Patents

Literature

133results about How to "Guaranteed whiteness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

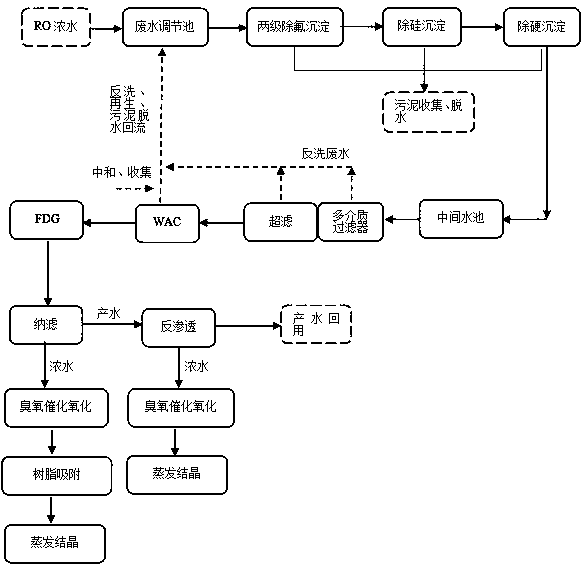

Recycling treatment process for coal coking high-salinity wastewater

PendingCN110606612AAchieving zero emissionsImplement resourcesWater contaminantsTreatment involving filtrationUltrafiltrationResource utilization

The invention relates to a recycling treatment process for coal coking high-salinity wastewater. The process comprises the following steps: (1) fluorine removing; (2) silicon removing; (3) softening;(4) treatment with a multi-medium filter; (5) ultrafiltration; (6) resin softening; (7) FDG; (8) nanofiltration and salt separation; (9) reverse osmosis concentration; (10) advanced oxidation; (11) resin adsorption; and (12) evaporative crystallization. The process has the advantages that the process of pretreatment, nanofiltration salt separation, reverse osmosis concentration, advanced oxidationand evaporative crystallization is adopted, so that zero emission and quality-divided resource utilization of the coal coking high-salinity wastewater are realized.

Owner:CHINA ELECTRONICS INNOVATION ENVIRONMENTAL TECH CO LTD +2

Novel coating material for ink jetting medium and its preparation method

InactiveCN1800491AStrong coverageHigh whitenessNon-fibrous pulp additionCoatings with pigmentsChemistryCalcium carbonate

The invention provides a plating solution of ink-jet print intermediate which comprises the calcium carbonate as main paint. It is formed by calcium carbonate, adhesive agent, and several additives (agents). Wherein, the calcium carbonate can be one or several ones of heavy calcium carbonate, light calcium carbonate or active calcium carbonate, while the average grain diameter is 0.1mu m-2mu m. The invention uses the calcium carbonate to replace the silicon dioxide, alumina and titanium oxide to be directly plated on the colorful ink-jet print paper and print photograph paper, without changing present paper plating processes, with lower cost and simple device. Therefore, it can make the lower-level paper into high-level paper and save the wood resource.

Owner:四川新泰克控股有限责任公司

Simple method for synchronous preparation of water glass and activated carbon with rice husk pyrolyzed ash

ActiveCN102515156AHigh yieldModulus controllableCarbon compoundsAlkali metal silicatesSilicon dioxideHydrolysis

The invention relates to a simple method for synchronous preparation of water glass and activated carbon with rice husk pyrolyzed ash, and especially relates to a simple method, which takes rice husks as raw materials that are first pyrolyzed so as to obtain pyrolyzed ash with a high C / SiO2 ratio, and then performs synchronous preparation of activated carbon during increasing the modulus of a water glass product. In the method, the main raw material sodium hydroxide is employed for hydrolysis of the pyrolyzed ash under heating and pressurization conditions so as to obtain a high modulus water glass solution, and simultaneously the surface of carbon is activated so as to obtain activated carbon. The pyrolysis method adopted in the invention ensures no secondary pyrolysis in pyrolysis, and also ensures that the volatile matter of the pyrolyzed ash can be fully pyrolyzed and contains no tar component, thus ensuring the whiteness of a silica product prepared in subsequent operations. Compared with other pyrolysis methods, the C / SiO2 ratio obtained in the invention is high, and is beneficial to improve the yield of activated carbon. Also, the produced water glass product has controllable modulus, and the produced activated carbon has good application performance. With simple process and low energy consumption, the method of the invention is easy to realize easy industrialized production and has broad application prospects.

Owner:JILIN UNIV

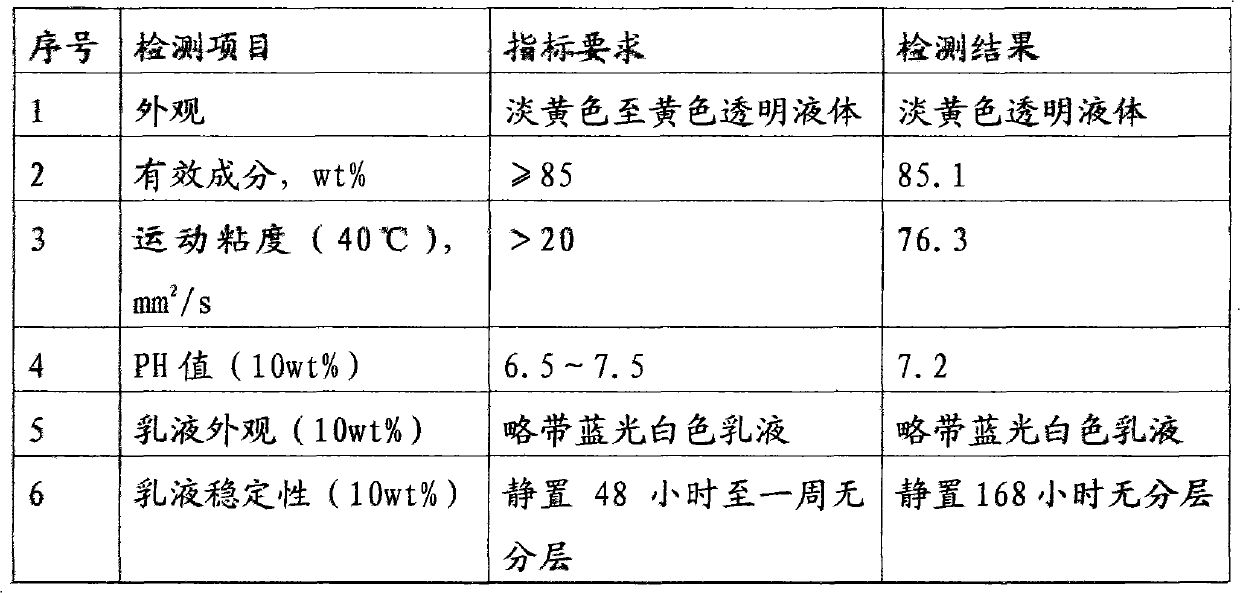

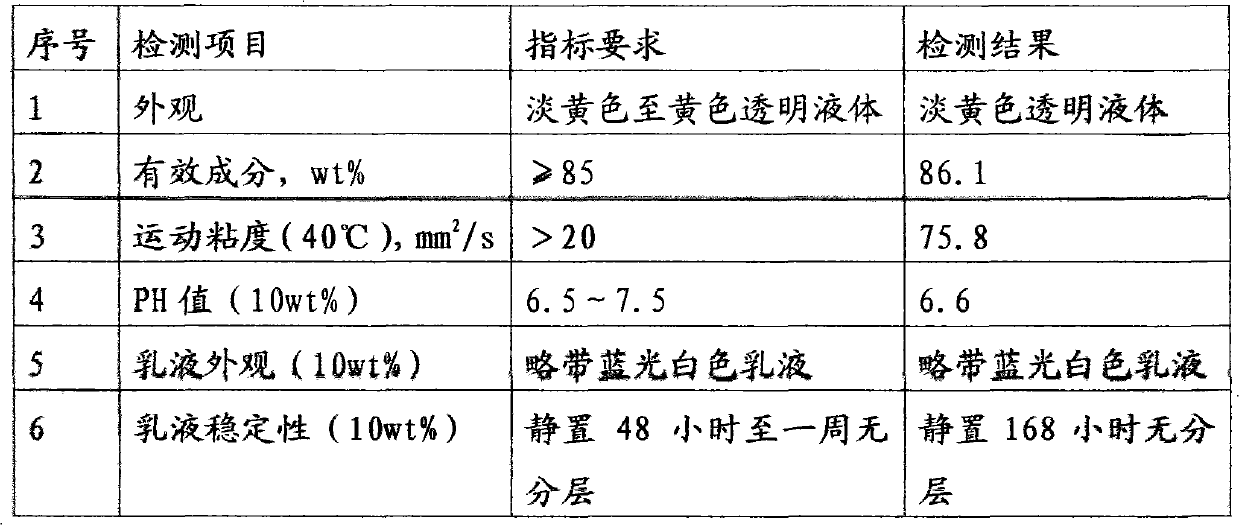

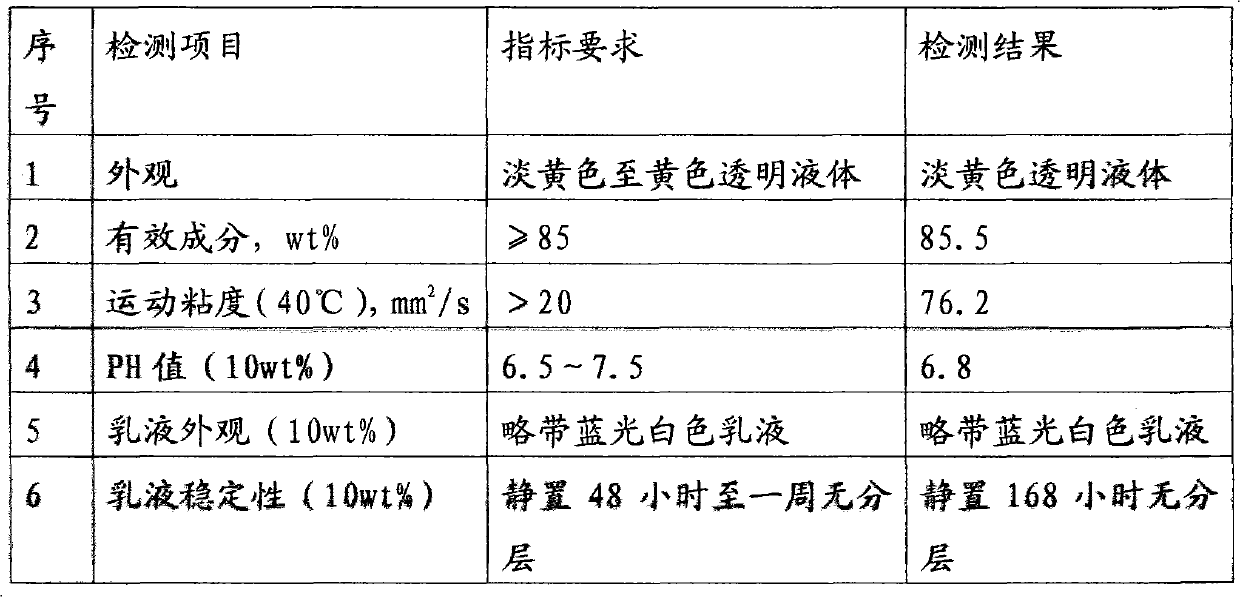

Environment-friendly polypropylene filament yarn oil agent and production method thereof

The invention discloses a preparation method of an environment-friendly polypropylene filament yarn oil agent, comprising the following steps of: weighing 40 to 60 parts by weight of fatty alcohol ether phosphate potassium salt, 2 to 8 parts by weight of polysiloxane polyether copolymer, 3 to 12 parts by weight of pentaerythritol oleate, 4 to 10 parts by weight of fatty alcohol polyoxyethylene ether, 2 to 12 parts by weight of ethylene oxide-epoxypropane block polyether, 20 to 45 parts by weight of polyethylene glycol laurate, 10 to 20 parts by weight of butter alcohol amine phosphate salt and 5 to 10 parts by weight of high-carbon heterogeneous alcohol phosphate potassium salt, heating to 40 to 80 DEG C, reacting under the stirring condition, then adding 20 to 40 parts of emulsifying agent EL-40, 1 to 5 parts of methyl-1-hydroxyethyl-2-stearyl imidazoline ammonium methosulfate, 5 to 15 parts of dimethyl silicon oil, 2 to 40 parts of deionized water and 0.001 to 0.02 part of preservative, reacting under the stirring condition at 50 to 70 DEG C, and separating to obtain the environment-friendly polypropylene filament yarn oil agent.

Owner:青岛荣达新材料研究所

Antibacterial deodorant and anti-wrinkle finishing process

ActiveCN105648771ATidy up steps simplifiedSave time organizingBiochemical fibre treatmentSingeingCooking & bakingHazardous substance

The invention provides an antibacterial deodorant and anti-wrinkle finishing process of cotton / silk blended fabric. The finishing process includes steps: (a), singeing; (b), performing one-bath desizing, scouring and bleaching; (c), performing antibacterial deodorant and anti-wrinkle finishing; (d), pre-baking; (e), baking; (f), washing with water; (9), drying. An antibacterial deodorant anti-wrinkle finishing agent is formed by reasonably proportioning components like citric acid, polyethylene glycol, waterborne polyurethane and beta-cyclodextrin, and is environment-friendly, free of releasing toxic and harmful substances like formaldehyde, safe and secure. By adding a softener into the finishing agent, the cotton / silk blended fabric of cotton fabric can be further ensured to be maintained soft without deforming, and practicability is improved.

Owner:深圳市歌中歌服饰有限公司

Bleaching method of fenther fabric

The present invention discloses a bleaching method of feather fabric. It includes the following steps: firstly, using ferrous ions to pretreat the feather fabric, then making selective oxidation in hydroperoxide solution, finally making reduction bleaching in sodium hydrosulfite. Said method not only can remove natural colour mater containing in feather fabric, but also can raise whiteness of fabric.

