Flue-gas cleaner

A purifier and flue gas technology, applied in chemical instruments and methods, dispersed particle separation, combined devices, etc., can solve the problems of small processing area, short flue gas flow, single processing object, etc., and achieve large processing area and purification effect. Good, good oxidation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

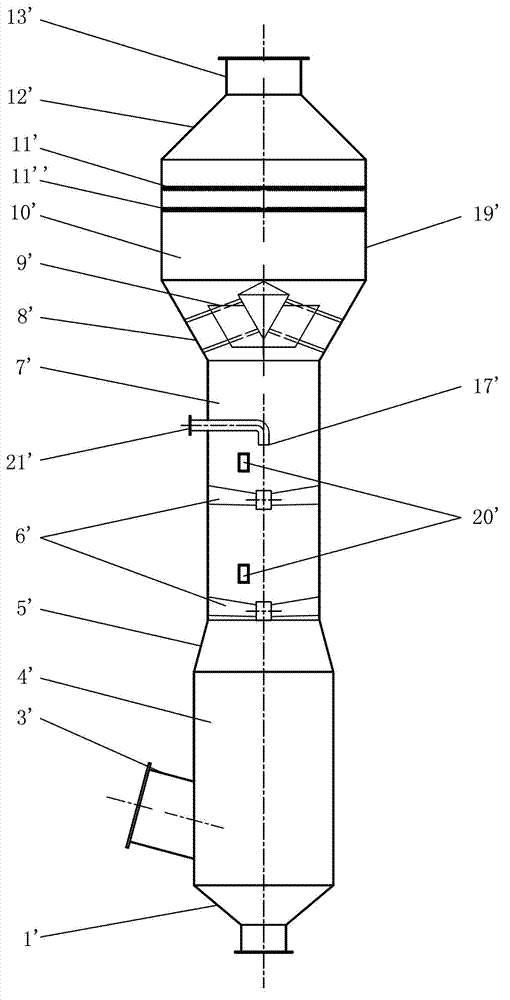

[0036] refer to figure 1 , an existing desulfurization tower, its defects have been described above, and will not be repeated here.

