Halogen-free flame-retardant wood-plastic co-extrusion composite material and preparation method thereof

A composite material and wood-plastic technology, applied in the direction of wood layered products, chemical instruments and methods, synthetic resin layered products, etc., can solve the problems of poor flame retardancy, high flame retardancy and mechanical properties, and low production energy consumption. problem, to achieve good wear resistance, good flame retardant effect, and low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

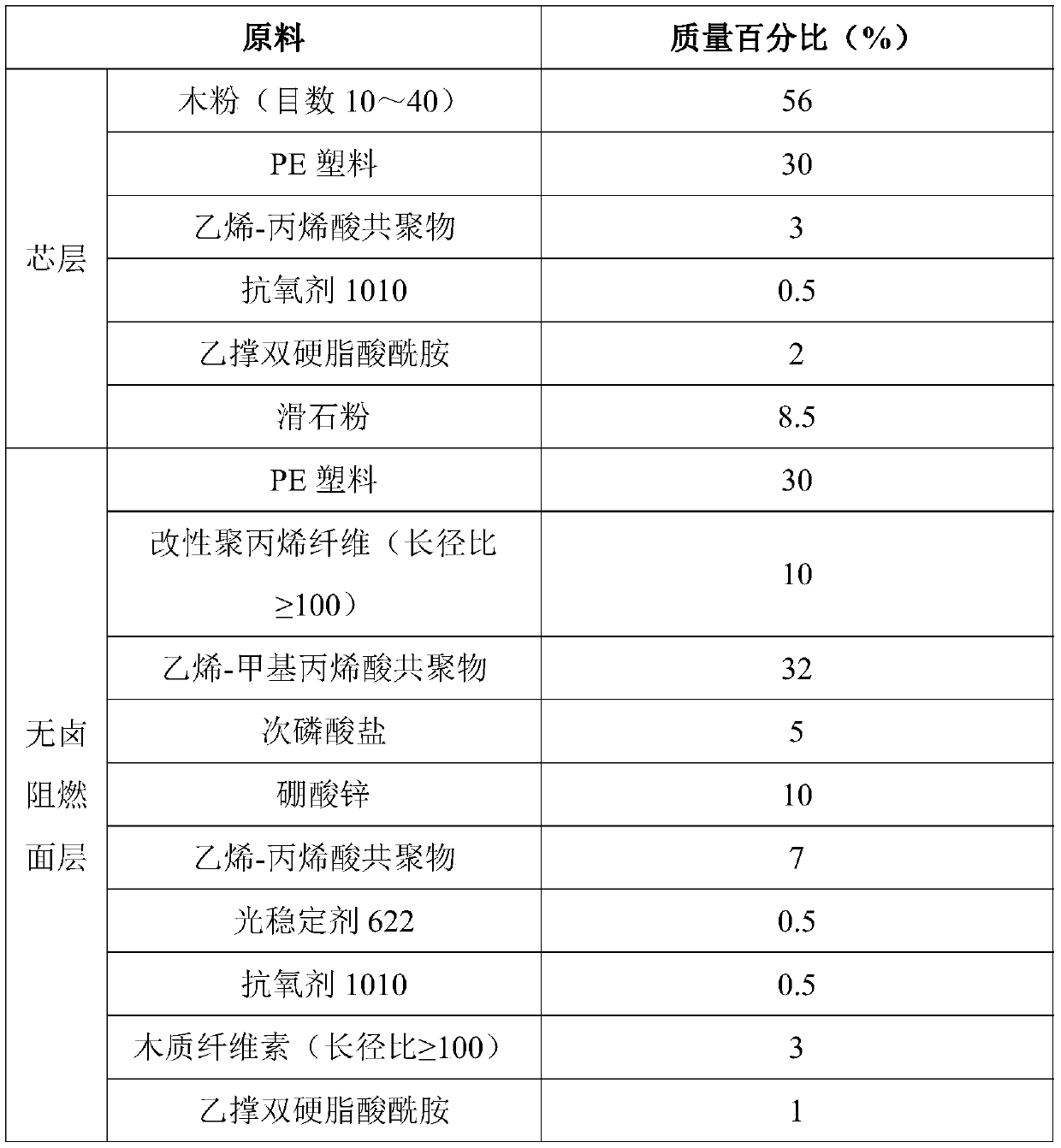

[0073] A halogen-free flame-retardant wood-plastic co-extrusion composite material, which consists of a core layer and a halogen-free flame-retardant surface layer. The composition of the core layer and the halogen-free flame-retardant surface layer is shown in the following table:

[0074] Table 1 Composition of the core layer and the halogen-free flame-retardant surface layer of a halogen-free flame-retardant wood-plastic co-extruded composite material

[0075]

[0076]

[0077] The preparation method of the above-mentioned halogen-free flame-retardant wood-plastic co-extruded composite material comprises the following steps:

[0078] 1) Preparation of core layer granules: fully dry the wood powder, then add wood powder, PE plastic, ethylene-acrylic acid copolymer, antioxidant 1010, ethylene bis stearic acid amide and talcum powder into a high-speed mixer, and carry out High-speed blending, and then the obtained blend is added to the granulation production line for mel...