Owner:SOUTH CHINA UNIV OF TECH

High-temperature resistant yellowing nylon material and preparation method thereof

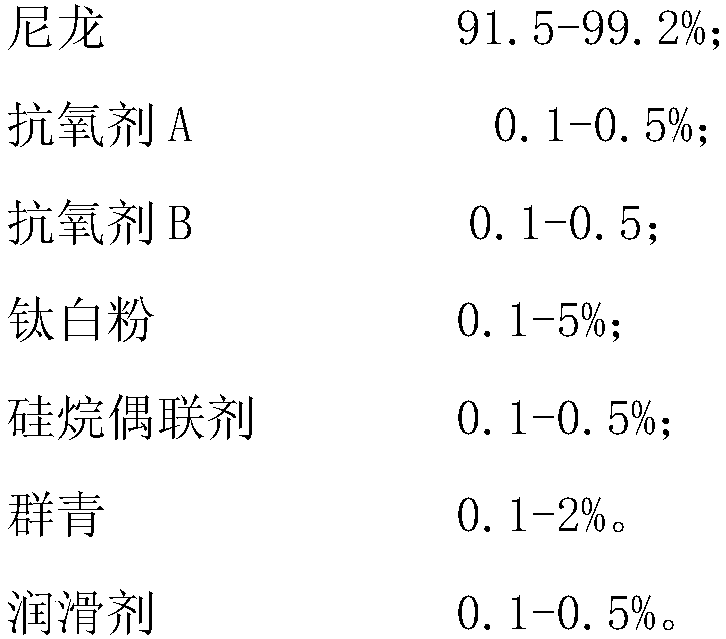

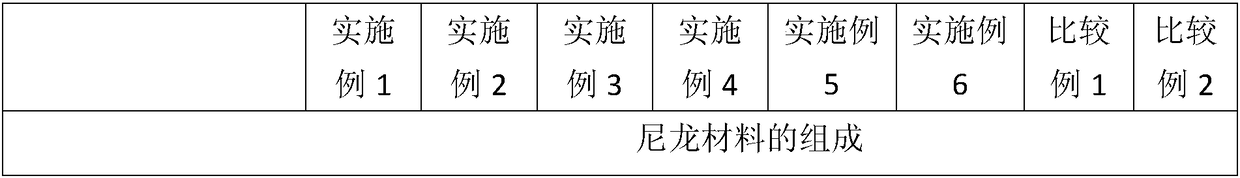

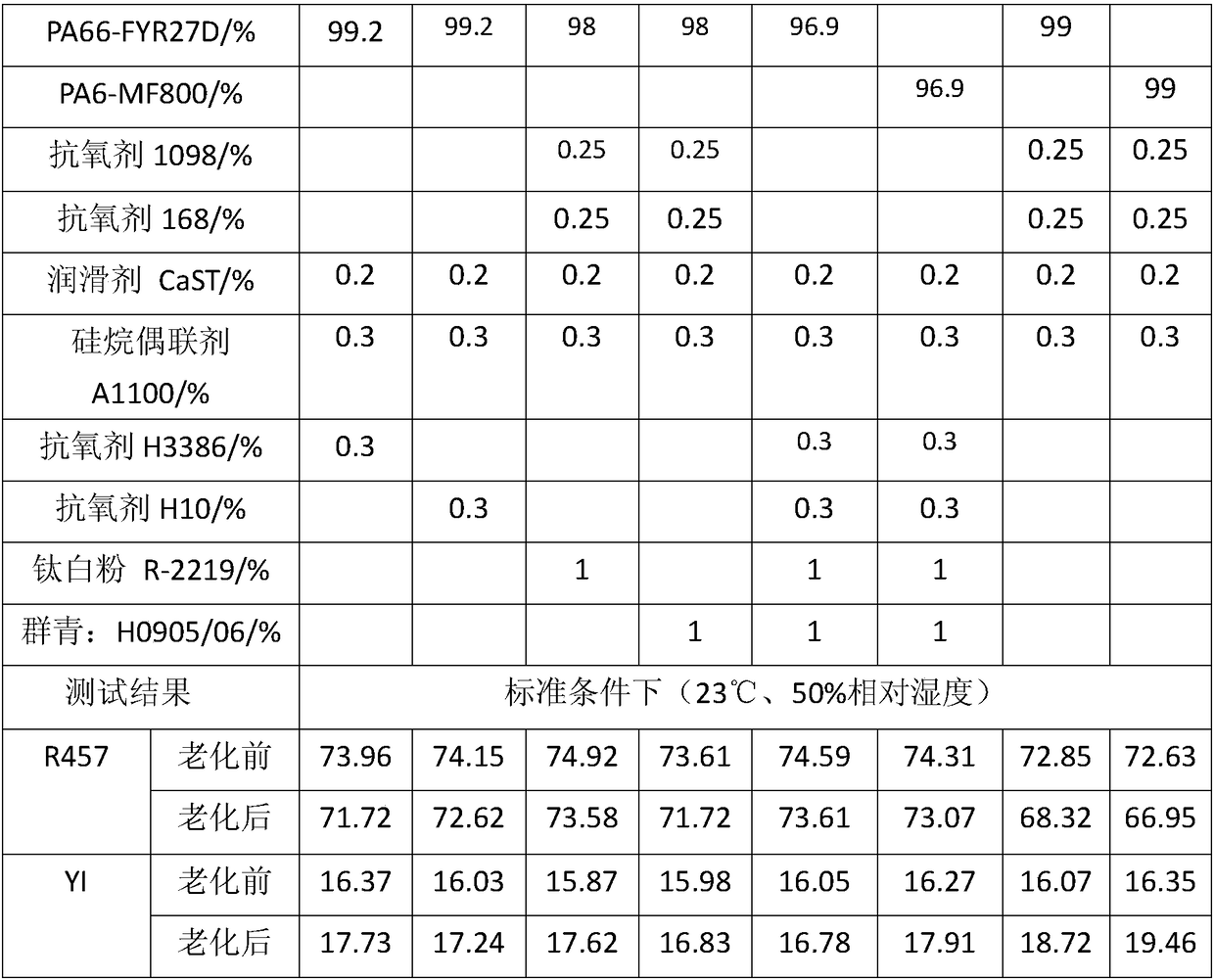

The invention discloses a high-temperature resistant yellowing nylon material and a preparation method of the high-temperature resistant yellowing nylon material. The high-temperature resistant yellowing nylon material comprises the following raw materials calculated in percentage by weight: 91.5 to 99.2% of nylon, 0.1 to 0.5% of an antioxidant A, 0.1 to 0.5% of an antioxidant B, 0.1 to 5% of TiO2, 0.1 to 0.5% of a silane coupling agent, 0.1 to 2% of Na6A14Si6S4020 and 0.1 to 0.5% of a lubricant. Compared with the prior art, the high-temperature resistant yellowing nylon material disclosed bythe invention has the advantages of inhibiting the thermal oxidative aging behavior and yellowing phenomenon of the nylon material through selecting organic copper salt and an anti-yellowing additiveto be in a compound use on the one hand, being capable of slowing down or inhibiting yellowing to some extent by reasonably selecting an aging system, and further having an eliminating effect and a covering effect on yellow color light through a toner system for solving inevitable yellowing under some particularly harsh conditions to ensure that the nylon material still remains whiteness under relatively harsh conditions, thereby ensuring that the nylon material meets strict requirements for whiteness at high temperature.

Owner:ZHEJIANG PRET NEW MATERIALS +4

Piece dyeing method of cotton binding textiles

InactiveCN101864677AUniform surfaceUniform colorBleaching apparatusDyeing processShrinkage rateEngineering

The invention discloses a piece dyeing method of cotton binding textiles, which is characterized in that the invention has the concrete processing process comprising the steps of singeing, desizing, light scouring and bleaching, pre-setting, rendering, color fixation soap washing, forming and preshrinking. The invention has the advantages that the cotton binding textiles obtained through being processed by the method have the advantages of uniform cloth surface color, good luster, high intensity and low washing shrinkage rate, and in addition, the production processing efficiency of the method is high. In addition, the mixed alkali treatment is adopted in the light scouring and bleaching process, so the invention ensures that the processed cotton binding textiles have certain whiteness and water absorption performance, in addition, the plant intensity of the textiles can not be damaged to the furthest extent, and the narrow width of the textiles caused by shrinkage in the following processing work procedure can be avoided through improving the hydrophilicity of the textiles and widening the width of the textiles via the pre-setting process.

Owner:浙江盛泰服装集团股份有限公司

Scouring method of real silk fabric

ActiveCN103469563ASpeed up refining timeLower refining temperatureBleaching apparatusAnimal fibresPre treatmentChemistry

The invention discloses a scouring method of a real silk fabric. The scouring method comprises the following steps: (1) pre-treating raw silks in an acid liquid at the temperature of 50-60 DEG C to swell the silks; (2) performing primary scouring with a scouring agent, namely a composite of an alkali scouring agent and a surfactant scouring agent; (3) performing secondary scouring, wherein a bleaching agent is added into a secondary scouring agent; and (4) after-treating, namely treating the scoured real silks from step (3) in water at 45-55 DEG C after swelling. The scouring method is simple, enhances the scouring effect of the scouring agents, and effectively solves the problem of unclean effluent of the alkali scouring agent; meanwhile, the scoured silks have the characteristics of high strength, good capillary effect, soft handfeel, excellent whiteness and low cost, and the product quality is ensured.

Owner:山东信开源科技创新发展有限责任公司

Novel refining agent for textile

The invention discloses a novel refining agent for textile, which is characterized by comprising the following components in parts by mass: 20-30 parts of fatty alcohol polyethenoxy ether, 3-10 parts of carboxyethyl thiosuccinic acid, 7-11 parts of alkyl polyglucoside, 3-8 parts of polyethyleneglycol, 2-8 parts of buffer solution, 3-7 parts of tea saponin, 10-15 parts of sodium hydroxide solution, 5-8 parts of oxydol, 3-6 parts of emulsifier, 3-6 parts of preservative, 4-8 parts of flame-retardant additive and 25-35 parts of ionized water. The carboxyethyl thiosuccinic acid can reduce the foam generation quantity, thereby ensuring the whiteness of the textile; the buffer solution can effectively regulate the pH value of the refining agent, so that the pH value does not need to be regulated by adding sulfuric acid and acetic acid, thereby reducing the number of times of water flushing; the preservative enables the pretreated textile to have certain bacterial resistance, so that the textile can inhibit bacteria, mold and the like; and the flame-retardant additive enables the pretreated textile to have certain flame retardancy.

Owner:ZHEJIANG YINAN FIBER TECH

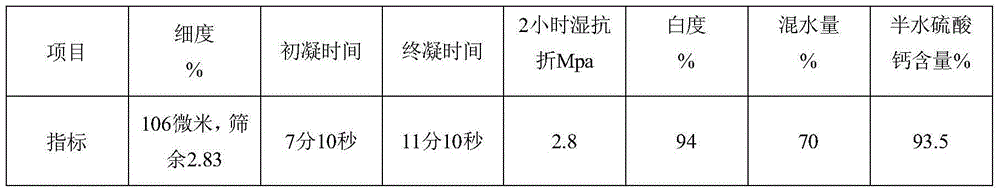

Method for producing beta-high-purity gypsum powder by using phosphogypsum

ActiveCN104310830ACalcination temperature is lowReduce energy consumptionFlexural strengthPhosphogypsum

The invention relates to a method for producing beta-high-purity gypsum powder by using phosphogypsum. The method comprises the following steps: (1) drying phosphogypsum until the mass content of free water is less than or equal to 3%, and calcining at a temperature of 130 to 150 DEG C under pressure of 99.0KPa to 100. 2KPa for 2.5 to 3.5 hours; (2) crushing a material calcined in the step (1) until the particle size is less than or equal to 125 microns and the screen residue is less than or equal to 3.00%; (3) hermetically aging the material obtained in the step (2) at normal temperature for 3 to 5 days, crushing the aged material to different grades of particle size between 75 to 125 microns, and carrying out graded mixing on products of different particle sizes to obtain beta-high-purity gypsum powder. The calcination is carried out under the negative pressure condition of 99.0KPa to 100. 2KPa, the energy consumption is low, and the obtained product has high performance index, strong stability and high performance cost ratio; the whiteness is more than or equal to 94, the content of calcium sulfate hemihydrate is more than or equal to 92%, the radioactivity index is low, and the wet flexural strength is up to 4.0Mpa at 2 hours.

Owner:KINGENTA ECOLOGICAL ENG GRP

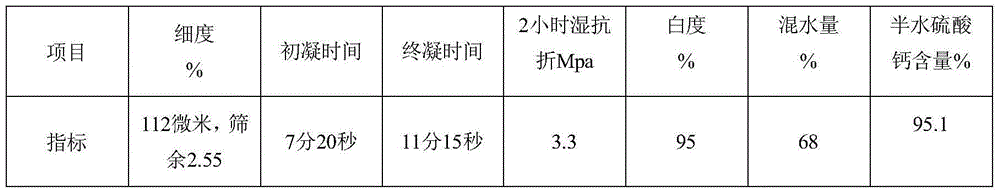

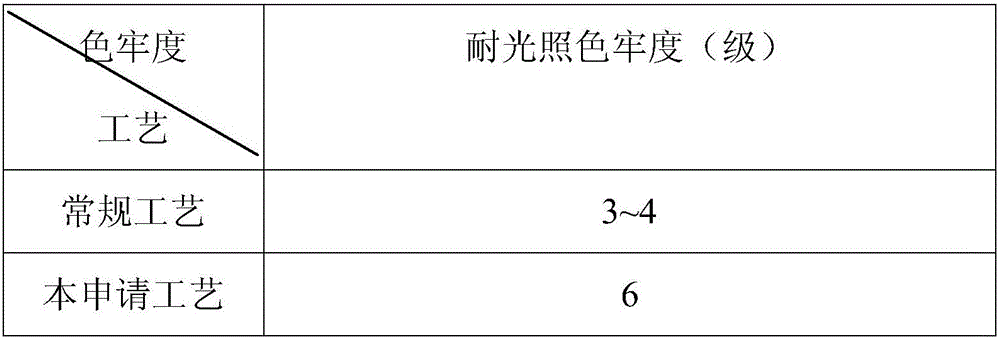

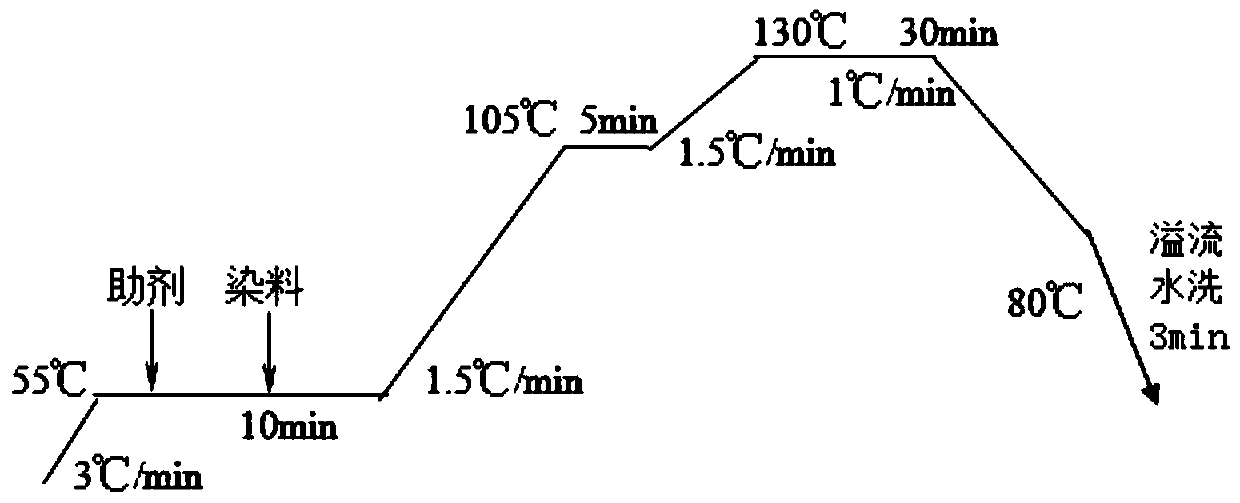

Dyeing process for modal/cotton blended fabric

ActiveCN106368014AMild staining conditionsSimple and efficient operationBiochemical treatment with enzymes/microorganismsDyeing processSodium carbonateSurface-active agents

The invention relates to a dyeing process for a modal / cotton blended fabric. The dyeing process comprises the steps that the fabric is placed in a vat body, water is input to the vat body to keep the bath ratio at 1:9, and snow white ginned cotton enzyme, glacial acetic acid and deoxidize enzyme are added; the modal / cotton blended fabric is dyed through the dyeing process at the constant temperature of 60 DEG C, wherein 6% of Avitera SE series dyestuff, anhydrous sodium sulphate and sodium carbonate are added for dyeing; after dyeing, the color of the modal / cotton blended fabric is compared with that of a dyeing board, after the color is consistent with the color of the dyeing board, the fabric is washed with clean water; a final treatment is conducted, wherein the alkaline liquor on the fabric surface is removed by adding surface active agent; glacial acetic acid and citric acid are added for adjusting the pH to 4.5; color softening agent and dye-fixing agent are added for color fixing. The dyeing process is mild in dyeing condition, convenient to operate, environmentally friendly, and capable of ensuring the fiber strength, fabric whiteness, capillary effect and the like after dyeing to meet the dyeing requirements. The Avitera SE series dyestuff is a novel high-fixation activated dye, lower in substantivity, good in leveling property and bright in color, and the dyed fabric with the Avitera SE series dyestuff is good in color fastnesses.

