Polyurethane elastomer for fine wear-resistant screen mesh and preparation method of polyurethane elastomer

A polyurethane elastomer and screen technology, which is applied in the field of materials, can solve the problems of limiting the popularization and application of polyurethane fine screens, reduced wear resistance, large deformation rate, etc., and achieves excellent mechanical properties and operational performance, long service life, and mechanical performance lasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

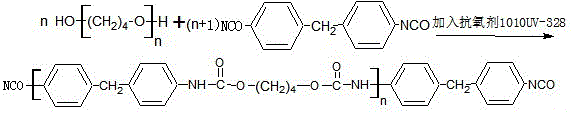

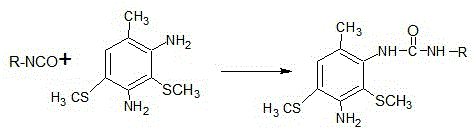

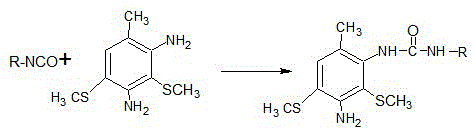

[0023] A polyurethane elastomer for fine wear-resistant screens, which is prepared from a prepolymer synthesized from polyether polyol and diisocyanate after curing and vulcanization. The prepolymer contains nano-scale potassium aluminum silicate powder with a particle size of 50-200nm , nano-scale potassium aluminum silicate powder is added to the prepolymer in the form of nano-potassium aluminum silicate additives, and the weight of nano-scale potassium aluminum silicate powder in the additives accounts for 30%-50% by weight of the weight of the organic solvent. The additive amount of the agent accounts for 10%-20% by weight of the weight of the prepolymer, and the free diisocyanate weight content in the prepolymer is lower than 0.1% by weight. The prepolymer also contains antioxidant 1010, and its chemical name is: four [β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester and UV stabilizer UV-328, chemical name: 2(2-hydroxy-3,5-di-tert-butyl Phenyl)-5-ch...

Embodiment 2

[0037] A polyurethane elastomer for fine wear-resistant screens, which is prepared from a prepolymer synthesized from polyether polyol and diisocyanate after curing and vulcanization. The prepolymer contains nano-scale potassium aluminum silicate powder with a particle size of 50-200nm , nano-scale potassium aluminum silicate powder is added to the prepolymer in the form of nano-potassium aluminum silicate additives, and the weight of nano-scale potassium aluminum silicate powder in the additives accounts for 30%-50% by weight of the weight of the organic solvent. The additive amount of the agent accounts for 10%-20% by weight of the weight of the prepolymer, and the free diisocyanate weight content in the prepolymer is lower than 0.1% by weight. The prepolymer also contains antioxidant 1010, and its chemical name is: four [β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester and UV stabilizer UV-328, chemical name: 2(2-hydroxy-3,5-di-tert-butyl Phenyl)-5-ch...

Embodiment 3

[0050] A polyurethane elastomer for fine wear-resistant screens, which is prepared from a prepolymer synthesized from polyether polyol and diisocyanate after curing and vulcanization. The prepolymer contains nano-scale potassium aluminum silicate powder with a particle size of 50-200nm , nano-scale potassium aluminum silicate powder is added to the prepolymer in the form of nano-potassium aluminum silicate additives, and the weight of nano-scale potassium aluminum silicate powder in the additives accounts for 30%-50% by weight of the weight of the organic solvent. The additive amount of the agent accounts for 10%-20% by weight of the weight of the prepolymer, and the free diisocyanate weight content in the prepolymer is lower than 0.1% by weight. The prepolymer also contains antioxidant 1010, and its chemical name is: four [β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester and UV stabilizer UV-328, chemical name: 2(2-hydroxy-3,5-di-tert-butyl Phenyl)-5-ch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com