High-brightness polyphenylene sulfide alloy and preparation method thereof

The technology of polyphenylene sulfide and polyphenylene sulfide resin is applied in the field of high whiteness polyphenylene sulfide alloy and its preparation, which can solve the problems of poor color stability and discoloration, and achieve excellent high temperature resistance to color denaturation and endogenous heat. The effect of reducing and improving thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

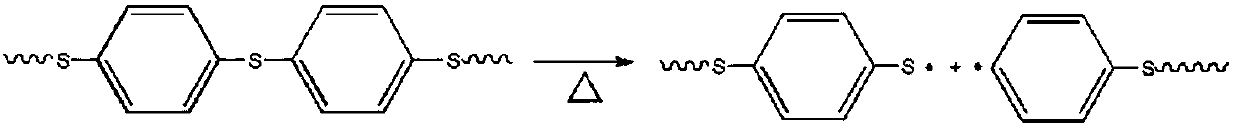

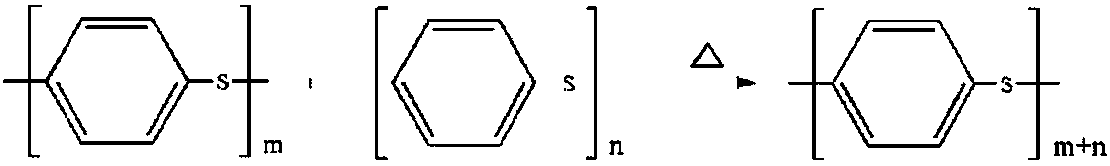

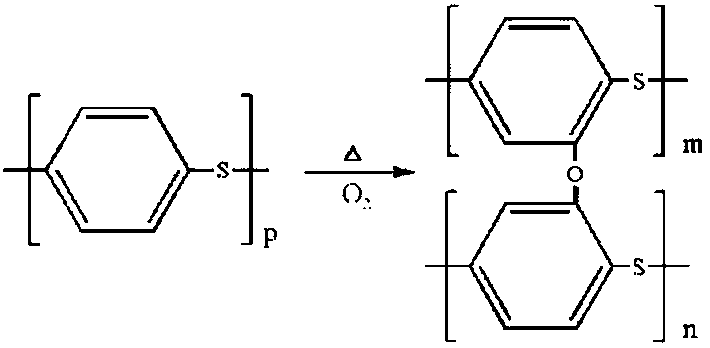

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0062] The preparation method of the above-mentioned high-whiteness polyphenylene sulfide alloy comprises the following steps:

[0063] [1] According to the weight ratio, mix polyphenylene sulfide resin, different resins, white inorganic mineral powder, glass fiber, antioxidant, coupling agent and lubricant in a high-speed mixer to obtain a mixed material;

[0064] [2] The mixed material obtained in step [1] is mixed and extruded on a twin-screw extruder;

[0065] [3] The material extruded in step [2] is drawn, pelletized, and dried to obtain a high-whiteness polyphenylene sulfide alloy material.

[0066] Preferably, the temperature of the high mixer described in step [1] is set between 30-120°C, the time is set to 2-4min, and the rotation speed is set to 800-1000rpm; the twin-screw described in step [2] The temperature of the extruder is set to 250-260°C for the first stage, 260-270°C for the second stage, 270-280°C for the third stage, 280-290°C for the fourth stage, 270-28...

Embodiment 1

[0076] Polyphenylene sulfide resin: 40wt%;

[0077] GMA-ethylene acrylate copolymer AX8900: 2wt%;

[0078] Calcium carbonate: 47wt%;

[0079] Glass fiber: 10wt%;

[0080] 1010 hindered phenolic antioxidant: 0.2wt%;

[0081] Vinyl alkoxy coupling agent: 0.4wt%;

[0082] Ethylene bis stearic acid amide: 0.4 wt%.

[0083] The preparation method is:

[0084] [1] Put the raw materials into the high mixer according to the formula, the temperature is 50°C, and mix at the speed of 800rpm for 2min;

[0085] [2] Extrude the mixed material in step [1] with a twin-screw extruder, pull, and pelletize to obtain the product.

[0086] The temperature settings are as follows: first-stage temperature 250°C, second-stage temperature 260°C, third-stage temperature 270°C, fourth-stage temperature 280°C, fifth-stage temperature 270°C, machine head temperature 300°C; host frequency: 30Hz; feeding frequency: 15Hz; Rotating speed of pelletizer: 600rpm.

Embodiment 2

[0088] Polyphenylene sulfide resin: 30wt%;

[0089] PA6: 10wt%;

[0091] Calcium carbonate: 40wt%;

[0092] Glass fiber: 10wt%;

[0093] 1076 hindered phenolic antioxidant: 0.5wt%;

[0094] Mercaptoalkoxysilane agent: 0.5wt%;

[0095] Pentaerythritol stearate: 0.5 wt%.

[0096] The preparation method is:

[0097] [1] Put the raw materials into the high mixer according to the formula, the temperature is 100 ℃, and the speed of mixing is 1000rpm for 4min;

[0098] [2] Extrude the mixed material in step [1] with a twin-screw extruder, pull, and pelletize to obtain the product.

[0099] The temperature settings are as follows: first-stage temperature 260°C, second-stage temperature 270°C, third-stage temperature 280°C, fourth-stage temperature 290°C, fifth-stage temperature 280°C, machine head temperature 300°C; host frequency: 40Hz; feeding frequency: 15Hz; Pelletizer speed: 800rpm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com