Owner:浙江雅雪纺织科技有限公司

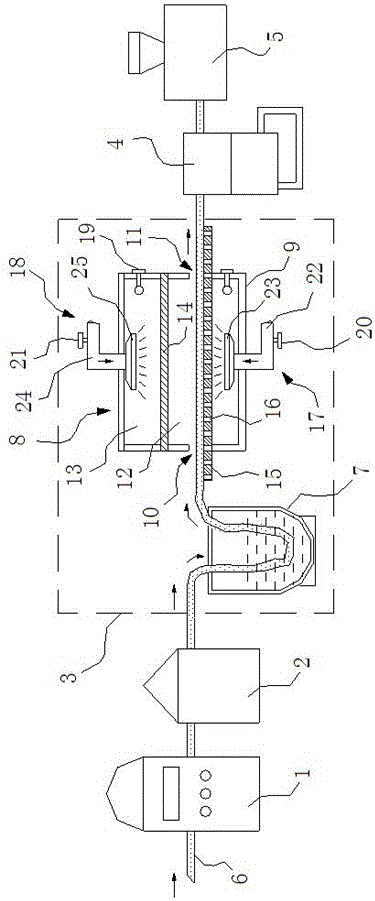

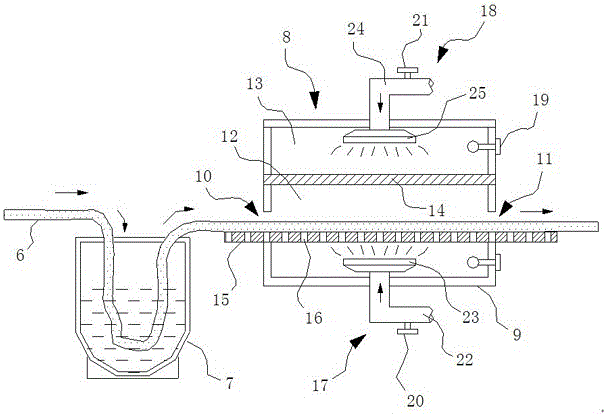

Long vehicle low-temperature steaming technology for fiber textiles and equipment

ActiveCN106637771AConserve waterSave energySucessive textile treatmentsTextile treatment machine arrangementsFiberEngineering

The invention discloses a long vehicle low-temperature steaming technology for fiber textiles and equipment. The technology comprises the following steps of (1) preparing gray cloth, (2) singeing, (3) desizing, (4) scouring, (5) rinsing and (6) drying. The invention further discloses long vehicle low-temperature steaming equipment for fiber textiles. The equipment comprises a scouring mechanism. The scouring mechanism has an immersion barrel and a steaming case connected with the immersion barrel, wherein the steaming case is provided with a case body equipped with an accommodating cavity; a steaming cavity steaming and heating textiles and a temperature balancing cavity preventing steam coagulation and on the upper part of the steaming cavity are disposed in the case body; the case body is equipped with a first steam supplying assembly and a second steam supplying assembly both providing high-temperature steam to the steaming cavity and the temperature balancing cavity. The steaming equipment can effectively reduce equipment energy consumption, save energy and improve production efficiency; and the long vehicle low-temperature steaming technology has short circulating, high efficiency, and can reduce water and energy use.

Owner:青岛奥洛思新材料有限公司

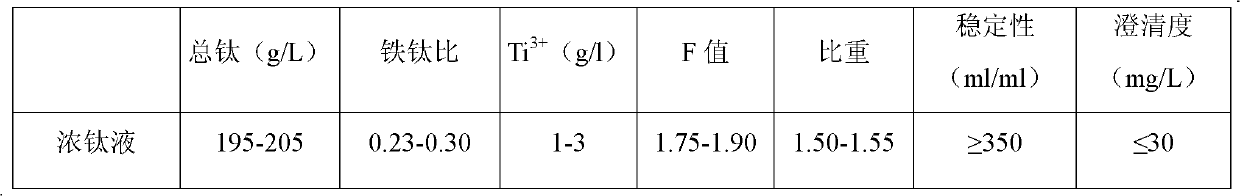

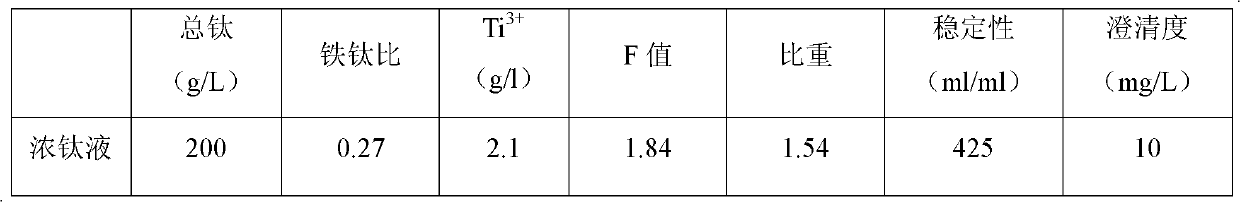

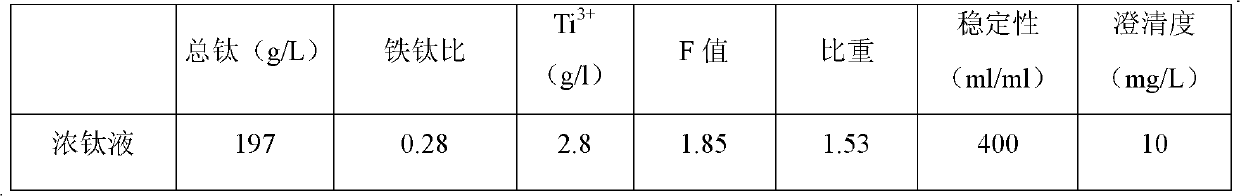

Production method of high-resistivity titanium dioxide

The invention relates to a production method of high-resistivity titanium dioxide, which belongs to the field of titanium dioxide production. The invention provides the production method of the high-resistivity titanium dioxide, which adopts a sulfuric acid method titanium dioxide production process and comprises the following steps of hydrolyzation of titanium liquid, washing, salt treatment, and calcination plus milling, wherein a potassic substance is added in the salt treatment step; the addition quantity of the potassic substance occupies 0.39 to 0.47 wt% of the titanium dioxide content; and the potassic substance is potassic alkali or salt. The resistivity of the titanium dioxide produced by utilizing the method provided by the invention is higher than the resistivity of the titanium dioxide produced in the prior art by 900 Omega.cm, and meanwhile, the brightness, the whiteness, the pH (potential of hydrogen) of the titanium dioxide are guaranteed to satisfy the operation requirements.

Owner:攀枝花鼎星钛业有限公司

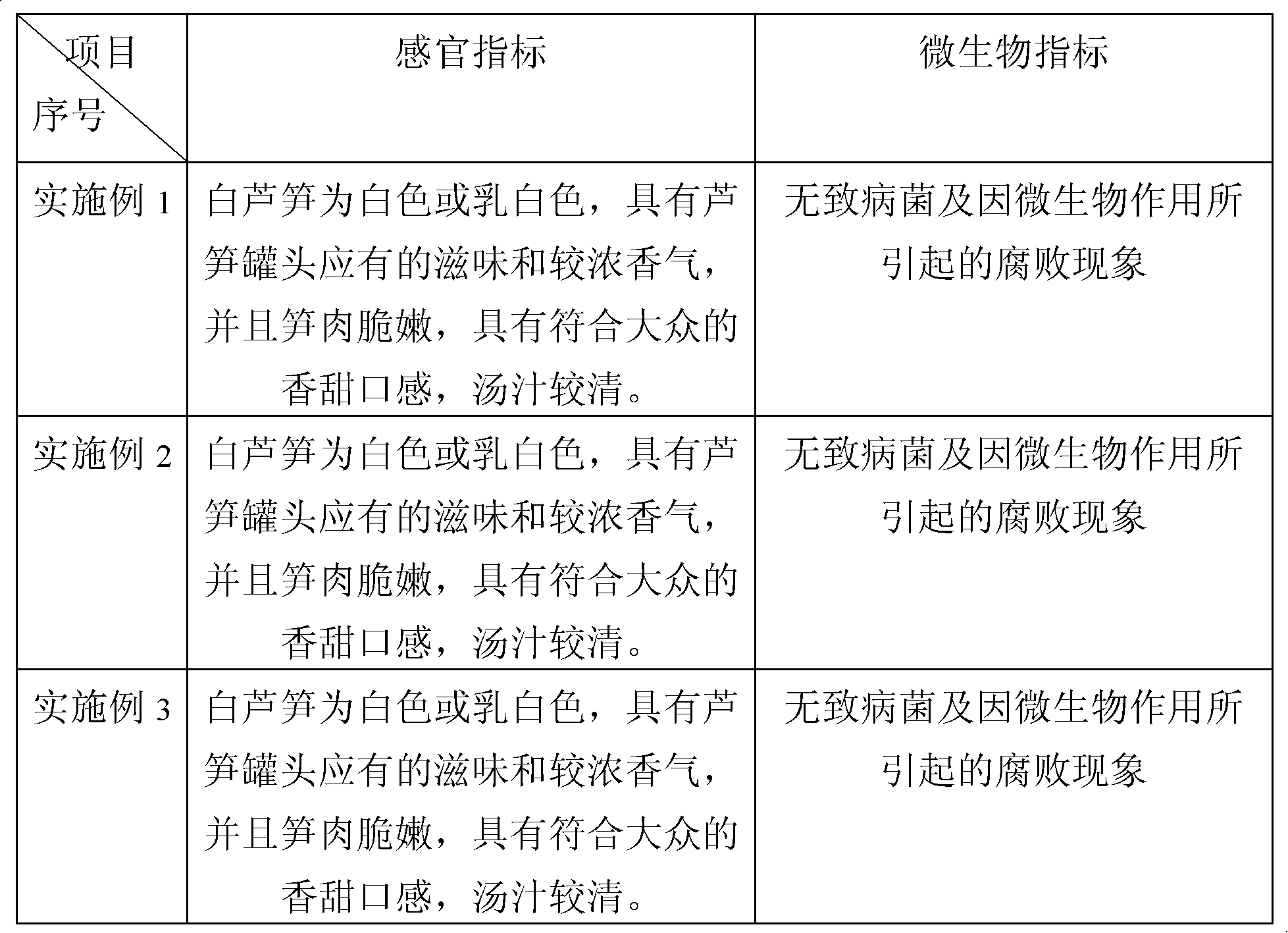

Method for processing canned white asparagus by vacuum acidification

ActiveCN102715228AImprove surface cleanlinessPrevent spoilageFruits/vegetable preservation by heatingChemistrySodium erythorbate

The invention discloses a method for processing canned white asparagus by vacuum acidification, comprising the following steps: carrying out ultrasonic cleaning with a frequency of 20-30 kHz on processed white asparagus for 10-15 min, wherein the cleaning effect is good, the speed is fast, and the white asparagus materials are prevented from tender stem deterioration caused by long time soaking; after cleaning, precooking, then carrying out spray cooling on the precooked white asparagus with cold water under the high pressure of 30*10<5>-40*10<5> Pa for 1 min, rapidly cooling the white asparagus, then conducting vacuum acidification by using a compound liquid of disodium hydrogen phosphate and citric acid under the vacuum degree of 0.070-0.085 MPa for 1.5-2h to achieve the purpose of preventing browning; and finally adding 0.01% phytic acid and 0.01% sodium erythorbate in the liquid of the canned white asparagus to carry out color protection on the white asparagus and further carry out acidification. The prepared canned white asparagus has good whiteness and strong fragrance, the pulp has popular sweet mouthfeel, and the liquid is clear.

