Corrosion-resistant and antistatic coating material and preparation method thereof

A coating material and antistatic technology, applied in the field of anti-corrosion and anti-static coating materials and their preparation, can solve problems such as the inability to meet anti-static and anti-corrosion requirements, achieve excellent electronic conductivity, improve dispersibility, and excellent salt spray resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

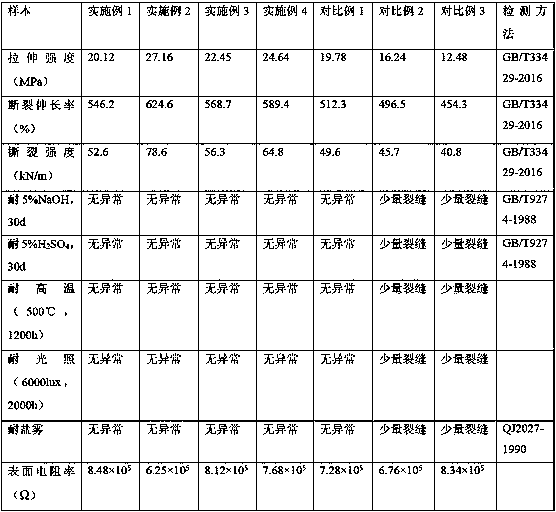

Examples

Embodiment 1

[0021] An anti-corrosion and anti-static coating material, prepared from the following raw materials in parts by weight: 20 parts of epoxy-modified acrylate, 10 parts of polyaniline, 11 parts of polycarbonate, acrylonitrile-butadiene-styrene copolymer 8 parts, 7 parts of polyethylene terephthalate, 6 parts of carbon nanotubes, 4 parts of silane coupling agent, 3 parts of hexadecyltrimethylammonium bromide, polyethylene glycol octyl phenyl ether 2 parts, 3 parts of acryloyloxyethyltrimethylammonium chloride, 2 parts of polyepoxysuccinic acid, 5 parts of anti-corrosion and antistatic pigments, 1 part of film-forming agent, 1 part of leveling agent, and 0.5 parts of defoamer.

[0022] The anti-corrosion and antistatic pigment is epoxy zinc phosphate, tin antimony oxide, graphene oxide and oxide-coated titanium dioxide with a mass ratio of 1:1:1:2, and the oxide-coated titanium dioxide is silicon Titanium dioxide coated with aluminum oxide, the molar ratio of silicon to aluminum i...

Embodiment 2

[0030] An anti-corrosion and anti-static coating material, prepared from the following raw materials in parts by weight: 35 parts of epoxy-modified acrylate, 15 parts of polyaniline, 15 parts of polycarbonate, acrylonitrile-butadiene-styrene copolymer 12 parts, 11 parts of polyethylene terephthalate, 9 parts of carbon nanotubes, 6 parts of silane coupling agent, 5 parts of cetyltrimethylammonium bromide, polyethylene glycol octyl phenyl ether 4 parts, 5 parts of acryloyloxyethyltrimethylammonium chloride, 3.5 parts of polyepoxysuccinic acid, 7.5 parts of anti-corrosion and antistatic pigments, 1.5 parts of film-forming agent, 2 parts of leveling agent, 7 parts of dispersant, disinfectant Foam agent 1.5 parts.

[0031] The anticorrosion and antistatic pigment is epoxy zinc phosphate, tin antimony oxide, graphene oxide and oxide-coated titanium dioxide with a mass ratio of 1:2:2.5:3.

[0032] The oxide-coated titanium dioxide is silicon-aluminum oxide-coated titanium dioxide, w...

Embodiment 3

[0040]An anti-corrosion and anti-static coating material, prepared from the following raw materials in parts by weight: 30 parts of epoxy-modified acrylate, 12 parts of polyaniline, 13 parts of polycarbonate, acrylonitrile-butadiene-styrene copolymer 10 parts, 7-15 parts of polyethylene terephthalate, 8 parts of carbon nanotubes, 5 parts of silane coupling agent, 4 parts of hexadecyltrimethylammonium bromide, polyethylene glycol octylbenzene 3 parts of base ether, 4 parts of acryloyloxyethyltrimethylammonium chloride, 3 parts of polyepoxysuccinic acid, 6 parts of anti-corrosion and antistatic pigment, 1.2 parts of film-forming agent, 1.5 parts of leveling agent, and 1 part of defoamer share.

[0041] The anticorrosion and antistatic pigment is zinc epoxy phosphate, tin antimony oxide, graphene oxide and oxide-coated titanium dioxide with a mass ratio of 1:1.5:2:2.5, and the oxide-coated titanium dioxide is silicon Titanium dioxide coated with aluminum oxide, wherein the molar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com