Patents

Literature

87results about How to "Reduce internal heat" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

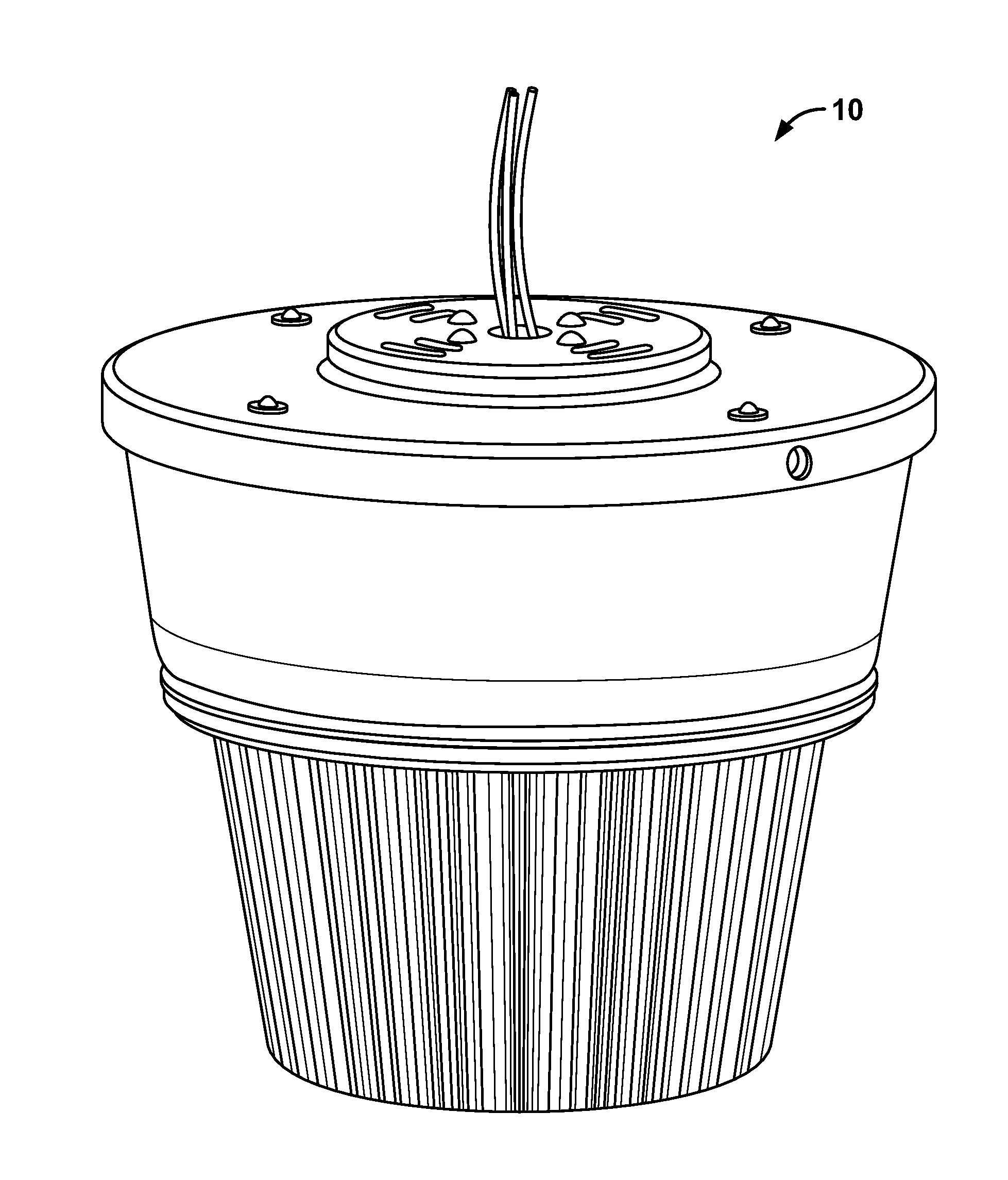

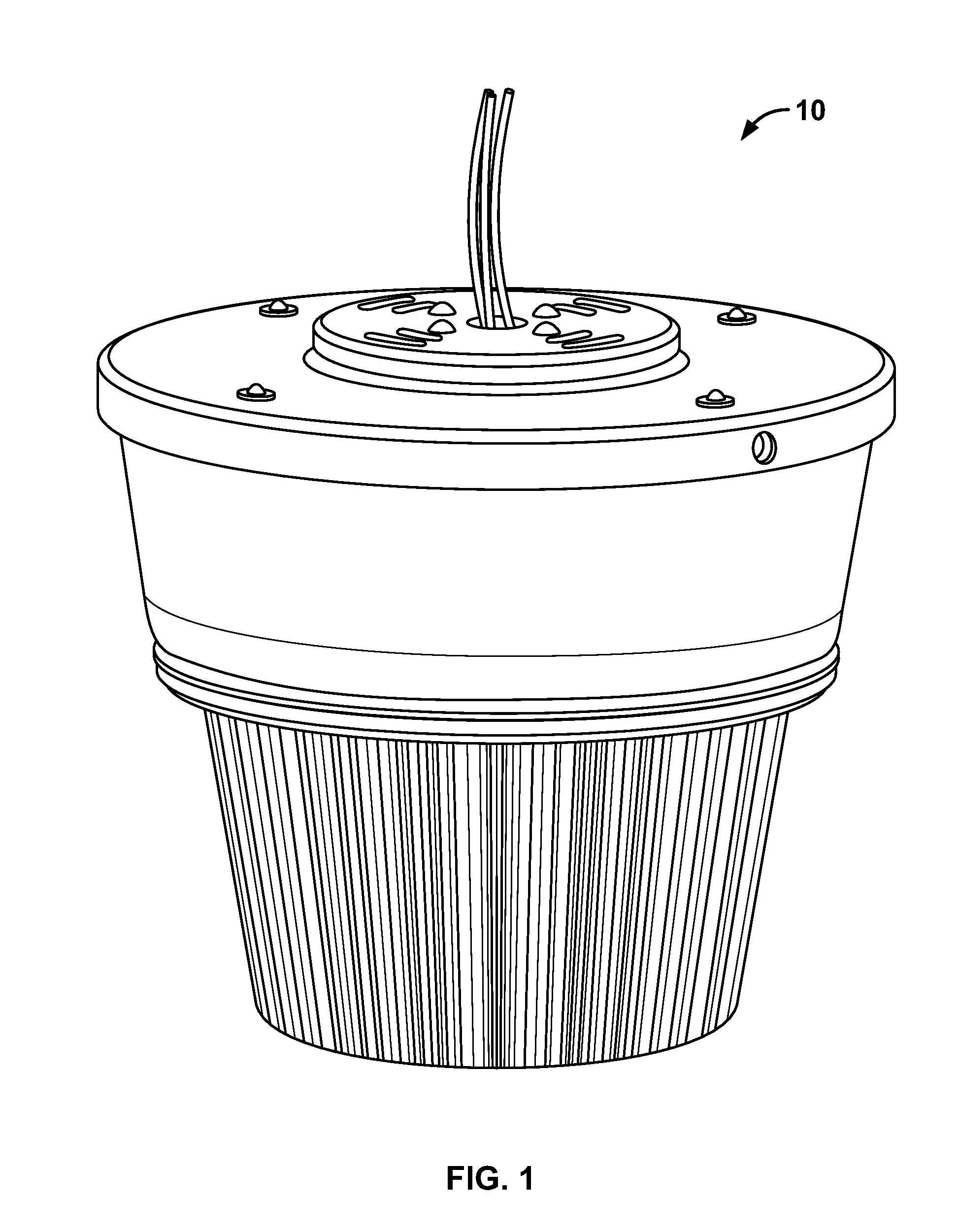

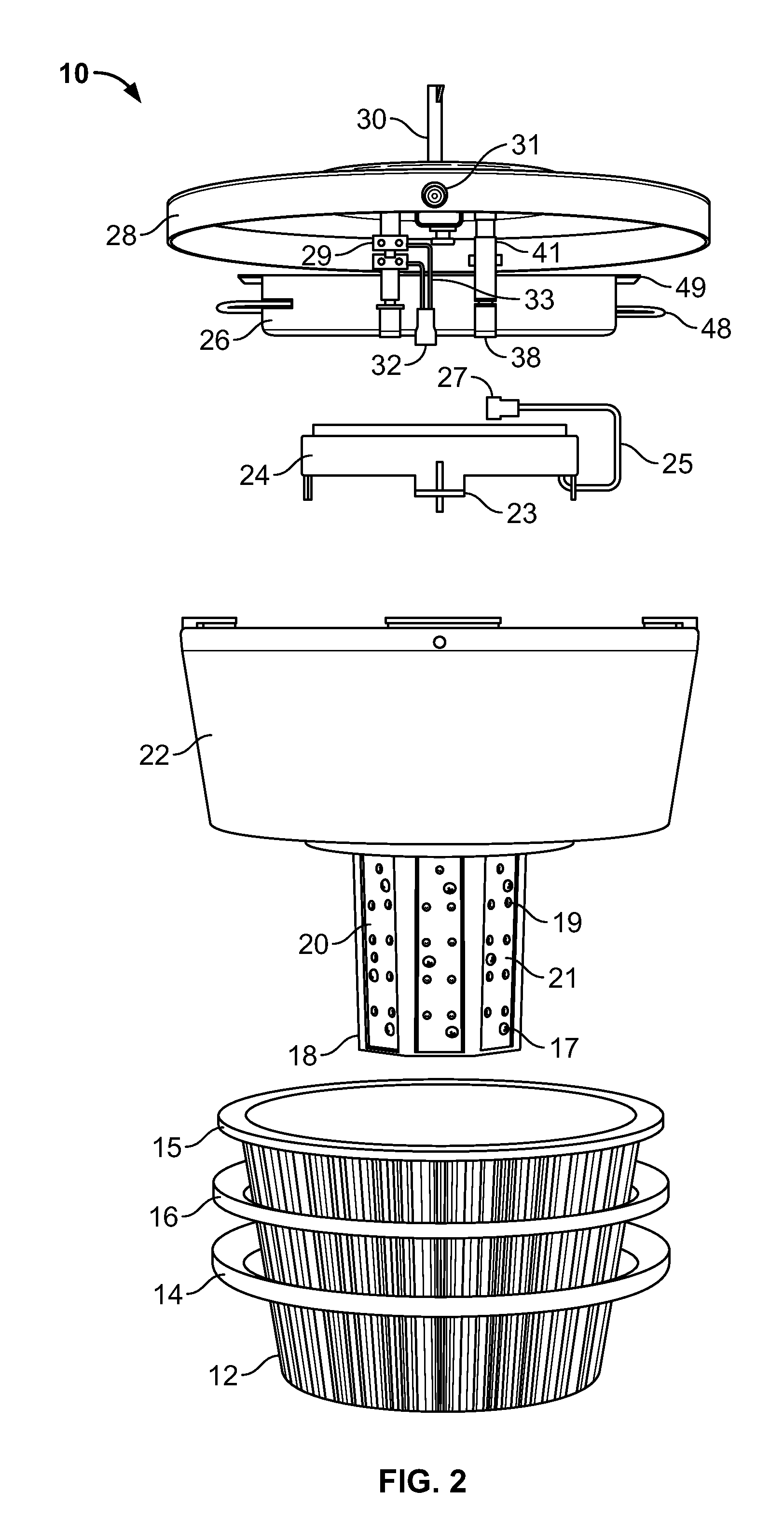

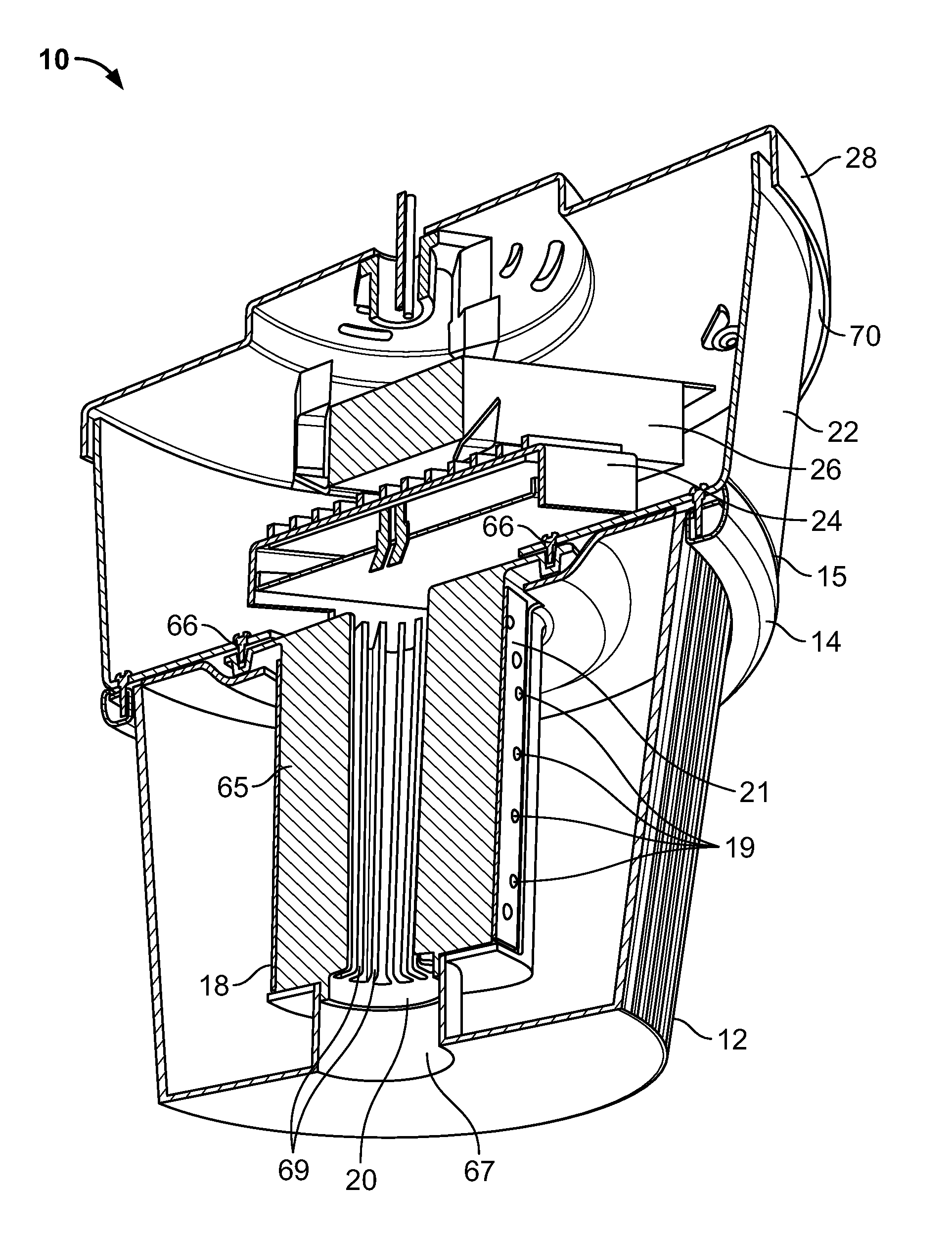

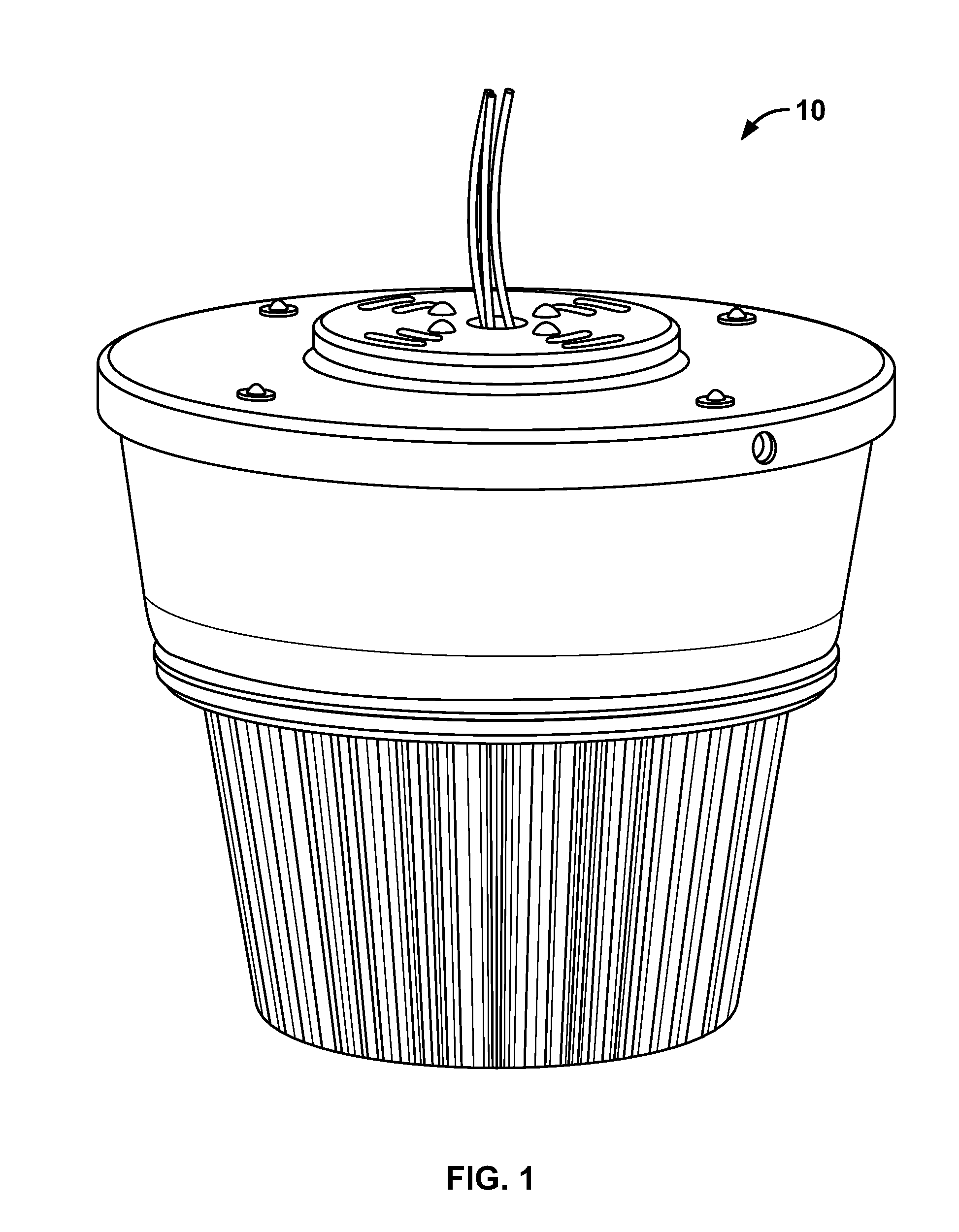

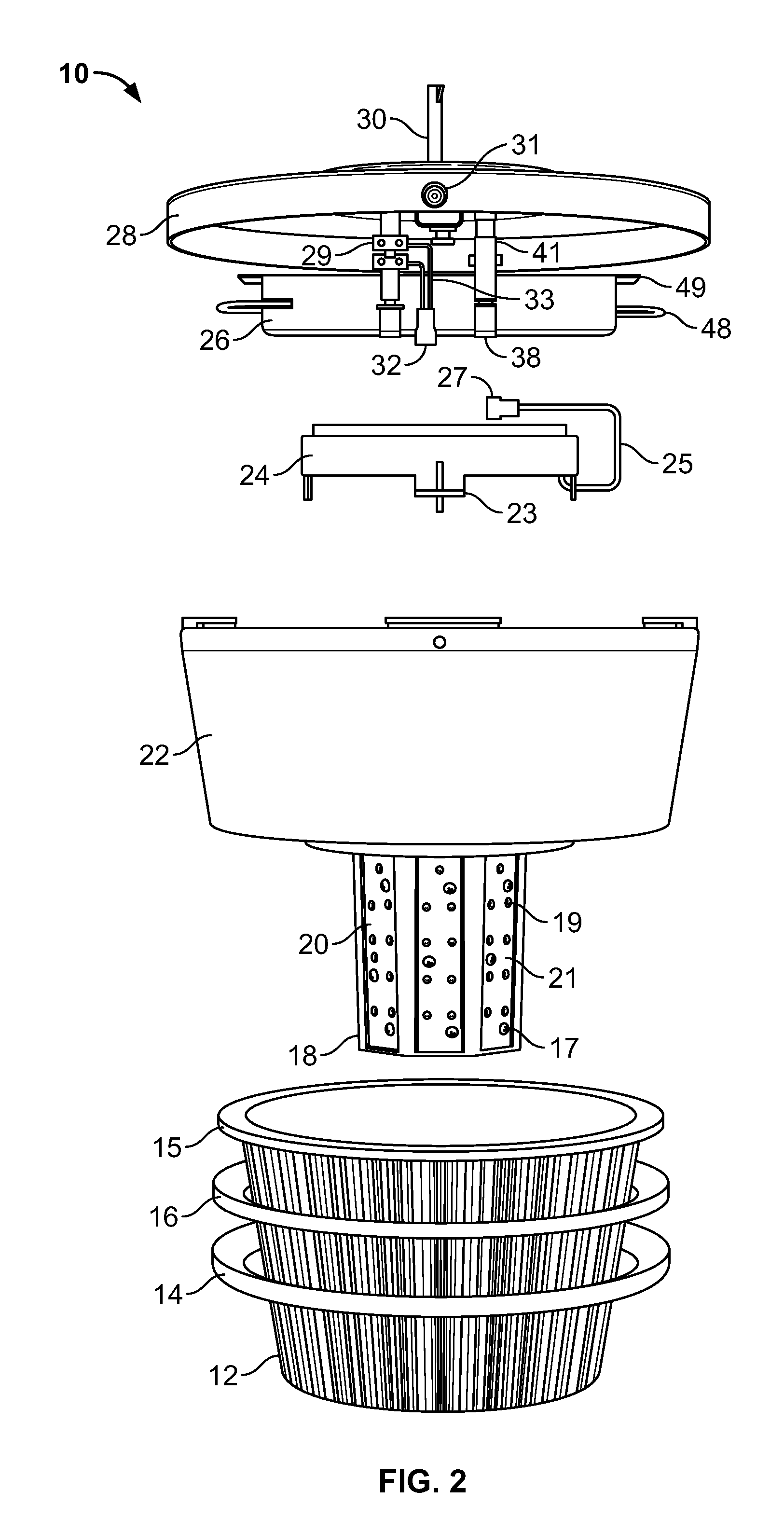

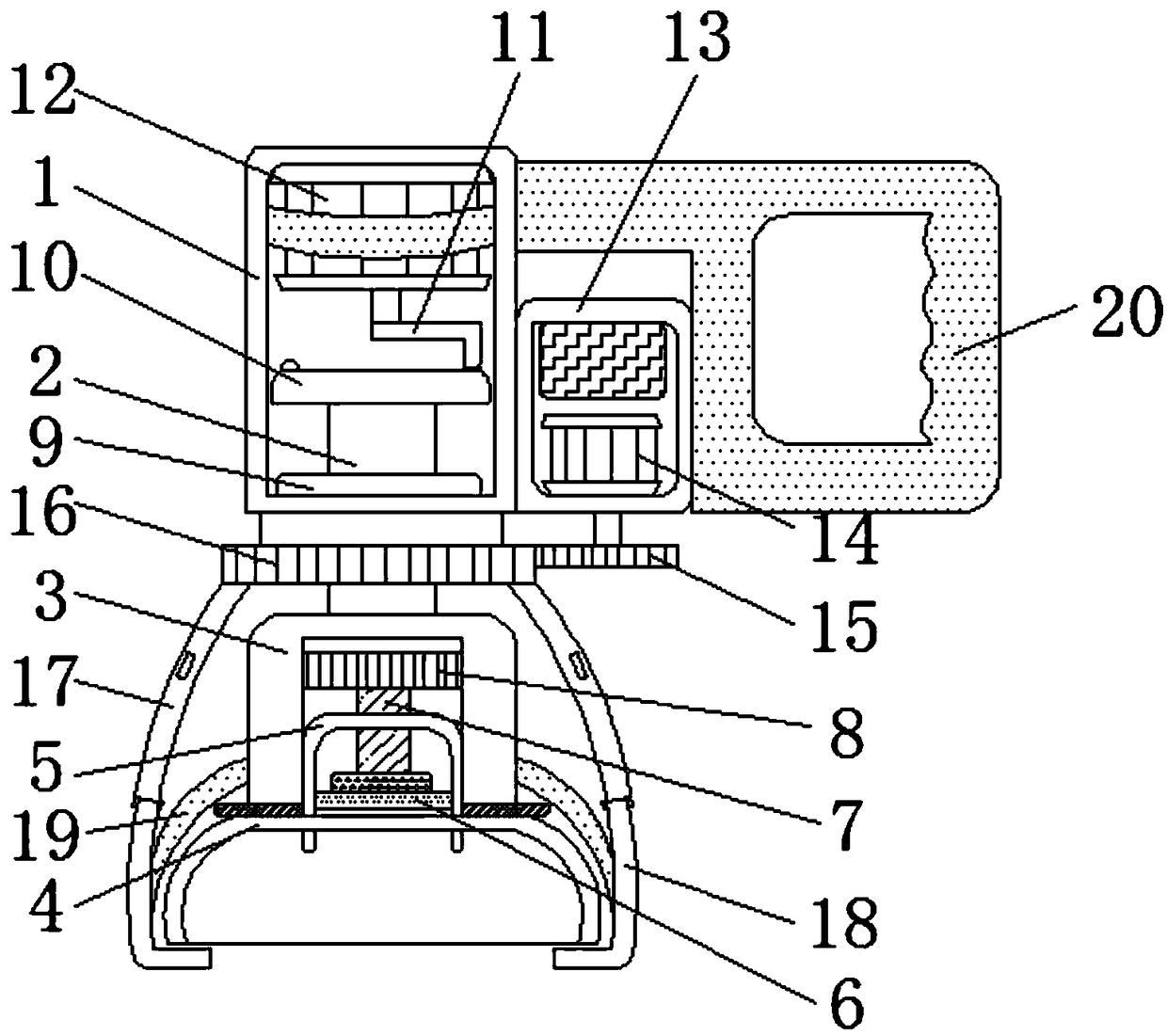

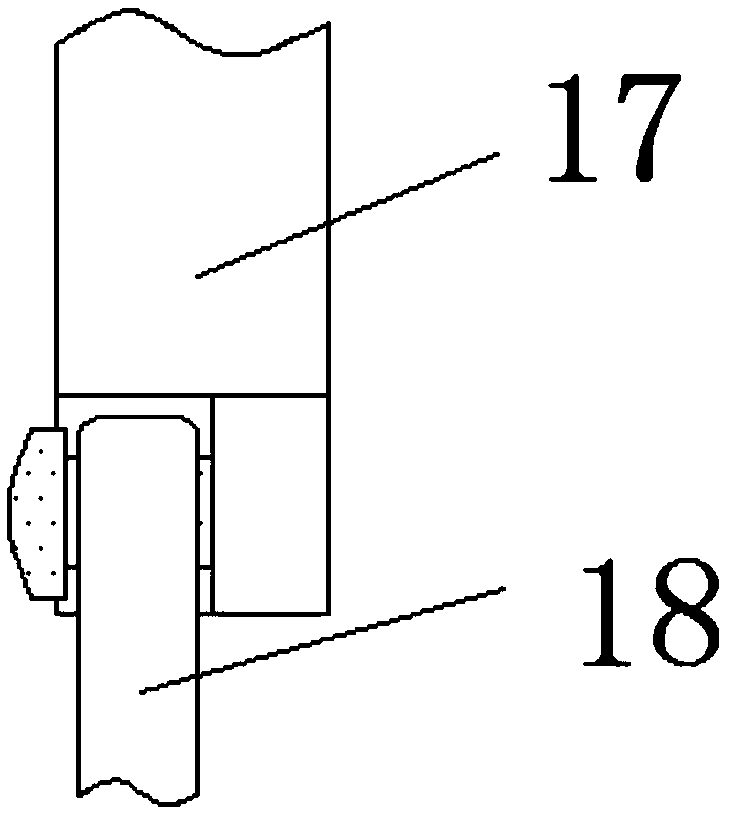

Solid state low bay light with integrated and sealed thermal management

InactiveUS20110228529A1Effective coolingIncrease airflowMechanical apparatusPoint-like light sourceSolid-stateAir current