Owner:福建立兴食品股份有限公司

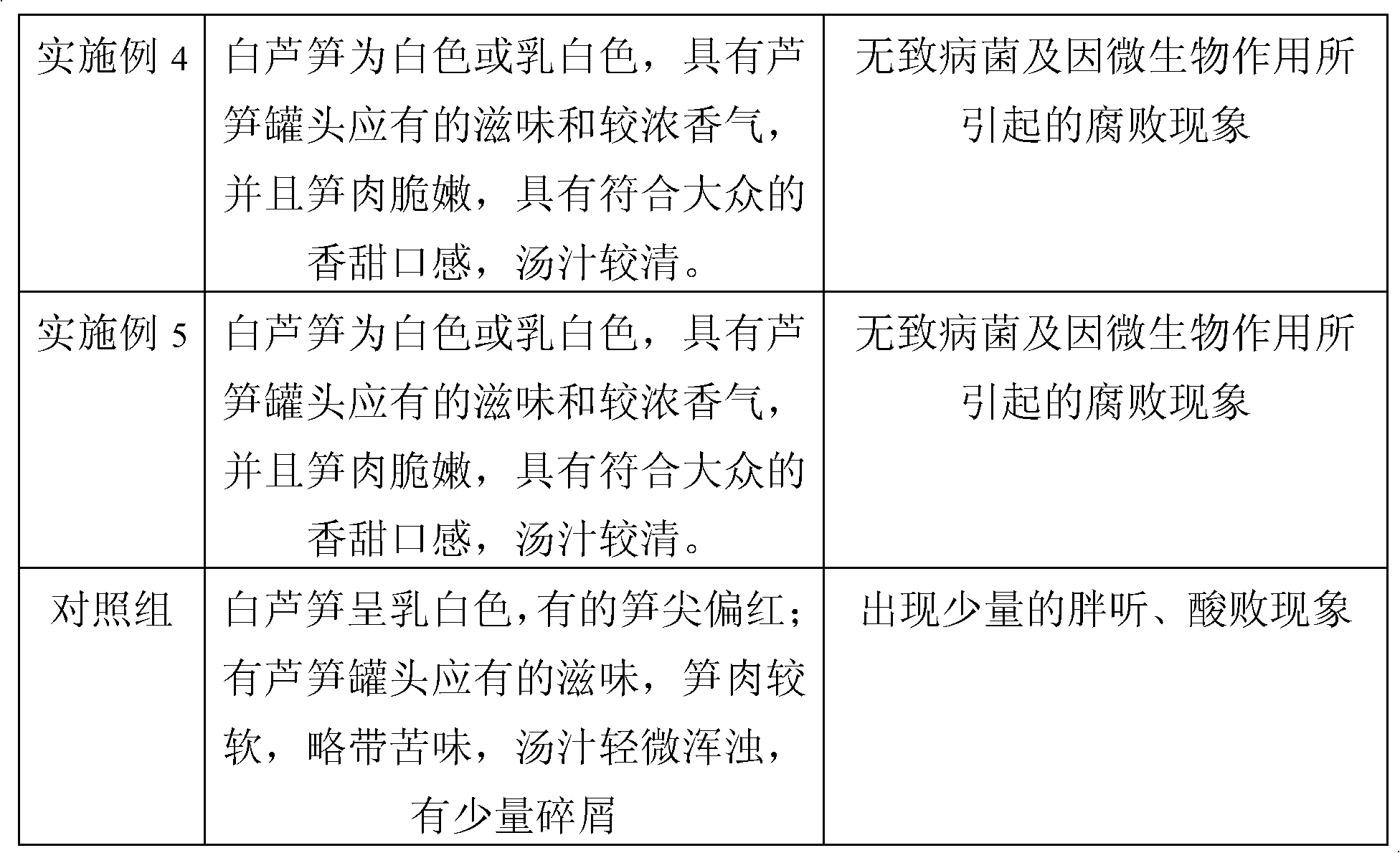

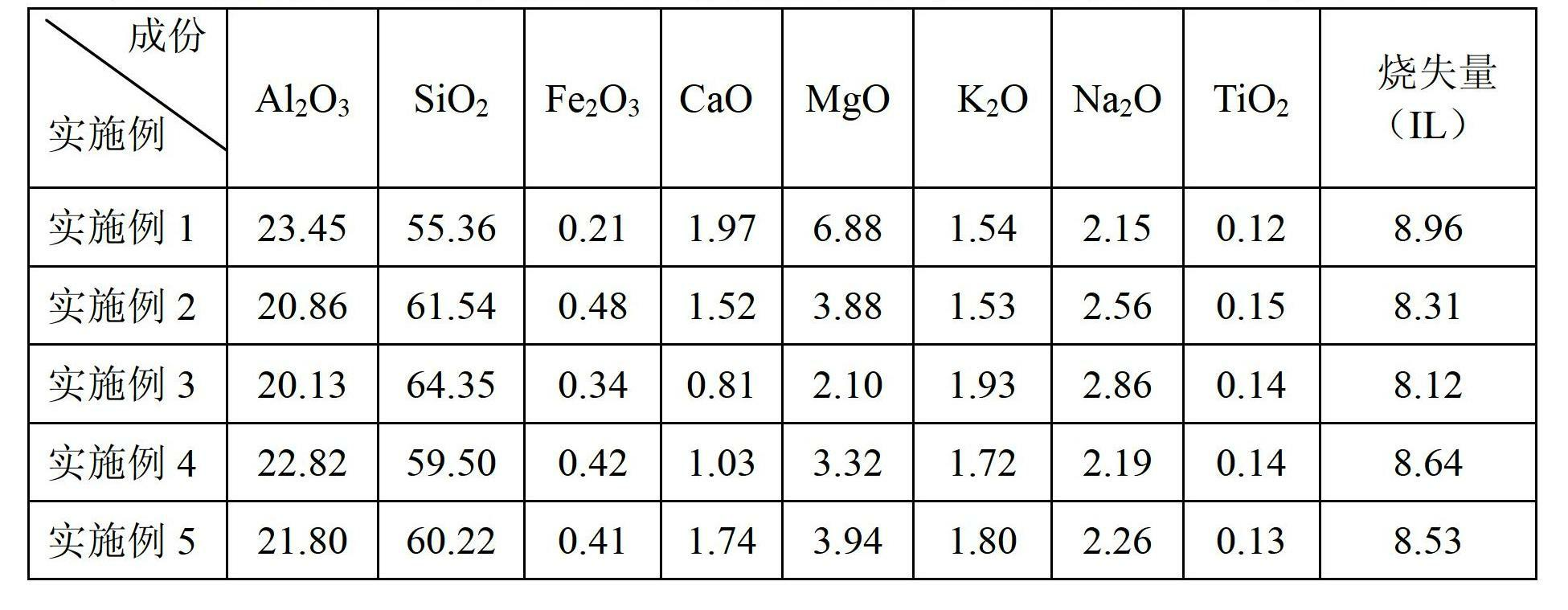

High-thermal stability and high-whiteness ceramic and preparation method thereof

The invention belongs to the technical field of daily use ceramics, and particularly relates to a high-thermal stability and high-whiteness ceramic and a preparation method thereof. The high-thermal stability and high-whiteness ceramic comprises a high-thermal stability and high-whiteness blank and a transparent glaze, and the high-thermal stability and high-whiteness blank comprises Inner Mongolia potash feldspar, Lincang kaolin, Longyan kaolin, bentonite and a low expansion agent; and the transparent glaze comprises, by weight, Jiangxi potash feldspar, quartz, Longyan kaolin, heavy calcium,calcined zinc oxide, barium sulfate, calcined talcum powder and a regulator. The prepared ceramic blank and glaze are well combined by adopting the method, so the ceramic of the invention has delicatetransparent porcelain and a smooth and bright glaze surface, has a whiteness reaching 81 or more, and achieves thermal exchange at 200-20 DEG C two times without cracking due to high thermal stability; and the preparation method has the advantages of easily availably preparation raw materials, wide firing range, simple preparation process and high product yield, and is suitable for being promotedand applied to the field of daily use ceramics.

Owner:FUJIAN QUANZHOU SHUNMEI GROUP

Down feather swelling agent and preparation method thereof

The invention discloses a down feather swelling agent, which is prepared from the following ingredients in parts by weight: 5 to 10 parts of softening agents, 5 to 15 parts of surface modifiers, 5 to15 parts of surface active agents, 0.1 to 0.5 part of antioxidants, 5 to 10 parts of pH regulators, 1 to 5 parts of protein filling agents, 5 to 10 parts of ethyl alcohol, 65 to 75 parts of pure waterand 0.1 to 1 part of auxiliary agents. The down feather swelling agent is prepared by the following steps of heating the ethyl alcohol to 40 to 55 DEG C; performing heat insulation; adding auxiliaryagents into the ethyl alcohol; performing stirring dissolution for 5 to 10min; heating the pure water to 40 to 55 DEG C; regulating the pH to 5.5 to 6.5 by the pH regulators; slowly adding the pure water into a mixture of the softening agents, the surface modifiers, the surface active agents, the antioxidants and the protein filling agents; performing high-speed shearing emulsification for 20 to 40 min at 2500 to 2800r / min; slowly adding the solution in the S1 into S2, continuously performing stirring in the period; continuously adding the rest pure water into the solution; performing stirringfor 5 to 15 min; after the solution cools to the normal temperature, performing sealed filling and putting the materials in a cool dry place. The down feather swelling agent has the advantages that the down feather swelling degree can be improved by about 10 to 15 percent, so that the down feather is light, soft and elastic.

Owner:东隆家纺股份有限公司

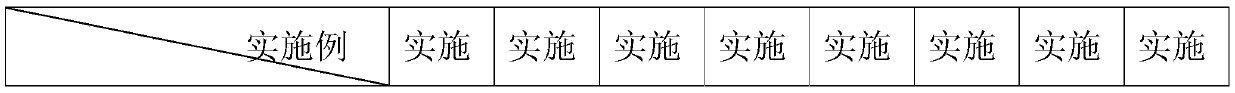

Method for preparing calcium-zinc stabilizer for shoe materials

InactiveCN110698867AReduce dustGuaranteed whiteness and yellowing resistanceSOYBEAN SEED OILAcetylacetone

The invention discloses a method for preparing a calcium-zinc stabilizer for shoe materials. The method comprises the following steps: S1. separately weighing 1-10 parts of zinc stearate, 10-25 partsof calcium stearate, 0.1-2 parts of zinc acetylacetone, 0.5-3 parts of calcium acetylacetonate, 20-50 parts of brucite, 5-15 parts of epoxidized soybean oil, 2-16 parts of lubricant, 5-20 parts of other metal soap, 5-25 parts of organic auxiliary heat stabilizer, 1-10 parts of unsaturated acid ester, 0.1-2 parts of antioxidant and 1-5 parts of dispersant; and S2. firstly, uniformly mixing variouspowder materials, then, adding a liquid ingredient, i.e., the epoxidized soybean oil, the lubricant and the dispersant, and continuing to carry out stirring until the material is of a wet powder or paste mixture, thereby obtaining the calcium-zinc stabilizer for the shoe materials. The calcium-zinc stabilizer for the shoe materials, prepared by the method, is free of organic lead salts and the like, thereby being environmentally friendly and safe; flying of dust can be effectively lowered; the whiteness and yellowing resistance of the shoe materials can be better guaranteed; the calcium-zinc stabilizer is difficult to separate out; and the color fastness and the like of the shoe materials can be improved.

Owner:浙江杰上杰新材料股份有限公司

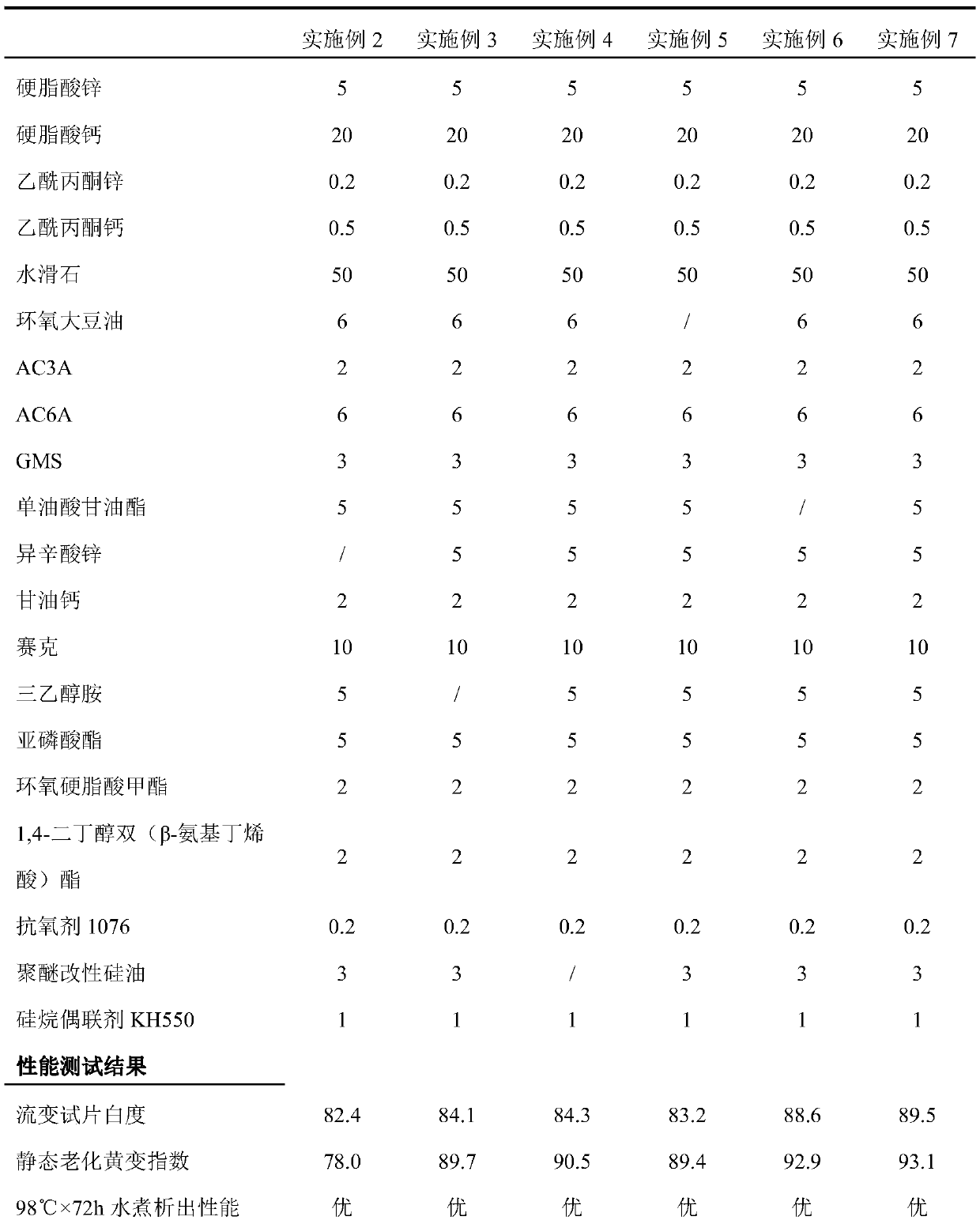

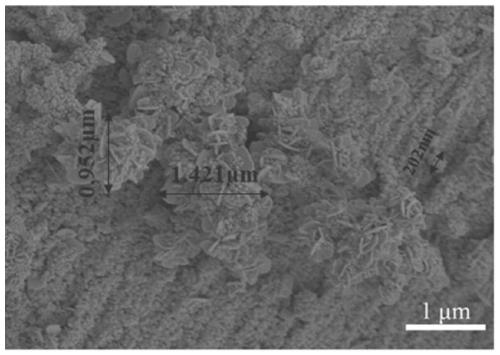

Waterproof cloth surface flexible composite material and preparation method thereof

ActiveCN111593570AExcellent durabilityGuaranteed strongSynthetic resin layered productsLiquid repellent fibresFiberPolymer science

The invention discloses a waterproof cloth surface flexible composite material and a preparation method thereof. The waterproof cloth surface flexible composite material is characterized in that one surface of a super-hydrophobic fabric is bonded with a plastic film by using an adhesive to obtain the washable waterproof cloth surface flexible composite material. The preparation method comprises the following steps of diazotizing a fluorine-containing alkyl aniline monomer in a dilute acid solution of sodium nitrite to form fluorine-containing alkyl benzene diazonium salt; carrying out reduction reaction on the fluorine-containing alkylbenzene diazonium salt under the action of a reducing agent to obtain a fluorine-containing alkylbenzene free radical monomer; and carrying out in-situ single-electron free radical covalent graft polymerization reaction on the fluorine-containing alkylbenzene free radical monomer in the fabric fiber to obtain the super-hydrophobic fabric. As the super-hydrophobic fabric obtained through chemical grafting, the fiber surface coating is combined with the fiber through covalent bonds, so that the super-hydrophobic fabric has excellent fastness, the flexibility and the hand feeling of the fabric are not influenced, and the problems of poor fastness and poor hand feeling of the super-hydrophobic fabric obtained through methods such as the coating are solved.

