Wood splicing adhesive

A technology of splicing glue and styrene-acrylic emulsion, applied in the field of splicing glue, can solve problems such as inability to meet indoor use, potential safety hazards, complicated production process, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

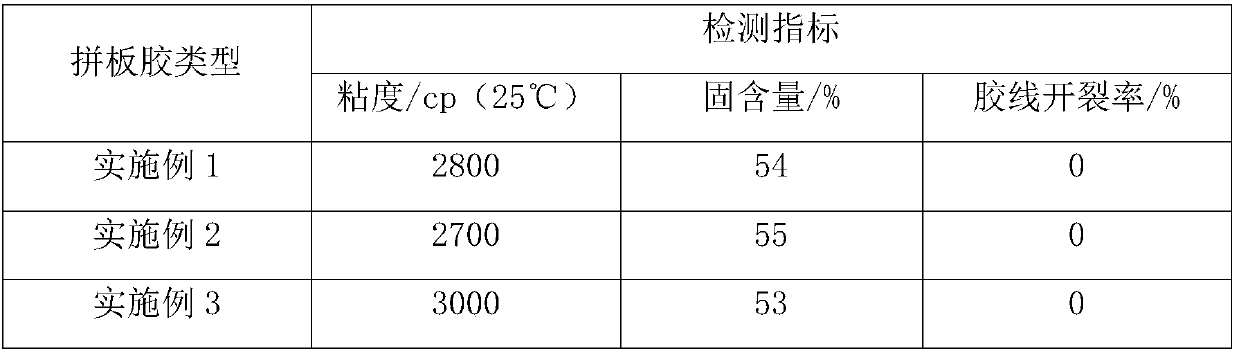

Embodiment 1

[0037]A jigsaw glue, the composition ratio of jigsaw glue is: styrene-acrylic emulsion 25%, heavy calcium 25%, polyvinyl alcohol emulsion 16.5%, vinegar-acrylic emulsion 12.5%, vinyl acetate-ethylene copolymer emulsion 12.5%, water 7.62% , 0.8% dibutyl diformate, 0.08% defoamer. Wherein, the fineness of the heavy calcium is 2000 mesh, and the solid content of the polyvinyl alcohol emulsion is 17%.

[0038] The preparation method of jigsaw glue, comprises the following steps:

[0039] (1) According to the above ratio, water, styrene-acrylic emulsion, polyvinyl alcohol emulsion, vinegar-acrylic emulsion and vinyl acetate-ethylene copolymer emulsion are added into the stirred reactor, and the mixed solution is obtained after stirring;

[0040] (2) Slowly and evenly add heavy calcium, plasticizer and defoamer to the mixed solution in step (1) according to the above proportioning ratio, and stir evenly to obtain a jigsaw glue with a solid content of 54%.

[0041] In the above sch...

Embodiment 2

[0058] A kind of jigsaw glue, the composition ratio of jigsaw glue is: 20% of styrene-acrylic emulsion, 26.5% of heavy calcium, 20% of polyvinyl alcohol emulsion, 12.5% of vinegar-acrylic emulsion, 12.5% of vinyl acetate-ethylene copolymer emulsion, and 7.62% of water , 0.8% dibutyl diformate, 0.08% defoamer. Wherein, the fineness of the heavy calcium is 2000 mesh, and the solid content of the polyvinyl alcohol emulsion is 17%.

[0059] The preparation method of jigsaw glue, comprises the following steps:

[0060] (1) According to the above ratio, water, styrene-acrylic emulsion, polyvinyl alcohol emulsion, vinegar-acrylic emulsion and vinyl acetate-ethylene copolymer emulsion are added into the stirred reactor, and the mixed solution is obtained after stirring;

[0061] (2) Slowly and uniformly add heavy calcium, plasticizer and defoamer to the mixed solution in step (1) according to the above proportioning, and stir evenly to obtain a jigsaw glue with a solid content of...

Embodiment 3

[0064] A jigsaw glue, the composition ratio of jigsaw glue is: styrene-acrylic emulsion 30%, heavy calcium 23.5%, polyvinyl alcohol emulsion 13%, vinegar-acrylic emulsion 12.5%, vinyl acetate-ethylene copolymer emulsion 12.5%, water 7.62% , 0.8% dibutyl diformate, 0.08% defoamer. Wherein, the fineness of the heavy calcium is 2000 mesh, and the solid content of the polyvinyl alcohol emulsion is 17%.

[0065] The preparation method of jigsaw glue, comprises the following steps:

[0066] (1) According to the above ratio, water, styrene-acrylic emulsion, polyvinyl alcohol emulsion, vinegar-acrylic emulsion and vinyl acetate-ethylene copolymer emulsion are added into the stirred reactor, and the mixed solution is obtained after stirring;

[0067] (2) Slowly and evenly add heavy calcium, plasticizer and defoamer to the mixed solution in step (1) according to the above proportioning ratio, and stir evenly to obtain a jigsaw glue with a solid content of 53%.

[0068] The ratio of ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com