Method for preparing calcium-zinc stabilizer for shoe materials

A technology of calcium zinc stabilizer and auxiliary heat stabilizer, which is applied in the field of stabilizers to achieve the effect of clean and comfortable environment, reducing dust flying and bright colors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A preparation method of a calcium-zinc stabilizer for shoe materials, comprising the following steps:

[0036] S1. Weigh 1-10 parts of zinc stearate, 10-25 parts of calcium stearate, 0.1-2 parts of zinc acetylacetonate, 0.5-3 parts of calcium acetylacetonate, 20-50 parts of hydrotalcite, epoxy soybean oil 5-15 parts, lubricant 2-16 parts, other metal soaps 5-20 parts, organic auxiliary heat stabilizer 5-25 parts, unsaturated ester 1-10 parts, antioxidant 0.1-2 parts, dispersant 1 ~5 copies;

[0037]S2. Use low-speed mixing equipment to mix the materials. First, mix the various powders evenly, then add the epoxy soybean oil, lubricant, and dispersant of the liquid components, and continue to stir until the materials are in the form of powder or paste with a certain humidity. mixture, namely to obtain the calcium-zinc stabilizer for shoe materials.

[0038] Preferably, the hydrotalcite is layered double metal oxides (Layered Double Hydroxides, LDHs for short), having a ...

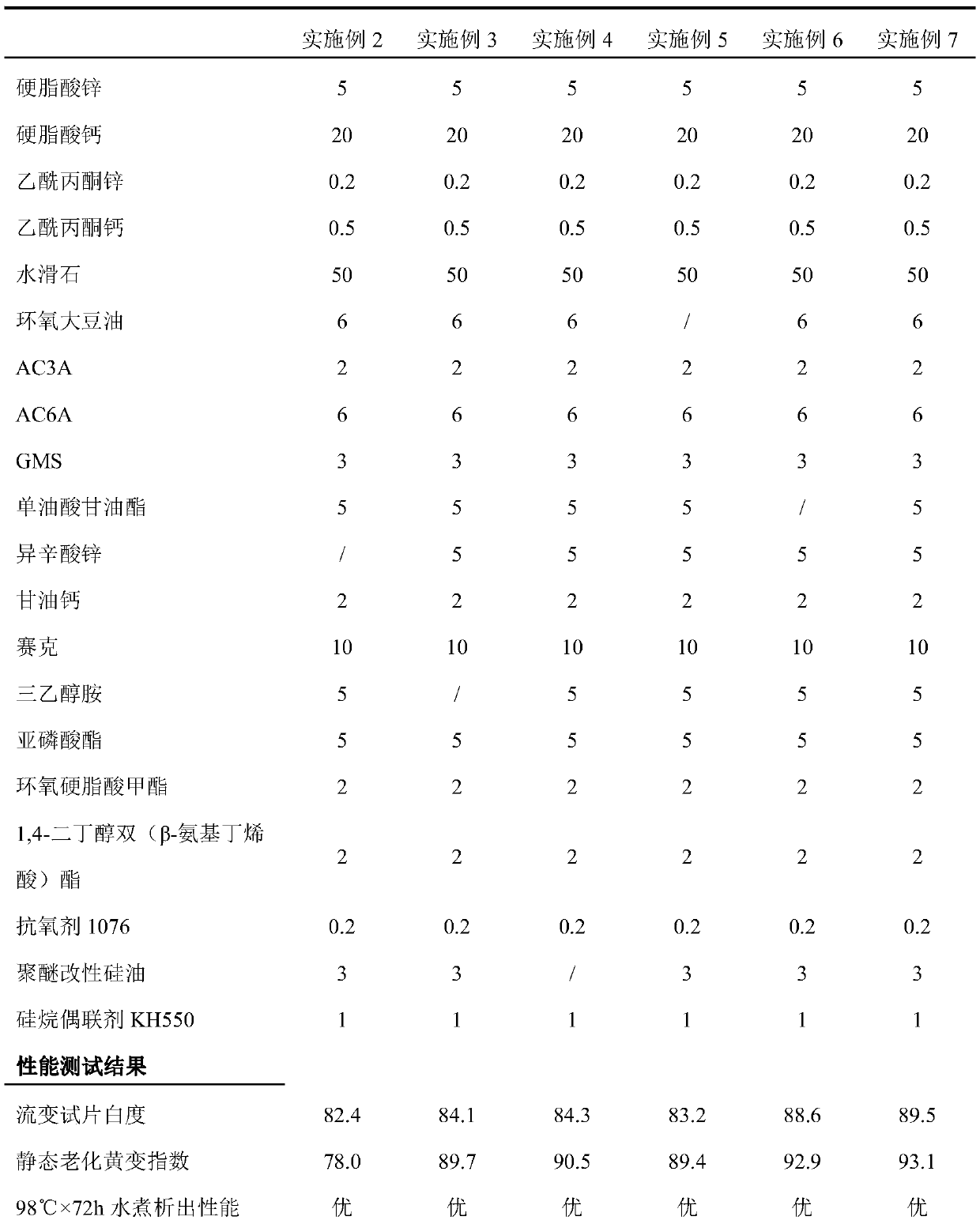

Embodiment 2 to 7

[0050] All adopt following a kind of preparation method of shoe material calcium-zinc stabilizer, comprise the following steps:

[0051] S1, weigh each raw material respectively;

[0052] S2. Use low-speed mixing equipment to mix the materials. First mix the various powders evenly, then add liquid components (such as epoxy soybean oil, lubricants, and dispersants), and continue to stir until the materials are powders with a certain humidity or Paste mixture to obtain the calcium-zinc stabilizer for shoe materials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com