Owner:SUZHOU UNIV

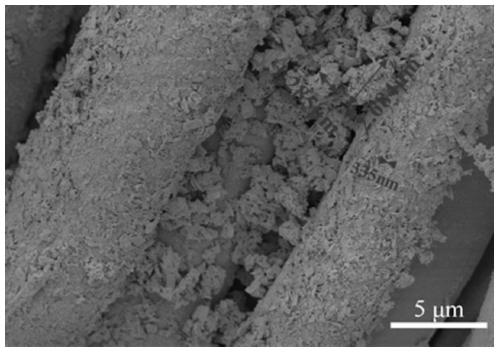

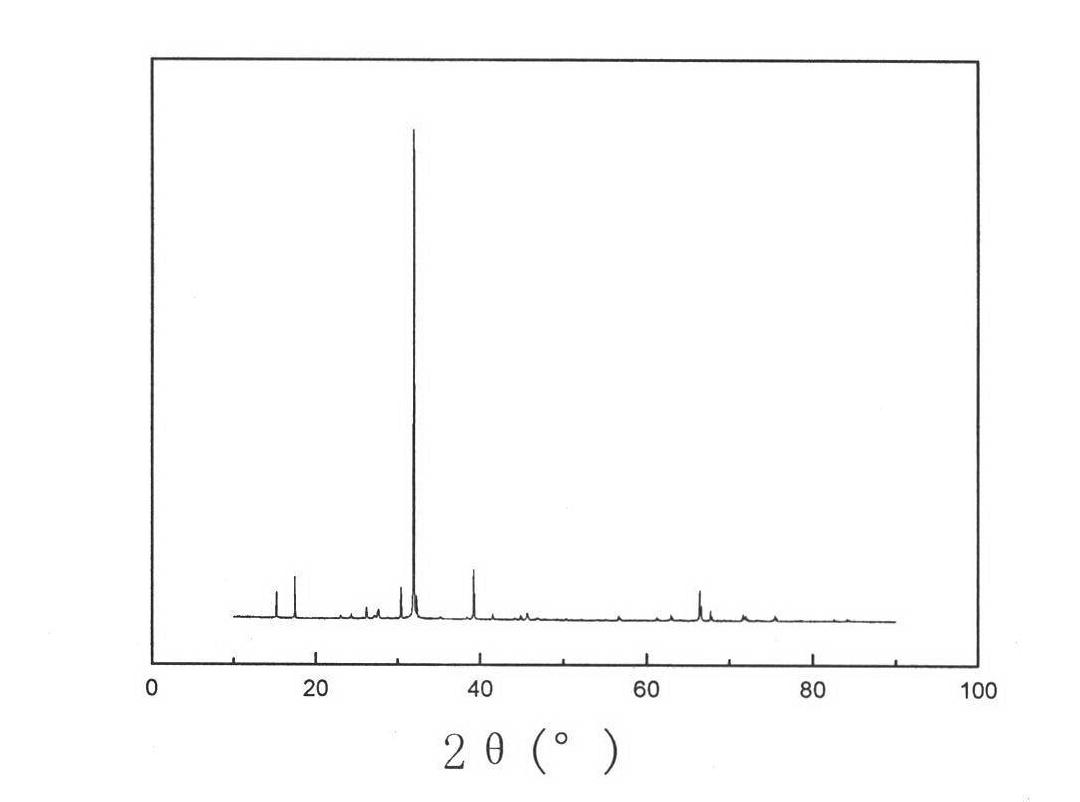

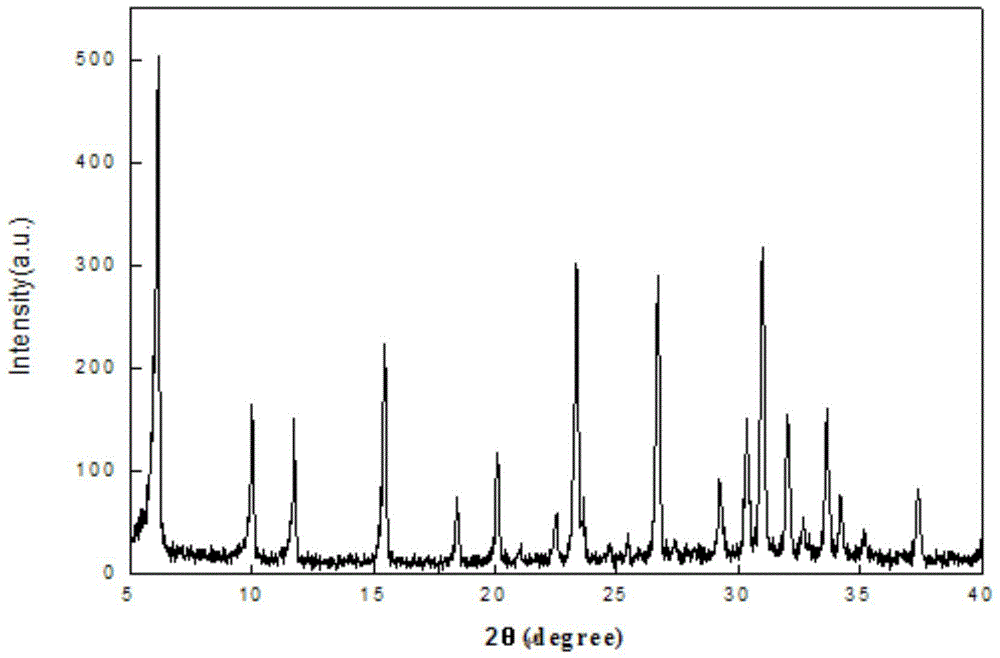

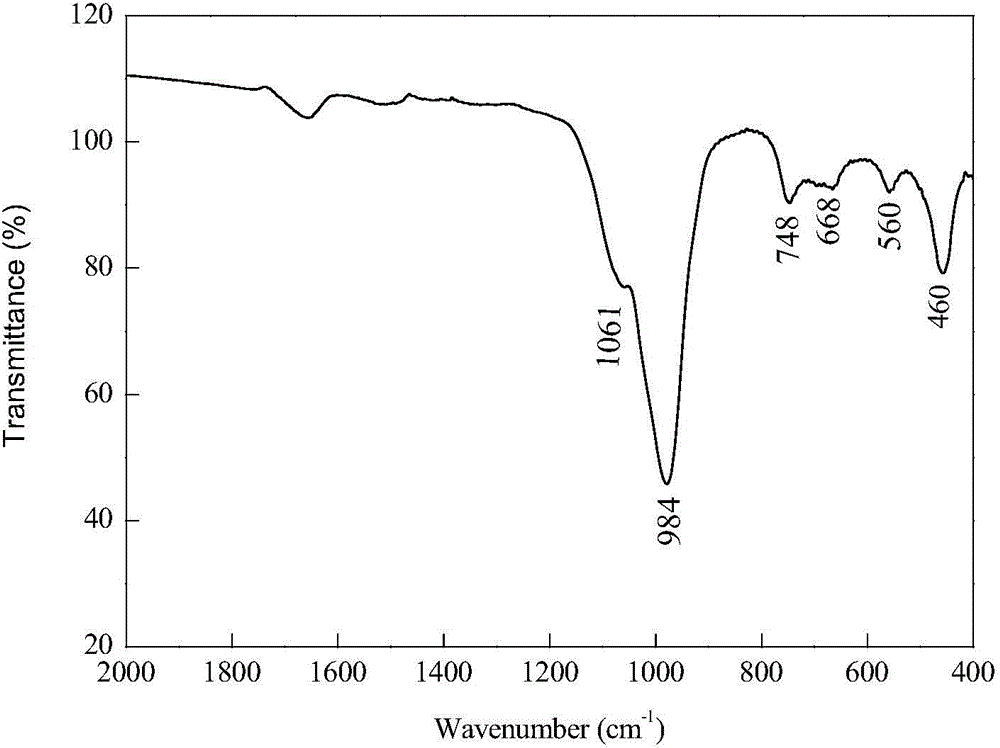

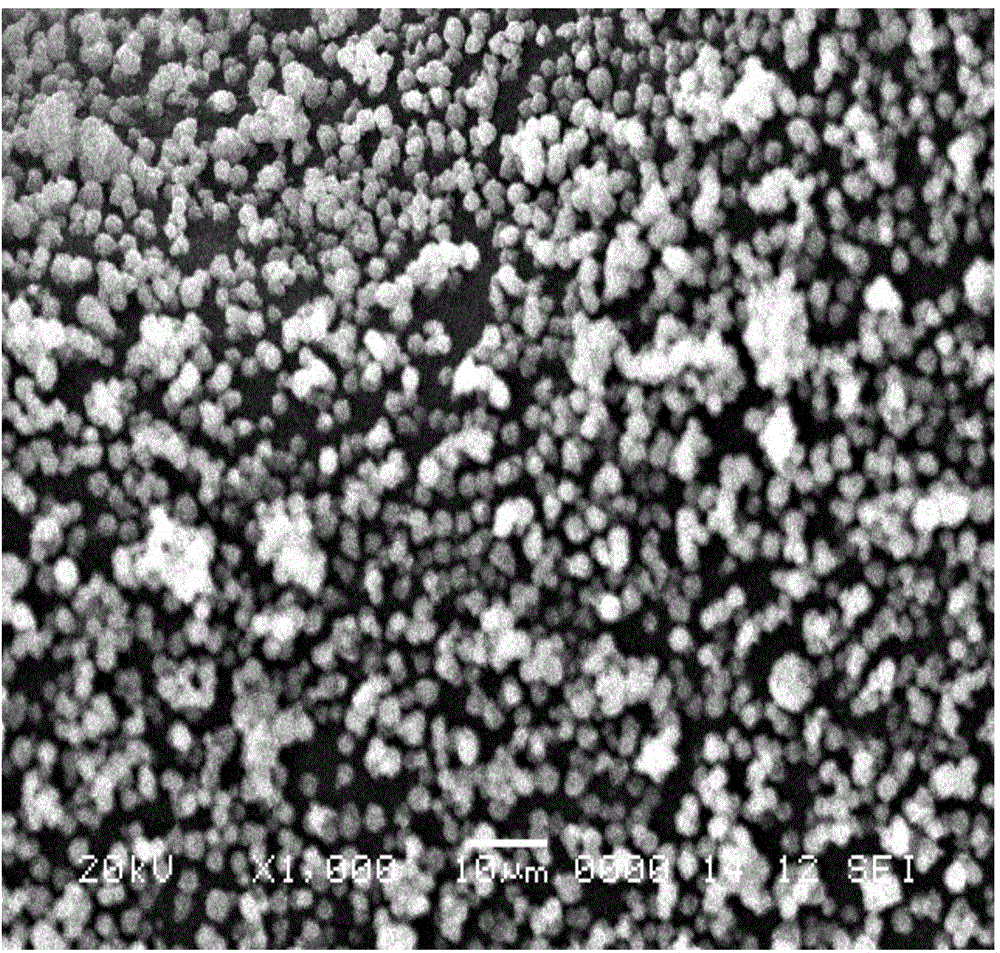

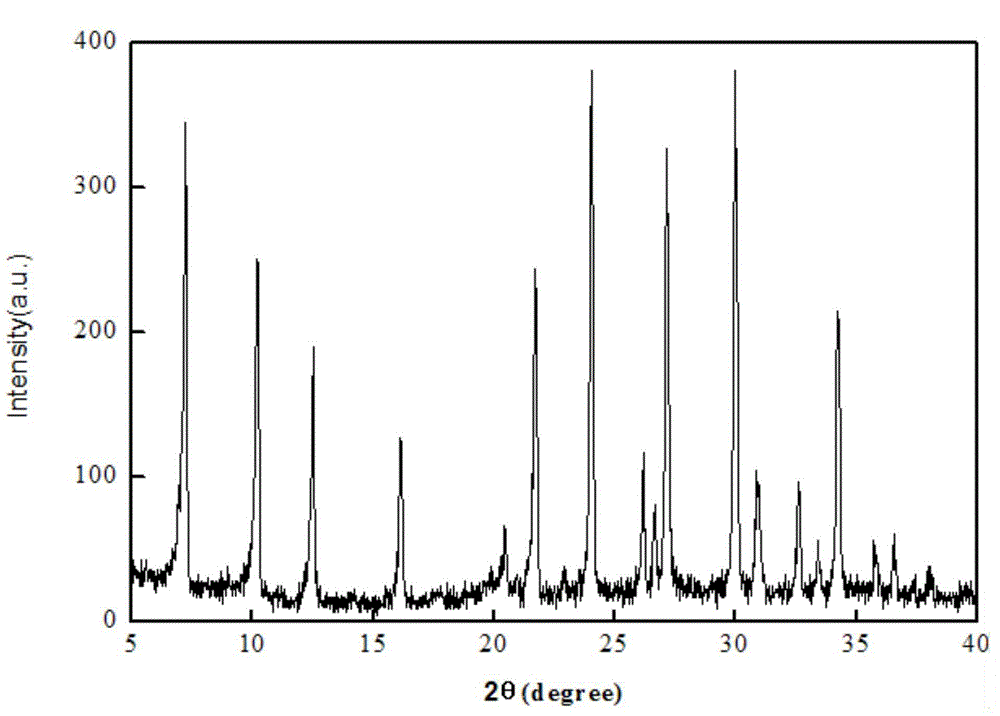

Comprehensive utilization method of hydrargillite-produced 4A zeolite waste residue

InactiveCN102167351AWell sourcedRealize comprehensive utilizationInorganic/elemental detergent compounding agentsAluminosilicate zeolite type-AAluminium chlorohydrateSynthesis methods

The invention provides a comprehensive utilization method of hydrargillite-produced 4A zeolite waste residue. The method comprises the steps of: separating the ferrosilicoaluminum component in the hydrargillite-produced 4A zeolite waste residue by means of acid leaching and filtering, wherein the obtained mixed liquor of filter liquor and filter residue washing liquor is used for preparing a polymeric aluminum ferric chloride water purifying agent; and removing iron from the wet slag obtained by washing the filter residue by means of alkali fusing, roasting and activating, and synthesizing the 4A zeolite by a hydrothermal method by means of adjusting and assembling. Triethanolamine is taken as a complexing agent of the microelement iron in the liquor during synthesizing the 4A zeolite, so that the produce of an iron precipitate is overcome, and the whiteness of a 4A zeolite product is guaranteed; sodium sulfide is reacted with a triethanolamine iron complex in the zeolite-synthesized mother liquor to reduce the triethanolamine and obtain an iron sulfide precipitate; and removing the mother liquor of the iron sulfide precipitate to realize the cycle utilization. The synthesis method of the 4A zeolite adopts a sealed cycle technology, thereby being stable in operation, and free of the generation of new waste liquor and new waste slag.

Owner:HEBEI UNIV OF TECH

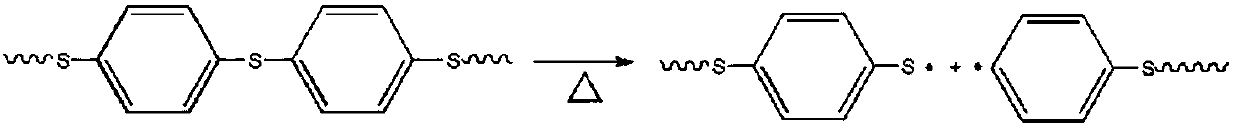

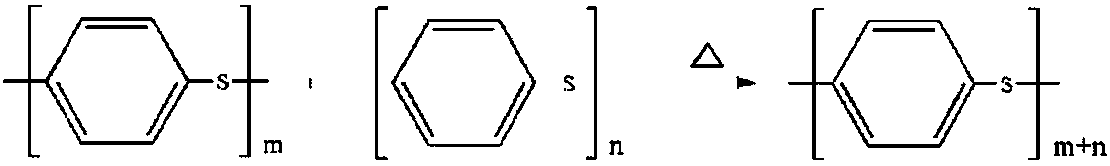

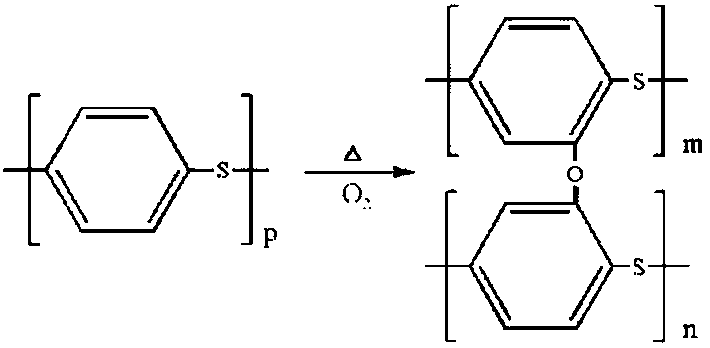

High-brightness polyphenylene sulfide alloy and preparation method thereof

InactiveCN108034249AWeaken or inhibit cross-linking reactionsImprove thermal stabilityHeat resistanceAntioxidant

The invention belongs to the technical field of high polymer composites, and particularly relates to a high-brightness polyphenylene sulfide alloy and a preparation method of the alloy. In order to solve the problems that a color of the existing high-brightness polyphenylene sulfide product is changed at high temperature and the color stability is poorer, the high-brightness polyphenylene sulfidealloy comprises the following materials by weight percentage: 30-40wt% of polyphenylene sulfide resin, 2-10wt% of heterogeneous resin, 17.5-57.1wt% of white inorganic mineral powder, 10-30wt% of glassfiber, 0.2-0.5wt% of an antioxidant, 0.4-1wt% of a coupling agent and 0.3-1wt% of a lubricant. A modified material is high in brightness and heat resistance and excellent in forming processability, and can be used for electric products, automobile structure parts and decoration materials.