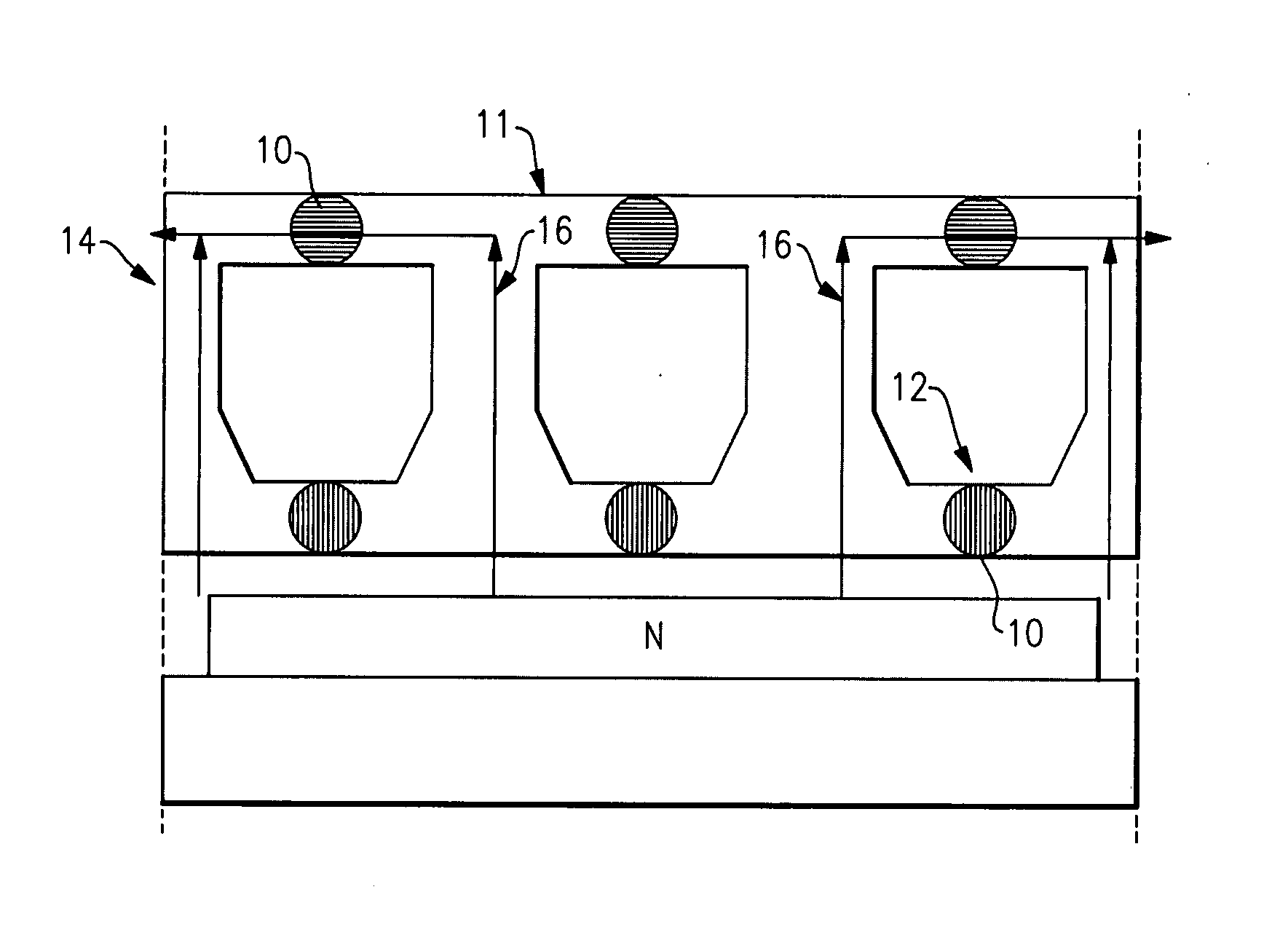

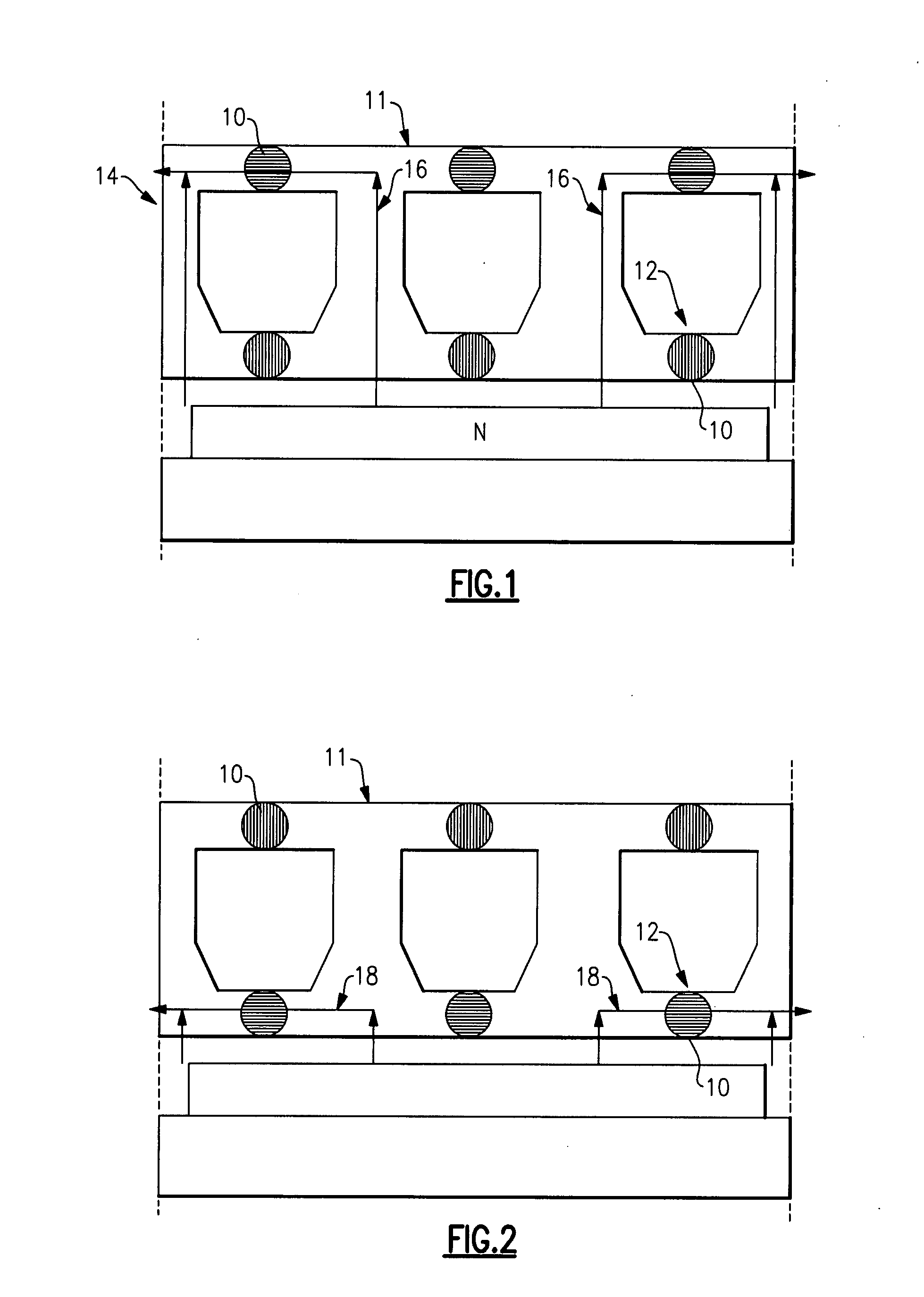

A lighting fixture utilizing LED light sources for illumination of commercial, outdoor and other large area applications incorporates efficient heat dissipation and improved convective air flow. An integrated heat transfer assembly is disclosed that is configured to enhance heat dissipation by providing an efficient thermal conductive pathway for radiation of heat to an external environment. The lighting fixture body is configured with a lens body and heat sink having a chimney tube with internally facing finned heat sink arrangement for providing enhanced convective air flow through the light fixture body. When the heat sink transfers heat from the LED light sources during operation so as to create heated air surrounding the heat sink, ambient air is drawn through the chimney and the heated air is exhausted through air gaps so as to create a conductive air current with the environment. The heat sink fins are configured to enhance the natural air draw through the chimney by tapering the surface areas of the fins.

Owner:INFINILUX

Solid state low bay light with integrated and sealed thermal management

InactiveUS8692444B2Efficient heat dissipationIncrease airflowMechanical apparatusPoint-like light sourceEngineeringAmbient air

A lighting fixture utilizing LED light sources for illumination of commercial, outdoor and other large area applications incorporates efficient heat dissipation and improved convective air flow. An integrated heat transfer assembly is disclosed that is configured to enhance heat dissipation by providing an efficient thermal conductive pathway for radiation of heat to an external environment. The lighting fixture body is configured with a lens body and heat sink having a chimney tube with internally facing finned heat sink arrangement for providing enhanced convective air flow through the light fixture body. When the heat sink transfers heat from the LED light sources during operation so as to create heated air surrounding the heat sink, ambient air is drawn through the chimney and the heated air is exhausted through air gaps so as to create a conductive air current with the environment. The heat sink fins are configured to enhance the natural air draw through the chimney by tapering the surface areas of the fins.