Embodiment 2

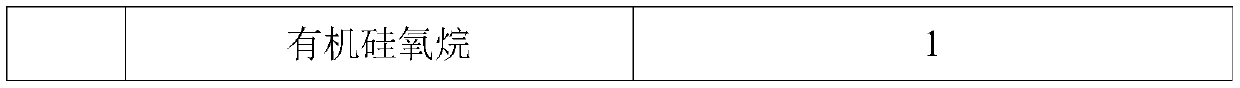

[0082] A halogen-free flame-retardant wood-plastic co-extrusion composite material, which consists of a core layer and a halogen-free flame-retardant surface layer. The composition of the core layer and the halogen-free flame-retardant surface layer is shown in the following table:

[0083] Table 2 Composition of the core layer and the halogen-free flame-retardant surface layer of a halogen-free flame-retardant wood-plastic co-extruded composite material

[0084]

[0085]

[0086] The preparation method of the above-mentioned halogen-free flame-retardant wood-plastic co-extruded composite material comprises the following steps:

[0087] 1) Preparation of core layer granules: fully dry the wood powder, then add wood powder, PE plastic, ethylene-acrylic acid copolymer, antioxidant 1010, ethylene bis stearic acid amide and talcum powder into a high-speed mixer, and carry out High-speed blending, and then the obtained blend is added to the granulation production line for mel...

Embodiment 3

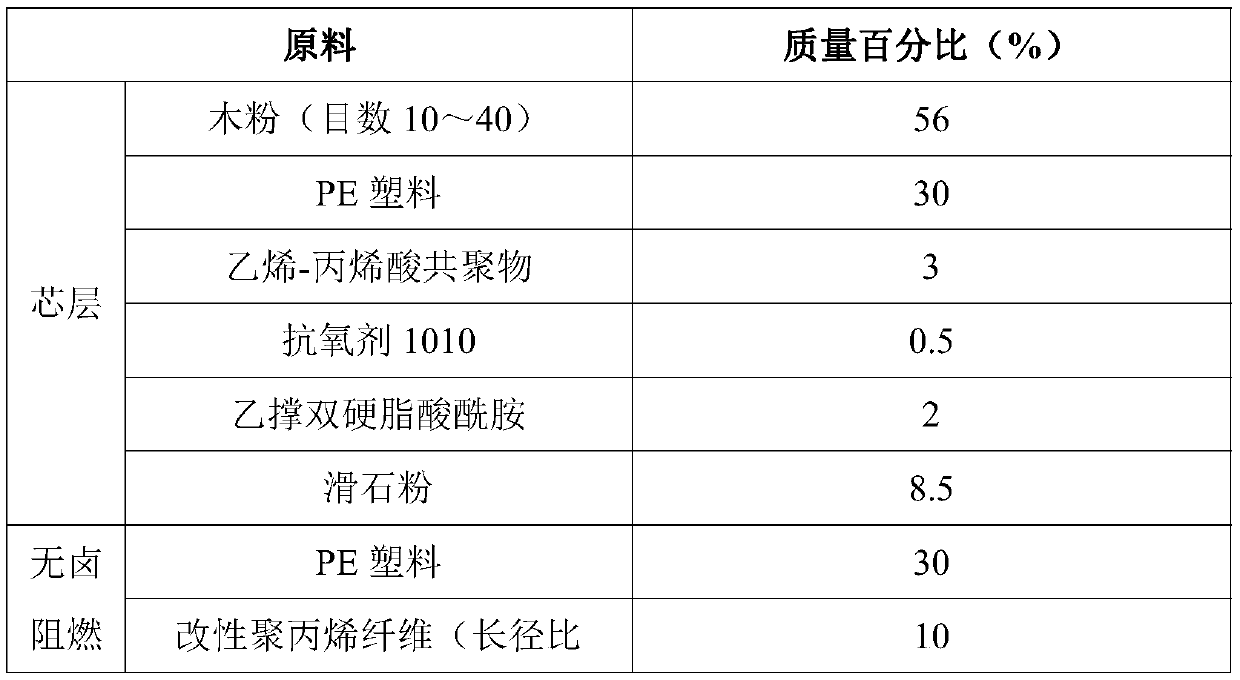

[0091] A halogen-free flame-retardant wood-plastic co-extrusion composite material, which consists of a core layer and a halogen-free flame-retardant surface layer. The composition of the core layer and the halogen-free flame-retardant surface layer is shown in the following table:

[0092] Table 3 Composition of the core layer and the halogen-free flame-retardant surface layer of a halogen-free flame-retardant wood-plastic co-extruded composite material

[0093]

[0094] The preparation method of the above-mentioned halogen-free flame-retardant wood-plastic co-extruded composite material comprises the following steps:

[0095] 1) Preparation of core layer granules: fully dry the wood powder, then add wood powder, PE plastic, ethylene-acrylic acid copolymer, antioxidant 1010, ethylene bis stearic acid amide and talcum powder into a high-speed mixer, and carry out High-speed blending, and then the obtained blend is added to the granulation production line for melting, kneadi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com