Owner:SICHUAN COREMER CO LTD

High-whiteness pure color full-body polishing brick, and production method and application thereof

The invention discloses a high-whiteness pure color full-body polishing brick, and a production method and application thereof. The polishing brick is produced by sintering 20 to 30 mass percent of feldspar, 10 to 28 mass percent of high-temperature sand, 20 to 27 mass percent of high-white clay, 0 to 12 mass percent of quartz sand, 10 to 20 mass percent of aluminum powder, 8 to 18 mass percent of calcined talcpowder, 0.5 mass percent of sodium tripolyphosphate and 0.1 to 0.15 percent of methylcellulose at the temperature of 1,180 DEG C for 45 minutes. According to the high-whiteness pure color full-body polishing brick, the whiteness is high (which is 68 to 75 degrees), the radioactivity is close to zero radiation, the water absorption rate is low and is less than 0.1 percent, and the anti-pollution capacity reaches 4 levels; the polishing brick is sintered quickly at low temperature during production, so that the production cost is reduced substantially, and energy conservation and emission reduction are achieved really; and the using amount of calcium oxide and magnesium oxide which serve as raw materials is reduced as far as possible in a formula, and the production defects of poor polishing degree of the sintered brick, narrow sintering range and the like due to a formula in which a large amount of calcium and a large amount of magnesium are required are solved.

Owner:广州锦盈新型材料有限公司

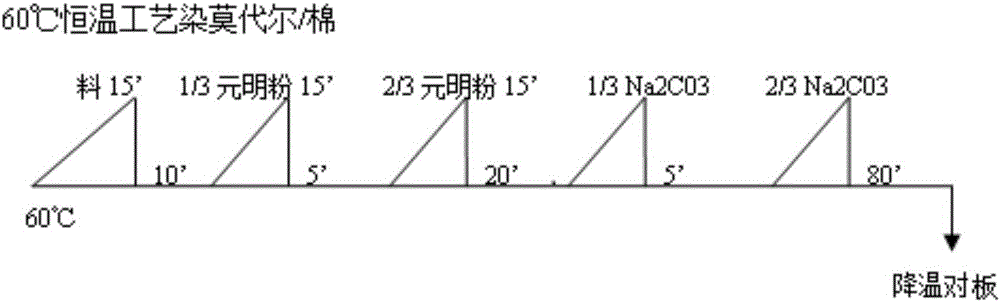

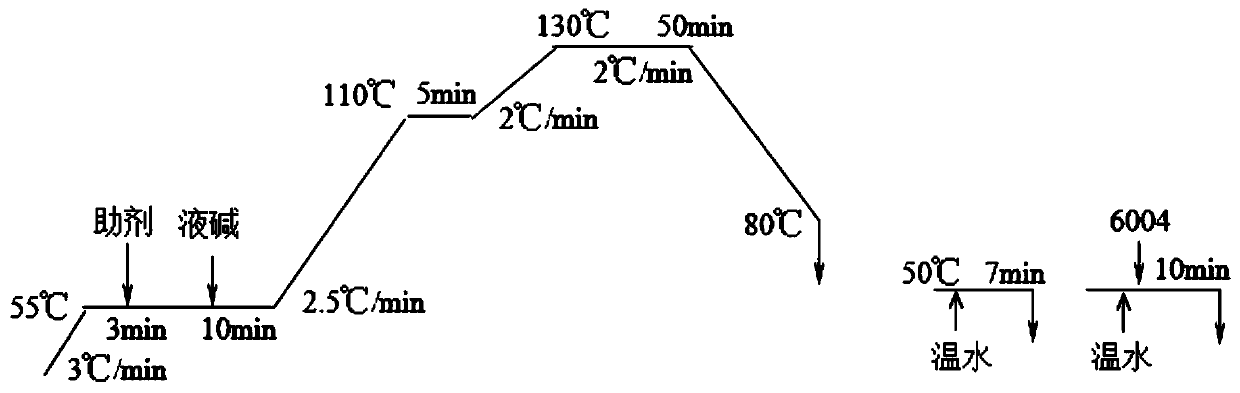

Modal/cotton blended fabric dyeing process

InactiveCN104420365AGuaranteed whitenessGuaranteed gross effectBiochemical fibre treatmentDyeing processColour fastnessHigh adhesion

The invention discloses a modal / cotton blended fabric dyeing process. The process comprises the following steps: presetting, refining, washing with hot water, washing with cold water, dyeing, carrying out color fixing, washing, carrying out soap cooking, washing with hot water, washing with cold water, dehydrating and drying. The refining condition is mild, the operation is simple and environment-friendly, the refined fiber strength, fabric whiteness and capillary effect can achieve the dyeing requirement. SumifixHF novel high-adhesion activted dye is low in substantivity, excellent in levelling property and bright in color, and various color fastness of the dyed fabric is excellent.

Owner:QINGDAO SINGAO TEX NEW TECH COMPOSITE MATERIAL

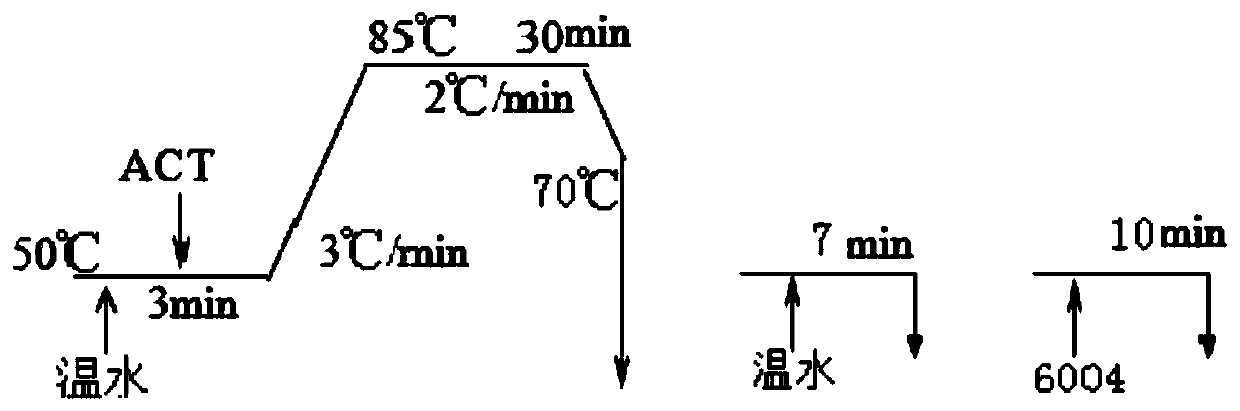

Comfortable permanent moisture absorption and quick drying polyester knitted fabric and making method thereof

InactiveCN109944089AGuaranteed whitenessGuaranteed qualityWeft knittingDyeing processPolyesterMoisture absorption

The invention relates to a comfortable permanent moisture absorption and quick drying polyester knitted fabric and a making method thereof, and belongs to the technical field of textile dyeing and finishing processes. The making method of the comfortable permanent moisture absorption and quick drying polyester knitted fabric includes the steps of gray cloth weaving, pre-treatment opening one-bathtreatment, dyeing, primary reduction washing, neutralizing, secondary reduction washing, cotton dyeing, post-treatment drying and sizing. Fiber of the obtained fabric has a large number of microporousstructures and can discharge a large amount of sweat generated by the human body out of the outer layer of clothes through micropores and accelerate the volatilization of sweat, so that the wearing comfort of the fabric is improved, the rigidity of polyester is reduced, the softness of the polyester fabric is improved, the polar light on the surface of the polyester fiber is eliminated, the handfeel and appearance of the polyester fabric are closer to those of natural fiber, and thus the comfort of the fabric is further improved.

Owner:FUJIAN FYNEX TEXTILE SCI & TECH

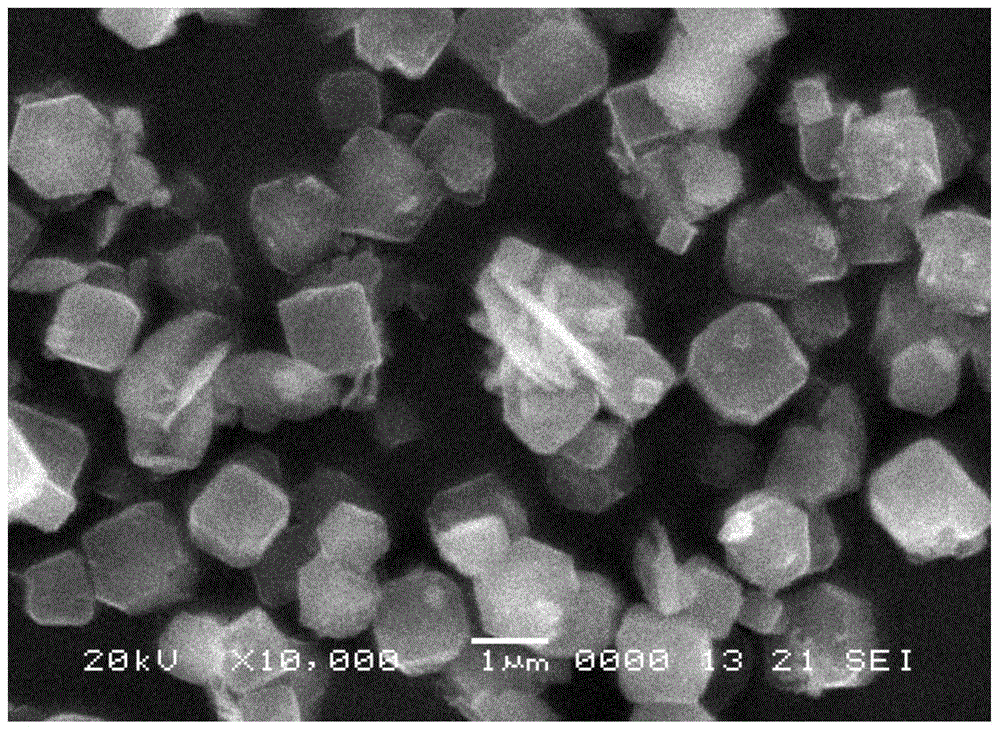

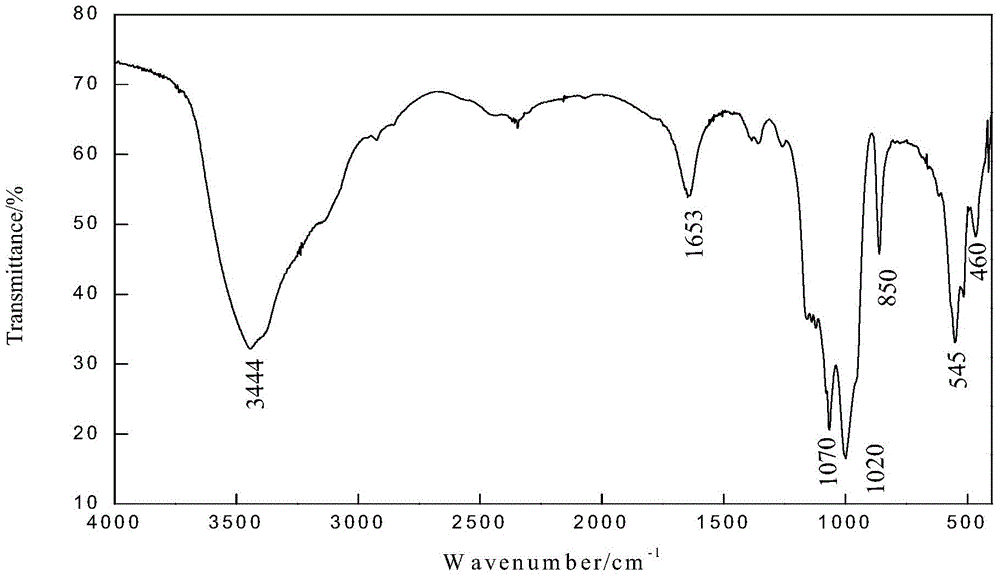

Method for preparing 13X molecular sieve by adopting coal slime

The invention discloses a method for preparing a 13X molecular sieve by adopting coal slime. The method comprises the steps of 1, grinding and sieving the coal slime, and calcining the sieved matter to obtain coal slime ash; 2, mixing a hydrochloric acid solution with the coal slime ash, reacting while stirring, filtering to obtain filter residue, and drying the filter residue for later use; 3, mixing NaOH with the dried filter residue, and performing alkali fusion to obtain slag; 4, adding sodium metaaluminate and water into the slag, and stirring uniformly to obtain a mixture; 5, ageing the mixture and then crystallizing to obtain a solid-liquid mixture; and 6, filtering the solid-liquid mixture in vacuum to obtain a filter cake, washing the filter cake with deionized water, and drying to obtain the 13X molecular sieve. By adopting the method, the coal slime can be sufficiently utilized, the utilization rate and the additional value of the coal slime are greatly improved, the preparation cost of the 13X molecular sieve is reduced, land occupation and environmental pollution caused by accumulating massive 13X molecular sieve are avoided, and the prepared 13X molecular sieve product has uniform granularity distribution and stable quality.

Owner:XIAN UNIV OF SCI & TECH

Fresh quick-frozen steamed bun dough, preparation method and steamed bun preparation method

The invention provides a fresh quick-frozen steamed bun dough which has good mouthfeel and large fermentation degree, a preparation method thereof and a steamed bun preparation method. The fresh quick-frozen steamed bun dough comprises the raw materials of high gluten flour, modified tapioca starch, wheat starch, quick-frozen grease, molecular distilled monoglyceride, yeast, white sugar, compositephosphate, alkali, salt, sour dough and water. The invention provides the fresh quick-frozen steamed bun dough, the preparation method and the preparation method of the steamed bun, the fresh quick-frozen steamed bun can be made by combining a Chinese tradition flour product fermentation technology and a modern quick-frozen technology, and the dough is fermented at low temperature of -10 DEG C ina cold storage, whiteness of the dough wrappers after steaming is effectively kept, mouthfeel is good, fermentation degree is large, and the method is better than dough fermentation at room temperature in a traditional method.