Owner:INFINILUX

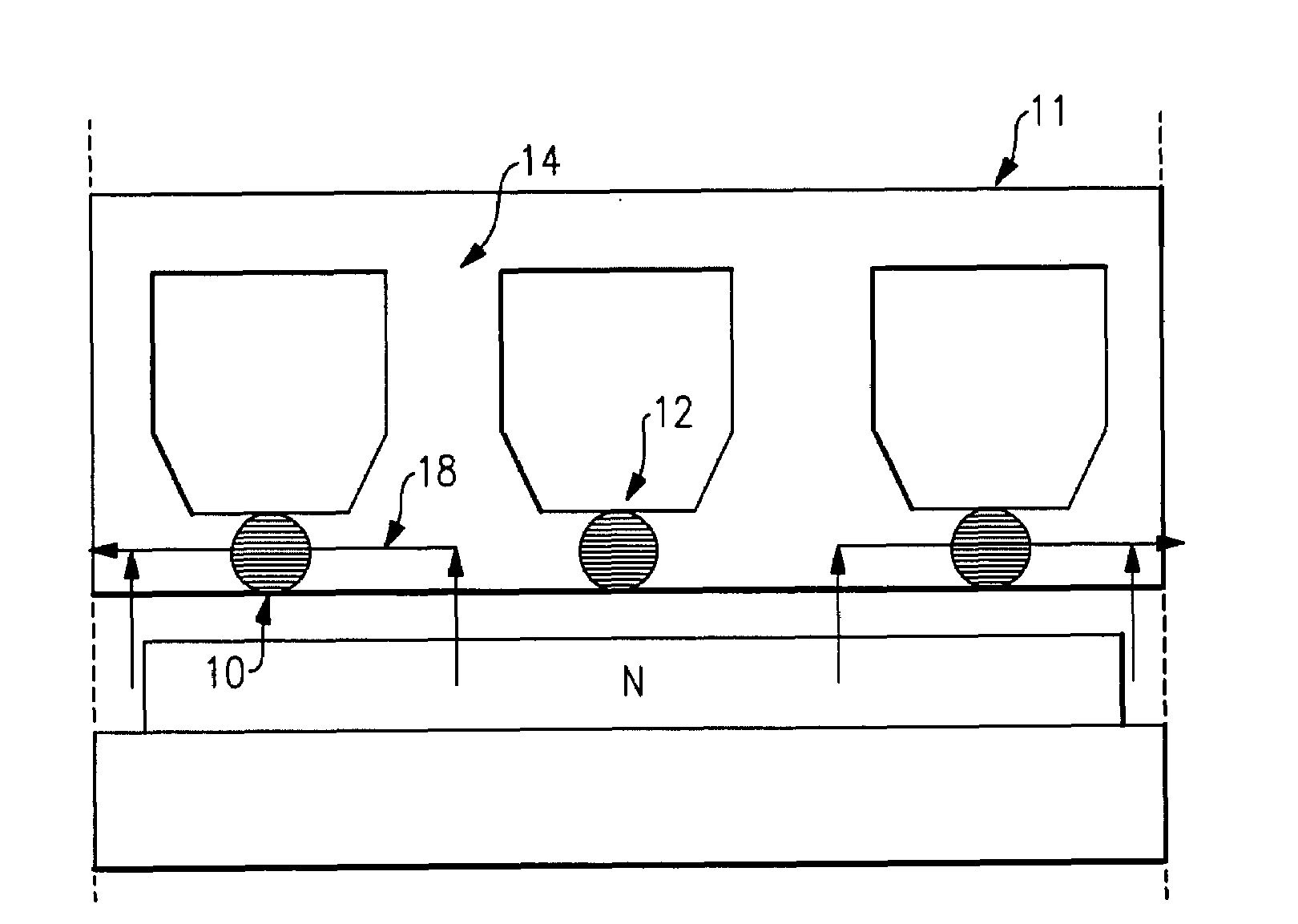

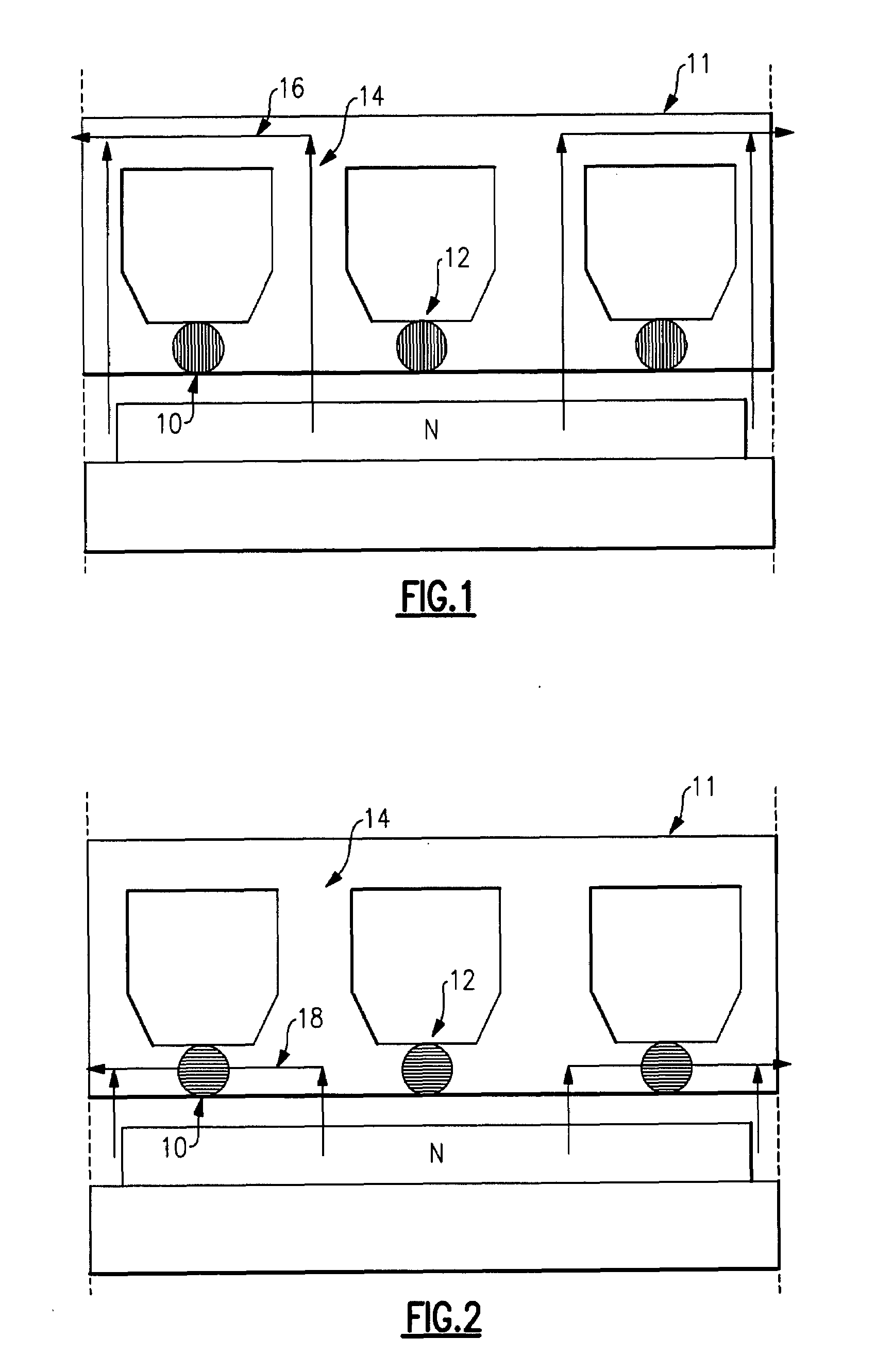

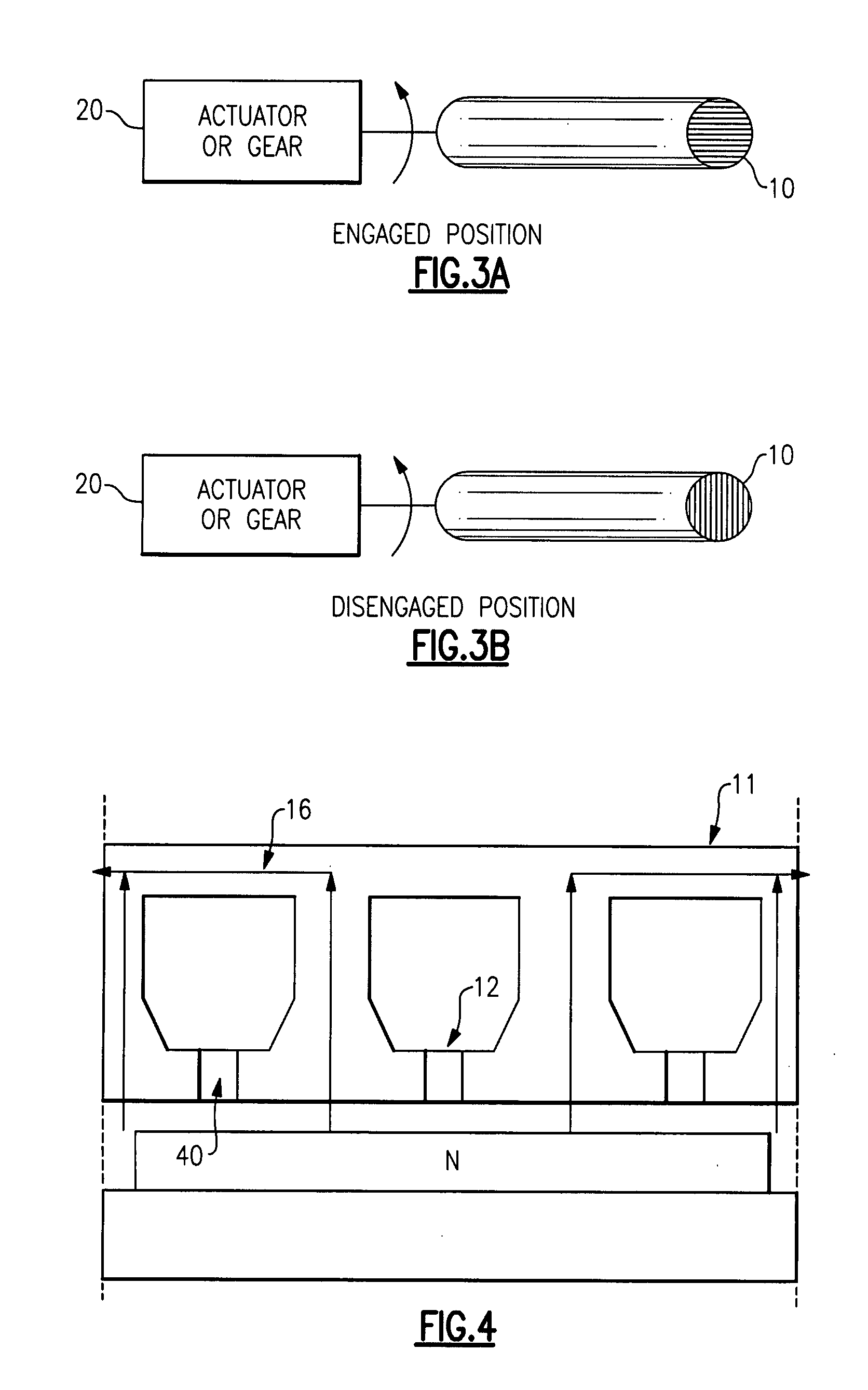

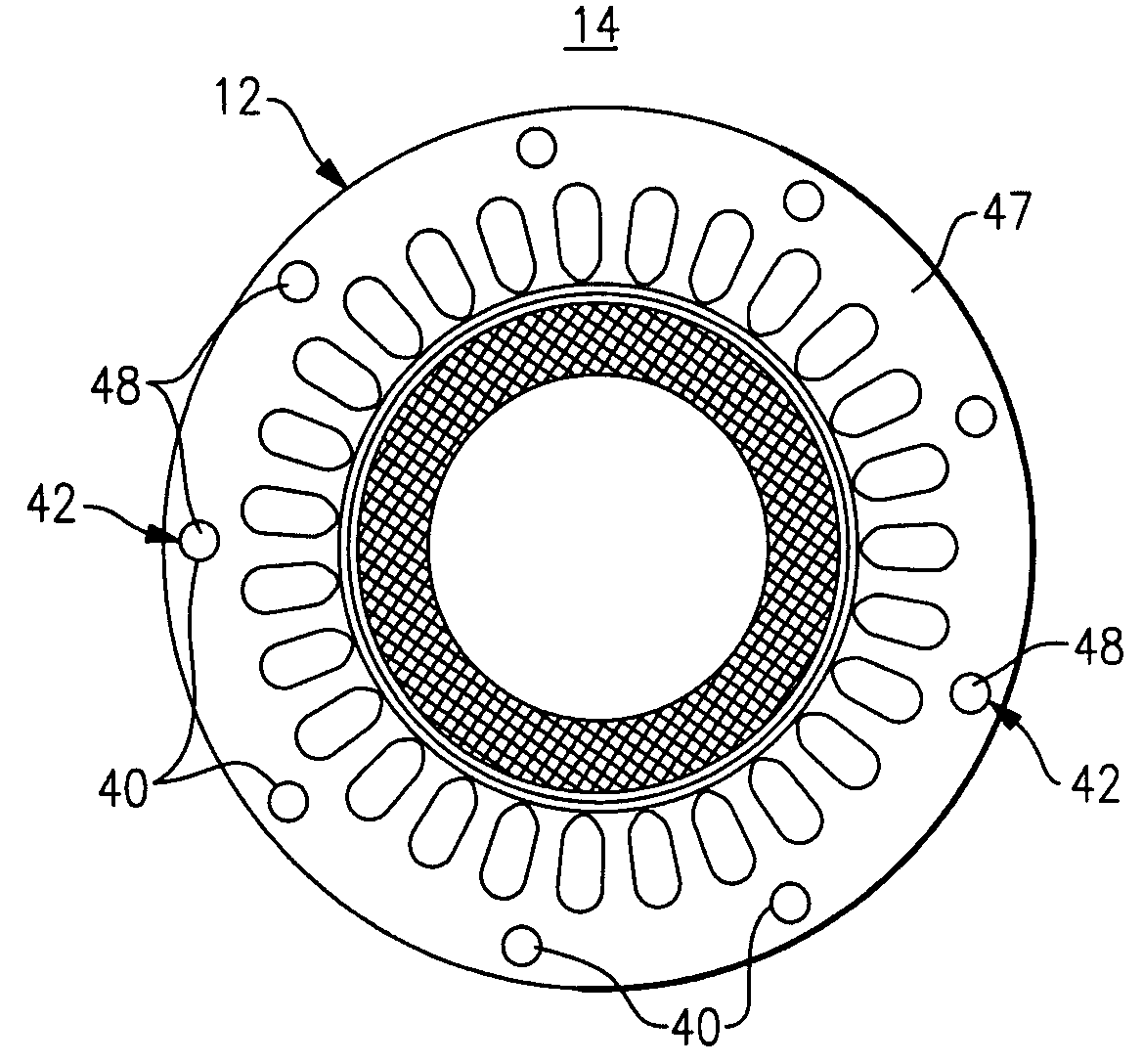

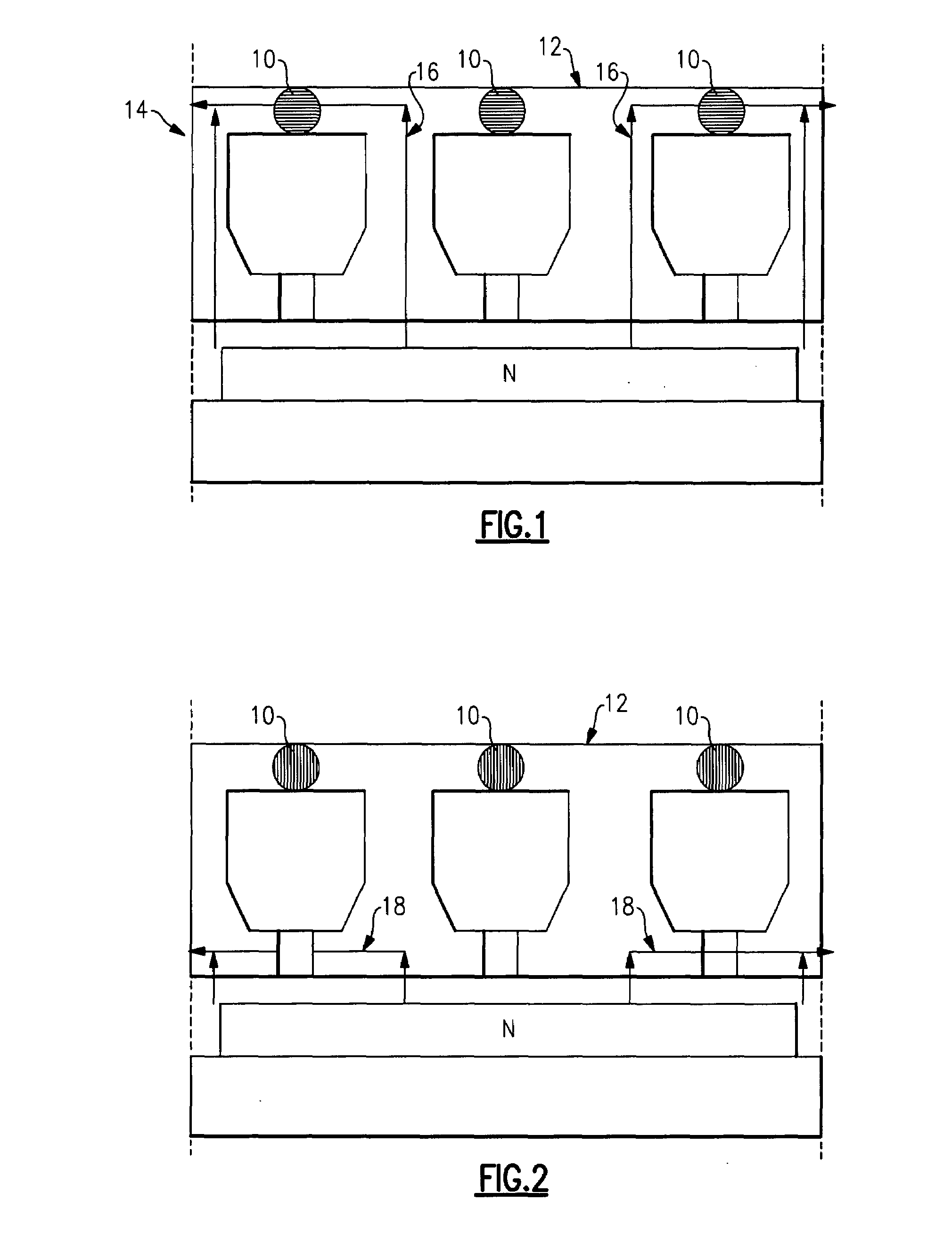

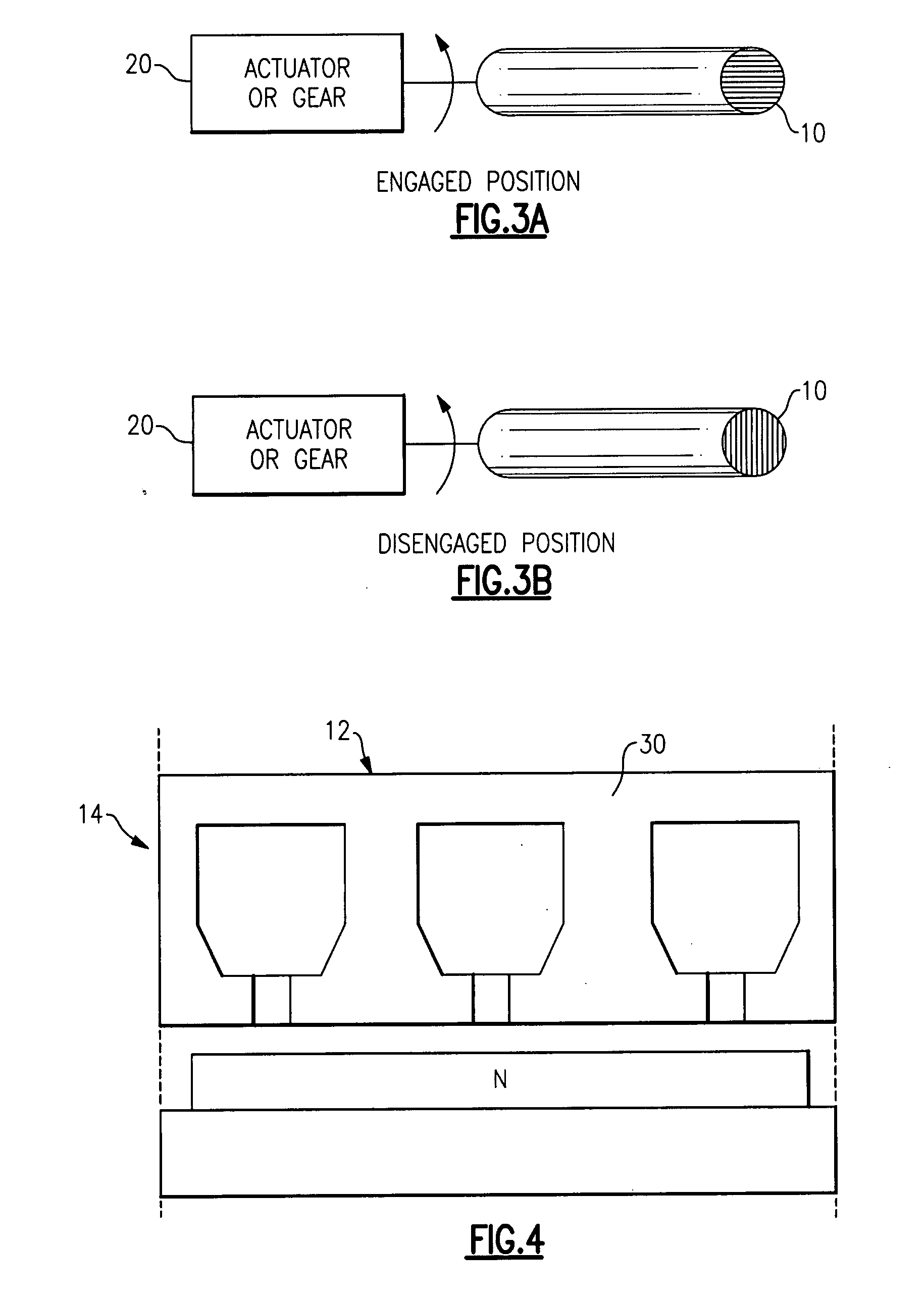

Fault-tolerant permanent magnet machine with reconfigurable stator core slot flux paths

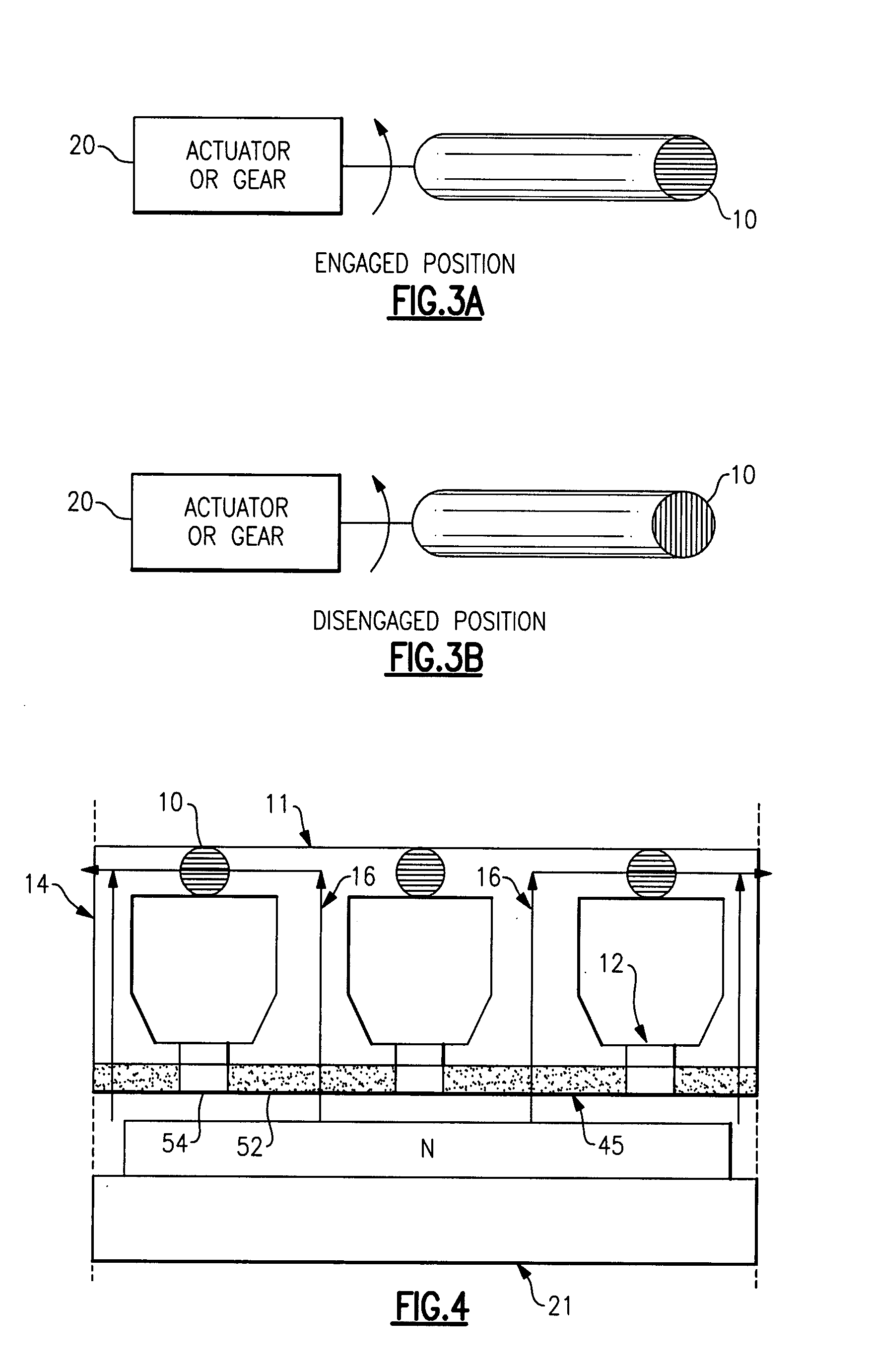

ActiveUS20080238220A1Reduce internal heatMagnetic circuit stationary partsMagnetic circuit characterised by magnetic materialsMagnetic anisotropyFerrofluid

A permanent magnet (PM) machine has a reconfigurable fault condition mechanism disposed solely within a stator core portion, wherein the mechanism is automatically reconfigurable to reduce fault currents associated with the PM machine during a fault condition. The reconfigurable fault condition mechanism is automatically reconfigurable to also reduce internal heat associated with the PM machine during a fault condition. A method of reconfiguring the fault condition mechanism upon detection of a fault condition includes the steps of 1) selecting the reconfigurable fault condition mechanism from a) a plurality of rotatable magnetically anisotropic cylinders disposed within stator core slots, b) a plurality of ferrofluid-fillable cavities associated with stator core slots, and c) a sliding shield within the stator core; and 2) reconfiguring the fault condition mechanism to automatically reduce fault currents associated with the PM machine upon detection of a fault condition.

Owner:GENERAL ELECTRIC CO

Fault-tolerant permanent magnet machine with reconfigurable flux paths in stator back iron

ActiveUS20080238217A1Reduce internal heatMagnetic circuit stationary partsEnergy production using magneto-hydrodynamic generatorsMagnetic anisotropyFerrofluid

A permanent magnet (PM) machine has a fault condition mechanism disposed within a back iron of the stator portion, the mechanism operational to automatically reduce fault currents associated with the PM machine during a fault condition. The fault condition mechanism disposed within the stator back iron is reconfigurable to automatically reduce internal heat associated with the PM machine during a fault condition. A method of reconfiguring the PM machine upon detecting a fault condition includes the steps of 1) selecting the reconfigurable fault condition mechanism from a) a plurality of magnetically anisotropic rotatable cylinders, b) a plurality of ferrofluid-filled cavities, and c) a dual-phase material selectively embedded within the stator core; and 2) reconfiguring the fault condition mechanism to automatically reduce fault currents or internal heat associated with the PM machine upon detection of a fault condition.

Owner:GENERAL ELECTRIC CO

Fault-tolerant permanent magnet machine with reconfigurable stator core slot opening and back iron flux paths

ActiveUS20080238233A1Reduce fault currentReduce internal heatWindingsAsynchronous induction motorsElectric machineConductor Coil

A permanent magnet (PM) machine includes a plurality of reconfigurable fault condition mechanisms disposed within a stator core portion, the plurality of reconfigurable fault condition mechanisms together automatically reconfigurable to reduce fault currents and internal heat associated with the PM machine during a fault condition. The plurality of reconfigurable fault condition mechanisms are disposed solely within the stator core portion according to one embodiment to automatically reduce stator winding fault currents and internal heat associated with the PM machine during a fault condition. A method of reconfiguring the fault condition mechanisms upon detecting a fault condition includes the steps of 1) selecting the plurality of reconfigurable fault condition mechanisms from a) a plurality of rotatable magnetically anisotropic cylinders disposed both within a stator back iron and stator slot openings, and b) a plurality of rotatable magnetically anisotropic cylinders disposed within a stator back iron and a sliding shield disposed with a stator slot opening portion of the stator core, and 2) reconfiguring the plurality of fault condition mechanisms together to automatically reduce fault currents associated with the PM machine upon detection of a fault condition.

Owner:GENERAL ELECTRIC CO

Making process of nutritious lycium chinense and date vinegar

The making process of nutritious wolfberry fruit and date vinegar includes heating bran at 100-120 deg.c for 20-400 min, adding bacteria strain S-324 at 32-36 deg.c, fermentation at 32-38 deg.c for 56-72 hr to prepare yeast, mixing kaoliang and the yeast for saccharifying fermentation, adding xiaoqu and saccharomycetes for liquid phase fermentation at 30-40 deg.c for 5-10 days, adding rice bran and husk for solid fermentation at 35-45 deg.c for 40-80 days, distillation, adding fruit and vegetable polysaccharide, adding wolfberry fruit and date steamed for 5-15 min, adding vinegar juice for reflux fermentation, ripening, disinfection, and packing. The vinegar of the present invention has rich vitamin C and vitamin E content, contains 18 kinds of amino acids essential for human body and thus has nutritive and health care functions.

