Reverse-polarity AlGaInP-based LED side wall coarsening method

A reverse polarity, periodic technology, applied in electrical components, circuits, semiconductor devices, etc., can solve problems such as difficulty in accurately controlling the rate and depth of corrosion, difficulty in optimizing light extraction effects, and difficulty in sidewall morphology. Improve light extraction efficiency, improve external quantum efficiency, and increase light extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

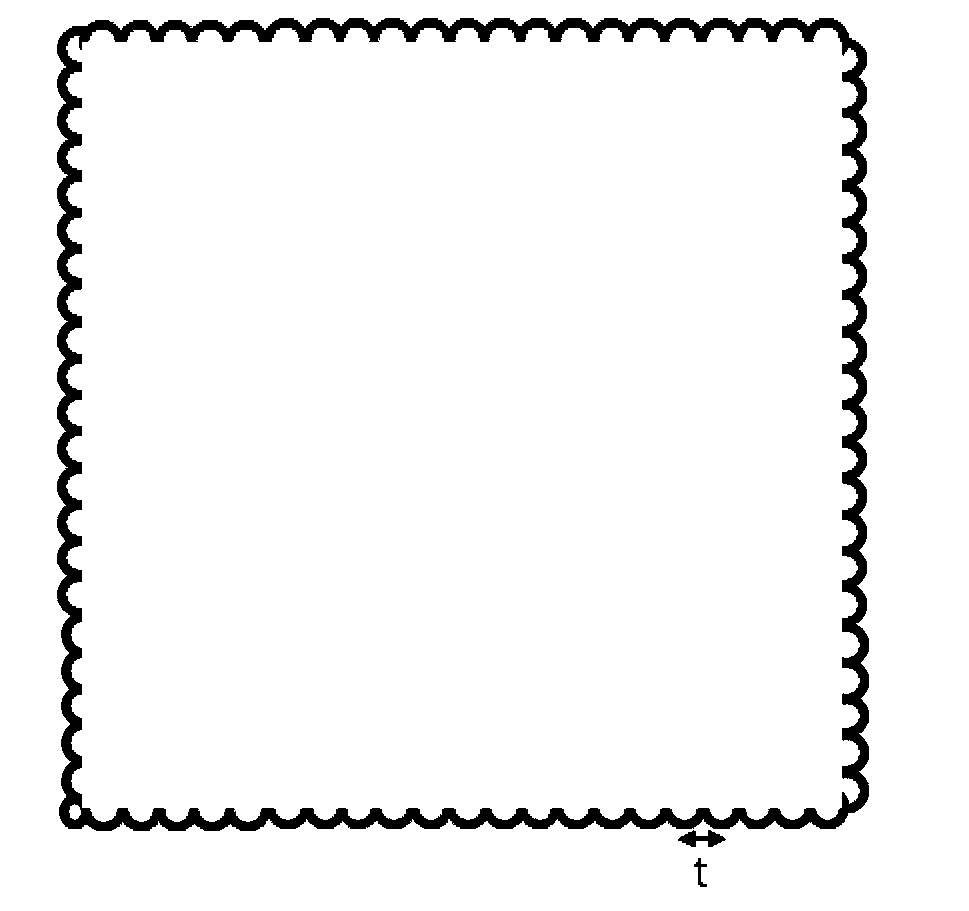

[0037] like Figure 1-3 shown.

[0038] A method for roughening the sidewall of a reverse polarity AlGaInP-based LED, comprising the following steps:

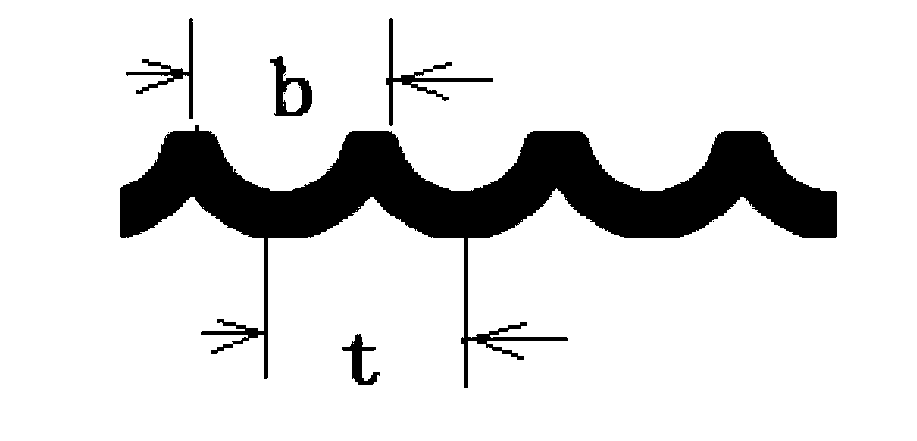

[0039] (1) Exposing and developing the mesa pattern epitaxial wafer of the reverse polarity AlGaInP-based LED by using the existing photolithography process, forming a fixed periodic edge pattern around the mesa pattern epitaxial wafer; the periodic edge pattern The period t is 1 μm; the periodic edge pattern is a circular tooth, and the base length b of each circular tooth is 1 μm;

[0040] (2) will Br 2 Added to deionized water to saturation to form saturated Br 2 Deionized water, using the saturated Br 2 Deionized water corrodes the mesa pattern epitaxial wafer developed in step (1); the corrosion depth penetrates the epitaxial structure and extends to the bonding layer;

[0041] (3) The mesa pattern epitaxial wafer etched in step (2) is cleaned and degummed according to a conventional process to form a roughened sidewa...

Embodiment 2

[0043] like Figure 4 , 5 shown. A method for roughening the sidewall of a reverse polarity AlGaInP-based LED as described in Example 1, the difference is that

[0044] The period t of the periodic edge pattern described in step (1) is 20 μm. The periodic edge pattern is conical teeth, and the length a of the base of each conical tooth is 20 μm; the height h of the conical teeth is 35 μm.

Embodiment 3

[0046] A method for roughening the sidewall of a reverse-polarity AlGaInP-based LED as described in Example 1, the difference is that the period t of the periodic edge pattern is 10 μm; the periodic edge pattern is a circular tooth , the base length b of each circular tooth is 10 μm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com