Owner:北京庆丰万兴食品科技研发有限公司

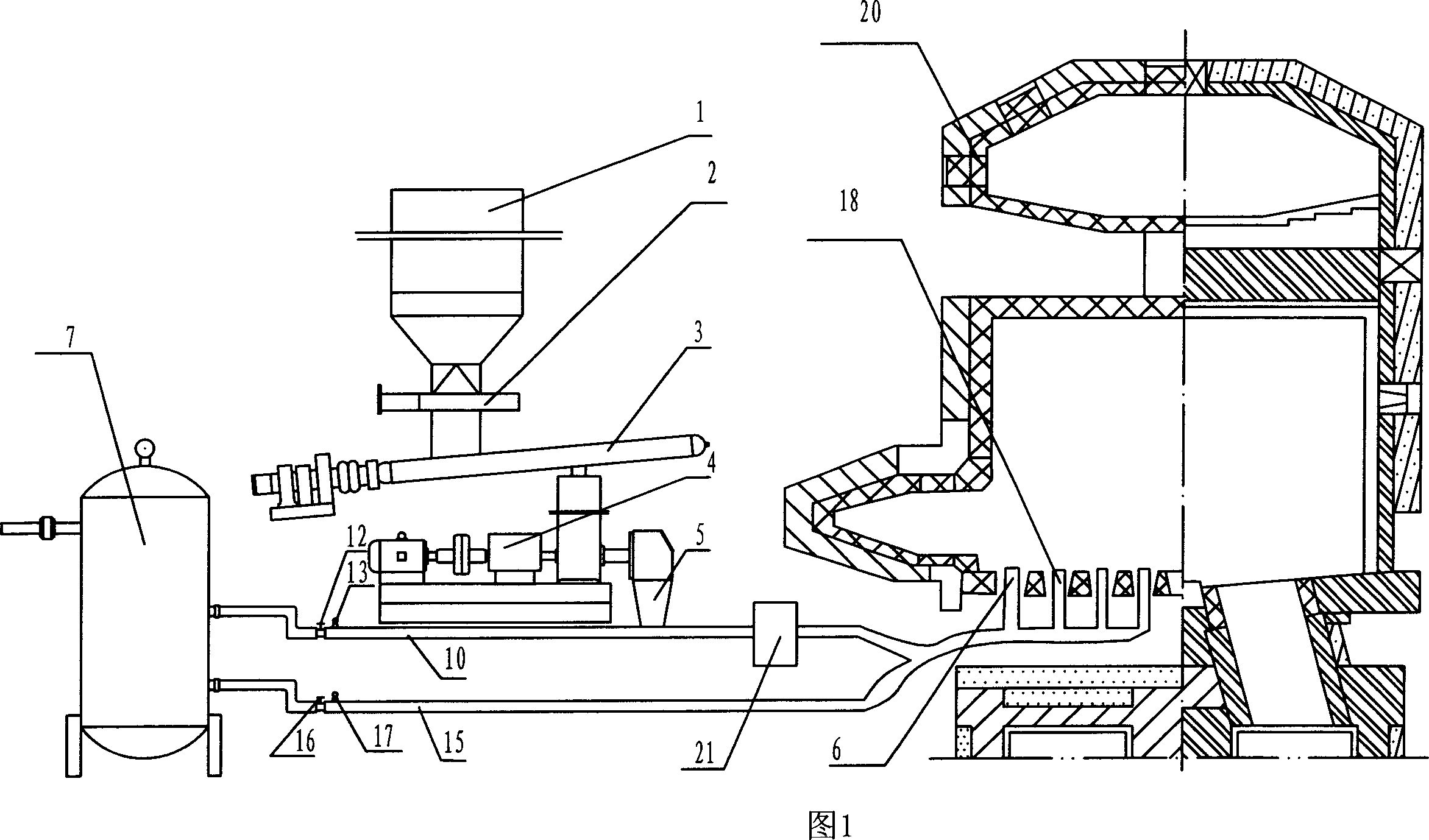

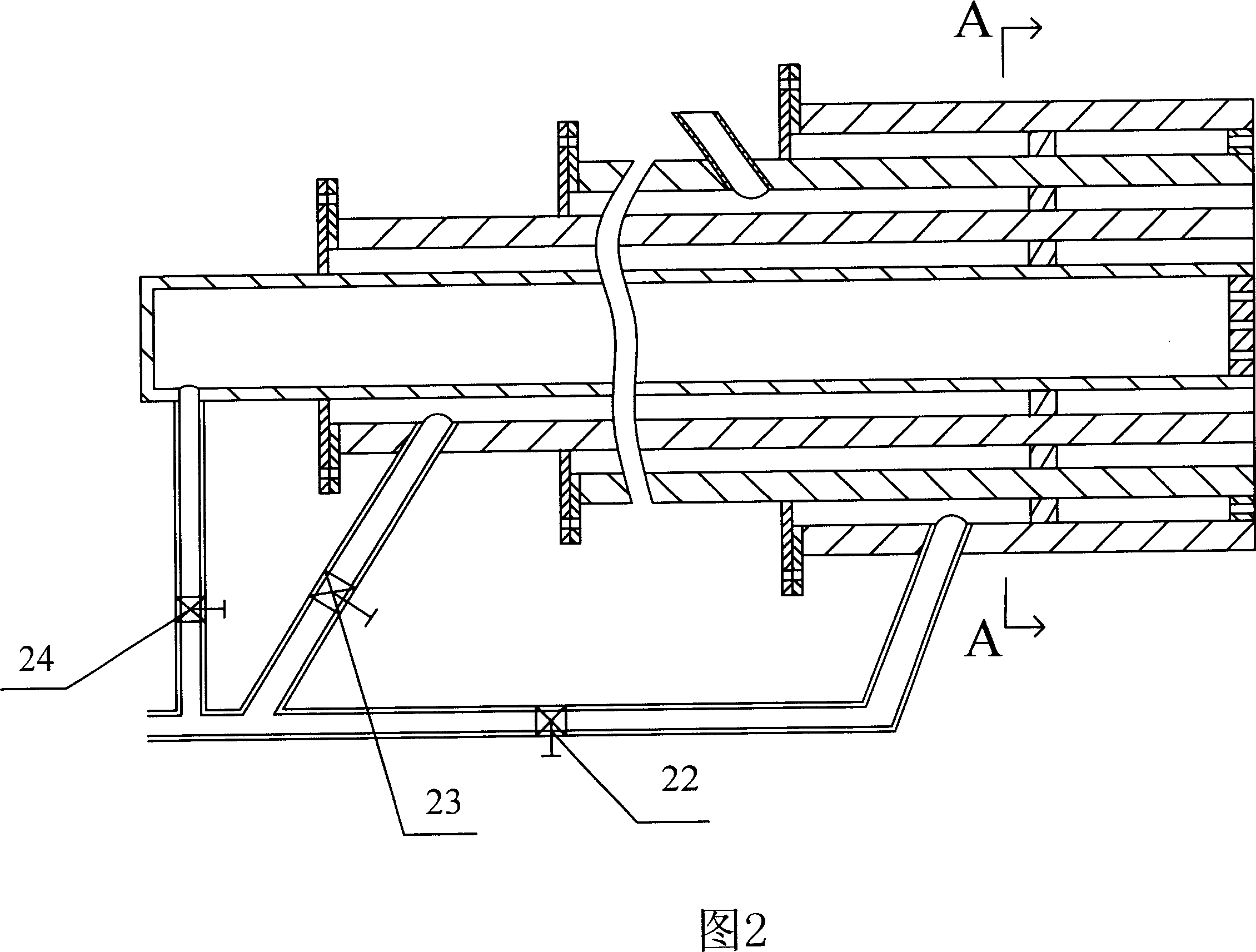

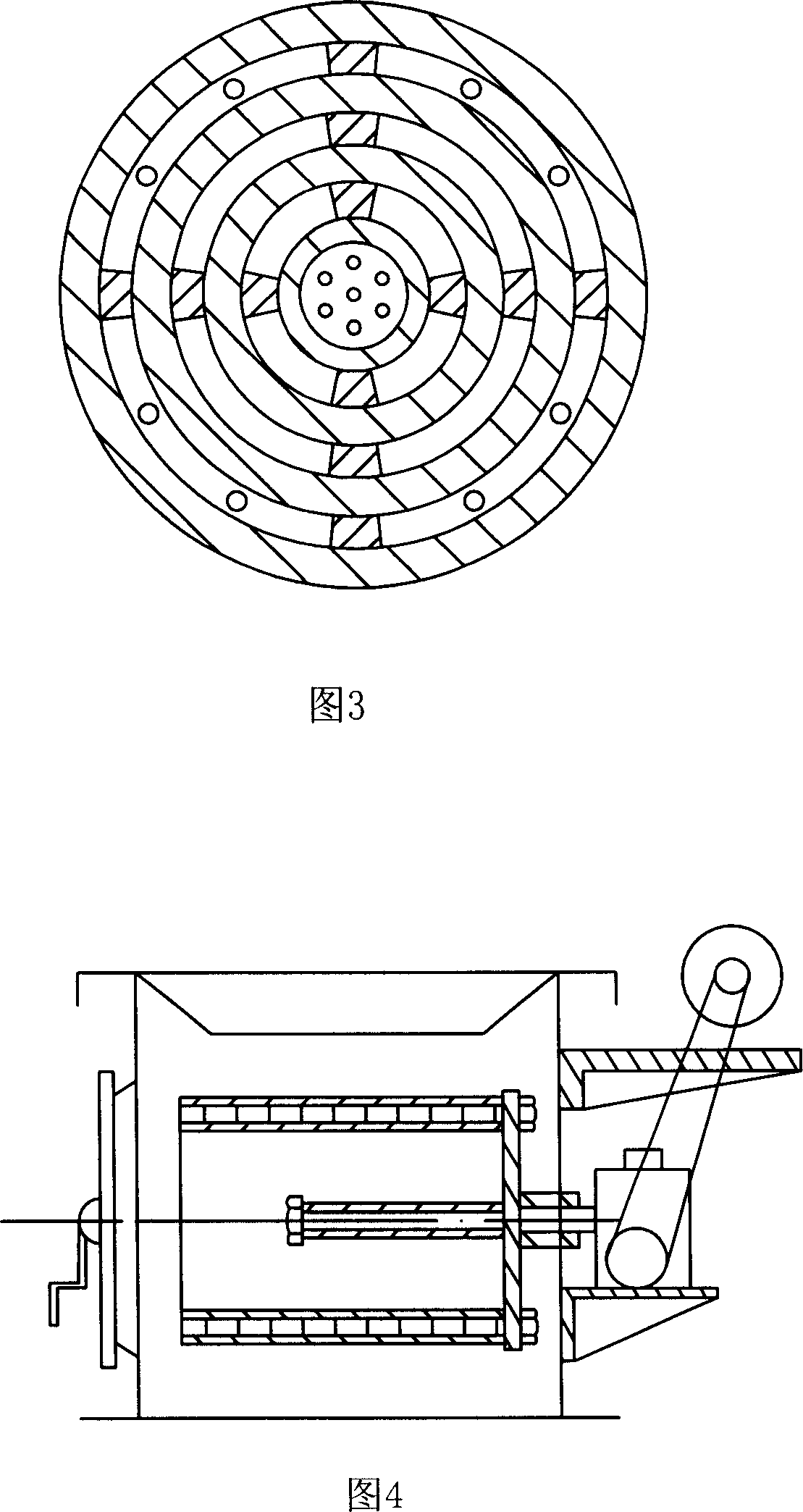

Using method and apparatus for petroleum coke powder fuel for smelting glass

InactiveCN1986462ALow costReduce manufacturing costGlass furnace apparatusSolid fuelsMolten glassEngineering

The present invention discloses one kind of petroleum coke powder fuel for smelting glass and its using method and apparatus. The using method includes the steps of screening fuel, crushing, grinding, eliminating iron, drying and burning. The apparatus includes one feeding machine, one powder feeder, one mixer, one first conveying pipe, one first burner, one gas storage tank and one kiln connected successively. The present invention can reach the technological requirement of smelting glass and has lowered production cost.