Owner:宋学军

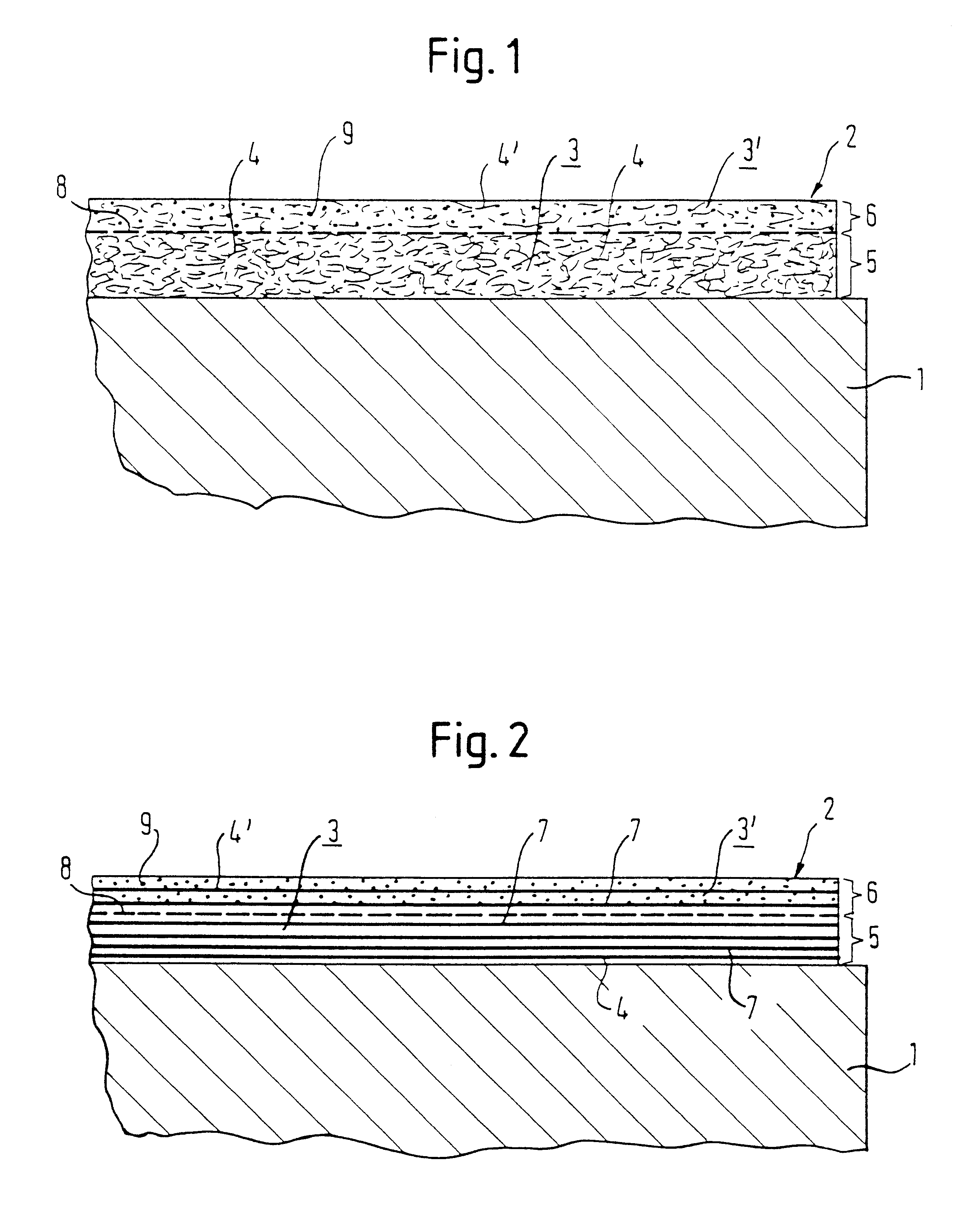

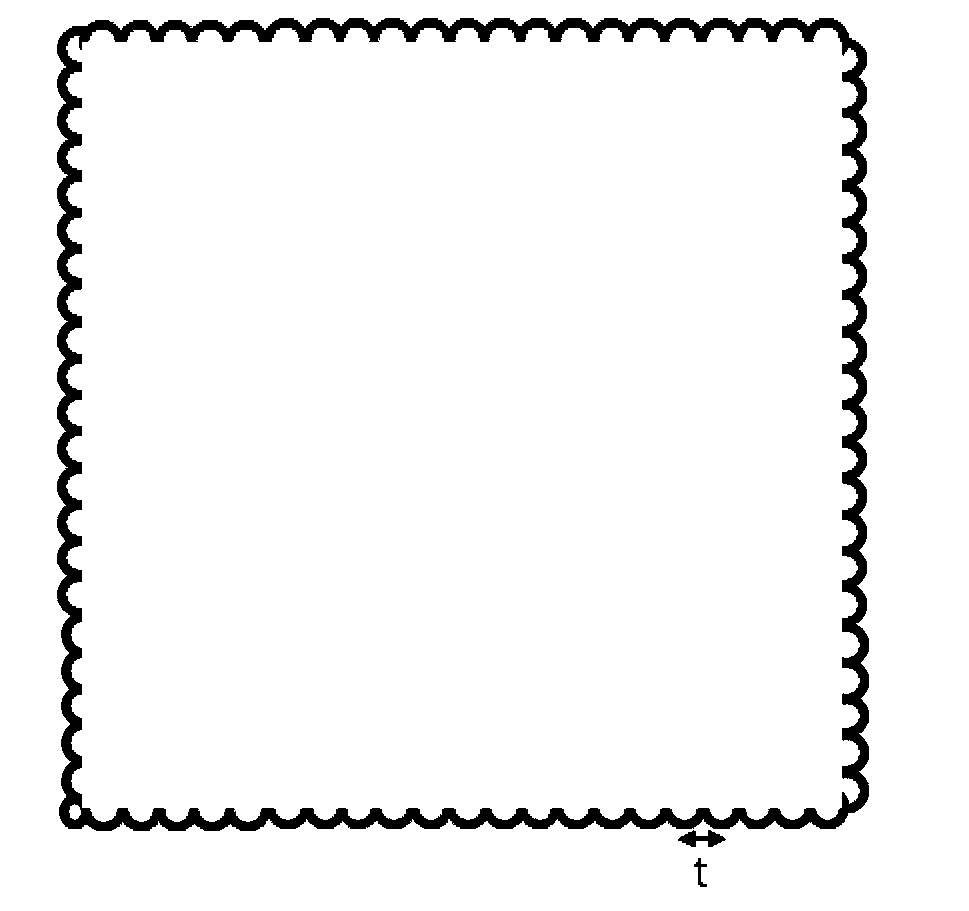

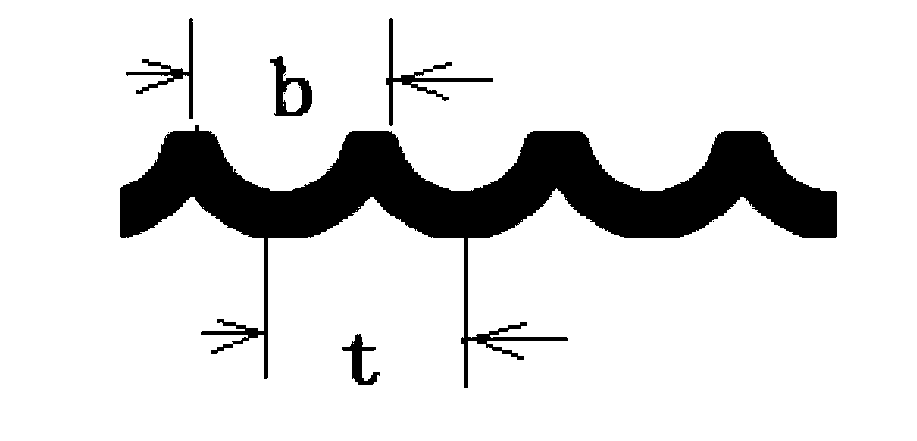

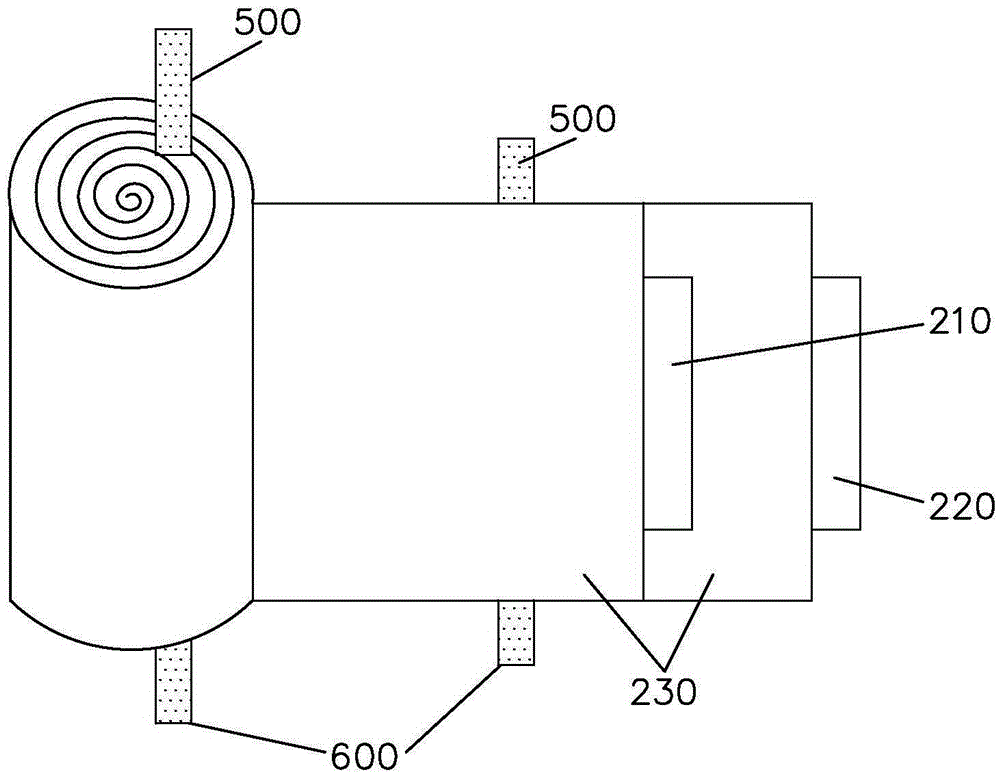

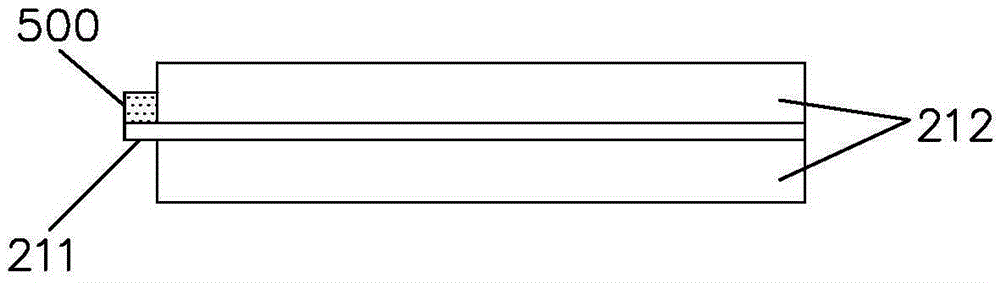

Elastic roll and process of producing the same

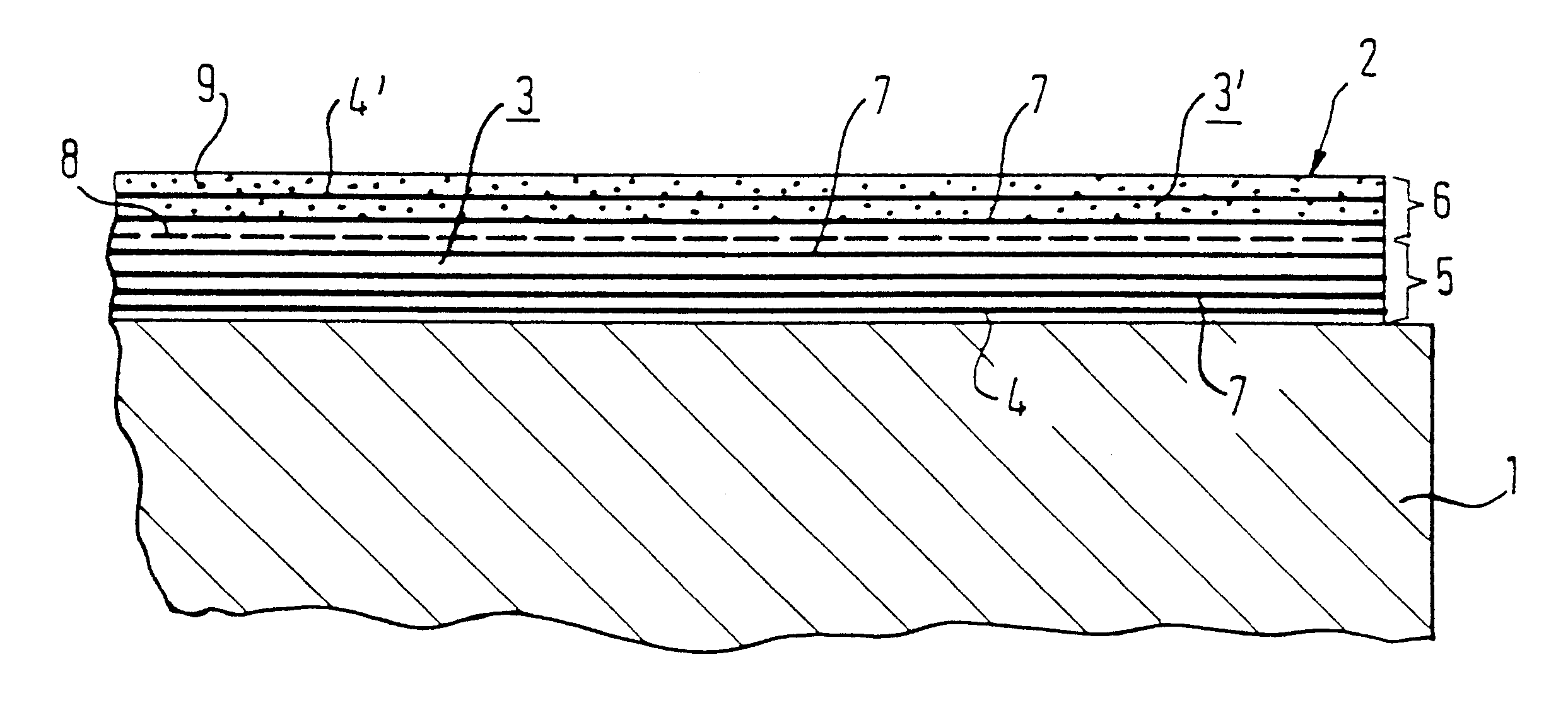

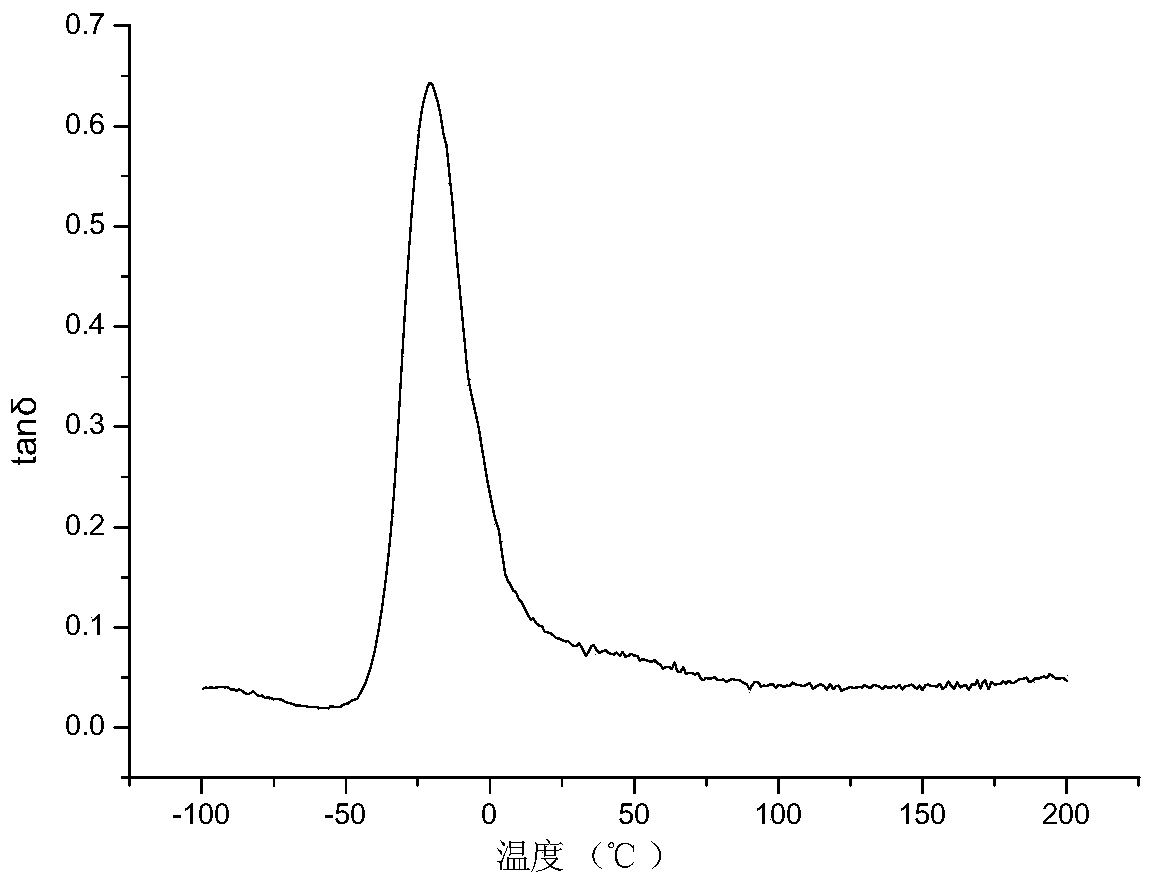

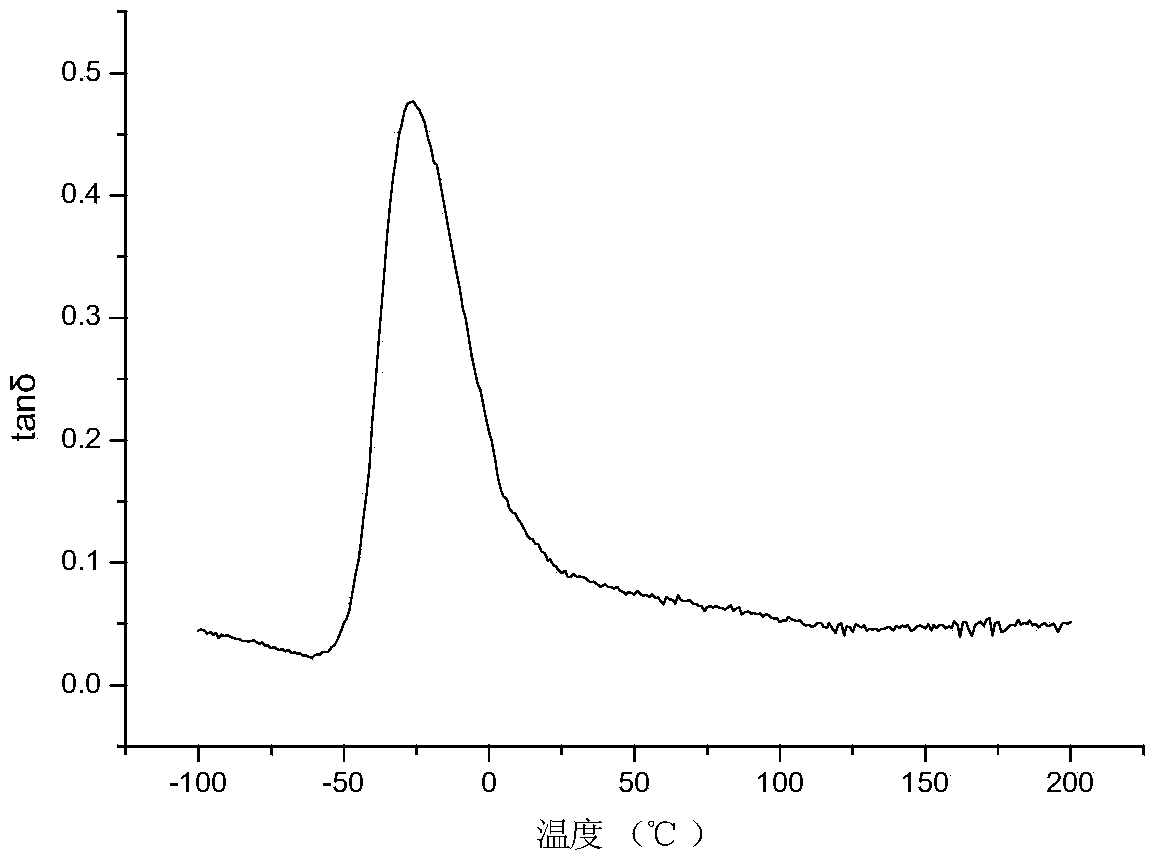

InactiveUS6379290B1Reduce internal heatHigh stressShaft and bearingsMetal-working apparatusDamping factorFiber

Roll for the smoothing paper webs and process for producing roll. The roll includes a hard core, and an elastic covering layer arranged on an outside of the hard core. The covering layer includes a radially outer functional layer and a radially inner connecting layer arranged to couple the functional layer to the hard core. The inner connecting layer and the outer functional layer each include a soft matrix material with embedded fibers. The matrix material of the functional layer includes an elastic material with a damping factor of tan delta less than about 0.02 and the matrix material of the connecting layer includes a damping material with a damping factor of tan delta greater than about 0.05. The process includes forming an outer functional layer with an elastic matrix material having a damping factor of tan delta less than about 0.02 and embedded fibers, forming an inner connecting layer with a damping matrix material having a damping factor of tan delta greater than about 0.05 and embedded fibers, and coupling the outer functional layer to the hard core through the inner connecting layer to form an elastic covering layer on an outside of the hard core.

