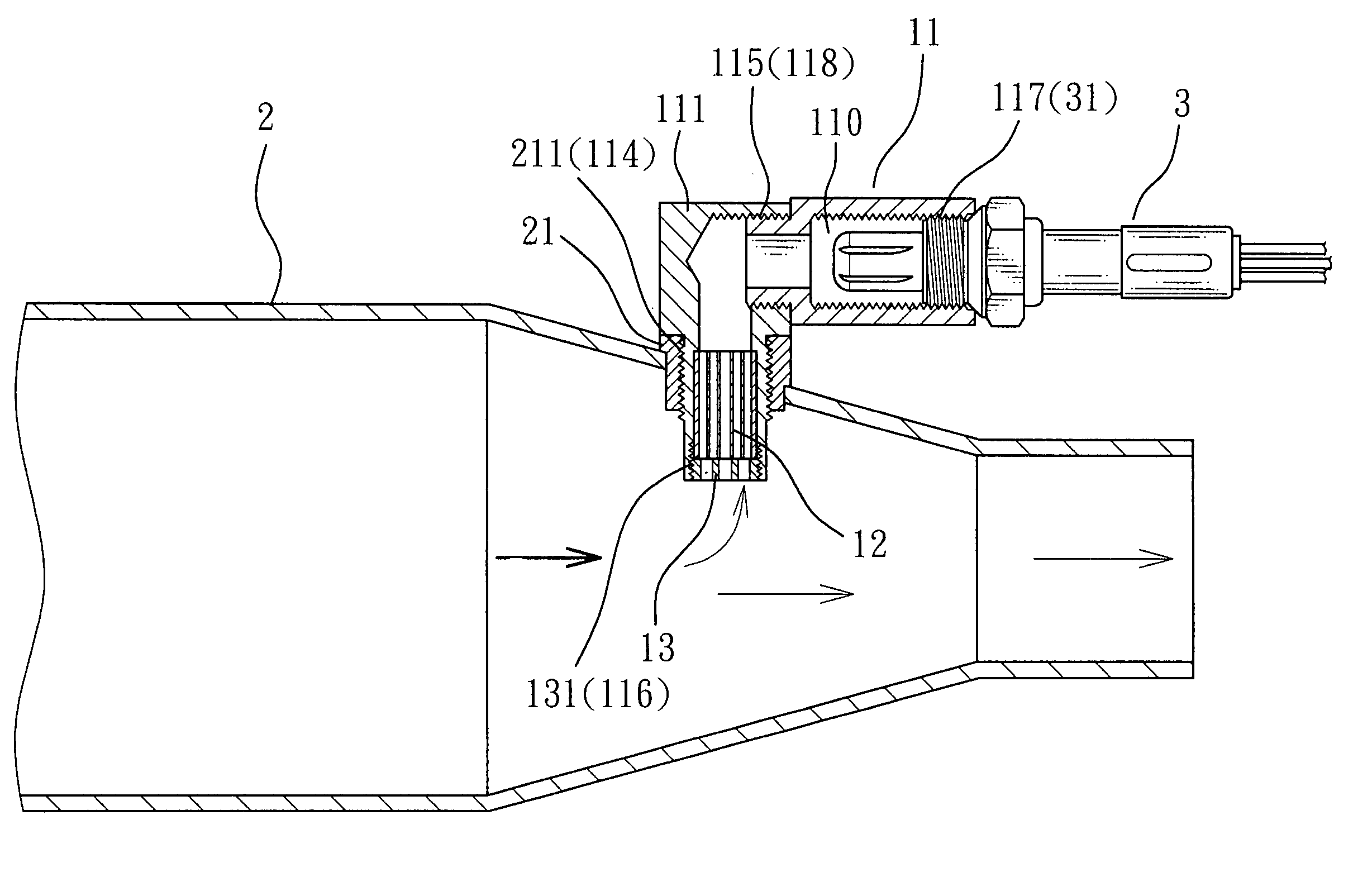

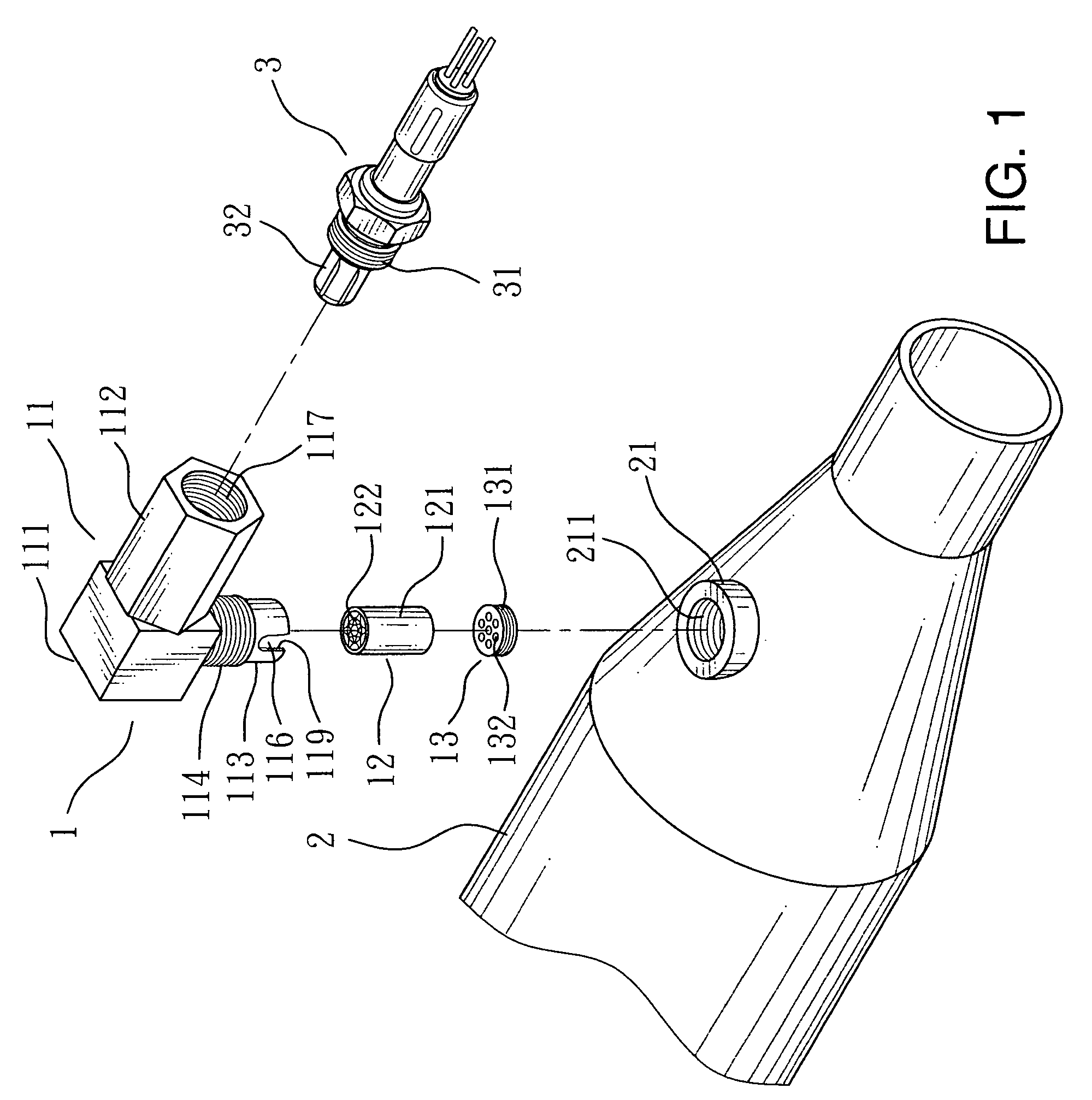

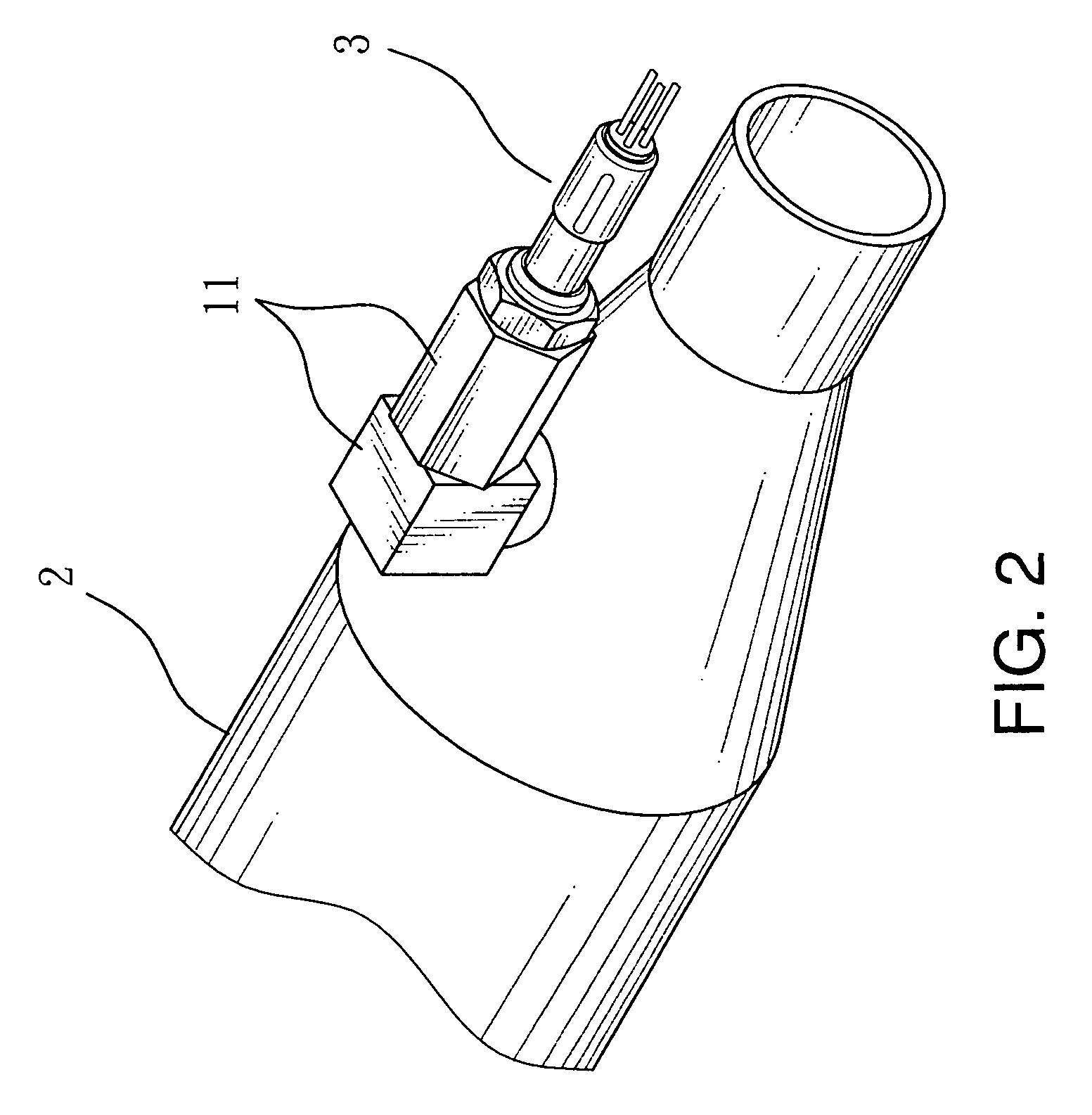

Oxygen sensor bung of motor vehicle exhaust pipe

InactiveUS8459004B2Large processing areaAccurate detectionInternal combustion piston enginesWeather/light/corrosion resistanceOxygen sensorEngineering

An oxygen sensor bung of motor vehicle exhaust pipe comprises at least a base, a catalytic converter and a seal lid. The base has an external connection section at one end that contains a first chamber to hold the catalytic converter and is fastened by the seal lid. The external connection section has a first external thread on the surface to fasten to a holding seat of an exhaust pipe. The base has a second chamber on another end with a third internal screw hole formed inside to hold an oxygen sensor by fastening with a second external thread formed thereon. The catalytic converter includes a barrel type casing containing a beehive structure made of precious metal to increase exhaust gas process area. Therefore impurities in the exhaust gas can be reduced and timely replacement of the catalytic converter can be accomplished, and accurate detection of oxygen content can be achieved.

Owner:LIANG FEI IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com