Owner:南通吉龙玻璃有限公司

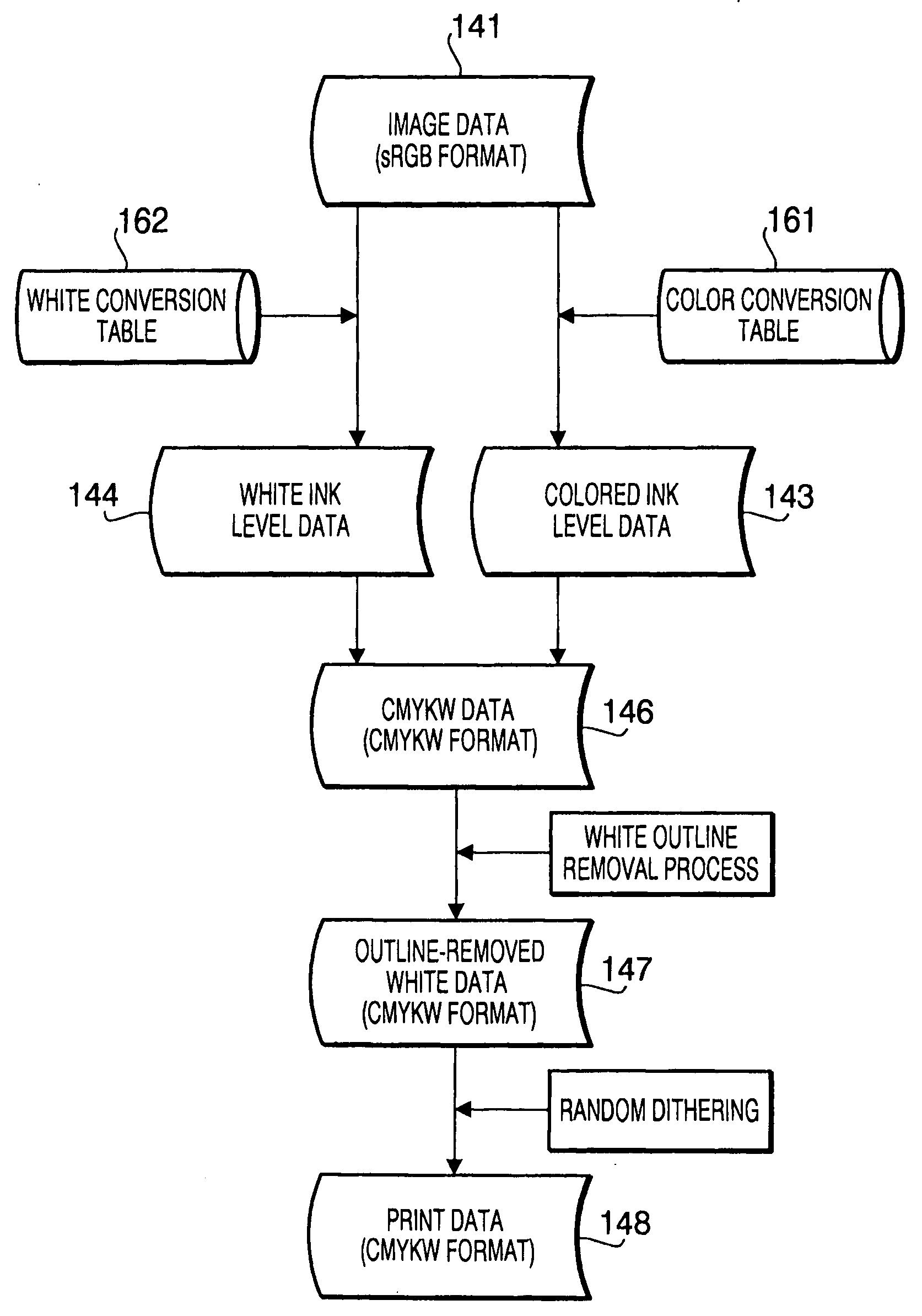

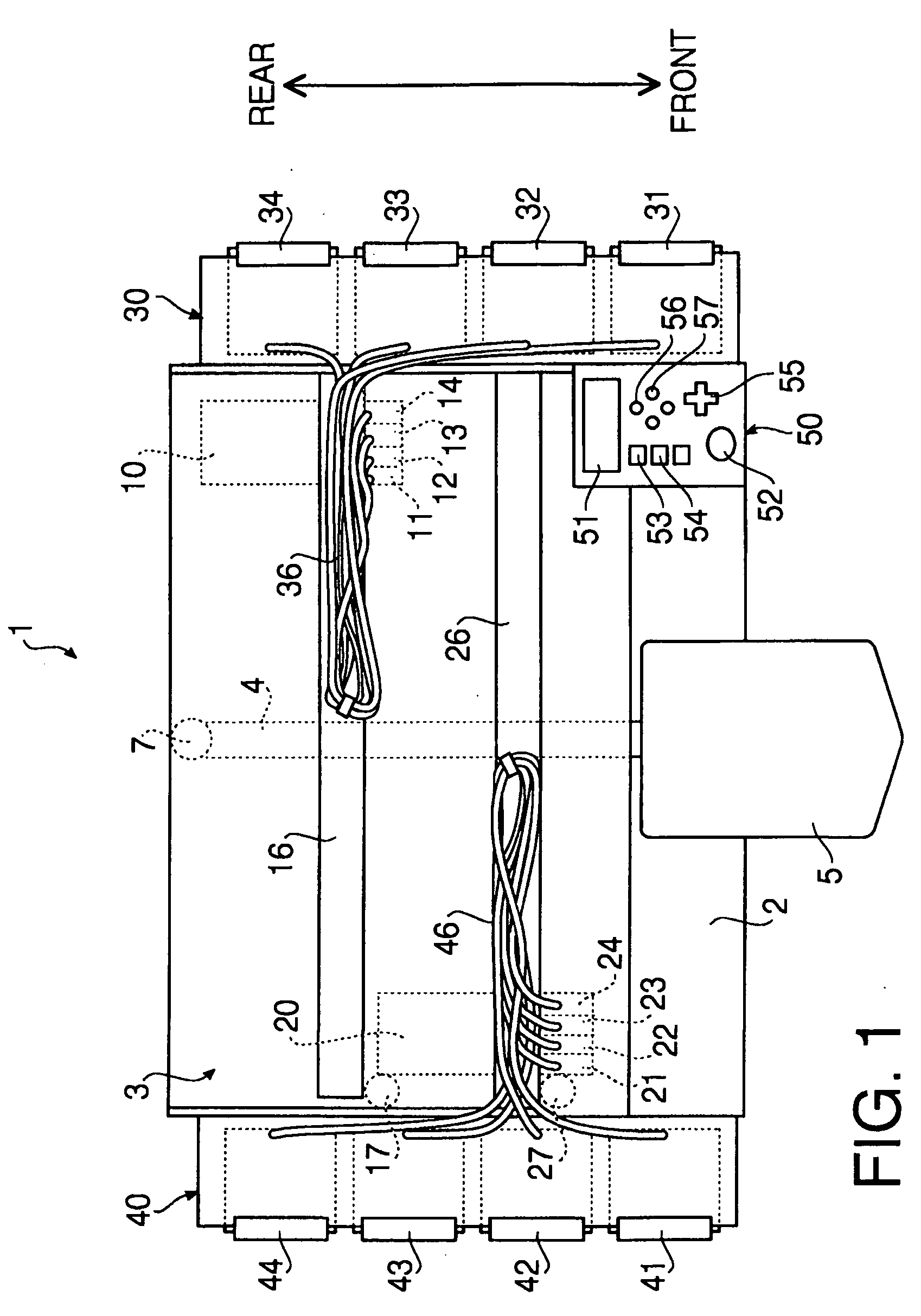

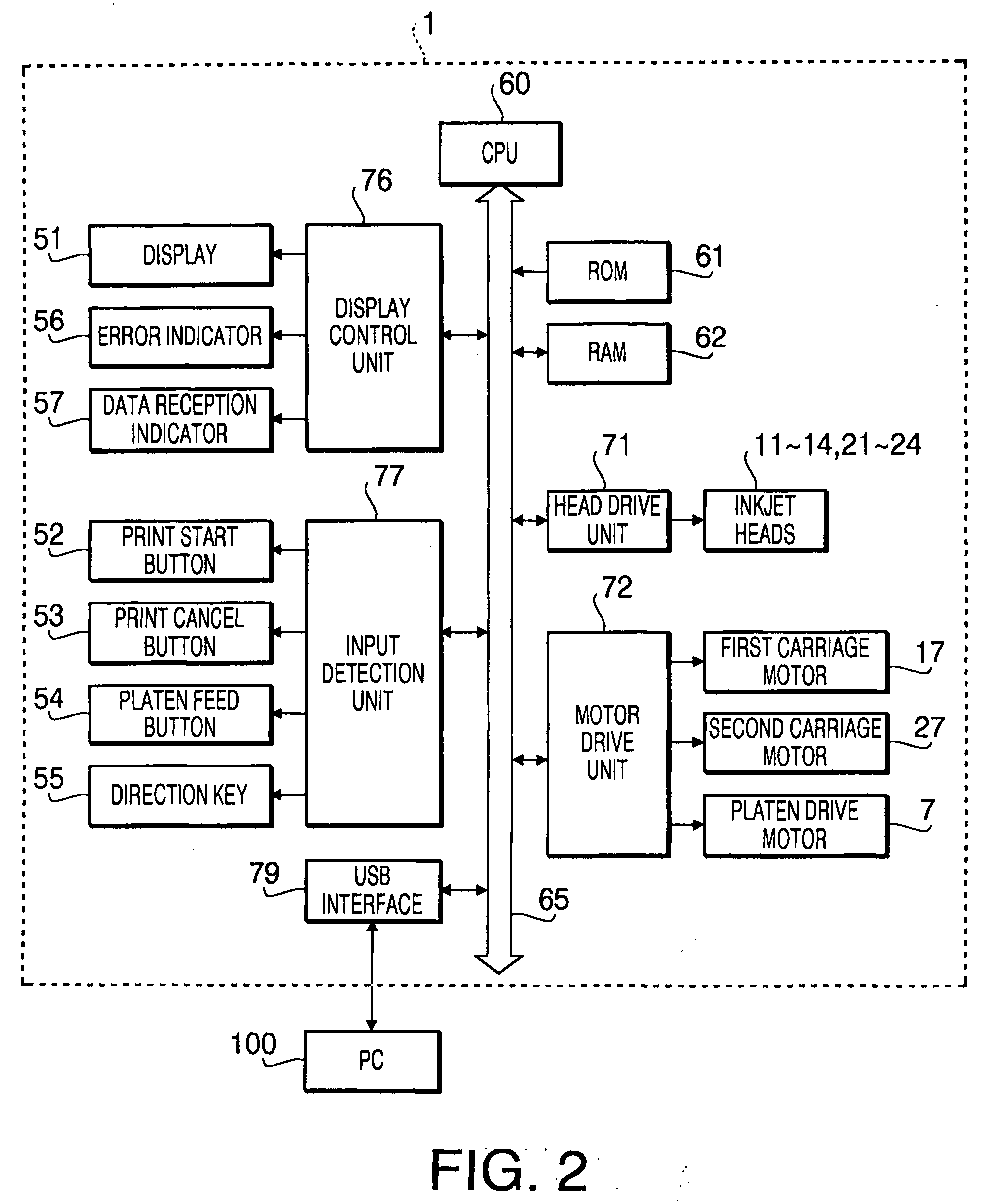

Print data generating device, method to generate print data, and computer usable medium therefor

ActiveUS20090225337A1Guaranteed whitenessEasily causedDigitally marking record carriersDigital computer detailsColor ScaleComputer science

A print data generating apparatus to generate print data based on inputted image data representing an image is provided. The print data generating apparatus includes a white data generating unit to generate white data, which indicates color scale values of white being used in the image, a white outline pixel judging unit, which examines a currently marked pixel among pixels included a white area to judge as to whether the marked pixel is a white outline pixel composing an outline of the white area with reference to the white data, and an outline-removed white data generating unit to generate outline-removed white data, which includes information to indicate that the outline of the white area is removed. The outline-removed white data generating unit removes the outline of the white area by clearing the color scale values of white of the white outline pixel to zero.

Owner:BROTHER KOGYO KK

Method for increasing green degree of ball-flower bud branches of loose-flower cauliflower

The invention relates to a method for increasing green degree of ball-flower bud branches of loose-flower cauliflower. The method increases green degree of ball-flower bud branches through changing cultivation patterns and methods. The method comprises measures of planting density changing, water management, fertilization management, leaf binding and flower protection. The planting density changing is realized by increasing row and line spacings of plants, and row spacing is 50cm to 60 cm, line spacing is 60 cm to 70 cm. A hole V-shaped mode is used, and the plants are planted in a staggered manner. Through increasing planting density, and water management, fertilization management, and leaf binding and flower protection and other comprehensive measures, an objective of increasing the green degree of ball-flower bud branches of loose-flower cauliflower is realized, and various produced cauliflowers are high in quality and good in commodity value.

Owner:江苏翰雅有机农场有限公司

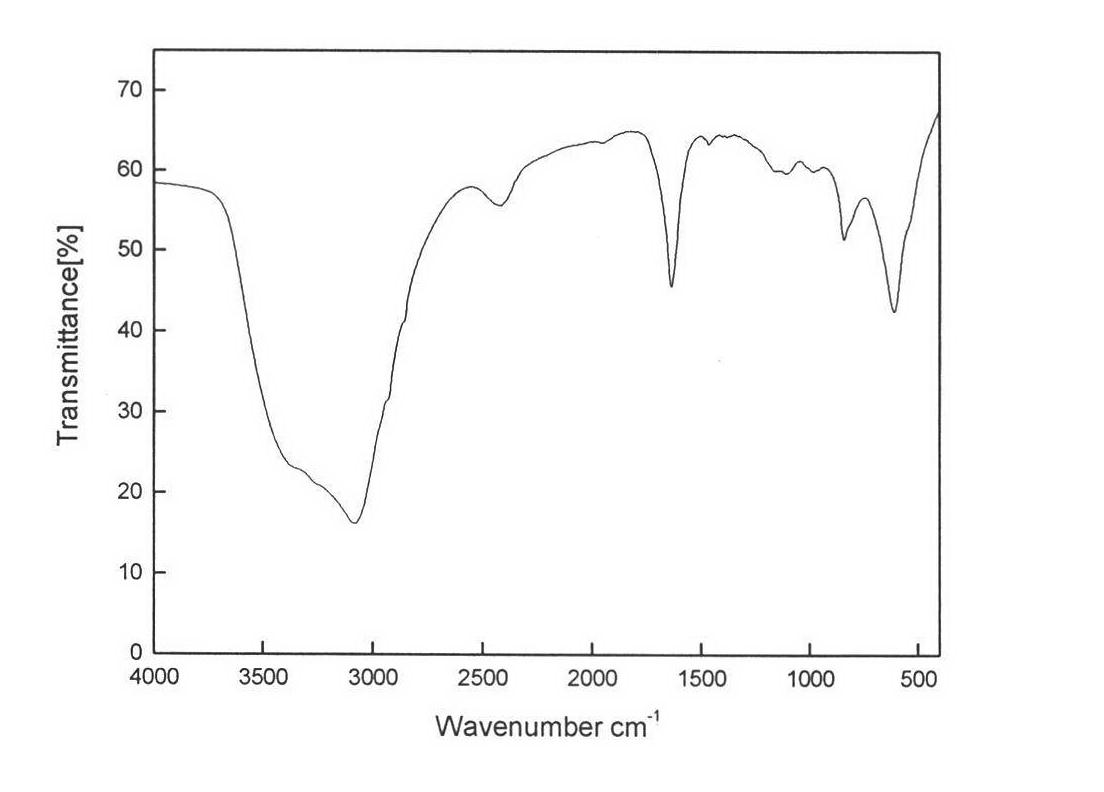

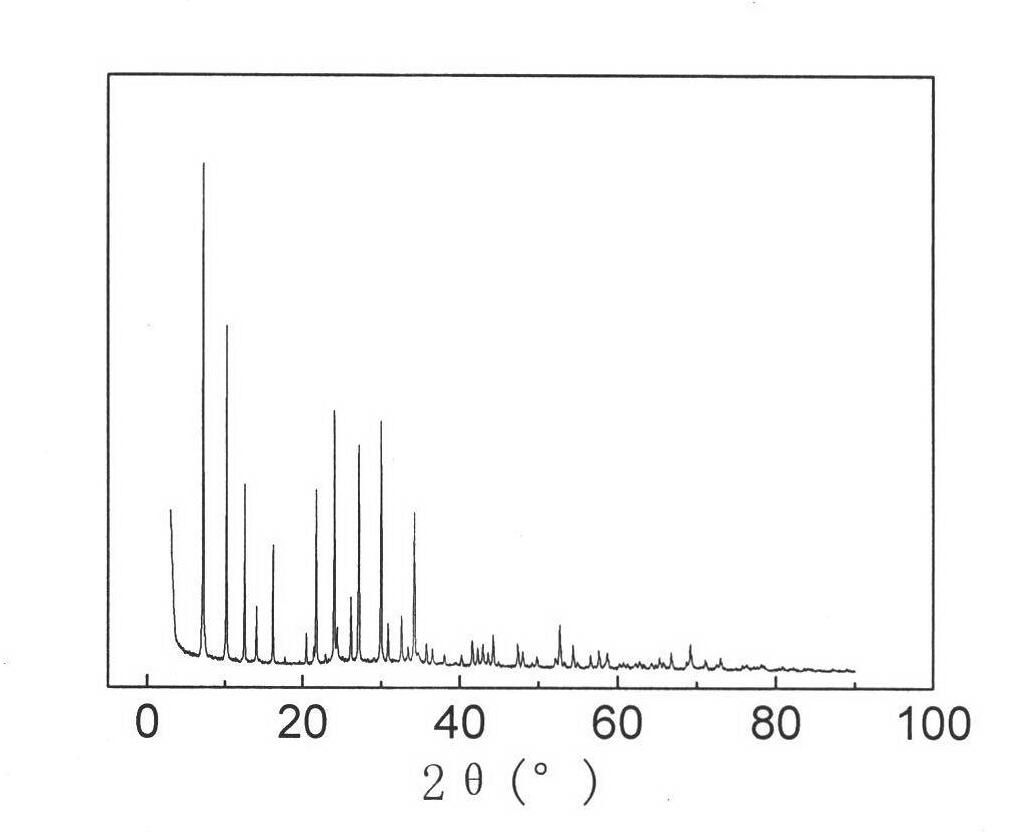

Method for preparing 4A molecular sieve by adopting coal slime

The invention discloses a method for preparing a 4A molecular sieve by adopting coal slime. The method comprises the steps: 1, grinding and sieving the coal slime, and calcining the sieved matter to obtain coal slime ash; 2, mixing a hydrochloric acid solution with the coal slime ash, reacting while stirring, filtering to obtain filter residue, and drying the filter residue for later use; 3, mixing NaOH with the dried filter residue, and performing alkali fusion to obtain slag; 4, adding sodium metaaluminate and water into the slag, and stirring uniformly to obtain a mixture; 5, ageing the mixture and crystallizing to obtain a solid-liquid mixture; and 6, filtering the solid-liquid mixture to obtain a filter cake, washing the filter cake with deionized water, and drying to obtain the 4A molecular sieve. By adopting the method, the coal slime can be sufficiently utilized, the utilization rate and the additional value of the coal slime are greatly improved, the preparation cost of the 4A molecular sieve is reduced, land occupation and environmental pollution caused by accumulating massive 4A molecular sieve are avoided, and the prepared 4A molecular sieve product has uniform granularity distribution and stable quality.

Owner:XIAN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com