Owner:VOITH PATENT GMBH

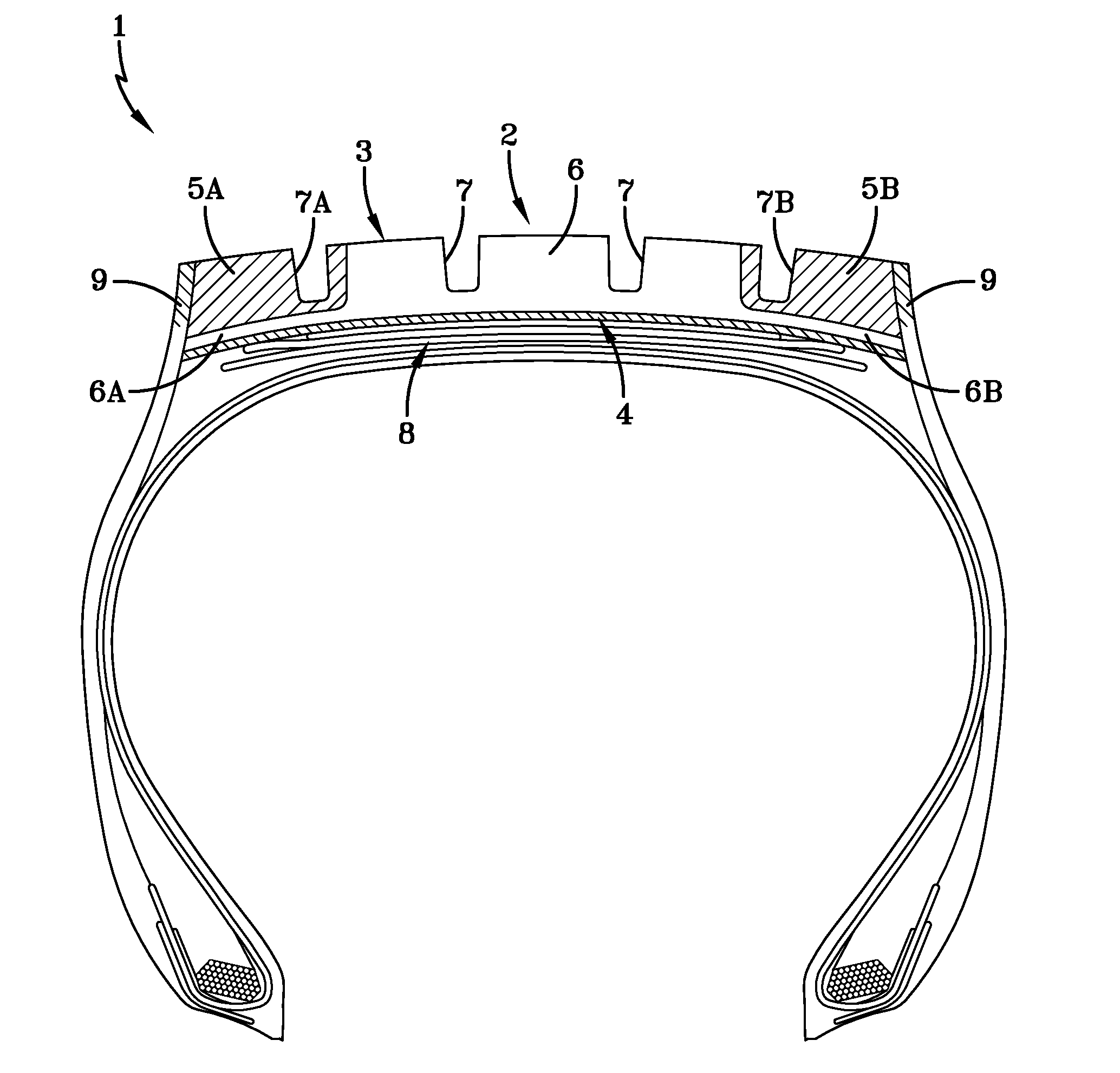

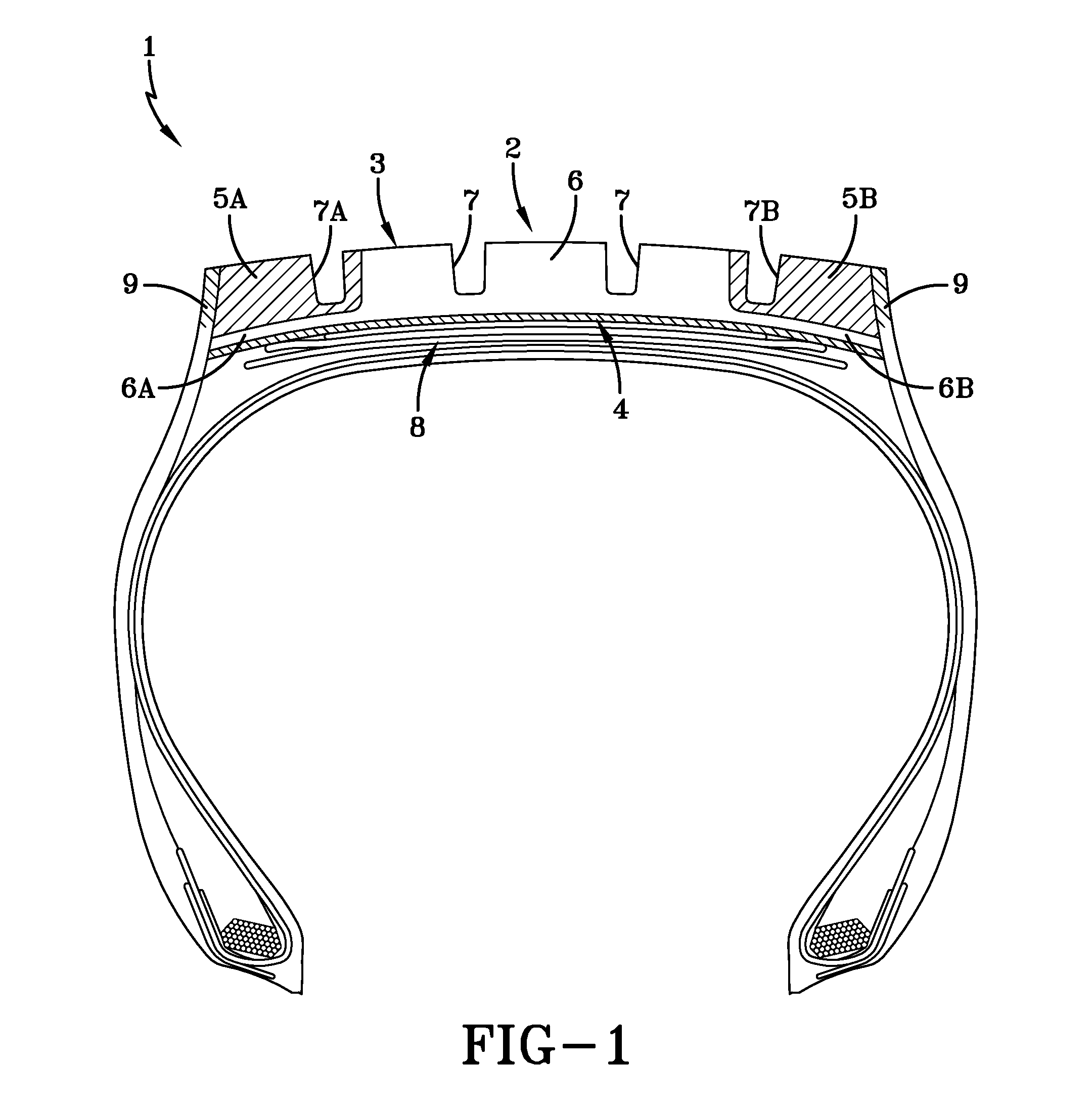

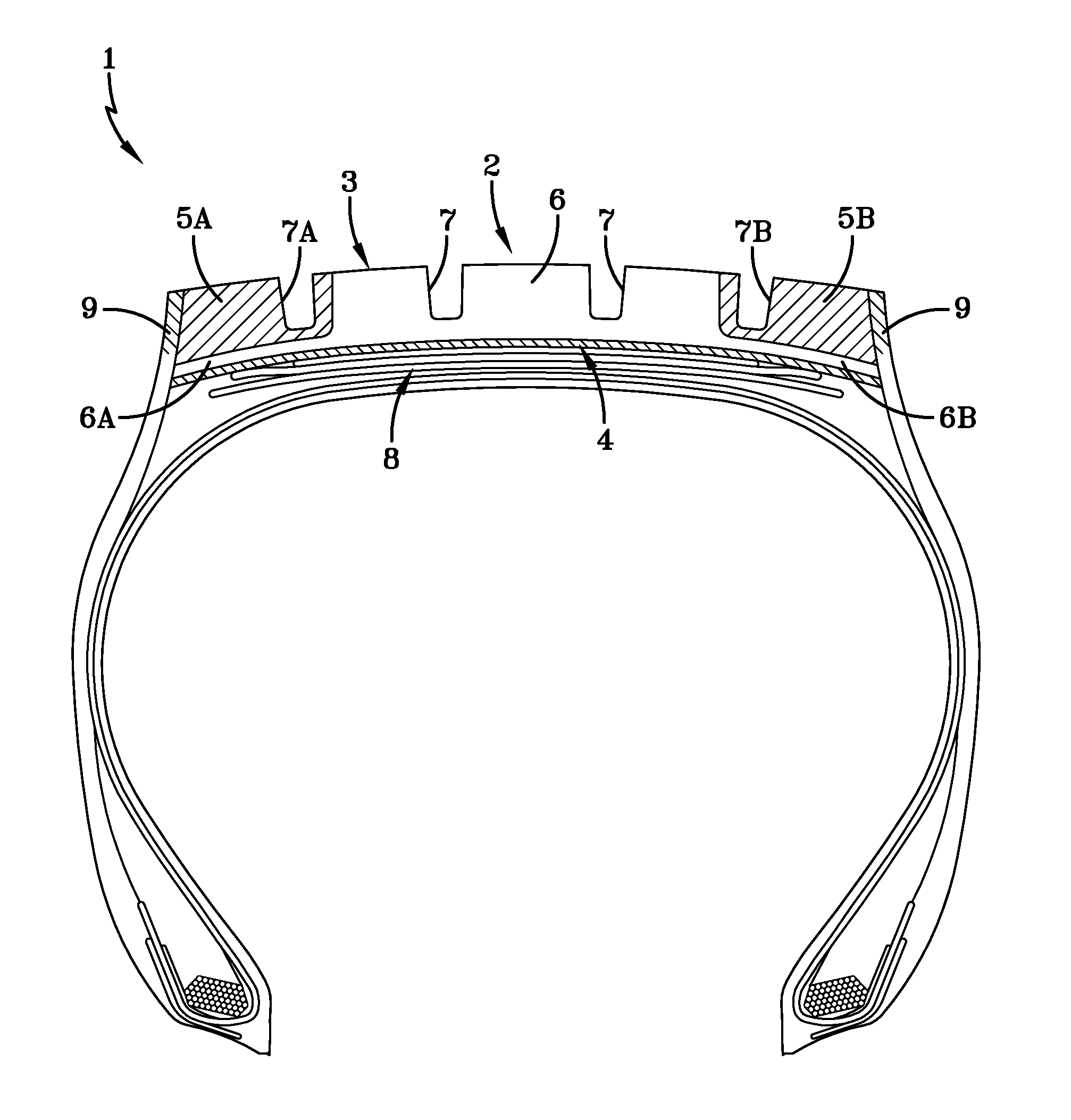

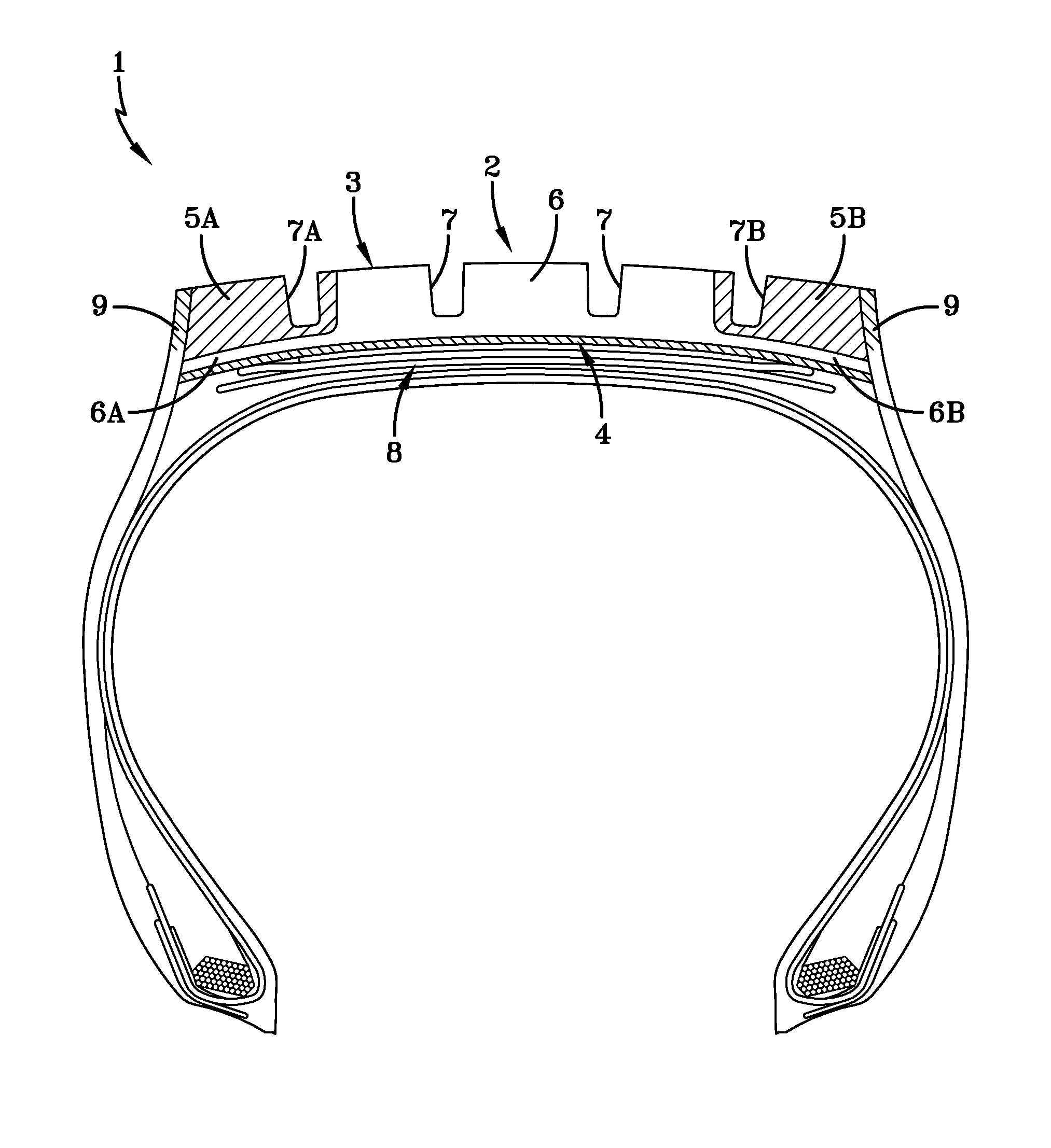

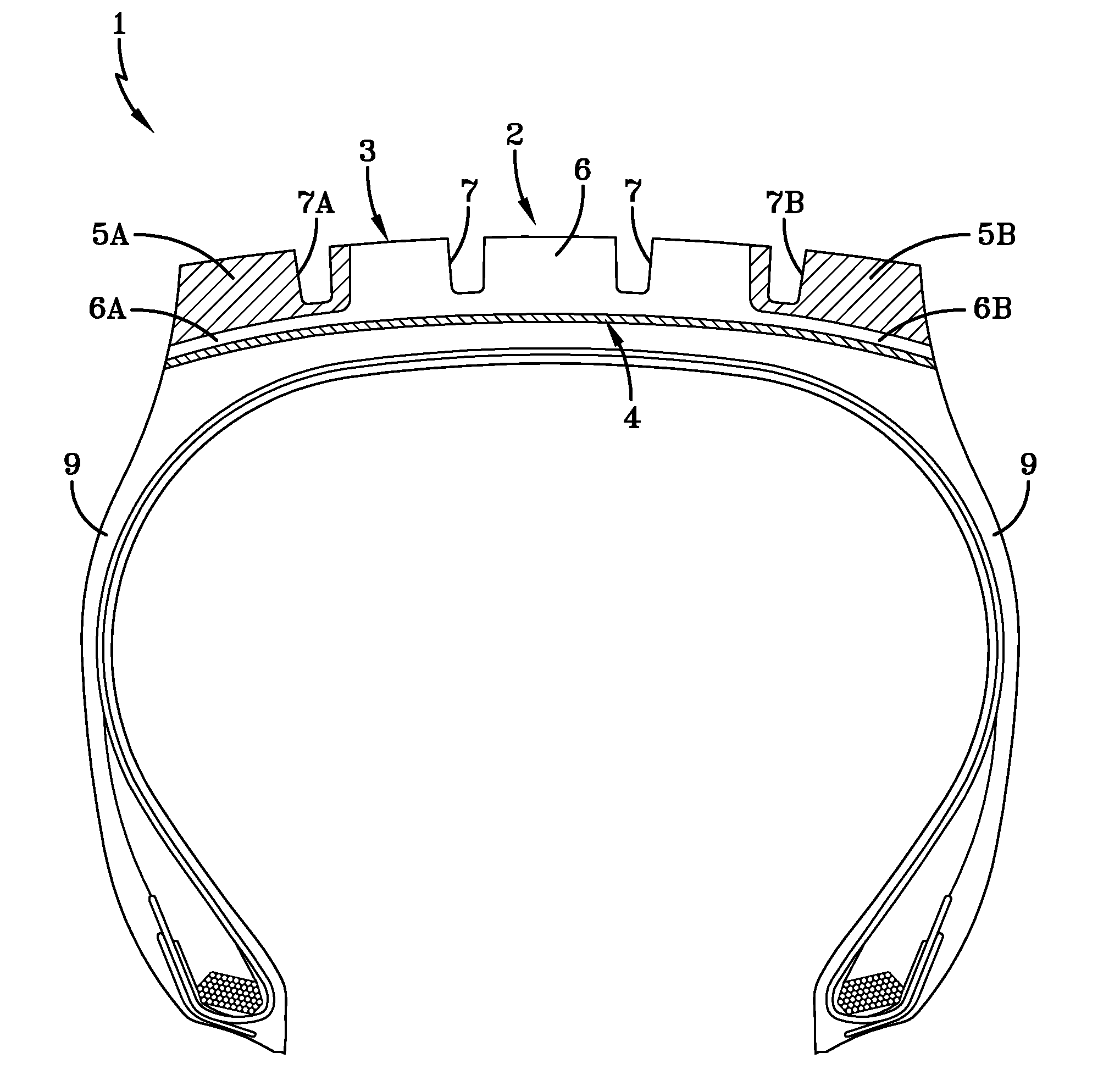

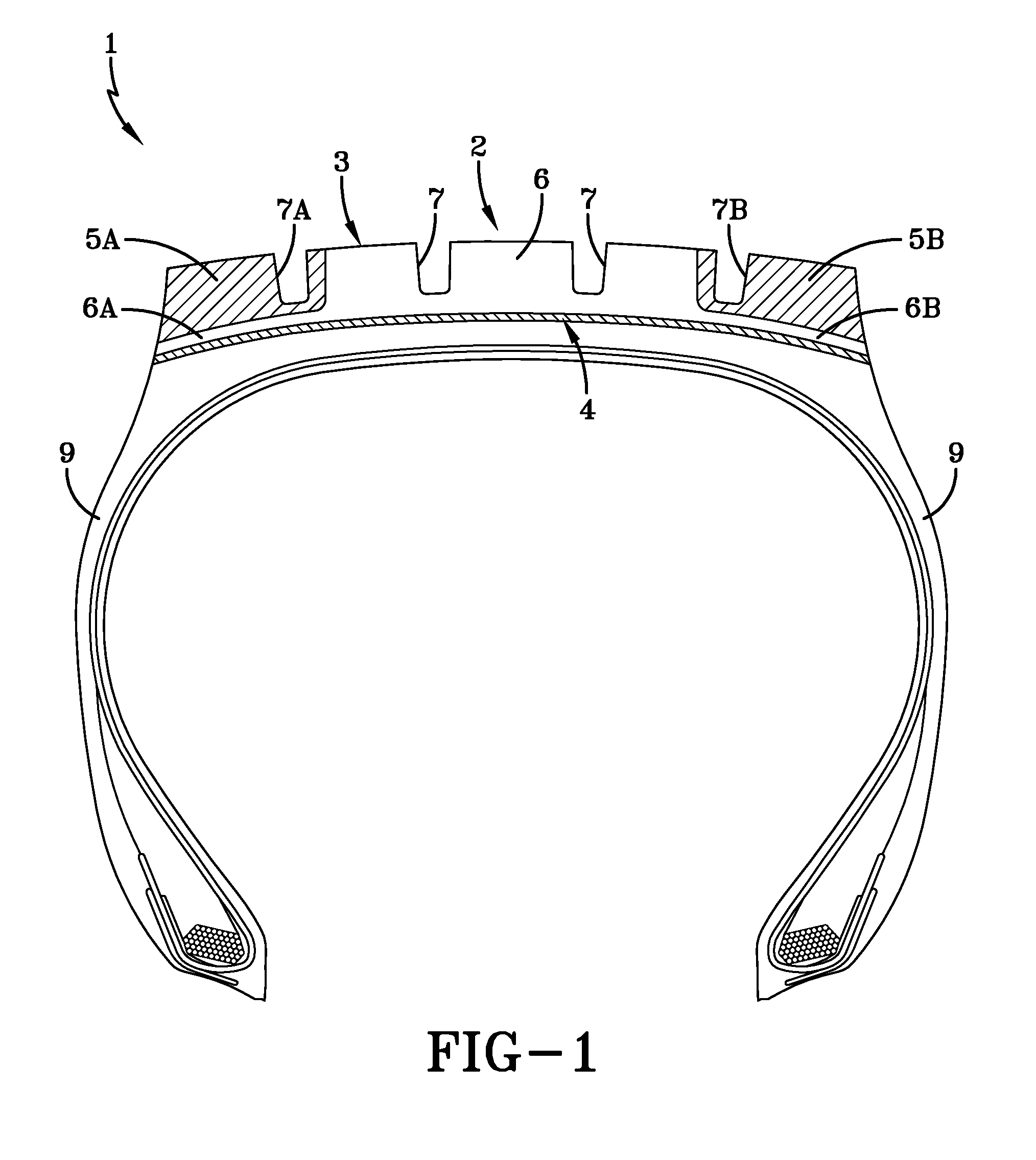

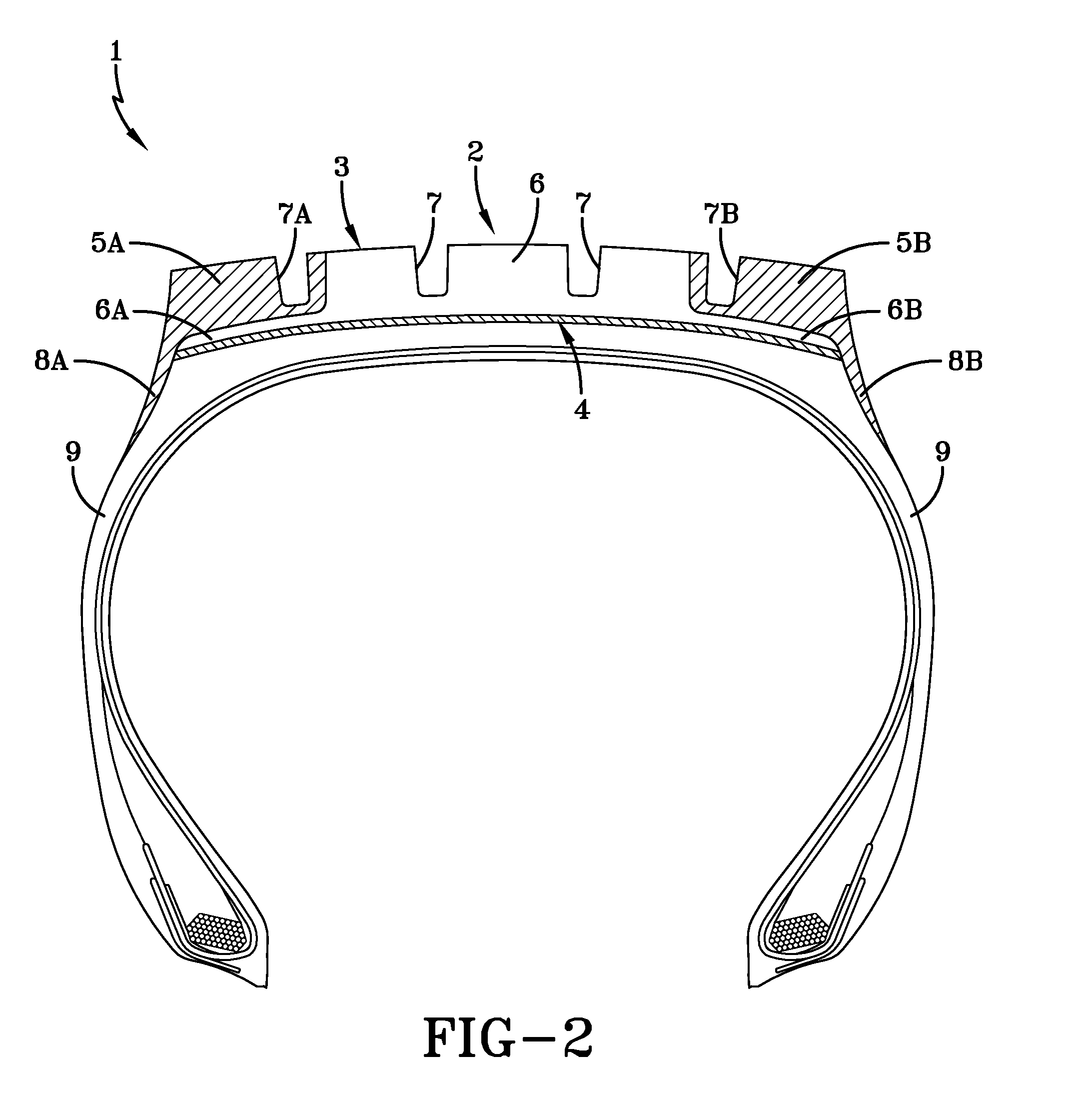

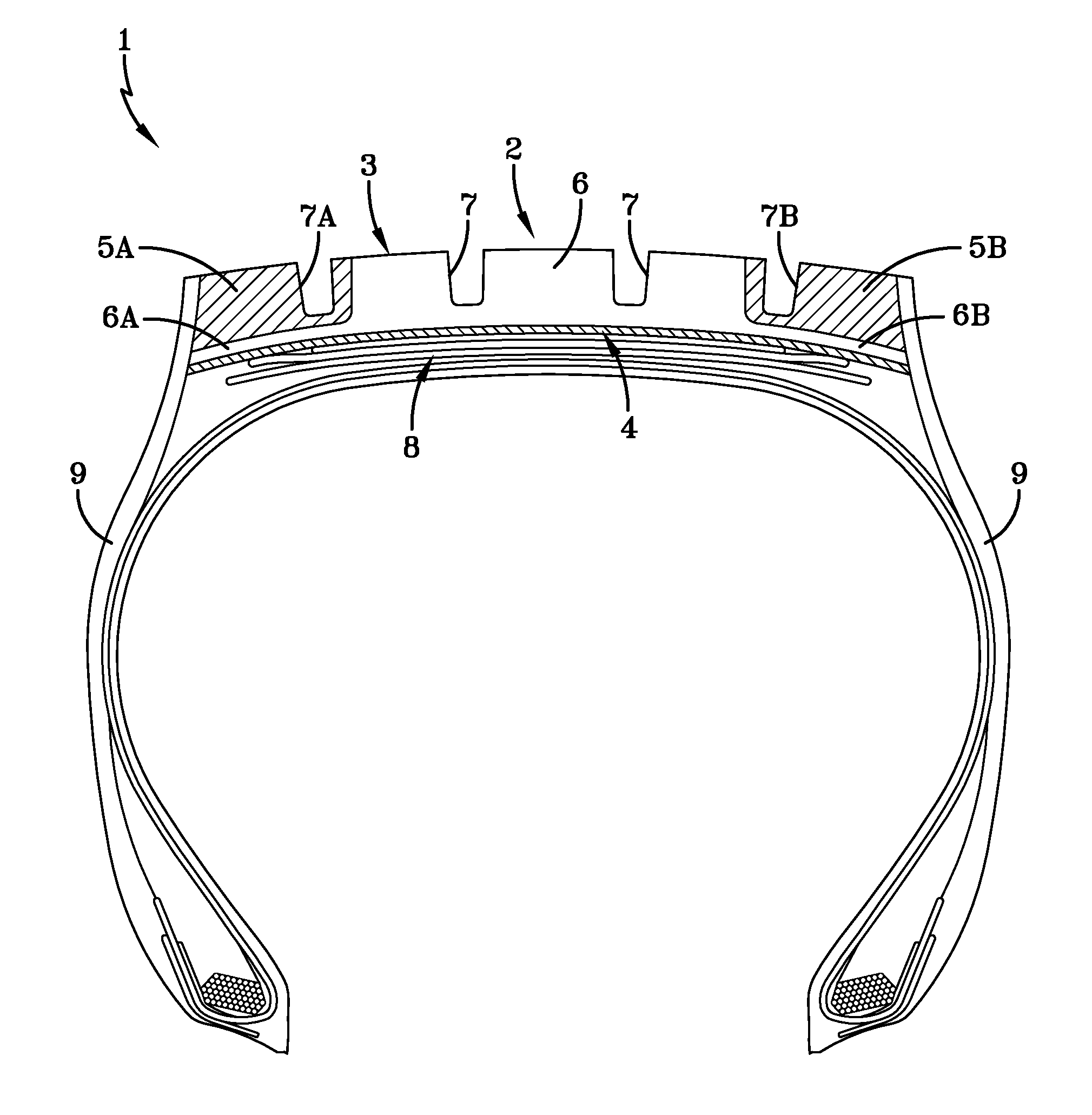

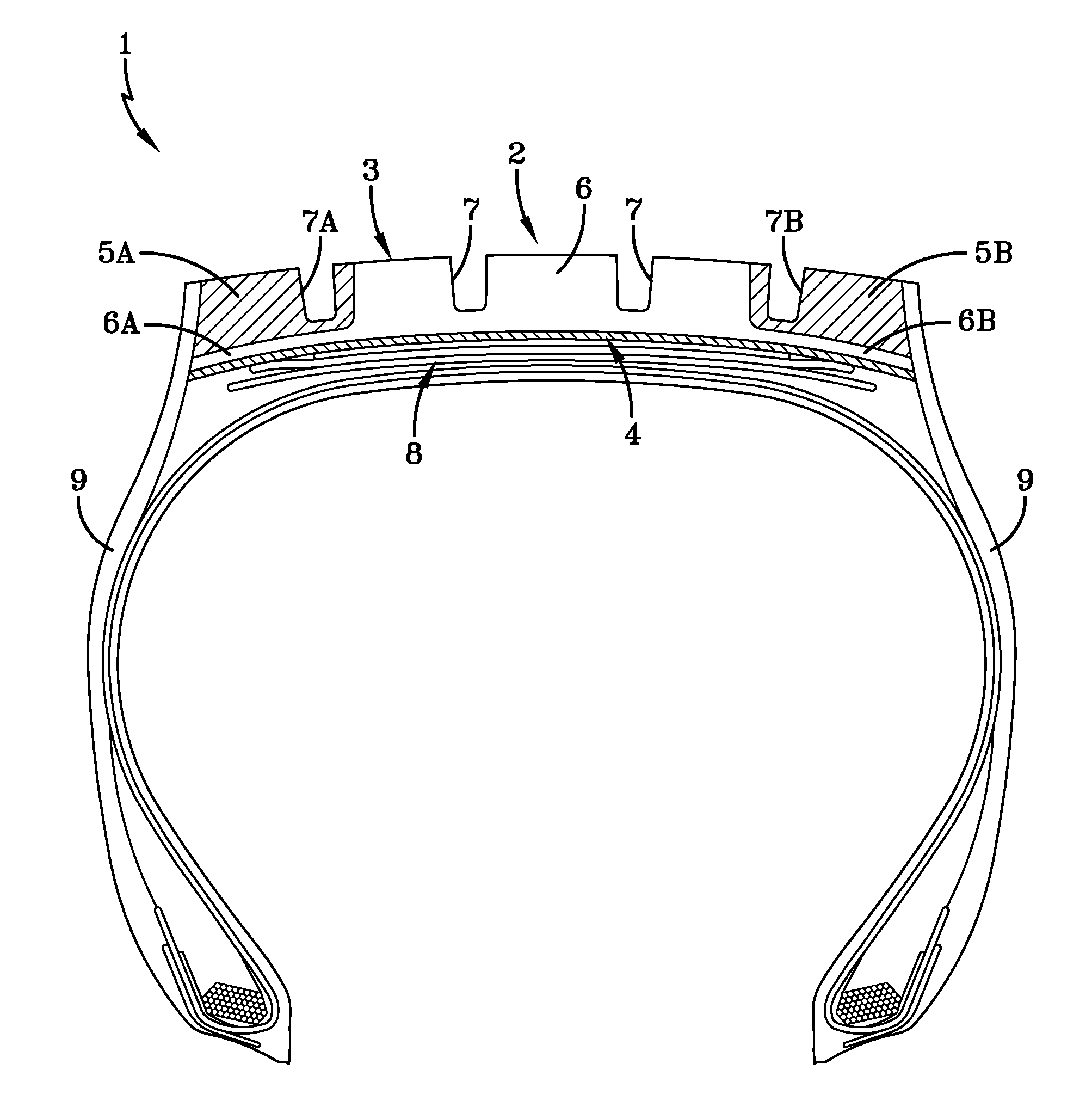

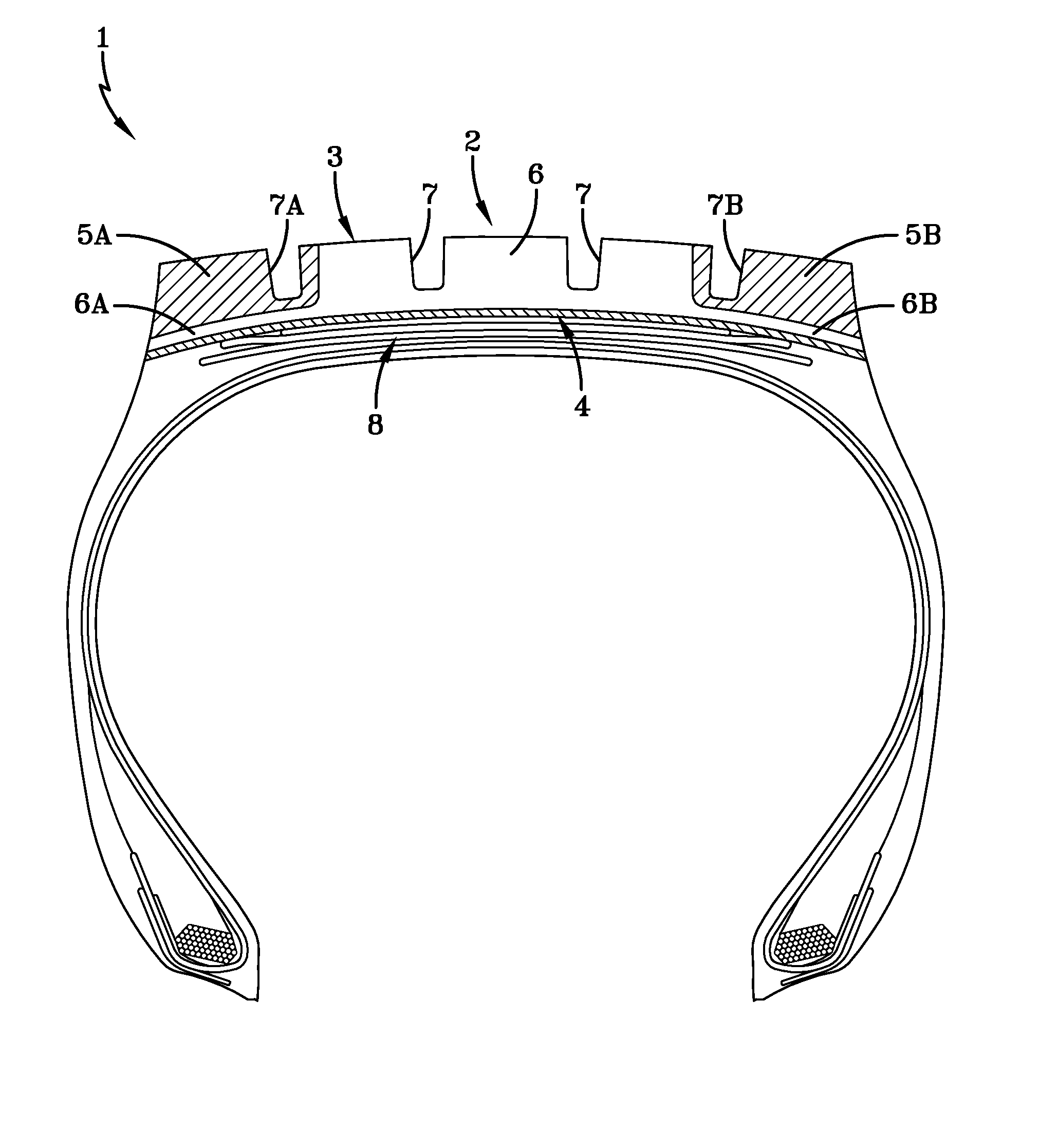

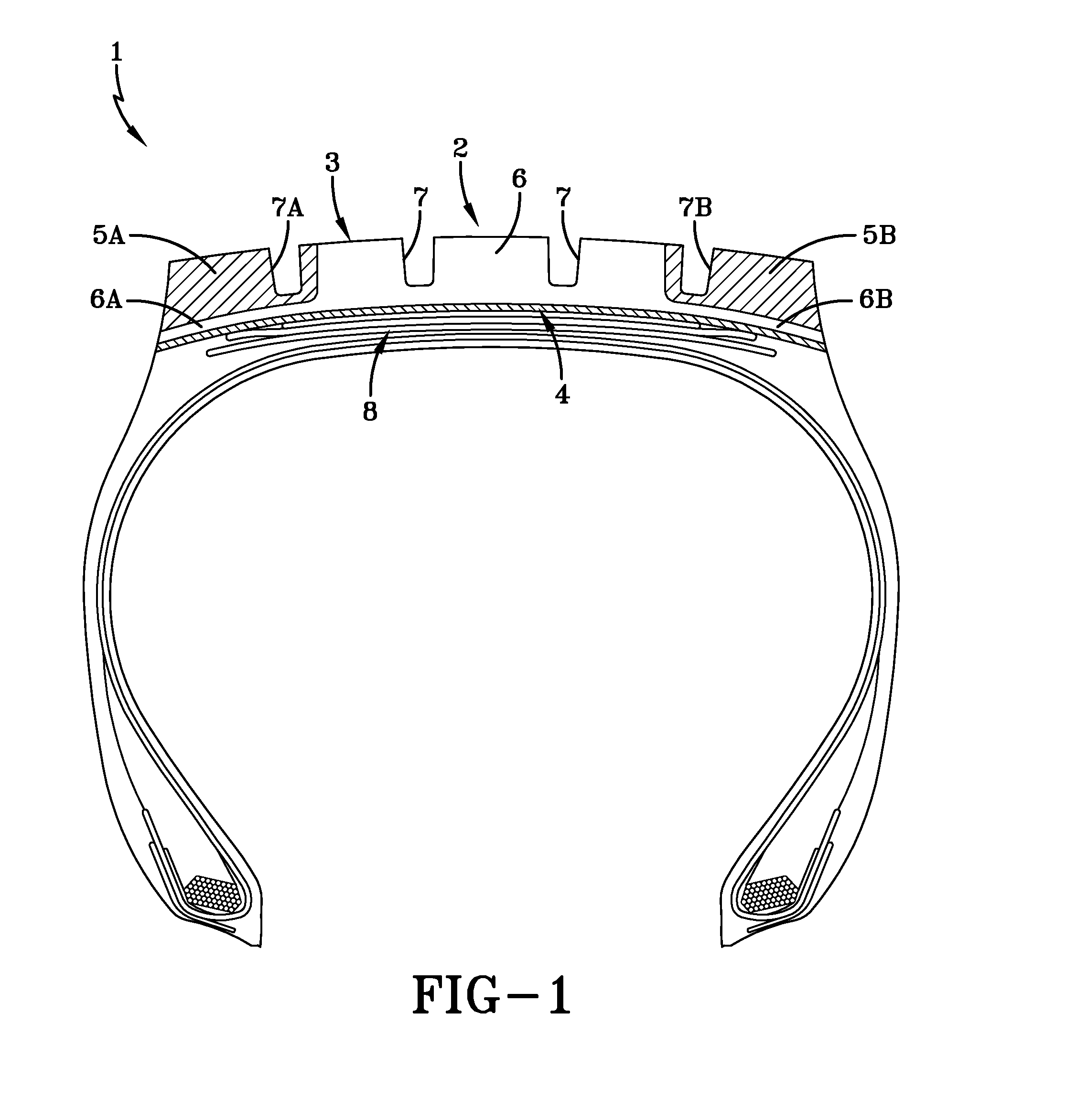

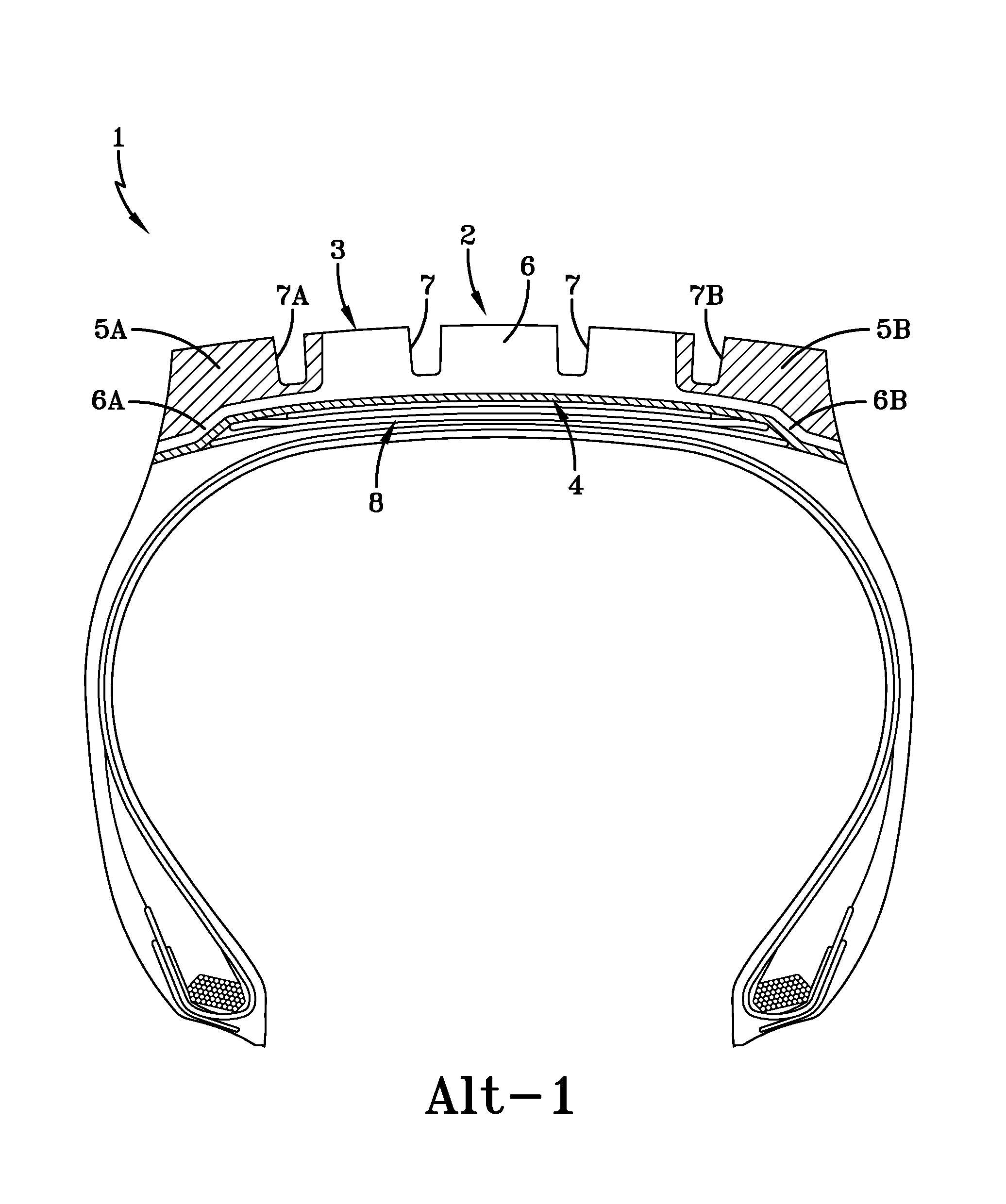

Tire with rubber tread of intermedial and lateral zones with periperial sidewall extensions

ActiveUS20160059636A1Reduce hysteresisReduce internal heatSpecial tyresTyre tread bands/patternsEngineeringReinforced rubber

The invention relates to a tire with circumferentially zoned tread including peripheral sidewall extensions. The tread zones are comprised of three circumferential load bearing zones, with each zone containing a portion of the running surface of the tread, comprised of an intermedial rubber zone positioned between and extending beneath two stratified lateral tread rubber zones and, in addition, peripheral sidewall extensions. The tread configuration contains a carbon black reinforced tread base rubber layer underlying the intermedial tread rubber zone. The lateral tread rubber zones are therefore spaced apart from each other with the intermedial tread zone therebetween and also at least partially spaced apart from the tread base rubber layer with the intermedial tread zone therebetween. The tread includes a peripheral carbon black reinforced rubber layer as an extension of the tire sidewall which extends radially outward from the outer tire sidewall to thereby join a portion of a lateral tread zone which may extend to and include a portion of the running surface of the tread.