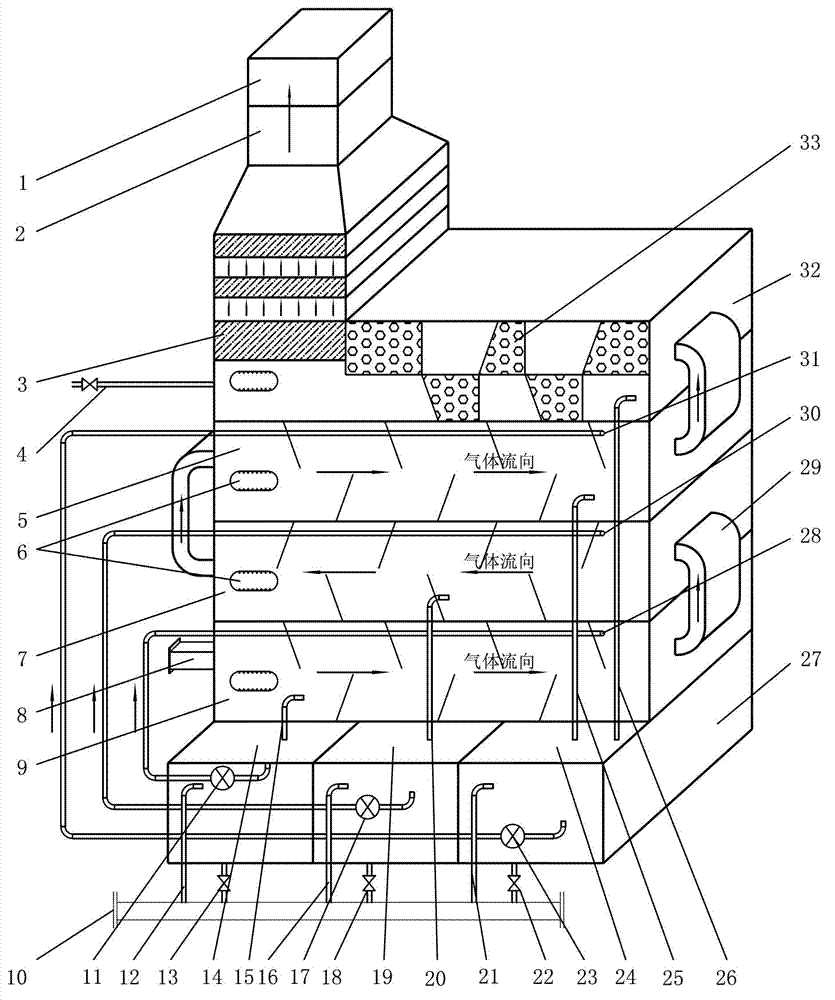

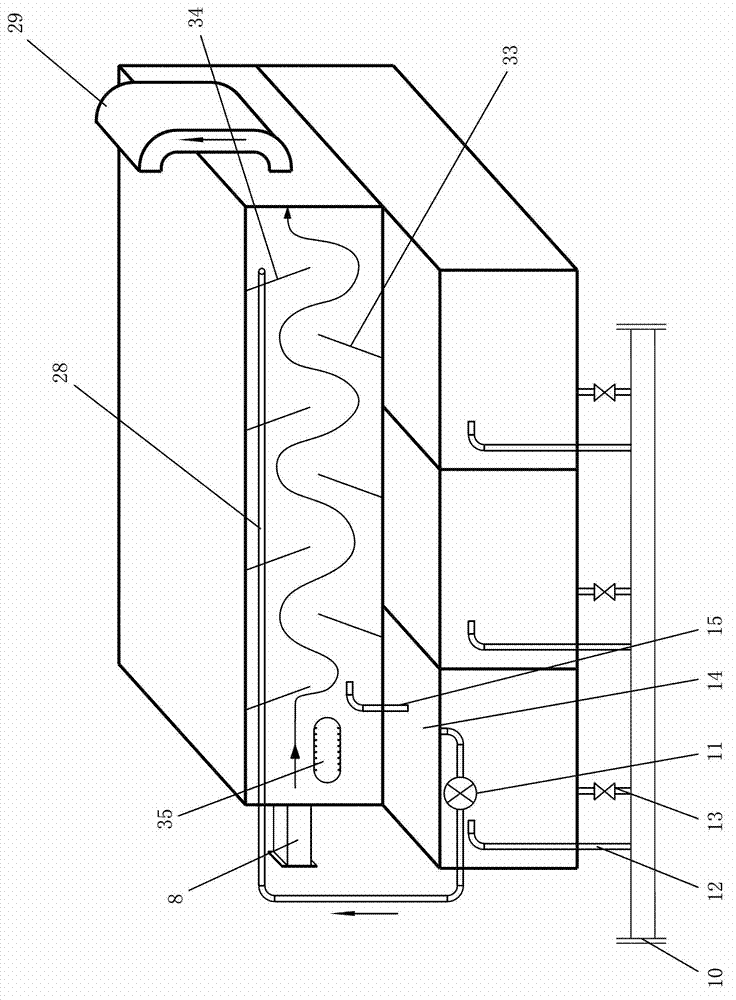

[0037] refer to figure 2 , a flue gas purifier of the present invention, comprising liquid storage tank 27, water mist chamber 9, lye spray chamber 7, oxidation spray chamber 5, gas-liquid separation chamber 32, activated carbon The adsorption chamber 3 and the purified gas outlet 1, the liquid storage tank 27 is at least divided into the first sub-slot 14, the second sub-slot 19 and the third sub-slot 25, and each sub-slot passes through the sewage branch pipes 13, 18, 22 respectively Connected to the sewage main pipe 10; the water mist chamber 9, the lye spray chamber 7, the oxidation spray chamber 5 and the gas-liquid separation chamber 32 are connected from end to end through the flue gas pipe 29 in order to form a horizontal reciprocating series channel; the water One end of the mist chamber 9 is provided with a flue gas inlet pipe 8, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com