Owner:THE GOODYEAR TIRE & RUBBER CO

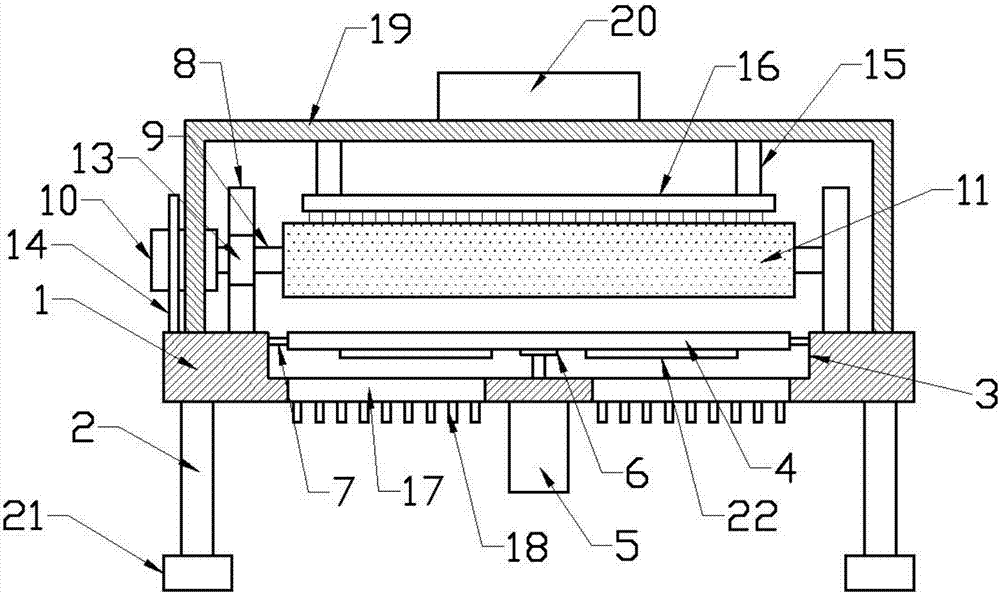

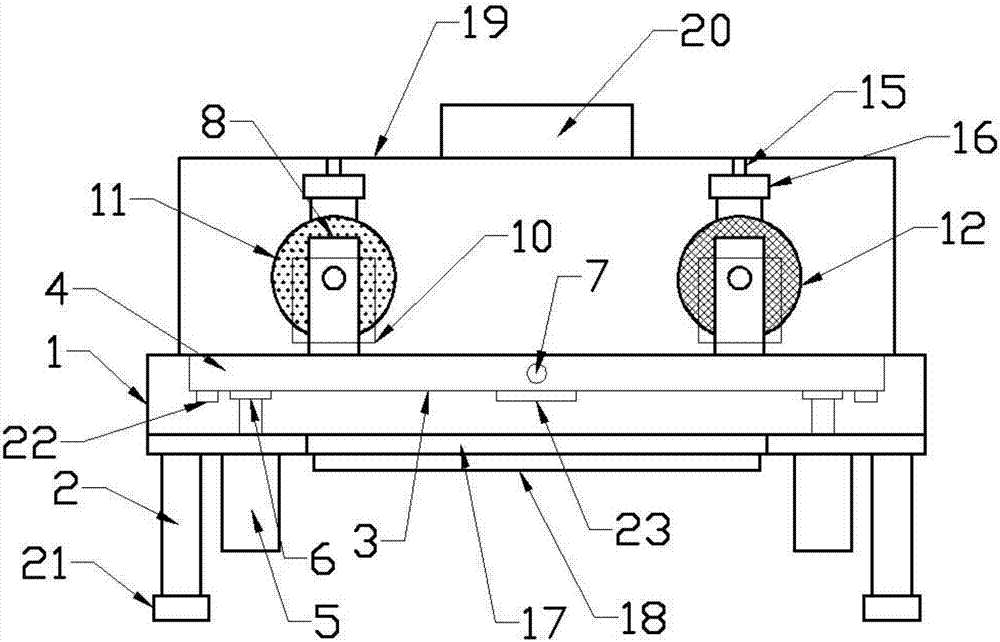

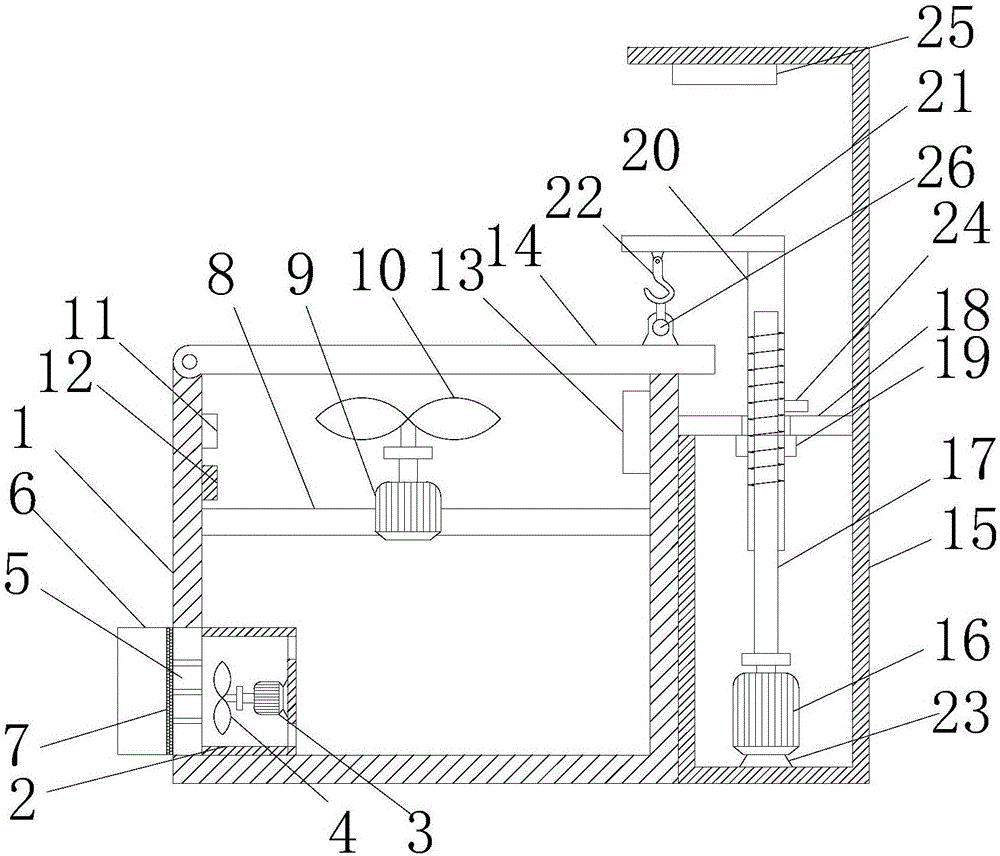

Rust removing and polishing device for steel plate machining

InactiveCN106881654AReduce the temperatureGuaranteed treatment effectEdge grinding machinesGrinding carriagesHydraulic cylinderPulp and paper industry

The invention discloses a rust removing and polishing device for steel plate machining. The rust removing and polishing device comprises a workbench, supporting legs, an adjusting plate, hydraulic cylinders and a motor. The adjusting plate is arranged in an installation groove. The two sides of the adjusting plate are rotationally connected to the side walls of the installation groove through a rotary shaft. The hydraulic cylinders are fixedly installed below the front end and the rear end of the adjusting plate. A horizontal polishing column and a rust removal roller are arranged above the adjusting plate. The workbench is covered with an outer cover. A brush plate is fixedly installed at the lower ends of supporting rods. A fan is installed at the top of the outer cover. According to the rust removing and polishing device, the adjusting plate is inclined by adjusting the hydraulic cylinders, so that the distance between the adjusting plate and the polishing column as well as the distance between the adjusting plate and the rust removal roller are adjusted, a steel pipe is polished and subjected to rust removal, the steel plate is pushed to move on the adjusting plate so that corresponding operation can be conducted, the labor intensity of workers is relieved, the processing efficiency of the steel plate is improved, the steel plate can be polished and subjected to rust removal through the device, the space in a plant is saved, and operation cost is reduced.

Owner:HEFEI ZHIHUI LONGTUTENG INTPROP CO LTD

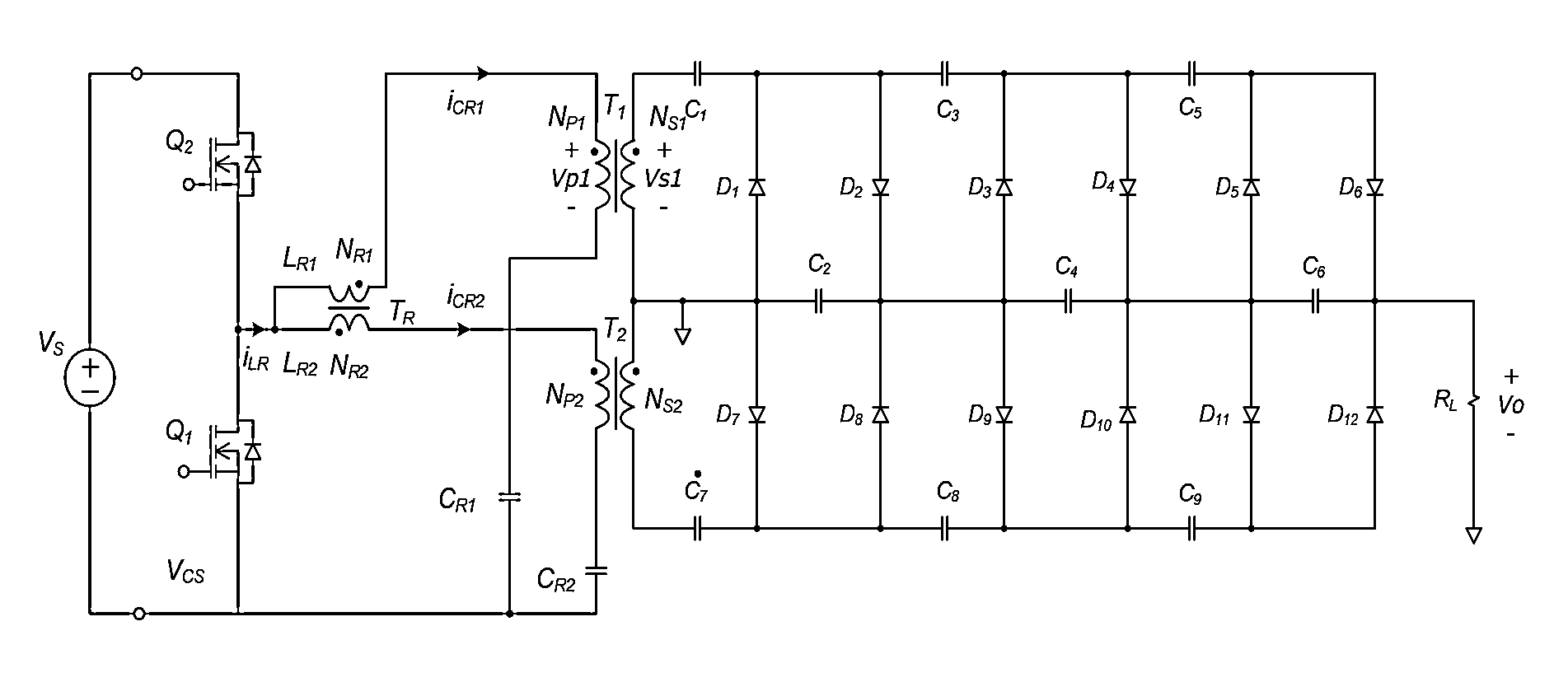

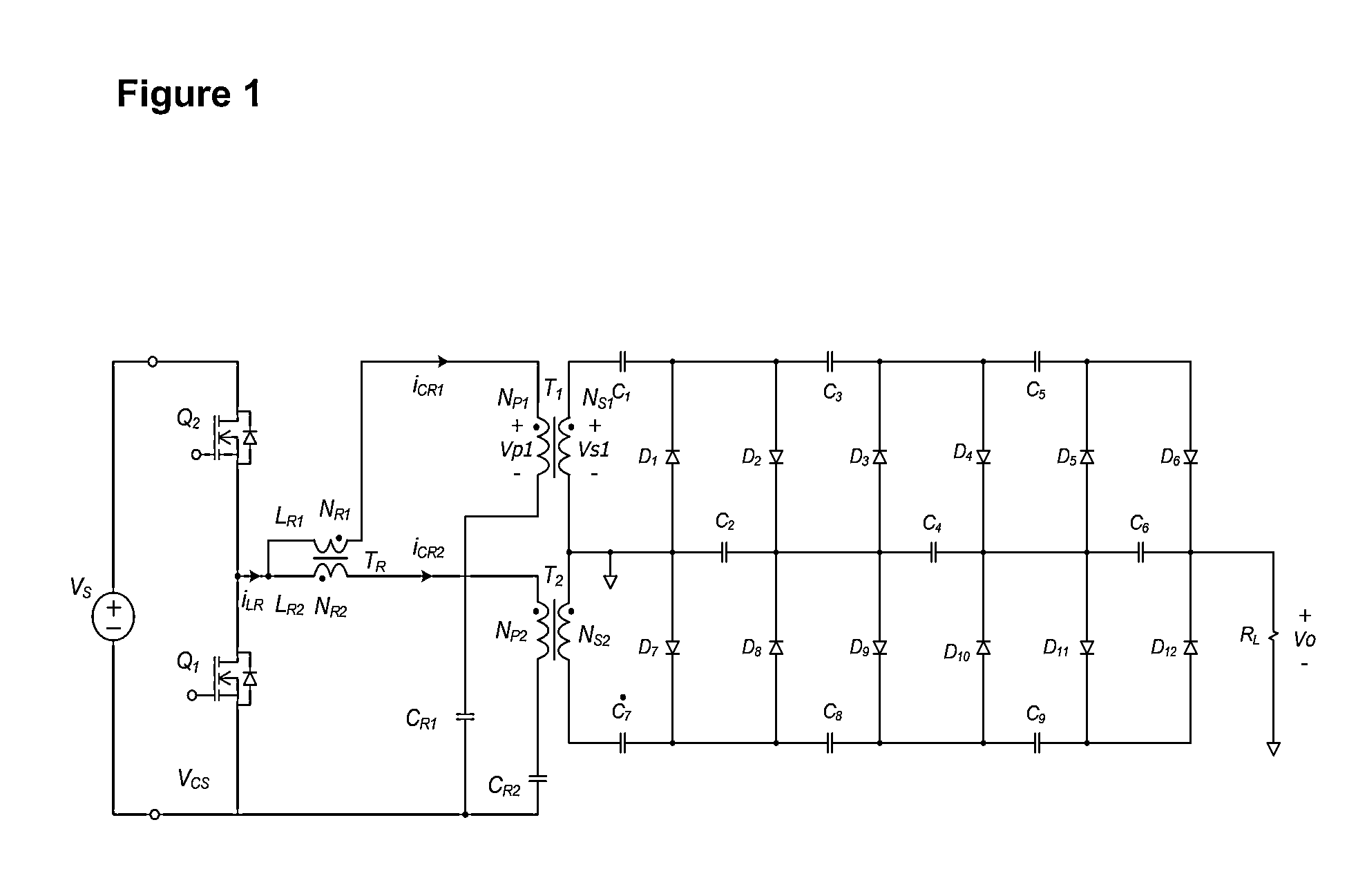

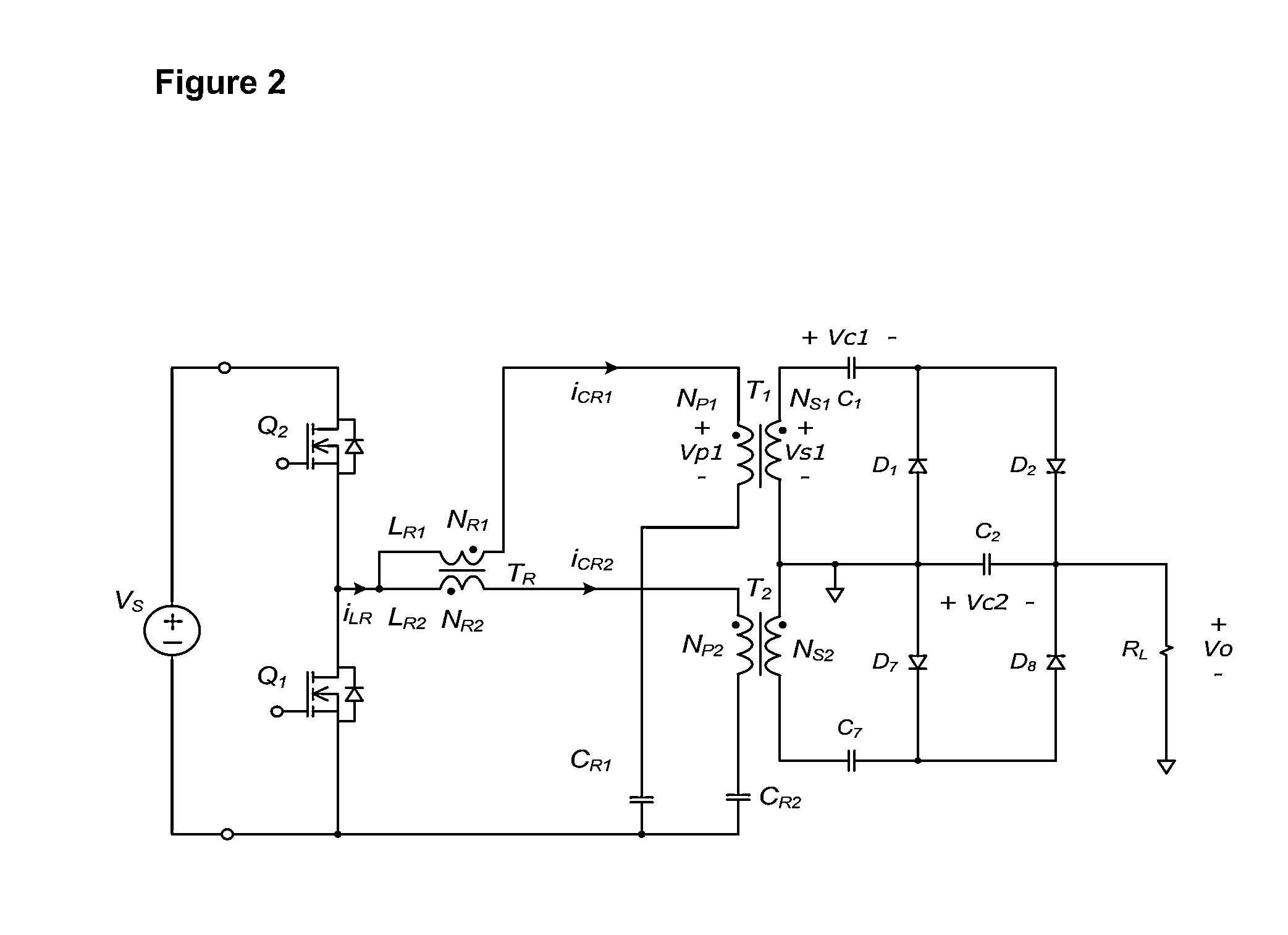

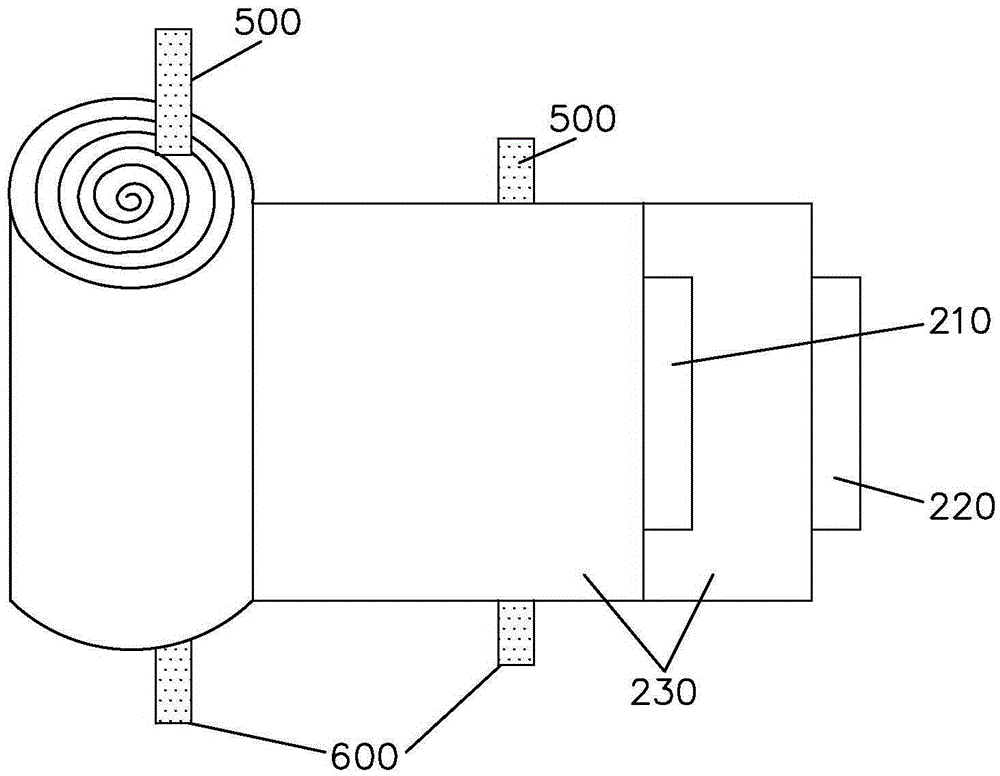

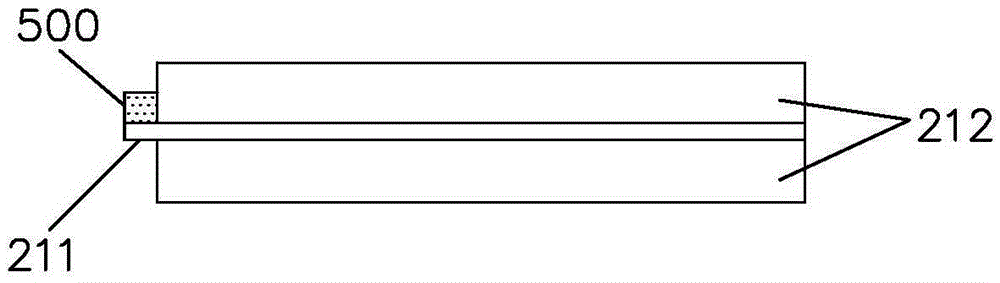

High voltage switching power supply

InactiveUS20140362616A1Reduce the overall heightThin structureAc-dc conversionApparatus with intermediate ac conversionResonanceHigh pressure

A dual resonance circuit is formed of two transformers, two resonance inductors and two resonance capacitors for a resonance type switching power supply employing parallel connected transformers. The secondary winding of the transformer is configured in a center tap structure, and a top and bottom symmetrical voltage multiplying rectifier is connected to the secondary winding coupled with the parallel connected transformers, thereby obtaining the same effect as when one transformer is used. The present invention achieves a low loss in the typical resonance type half bridge power supply even though two transformers are employed, and the switching power supply with a lowered height and thinned structure can be provided with the aid of the optimized arrangements of the resonance devices. The internal power loss can be lowered by using two parallel connected transformers as compared to a resonance type switching power supply which employs one transformer.

Owner:CHEONGJU UNIV IND & ACADEMY COOPERATION FOUND +1

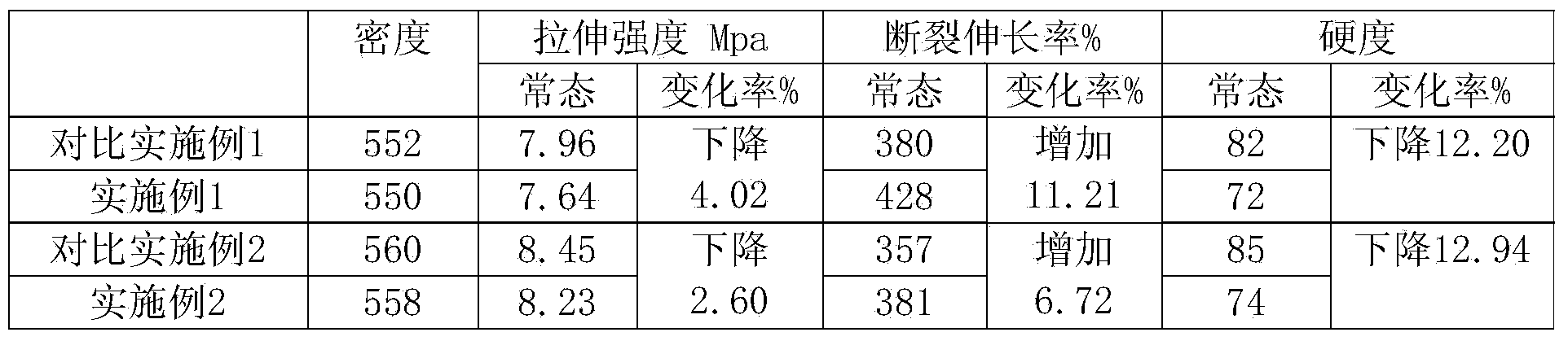

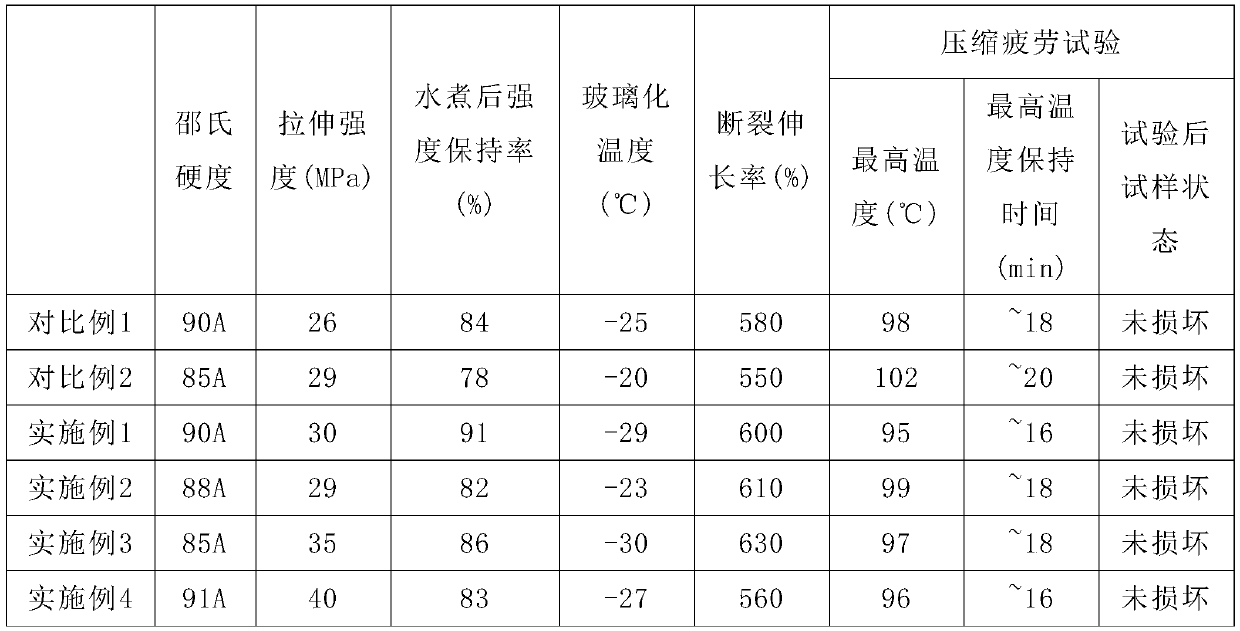

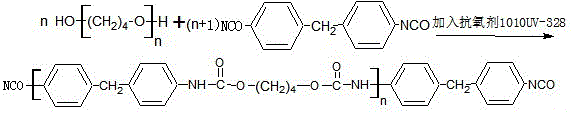

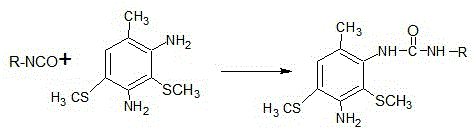

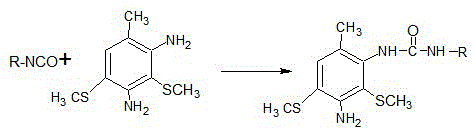

Formula used for synthesizing NDI-based polyurethane microcellular elastomer

The invention discloses a formula used for synthesizing an NDI-based polyurethane microcellular elastomer. The formula comprises, by weight, 100 parts of prepolymer, 3-5.5 parts of chain extender and 1.9-2.4 parts of compound catalysts. Compared with the prior art, the compound catalysts are adopted to increase reaction speed, and time needed for later curing is shortened. By means of reasonable selection of the formula and balancing of the ratios of components, on the premise that dynamic and static performance is not influenced, the advantages that hardness is low, plasticity is high and internally generated heat is little are kept, and the application range of a product is widened.

Owner:SHANGHAI NDI CHEM TECH

Reverse-polarity AlGaInP-based LED side wall coarsening method

InactiveCN104078535AAchieve sidewall rougheningImprove light extraction efficiencySemiconductor devicesQuantum efficiencyEngineering

The invention relates to a reverse-polarity AlGaInP-based LED side wall coarsening method. The method includes the following steps that (1) exposure and development are conducted on a mesa image epitaxial wafer of a reverse-polarity AlGaInP-based LED through an existing photolithographic process, and a constant periodicity edge figure is formed at the periphery of the mesa image epitaxial wafer; (2) the mesa image epitaxial wafer obtained after development in the step (1) is corroded through deionized water containing saturation Br2; (3) cleaning and photoresist removing are conducted on the mesa image epitaxial wafer after being corroded through the step (2) according to the conventional process, and coarsening side wall corresponding to the periodicity edge figure shape is formed. According to the reverse-polarity AlGaInP-based LED side wall coarsening method, the mode that coarsening of the side wall of the LED chip is achieved through the photolithographic technology is first proposed, the light extraction efficiency of the LED, especially the LED chip side face, is improved greatly compared with the prior art, the external quantum efficiency of LED devices is improved, internal heat is reduced, and the service life of the LED is prolonged.

Owner:SHANDONG INSPUR HUAGUANG OPTOELECTRONICS

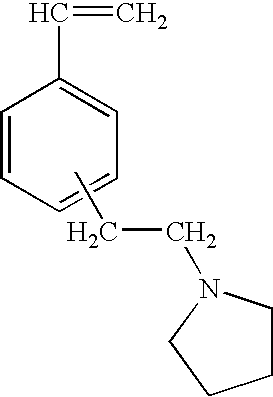

Rubber composition containing silica reinforcement and functionalized polybutadiene rubber and tires having a component thereof

ActiveUS8426512B2Reduce rolling resistanceReduce internal heatSpecial tyresInflatable tyresRolling resistanceEngineering

This invention relates to a silica reinforcement-containing rubber composition which contains a functionalized polybutadiene rubber to promote a relatively low hysteretic loss to thereby enhance its desirability for tire sidewall and subtread applications in a sense of advantageously promoting reduced tire rolling resistance without significantly compromising various other desirable tire performance parameters.

Owner:THE GOODYEAR TIRE & RUBBER CO

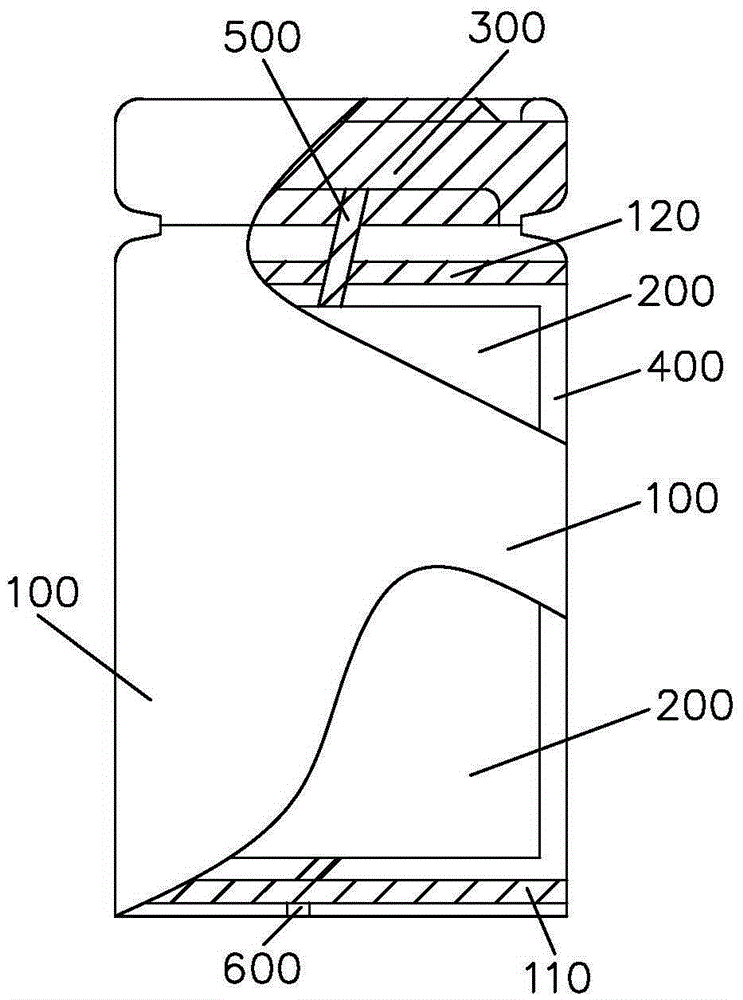

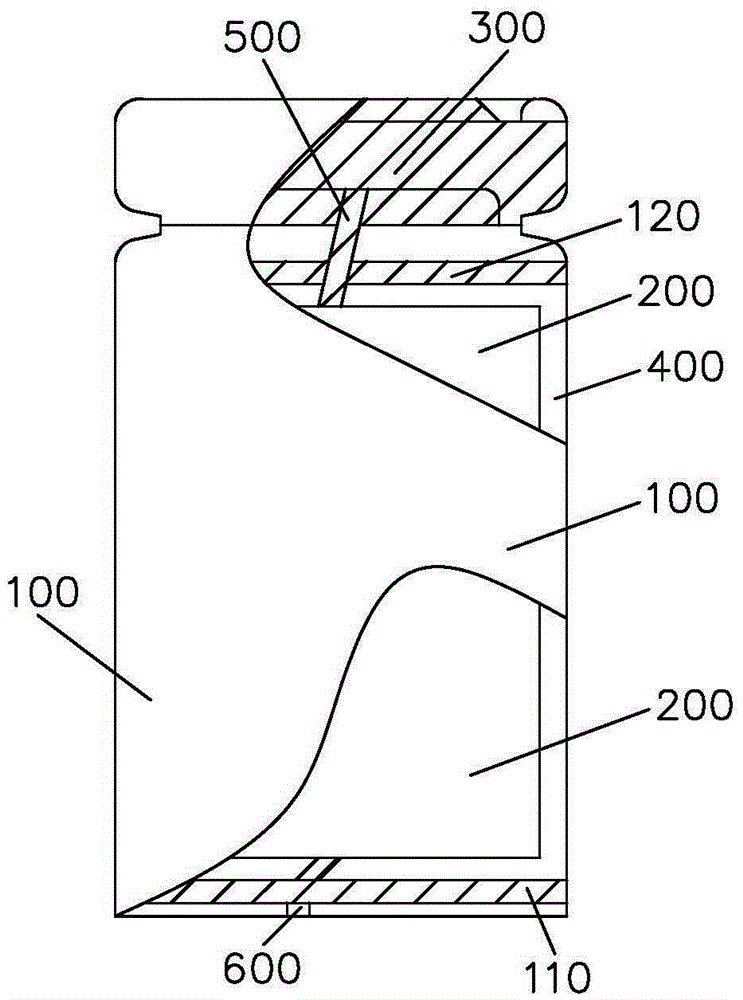

Graphene ultralow-temperature power lithium battery

ActiveCN105390695AImprove conductivityChange smoothing structureMaterial nanotechnologyCell electrodesLithium iron phosphateNanoparticle

The invention discloses a graphene ultralow-temperature power lithium battery. The power lithium battery comprises a battery case, a negative electrode insulation sheet, a battery cell, a positive electrode insulation sheet and a cap. The battery cell comprises a positive electrode plate, a negative electrode plate and a diaphragm. The positive electrode plate comprises a positive electrode current collector, and positive electrode material coatings arranged on two side surfaces of the positive electrode current collector respectively; each positive electrode material coating is prepared by coating the surface of the positive electrode current collector with a positive electrode material mixture; and the positive electrode material mixture contains a nanoparticle positive electrode material, a positive electrode binder, a positive electrode mixed conductive agent and a positive electrode solvent, wherein the nanoparticle positive electrode material is a lithium iron phosphate nanoparticle, and the positive electrode mixed conductive agent contains, by weight, 97-99 parts of a positive electrode conductive agent base material, 0.2-0.4 parts of graphene, 0.2-0.4 parts of SP and 0.2-0.4 parts of KS-6.

Owner:王立军

Polyurethane for CMP polishing pad and preparation method of polyurethane

The invention belongs to the technical field of polyurethane application, and particularly relates to polyurethane for a CMP polishing pad and a preparation method of the polyurethane. The polyurethane for the CMP polishing pad comprises a polyurethane prepolymer component A and a curing agent component B. The component A is composed of polymeric polyol A, diisocyanate and an anti-hydrolysis agent, and the component B is composed of an amine chain extender, polymeric polyol B, a hollow filler, a plasticizer and a catalyst. The structures of prepolymer molecules are arranged more regularly, andthe forming speed is high; the stability is good; the quality risk is reduced; the high-content prepolymer component does not crystallize at room temperature, has low initial viscosity, and has higher proportion when being mixed with the curing agent component, the uniform mixing is easier, consistency of hardness and uniformity after slicing of the prepared product is guaranteed, the breakage rate of electronic elements in the later polishing process is greatly reduced, and on the basis of micro-foaming, the hollow filler is added, so that the product has longer service life and storage lifeand good mechanical performance.

Owner:SHANDONG INOV POLYURETHANE

Polyurethane elastomer printing rubber roller and preparation method thereof

ActiveCN103483541AComponents with low viscosityImprove performanceRotary pressesPolyesterPolyurethane elastomer

The invention belongs to the technical field of organic polymer material products and in particular relates to a polyurethane elastomer printing rubber roller and a preparation method thereof. The polyurethane elastomer printing rubber roller is prepared from the following raw materials in parts by weight: 0.8-1.2 parts of polyalcohol, 0.25-0.4 part of polyisocyanate, 0.1-0.2 part of curing agent, and 0.00001 part of reaction control agent, wherein polyalcohol is polyester polyalcohol 218. The invention further provides the preparation method of the polyurethane elastomer printing rubber roller. The preparation method comprises the following steps of: preparing a prepolymer and a curing component at first; and pouring to obtain the polyurethane elastomer printing rubber roller. According to the invention, the processing technology is simplified, so that mixing, forming and vulcanizing of materials are integrated; the printing and dyeing rubber roller prepared by the invention is good in solvent resistance, easy for machining and good in elasticity; in the aspect of solvent resistance, the printing and dyeing rubber roller prepared by the invention is 2 times of other rubber rollers; the surface smoothness of the printing and dyeing rubber roller prepared by the invention can be up to the mirror state; the service life of the printing and dyeing rubber roller prepared by the invention is 2-3 times that of other rubber rollers; the service life of the general printing and dyeing rubber roller is 36 hours; and the service life of the printing and dyeing rubber roller prepared by the invention is about 80 hours.

Owner:淄博启明星新材料股份有限公司

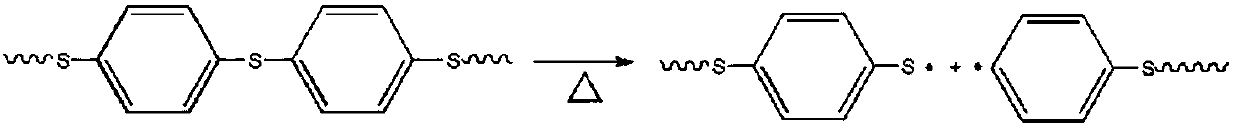

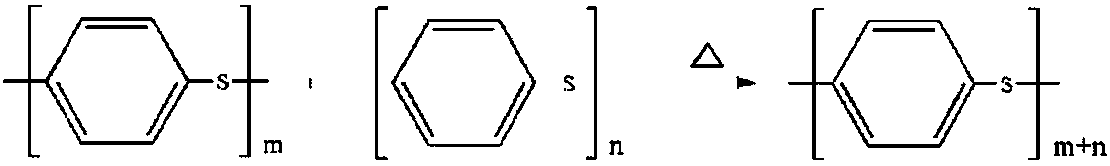

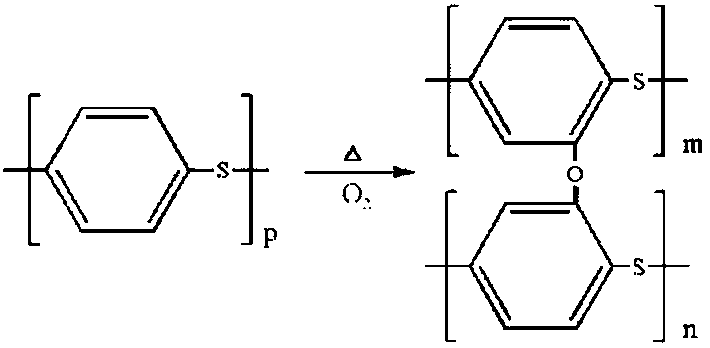

High-brightness polyphenylene sulfide alloy and preparation method thereof

InactiveCN108034249AWeaken or inhibit cross-linking reactionsImprove thermal stabilityHeat resistanceAntioxidant

The invention belongs to the technical field of high polymer composites, and particularly relates to a high-brightness polyphenylene sulfide alloy and a preparation method of the alloy. In order to solve the problems that a color of the existing high-brightness polyphenylene sulfide product is changed at high temperature and the color stability is poorer, the high-brightness polyphenylene sulfidealloy comprises the following materials by weight percentage: 30-40wt% of polyphenylene sulfide resin, 2-10wt% of heterogeneous resin, 17.5-57.1wt% of white inorganic mineral powder, 10-30wt% of glassfiber, 0.2-0.5wt% of an antioxidant, 0.4-1wt% of a coupling agent and 0.3-1wt% of a lubricant. A modified material is high in brightness and heat resistance and excellent in forming processability, and can be used for electric products, automobile structure parts and decoration materials.

Owner:SICHUAN COREMER CO LTD

Ice block removing device in refrigerator with reciprocating vibration mode

ActiveCN109297241AChange state of motionImprove adsorption capacityLighting and heating apparatusDefrostingEngineeringRefrigerated temperature

The invention provides an ice block removing device in a refrigerator with a reciprocating vibration mode, and relates to the field of articles for daily use. The ice block removing device in the refrigerator with the reciprocating vibration mode comprises a fixed left box, a reciprocating driving rod is arranged at the bottom of the fixed left box, the bottom of the reciprocating driving rod is adhered to the top of a side control fixed cylinder, the bottom of the side control fixed cylinder is adhered to the top of a connecting sucker, and a right box and a grabbing handle are adhered to theright side of the fixed left box. The ice block removing device in the refrigerator with the reciprocating vibration mode, after the connecting sucker is adsorbed on the ice surface, a driving motoris used for controlling a poking rod to be in contact with convex particles, so that the connecting sucker can continuously vibrate in a reciprocating mode after being connected with the ice blocks, the vibration force formed by vibration is used for gradually reducing the bonding force between the ice blocks and the inner wall of the refrigerator, so that the ice blocks can be removed conveniently, no force is applied to the refrigerator without being in contact with the refrigerator, so that the traditional mode of removing ice by scraping or heating is avoided, the damage to the refrigerator is avoided, and the service life of the refrigerator is guaranteed.

Owner:邵帅

Graphene modified lithium ion battery and manufacturing method therefor

ActiveCN105390738ALower resistanceImprove conductivityFinal product manufactureCell electrodesNanoparticleEngineering

The invention discloses a graphene modified lithium ion battery and a manufacturing method therefor. The battery comprises a battery case, a negative electrode insulation sheet, a positive electrode insulation sheet, a battery cell and a cap. The battery cell comprises a positive electrode plate, a negative electrode plate and a diaphragm. The positive electrode plate comprises a positive electrode current collector and a positive electrode material coating, wherein the positive electrode material coating is prepared by coating the surface of the positive electrode current collector with a positive electrode material mixture; and the positive electrode material mixture contains a nanoparticle positive electrode material, a positive electrode binder, a positive electrode mixed conductive agent and a positive electrode solvent. The negative electrode plate comprises a negative electrode current collector and a negative electrode material coating, wherein the negative electrode material coating is prepared by coating the surface of the negative electrode current collector with a negative electrode material mixture. The positive electrode mixed conductive agent contains, by weight, 97-99 parts of a positive electrode conductive agent base material, 0.2-0.4 parts of graphene, 0.2-0.4 parts of SP, 0.2-0.4 parts of KS-6.

Owner:王立军

Tire with rubber tread of intermedial and lateral zones with periperial sidewall extensions

ActiveUS9539860B2Reduce hysteresisReduce internal heatSpecial tyresTyre tread bands/patternsEngineeringReinforced rubber

The invention relates to a tire with circumferentially zoned tread including peripheral sidewall extensions. The tread zones are comprised of three circumferential load bearing zones, with each zone containing a portion of the running surface of the tread, comprised of an intermedial rubber zone positioned between and extending beneath two stratified lateral tread rubber zones and, in addition, peripheral sidewall extensions. The tread configuration contains a carbon black reinforced tread base rubber layer underlying the intermedial tread rubber zone. The lateral tread rubber zones are therefore spaced apart from each other with the intermedial tread zone therebetween and also at least partially spaced apart from the tread base rubber layer with the intermedial tread zone therebetween. The tread includes a peripheral carbon black reinforced rubber layer as an extension of the tire sidewall which extends radially outward from the outer tire sidewall to thereby join a portion of a lateral tread zone which may extend to and include a portion of the running surface of the tread.

Owner:THE GOODYEAR TIRE & RUBBER CO

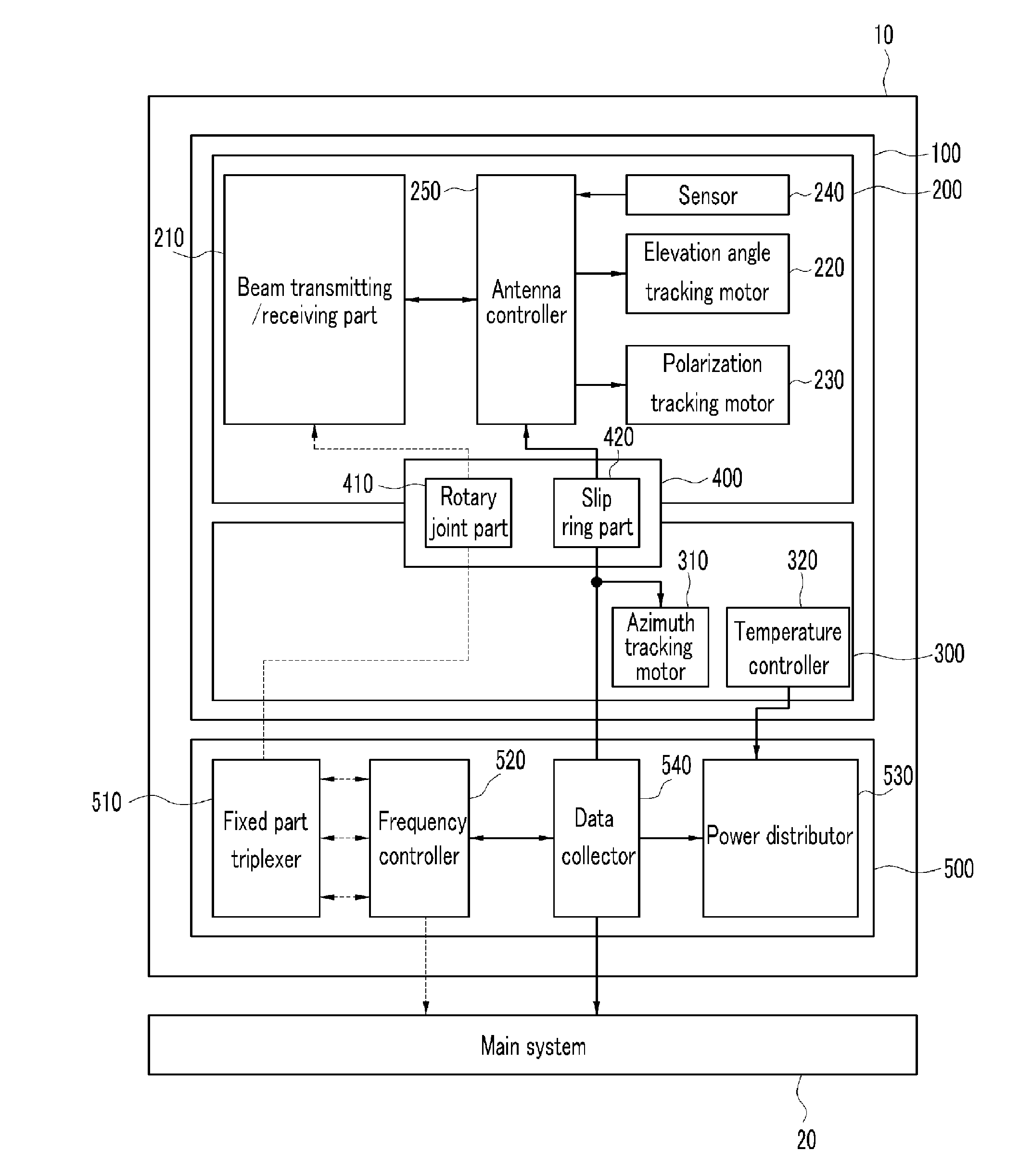

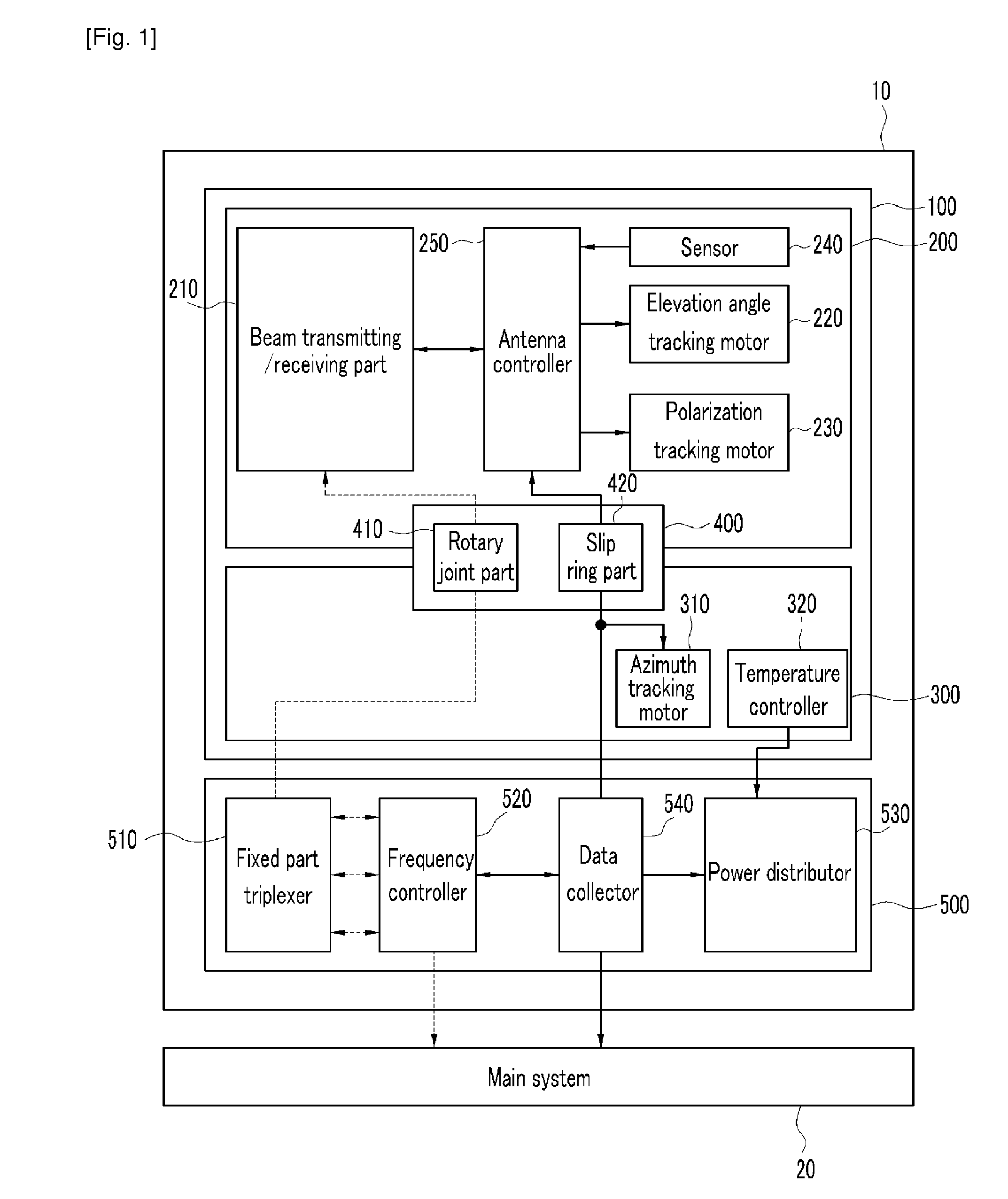

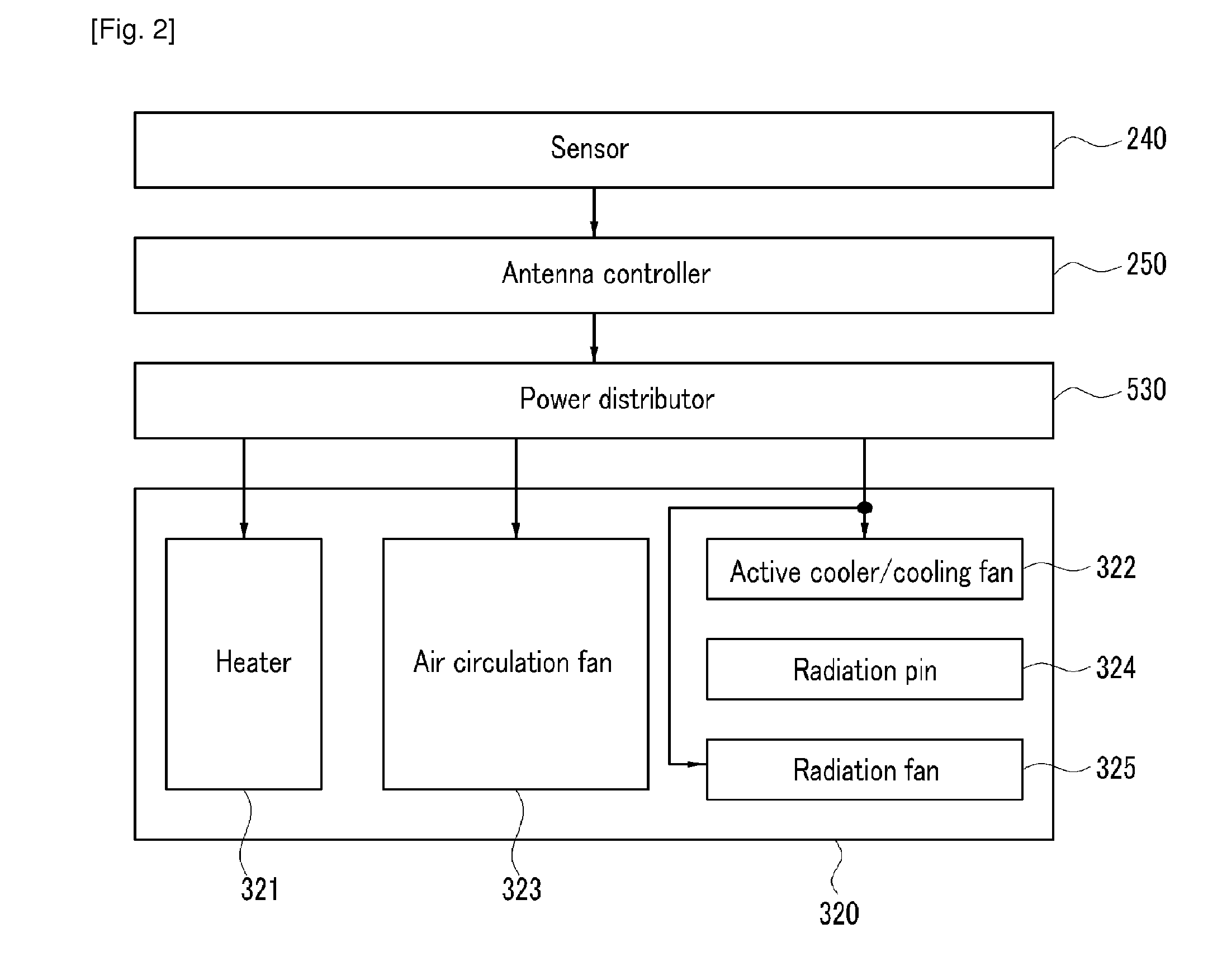

Antenna system for mobile vehicles

InactiveUS20100259443A1Small sizeReduce power consumptionAntenna adaptation in movable bodiesDisturbance protectionMobile vehicleActive cooling

The present invention relates to an antenna system mounted on a mobile vehicle. In the present invention, a power distributor and a part of a high-frequency module that includes a frequency converter are placed in an external fixed unit that is placed outside a radome. In addition, an active cooler / cooling fin, a heater, and an air circulation fan are placed at an internal bottom plane of the antenna system, and a cooling fin and cooling fan are placed at an external bottom plane of the antenna system.

Owner:ELECTRONICS & TELECOMM RES INST

1,5-naphthalene diisocyanate type polyurethane elastomer and preparation method and application thereof

InactiveCN107325261AImprove the degree of phase separationImprove mechanical propertiesPolyurethane elastomerHydroxyl value

The invention discloses a 1,5-naphthalene diisocyanate type polyurethane elastomer and a preparation method and application thereof. The 1,5-naphthalene diisocyanate type polyurethane elastomer comprises a component A and a component B, and the mass ratio of the component A to the component B is 100:21.5-22.5; the component A is prepared from, by weight, 100-105 parts of polycaprolactone polyol and 26-28 parts of polyisocyanates, the content of isocyanate groups of polycaprolactone polyol is 6% by mass, the hydroxyl value is 109-115 mg KOH / g, and the polyisocyanates is 1,5-naphthalene diisocyanate; the component B is prepared from, by weight, 60-65 parts of polycaprolactone polyol with the hydroxyl value being 109-115 mg KOH / g, 35-40 parts of 1,4-butanediol and 2 parts of organic tin catalyst; trundles manufactured from the elastomer can be used for high dynamic load and continuous high-speed running and heat resisting occasions, and can be adopted as heavy type high-end forklift driving wheels and bearing wheels, and the effect is remarkable.

Owner:杭州重力脚轮科技有限公司

Intelligent high-low voltage distribution switch cabinet

ActiveCN106786039AAchieve the effect of rotationTo achieve the effect of exhaust and heat dissipationSubstation/switching arrangement cooling/ventilationSubstation/switching arrangement casingsLow voltageEngineering

The invention discloses an intelligent high-low voltage distribution switch cabinet, and belongs to the technical field of distribution switch cabinets. The intelligent high-low voltage distribution switch cabinet comprises a cabinet body, wherein the bottom of the left side of an inner cavity of the cabinet body is fixedly connected with a motor case; the right side of the inner cavity of the motor case is fixedly connected with a first motor; an output shaft of the first motor is fixedly connected with a first fan; an exhaust hole is formed in the bottom of the left side of the cabinet body; the bottom of the left side of the cabinet body is fixedly connected with a blast blower; the middle part of the inner cavity of the cabinet body is fixedly connected with a cross bar; the middle part of the cross bar is fixedly connected with a second motor; and the output shaft of the second motor is fixedly connected with a second fan. Through coordination of the third motor and a threaded rod, the rotating effect of the threaded rod is achieved; through coordination of the threaded rod and a threaded bushing, so that the effect of adjusting up-and-down motion of the threaded bushing is achieved; and through coordination of the second motor and the second fan, the exhaust and heat dissipation effects of the second fan are finally achieved, the internal heat of the cabinet body is reduced, the work efficiency of equipment is improved and operation of a system is ensured.

Owner:合肥华义电气科技有限公司

Tire with rubber tread of intermedial and lateral zones with path of least electrical resistance

ActiveUS20160059634A1Reduce hysteresisReduce internal heatSpecial tyresTyre tread bands/patternsEngineeringSilicon dioxide

The invention relates to a tire having a rubber tread of a circumferentially zoned tread. The tread zones are comprised of three circumferential load bearing zones, with each zone containing a portion of the running surface of the tread, comprised of a silica-rich intermedial rubber zone positioned between and extending beneath two carbon black-rich lateral tread zones. The tread configuration contains an underlying carbon black-rich base rubber layer. The intermedial and stratified lateral zones are comprised of rubber compositions having differentiated rebound physical properties. A path of least electrical resistance extends from a lateral carbon black-rich rubber tread zone to the carbon black-rich tread base layer by an extension of a lateral tread zone or by an intermediate carbon black-rich rubber bridge.

Owner:THE GOODYEAR TIRE & RUBBER CO

Tire with circumferentially zoned tread including stratified lateral zones and peripheral sidewall extensions

ActiveUS9545823B2Significant degreeReduce hysteresisSpecial tyresTyre tread bands/patternsEngineeringTread

The invention relates to a tire having a rubber tread of a circumferentially zoned tread including stratified lateral tread zones and peripheral sidewall extensions. The tread zones are comprised of three circumferential load bearing zones, with each zone containing a portion of the running surface of the tread, comprised of an intermedial zone positioned between and two stratified lateral tread zones together and, in addition, peripheral sidewall extensions. The intermedial and stratified lateral zones are comprised of rubber compositions having differentiated 100° C. hot rebound physical properties. The intermedial rubber zone, or layer, overlays a tread base rubber layer and underlies the lateral tread layer zones. The lateral tread zones are stratified in a sense of being separated from each other and also separated from the from the tread base rubber layer by the intermedial rubber layer. The tread includes a peripheral carbon black rich rubber layer as a sidewall extension which extends radially outward from the outer tire sidewall to thereby join a portion of the peripheral tread zone rubber layer and extends to and includes a portion of the running surface of the tread.

Owner:THE GOODYEAR TIRE & RUBBER CO

Polyolefin polyol modified thermoplastic polyurethane elastomer and preparation method thereof

InactiveCN111057208AImprove dynamic mechanical propertiesImprove low temperature resistancePolyesterPolymer science

The invention discloses a polyolefin polyol modified thermoplastic polyurethane elastomer which comprises the following components in parts by weight: 20-30 parts of polyolefin polyol, 30-40 parts ofpolyester / ether polyol, 20-40 parts of diisocyanate, and 5-20 parts of a chain extender. The invention also discloses a preparation method of the polyolefin polyol modified thermoplastic polyurethaneelastomer. The material provided by the invention has the advantages of excellent wear resistance, high hardness, rich elasticity, good mechanical strength, excellent oil resistance and excellent oxidation resistance of a thermoplastic polyurethane elastomer, and also has the characteristics of excellent low-temperature performance, excellent hydrolysis resistance and small dynamic heat generationof polyolefin rubber.

Owner:SHANGHAI HUIDE TECH CO LTD

Polyurethane elastomer for fine wear-resistant screen mesh and preparation method of polyurethane elastomer

The invention relates to a polyurethane elastomer for a fine wear-resistant screen mesh and a preparation method of the polyurethane elastomer. The polyurethane elastomer disclosed by the invention is characterized in that a nano-silicon powder additive is added in a reaction process; the average particle diameter of nano-silicon powder in the additive is smaller than or equal to 200 nm; free diisocyanate in a prepolymer is effectively removed by utilization of a scraper film evaporator at a later stage of prepolymer synthesis; the weight content of the diisocyanate is smaller than 0.1 percent; an antioxidant and an ultraviolet stabilizing agent are reasonably added. The preparation method has the advantages that the reaction tends to be reasonable; the prepared polyurethane elastomer has the features of regular molecular chain structure, low viscosity, little smell, excellent mechanical property and excellent operation property; the abrasion resistance of the polyurethane elastomer is obviously higher than that of the conventional elastomer, the internally produced heat can be effectively reduced, and the polyurethane elastomer is especially suitable for being used in a high-frequency vibration environment.

Owner:WEIHAI HAIWANG HYDROCYCLONE

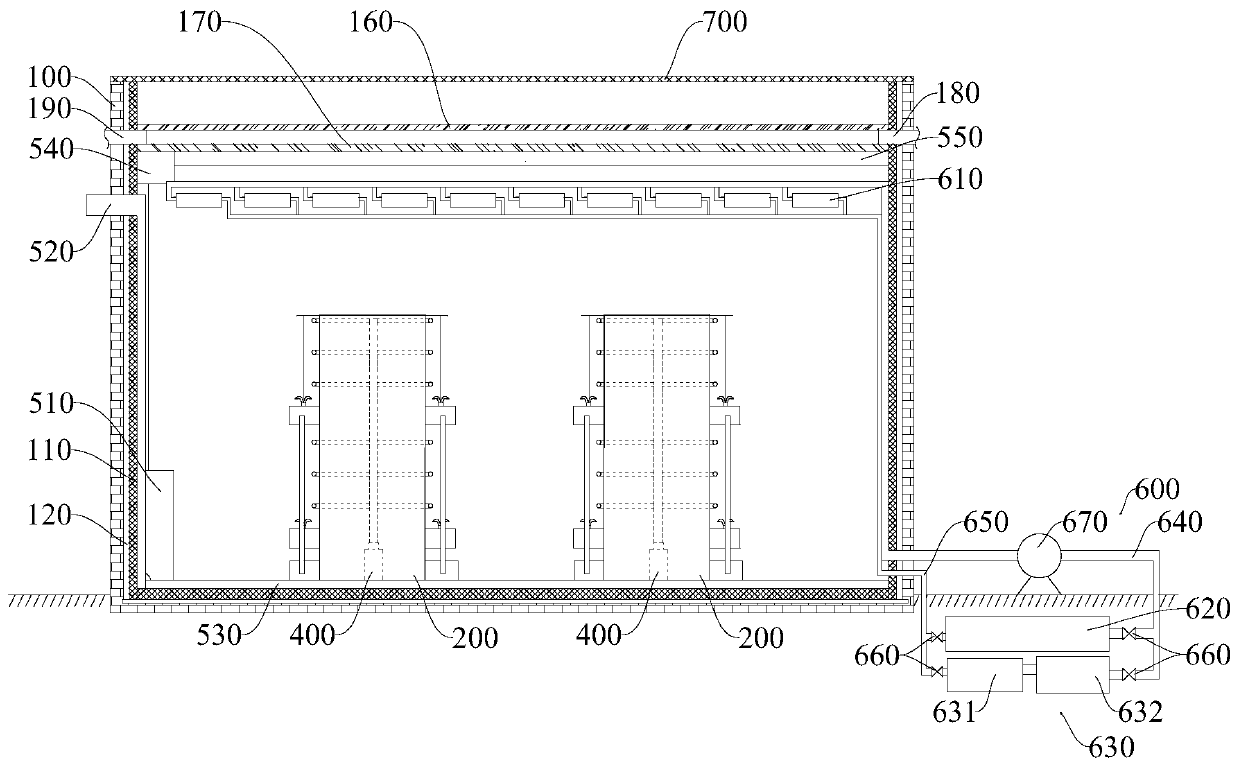

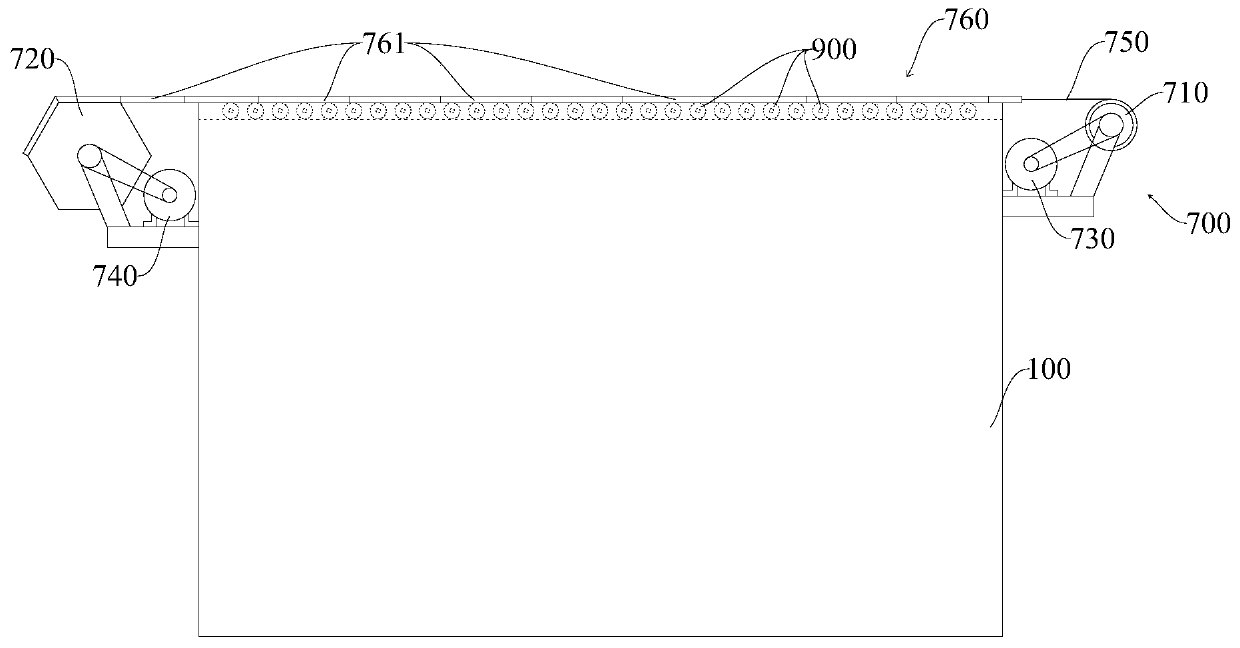

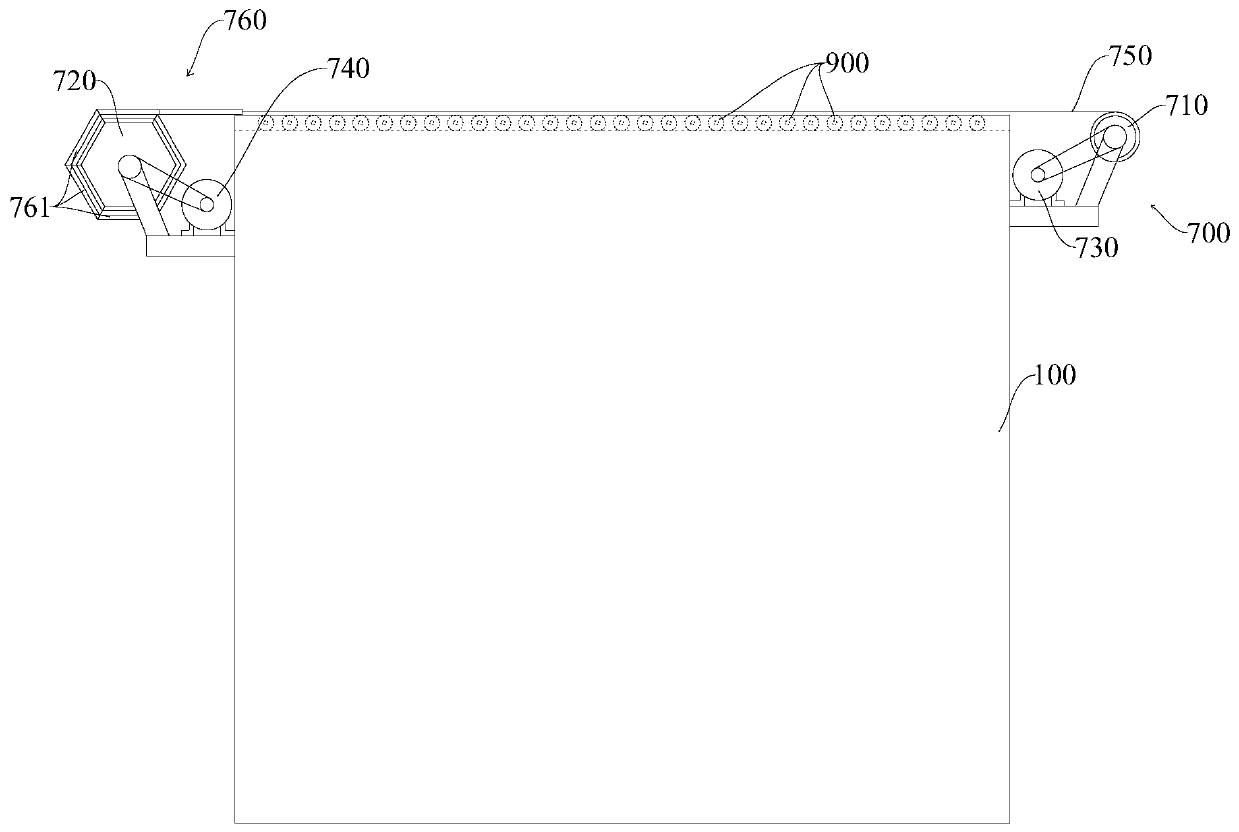

Solar and energy-saving type plant factory

PendingCN110214598AReduce artificial lightReduce energy consumption and internal heatClimate change adaptationSaving energy measuresExhaust gasFlue

The invention provides a solar and energy-saving type plant factory and belongs to the technical field of plant factories. The solar and energy-saving type plant factory comprises a factory building,LOW-E (low-emissivity) glass and high-scattering glass, wherein the top of the factory building is provided with an openable automatic roll-up roof system; the LOW-E glass is arranged at the top inside the factory building and under the automatic roll-up roof system; the side walls of the LOW-E glass are connected with the side walls of the factory building; the high-scatting glass is arranged atthe top inside the factory building and under the LOW-E glass; the side walls of the high-scattering glass are in closed connection with the side walls of the factory buildings to enclose a closed planting area; the high-scatting glass and the LOW-E glass are arranged in parallel to define an air flue, one end of the air flue is provided with a cold air device for blowing cold air into the air flue, and the other end of the air flue is provided with a induced draft device for exhausting gas inside the air flue out of the factory building. The solar and energy-saving type plant factory can effectively avoid phenomena inside the factory such as pests and diseases and non-uniformity of applied pesticides, temperature, humidity and concentration of carbon dioxide, thereby ensuring good plant growth.

Owner:刘书元

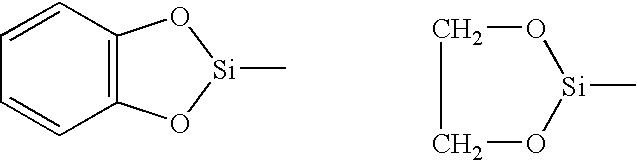

Rubber compositions comprising two different coupling agents and also inorganic fillers

InactiveUS20090215952A1Improved hysteresis propertyImprove the coupling effectSolesSpecial tyresElastomerPolymer science

Elastomer isoprene rubber compositions contain an effective amount of a polyfunctional coupling system (A) as an inorganic-elastomer filler coupling agent, and (B) at least one elastomer of natural or synthetic rubber; (C) an inorganic filler as reinforcing filler; (D) other conventional constituents or additives comprising one or more vulcanizing agent(s), the polyfunctional coupling system being of the constituents (A1) and (A2): (A1) is at least one coupling agent selected from among the functionalized organosilicon compounds of formula (I): [(G0)3SiO1 / 2]m [(G0)2SiO2 / 2]n [G0SiO3 / 2]o [SiO4 / 2]p [(G2)a(G1)a′(Z-CO—N═N—CO-A)SiO(3-a-a′) / 2]q and (A2) is at least one coupling agent selected among polysulfurated “symmetric” silanes, or sulfurated “asymmetric” silanes.

Owner:RHODIA CHEM SA

Tire with rubber tread of intermedial and peripheral stratified zones

InactiveUS20160059632A1Reduce hysteresisReduce internal heatSpecial tyresInflatable tyresEngineeringLoad bearing

The invention relates to a tire having a rubber tread of a circumferentially zoned tread including stratified lateral tread zones. The tread zones are comprised of three circumferential load bearing zones, with each zone containing a portion of the running surface of the tread, comprised of an intermedial zone positioned between and two stratified lateral tread zones. The intermedial and stratified lateral zones are comprised of rubber compositions having differentiated rebound physical properties. The intermedial rubber zone, or layer, overlays a tread base rubber layer and underlies the lateral tread layer zones. The lateral tread zones are stratified in a sense of being separated from each other and also separated from the from the tread base rubber layer by the intermedial rubber layer. The stratified lateral tread zones are peripheral tread zones, or layers.

Owner:THE GOODYEAR TIRE & RUBBER CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com